Mucky soil resistance-increasing steel pipe pile foundation reinforcing structure and construction method

A technology for foundation reinforcement and silty soil, which is applied in basic structure engineering, excavation, sheet pile wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

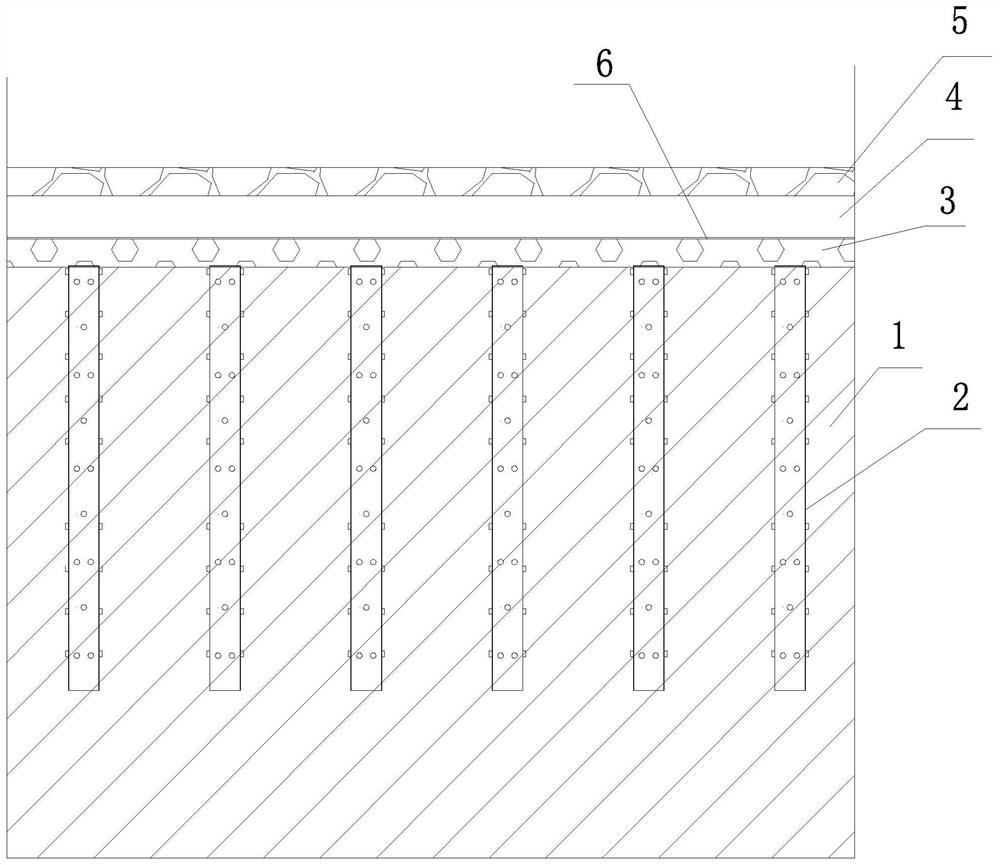

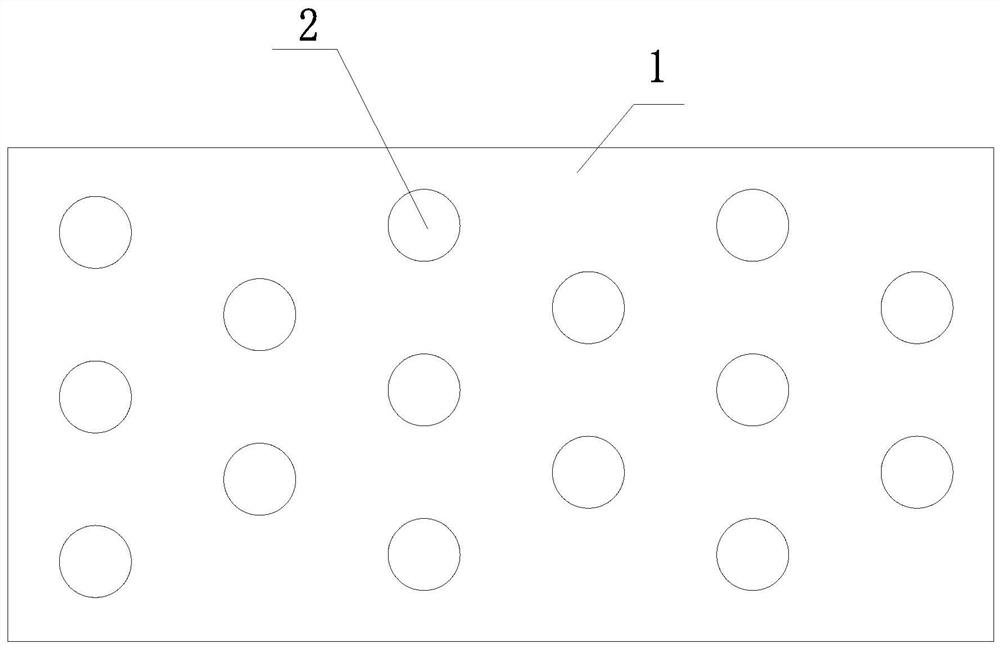

[0027] Such as Figure 1 to Figure 3 As shown, the present invention is a silty soil resistance-increasing steel pipe pile foundation reinforcement structure, which includes silty soil 1; the silty soil 1 is vertically provided with a number of reinforcements whose top is higher than the top of the silty soil 1. The resistance-type steel pipe pile 2 is provided with a crushed stone layer 3 , a plain soil layer 4 and a concrete cushion layer 5 sequentially from bottom to top on its upper surface, and a reinforcement mesh 6 is arranged at the bottom of the plain soil layer 4 .

[0028] Further, the resistance-increasing steel pipe piles 2 are distributed in a quincunx shape in the muddy soil 1 .

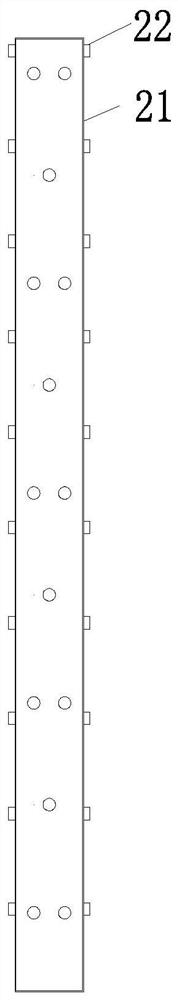

[0029] Further, the resistance-increasing steel pipe pile 2 includes a steel pipe pile 21 and several resistance-increasing cylinders 22 arranged at intervals on the steel pipe pile 21 in a quincunx shape. The diameter of the steel pipe pile 21 can be a steel pipe of φ219 mm, and the ...

Embodiment 2

[0033] A construction method of the silty soil resistance-increasing steel pipe pile foundation reinforcement structure described in Embodiment 1 of the present invention is used for the construction of foundation pits with more silt and deeper foundation pits, which includes the following steps:

[0034] Step 1: Install resistance-increasing steel pipe piles 2; after excavating the foundation pit to the design bottom elevation, that is, the top elevation of the muddy soil 1 in the foundation pit, then use resistance-increasing steel pipe piles 2 to drive into the muddy soil In 1, each resistance-increasing steel pipe pile 2 is smeared with asphalt liquid on its surface for anti-corrosion treatment before being driven, and the driving method is arranged in a plum blossom shape with a distance of 1m (if the effect of the resistance-increasing steel pipe pile 2 is not good after driving, the The resistance-increasing steel pipe pile 2 can be encrypted), and the setting depth of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com