Mucky soil dewatering device and application thereof

A kind of silty soil and silty technology, which is applied in the direction of soil protection, fixed filter element filter, filtration separation, etc., can solve the problems of low permeability, difficult drainage, slow time, etc., to improve drainage speed and efficiency, and realize Cost saving and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

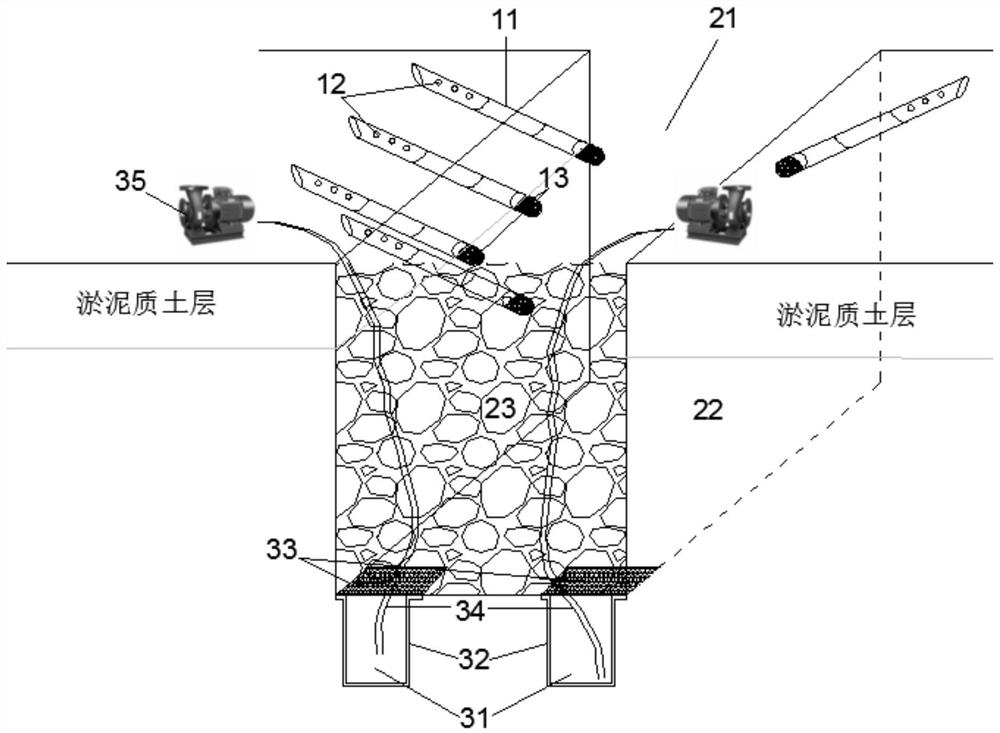

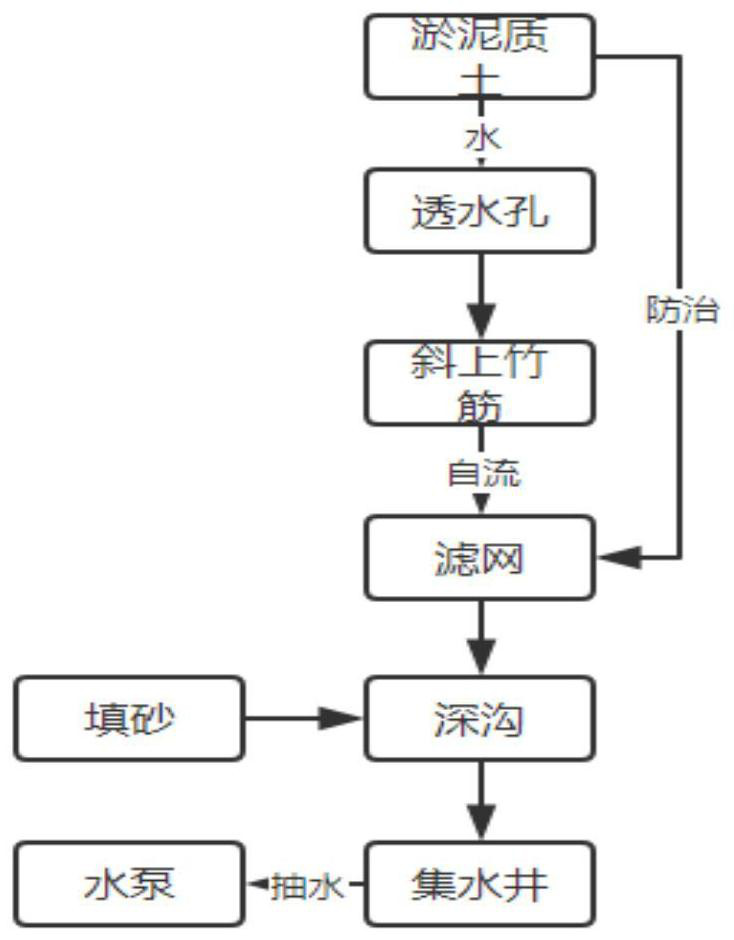

[0030] A kind of muddy soil drying device, such as Figure 1-2 , the device includes: a bamboo tube drainage mechanism, used to extract groundwater in the muddy soil layer; a trench working mechanism, used to undertake the groundwater extracted by the bamboo tube drainage mechanism; a water collection well mechanism, used to collect and discharge the trench working mechanism Undertaken groundwater; the ditch working mechanism is set in the silty soil layer, and the bamboo tube drainage mechanism is interspersed between the silty soil layer and the ditch working mechanism; the water collection well mechanism is located under the ditch working mechanism. The part of the bamboo tube drainage mechanism in the muddy soil layer is higher than the part of the bamboo tube drainage mechanism in the trench working mechanism.

[0031] The bamboo tube drainage mechanism includes bamboo tendons 11, which are moso bamboo tubes whose tails are cut into sharp shapes. The bamboo tube drainage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com