Deep mine hard rock roadway stress adsorption layer structured support method

An adsorption layer and structuring technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve problems such as ignoring secondary dynamic disturbances, secondary damage to roadway surrounding rocks, difficulty adapting to deep hard rock engineering environments, etc., to achieve enhanced surrounding The self-stabilization ability of rock, the suppression of rockburst, and the effect of realizing safe and efficient construction of tunneling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

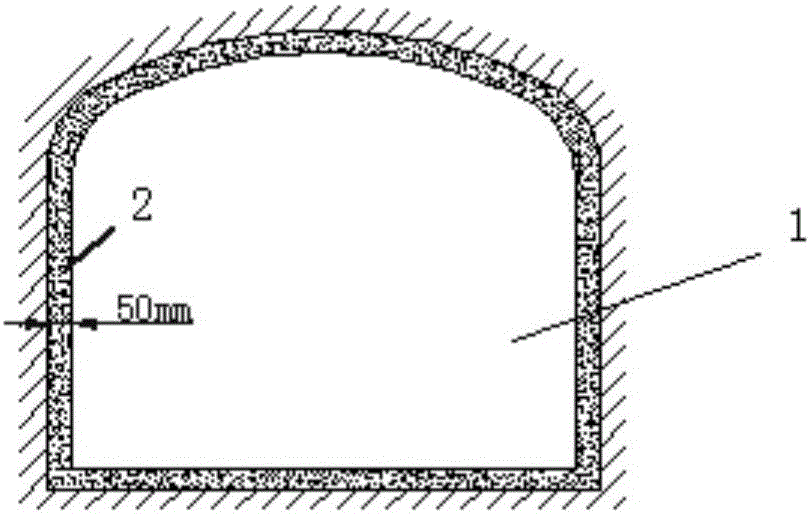

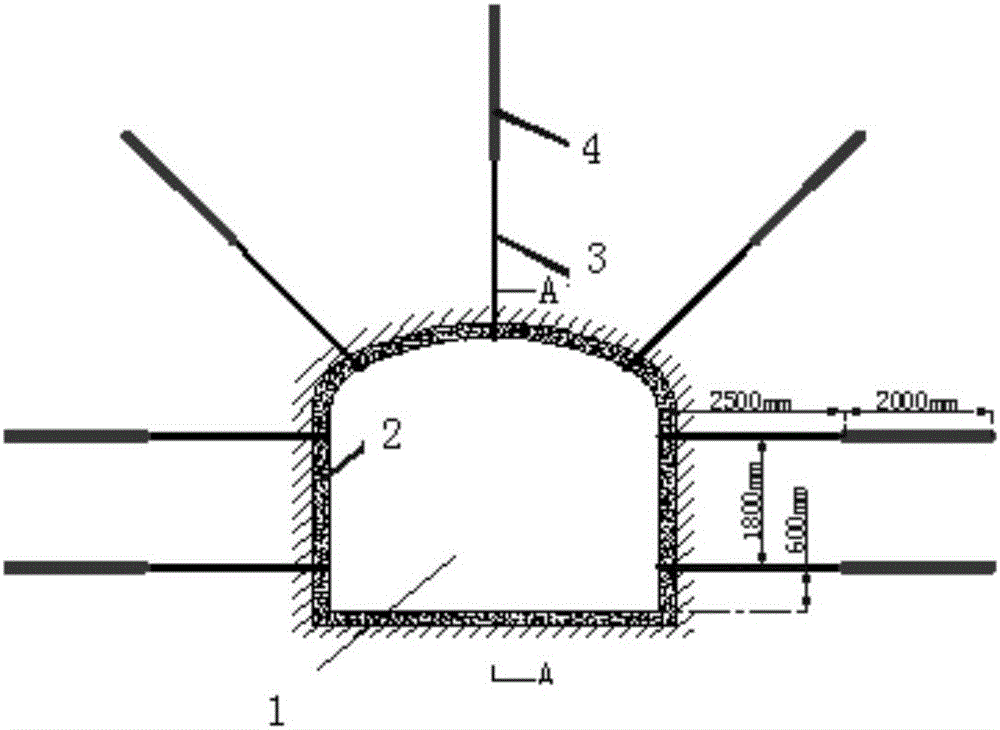

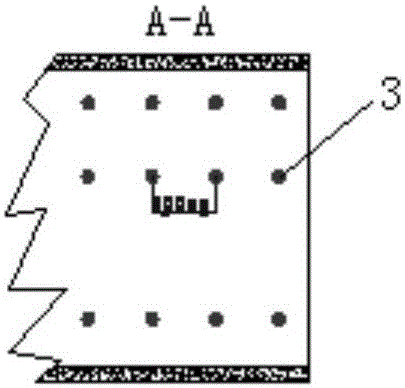

[0025] The method for structural support of the stress adsorption layer of the hard rock roadway in deep mines provided by the present invention, after the excavation of the deep roadway, initially sprays concrete to form a concrete flexible support layer, and drills 4.5m-5.0m blastholes in the two sides of the roadway and the vault top And fill the explosives within 2m~2.5m of the bottom of the hole to implement loose crushing and blasting to construct an arched broken rock stress adsorption layer, use the blasthole to drill into the grouting duct anchor, and inject the cement slurry into the grouting duct anchor to reconstruct the structure Supporting body, grouting fixed grouting conduit anchor rod in the blasthole, realizing arch-shaped broken rock stress absorption layer, structural supporting body, isolated rock mass and concrete flexible supporting layer and grouting in high-stress deep hard rock roadway A rockburst prevention support structure coordinated with duct-type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com