Drainage and anti-seepage method of cofferdam space in high water content dredged mud yard

A high water content, cofferdam technology, applied in soil protection, protection devices, buildings, etc., can solve the problems of increasing the seepage instability of the cofferdam, the impermeable water concentration point of the sealing layer, and the high price. Long-term seepage stability, beneficial to seepage stability, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

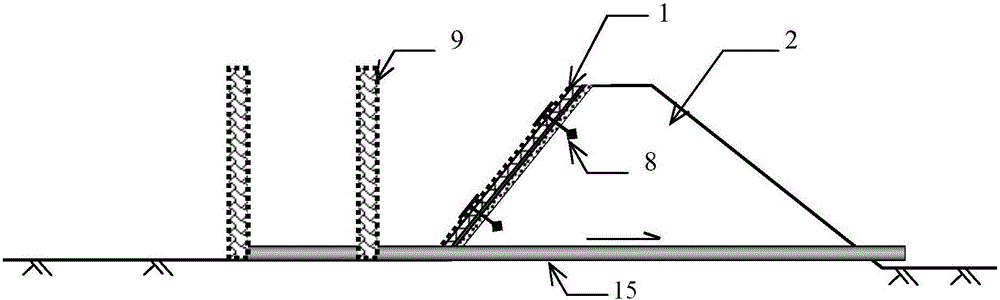

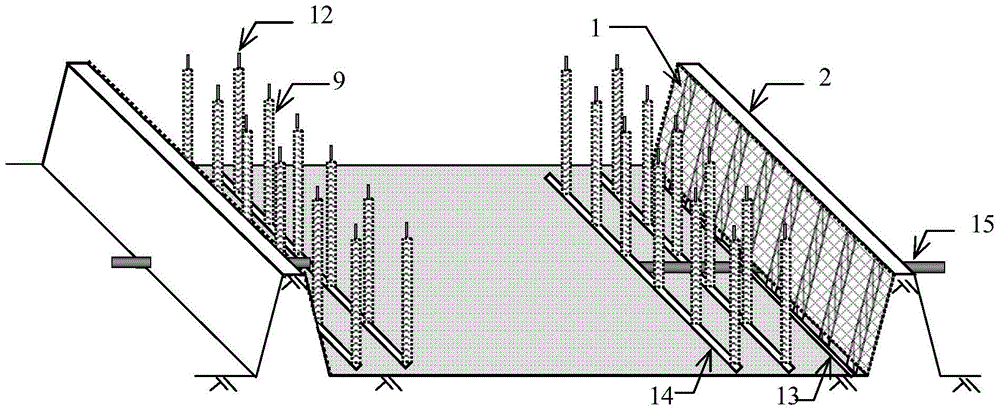

[0033] Such as figure 1 As shown, the high water content dredging mud stockyard cofferdam space drainage and anti-seepage method of the present embodiment is implemented in a certain stockyard, and the cofferdam 2 is filled with silty soil nearby, with a filling height of 4m, a top width of 2m, and an outside The slope is 1:2, the inner slope is 1:1.5, the soil permeability coefficient of cofferdam 2 is 10-4cm / s, and the dredged mud is silty clay. If anti-seepage treatment is not adopted for cofferdam 2, the design does not meet the seepage stability requirements. refer to Figure 1~5 , the high water content dredging mud stockyard cofferdam space drainage anti-seepage system structure description in the present embodiment is as follows:

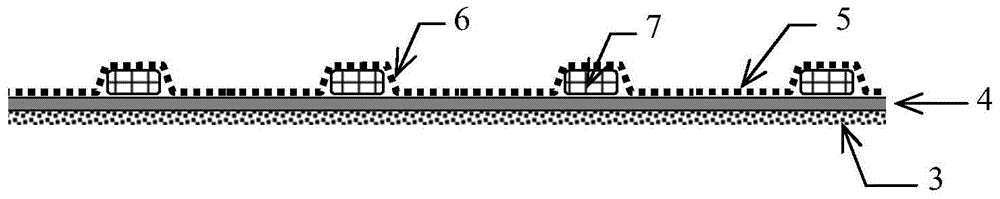

[0034]According to the width of the inner slope of the cofferdam 2, the geotextile 3, the plastic sealing film 4 and the filter screen 5 with a width of 7.2m were cut respectively, and the geotextile 3 was bonded to one side of the plastic ...

Embodiment 2

[0037] The method for drainage and anti-seepage of the cofferdam space of the high moisture content dredged mud stockyard in this embodiment is implemented in a certain stockyard. Slope 1: 1.5, the soil permeability coefficient of cofferdam 2 is 10-4~10-5cm / s, and the dredged mud is sandy loam. If anti-seepage treatment is not adopted for cofferdam 2, the design does not meet the seepage stability requirements. Refer to Figure 1~5 , the high water content dredging mud stockyard cofferdam space drainage anti-seepage system structure description in the present embodiment is as follows:

[0038] According to the width of the inner slope of the cofferdam 2, the geotextile 3, the plastic sealing film 4 and the filter screen 5 are respectively cut out, and the geotextile 3 is bonded to one side of the plastic sealing film 4 by thermal bonding, and the filter is placed along the length direction. The net 5 is glued to the other side of the plastic sealing film 4 at intervals of 0.35...

Embodiment 3

[0041] The space drainage and seepage prevention method of the high moisture content dredged mud stockyard cofferdam space in this embodiment is implemented in a certain stockyard. The cofferdam 2 is filled with silty soil nearby, the filling height is 6m, the outer side slope is 1:3, and the inner side slope is 1:3. Slope 1:2, the soil permeability coefficient of cofferdam 2 is 10-4cm / s, and the dredged mud is cohesive soil. If anti-seepage treatment is not adopted for cofferdam 2, the design does not meet the seepage stability requirements. Refer to Figure 1~5 , the high water content dredging mud stockyard cofferdam space drainage anti-seepage system structure description in the present embodiment is as follows:

[0042] According to the width of the inner slope of the cofferdam 2, the geotextile 3, the plastic sealing film 4 and the filter screen 5 are respectively cut out, and the geotextile 3 is bonded to one side of the plastic sealing film 4 by thermal bonding, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com