Patents

Literature

32 results about "Plaggen soil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plaggen soil or plaggic anthrosol is a type of soil created in parts of northwest Europe in the Middle Ages, as a result of so-called "plaggen" agriculture on marginal podzol soils. In order to fertilize the fields, pieces of heath or grass including roots and humus ("plaggen") were cut and used as bedding for cattle. In springtime, this bedding, enriched with slurry was then spread over the fields near the village as manure. The long term practice of this form of agriculture created a rich agricultural soil to a depth of between 40 cm and over 1.50 m, unlike modern arable soils, which tend to be just 30 centimetres deep. The raised fields give rise to a typical landscape with sharp breaks in elevation and are called Plaggenesche in Germany or Es in Dutch. This form of agriculture stopped around 1900 with the introduction of fertilizers.

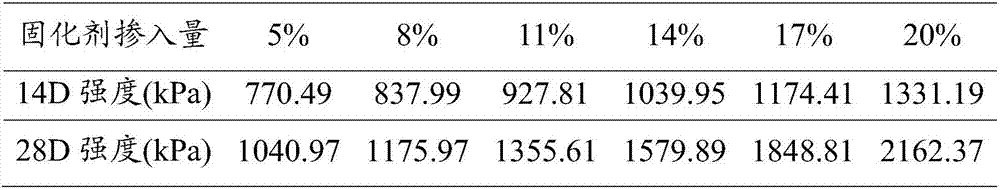

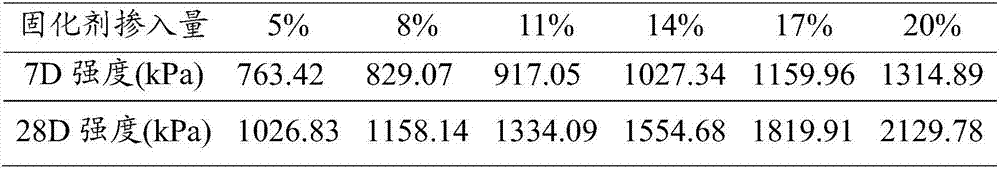

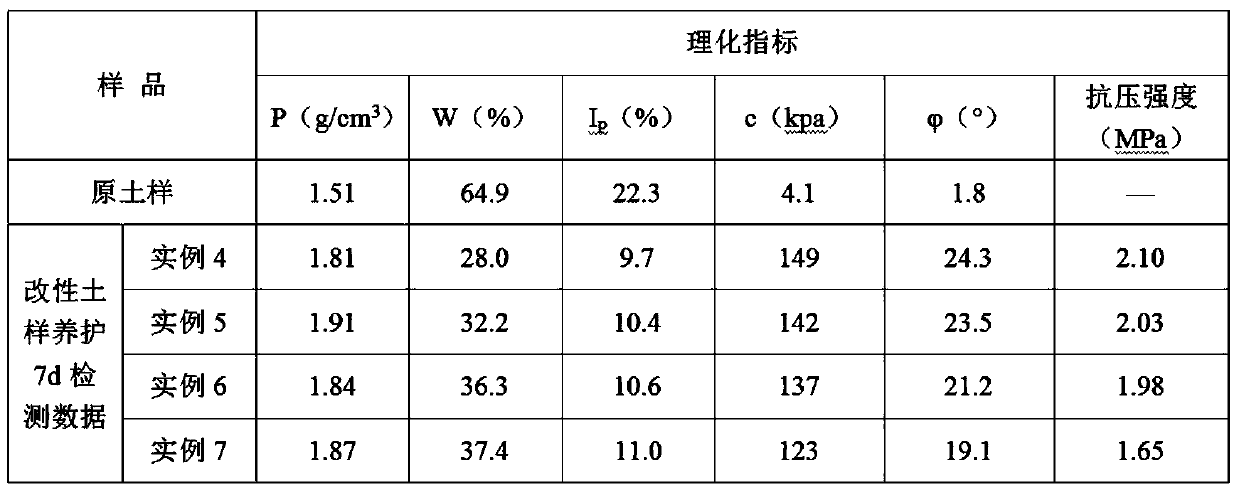

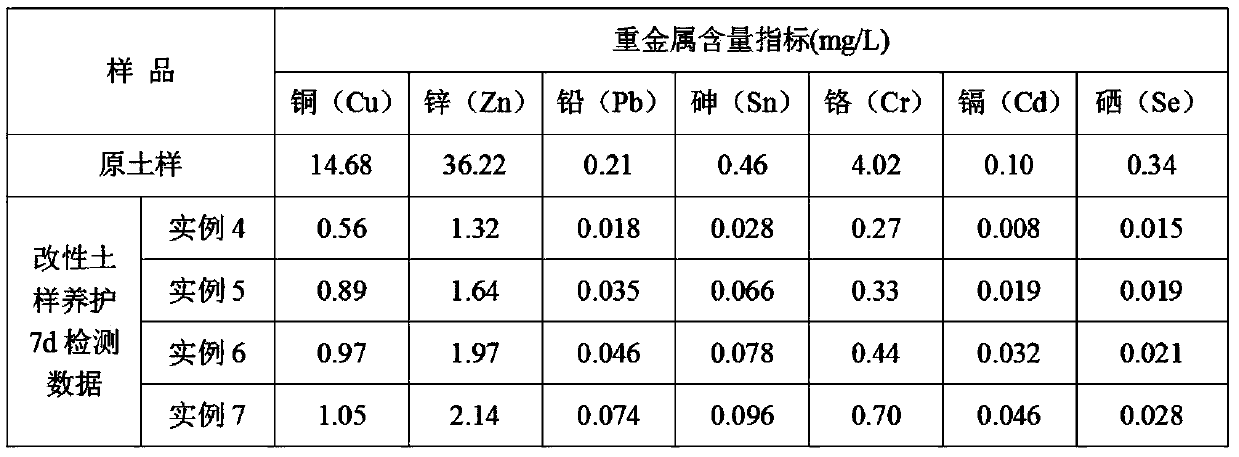

Compound solidifier for mucky soil and application thereof

The invention discloses a compound solidifier for mucky soil, which includes, by weight, 46% of cement, 34% of slag, 15% of fly ash, and 5% of triethanolamine. In the invention, cement is used as a main solidifying material, the fly ash and the slag are used as alkaline activators, and the triethanolamine is used as a surfactant. The compound solidifier, on the basis of solidification mechanism, aims to increase pH value of soil body, promote procedure of hydration reaction of cement and setting and hardening of a hydrate, and enhance activity of ions participating in the reaction; by selecting the solidifying material and other components, the optimal solidification effect is achieved through a series of reactions. The invention also provides applications of the compound solidifier for mucky soil in solidification treatment of soft soil foundation. In practical engineering, addition amount of the compound solidifier is regulated so as to fit and solidify soft soil in different organic matter content and water content, thereby achieving best solidification and economic effect.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

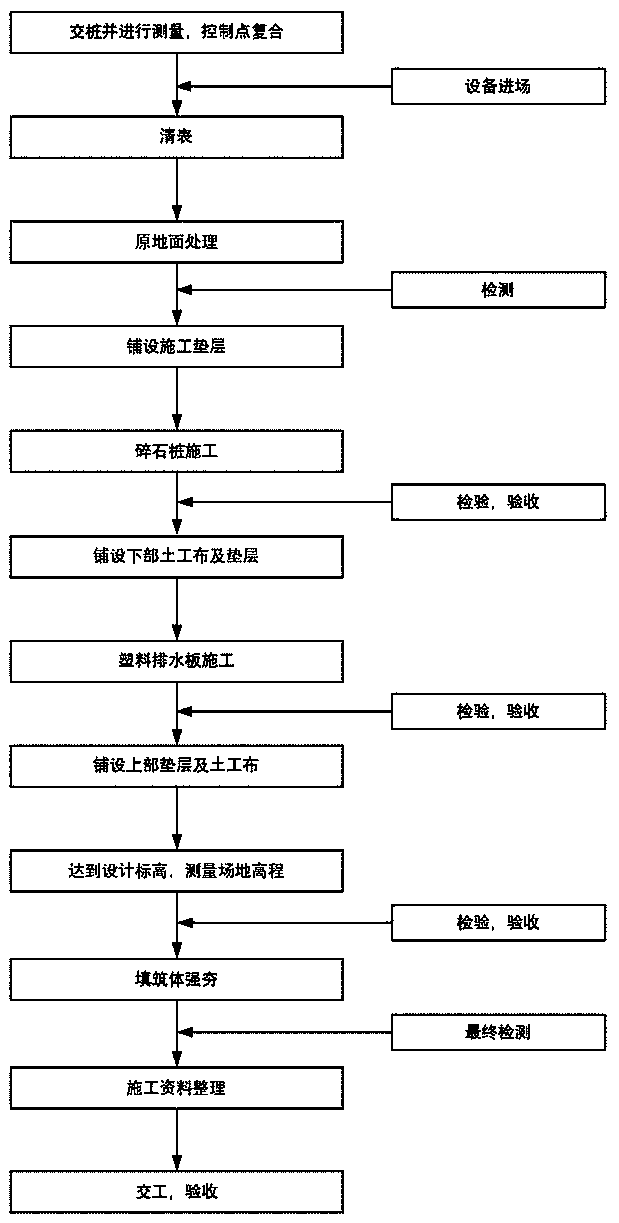

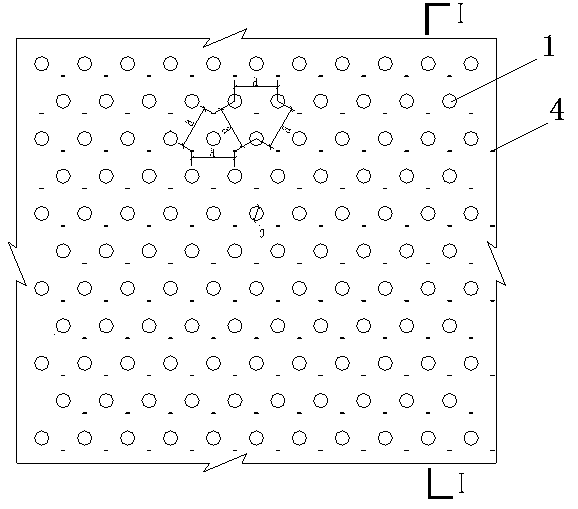

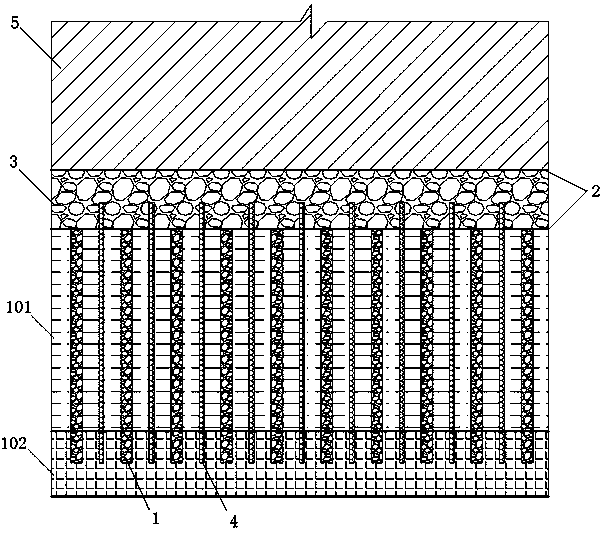

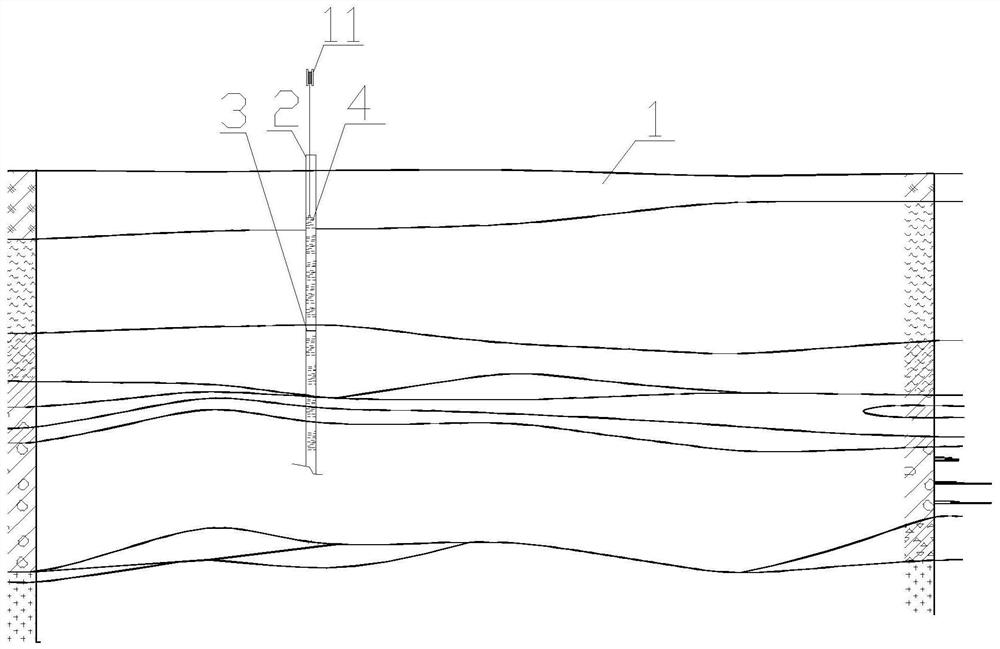

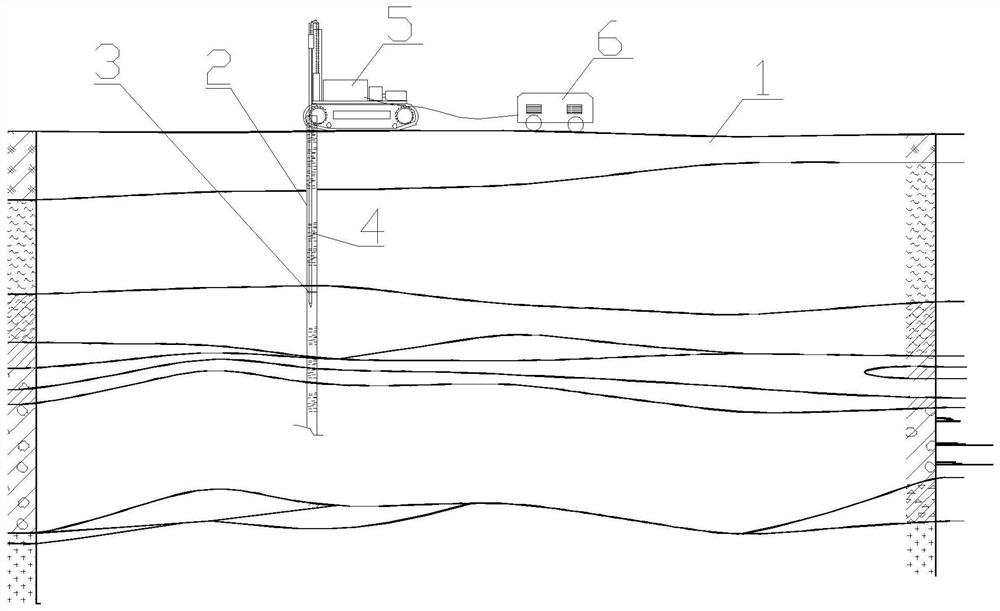

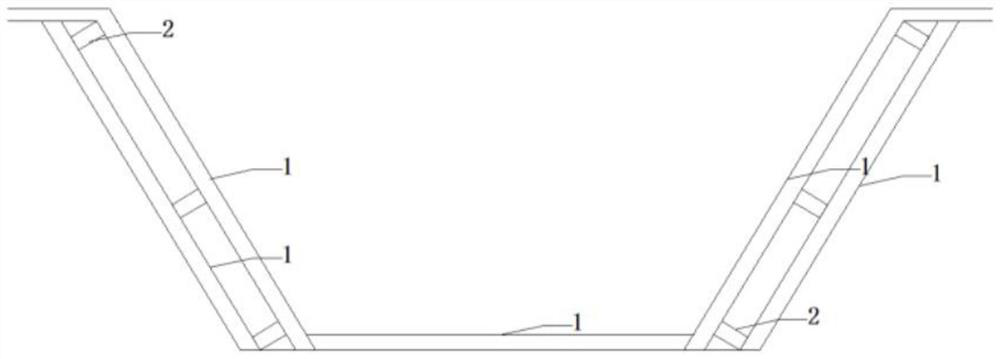

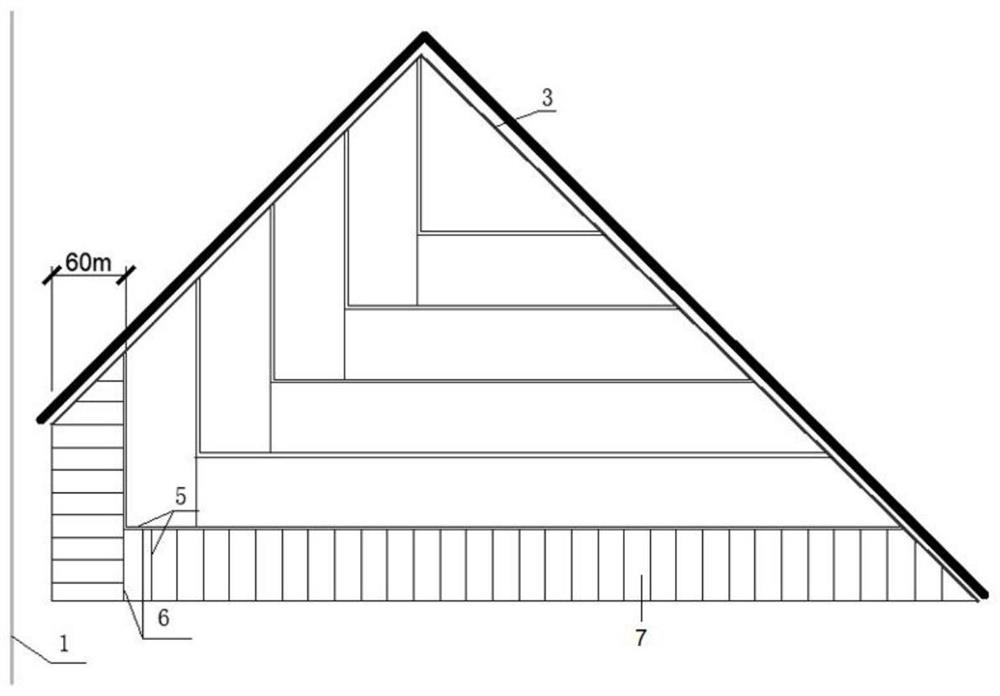

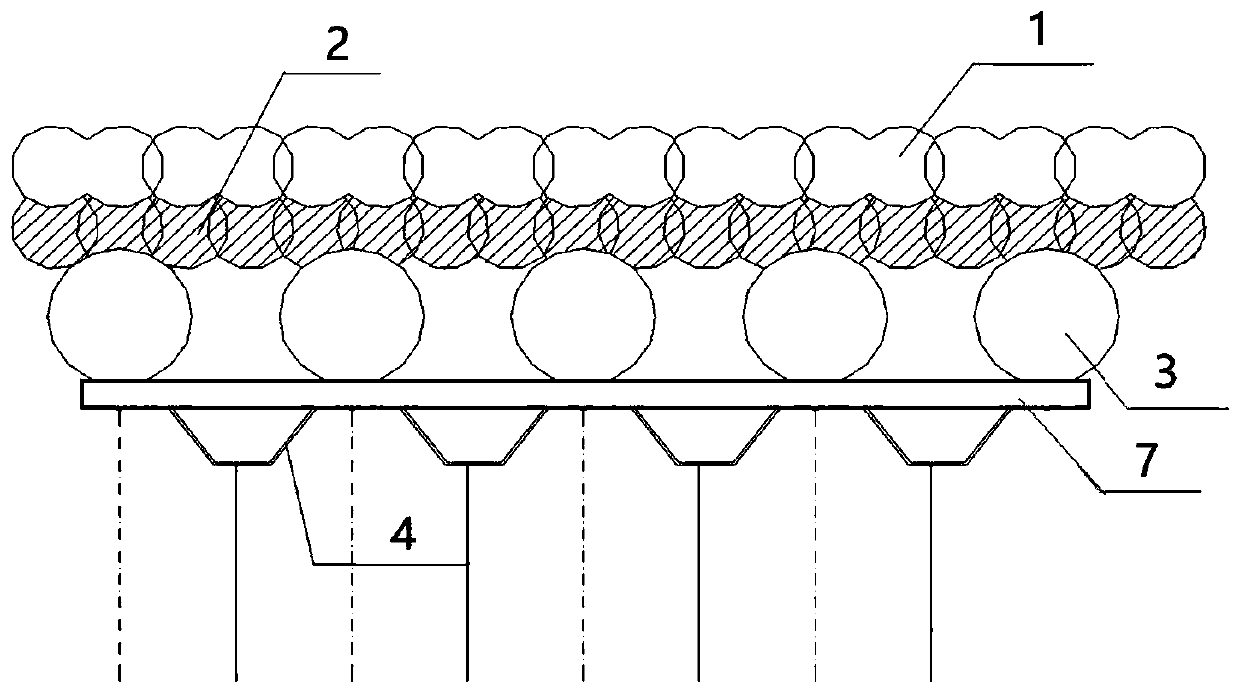

Method for carrying out dynamic compaction composite treatment on sludge soil foundation through gravel piles, drain board and upper filling body

InactiveCN110820716AEasy constructionImprove drainage capacitySoil preservationSoil scienceDynamic compaction

The invention provides a method for carrying out dynamic compaction composite treatment on a sludge soil foundation through gravel piles, a drain board and an upper filling body, and belongs to the technical field of building foundation treatment. The method comprises the steps that S1, a construction cushion layer is laid; S2, construction of the gravel piles is achieved, and a vibration sunken tube method is adopted; S3, geotechnical cloth and a cushion layer below the tops of the gravel piles are laid; S4, construction of the plastic drain board is achieved; S5, an upper cushion layer and geotechnical cloth are laid; and S6, layered and staged dynamic compaction of the filling body is achieved. By means of the method, the advantages of preloading and dynamic compaction dynamic consolidation of the gravel piles and the plastic drain board are achieved fully, the advantages are complemented, and the defects of a single foundation treatment method are avoided.

Owner:山西机械化建设集团有限公司

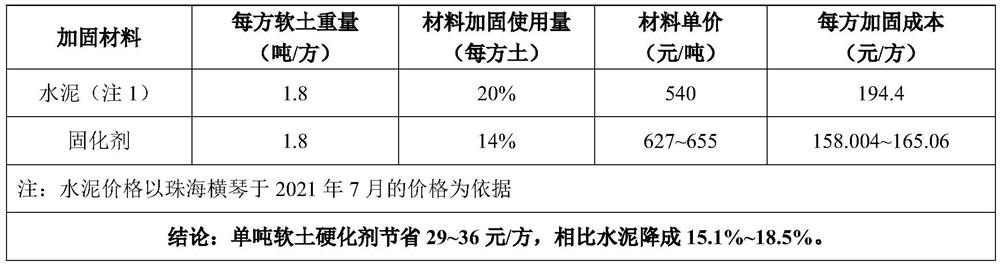

Soft soil hardening agent for sea area environment

PendingCN113735526AReduce economic costsShorten the construction periodOrganic fertilisersSoil conditioning compositionsSoil scienceEnvironmental engineering

The invention relates to the technical field of soft soil solidification, in particular to a soft soil hardening agent for a sea area environment, which comprises the following components in parts by weight: 20-40 parts of cement, 8-12 parts of ground fly ash, 34-50 parts of slag powder, 13-15 parts of gypsum and 3-5 parts of an early strength activator. The soft soil hardening agent is suitable for soft foundation treatment processes of deep mixing piles, high-pressure jet grouting piles and the like in a sea area environment, marine silt and mucky soil with high water content, high organic matter content and high salt content are solidified, and compared with traditional cement, the soft soil hardening agent has better gelling property and economic value; and the soft soil hardening agent has the advantages of simple production process, low cost, wide raw material source, environmental protection and the like.

Owner:北京安科兴业科技股份有限公司

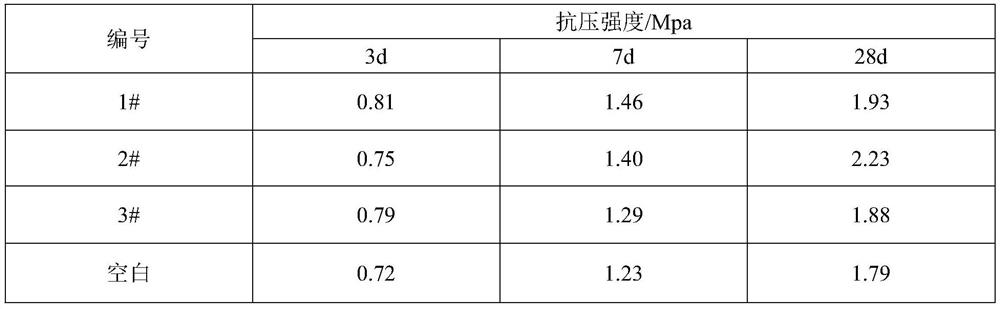

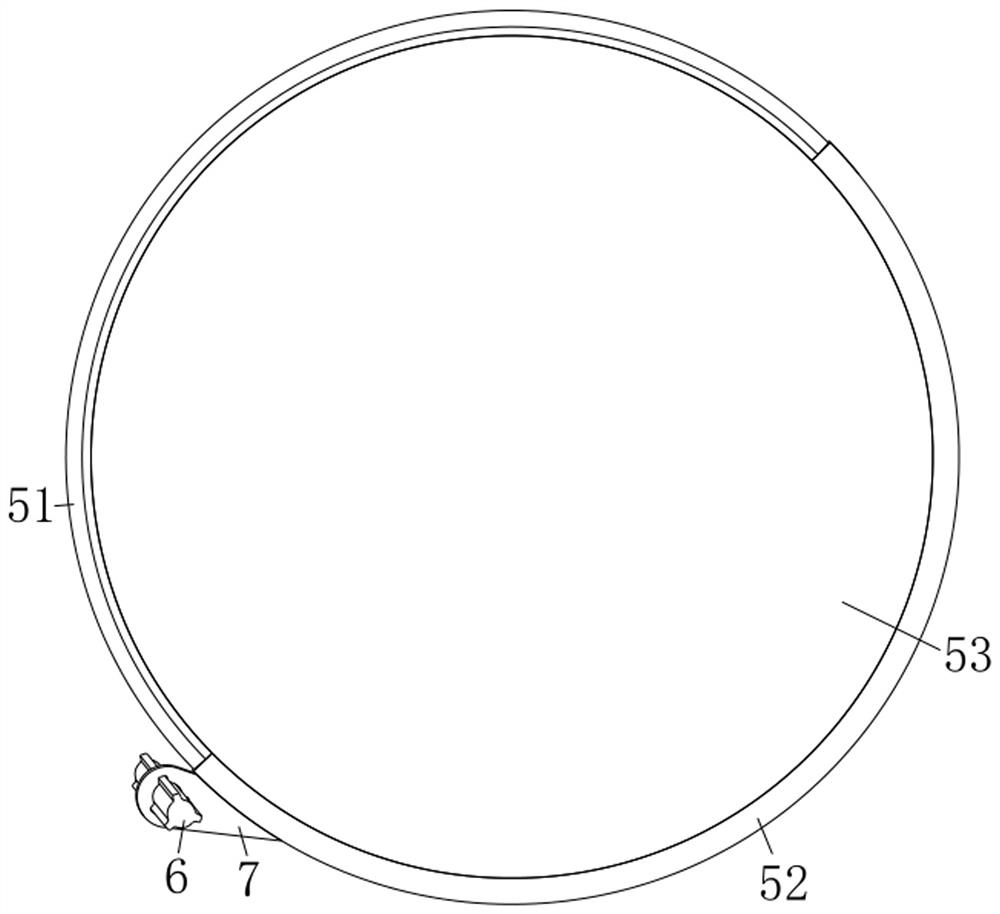

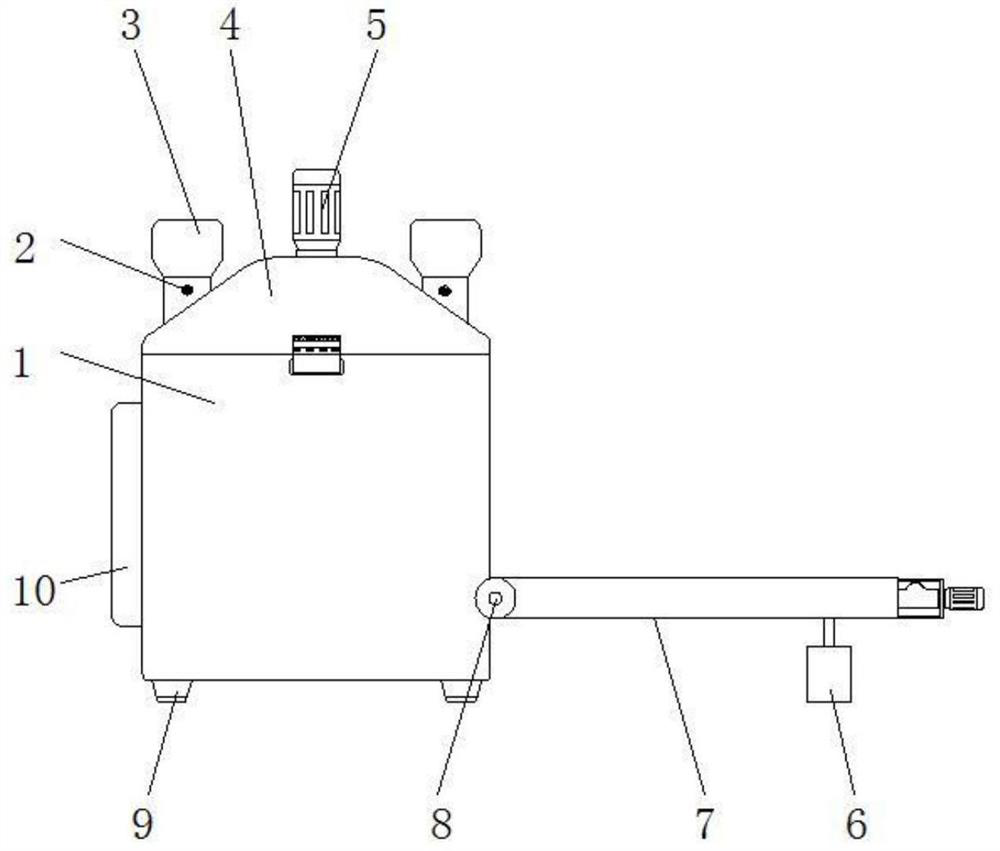

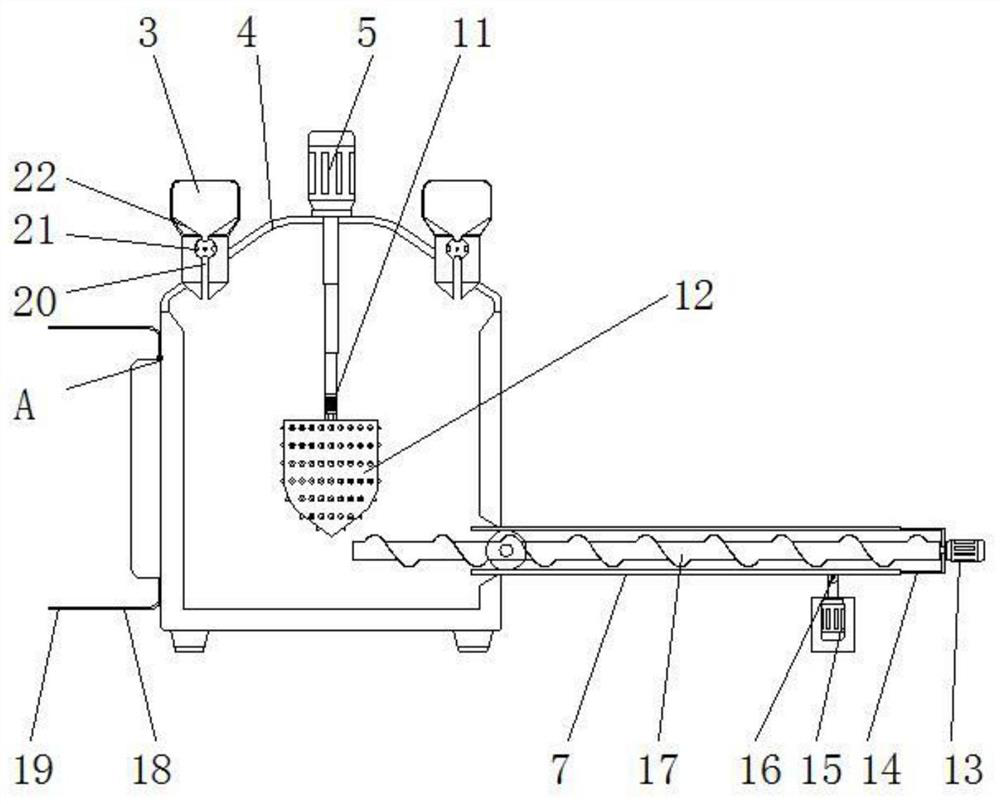

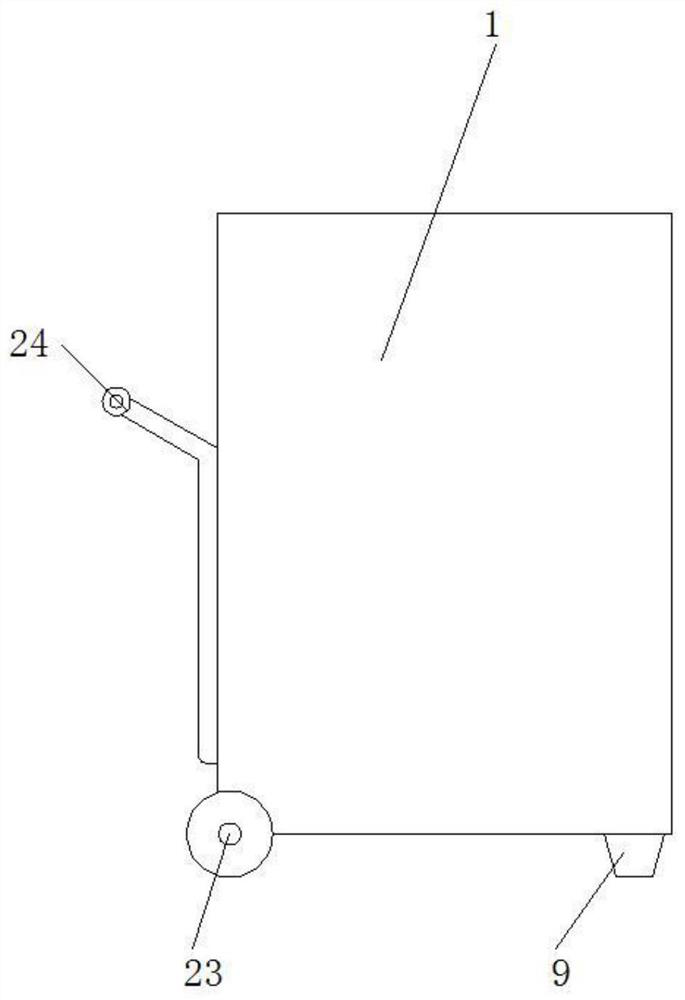

Mucky soil dehydration device vehicle and using method thereof

InactiveCN112144600AProcess jobs fasterImprove filtration efficiencyMechanical machines/dredgersSoil scienceSludge

The invention discloses a mucky soil dehydration device vehicle and a using method thereof. The mucky soil dehydration device vehicle comprises a sludge treatment vehicle body, a curing chamber and afilter pressing chamber are arranged on the sludge treatment vehicle body, the filter pressing chamber is located at the lower end of the curing chamber, the upper end of the curing chamber is connected with a sludge inlet pipe, an opening is formed in the bottom of the curing chamber, the curing chamber is communicated with the filter pressing chamber, a storage barrel is connected to one side ofthe curing chamber, a second motor is arranged at the lower end of the curing chamber, and a connecting shaft is arranged on the inner wall of the curing chamber. According to the mucky soil dehydration device, sludge is added into the curing chamber, a curing agent in the storage barrel is added into the sludge, then the sludge is stirred by stirring blades, so that the sludge is cured firstly,the sludge and sewage are preliminarily filtered through a first filter screen plate, finally, the sludge and the sewage are subjected to filter pressing through cooperation of a pressing plate and asecond filter screen plate, drying is conducted through a heating pipe while filter pressing treatment is conducted, so that the filter pressing efficiency is improved, and the sludge treatment work is accelerated.

Owner:CHINA FIRST METALLURGICAL GROUP

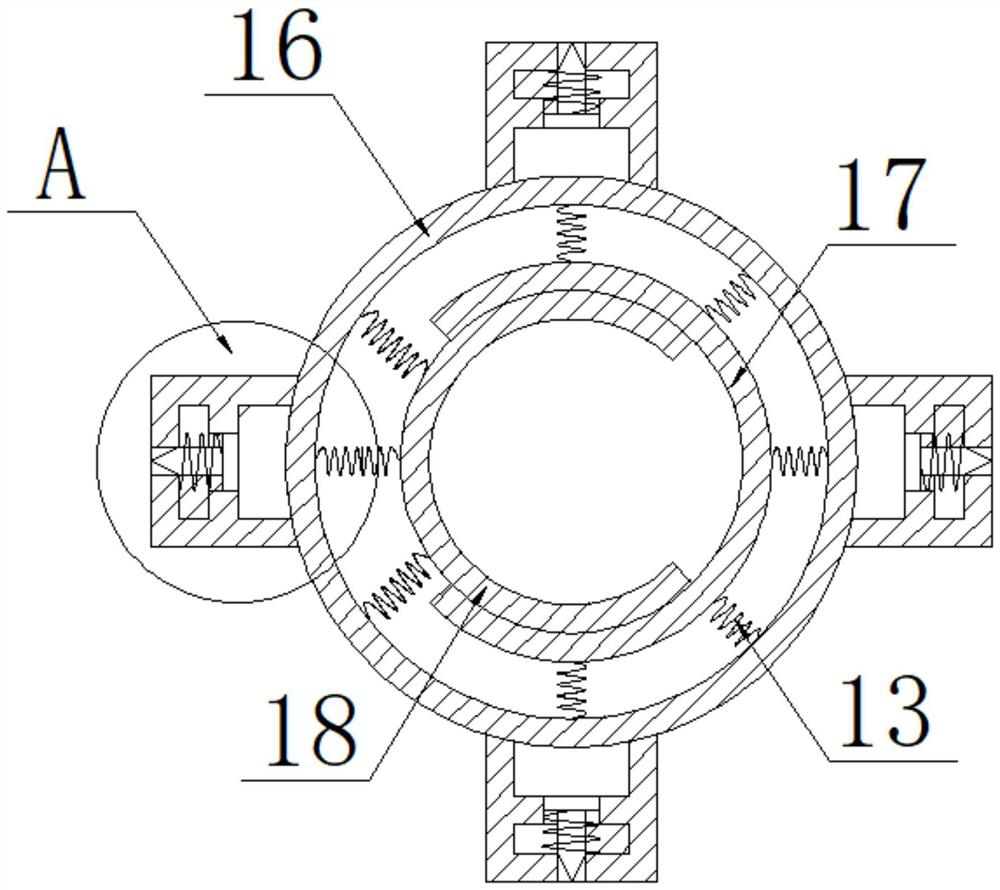

Pile casing device for brine stratum mucky soil cast-in-place pile construction

The invention discloses a pile casing device for brine stratum mucky soil cast-in-place pile construction, which comprises a pile casing head, a fixed transverse plate and an outer pile casing body, the upper surface of the pile casing head is fixedly connected with the fixed transverse plate, the lower surface of the pile casing head is fixedly connected with the outer pile casing body, and reinforcing ribs are fixedly arranged on the outer surface of the outer pile casing body. The number of the reinforcing ribs is four, a plurality of first through holes are fixedly formed in the outer surfaces of one sides of the reinforcing ribs, a partition plate is fixedly arranged on one sides of the first through holes, a plurality of second through holes are formed in the partition plate, and the second through holes correspond to the first through holes in position. The outer pile casing body, the first inner pile casing body and the second inner pile casing body are arranged, so that the phenomena that a pile body deflects, a pile hole shrinks, collapses and even cannot be formed easily in the drilling process when a sludge layer is thick or located in a middle layer are effectively avoided, a mud wall protection process is avoided, and pollution to underground soil and water is completely eradicated.

Owner:SHANDONG JIAOTONG UNIV

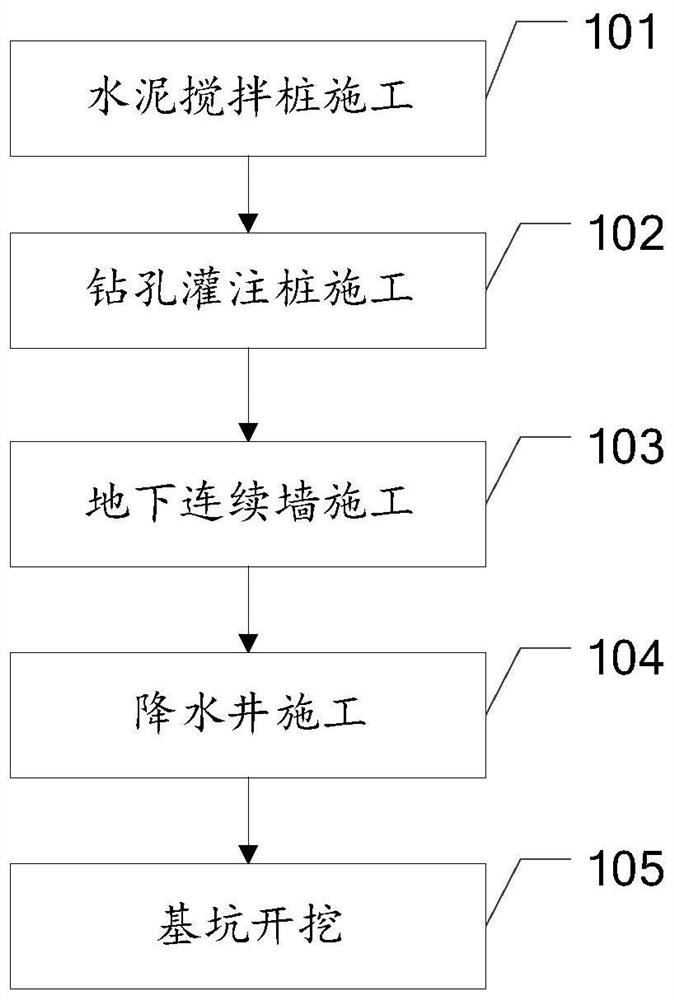

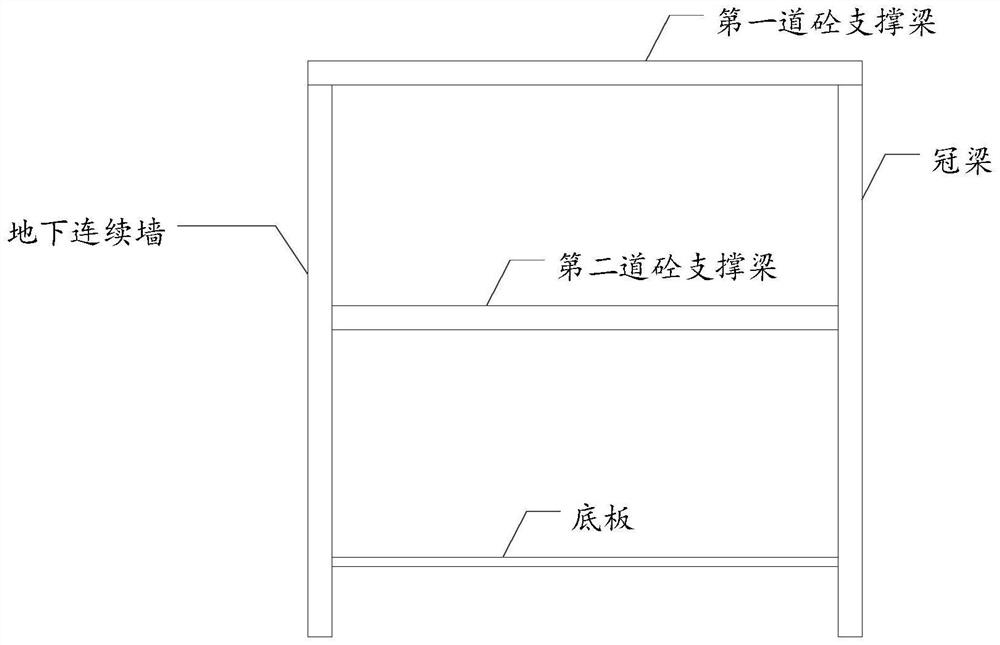

Foundation pit reinforcement construction method for mucky soil layer

PendingCN114108649APrevent collapseImprove stabilityFoundation testingExcavationsSlurry wallPlaggen soil

The invention relates to the technical field of building construction, and discloses a foundation pit reinforcement construction method for a mucky soil layer, which is used for improving the stability of a foundation pit in a foundation pit construction process. The foundation pit reinforcing construction method for the mucky soil layer comprises the steps that firstly, cement mixing piles are constructed; step 2, constructing a cast-in-situ bored pile; step 3, underground diaphragm wall construction; step 4, precipitation well construction; and fifthly, the foundation pit is excavated. And foundation pit reinforcement construction is conducted through an enclosure structure formed by the cement mixing piles, the cast-in-situ bored piles and the underground continuous wall and a dewatering well drainage system.

Owner:CHINA RAILWAY SIXTH GROUP +1

Tunneling method of EPB-TBM dual-mode tunnel boring machine composite stratum

The invention discloses a tunneling method of an EPB-TBM dual-mode tunnel boring machine composite stratum. The tunneling method is characterized in that in terms of water-rich sandy soil with a stratum of 18.8-21.4 meters in buried depth, silt soil with a stratum of 21-23.5 meters in buried depth, sludge and muddy soil with a stratum of 23.8-24.4 meters in buried depth and an upper-soft and lower-hard stratum of 23 meters in buried depth, a tunnel boring machine is in an EPB mode and adopts a soil pressing balance mode for tunneling; in terms of tunneling on a hard-rocky stratum, the tunnel boring machine is in a TBM mode and adopts an open mode for tunneling; in terms of an upper-soft and lower-hard with a stratum of 16 meters in buried depth, the tunnel boring machine is in the EPB modeand adopts the soil pressing balance mode for tunneling; and in terms of soft rock with a stratum of 16 meters in buried depth, the tunnel boring machine is in the EPB mode and adopts a half-open mode for tunneling. According to the tunneling method, ground settlement or bumping amount can be decreased to the greatest extent, the tunneling efficiency can be ensured, and construction risks and engineering investment are reduced.

Owner:CCCC THIRD HARBOR ENG +2

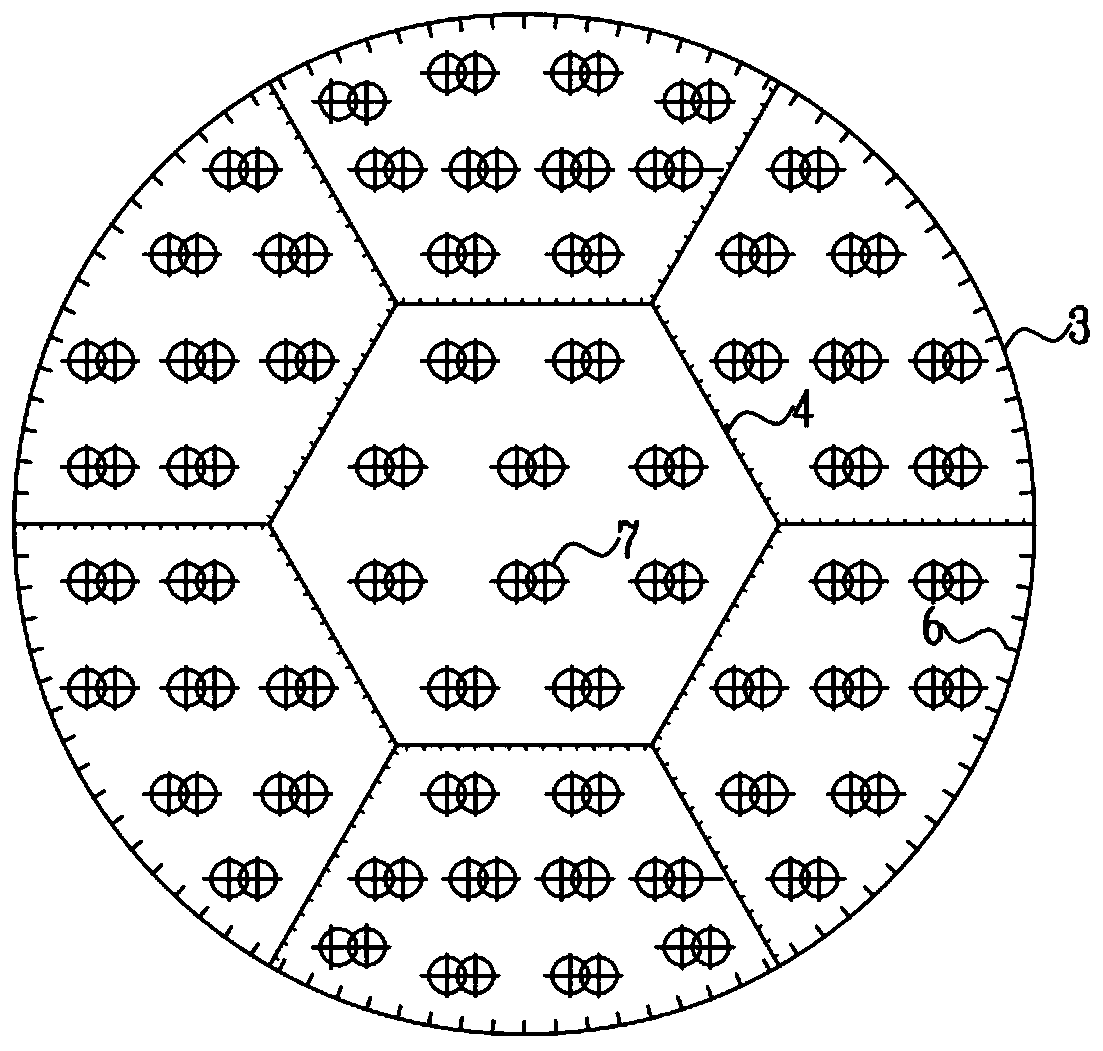

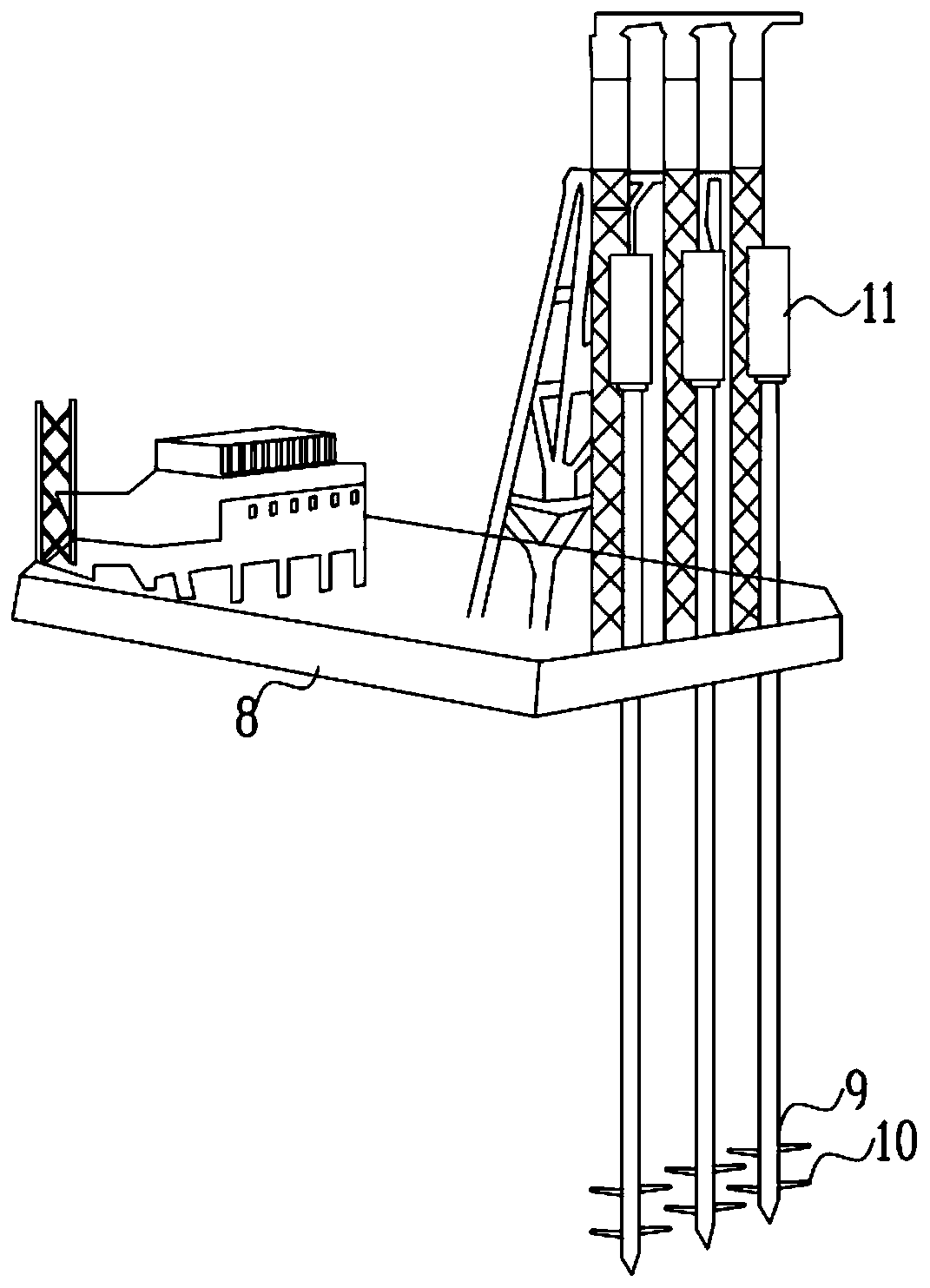

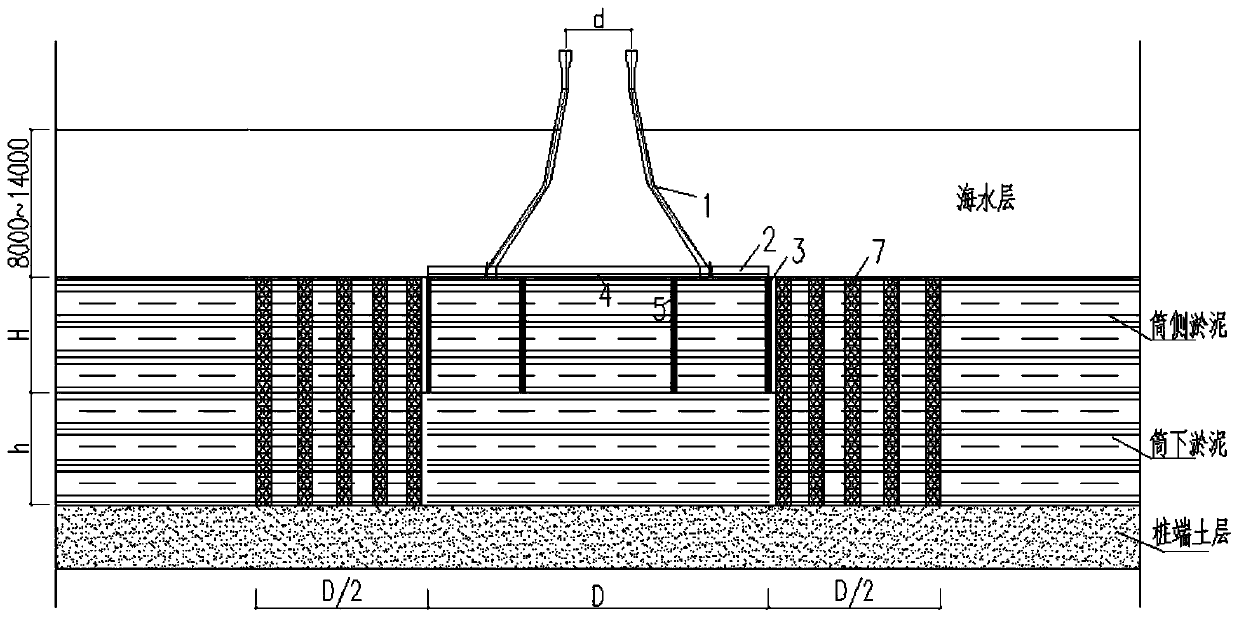

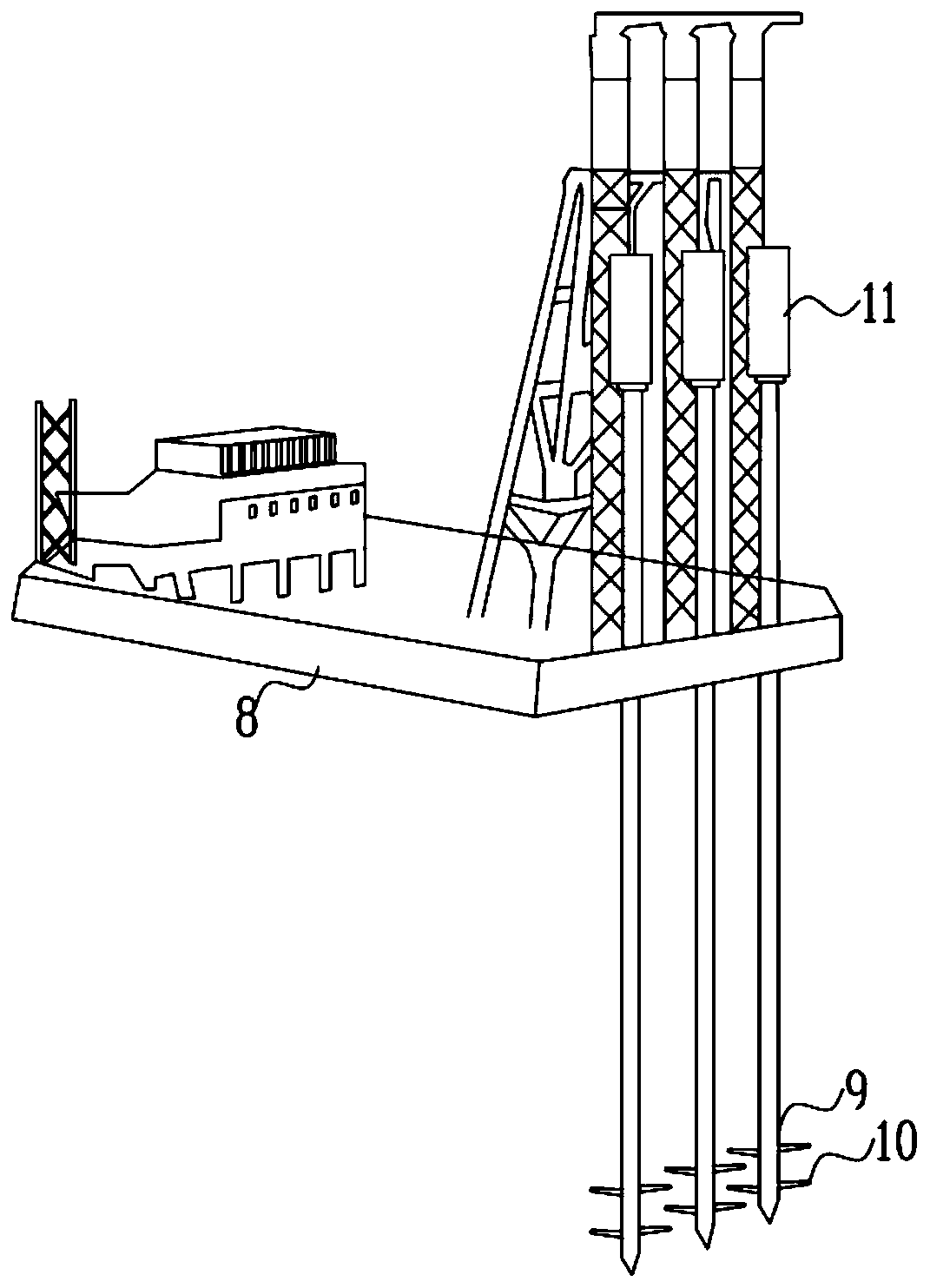

Composite foundation-bucket offshore wind power foundation with piles distributed in bucket and construction method

PendingCN110847217AIncrease the carrying areaImprove stabilityFoundation engineeringStructural engineeringOffshore wind power

The invention relates to a composite foundation-bucket offshore wind power foundation with piles distributed in a bucket and a construction method. The wind power foundation is suitable for the sea area with offshore surface layers covered with weak soil such as thick mud, mucky soil and silty soil in China and comprises a concrete transition section, a composite bucket foundation, a concrete circular bottom plate and the in-bucket piles, wherein the composite bucket foundation is of a multi-bin structure with a lower open cavity and is sunk in soft soil on the surface layer, the top of the bucket is in contact with the mud surface, and the in-bucket piles are uniformly distributed in each compartment plate in the bucket. The advantages of underwater deep cement mixing piles (or compactedsand piles) and the bucket foundation are combined, the bearing area of the bucket foundation is large, the stability is good, piling is not needed, but under the soft soil condition, the settlement and inclination of the bucket foundation are large, and the cement piles (or the compacted sand piles) are arranged in the bucket foundation, so that the problem of foundation deformation of the bucketfoundation is solved, the manufacturing size of a suction bucket is reduced, and the foundation manufacturing cost is reduced.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

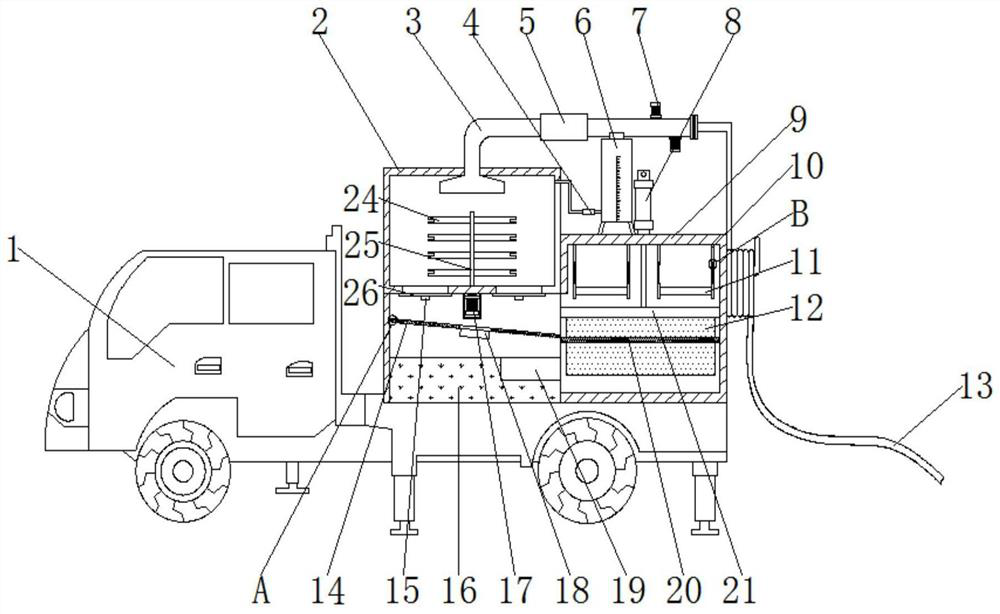

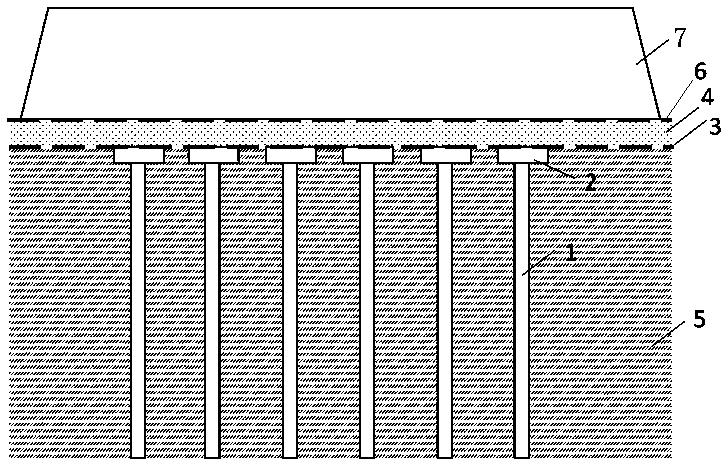

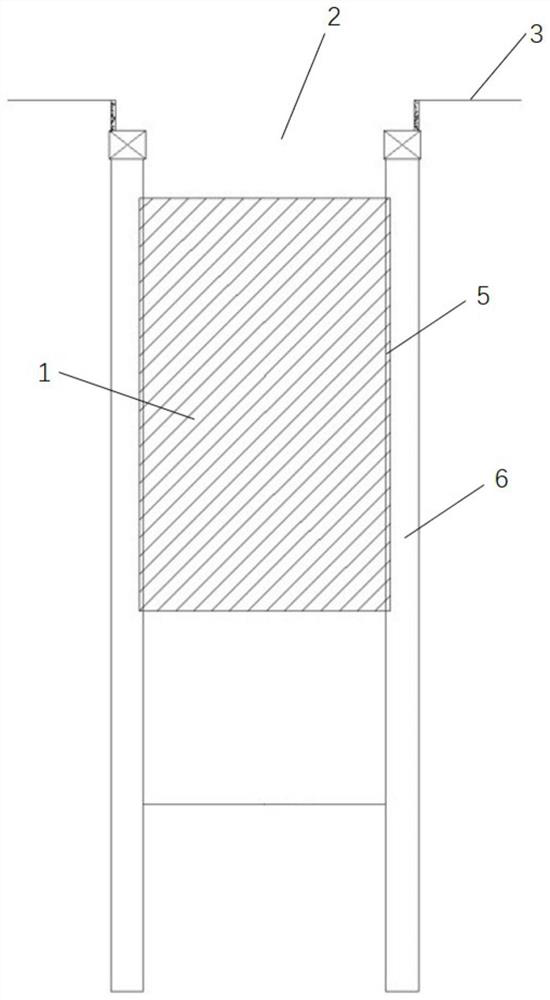

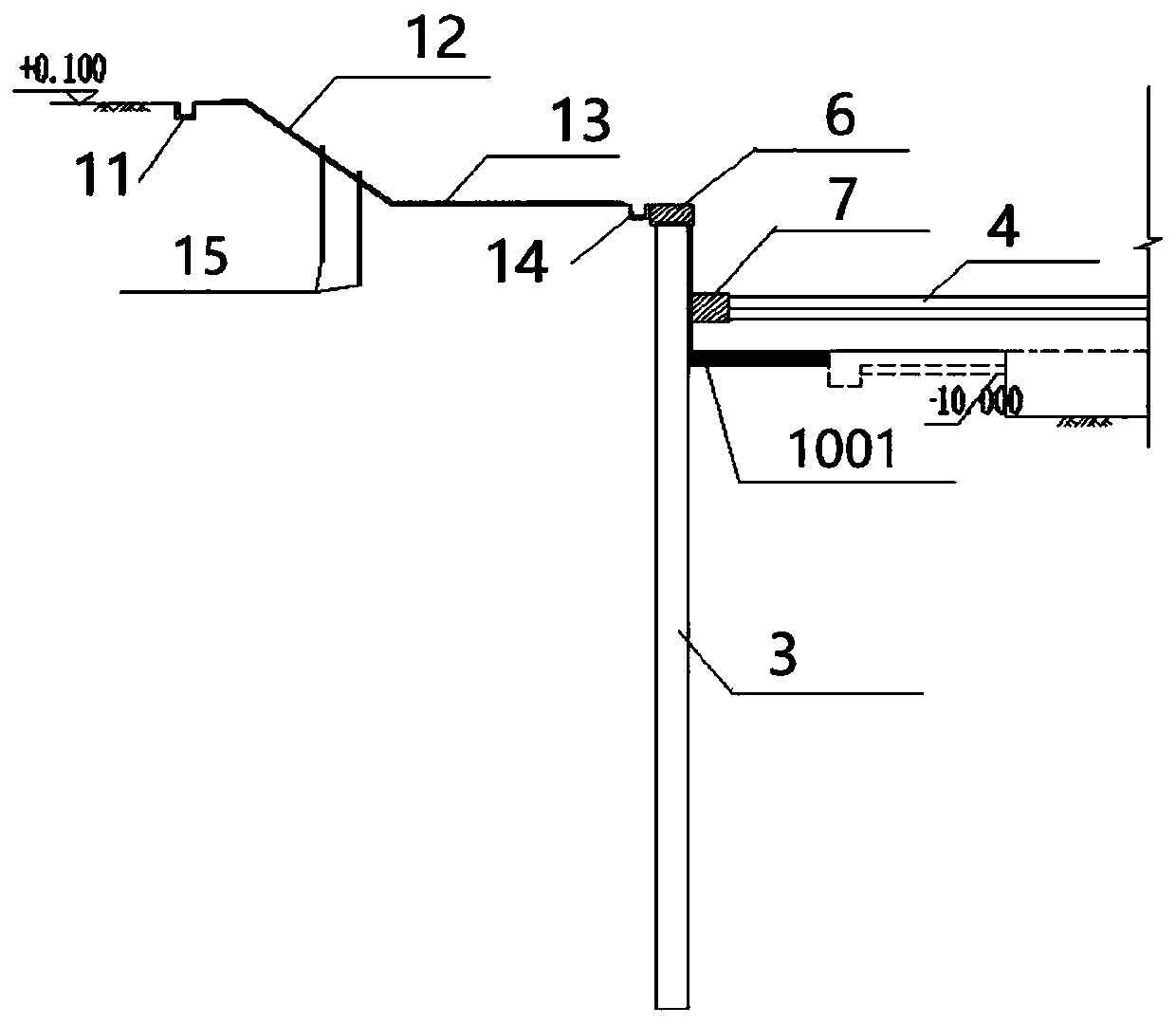

Foundation structure of soft soil stratum and construction method thereof

InactiveCN111424634AReduce frictional resistanceAvoid cloggingBulkheads/pilesSoil preservationPile capPipe

The invention discloses a foundation structure of a soft soil stratum and a construction method thereof, and relates to the field of foundation construction. The problems that high backfill soil and adeep soft muddy soil foundation are poor in stability, and foundation settlement and differential settlement are difficult to control are solved. According to the construction method, small holes aredistributed in the pile periphery of a prefabricated pipe pile in a staggered mode at will, pre-buried barbs are arranged at the small holes, the prefabricated pipe pile is sleeved with geotextile tobe implanted into a soft soil layer, water in soil around the pile permeates through the geotextile and enters an inner pipe from the small holes to be pumped out, after drainage consolidation, the geotextile is torn off, soil around the prefabricated pipe pile enters the pipe through the small holes in the side surface of the prefabricated pipe pile, then foundation soil is backfilled in the pipe of the prefabricated pipe pile, a pile cap is cast in place at the top end of the prefabricated pipe pile, and a first reinforced layer, a cushion layer, a second reinforced layer and a soil fillinglayer are sequentially laid on the pile cap. According to the foundation structure, the foundation bearing capacity of a coastal soft mudflat area can be effectively improved, the filling load borneby soil between piles is small, filling settlement is reduced, and the construction period is effectively shortened.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

Stratum cast-in-situ bored pile with soft upper part and hard lower part

PendingCN112575770AReasonable designFacilitate continuous soil dischargeBorehole drivesSealing/packingSlurryRebar

The invention discloses a stratum cast-in-situ bored pile with a soft upper part and a hard lower part. The stratum cast-in-situ bored pile comprises a foundation, a strongly weathered granite layer,coarse sand, silty clay, mucky soil, a formed hole, a sleeve, a drill rod, drill teeth, a down-the-hole hammer, a reinforcement cage, vertical reinforcements, connecting reinforcements and a concretefilling mechanism. The stratum cast-in-situ bored pile has the beneficial effects that the drill rod and an outer side sleeve are used for double-combination drilling, an outer side sleeve protectionwall facilitates continuous soil discharging of the drill rod, the overall rigidity is high, the drilling force is large, the hole forming precision is high, the drill rod and outer side sleeve can adapt to powerful drilling of various complex stratums and is suitable for construction of various construction methods, a mud protection wall is replaced with the sleeve following protection wall in the drill rod drilling process, environmental pollution caused by slurry can be reduced conveniently, drilling is conducted through double combination of a drill rod drill bit and the outer side sleeve,hole forming can be achieved conveniently and rapidly, dust is little, noise is low, environmental pollution is small in the hole forming process, the reinforcement cage is hung on the steel casing through threaded steel bars, and the reinforcement cage can be prevented from falling off the cage or floating in the pouring process.

Owner:NO 1 ENG CO LTD OF CHINA RAILWAY 22ND CONSTR BUREAU +1

Sludge soil layer mixing pile reinforcing structure and construction method

PendingCN114277760AReduce resistanceImprove connection strengthBulkheads/pilesSoil preservationSoil scienceStructural engineering

The invention relates to a mucky soil layer mixing pile reinforcing structure and a construction method, and is applied to the field of mixing pile technology, the mucky soil layer mixing pile reinforcing structure comprises a mixing pile body used for reinforcing a mucky soil layer, and reinforcing ribs are arranged in the mixing pile body used for reinforcing the mucky soil layer in the depth direction; the reinforcing ribs are provided with reinforcing mechanisms used for improving the connecting strength between the mixing pile body and a muddy soil layer on the peripheral side of the mixing pile body. The reinforcing mechanism comprises a connecting core and a plurality of external expansion ribs, the connecting core is arranged on the reinforcing rib in a sleeving mode, the external expansion ribs are hinged to the peripheral side of the connecting core at intervals, and the reinforcing rib is provided with an external supporting mechanism used for abutting the external expansion ribs into a muddy soil layer on the peripheral side of the mixing pile body. The stirring pile has the advantages that the stirring pile and the surrounding muddy soil layer are connected more tightly, and then the connecting strength of the stirring pile and the surrounding muddy soil layer is improved.

Owner:深圳市蛇口招商港湾工程有限公司

Construction method for reinforcing PHC pipe pile core in mucky soil layer area

InactiveCN112878320AEnsure the construction period of the projectLow construction costFoundation testingBulkheads/pilesSludgeRebar

The invention discloses a construction method for reinforcing a PHC pipe pile core in a mucky soil layer area. The construction method comprises the following steps that according to a pile body quality report of low strain detection of the PHC pipe pile after excavation of a mucky soil body foundation, and sludge filled in an inner cavity of the PHC pipe pile which is judged to be in class II and class III quality grades by using a high-pressure jet grouting drilling machine is stirred and diluted; and then high-pressure compressed air of a high-pressure jet grouting drilling machine is used for gradually extruding slurry water formed through stirring and dilution out of an inner cavity of the PHC pipe pile; then reinforcing steel bars are continuously arranged in the weld joint cracking position area of a PHC pipe pile connector, then concrete is used for filling a pile core reinforcing space, and therefore pile core reinforcing work at the weld joint cracking position of the PHC pipe pile connector is completed. According to the construction method for reinforcing the PHC pipe pile core in the mucky soil layer area, the project construction period can be ensured, and the project construction cost increased by follow-up pile refilling can be reduced.

Owner:CHINA MCC17 GRP

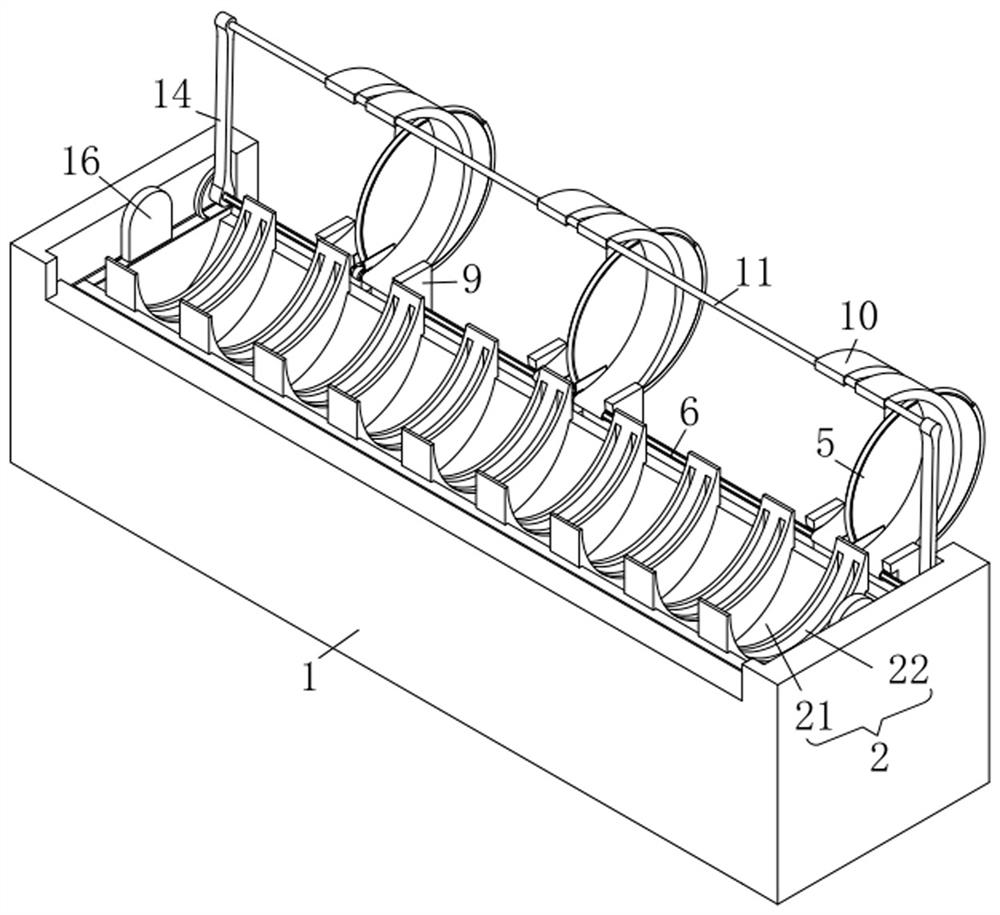

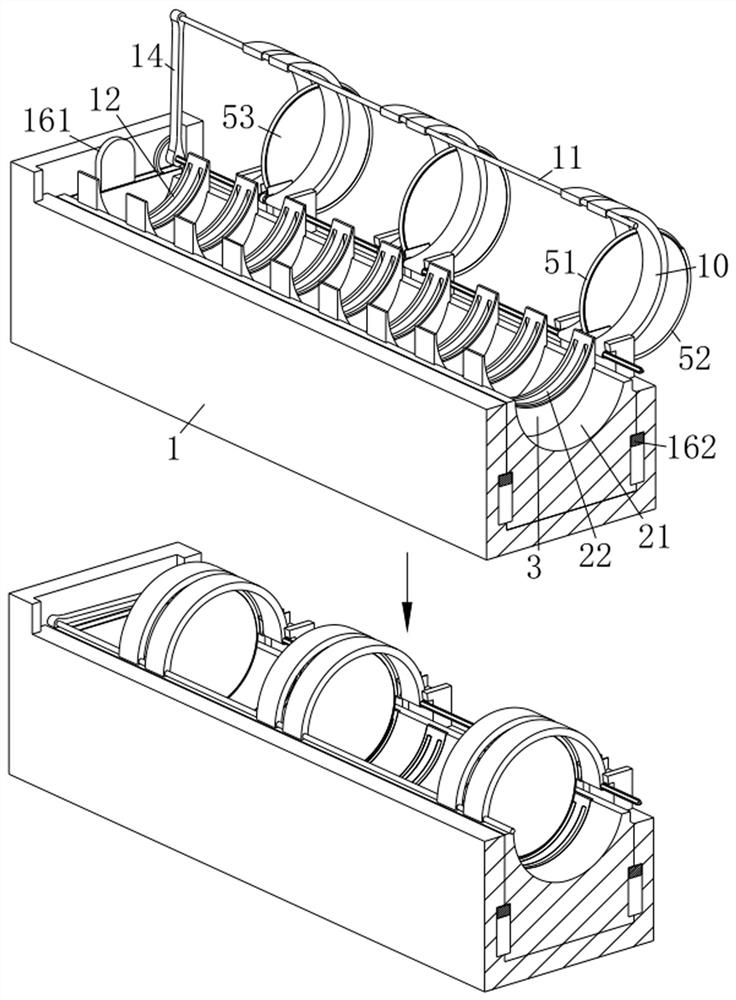

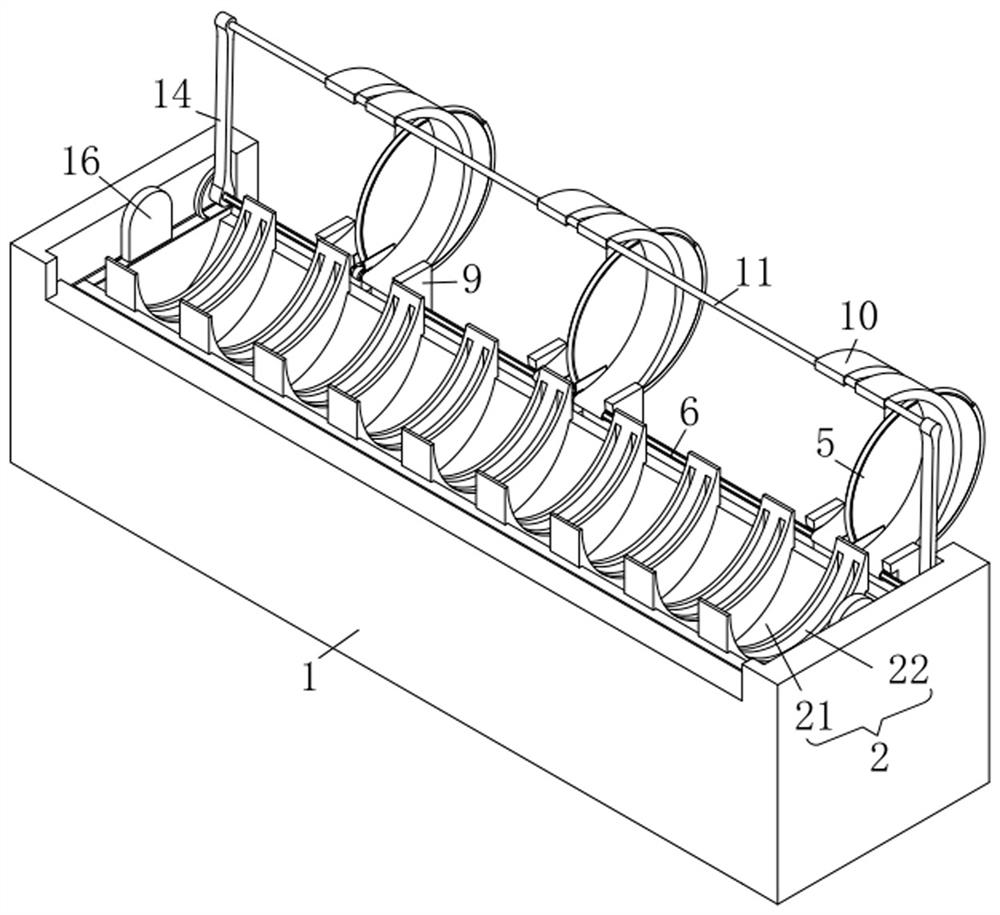

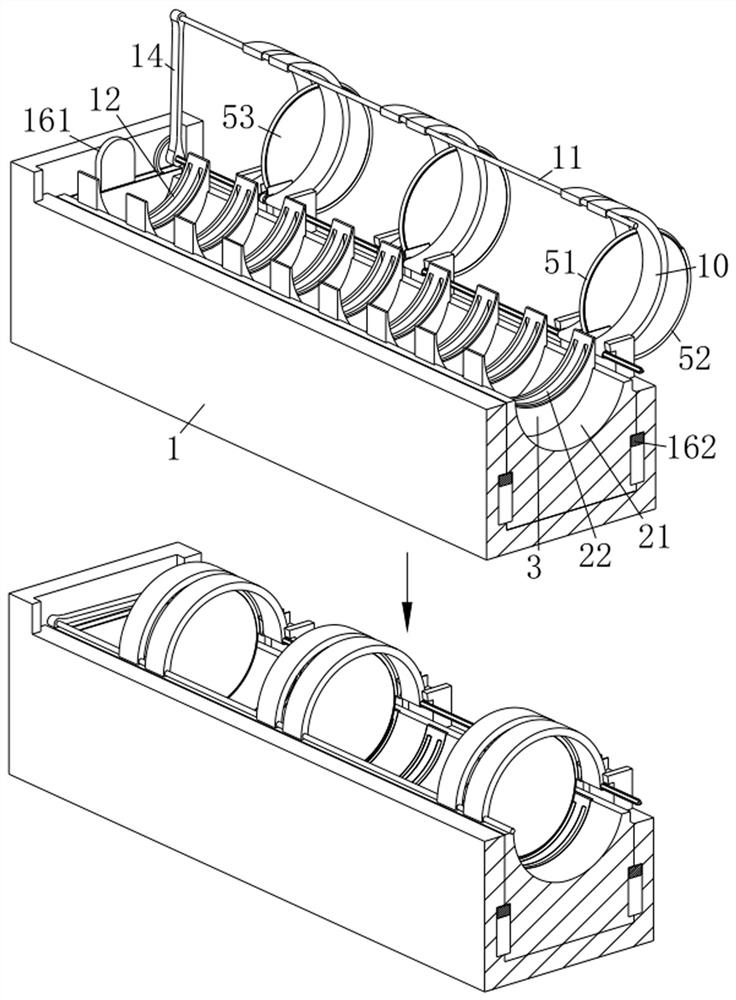

Sample layering treatment device for detecting argillaceous soil core column sample

ActiveCN114199651AImprove efficiencyImprove slitting accuracyWithdrawing sample devicesPreparing sample for investigationDirect observationClassical mechanics

The invention provides a sample layering treatment device for argillaceous soil core column sample detection, and belongs to the technical field of geological survey, the sample layering treatment device comprises a sample placing part and a slitting and dividing part which are matched for use, and the slitting and dividing part is used for slitting and dividing a core column sample into independent sample units; the slitting and dividing part comprises a plurality of slitting discs which have an anti-sticking function and expand gaps between adjacent independent sample units to facilitate taking of the independent sample units, a radial limiting shaft is rotationally connected to the processing seat, middle connecting pieces are connected to the slitting discs, and the slitting discs are axially connected to the radial limiting shaft in a sliding mode through the middle connecting pieces. According to the sample layering treatment device for detecting the argillaceous soil core column sample, the sample slitting and dividing treatment efficiency and the slitting precision are effectively improved, the whole slitting process has the advantages of being high in stability and good in cut sample quality, the geological structure can be known by directly observing the sample in the slitting process, and the sample is fully and effectively utilized.

Owner:山东省地质矿产勘查开发局第四地质大队

Drying device for treating mucky soil and using method thereof

InactiveCN112097503AEasy to useEasy dischargeSludge treatment by de-watering/drying/thickeningDrying solid materialsAugerElectric machine

The invention discloses a drying device for treating mucky soil and a using method thereof. The drying device comprises an outer shell, a first rotating shaft is arranged on an outer sleeve, and the outer sleeve and an auger are movably connected with the outer shell in an overturning mode through a first rotating shaft. The auger is arranged in the outer sleeve of the drying device for treating the mucky soil; the auger is concentrically distributed in the outer sleeve; the auger is connected with the outer shell in a penetrating mode; a third rotating motor is arranged at one end of the auger, and a supporting frame is arranged on the third rotating motor; the third rotating motor is connected with the outer sleeve in a supporting mode through a supporting frame; the auger is rotatably and movably connected with the interior of the outer shell through the third rotating motor; the supporting frame is of a hollowed-out structure; and a first rotating shaft is arranged on the outer sleeve, and the outer sleeve and the auger are movably connected with the outer shell in an overturning mode through the first rotating shaft, so that the auger can be overturned and adjusted through thedevice, discharging is facilitated, and the use is more convenient.

Owner:CHINA FIRST METALLURGICAL GROUP

Prefabricated caisson mold construction method capable of replacing brick forming die with mucky soil

InactiveCN113550318APrevent sinking and crackingEnsure safetyArtificial islandsProtective foundationBrickMuck

The invention discloses a prefabricated caisson mold construction method capable of replacing a brick forming die with mucky soil, and relates to the technical field of buildings. The prefabricated caisson mold construction method capable of replacing the brick forming die with the mucky soil comprises the following specific operation steps that S1, a current geological condition is judged, and if the mucky soil is very poor in cohesive force, prone to collapse and large potential safety hazards are caused, the step S2 is carried out; according to the prefabricated caisson mold construction method capable of replacing the brick forming die with the mucky soil, a caisson type steel mold is prefabricated in advance, the mold can be immediately hoisted in place after a foundation pit is excavated, the risk of slope collapse is prevented, the safety of elevator shaft and water-collecting well earth excavation is ensured, the engineering cost is reduced, the later maintenance cost is eliminated, the soft foundation bed forming die can replace a brick forming die, can play a role in protecting a wall, prevents earthwork collapse, forms a whole with a cushion layer, is good in waterproof performance and integrality, and can prevent the soft foundation bed layer from sinking and cracking due to uneven settlement.

Owner:CHINA MCC17 GRP

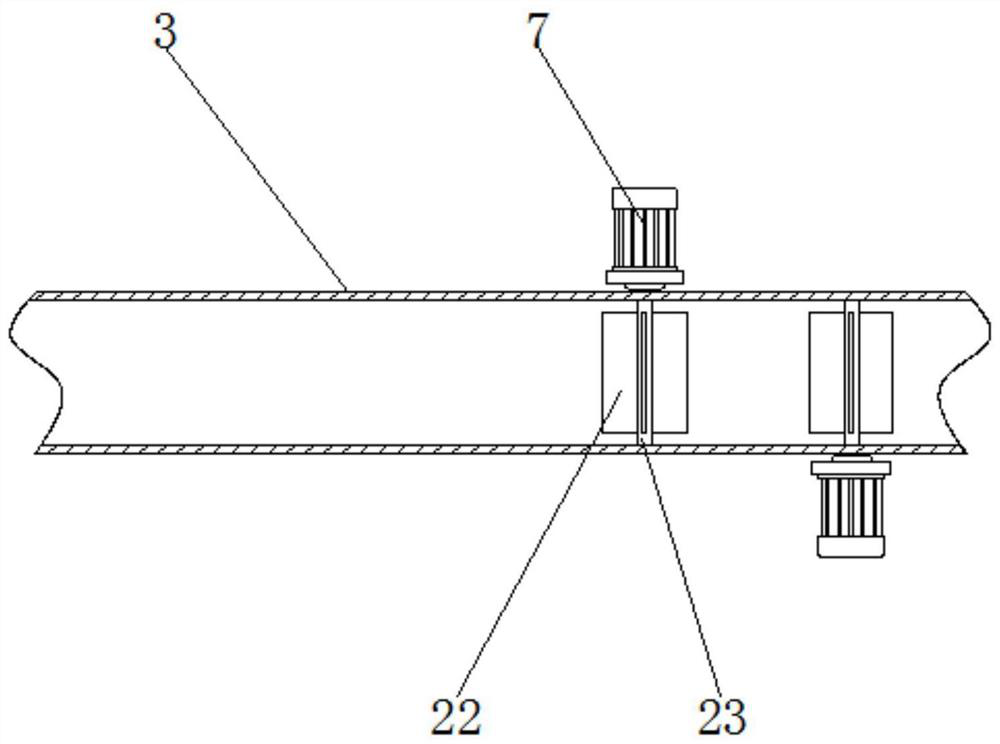

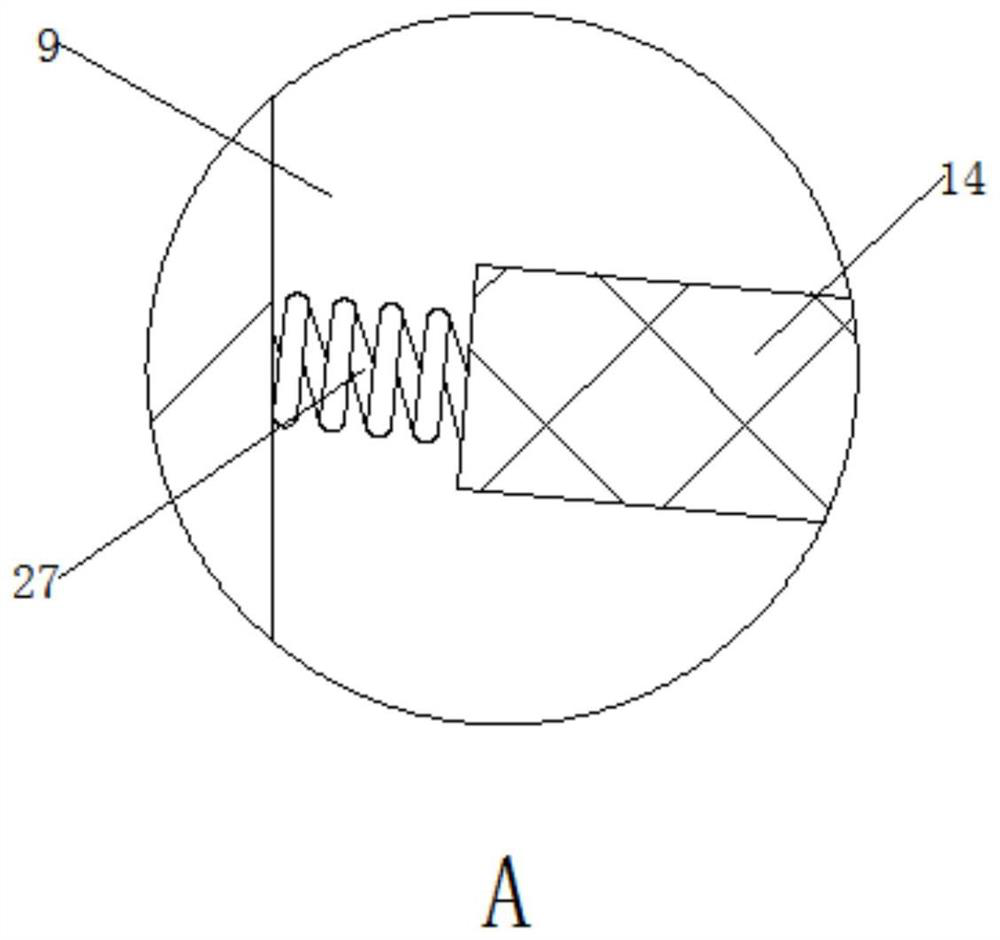

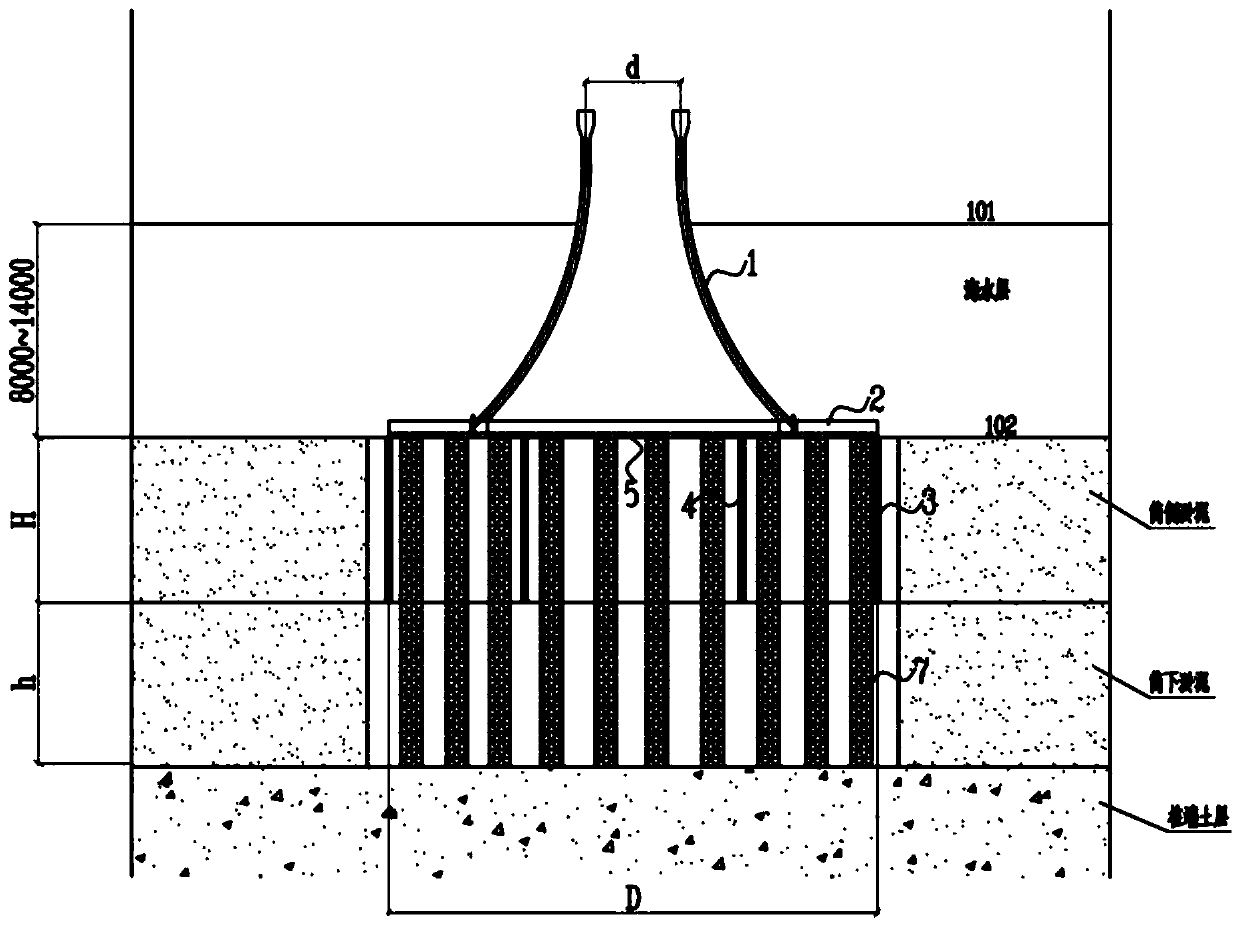

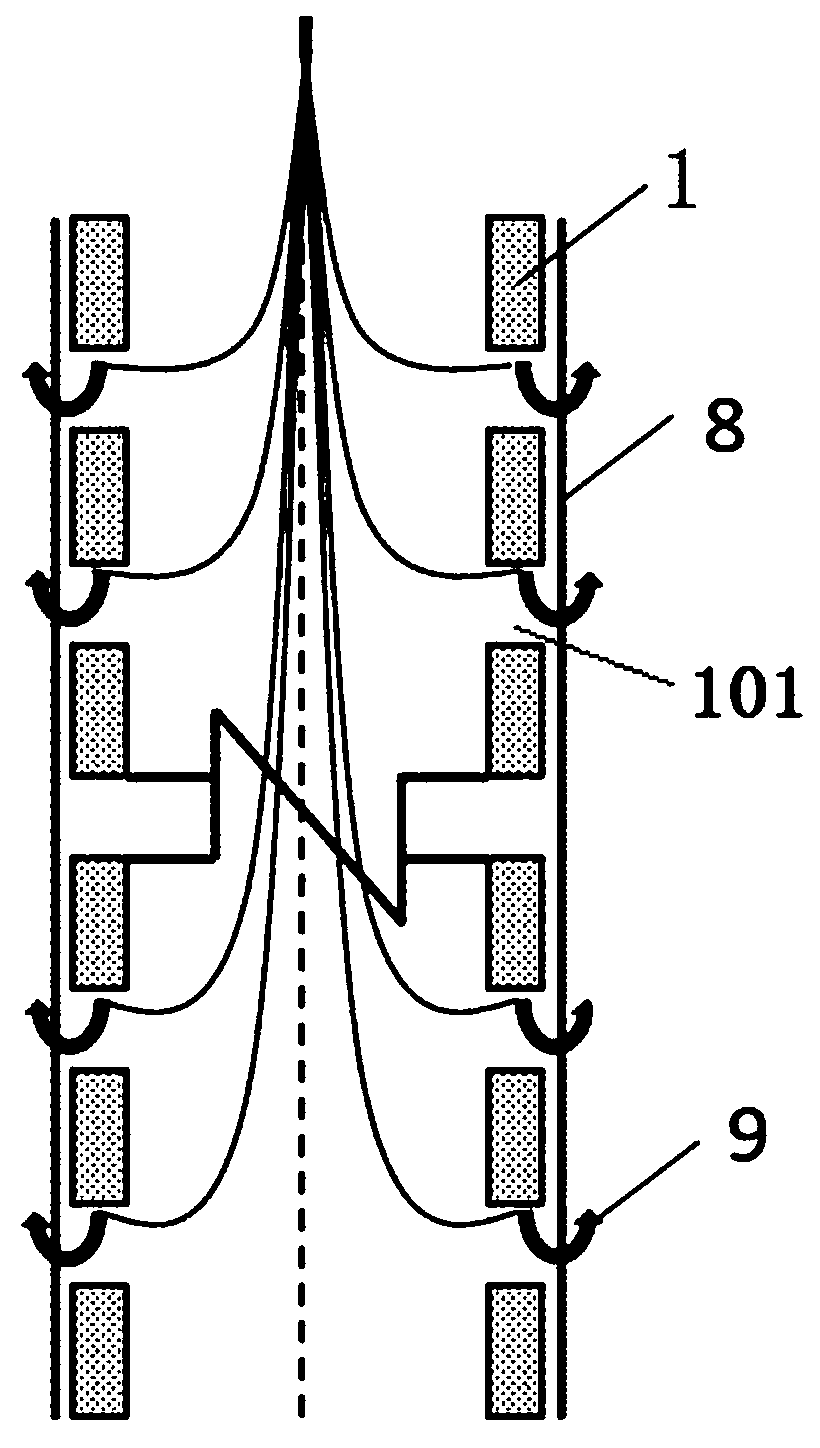

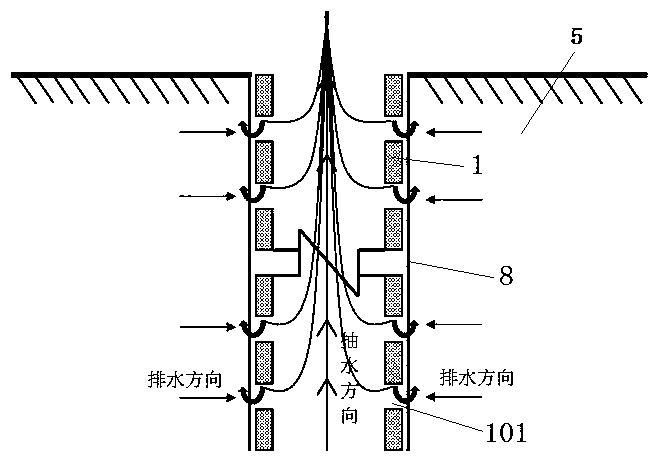

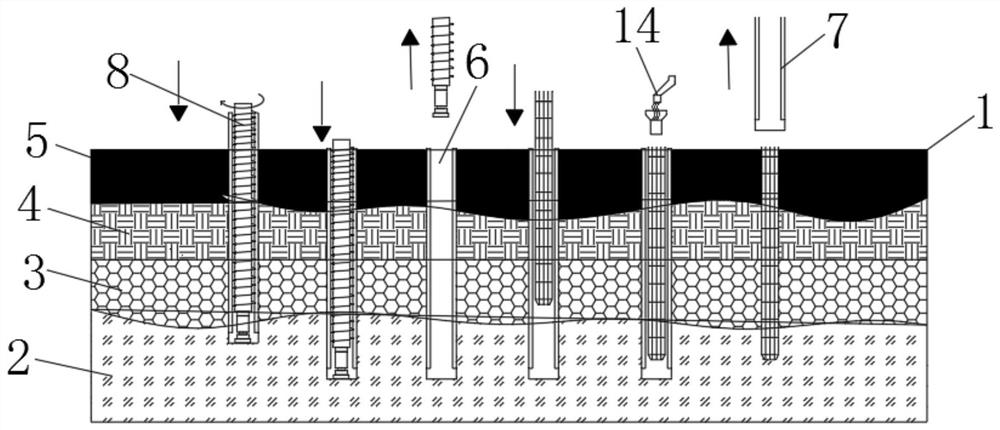

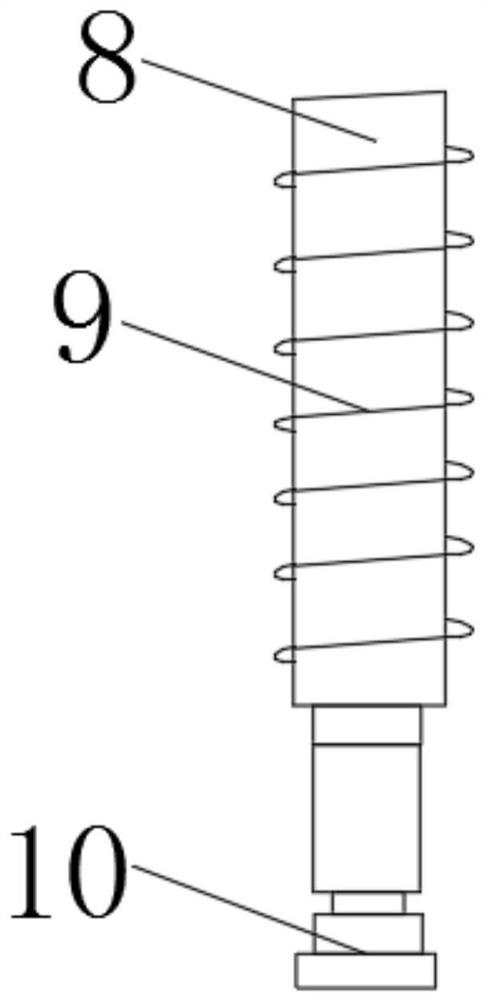

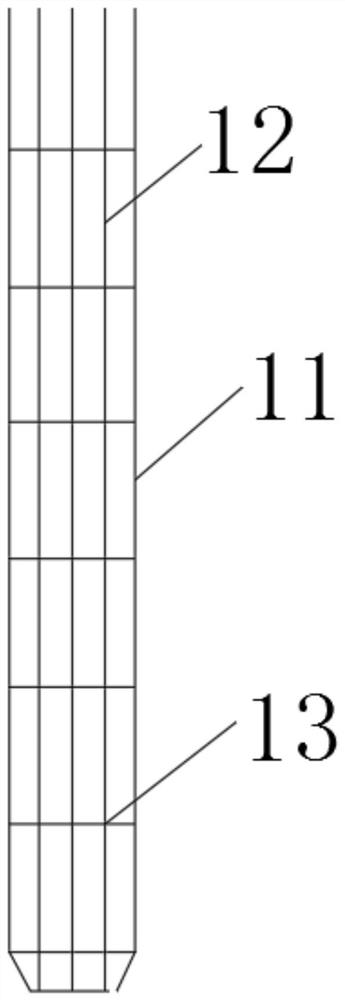

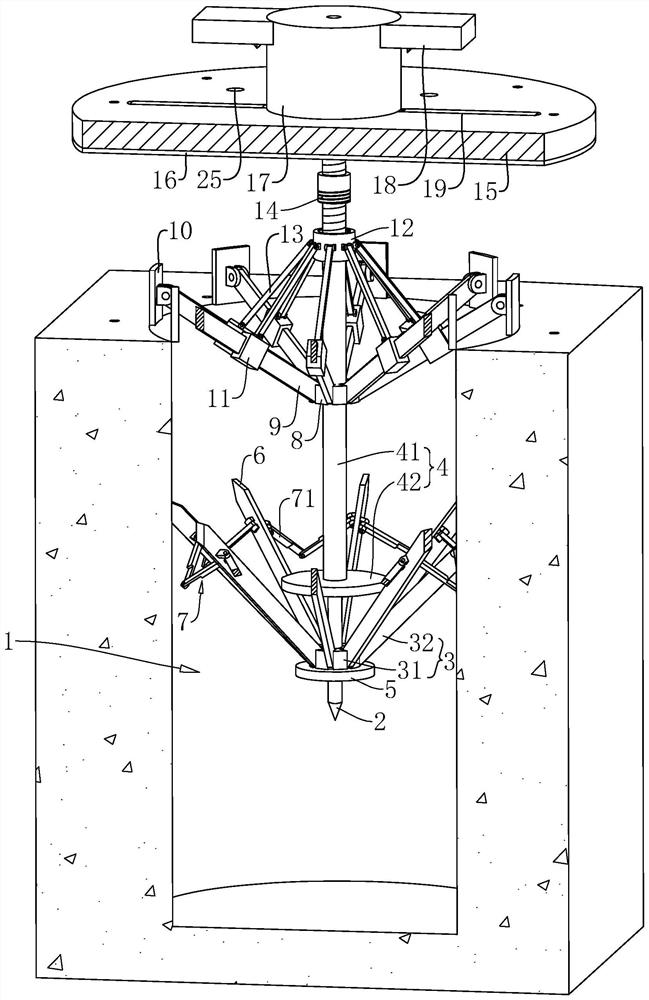

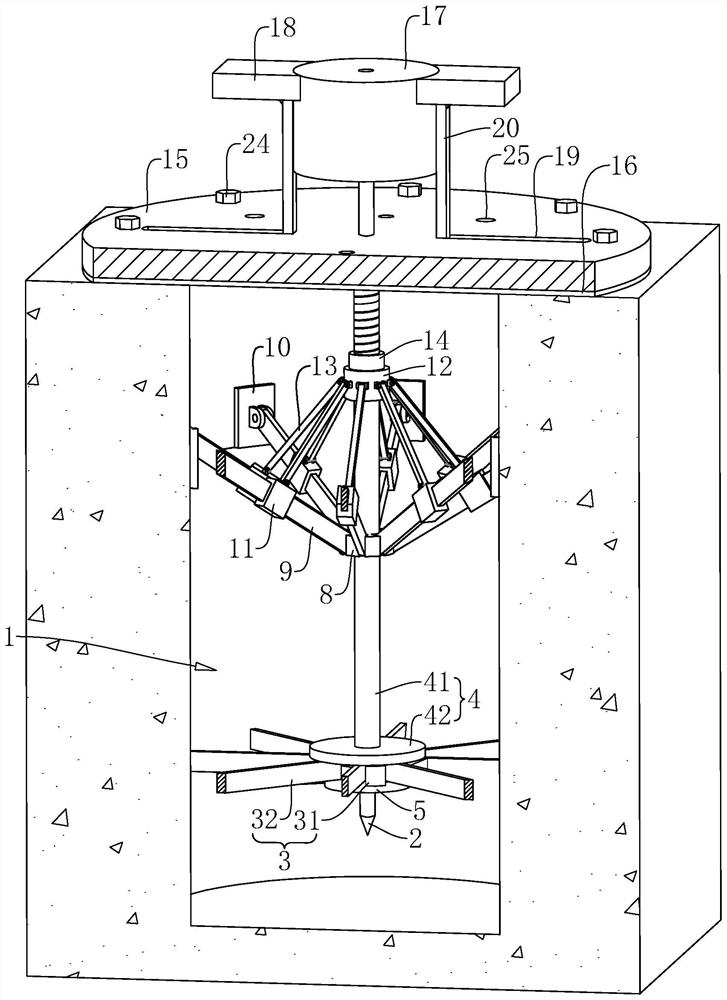

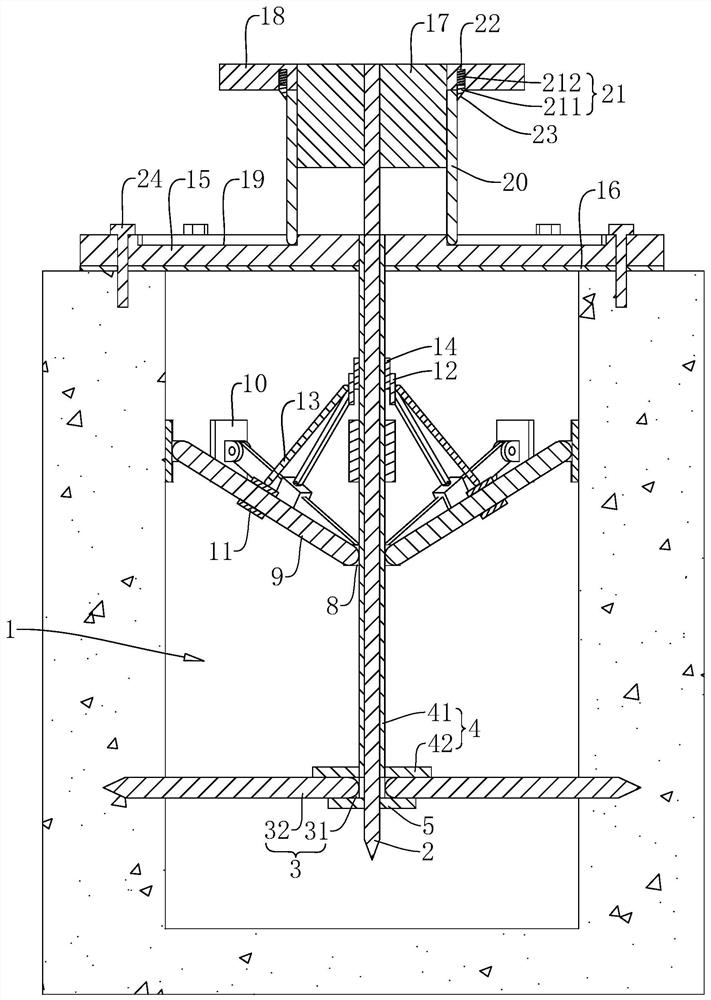

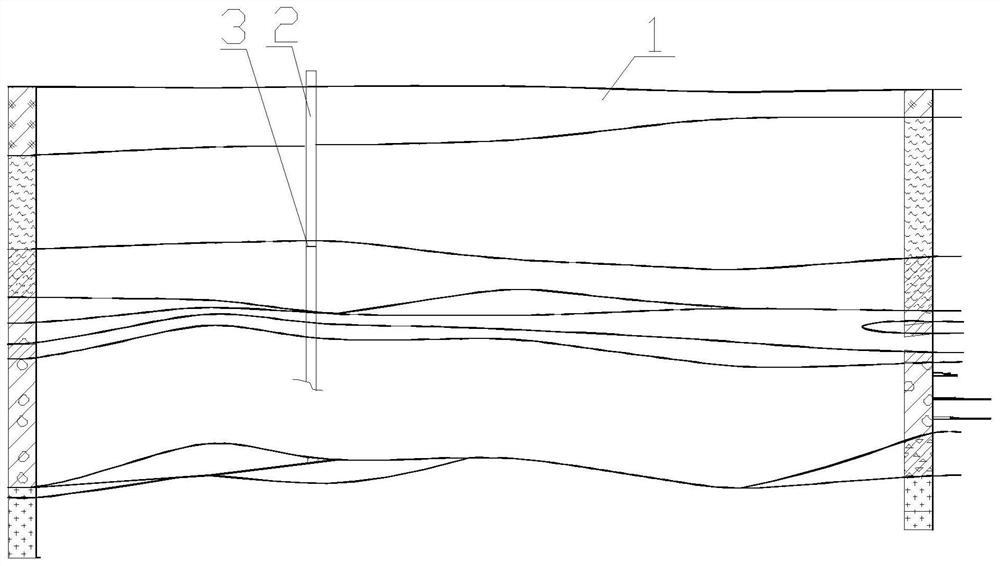

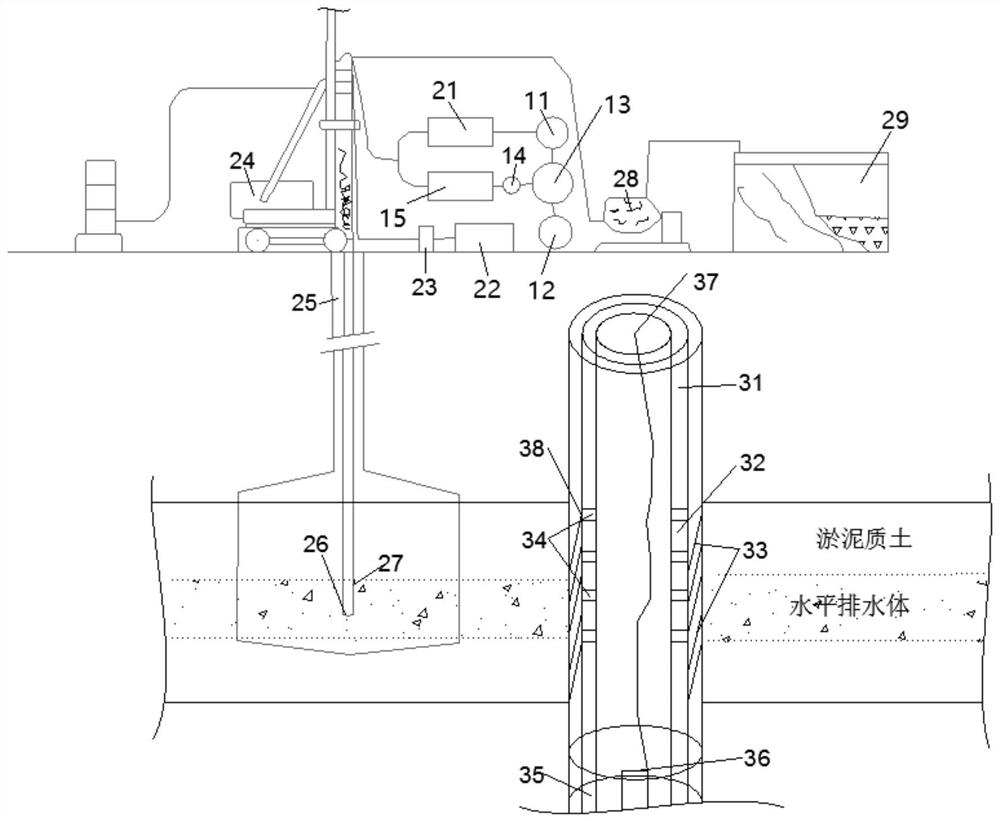

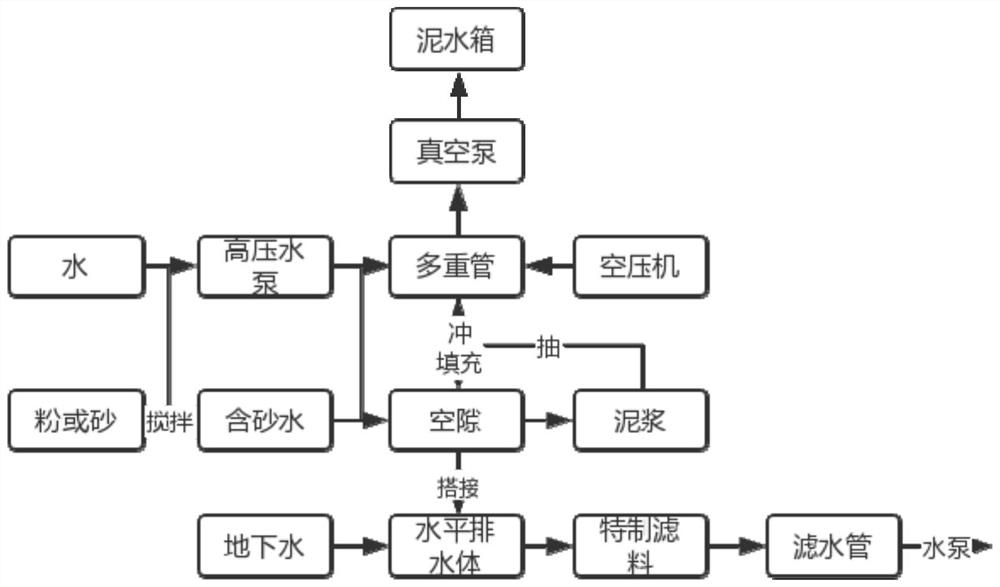

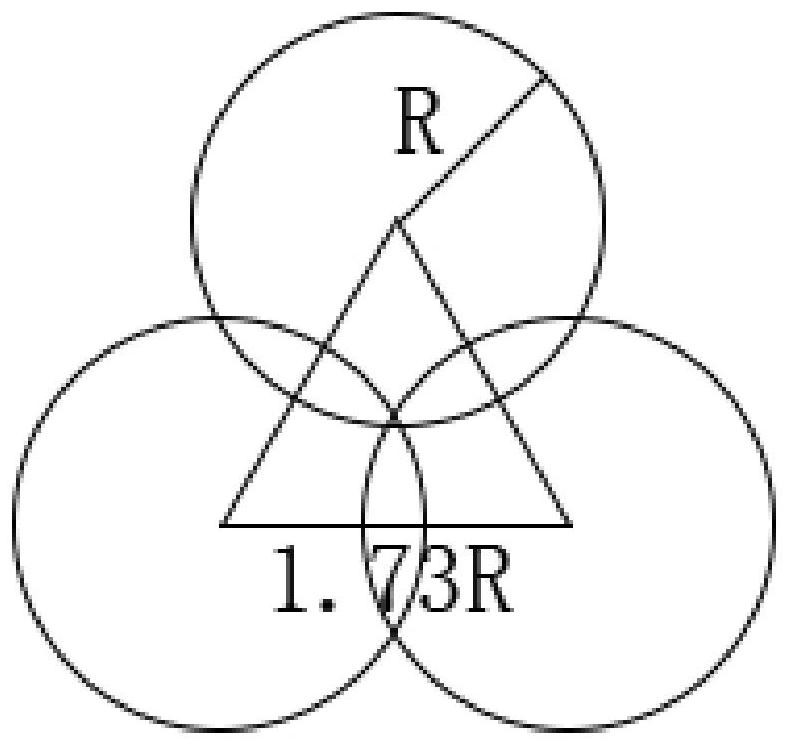

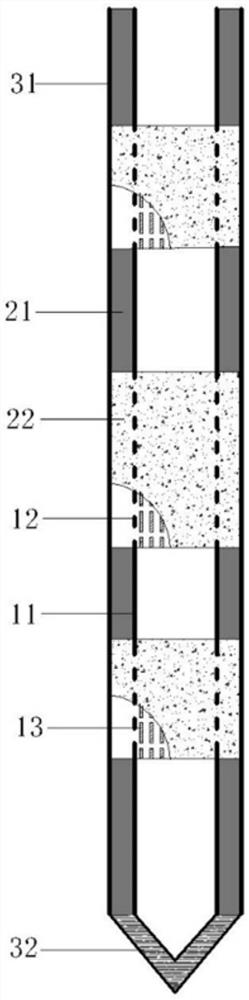

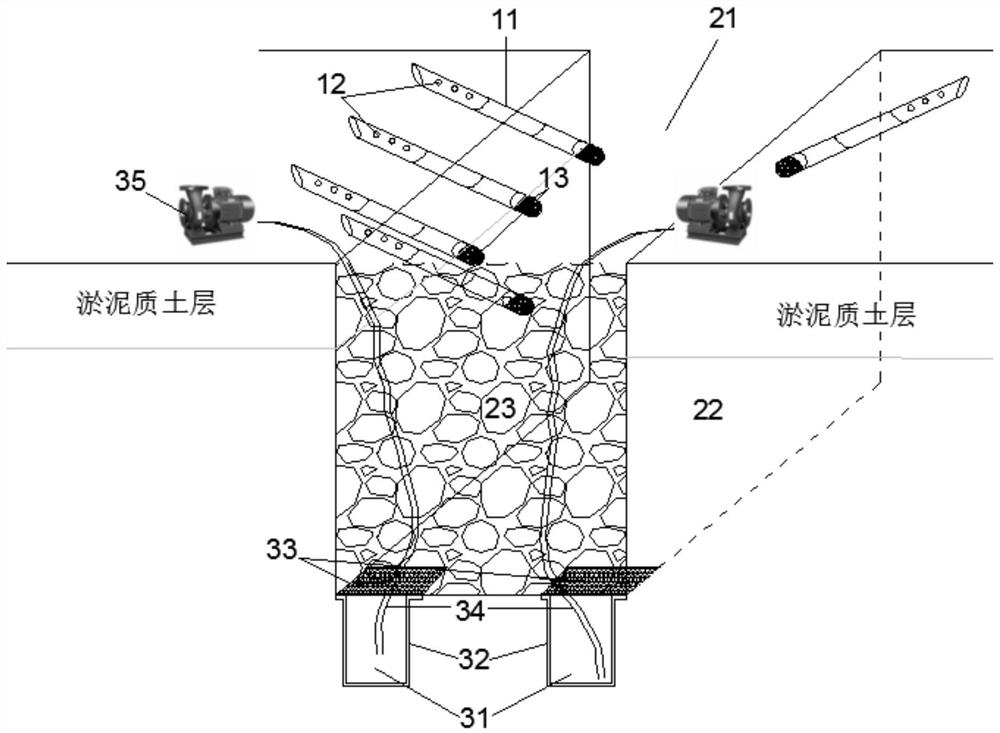

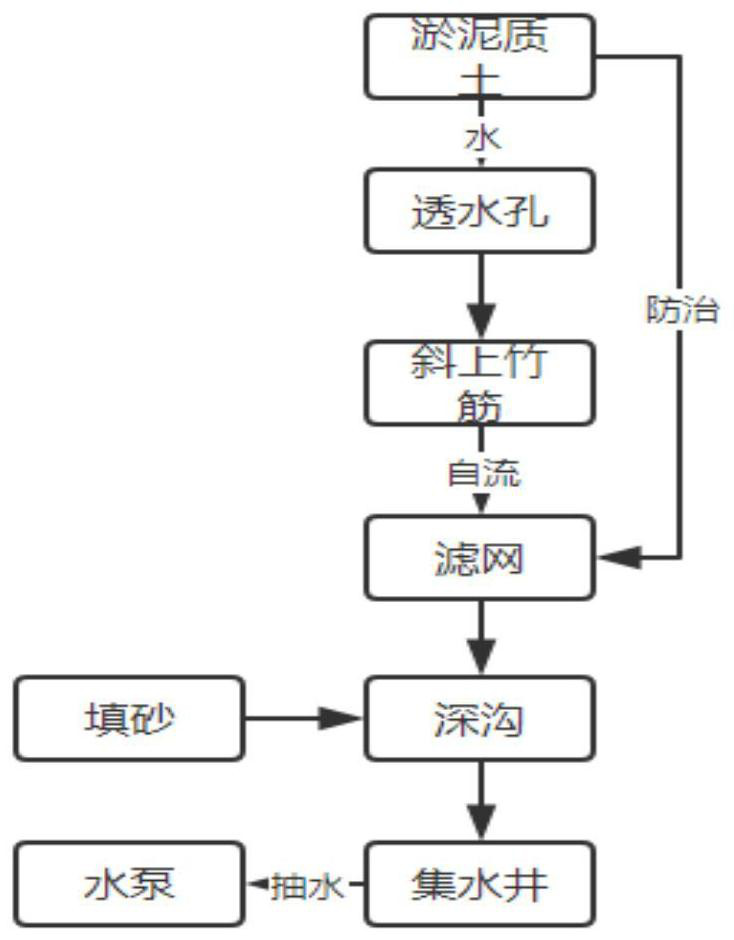

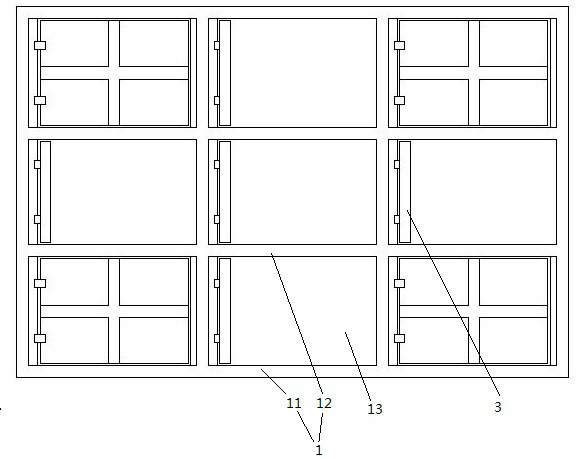

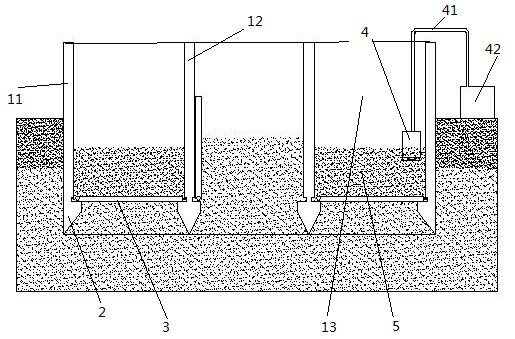

Sludge soil draining and dewatering system and construction method

The invention relates to a draining and dewatering system, in particular to a sludge soil draining and dewatering system and a construction method. The sludge soil draining and dewatering system comprises sand-containing water flow subsystems, a high-pressure rotary spraying subsystem and an draining well subsystem; a plurality of sand-containing water flow subsystems are arranged around the drainage well subsystem and are respectively connected with the high-pressure rotary spraying subsystem; sludge soil is replaced by sand-containing water through the high-pressure rotary spraying subsystem, so that a horizontal drainage body is formed; the high-pressure rotary spraying subsystem comprises a plurality of pipes, a nozzle is arranged at the bottom of the high-pressure rotary spraying subsystem, and the upper part of the high-pressure rotary spraying subsystem is respectively connected with a water pump, an air compressor and a vacuum pump; the sand-containing water flow subsystem comprises a sand-containing water pump and a sand-containing water bucket connected with the multiple pipes through the sand-containing water pump; the drainage well subsystem comprises a drainage well, a drainage pump is arranged in the drainage well, and water permeable holes are formed in the side wall of the drainage well. Compared with the prior art, the sludge soil is replaced with a soil body with good permeability through sand-containing water preparation, high-pressure water flushing, high-pressure rotary spraying, horizontal drainage and the like, permeation and collection of underground water are facilitated, and then the purpose of drainage and dewatering is effectively achieved through the drainage well.

Owner:TONGJI UNIV

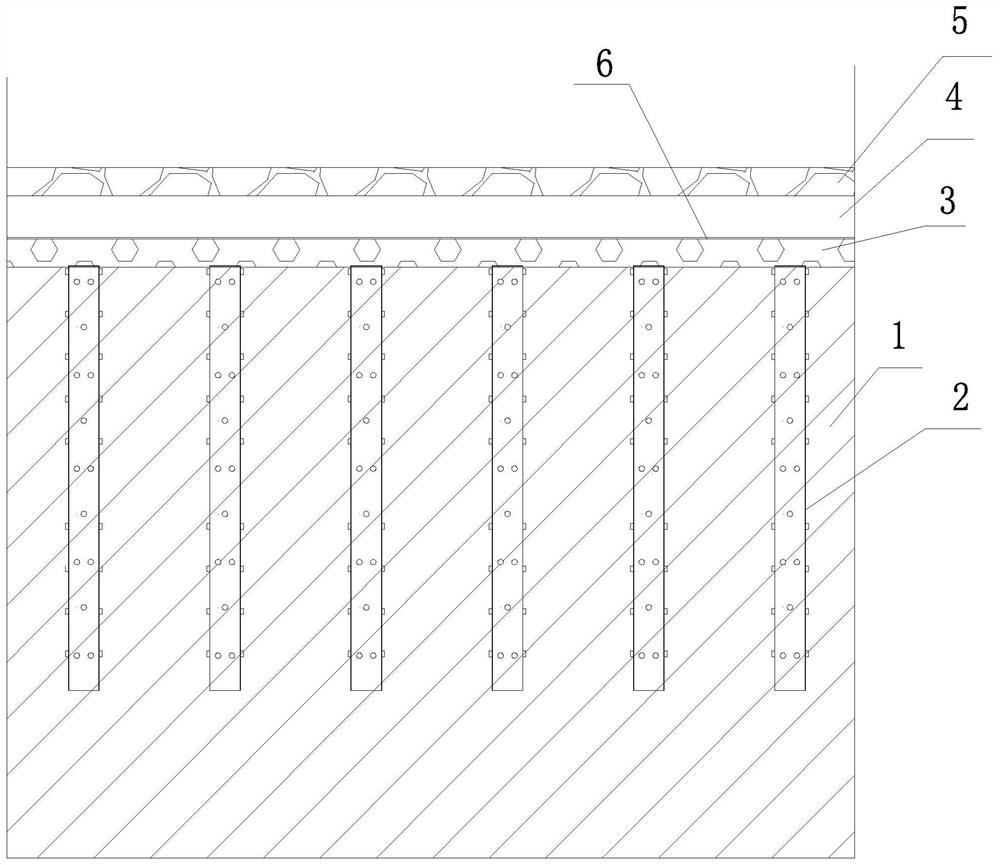

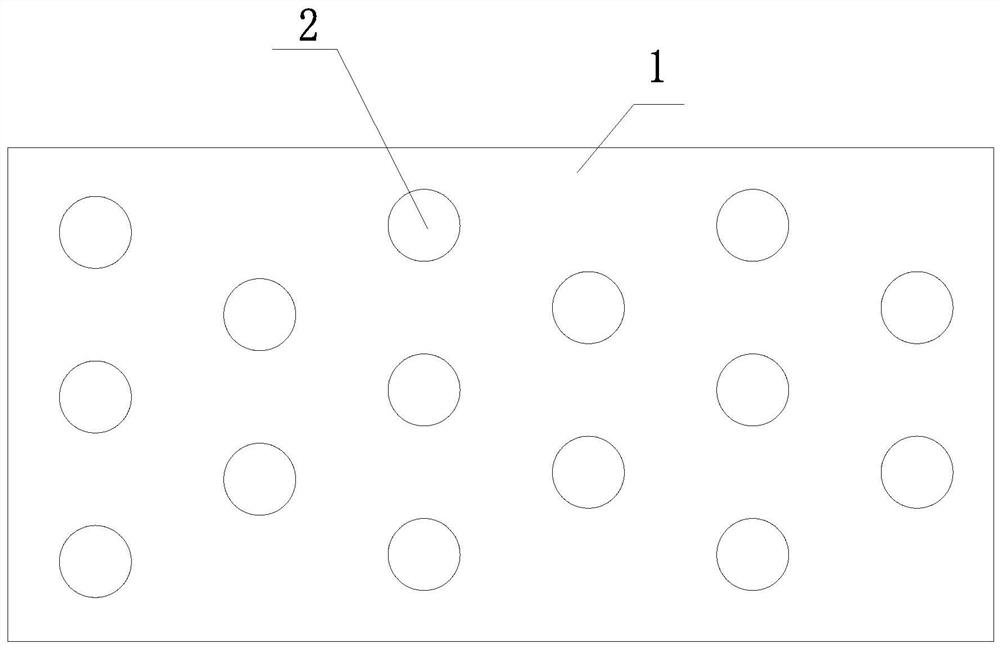

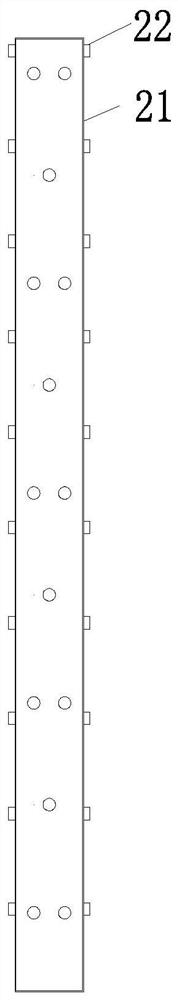

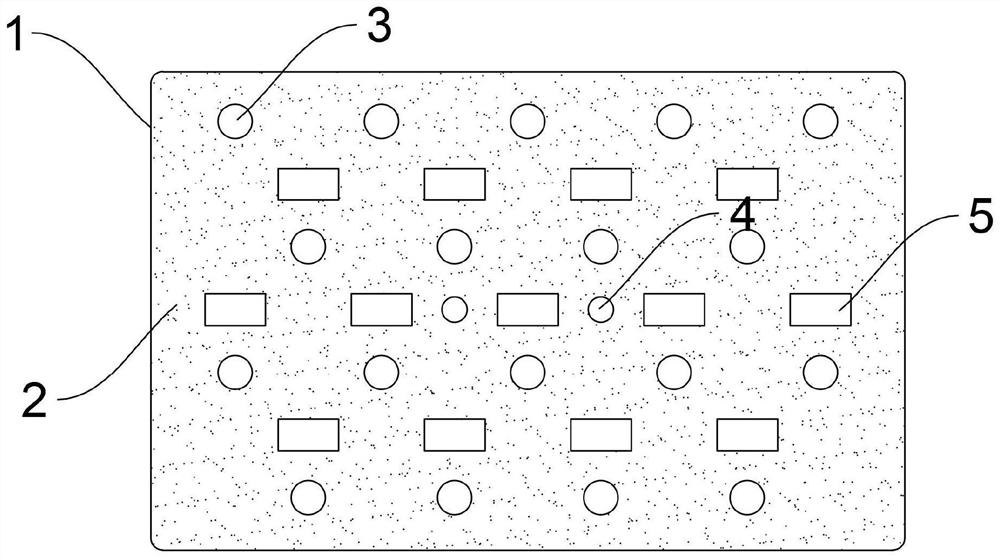

Mucky soil resistance-increasing steel pipe pile foundation reinforcing structure and construction method

InactiveCN112281801ATo achieve reinforcementReasonable designExcavationsBulkheads/pilesMesh reinforcementMechanical equipment

The invention discloses a mucky soil resistance-increasing steel pipe pile foundation reinforcing structure. The mucky soil resistance-increasing steel pipe pile foundation reinforcing structure comprises mucky soil, a plurality of resistance increasing type steel pipe piles with the tops higher than the top of the mucky soil are vertically arranged in the mucky soil, a gravel layer, a plain soillayer and a concrete cushion layer are sequentially arranged on the upper surfaces of the mucky soil from bottom to top, and a reinforcing mesh is arranged at the bottom of the plain soil layer; and the invention further discloses a construction method of the mucky soil resistance-increasing steel pipe pile foundation reinforcing structure. The mucky soil resistance-increasing steel pipe pile foundation reinforcing structure and the construction method mainly aim at solving the problem that silt soil in some foundation pits is too much and deep and is not easy to construct, foundation reinforcement can be rapidly achieved through the implementation of the mucky soil resistance-increasing steel pipe pile foundation reinforcing structure and the construction method, large mechanical equipment does not need to be adopted, and the construction period and the construction cost both can be guaranteed.

Owner:CHINA MCC17 GRP

Deep and thick soft soil deep foundation pit soft soil body pre-reinforcement method

ActiveCN113882348AEnsure safe implementationHigh strengthExcavationsBulkheads/pilesStructural deformationSoil science

The invention belongs to the technical field of deep foundation pit construction, and particularly discloses a deep and thick soft soil deep foundation pit soft soil body pre-reinforcement method. The method comprises the steps that a foundation pit supporting structure is constructed firstly, then soft soil body in a deep foundation pit is subjected to pre-reinforcement treatment to form a reinforcement body, the side face of the reinforcement body is tightly attached to the foundation pit supporting structure, the top of the reinforcement body is close to the ground, and the thickness of the reinforcing body is smaller than or equal to the thickness of the soft soil body above the excavation face of the deep foundation pit. According to the method, soft soil layers such as upper sludge and mucky soil in the foundation pit are subjected to pre-reinforcement treatment, the soil body strength is improved, and deformation of the foundation pit supporting structure is effectively controlled, so that the construction safety of the deep and thick soft soil deep foundation pit is guaranteed.

Owner:WUHAN MUNICIPAL ENG DESIGN & RES INST

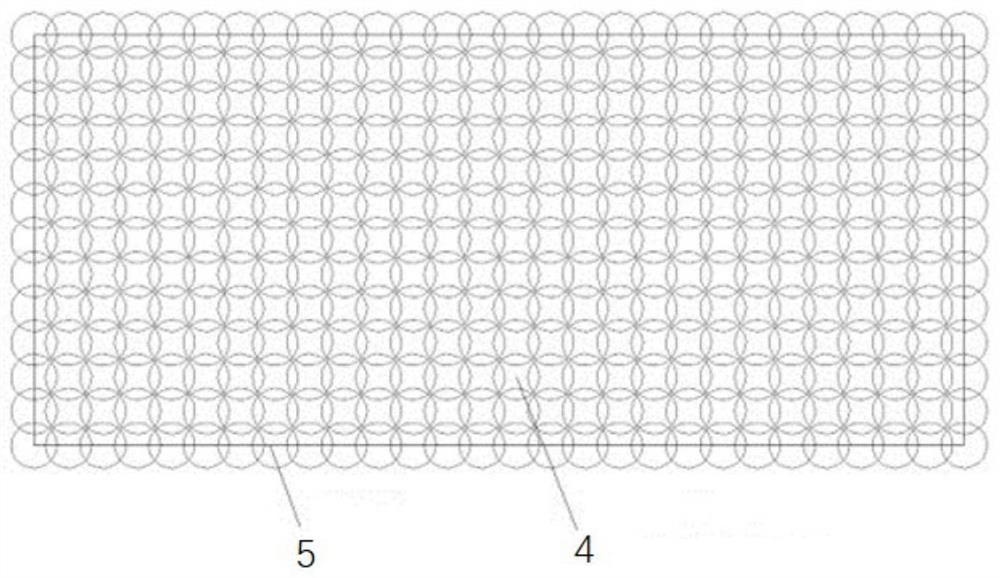

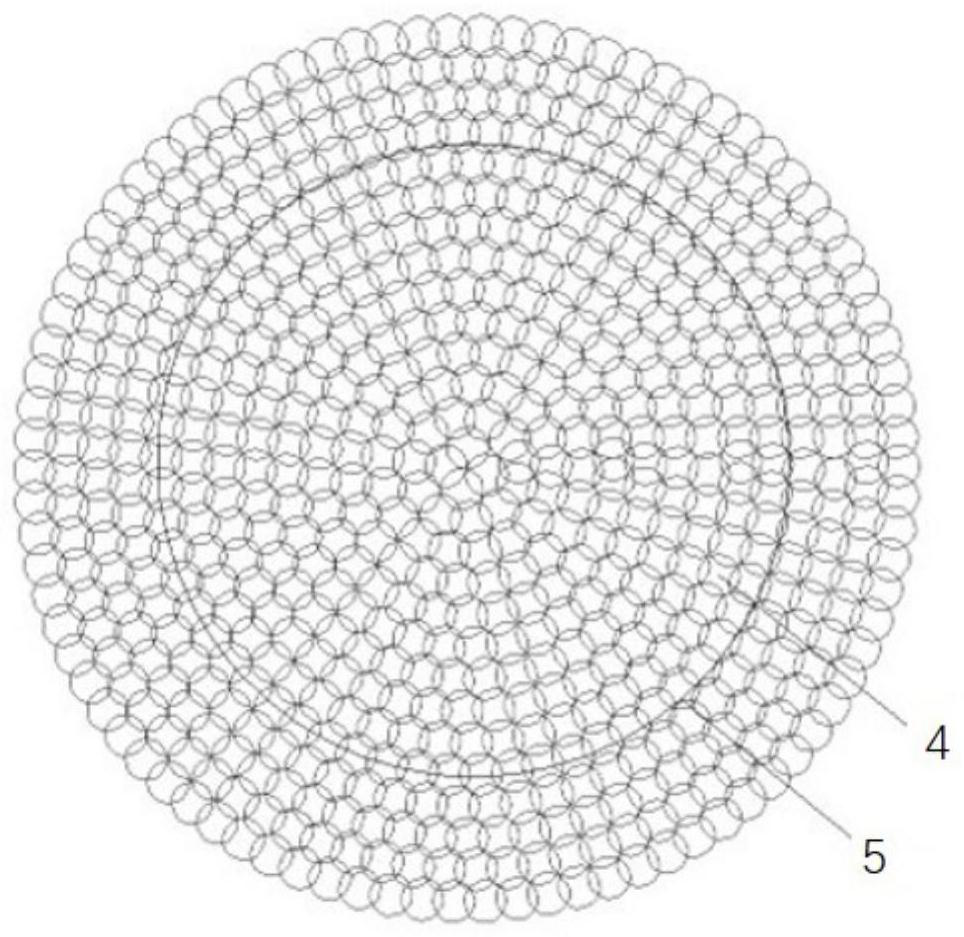

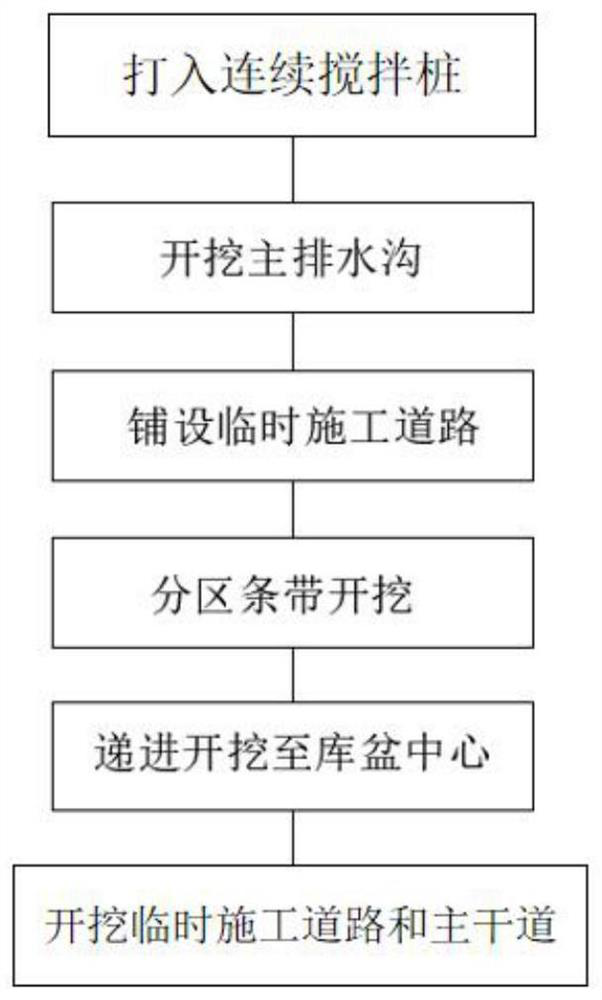

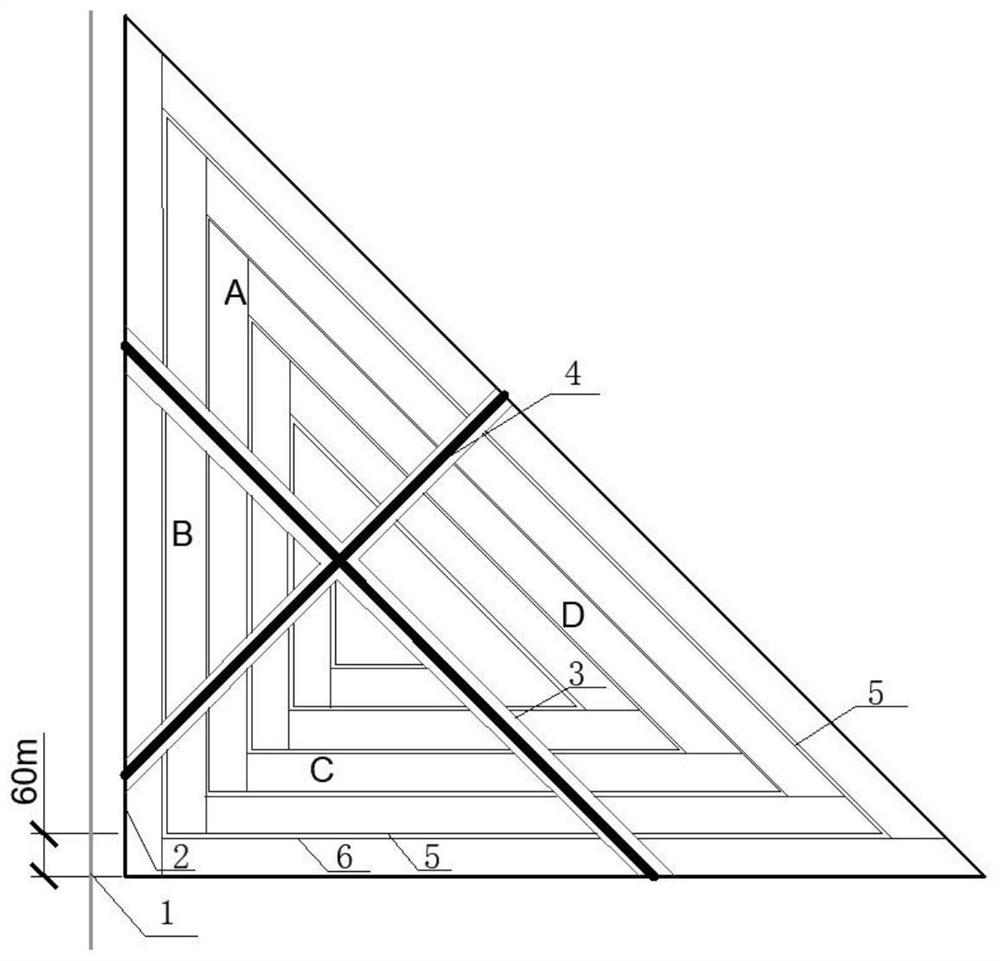

Construction method for progressive excavation of plain river-adjacent reservoir basin under mucky soil condition

ActiveCN114775620ASolve the problems of long excavation construction period and inconvenient operation of construction machinerySewerage structuresExcavationsStructural engineeringRoad surface

The invention discloses a construction method for progressive excavation of a plain river-adjacent reservoir basin under a mucky soil condition. The construction method comprises the following steps: driving a circle of continuous stirring piles at a dam foot; a reservoir is divided into four large areas, and main drainage ditches are dug in the two sides of a main road; paving a temporary construction road by utilizing the surface muck of the reservoir basin area, compacting the road surface, and excavating a secondary drainage ditch on the outer side of the temporary construction road; each small area is divided into a plurality of strip areas, and strip excavation is conducted from the small area on the outermost side of each large area; after the excavation of the outermost strip is completed, excavating the next small-area strip, and progressively excavating to the center of the reservoir basin in sequence; and the temporary construction road and the main road are excavated. According to the method, progressive partition excavation is conducted from the periphery to the center, and unexcavated mucky soil is solidified, so that construction vehicles and workers can enter the interior to conduct excavation construction of the center area. And a flow construction method is adopted and can be carried out simultaneously, so that the construction period is effectively shortened.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

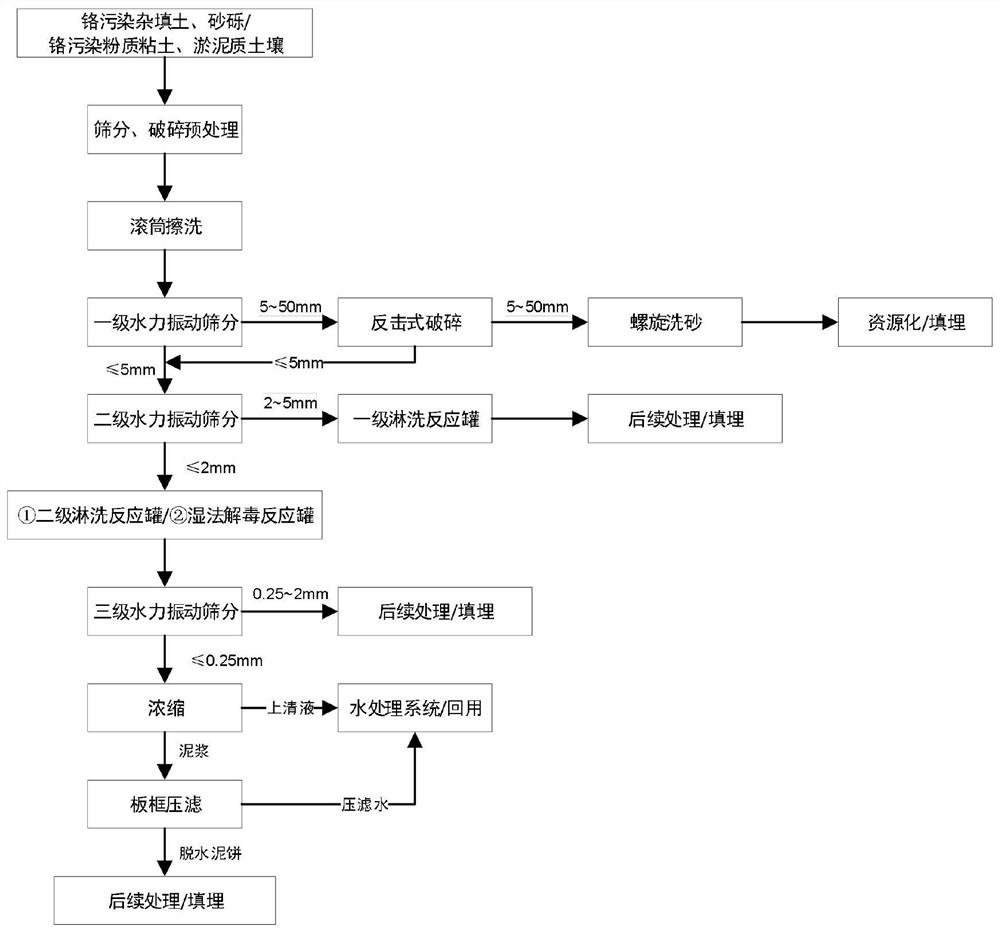

Leaching/wet detoxification method for different chromium pollution media

PendingCN113732042AConducive to reasonable additionGuarantee adequacyContaminated soil reclamationChromium contaminationSoil science

The invention discloses a leaching / wet detoxification method for different chromium pollution media. According to the method, miscellaneous fill and gravels which are subjected to chromium pollution are subjected to pretreatment, scrubbing and screening, then graded leaching is conducted, and the content of hexavalent chromium in the miscellaneous fill and gravels is reduced. Chromium-polluted silty clay and mucky soil are pretreated, scrubbed and screened, then materials larger than 2 mm are leached, the content of hexavalent chromium in the silty clay and mucky soil is reduced, materials of 2 mm or less are subjected to wet detoxification, and the content of hexavalent chromium in the silty clay and mucky soil reaches the standard. By adopting the organic combination of a same set of treatment system, the two working procedures of leaching and wet detoxification can be switched respectively, so that the investment and operation cost is reduced while the treatment effect is ensured.

Owner:湖南新九方科技有限公司

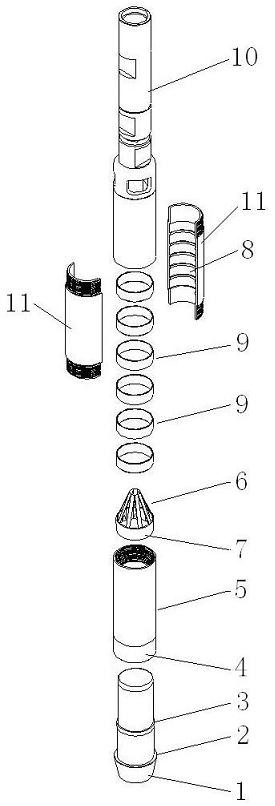

Quick press-in type tubular pile well and application thereof

ActiveCN113431067AImprove permeabilityImprove efficiencyFoundation engineeringFiltration separationWater flowStructural engineering

The invention relates to a quick press-in type tubular pile well and application thereof. The quick press-in type tubular pile well comprises a quick press-in type tubular pile well body and a high-pressure water disturbance mechanism. The quick press-in type tubular pile well body is a high-strength prefabricated part and comprises a well pipe layer, a packing layer and an outer reinforcing layer, and the quick press-in type tubular pile well body can be pressed into a soil body through a hydraulic pile press. The high-pressure water disturbance mechanism can generate high-pressure water flow and oscillation water flow and is used for flushing away net plugs and sealing wax on the surfaces of water permeable holes and cleaning mud cakes on the inner surface of a well pipe and sediment at the bottoms of the holes, meanwhile, the pore structure of mucky soil can be changed under the impact effect of the water flow, and the permeability of the mucky soil is improved. The quick press-in type tubular pile well is used for tubular well dewatering engineering in the field of foundation pit dewatering engineering, is a complex stratum with sudden changes, gradual changes and the like, and can replace a traditional tubular well to be used in the foundation pit dewatering engineering, the permeability of the mucky soil is improved, the tubular well forming efficiency and the tubular well dewatering efficiency are improved, the dewatering construction period can be shortened, and the engineering cost is saved.

Owner:TONGJI UNIV +1

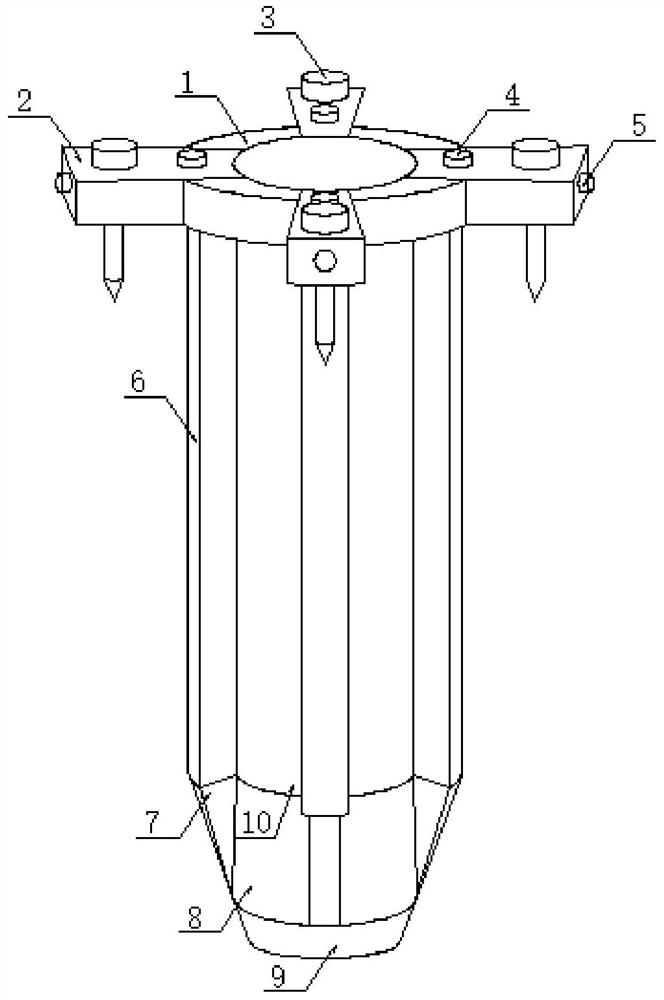

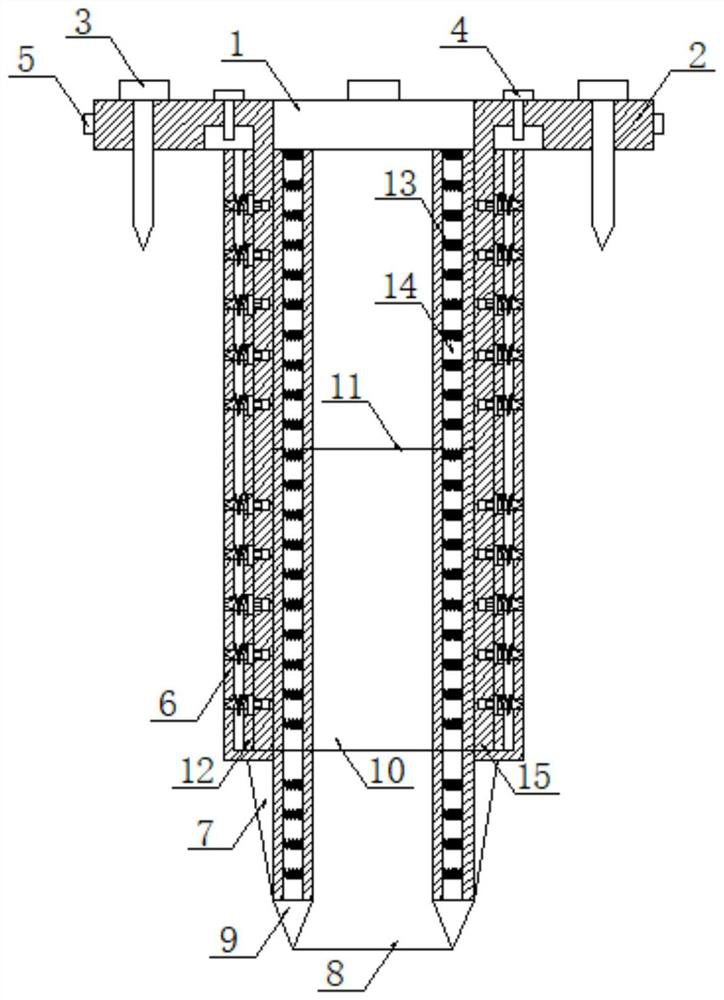

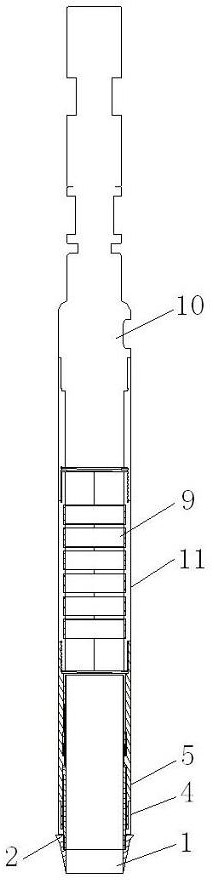

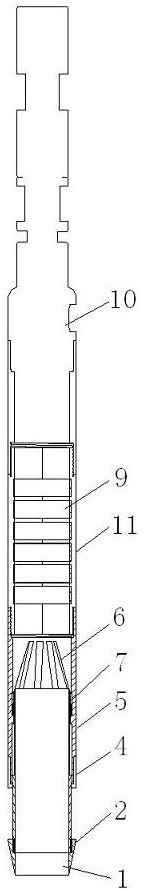

Half-closed pipe type soil sampler

The invention provides a semi-closed pipe type soil sampler, which comprises a sampling barrel, the rear end of the sampling barrel is connected with a drill pipe connecting pipe, and the front end of the sampling barrel is provided with a blade, and is characterized in that the sampling barrel is formed by splicing two semi-closed pipes, the front ends and the rear ends of the two semi-closed pipes are respectively connected with an outer cavity and the drill pipe connecting pipe to hoop and fix the outer cavity and the drill pipe connecting pipe, and an opening and closing cable spring is arranged in the outer cavity; an opening and closing claw of the opening and closing cable spring faces the rear end, the blade is movably connected to the front end of the outer cavity in an inserted mode and movably connected with the outer cavity in a telescopic mode, the rear end of the blade is inserted into the opening and closing cable spring, and opening and closing of the opening and closing claw of the opening and closing cable spring are controlled through front-back stretching and retracting of the blade in the outer cavity. The sampling operation is simple and easy to implement, the performance is reliable, the universality is good, the original state sampling effect of flow mud, sludge, mucky soil and soft plastic cohesive soil is obviously improved, the sampling quality is greatly improved, and the industrial problem is well solved.

Owner:山东省第三地质矿产勘查院

A kind of layered sample processing device for muddy soil core column sample detection

ActiveCN114199651BImprove efficiencyImprove slitting accuracyWithdrawing sample devicesPreparing sample for investigationSoil scienceGeological survey

Owner:山东省地质矿产勘查开发局第四地质大队

A kind of geopolymer soft soil binder and preparation method thereof

ActiveCN107663044BImprove engineering mechanical propertiesImprove dehydration effectSolid waste managementCement productionSludgeSoft clay

The invention provides a geopolymer type soft soil bonding agent and a preparation method thereof, wherein the geopolymer type soft soil bonding agent is prepared from the following raw materials in parts by weight: 65 to 75 parts of industrial waste residue, 20 to 30 parts of metakaolin, 5 to 12 parts of potassium metasilicate and 0.3 to 1 part of activating agents. The bonding agent has excellent modification dewatering and bonding effects on soft soil type fine particles (including silt, mucky soil, sludge, over-wet soil and the like); the action object of the soft soil bonding agent is soft soil type fine particles; 65 percent or more of raw materials are industrial solid wastes. Therefore during the industrial solid waste treatment, the waste treatment by waste can be realized; the raw material composition ingredients of the soft soil bonding agent are simple; the material taking is convenient; the product quality can be easily controlled. The energy consumption of the preparationmethod is low; the environment pollution is low; the environment-friendly effect is very good.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

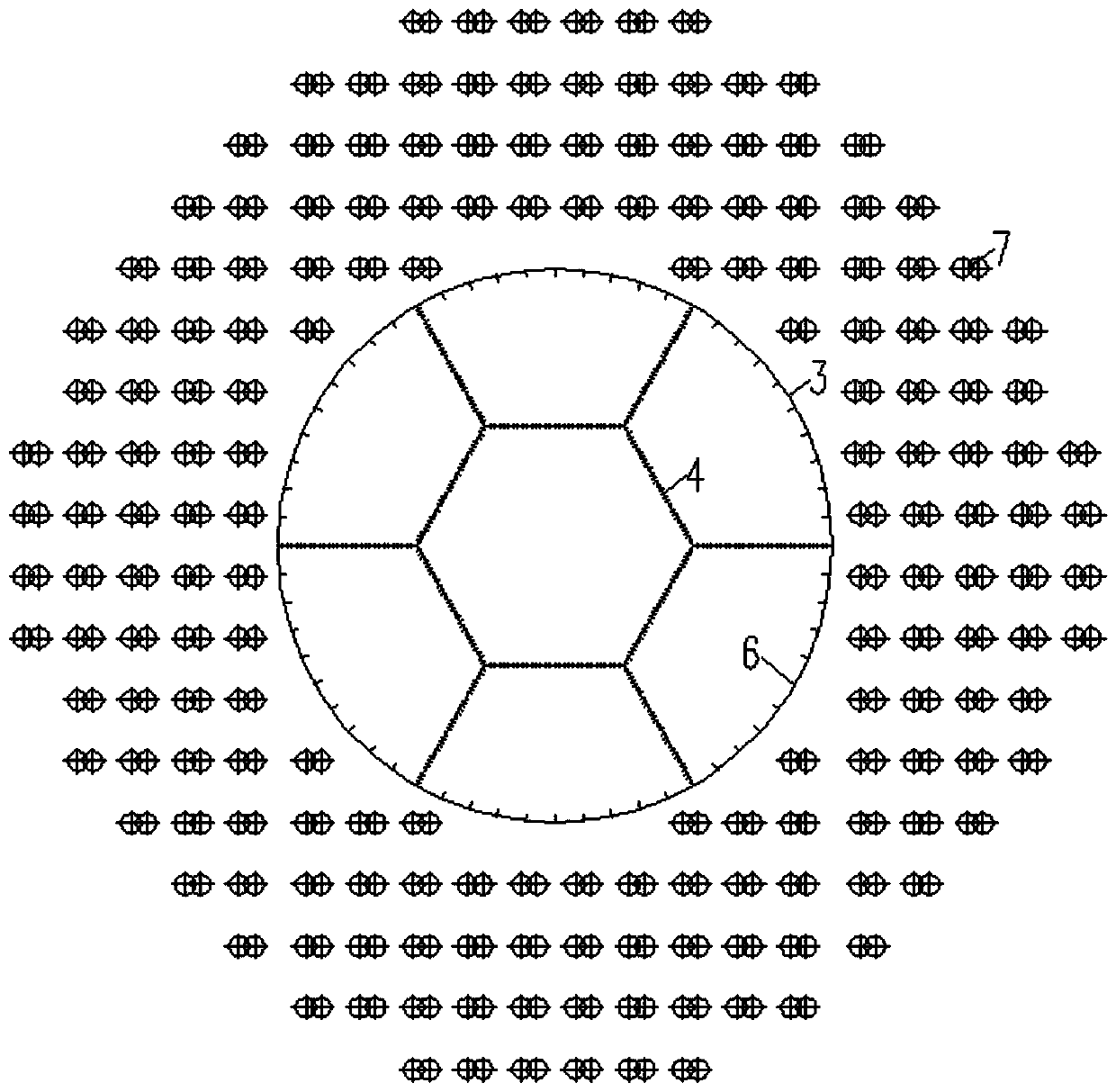

Out-of-cylinder pile distributed composite foundation-cylinder type offshore wind power foundation and construction method

PendingCN110847218AIncrease the carrying areaImprove stabilityFoundation engineeringSludgeStructural engineering

The invention relates to an out-of-cylinder pile distributed composite foundation-cylinder type offshore wind power foundation and a construction method. The out-of-cylinder pile distributed compositefoundation-cylinder type offshore wind power foundation is suitable for a sea area with soft soil such as thick sludge, mucky soil and silt covering the offshore surface layer in China. The wind power foundation comprises a concrete transition section, a composite cylinder type foundation, a concrete circular bottom plate and cylinder periphery piles. The composite cylinder type foundation is ofa lower-opening cavity multi-branch-bin structure and sinks in the soft soil of the surface layer, the cylinder top makes contact with the mud surface, and the cylinder periphery piles are evenly distributed on the periphery of the composite cylinder type foundation. The advantages of underwater deep cement mixing piles (or sand compaction piles) and the advantages of the cylinder type foundationare combined, the bearing area of the cylinder type foundation is large, stability is good, and piling is not needed; but under the condition of the soft soil, the cylinder type foundation is large insedimentation and inclination, the cement piles (or the sand compaction piles) are arranged in the cylinder type foundation, the foundation deformation problem of the cylinder type foundation is solved, the manufacturing size of a suction cylinder is reduced, and the foundation manufacturing cost is reduced.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

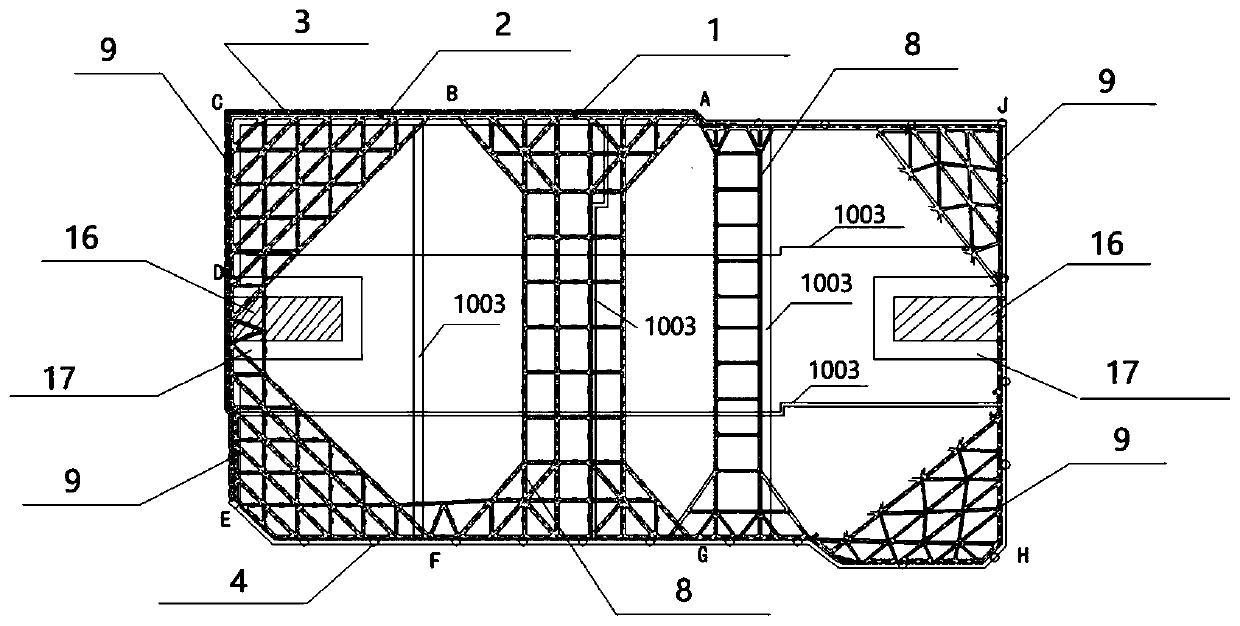

Synthetic system and method for sludge soil layer deep foundation pit supporting

InactiveCN111501775AAddress deficiencies in the applicationReduce dosageExcavationsBulkheads/pilesSoil scienceSoil mass

The invention discloses a synthetic system and method for sludge soil layer deep foundation pit supporting. The system comprises ABCD sludge soil mass supporting portion regions, EFGHJA soft soil layer supporting portion regions, a bottom plate layer, ESC-H Larsen piles, reinforced high-pressure jet grouting cement soil pile anchor rods, annular crown beams and waist beams. The multiple reinforcedhigh-pressure jet grouting cement soil pile anchor rods are fixedly arranged in soil mass around the wall of a foundation pit. The ABCD sludge soil mass supporting portion regions and the EFGHJA softsoil layer supporting portion regions are connected end to end to form a polygon. The annular crown beams are fixedly arranged on the top of the polygon in the ABCD sludge soil mass supporting portion regions, the annular waist beams are arranged in the middle of an inner cavity, and the bottom plate layer is arranged at the bottom of the inner cavity. The multiple ESC-H Larsen piles are arrangedbetween the annular crown beams. The shortage in traditional steel plate pile application is overcome, the use amount of steel is optimized and reduced, envelop structure potential safety hazards caused by the fact that the rigidity of a supporting plate belt is too high in a weak portion of a water stop envelop structure are avoided, and the synthetic system and method have high cost performancein a deep foundation pit supporting structure.

Owner:CHINA FIRST METALLURGICAL GROUP

Artificial freeze-thaw sludge dewatering and coal blending incineration treatment method

PendingCN113651521AImprove settlement performanceImprove filtering effectSludge treatmentFreeze thawingFreeze and thaw

The invention discloses an artificial freeze-thaw sludge dewatering and coal blending incineration treatment method which comprises the following steps: arranging a freezing pipe, a temperature measuring pipe and a drainage structure in a sludge layer, then freezing mucky soil, then unfreezing the sludge layer, draining water in cooperation with a drainage device, and after at least one time of freeze-thaw treatment, enabling that the mucky soil and high-moisture coal are subjected to blending combustion power generation treatment in a circulating fluidized bed boiler. According to the method, firstly, the mucky soil is dewatered by adopting a freezing and thawing or repeated freezing and thawing mode in cooperation with the drainage device, so that the settling performance and the filtering performance of the mucky soil are obviously improved, the effective particle size of the mucky soil is increased, the water content tends to 60%, and in addition, odor pollution of the mucky soil can be inhibited; and then the mucky soil which is frozen and thawed or repeatedly frozen and thawed and bituminous coal are subjected to blending combustion treatment on the circulating fluidized bed boiler according to the blending combustion ratio of 4-20%, so that normal operation and power generation of a boiler unit can be ensured, and the emission amount of dioxin in flue gas is below a detection limit value.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

A kind of excavation method of epb-tbm dual-mode shield machine in compound stratum

Owner:CCCC THIRD HARBOR ENG +2

Mucky soil dewatering device and application thereof

PendingCN113445489AWill not polluteAchieve drainageStationary filtering element filtersSoil preservationSoil scienceWater well

The invention relates to a mucky soil dewatering device and application thereof. The device comprises a bamboo pipe drainage mechanism, a groove working mechanism and a water collecting well mechanism. The groove working mechanism comprises a deep groove, a side wall working face and filling sand; the deep groove is formed in a foundation pit project; the wall face of the deep groove is a lateral working face; bamboo ribs are inserted into the inclined upper portion of the side wall working face through a pressure device; and the filling sand is arranged in the deep groove after a water collecting well system is arranged. The water collecting well mechanism comprises a water collecting well body, a concrete layer, a stainless steel filter screen, a water outlet pipe and a water pump; a water collecting well is arranged below the deep groove; the concrete layer is poured on the periphery of the water collecting well; the stainless steel filter screen covers the water collecting well; and the water outlet pipe is inserted into the water collecting well. The water pump is connected to pump water from the water collecting well. The mucky soil dewatering device is used for a precipitation project, the bamboo pipe drainage system, the working face system and the water collecting well system are applied, dewatering and precipitation of mucky soil can be achieved through the steps of deep groove excavation, bamboo pipe drainage, water collecting well water collection, deep groove filling sand and the like, and the mucky soil dewatering device has great significance in mucky soil layer self-flowing drainage and environment protection.

Owner:TONGJI UNIV

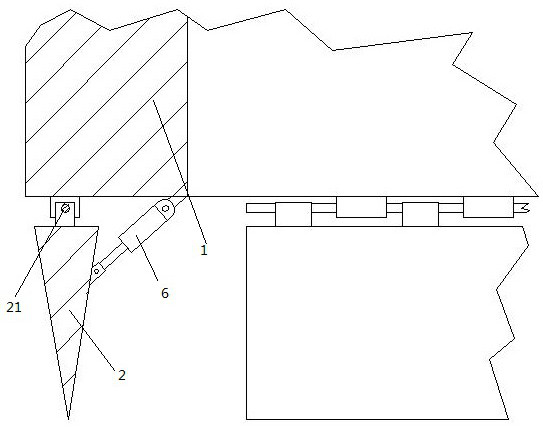

Construction method of caisson in underground space of muddy soil

The invention relates to a mucky soil position underground space open caisson construction method. The method comprises the steps that 1, a first open caisson section provided with a plurality of grids is manufactured; 2, hydraulic valves are installed in the grids; 3, the first open caisson section sinks under action of the self weight; 4, the opening quantity of the hydraulic valves in the firstopen caisson section is controlled so that the sinking speed of an open caisson can be controlled, and sudden sinking of the open caisson is prevented, and if the open caisson inclines, deviation rectifying is conducted through the hydraulic valves; and 5, after the first open caisson section sinks in place, all the hydraulic valves are closed, a second open caisson section is formed at the top of the first open caisson section, after the second open caisson section sinks in place, all the hydraulic valves are closed, a third open caisson section is installed at the top of the second open caisson section, then, in the same mode, manufacturing and sinking of all open caisson sections are completed, and accordingly, an open caisson is formed. Through the method, the problems that accordingto an existing open caisson construction method, when construction is conducted in mucky soil, the sinking speed of the open caisson is difficult to control, and sudden sinking is prone to occurring are solved.

Owner:GEOTECHN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com