Foundation structure of soft soil stratum and construction method thereof

A construction method and stratum technology, applied in the fields of infrastructure engineering, soil protection, construction, etc., can solve the problems of difficult control and poor stability of soft soil foundation under high backfill soil, so as to speed up construction and reduce friction around piles Effect of resistance, settlement reduction of fill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

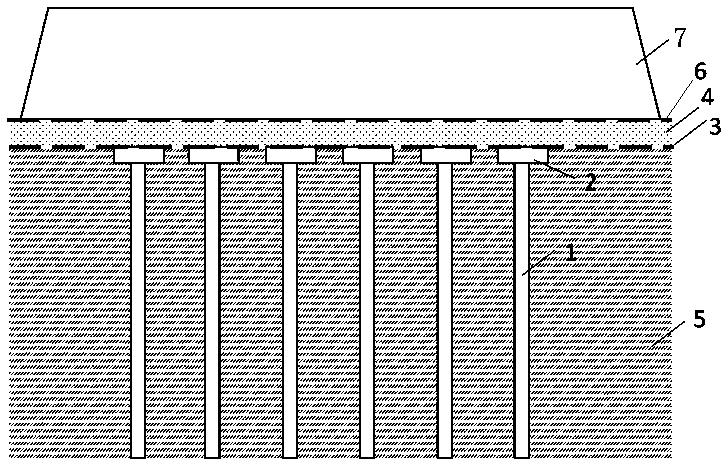

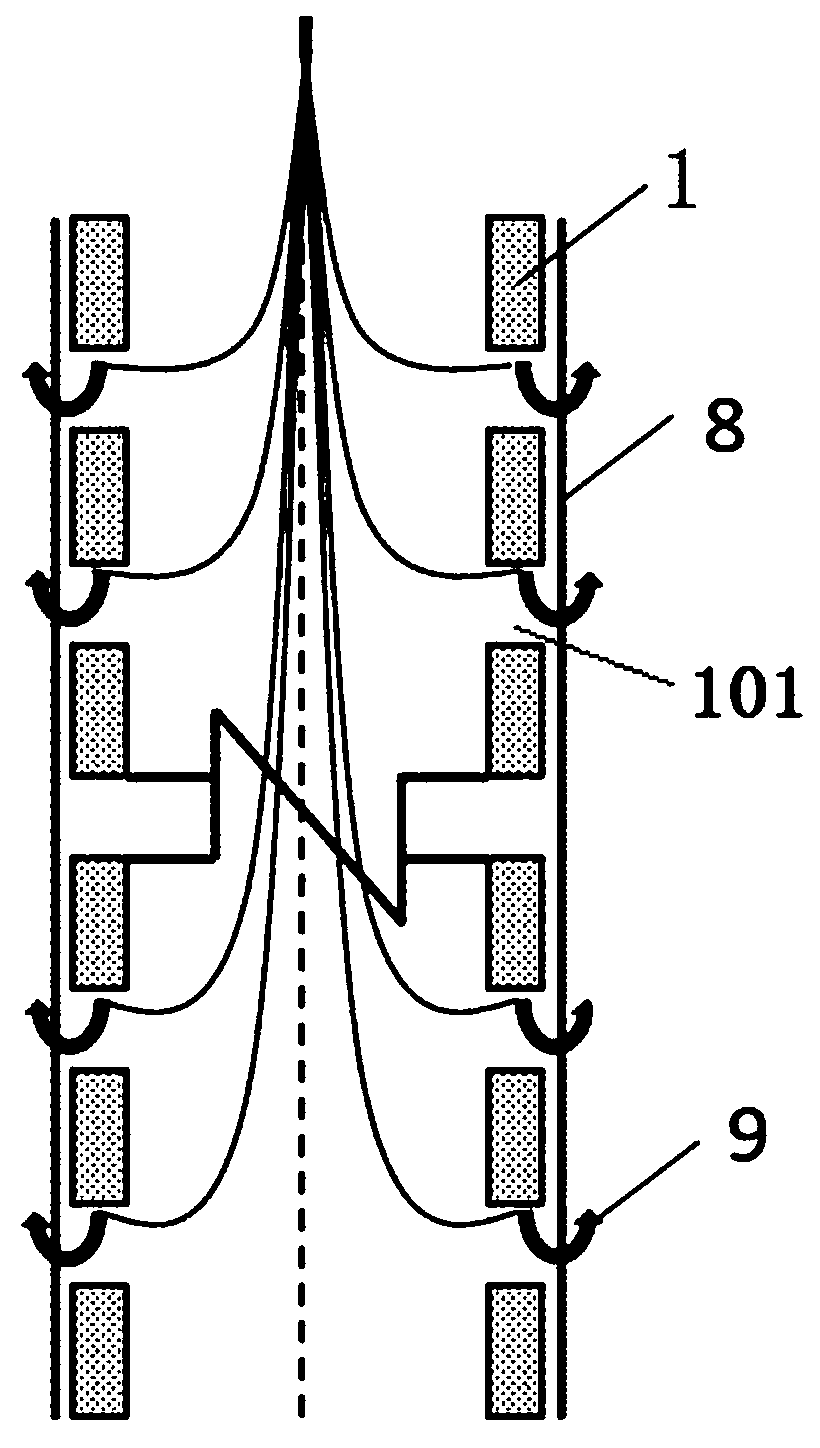

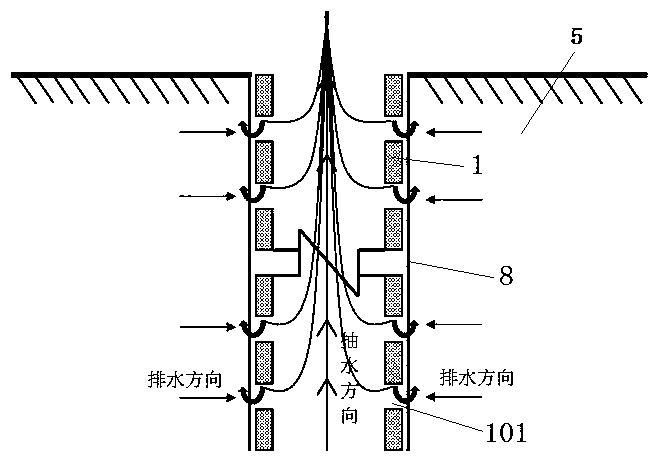

[0028] Such as Figure 1-4 As shown, a foundation structure of a soft soil layer includes a prefabricated pipe pile 1 implanted in a soft soil layer 5, the top of the prefabricated pipe pile 1 is provided with a cast-in-place pile cap 2, and the pile cap 2 is sequentially laid with the first reinforcement layer 3, cushion layer 4, second reinforcement layer 6 and soil filling layer 7, the prefabricated pipe pile 1 is distributed with small holes 101 for drainage and entry of soil around the pile, and the small holes 101 are randomly distributed in dislocation, prefabricated The interior of the pipe pile 1 is backfilled with foundation soil.

[0029] A construction method for a foundation structure of a soft ground layer, the process comprising the following steps:

[0030] 1) Put the prefabricated tubular pile 1 with small holes 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com