A kind of geopolymer soft soil binder and preparation method thereof

A geopolymer and cementing agent technology, used in solid waste management, sustainable waste treatment, cement production, etc., can solve problems such as water resistance and durability hidden dangers, environmental pollution, poor acid and alkali resistance, etc., to improve engineering mechanics Simple performance, simple composition and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

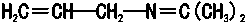

[0032] Embodiment 1, a geopolymer soft soil cementing agent, comprising the following raw materials in parts by weight: 65-75 parts of industrial waste residue, 20-30 parts of metakaolin, 5-12 parts of potassium silicate, 0.3 parts of activator Part-1 part, wherein the industrial waste residue is silicon-aluminum-based industrial waste residue, the potassium silicate is solid potassium silicate with a modulus of 1.65-1.95, and the activator is side group modified polymethylpropylamine siloxane.

Embodiment 2

[0033] Embodiment 2, a geopolymer soft soil cementing agent, including the following raw materials in parts by weight: 65 parts of industrial waste residue, 20 parts of metakaolin, 5 parts of potassium silicate, 0.3 part of activator, wherein the industrial waste residue is a silicon-aluminum base Industrial waste, potassium silicate is solid potassium silicate with a modulus of 1.65-1.95, and the activator is side group modified polymethylpropylamine siloxane.

Embodiment 3

[0034] Embodiment 3, a geopolymer soft soil cementing agent, including the following raw materials in parts by weight: 75 parts of industrial waste residue, 30 parts of metakaolin, 12 parts of potassium silicate, 1 part of activator, wherein the industrial waste residue is a silicon-aluminum base Industrial waste, potassium silicate is solid potassium silicate with a modulus of 1.65-1.95, and the activator is side group modified polymethylpropylamine siloxane.

[0035] In a preferred but non-limiting embodiment of the present invention, the silicon-aluminum-based industrial waste residue is an industrial solid waste containing low-polymerization silicon-oxygen tetrahedron and aluminum-oxygen tetrahedral structures, and has latent gelation activity. More preferably, silicon-aluminum-based industrial waste The base industrial waste slag is: at least one of granulated blast furnace slag, fly ash, high-temperature power plant bottom ash, or silicon-aluminum-based industrial waste s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com