Sludge soil draining and dewatering system and construction method

A silty soil and drying technology, applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as long time required, poor drainage effect, slow drainage, etc., and achieve the effect of improving precipitation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

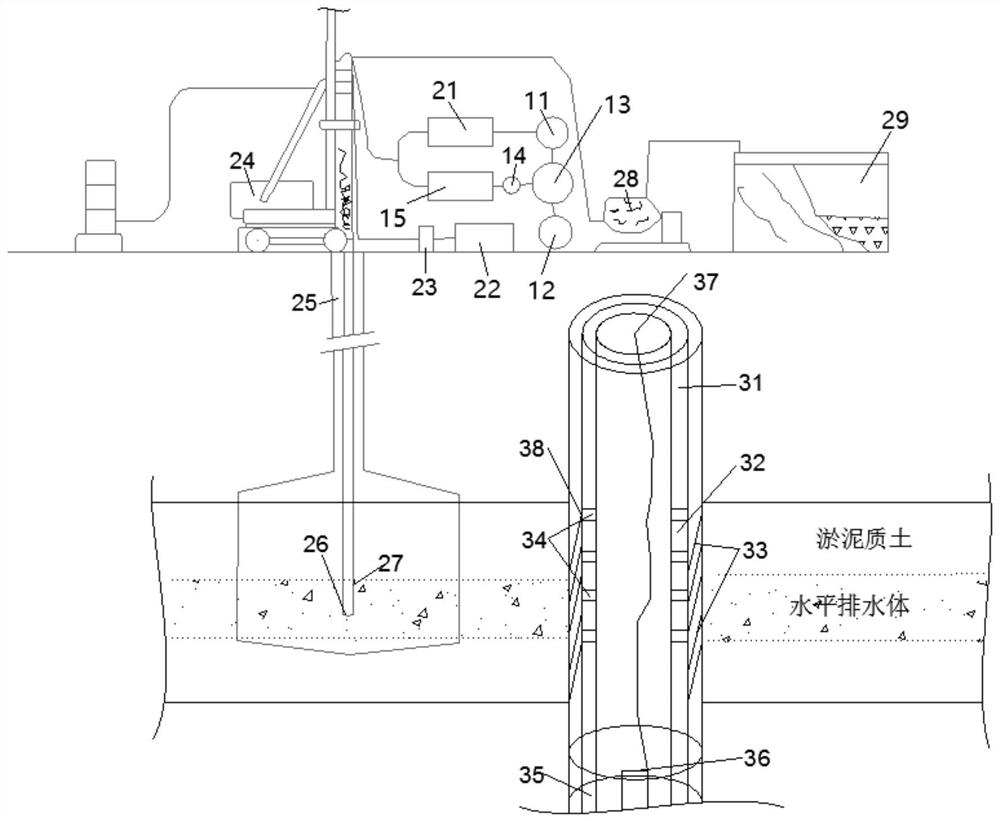

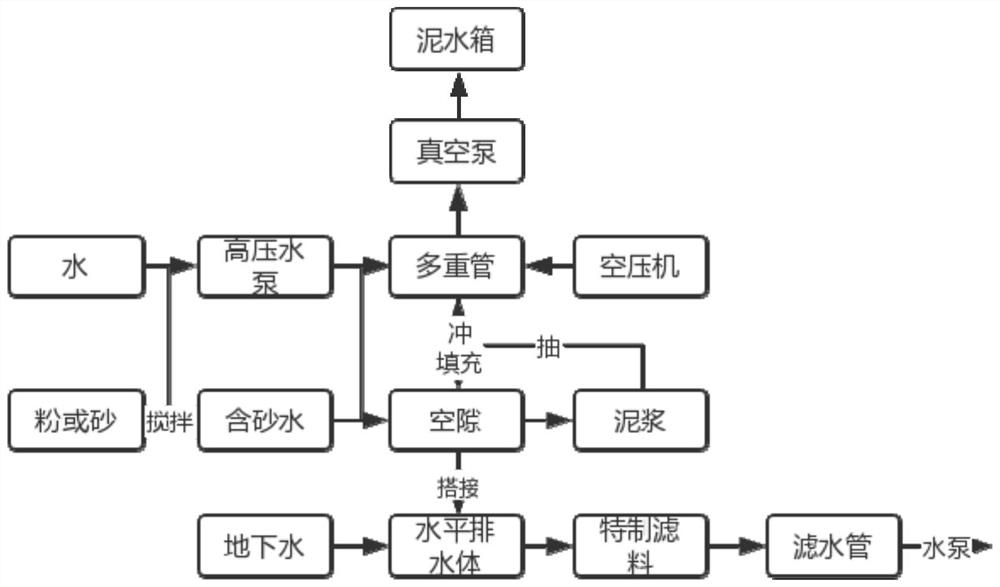

[0055] A silty soil dewatering precipitation system, such as figure 1 As shown, it includes the sand-containing water flow subsystem, the high-pressure swirl jet subsystem and the drainage well subsystem; there are several sand-containing water flow subsystems around the drainage well subsystem, and each sand-containing water flow subsystem is connected to the high-pressure swirl jet subsystem; through The high-pressure rotary spray subsystem discharges the muddy soil from each sand-containing water flow subsystem and inputs sand-containing water to form a horizontal drainage body;

[0056] The high-pressure jet spray subsystem includes multiple pipes 25, the bottom of which is provided with a nozzle 26, and the upper part is respectively connected to a water pump 21, an air compressor 22 and a vacuum pump 28;

[0057] The sand-containing water flow subsystem includes a sand-containing water bucket 14 and a sand-containing water pump 15, and the sand-containing water bucket 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com