Micro-crack triaxial stress seepage grouting test system and its application method

A triaxial stress and grouting test technology, applied in the field of machinery, can solve the problems of small opening of micro-cracks, difficult to realize the seepage mechanism of micro-cracks, and difficult to directly observe the dynamic change process of micro-scale cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention proposes a micro-crack triaxial stress seepage grouting test system and its application method. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific examples.

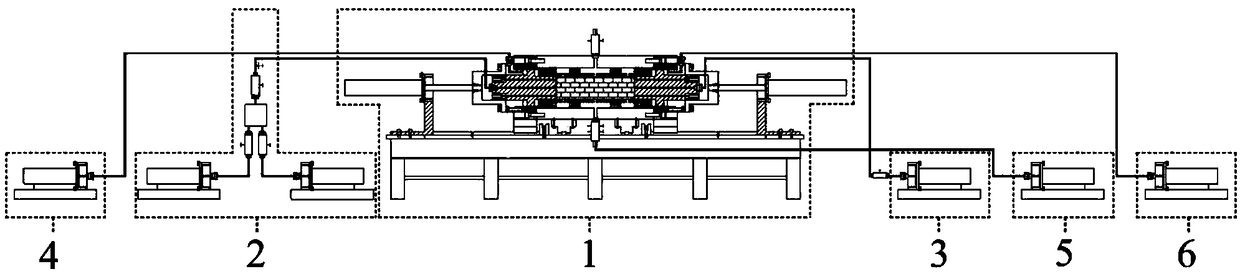

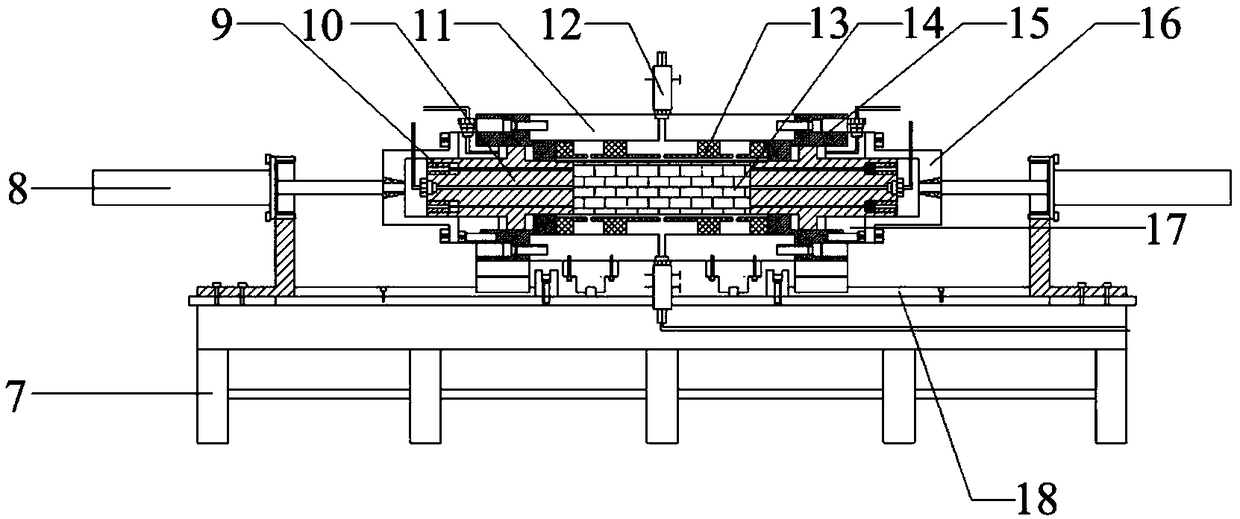

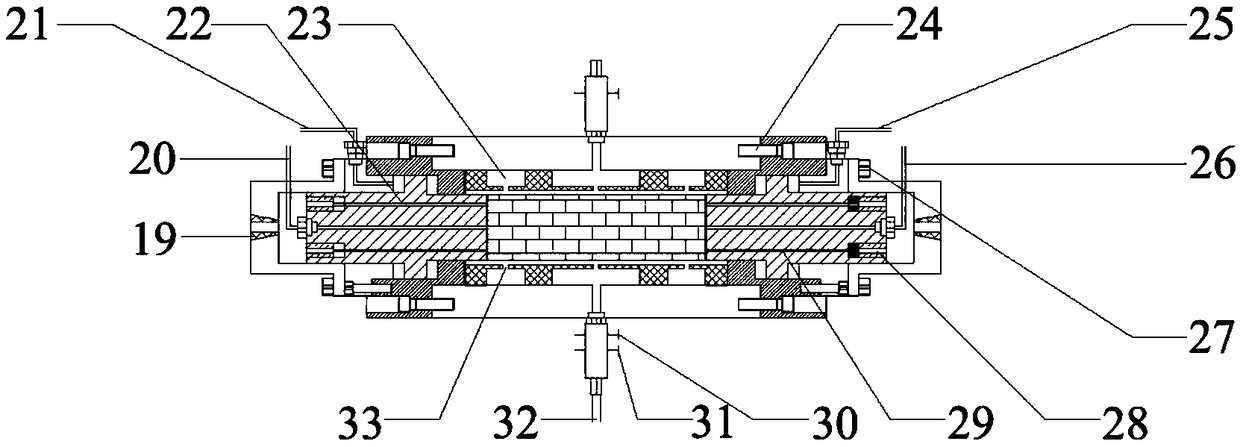

[0051] like figure 1 As shown, the micro-crack triaxial stress seepage grouting test system of the present invention includes a micro-crack triaxial stress seepage grouting test platform 1, a seepage grouting injection system 2, a drainage pump 3, a No. 1 axial pressure inlet pump 4, Confining pressure oil pump 5, No. 2 axial pressure inlet pump 6, among them, seepage grouting injection system 2, liquid discharge pump 3, No. 1 axial pressure inlet pump 4, confining pressure oil pump 5, No. 2 axial pressure inlet pump 6 They are all connected to the micro-crack triaxial stress seepage grouting experimental platform 1. The specific connection relationship is: t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com