Artificial freeze-thaw sludge dewatering and coal blending incineration treatment method

A treatment method and freeze-thaw technology, applied in the field of artificial freeze-thaw sludge dehydration and coal incineration treatment, can solve the problems of high water content of dredged sludge, slow sludge settling speed and filtration speed, and reduced boiler combustion efficiency, so as to ensure normal operation. The effect of generating electricity, suppressing odor pollution, and stabilizing combustion in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

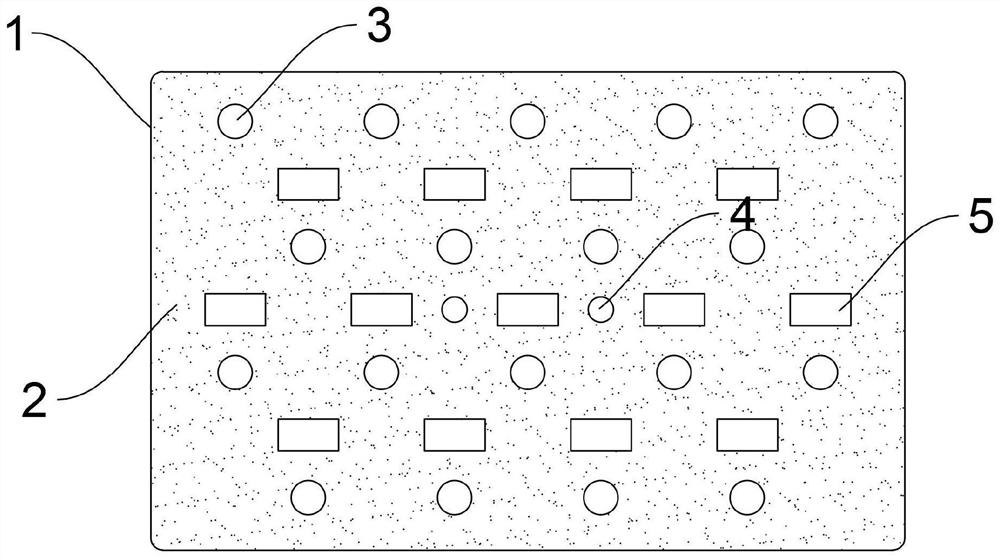

[0026] The present invention will be further described below in conjunction with accompanying drawing.

[0027] see figure 1 Shown, a kind of artificial freeze-thaw sludge dehydration blending coal incineration processing method comprises the following steps:

[0028] S1. Dry the muddy soil for precipitation, the general period is 4 to 6 months;

[0029] S2. Pour the muddy soil after drying and sedimentation into the earthen pond 1 to form a mud layer 2 in the earthen pond 1;

[0030] S3, arranging a number of freezing holes 3 in the mud layer 2, the freezing holes 3 extending vertically downward from the top surface of the mud layer 2 to the bottom of the mud layer 2, and freezing pipes are placed in each freezing hole 3, wherein the freezing holes 3. In the mud layer 2, they are equally spaced in a quincunx shape, and the spacing of the freezing holes 3 is 0.9-1.5m;

[0031] S4, arranging several temperature measuring holes 4 in the mud layer 2, the temperature measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com