Patents

Literature

88results about How to "Safe and efficient construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

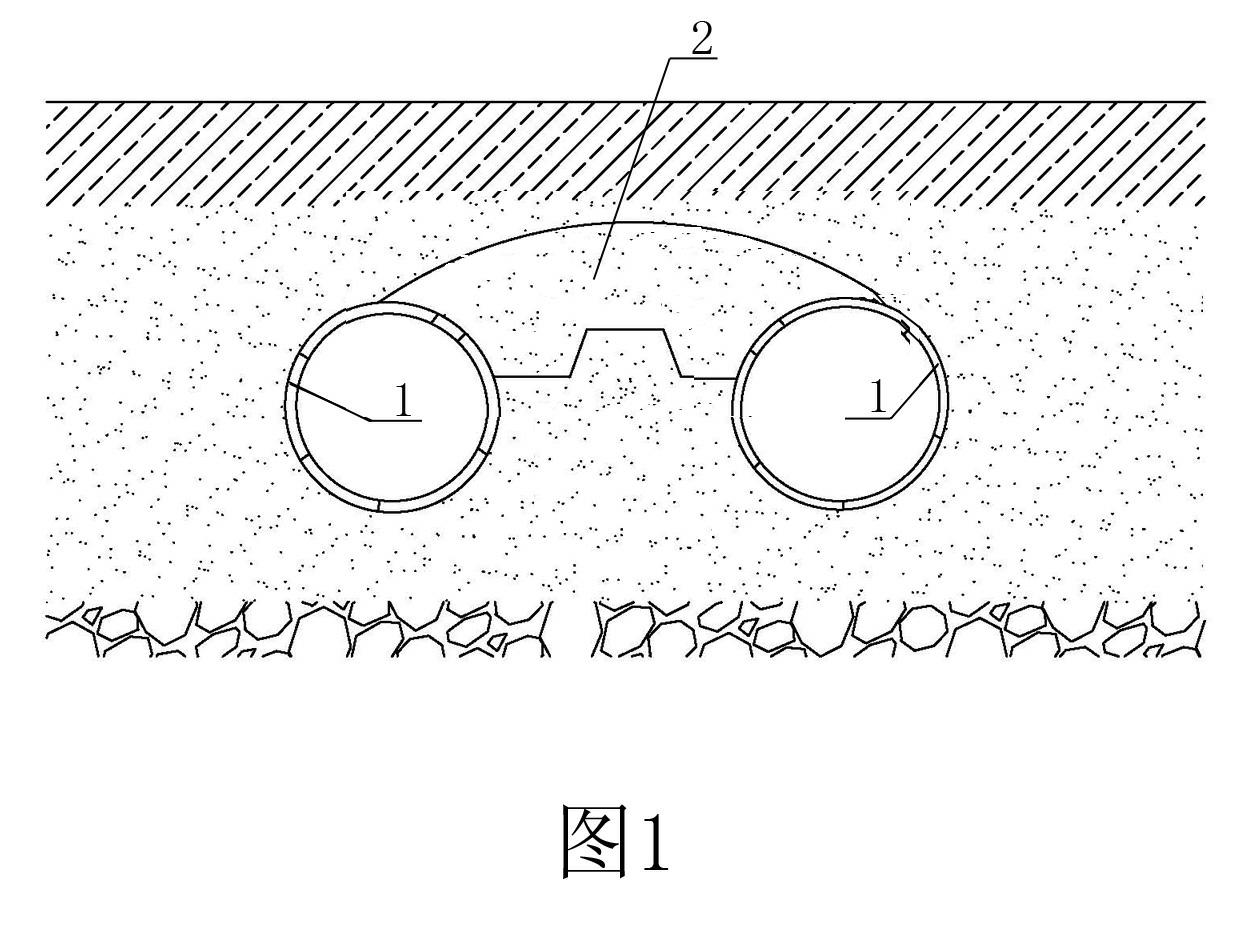

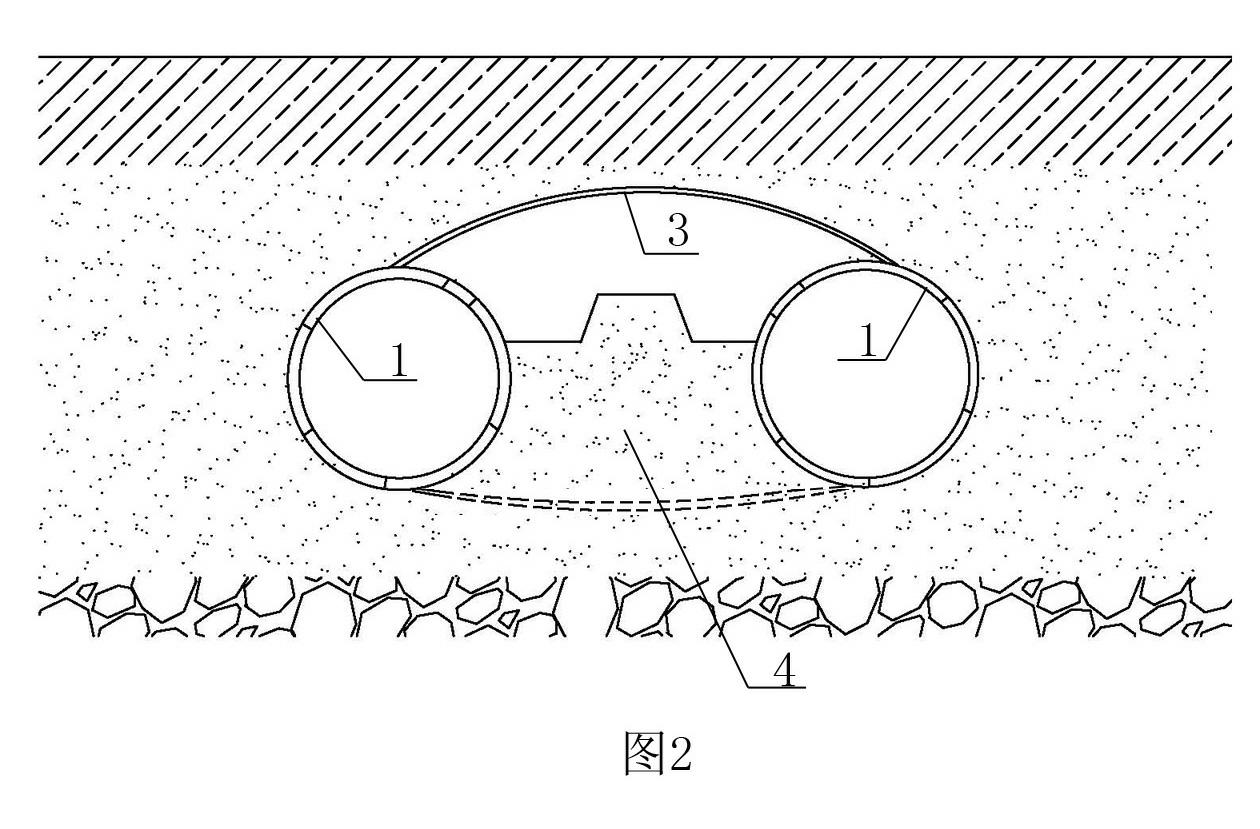

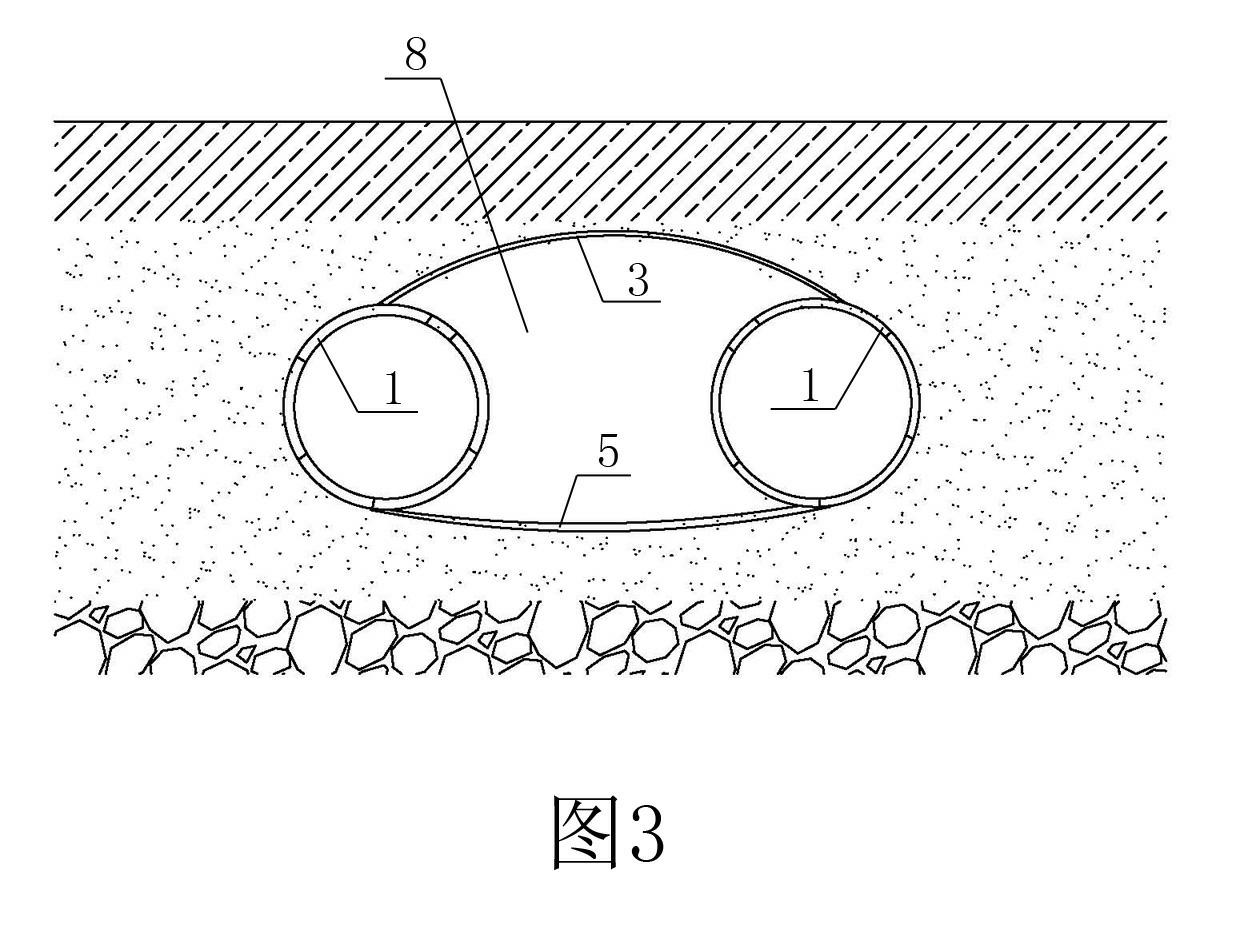

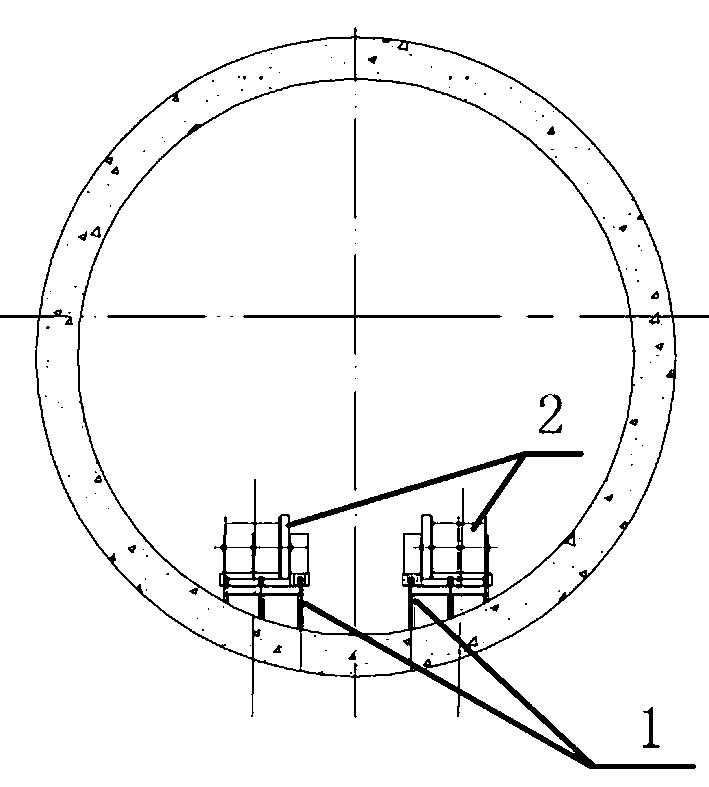

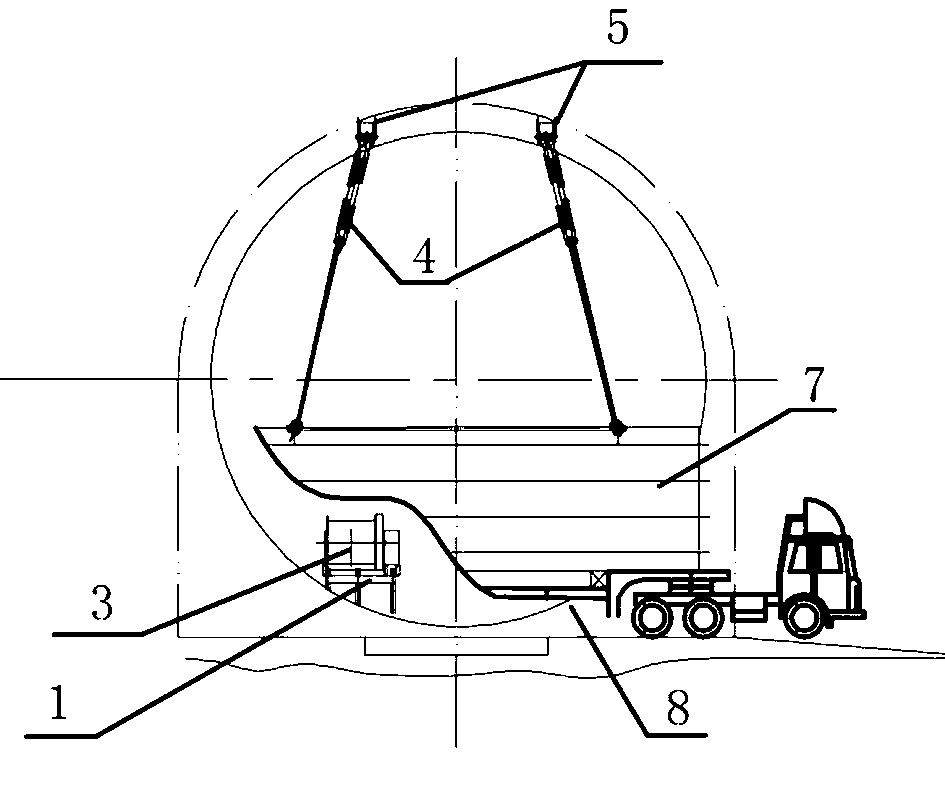

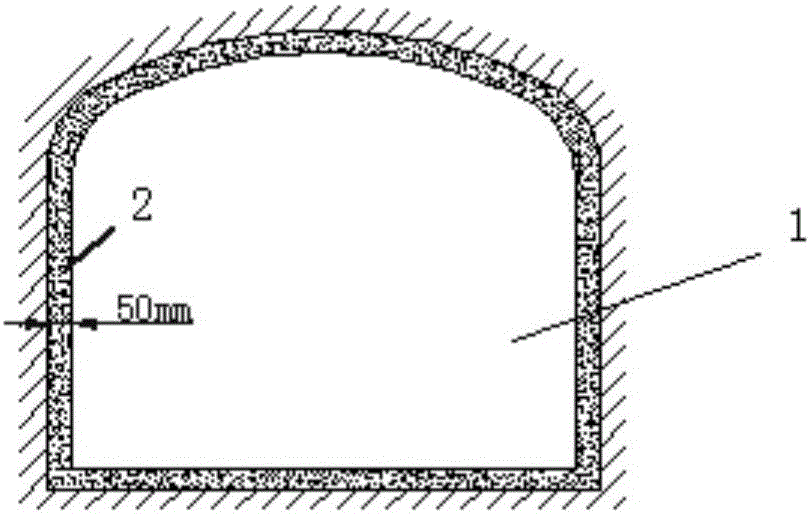

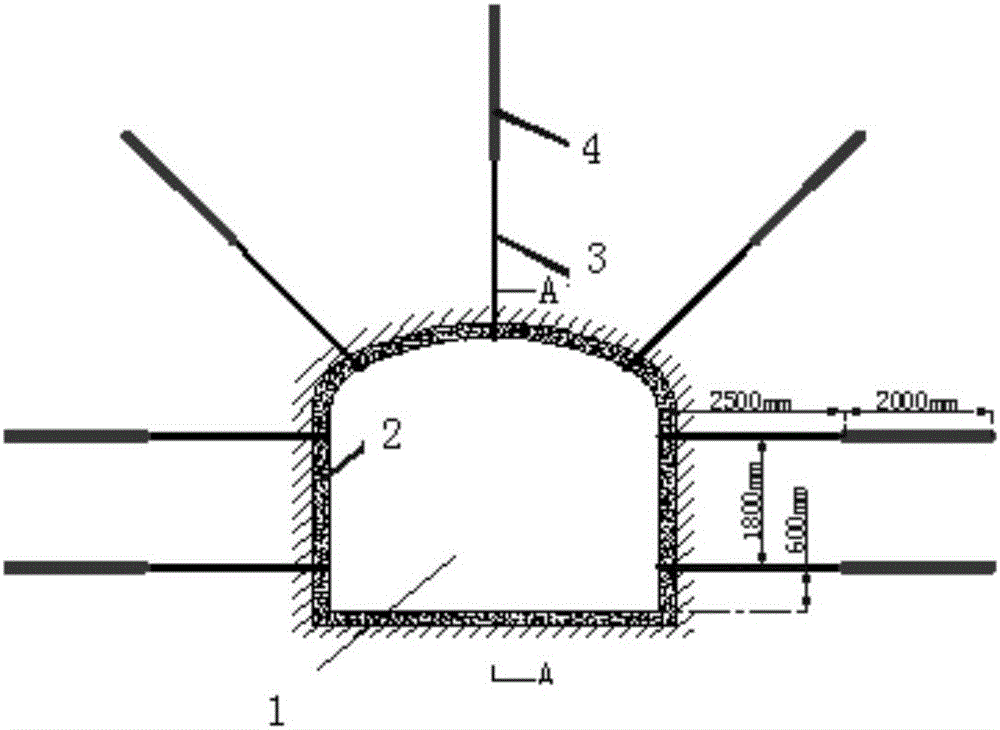

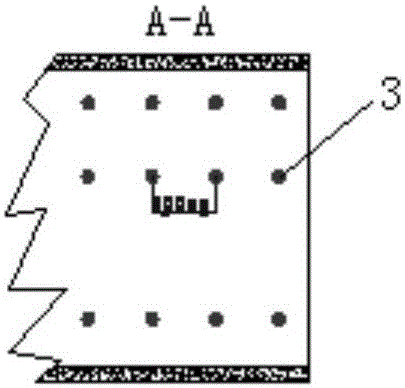

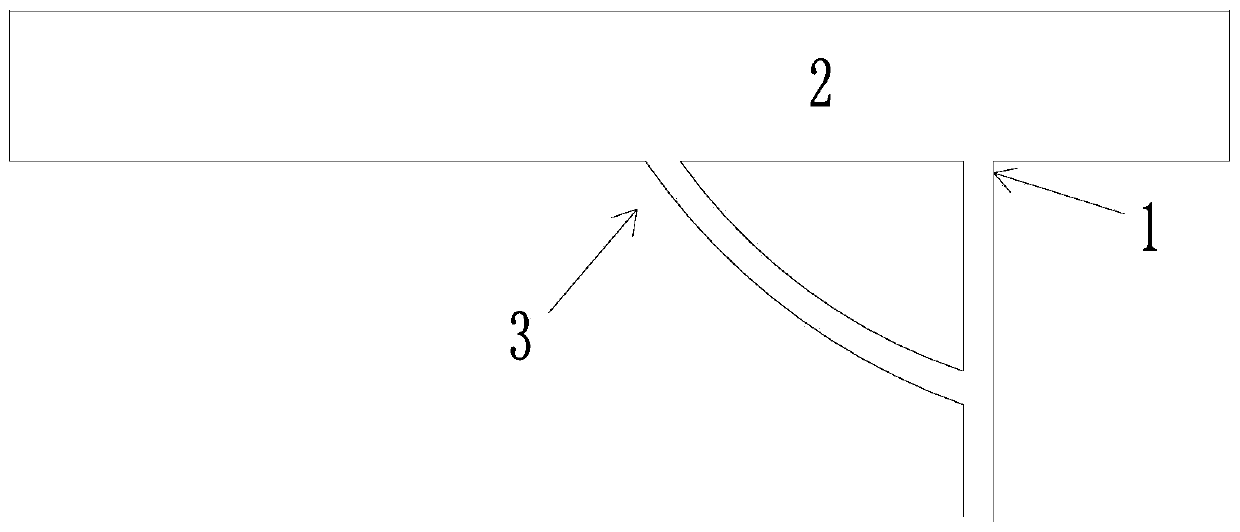

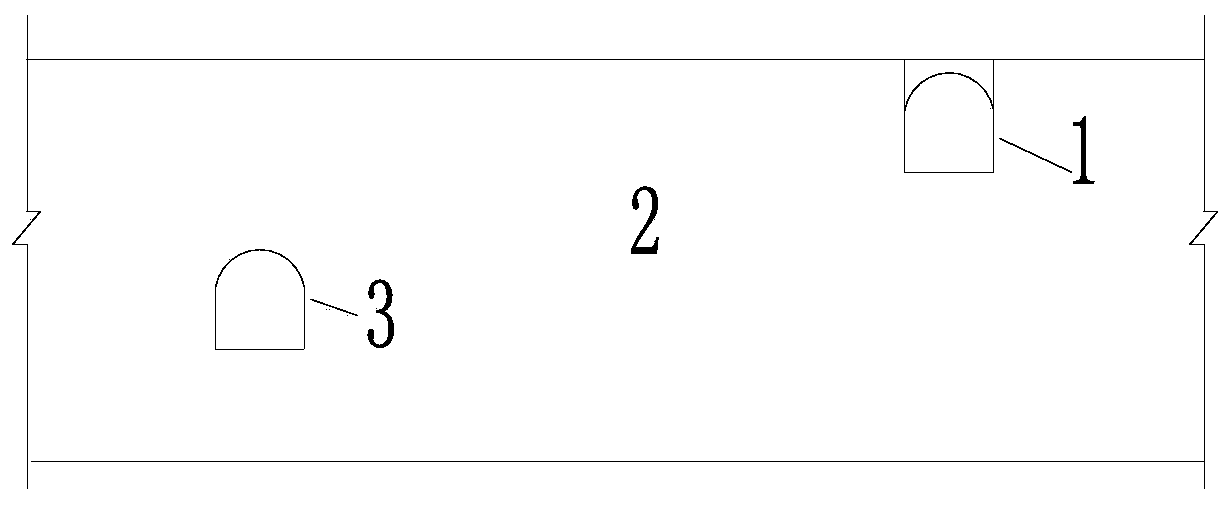

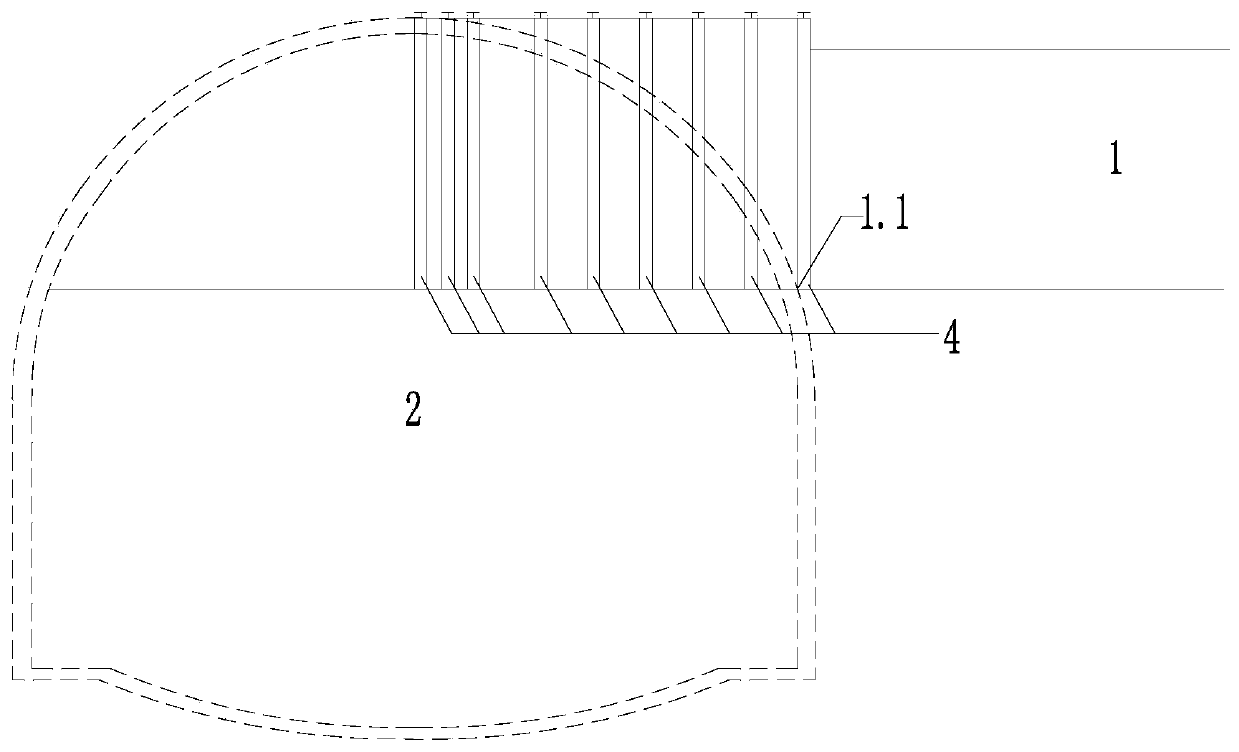

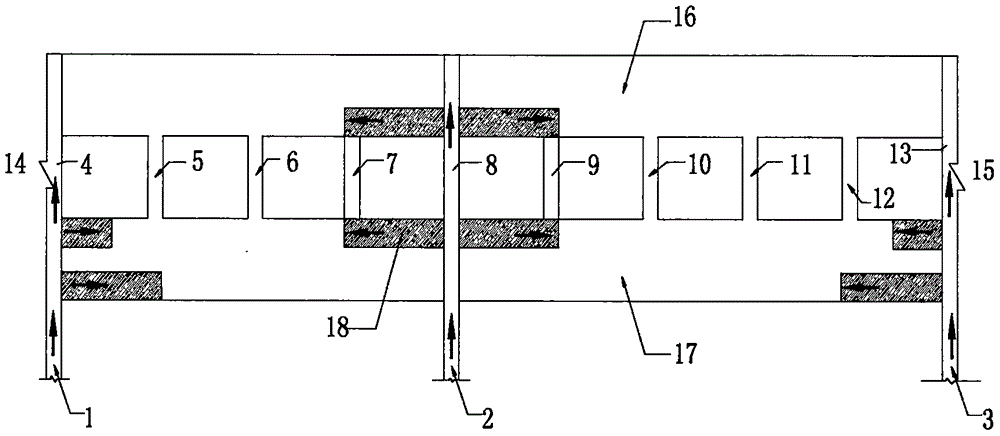

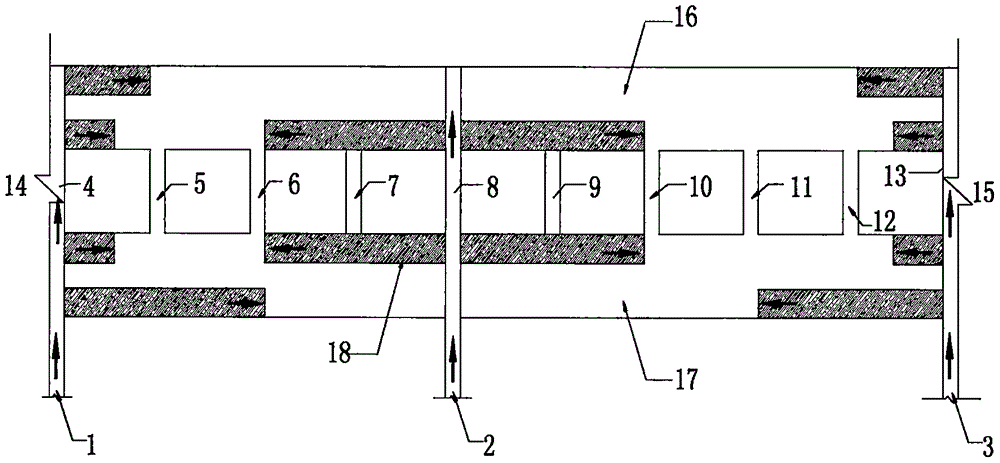

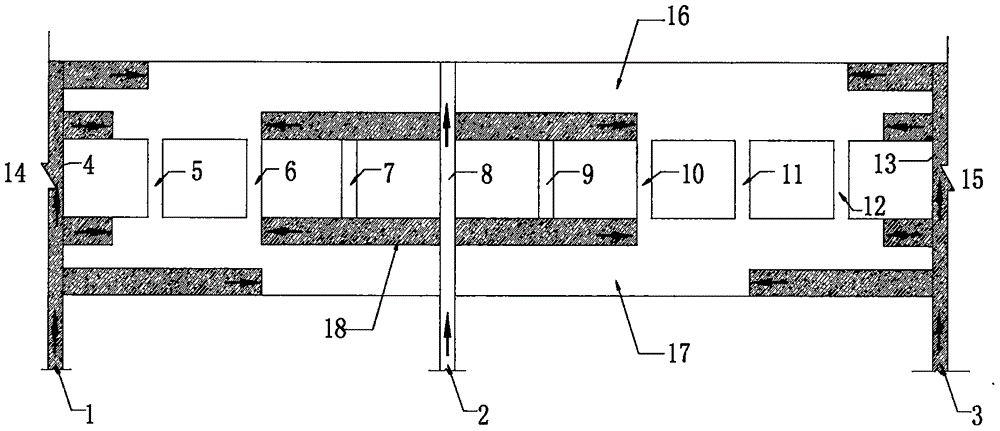

Method for constructing underground space by shield-shallow buried covered excavation composite method

InactiveCN102094649AReduce disturbanceReduce construction riskUnderground chambersTunnel liningStructural engineeringShield tunnelling

The invention relates to a method for constructing an underground space by a shield-shallow buried covered excavation composite method, and belongs to the technical field of construction methods of the underground space. The construction method comprises the following steps of: constructing two or more shield tunnels in advance by a shield method; and excavating a soil body between the shield tunnels by a shallow buried covered excavation method. By the method, the construction of the underground space with a large cross section is safe and high-efficiency, a structure is definitely stressed, construction speed is high and construction cost is low. The method can be used for constructing large-scale underground spaces in various forms.

Owner:乐贵平 +1

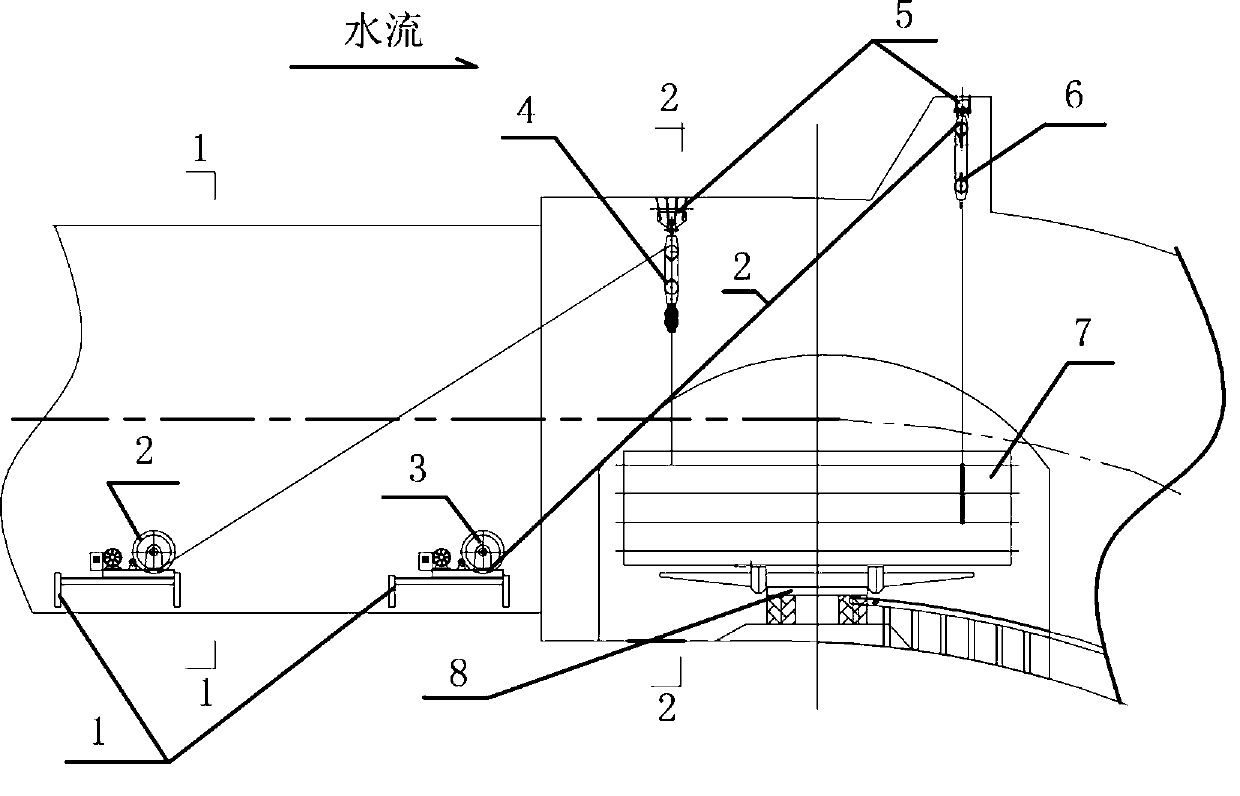

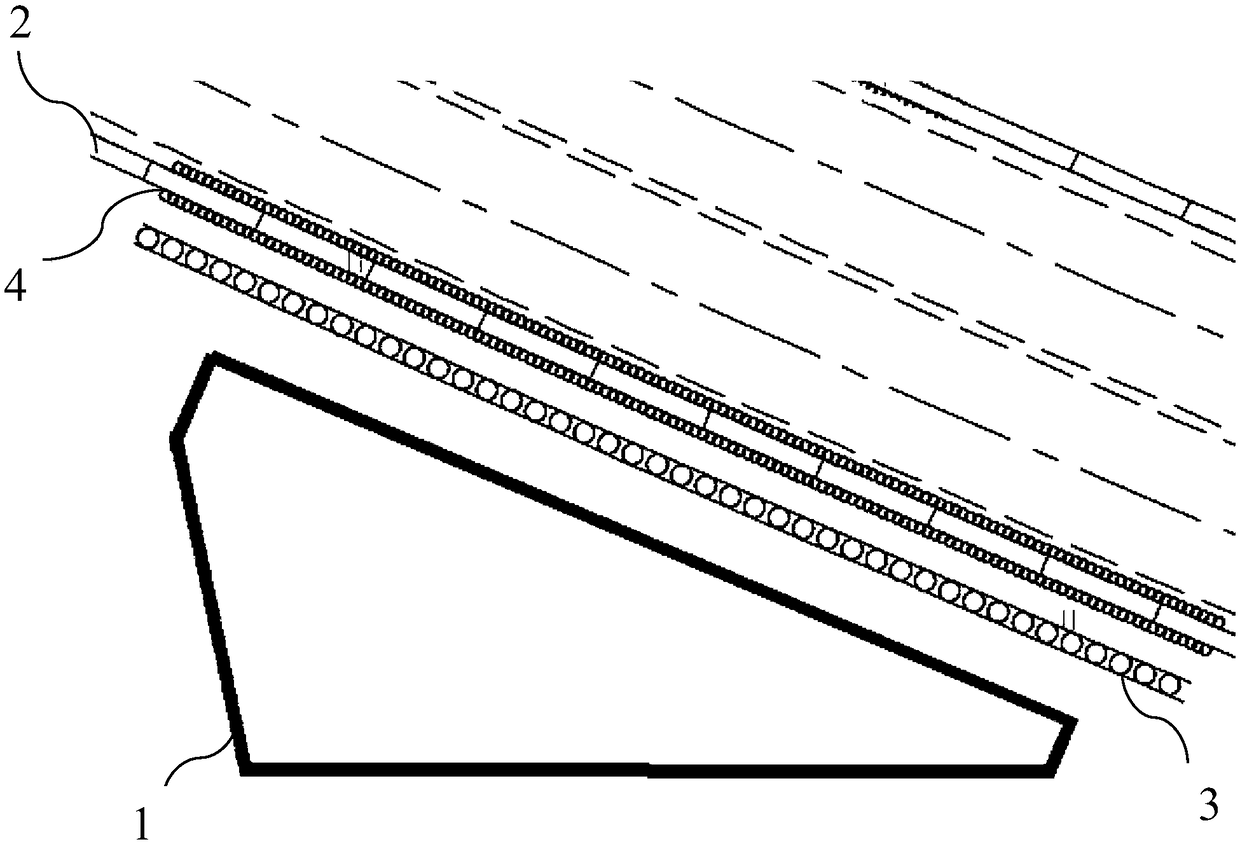

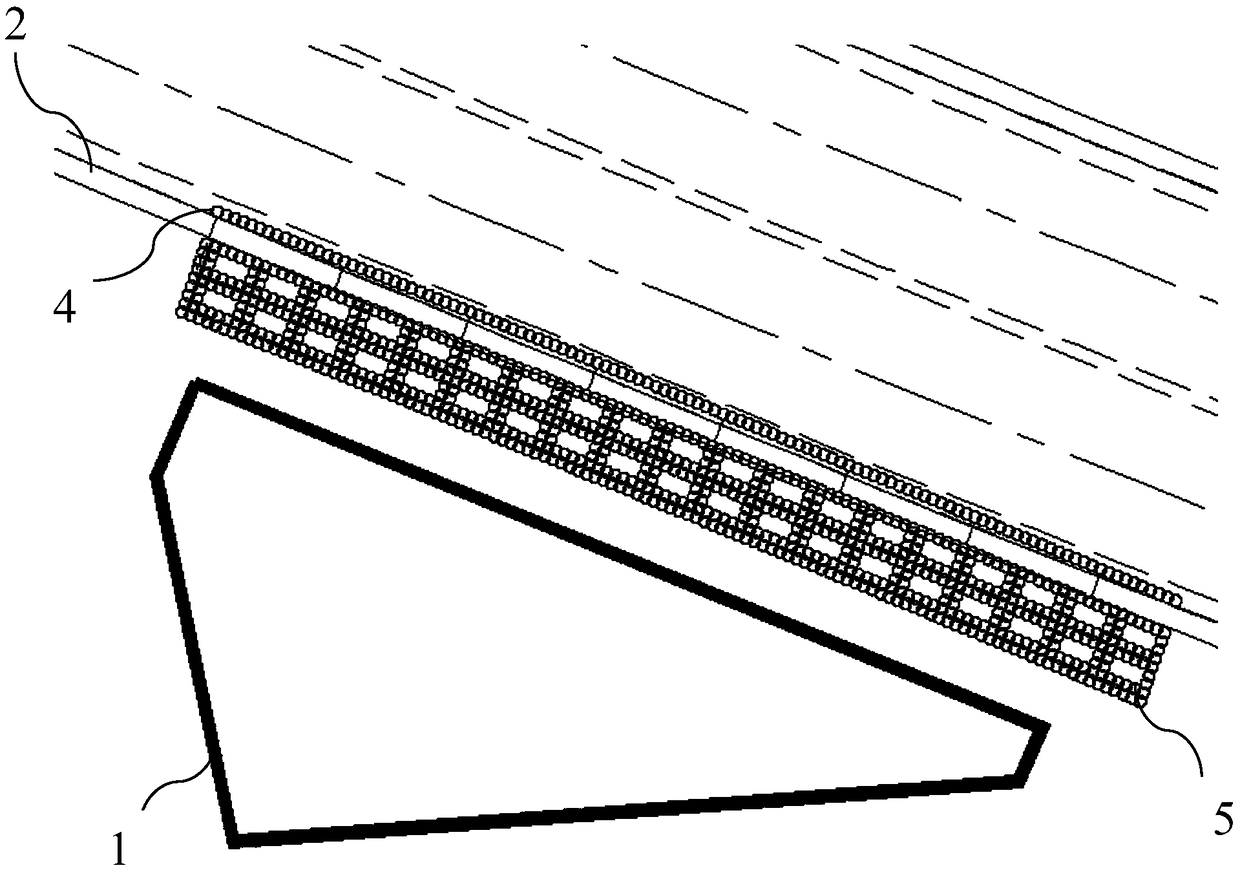

Method for mounting inclined shaft internal pressure steel tube

InactiveCN103277582ASafe and efficient constructionPipe laying and repairMathematical modelEngineering

The invention relates to a method for mounting an inclined shaft internal pressure steel tube. The method comprises the steps of hoisting a hauling system, enabling a rail to slide downwards, enabling a trolley to slide downwards to complete a load test, conveying a tube coupling to be mounted of the pressure steel tube to a site, hoisting, unloading and turning over an upper slipway vehicle and a lower slipway vehicle by a winch hoisting system, tying the vehicles, connecting a gliding hauling system and the steel tube, removing a hoisting cable, enabling the hauling system to work, finishing gliding and humping of the tube coupling, unloading the tube coupling and enabling the lower slipway vehicle to reset. According to the method for mounting the inclined shaft internal pressure steel tube, a mathematical model calculation achievement which is established according to the mechanics principle is combined with a model test and a prototype test to demonstrate the feasibility of two-point towing gliding, a series of technical problems of optimizing of the structure of an anchor inside a cave chamber, rope jumping and nesting of a winch in the heavy loading process, selecting, calculating and demonstrating of a gliding towing point, designing of the structure of the trolley, synchronization balancing of double-traction, preventing abnormal abrasion of a steel wire rope of a multiplying power pulley block and gliding in-place unloading of the steel tube are solved comprehensively and systematically, and construction is safe and efficient.

Owner:CHINA GEZHOUBA GROUP CO LTD +1

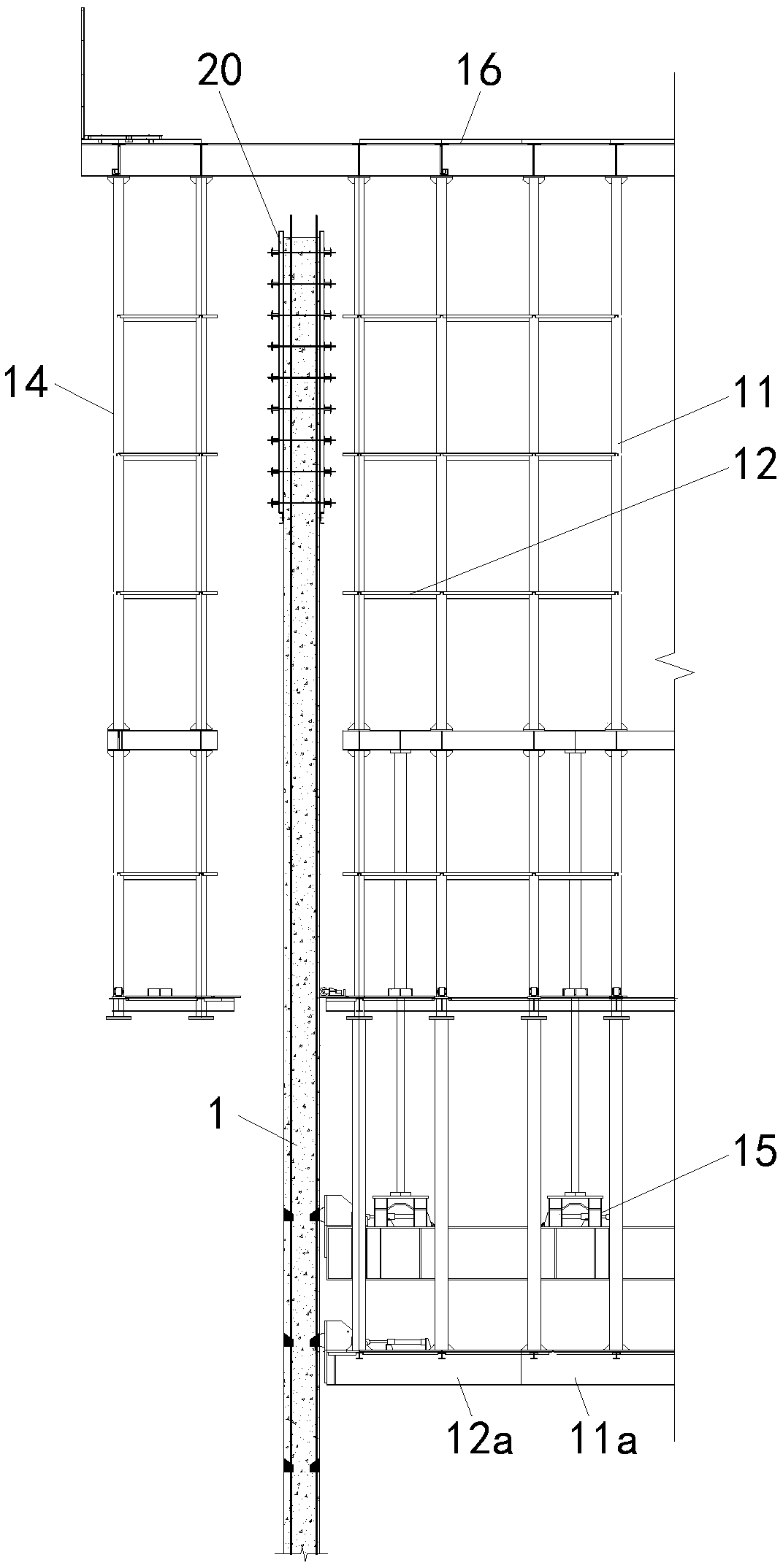

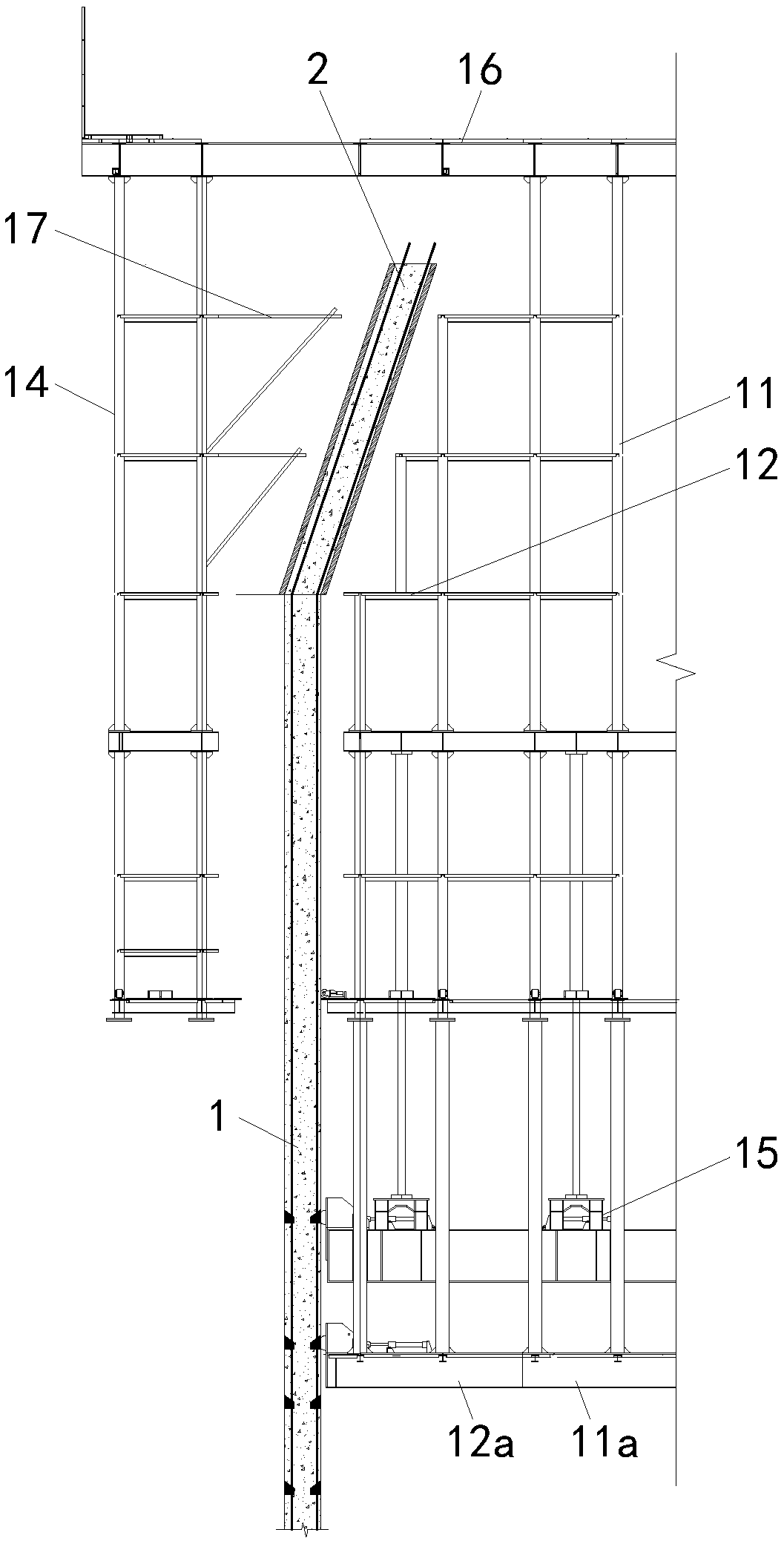

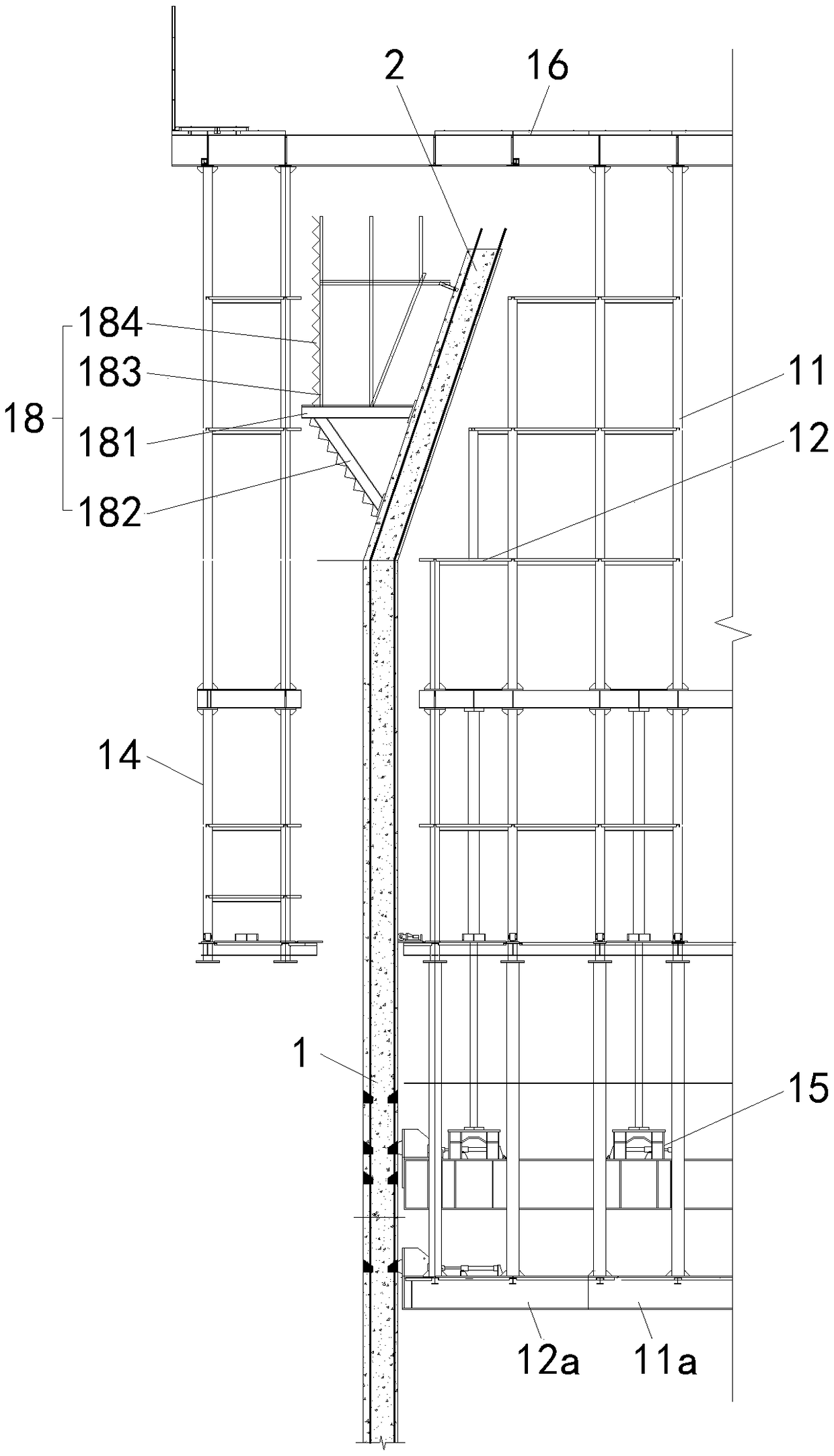

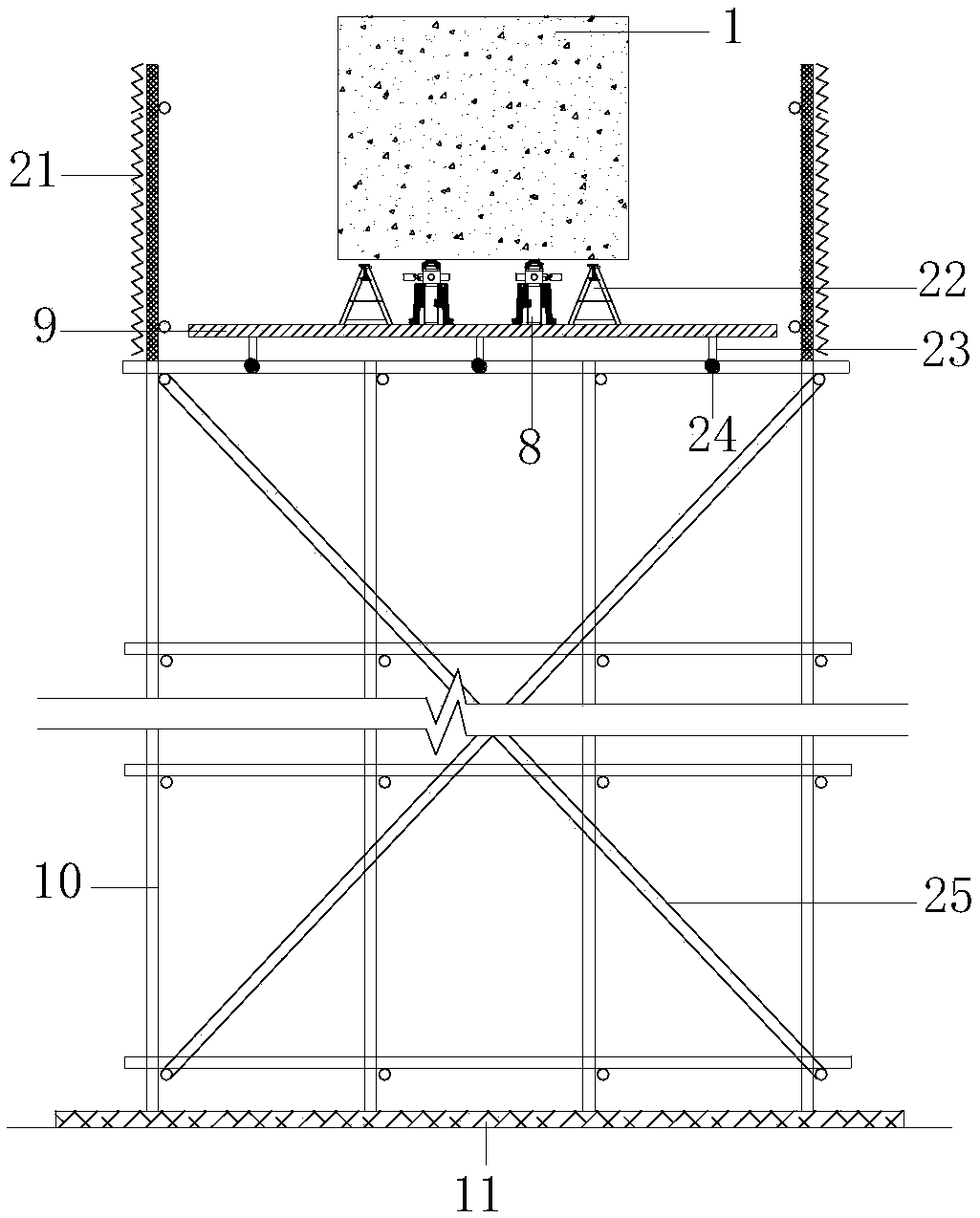

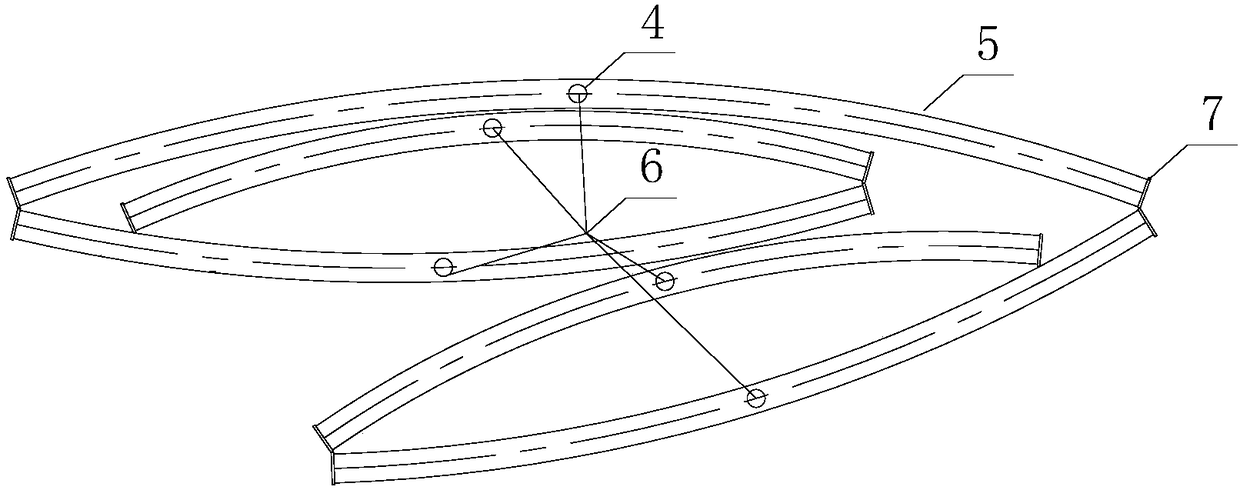

Cylinder frame support type integral steel platform suitable for inclined wall construction and construction method thereof

PendingCN109457931ASafe and efficient constructionSafe and efficient demolitionForms/shuttering/falseworksBuilding support scaffoldsVertical projectionSupporting system

The invention discloses a cylinder frame support type integral steel platform suitable for inclined wall construction and a construction method thereof, and relates to the technical field of buildingconstruction equipment. And aims at the problem that the current cylinder frame supporting type integral steel platform cannot be used for safe and efficient construction of an inclined wall body of acore cylinder shear wall. The device comprises a main frame body which comprises a steel platform, a supporting system and a climbing system, a branch frame body which comprises at least one inner cylinder frame support arranged between the inclined wall body to be poured and the main frame body, the top of the branch frame body connected with the bottom of the steel platform, the bottom beam ofthe branch frame body movably connected with the bottom beam of the main frame body, the bottom of the branch frame body provided with at least one hydraulic oil cylinder, the width of the branch frame body equal to or larger than the width of vertical projection of the inclined wall body to be poured; and a suspension anchor scaffold, which is installed on the outside of the core cylinder shear wall, the bottom of the suspension anchor scaffold connected with the bottom of the poured inclined wall body, and the top of the suspension anchor scaffold is connected with the end part of the top beam of the steel platform.

Owner:SHANGHAI CONSTR NO 1 GRP

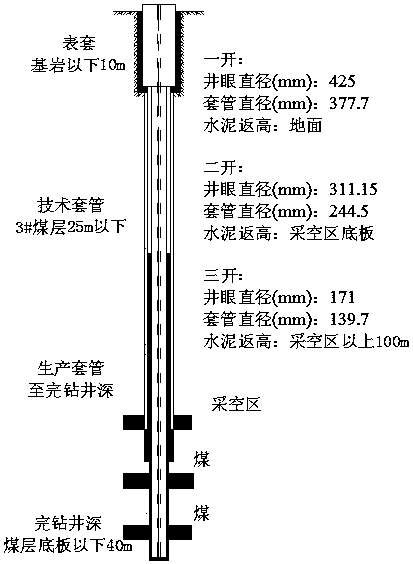

Overmined-goaf coal-bed methane surface well drilling method

InactiveCN109057795AEnsure construction safetyNon-flammableMining devicesUnderground miningWell drillingNitrogen gas

The invention aims at solving the problems in a well drilling process of a surface extraction goaf underlying coal-bed methane well of a coal mining area and provides an overmined-goaf coal-bed methane surface well drilling method according to requirements of an overmined-goaf well drilling technology. The method comprises the following specific steps: firstly, exploiting; drilling down to a surface soil layer for 10m by adopting a conventional well drilling method; carrying out well cementation through a sleeve and returning cement to the surface; secondly, constructing by adopting a nitrogengas well drilling manner when constructing to a 90m part of a goaf top plate; finishing drilling when drilling down to a coal bed bottom plate for 25m and carrying out the well cementation through technical sleeve; returning cement to a goaf coal bed bottom plate; thirdly, exploiting; finishing drilling when drilling down to a target layer for 40m by adopting a clean water drill carrying out thewell cementation through the sleeve; returning the cement to a part which is 100m above the goaf top plate. The overmined-goaf coal-bed methane surface well drilling methodis characterized in that overmined-goaf drilling of nitrogen gas can be realized and underground potential safety hazards can be eliminated; safe and efficient construction of overmined-goaf well drilling of coalmines is ensured.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

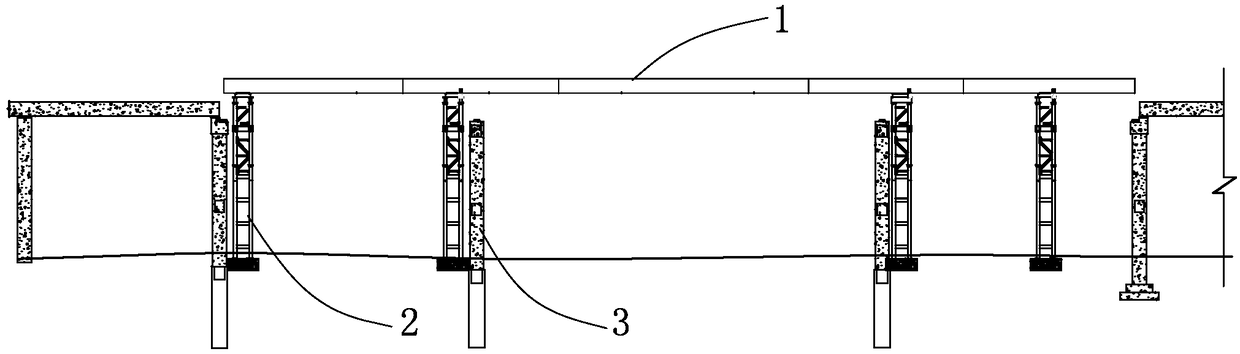

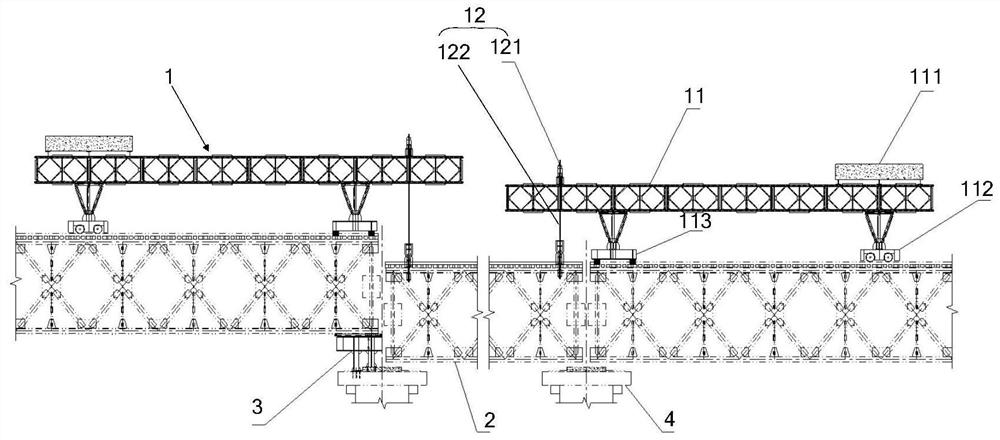

Steel truss jacking device

PendingCN108589928AGuaranteed verticalityFunctionalBuilding material handlingSafety controlArchitectural engineering

The invention discloses a steel truss jacking device. The technical problems that steel truss large hoisting equipment in a whole building group is unable to use, difficult to assemble, difficult in assemble quality and safety control in the prior art are solved. The steel truss jacking device comprises a jacking seat and jacking frames. The jacking frames comprise lattice column standard sectionsmatched with the jacking seat and bearing seats used for connecting the lattice column standard sections and the steel truss. The jacking seat comprises a base and a jack arranged on the base, a lifting seat is arranged at the top end of the jack, and the lifting seat is connected with the lattice column standard sections through pull rods. The steel truss jacking device has practical functions and convenient operation, and can complete the construction of the steel truss in the whole building group efficiently and safely.

Owner:CHINA CONSTR SENVENTH ENG BUREAU INSTALLATION ENG

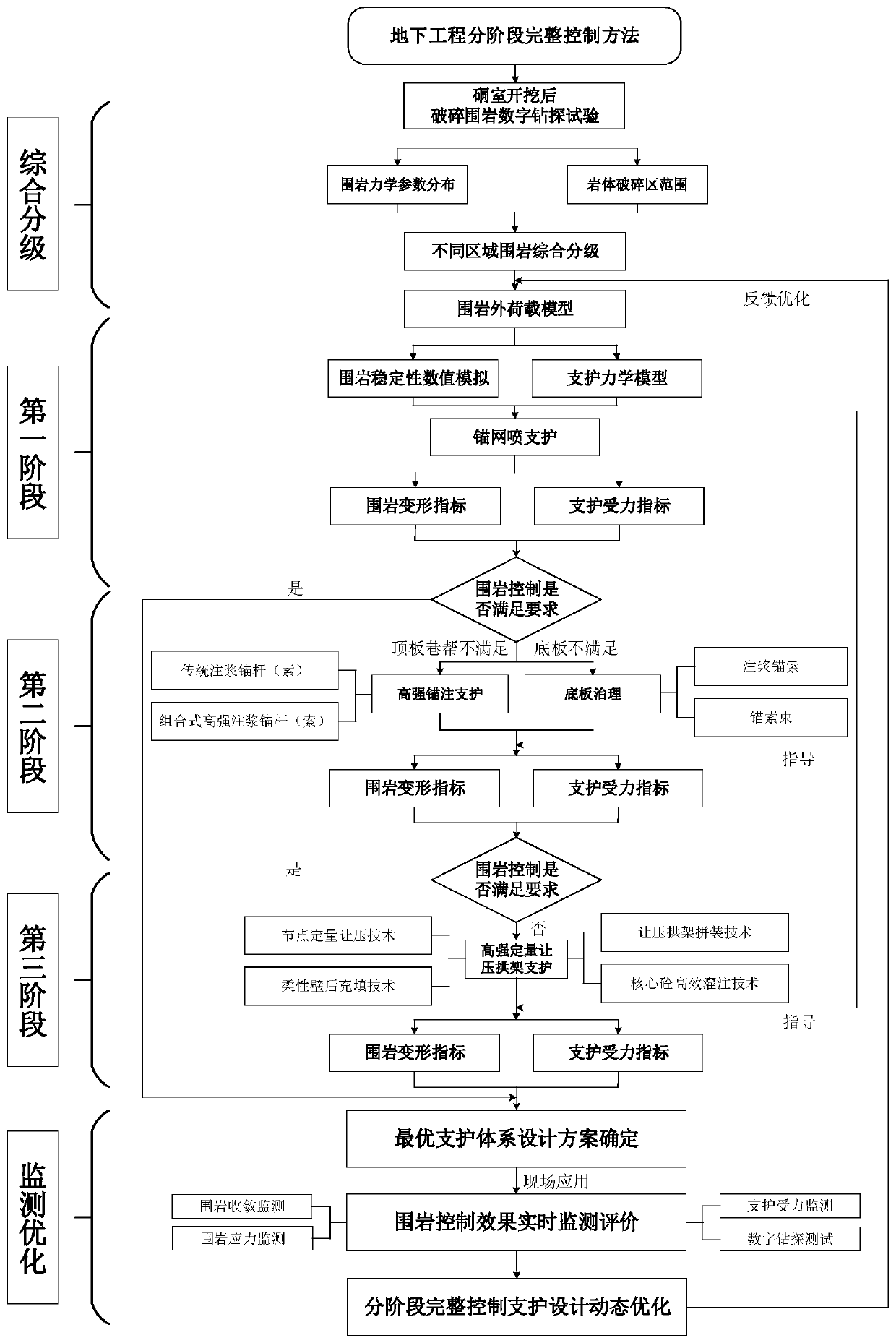

Underground engineering multi-stage complete control method

ActiveCN109854252AReal-time monitoring and evaluationReal-time dynamic optimizationUnderground chambersTunnel liningMechanical modelsOptimal design

The invention discloses an underground engineering multi-stage complete control method. The problem that in the prior art, a surrounding rock control method is prone to initiating safety accidents issolved. The underground engineering multi-stage complete control method has the beneficial effects that underground surrounding rock under complex conditions can be effectively retained and protectedaccording to a multi-stage retaining and protecting method. According to the scheme, the underground engineering multi-stage complete control method comprises the steps that after underground engineering is excavated, the surrounding rock is subjected to comprehensive classification; according to a surrounding rock comprehensive classification result, a surrounding rock external loading model is established, and surrounding rock stability numerical simulation and retaining and protecting mechanical models of different retaining and protecting stages are established; surrounding rock deformation indexes and retaining and protecting force-wearing indexes are obtained according to the surrounding rock stability numerical simulation and retaining and protecting mechanical models, and an optimal design scheme of multi-stage retaining and protecting is chosen; after the optimal design scheme is applied on site, the surrounding rock control effect is estimated in real time; and according to areal-time estimation result of the surrounding rock control effect, the multi-stage complete control retaining and protecting design is dynamically optimized.

Owner:王琦

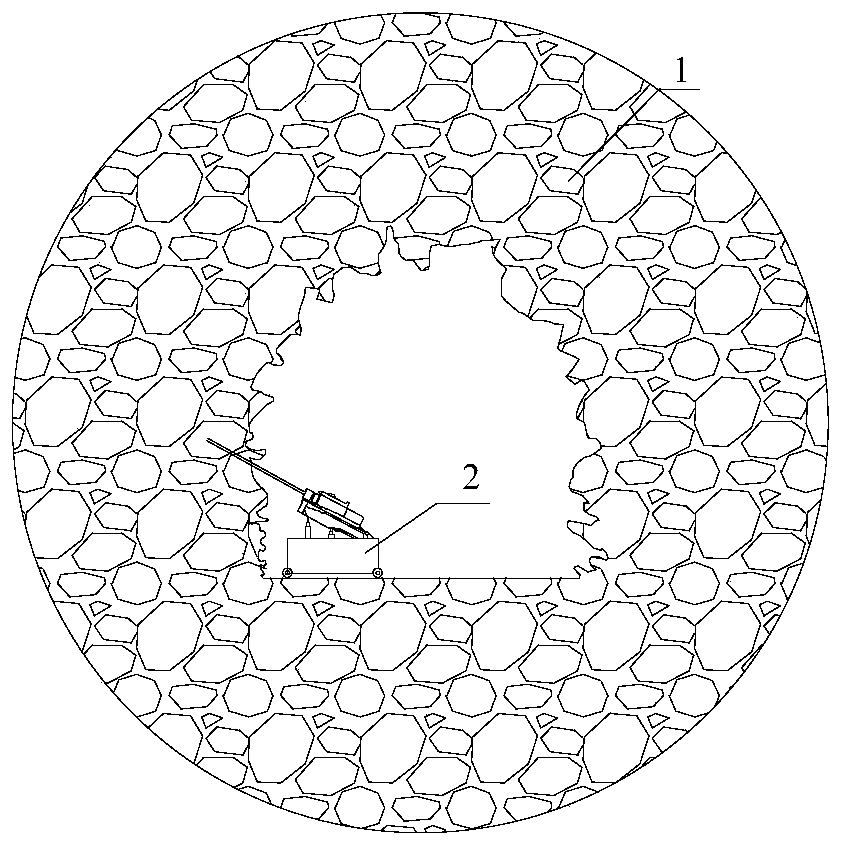

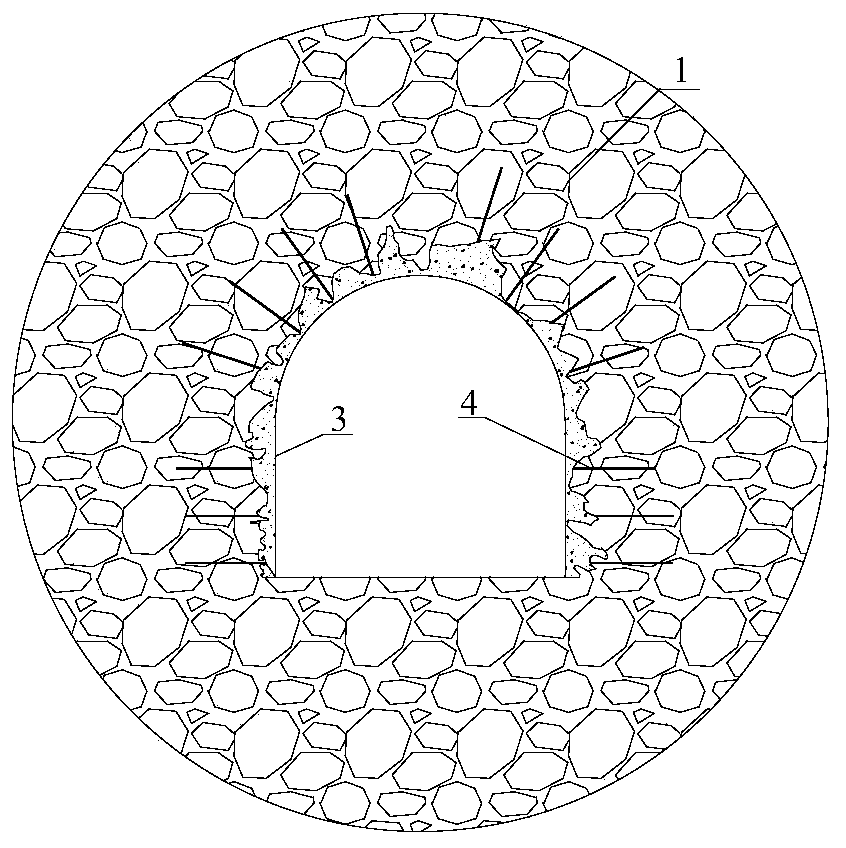

Large-embedded-depth TBM construction tunnel rock burst treatment structure

The invention belongs to the technical field of tunnel TBM construction and discloses a large-embedded-depth TBM construction tunnel rock burst treatment structure and method. The large-embedded-depth TBM construction tunnel rock burst treatment structure comprises a plurality of advance boreholes formed in the vault area of the working face of a tunnel. The advance boreholes penetrate through the rock burst area. All the advance boreholes are connected through fracture crushed zones formed through presplitting blasting in the boreholes. According to the large-embedded-depth TBM construction tunnel rock burst treatment structure and method, the positions and directions of the boreholes are reasonably arranged in the working face of the tunnel through the operation space in a TBM, the crushed zones of a rock body are formed in the vault and spandrel of the rock burst area through borehole blasting, high-pressure water injection is utilized for further promoting development of crushed zone fractures and softening the rock body, high ground stress in the rock burst area is released, the rock burst risk is eliminated, the whole construction process is safe, efficient, low in cost and good in treatment effect, subsequent borehole high-pressure grouting treatment can be conducted to improve the integrity of the crushed zone fractures of the rock body, the collapse quantity and backfilling quantity of the vault during subsequent TBM excavation are decreased, and remarkable economic and social benefits are achieved.

Owner:POWERCHINA CHENGDU ENG

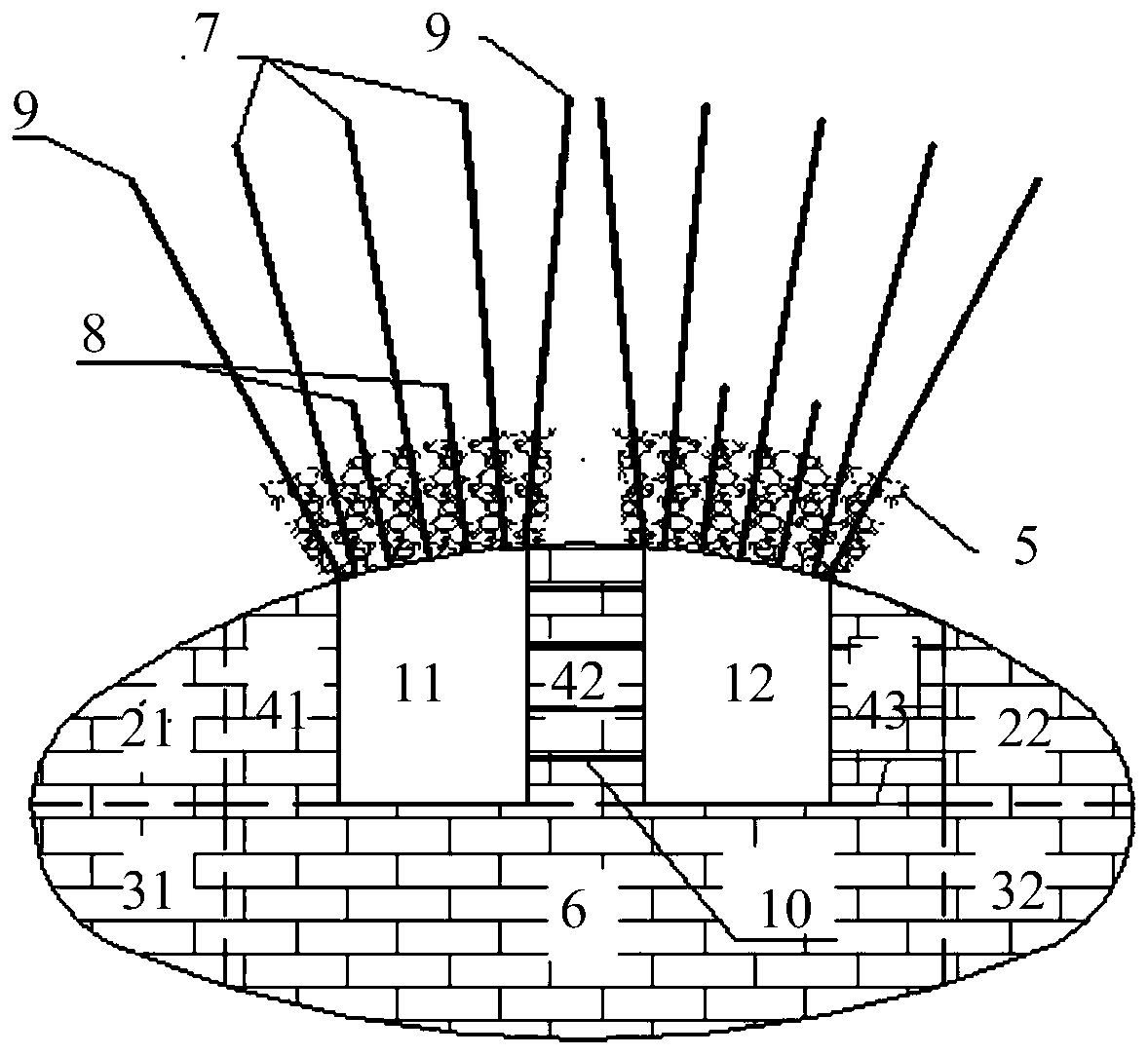

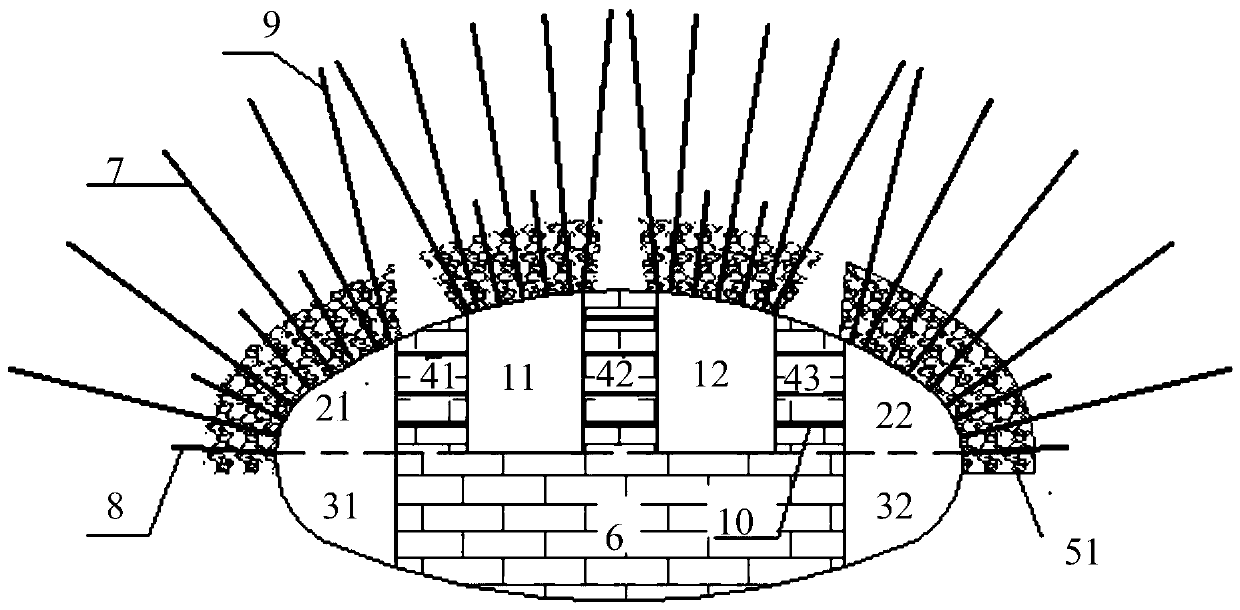

Deep mine hard rock roadway stress adsorption layer structured support method

ActiveCN105781572ARealize synergy and unificationTo achieve reinforcementUnderground chambersBlastingShotcreteStructure of the Earth

The invention discloses a deep mine hard rock roadway stress adsorption layer structured support method. In the initial stage after a deep roadway is excavated, concrete is sprayed to form a concrete flexible support layer. 4.5 m-5.0 m blastholes are drilled in the two sides of the roadway and an arch top, the spaces in the range of 2 m-2.5 m of the bottoms of the blastholes are filled with explosive for conducting soft fragmentation explosion to construct an arch broken rock stress adsorption layer. Grouting conduit anchor rods are driven in through the blastholes, cement paste is poured into the grouting conduit anchor rods to reconstruct structure support bodies. Paste is poured into the blastholes so as to fix the grouting conduit anchor rods, so that a rockburst prevention support structure formed by the arch broken rock stress adsorption layer, the structure support bodies, an isolation rock body, the concrete flexible support layer and the grouting conduit anchor rods of the high-stress deep hard rock roadway in a cooperative mode is achieved. Through the stress adsorption layer formed by the support technology, high stress and gathering of stress energy of surrounding rock of the isolation rock body can be effectively reduced, rockburst is restrained, and tunneling safety and efficient construction of the deep hard rock rockburst type roadway can be well achieved.

Owner:CENT SOUTH UNIV +1

Method for excavating and supporting subway station tunnel by adopting underground excavation construction channel

InactiveCN110905524AReduce construction difficultyReduce the number of temporary supportsUnderground chambersTunnel liningArchitectural engineeringSubway station

The invention discloses a method for excavating and supporting a subway station tunnel by adopting an underground excavation construction channel, relates to the technical field of tunnel construction, and mainly aims to solve the problems of complicated conversion procedures, high risk, high temporary support consumption and the like in a station tunnel construction method. The method comprises the steps of conversion construction of a main construction channel and a station tunnel, conversion construction of an auxiliary construction channel and the station tunnel and excavation support of the station tunnel; the top of the main construction channel is lifted to be flush with an arch crown of the station, and parallel station entering and portal steel arch frame support are adopted; andthe auxiliary construction channel adopts footage from the station tunnel, relates to the station excavation construction step sequence in the range of the conversion section and support at the connection position of the station tunnel and the auxiliary construction channel. The method aims to solve the problems of complicated construction steps, large construction risk of key sections and more temporary supports in the traditional construction method so as to expect the underground station tunnel construction to achieve safer and more efficient purposes.

Owner:ZHONGJIAN SUIDAO CONSTR CO LTD +1

Ultra-flat cavern middle rock pillar supporting structure and construction method

PendingCN111206950ASafe and efficient constructionControl deformationAnchoring boltsRock boltWall rock

The invention discloses a construction method of an ultra-flat cavern middle rock pillar supporting structure. The construction method of the ultra-flat cavern middle rock pillar supporting structurecomprises the following steps that partitioning the cross section of a cavern is carried out, the cross section of the cavern is partitioned into a middle pilot tunnel, an upper pilot tunnel, a lowerpilot tunnel and lower-layer reserved core rock soil, a middle rock pillar is formed through the middle pilot tunnel, the upper pilot tunnel and the lower pilot tunnel; the middle pilot tunnel, an upper layer side pilot tunnel and a lower layer side pilot tunnel are excavated in sequence, a radial system anchor cable supporting structure and a radial system anchor rod supporting structure are installed; inclined anchor cables are arranged from the middle pilot tunnels on the two sides and the upper-layer side pilot tunnels on the two sides to be above the middle rock pillar in a driving manner, pre-reinforcing surrounding rocks above the middle rock pillar is carried out; a transverse opposite-pull anchor rod is driven into the middle rock pillar and reinforcing is carried out, prestressing force is applied to the anchor rod; the middle rock pillar is dismantled, simultaneously the radial system anchor rod supporting structure is installed; and the lower layer reserved core rock soil is dismantled. In the construction stage of the construction method of the ultra-flat cavern middle rock pillar supporting structure, a middle rock pillar supporting structure is reserved and is combined with a local bearing arch above the pilot tunnels, stable conversion of a surrounding rock overall stress system is achieved, a surrounding rock natural bearing arch is closed step by step, and safety construction of the ultra-flat cavern is achieved.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD +1

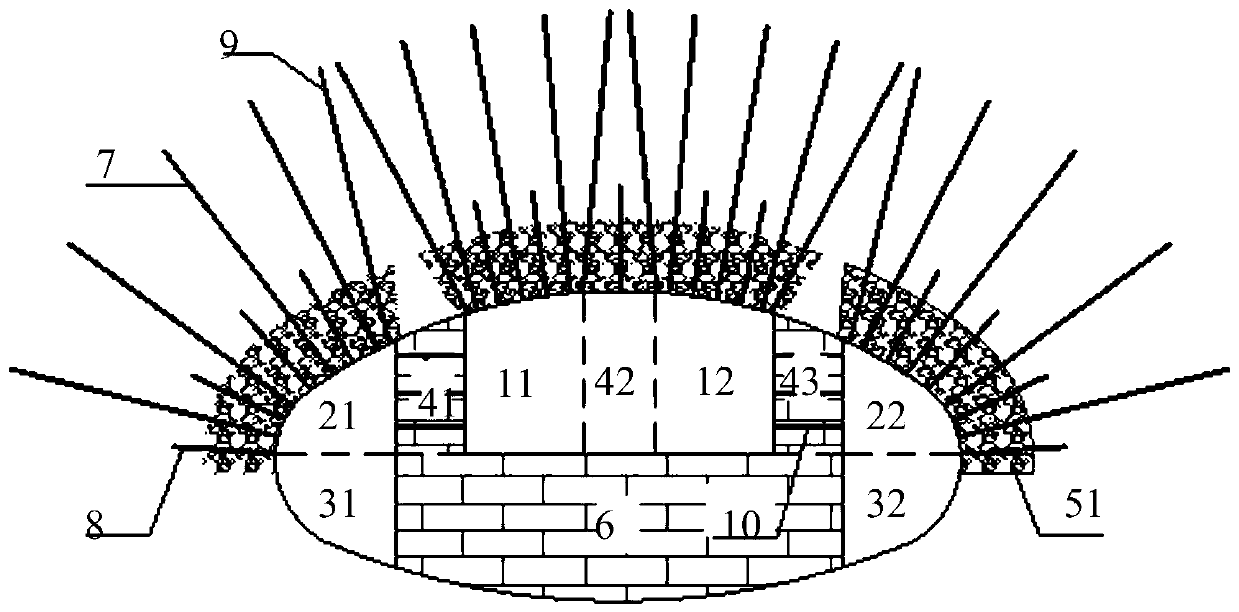

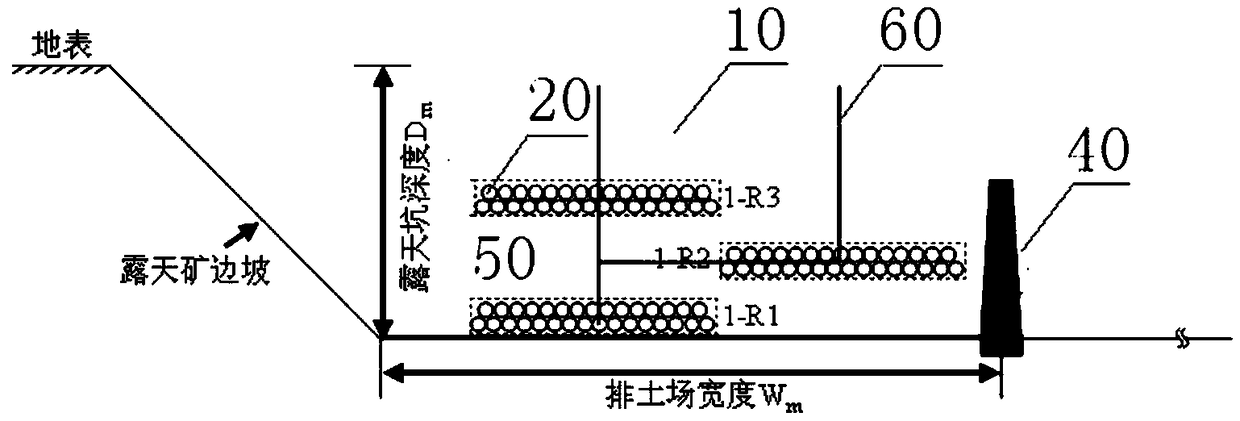

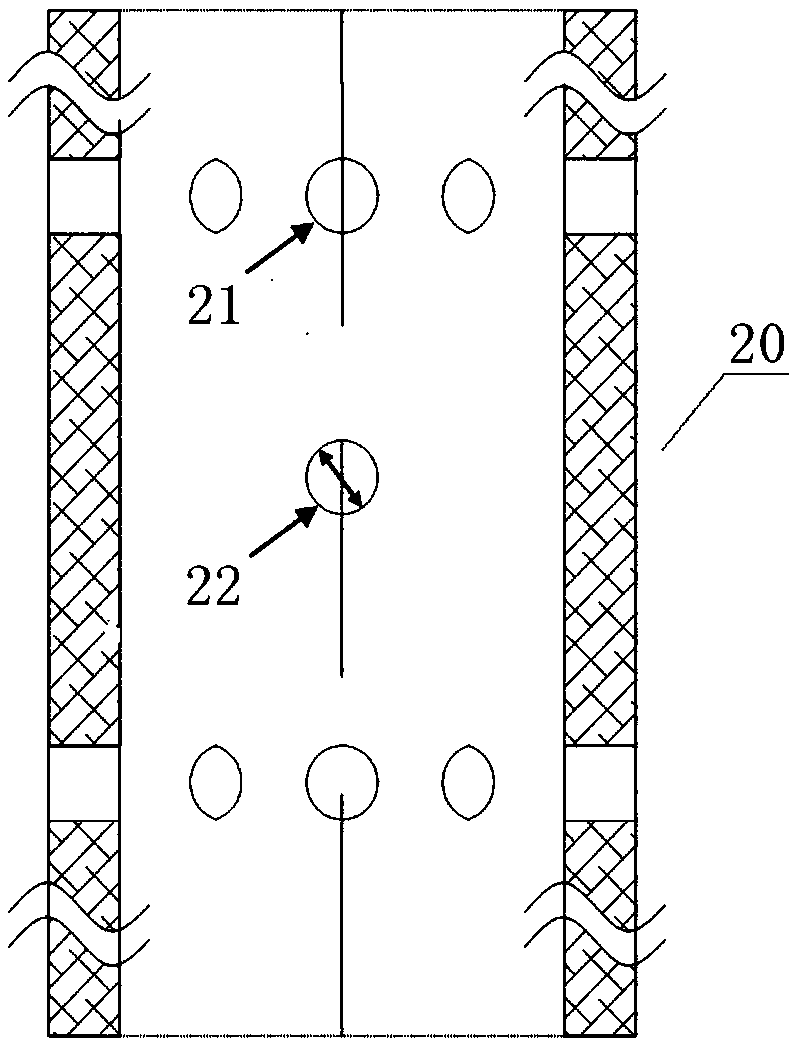

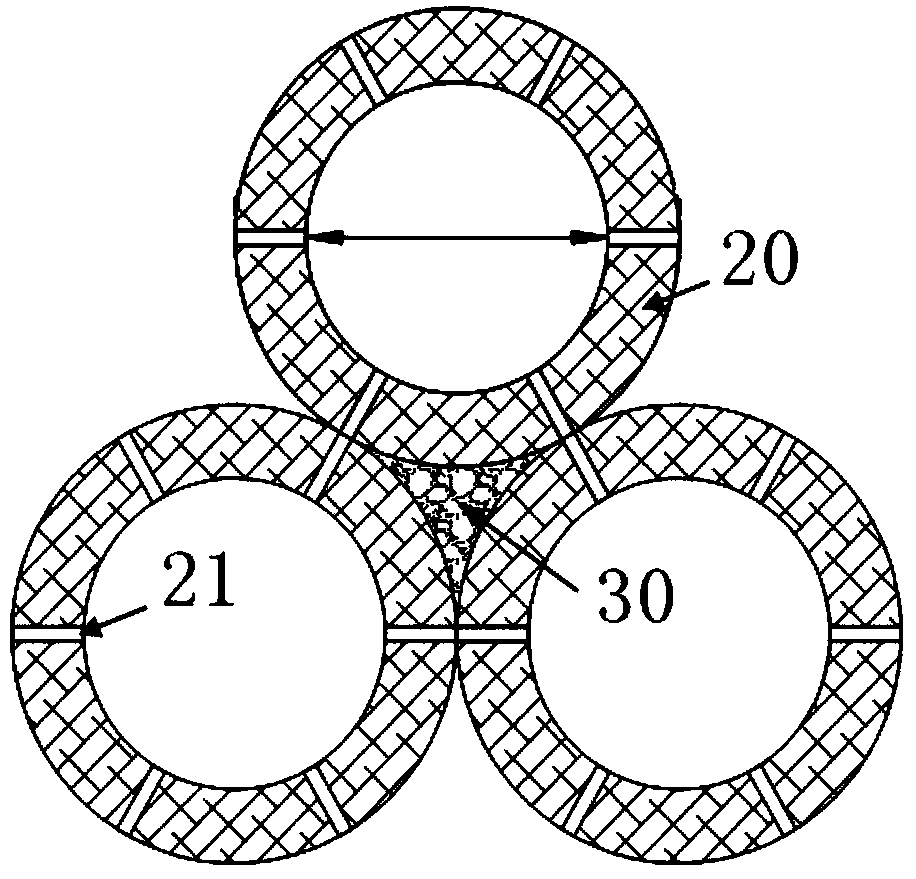

Open-pit coal mine underground reservoir, reservoir water storage body and reservoir storage capacity calculation method

The invention provides an open-pit coal mine underground reservoir water storage body. The water storage body is formed by stacking 2-6 rows of prefabricated pipe culverts from the reservoir bottom ofan underground reservoir to the top in a staggered mode, stacking gaps among the prefabricated pipe culverts are filled with gravels or rubble, a plurality of rows of culvert holes are formed in theprefabricated pipe culverts, and 4-8 culvert holes are formed in each row and uniformly formed in the same circumference of the corresponding prefabricated pipe culvert, a center hole is formed in every two culvert hole rows, water diversion among all the prefabricated pipe culverts is facilitated, and the outer walls of the prefabricated pipe culverts located at the peripheral boundary of the underground reservoir are not provided with culvert holes to ensure the effective water storage of the underground reservoir. The invention further provides the open-pit coal mine underground reservoir with the prefabricated pipe culverts as the water storage body and a storage capacity calculation method of the underground reservoir. The open-pit coal mine underground reservoir with the prefabricated pipe culverts as the water storage body is large in storage capacity and stable in structure, and the storage capacity is convenient and accurate to calculate.

Owner:TSINGHUA UNIV

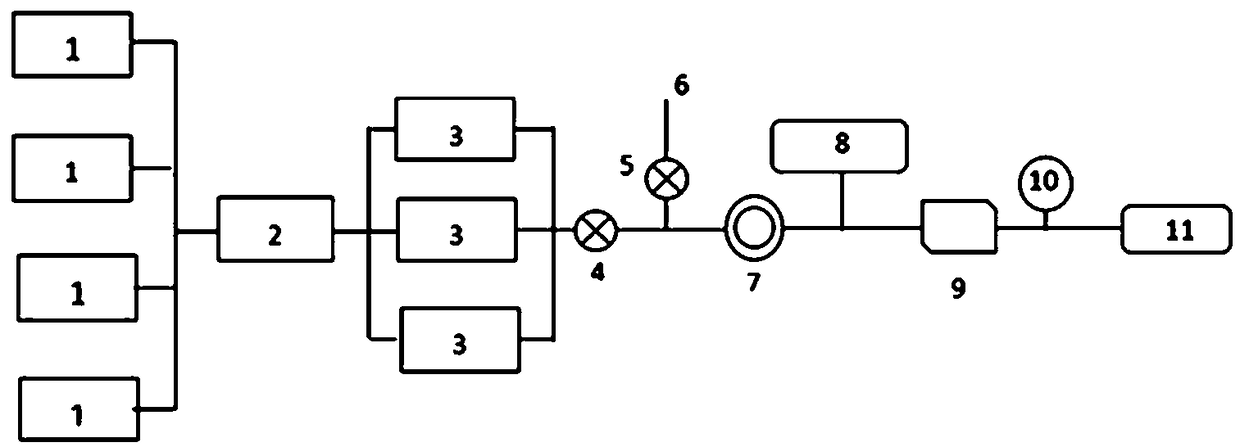

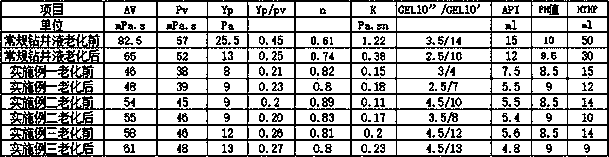

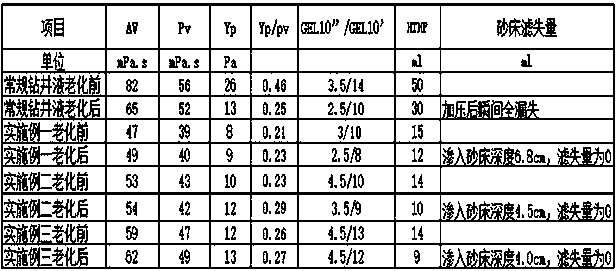

Water-based drilling fluid for shale gas wells and production method thereof

ActiveCN110628398AEnhanced inhibitory effectImprove the blocking effectDrilling compositionWater basedHorizontal wells

The invention relates to a water-based drilling fluid for shale gas wells and a production method thereof. The method sequentially includes the following steps of: (1) preparing the following raw materials: 1000 parts of water, 45-50 parts of sodium bentonite, 500 parts of a water-soluble inhibition weighting agent II; 100 parts of a water-soluble inhibition weighting agent III; 15-20 parts of aninhibiting and anti-collapse agent non-fluorescence white asphalt, 10-20 parts of solid polymeric alcohol, 10-20 parts of a filtrate reducer, 0.5-1 part of a polyamine inhibitor, 20-30 parts of ultrafine calcium carbonate, 10-25 parts of an extreme pressure lubricant, and 0.5-1 part of a coating inhibitor; (2) mixing the sodium bentonite and water, and performing curing for at least 24h at normaltemperature; and (3) adding the water-soluble inhibition weighting agent II and water-soluble inhibition weighting agent III under stirring, then adding the inhibiting and anti-collapse agent non-fluorescence white asphalt and the solid polymeric alcohol, then adding the filtrate reducer and the polyamine inhibitor, then adding the ultrafine calcium carbonate and the extreme pressure lubricant, finally adding the coating inhibitor, and then adjusting the pH value and density. The drilling fluid has the advantages of high plugging properties, strong inhibition and excellent lubricating properties, and can meet the safe drilling requirements of shale gas horizontal wells.

Owner:SINOPEC EAST CHINA PETROLEUM ENG CO LTD

Construction method for single-construction-channel dual-line same direction and same platform subway stations

InactiveCN106050241AIncrease operating channelsAvoid it happening againUnderground chambersTunnel liningTransportation capacitySubway station

The invention discloses a construction method for single-construction-channel dual-line same direction and same platform subway stations. According to the plane position relation of every two adjacent subway stations, a main construction channel, construction subchannels and a construction communication channel of the two stations are determined, and station excavation and support are implemented through four steps: excavation of the main construction channels and the construction subchannels, the excavation sequence and switching of station connection sections, the excavation and support sequence of pilot tunnels in station bodies on the left line and the right line of each station, excavation and support of the communication channel, construction of secondary linings of the station bodies on the left line and the right line of each station, and release of core soil. By reasonably arranging the communication construction channel for every two adjacent stations, adjusting the spatial position relation between the construction channels and the stations, and setting the construction sequence of the communication channels and the subway stations, the working efficiency of the tunnel face is enlarged to a great extent, the transportation capacity of the main construction channels and the construction subchannels is brought into a full play, the construction period is remarkably shortened, and the project cost is lowered.

Owner:CHONGQING UNIV

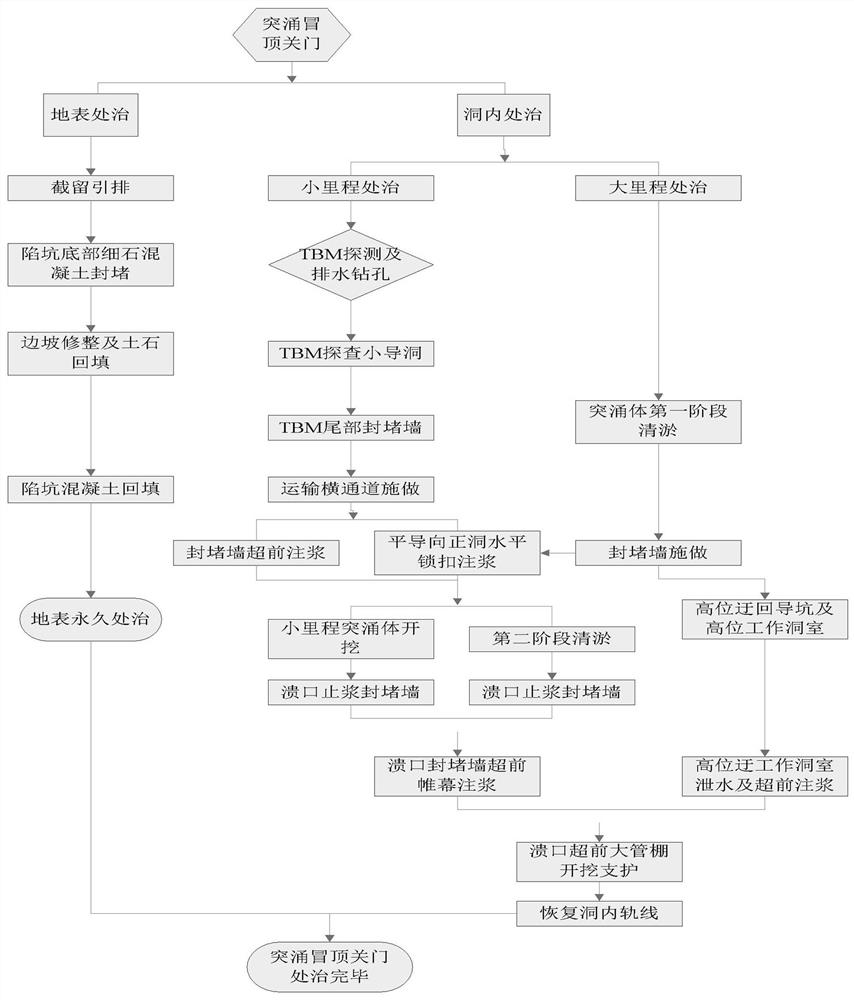

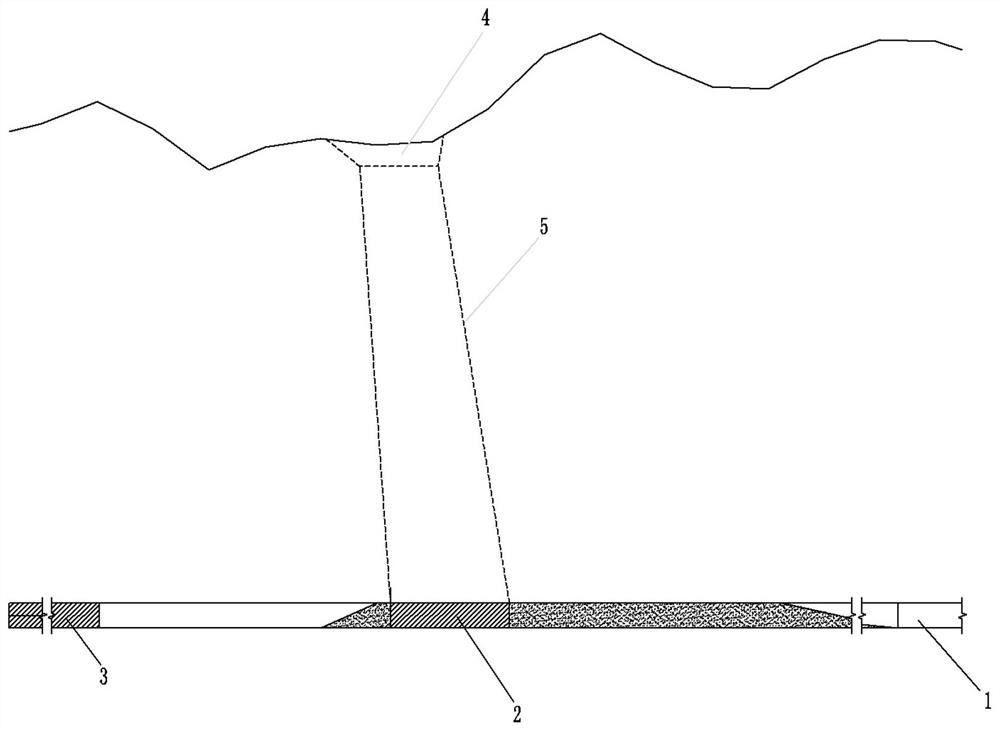

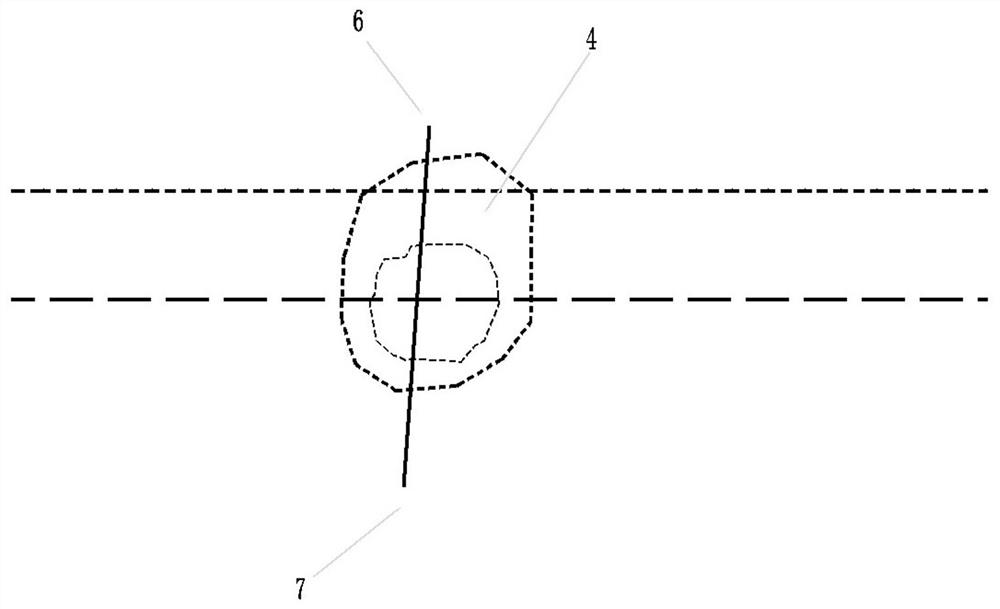

Tunnel gushing roof fall door closing treatment method

ActiveCN112502777AAvoid causing safety accidentsPrecise positioningMining devicesUnderground chambersEmergency treatmentArchitectural engineering

The invention discloses a tunnel gushing roof fall door closing treatment method. Accidents such as tunnel gushing roof fall door closing can be effectively dealt with timely, disaster loss can be reduced to the maximum extent and TBM construction is smoothly recovered. The tunnel gushing roof fall door closing treatment method mainly comprises the steps of emergency treatment of the ground surface, emergency treatment in a tunnel, permanent treatment of the ground surface, staged desilting of a gushing body, arrangement of a circuitous pilot tunnel and a high-position working chamber, treatment of a gushing roof fall breach, treatment of an influence range and the like. The tunnel gushing roof fall door closing treatment method is short in construction period, clear in construction organization, high in applicability and suitable for rapid construction and cost control of the TBM after the gushing roof fall door is closed.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

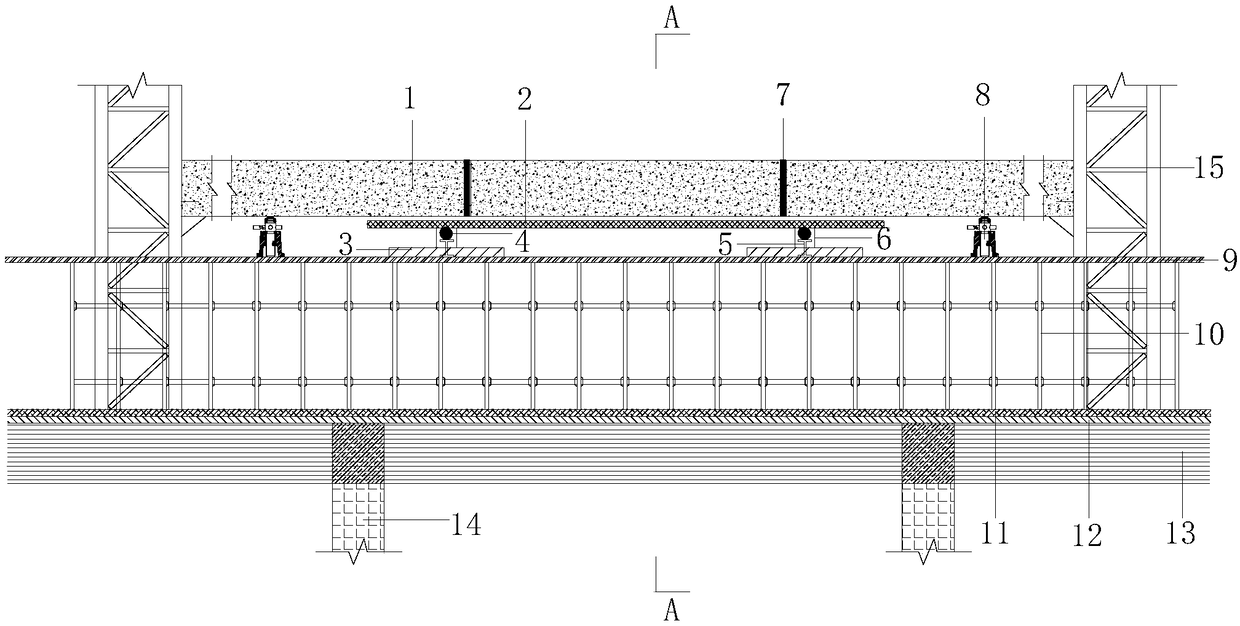

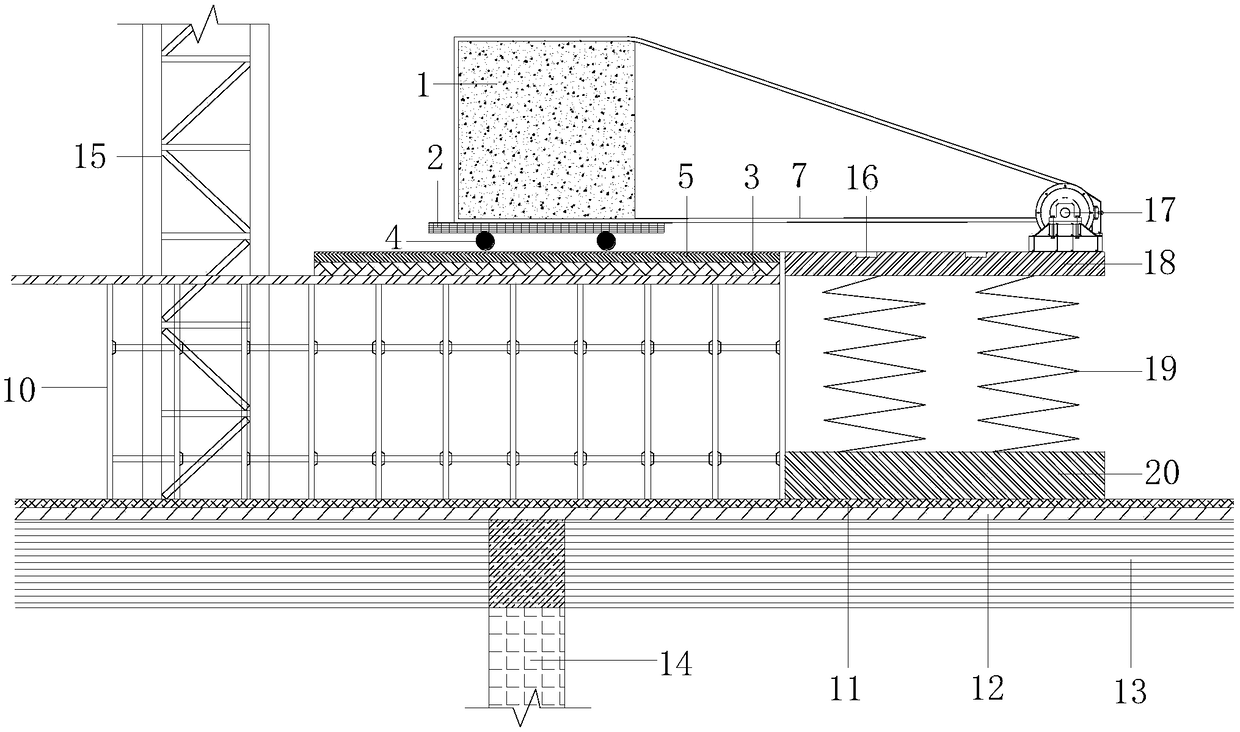

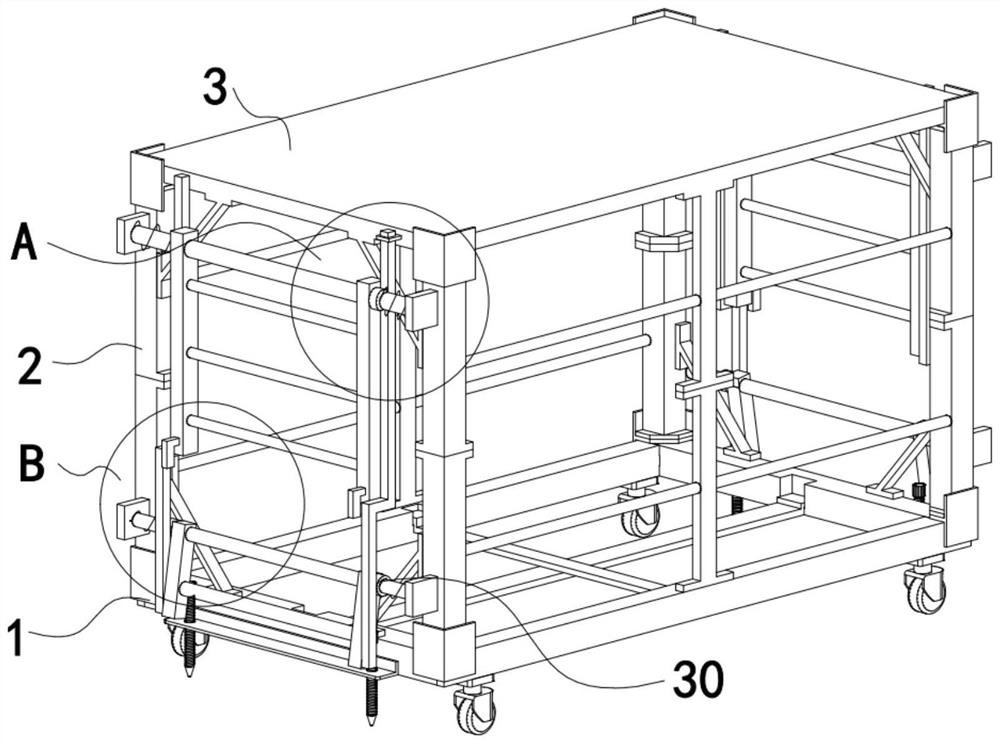

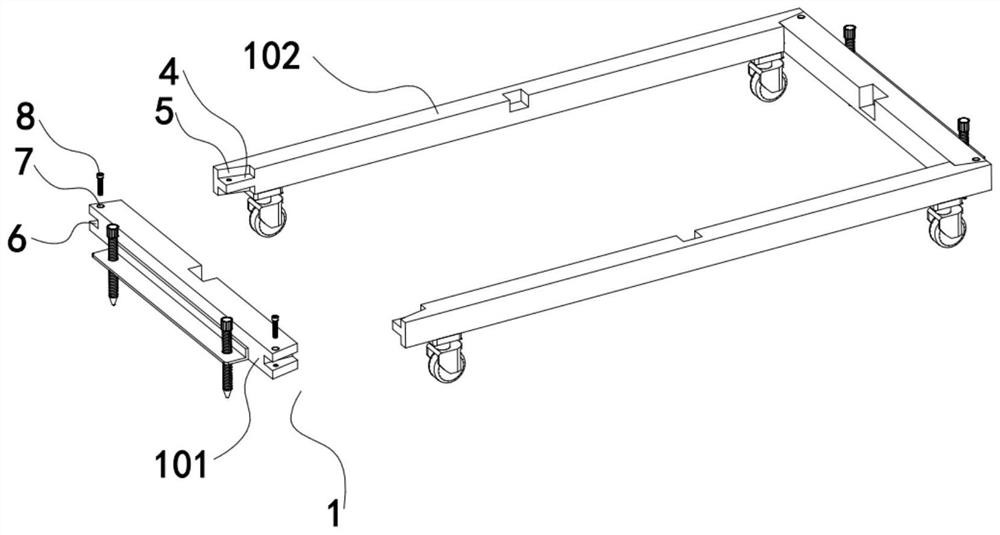

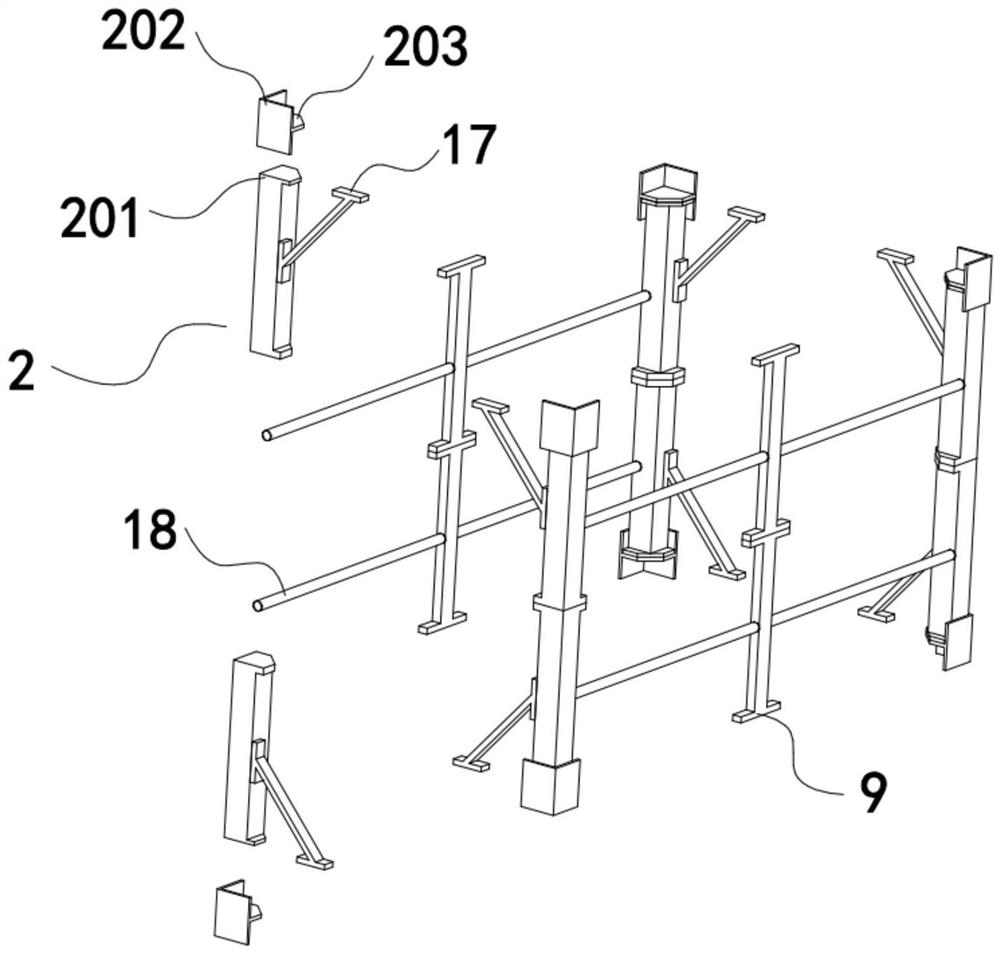

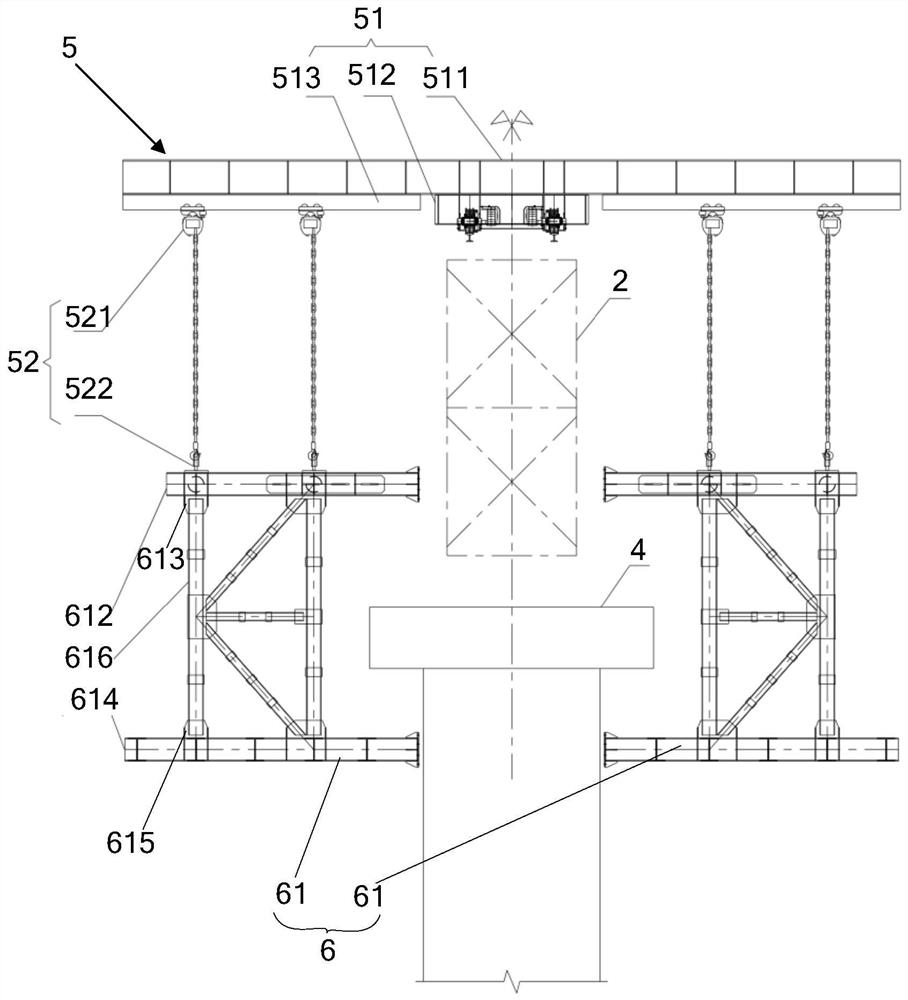

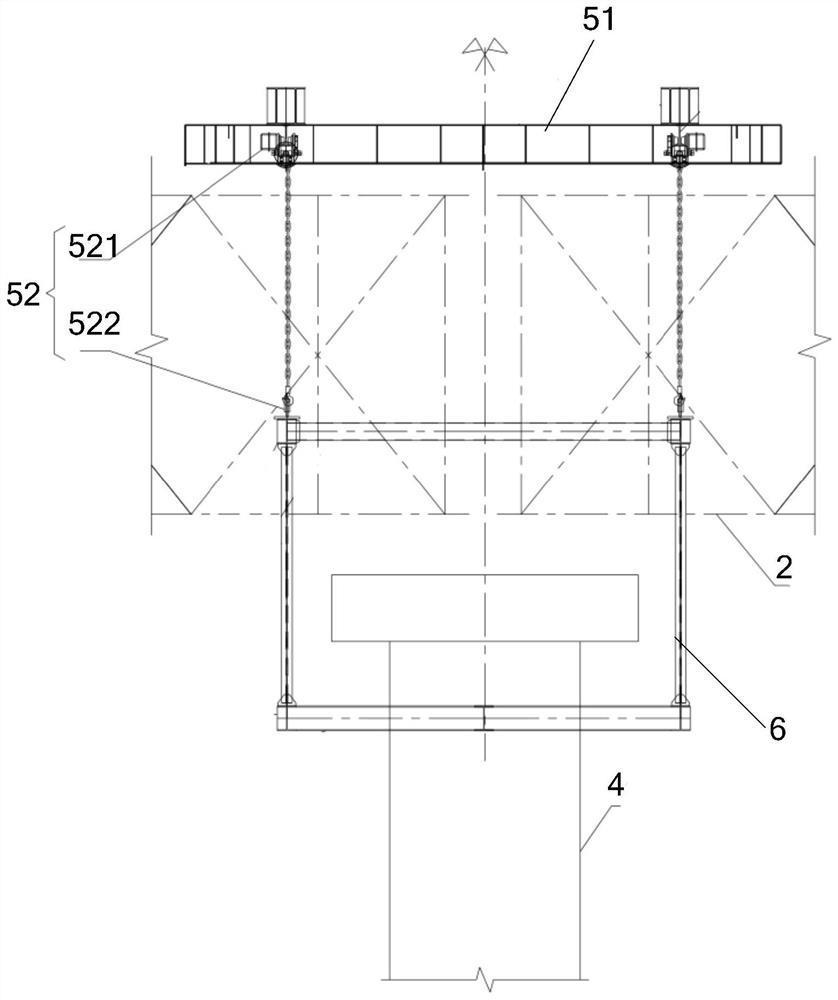

Deep foundation pit support dismounting system and construction method

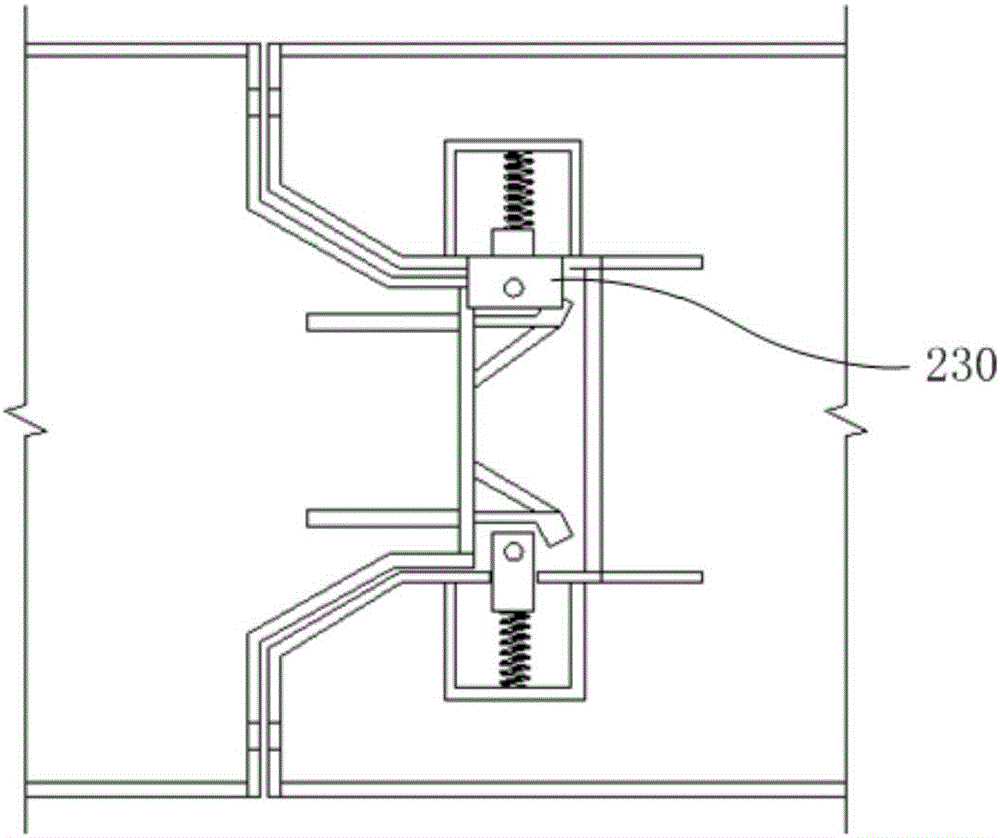

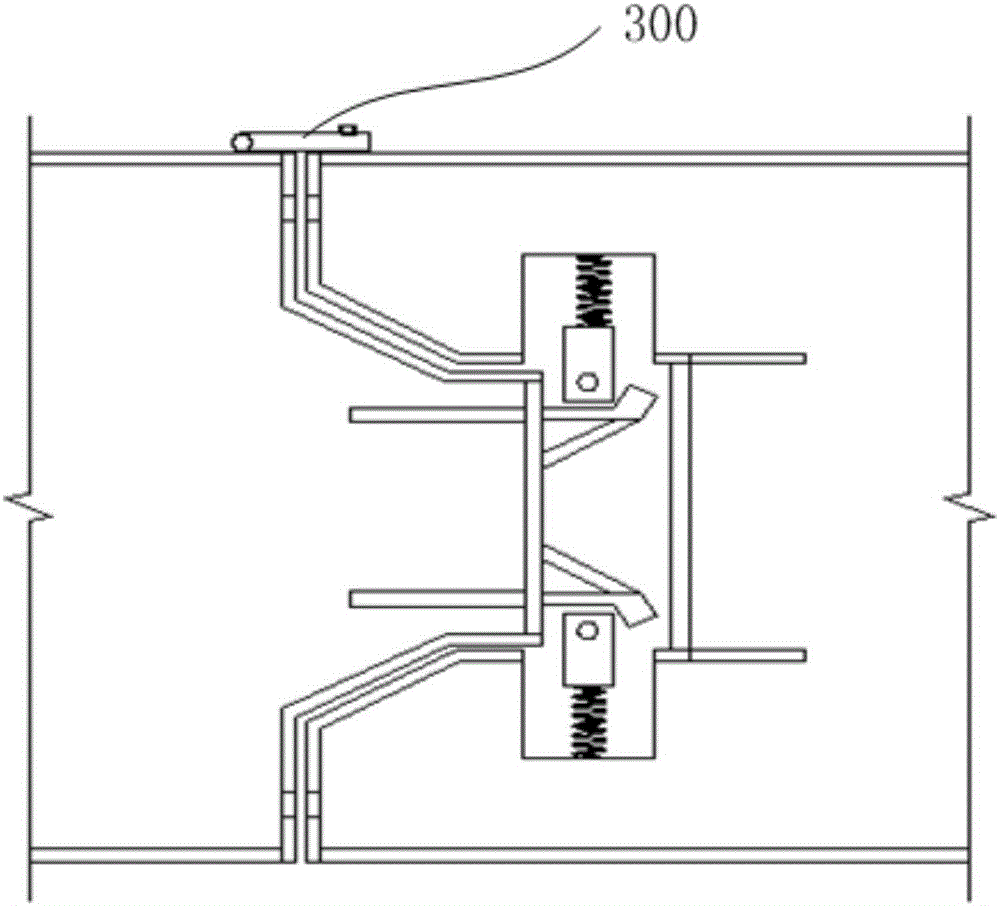

ActiveCN109356167ASafe and efficient constructionFast constructionExcavationsSteel tubeProtective system

The invention relates to a deep foundation pit support dismounting system. The deep foundation pit support dismounting system comprises a protective frame system, a sliding carrying support bracket system, an inner support steel tube stand column dismounting system and a frame column safety protective system, wherein the protective frame system comprises an integral type frame bottom plate, a scaffold support and tool type guard bars; the scaffold support is erected on the integral type frame bottom plate, and a section bar reinforcing top plate is arranged on the top of the scaffold support;split heads and lifting jacks are symmetrically distributed on the section bar reinforcing top plate; the tool type guard bars are mounted at the two sides of the section bar reinforcing top plate; the sliding carrying support bracket system comprises a horizontal moving slide plate, a traction system and a lifting system; a slide rail is arranged on the section bar reinforcing top plate; the horizontal moving slide plate with a slide wheel is mounted on the slide rail; and a dismounted supporting beam is arranged on the horizontal moving slide plate. The deep foundation pit support dismounting system has the beneficial effects that: foundation pit support dismounting adopts the integral lifting type protective frame system, the supporting beam slowly drops through the lifting jacks, the combined tool type guard bars replace the conventional supporting protective structure, and construction is safe and efficient.

Owner:SHENZHEN FUTIAN JIANAN CONSTR GRP

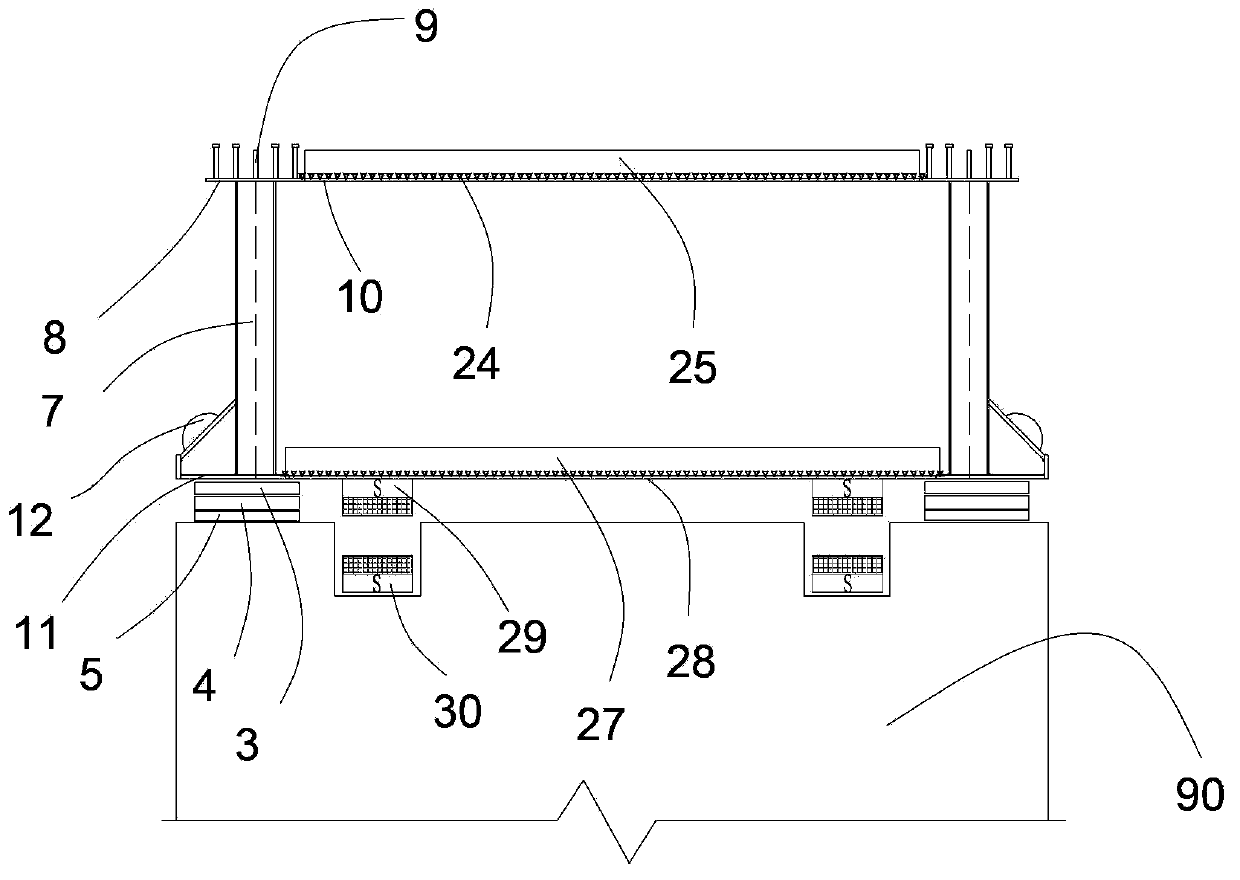

Bridge magnetic levitation pushing system and two-stage cantilever manufacturing method

A bridge magnetic levitation pushing system comprises a magnetic levitation pushing main beam hollow box-shaped structure and a magnetic levitation pushing platform. The magnetic levitation pushing platform comprises a pushing platform base, two bottom surface steel plates, two electromagnets, two Teflon sliding plates and a plurality of steel tube concrete rollers. The magnetic levitation pushing main beam hollow box-shaped structure comprises a steel truss abdomen bridge framework and two permanent magnets. According to the bridge magnetic levitation pushing system, by means of the repulsive force of a magnetic field, the magnetic levitation pushing main beam hollow box-shaped structure is pushed so that friction force and resistance in pushing-pulling traction can be reduced and continuous pushing operations can be carried out, pushing is needless to be interrupted, the construction progress is quick, construction is safe and efficient, construction cost is reduced, noise is low in pushing, fuel is needles, environment is protected, energy is saved, and operations are simple. The invention further relates to a two-stage cantilever manufacturing method.

Owner:桥博建筑科技(东莞)有限公司 +1

Method of adjacent buildings protection and tunnel foundation pit excavation in urban large section open excavation tunnel

InactiveCN108867692AReduce the impactSafe and efficient constructionArtificial islandsExcavationsSoil horizonBuilding construction

The invention provides a method of adjacent buildings protection and tunnel foundation pit excavation in urban large section open excavation tunnel, which includes the following steps: 1) before the excavation of the tunnel foundation pit, a first isolation structure of a first predetermined length is arranged along the excavation direction of adjacent buildings in a soil layer between adjacent buildings and a preset position of the enclosure structure of foundation pit; 2) a second isolation structure of a second predetermined length is arranged at both sides of the preset position of the enclosure structure of foundation pit; 3) the enclosure structure of foundation pit is applied to the preset position of the enclosure structure of foundation pit; 4) a tunnel foundation pit is excavatedin section. The method of adjacent buildings protection and tunnel foundation pit excavation in urban large section open excavation tunnel has the advantages of safe and efficient construction, easyoperation, and easy application.

Owner:THE 2ND ENG OF THE 12TH BUREAU GROUP OF CHINA RAILWAY +1

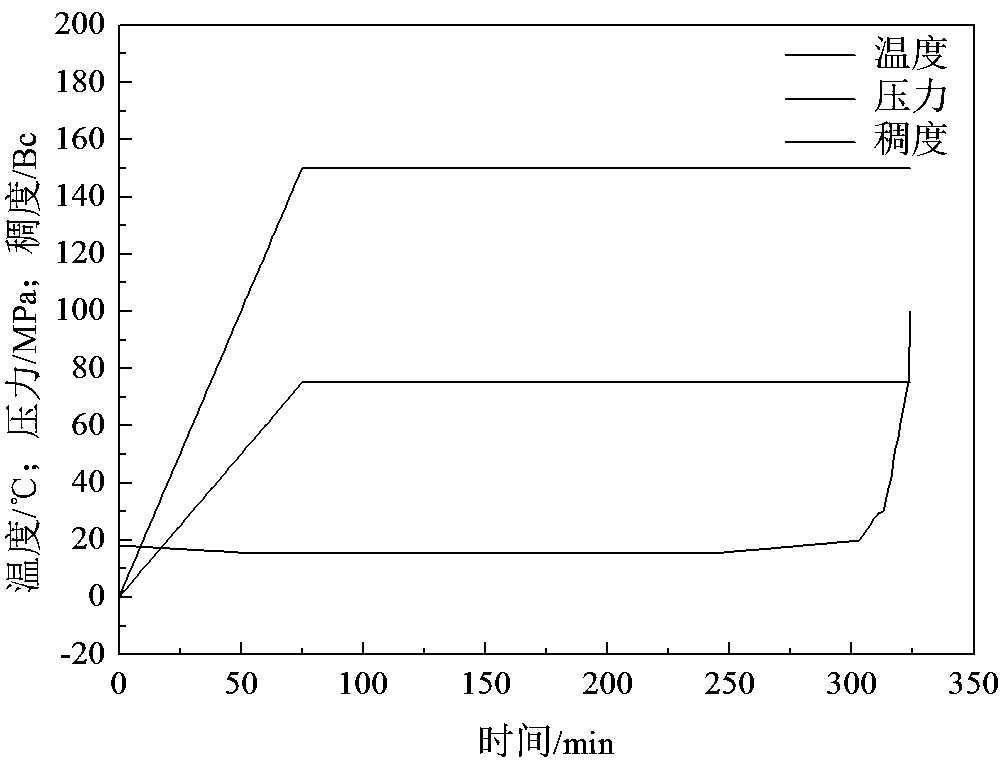

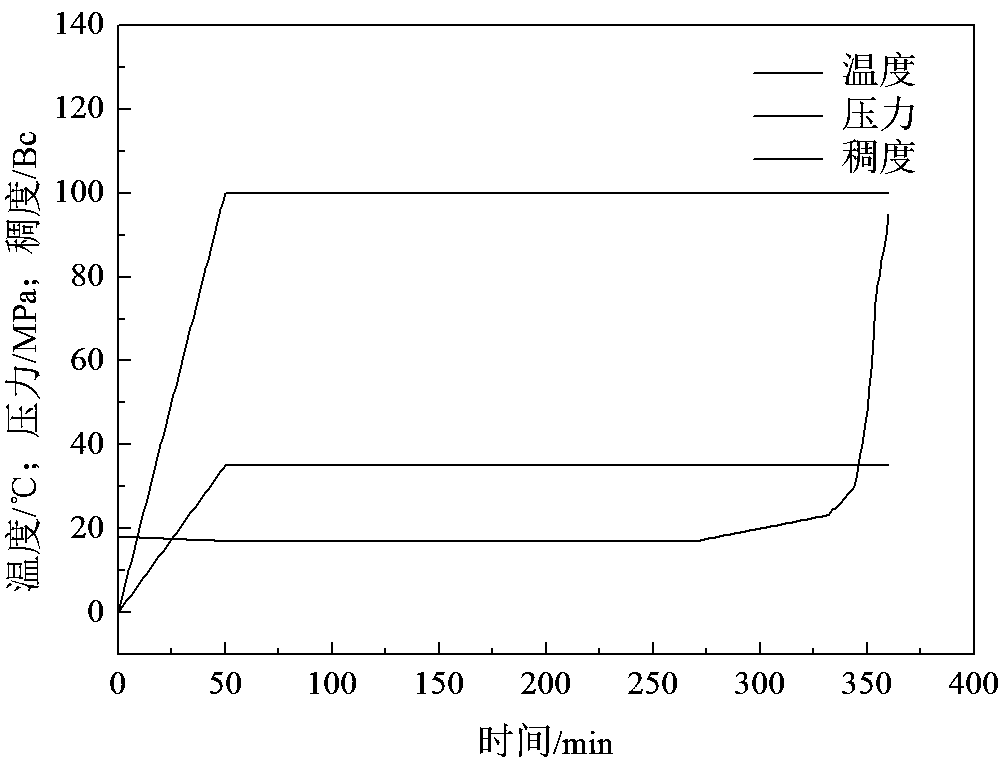

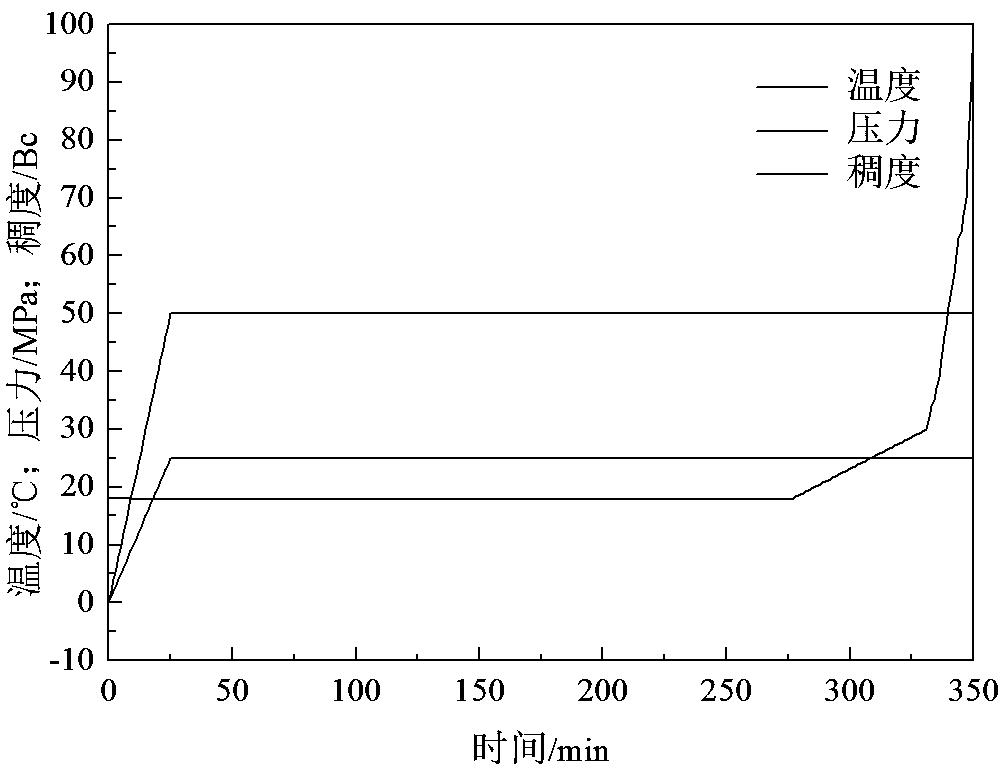

Well cementing slurry large temperature difference retarder and its preparation method

ActiveCN107779183AWeak temperature sensitivitySafe and efficient constructionDrilling compositionEmulsionEmulsion polymerization

The invention discloses a well cementing slurry large temperature difference retarder and its preparation method, and relates to a field of casing and cementing of exploration and development of oil and gas. The large temperature difference retarder mainly comprises three structure units which are anion monomer 2- acrylamide-2- methyl propanesulfonic acid (AMPS), cationic monomer methylacryloyl yloxyethyl trimethyl ammonium chloride (DMC) and nonionic monomer acrylamide (AM); the mass by part of every component is: AMPS is 60-70 parts, DMC is 20-25 parts and AM is 10-15 parts. The large temperature difference retarder is prepared by an inverse emulsion polymerization method; the inverse emulsion fluid is prepared from, by mass, 60-65 parts of white oil, 35-40 parts of deionized water, 6.0-6.4 parts of Span 80, 0.6-1.0 part of Tween 80. The retarder can realize the retarding function of cement slurry in the whole temperature zone where the upper and lower ends of the cement injection well section for well cementing construction are 50 and 150 DEG C; the comprehensive performance of the cement slurry system can meet the requirement of the well cementing construction of a thermal production well.

Owner:SOUTHWEST PETROLEUM UNIV

Method for high beam falling construction based on push method

ActiveCN108729357AShorten the construction periodAvoid damageBridge erection/assemblyJackscrewSteel tube

The invention provides a method for high beam falling construction based on a pushing method. The beam falling construction is performed by directly utilizing a pushing bracket. The method comprises the following steps: firstly jacking a steel box girder by utilizing two jacks from a bridge to a first bracket, sequentially pulling out a slideway on a top platform of the bracket and a cross beam, matching with the two jacks by utilizing four steel pipe upright posts of the bracket, reducing the elevations of the steel pipe upright posts by alternately adopting modes of supporting by the steel pipe upright posts and the jacks and finally falling the steel box girder to a designed position. In the beam falling construction, a beam falling bracket or a beam falling support pad is not requiredto be re-erected, and a permanent pier is not utilized, so that the damage caused to the permanent pier in the falling process is prevented.

Owner:ROAD & BRIDGE INT +1

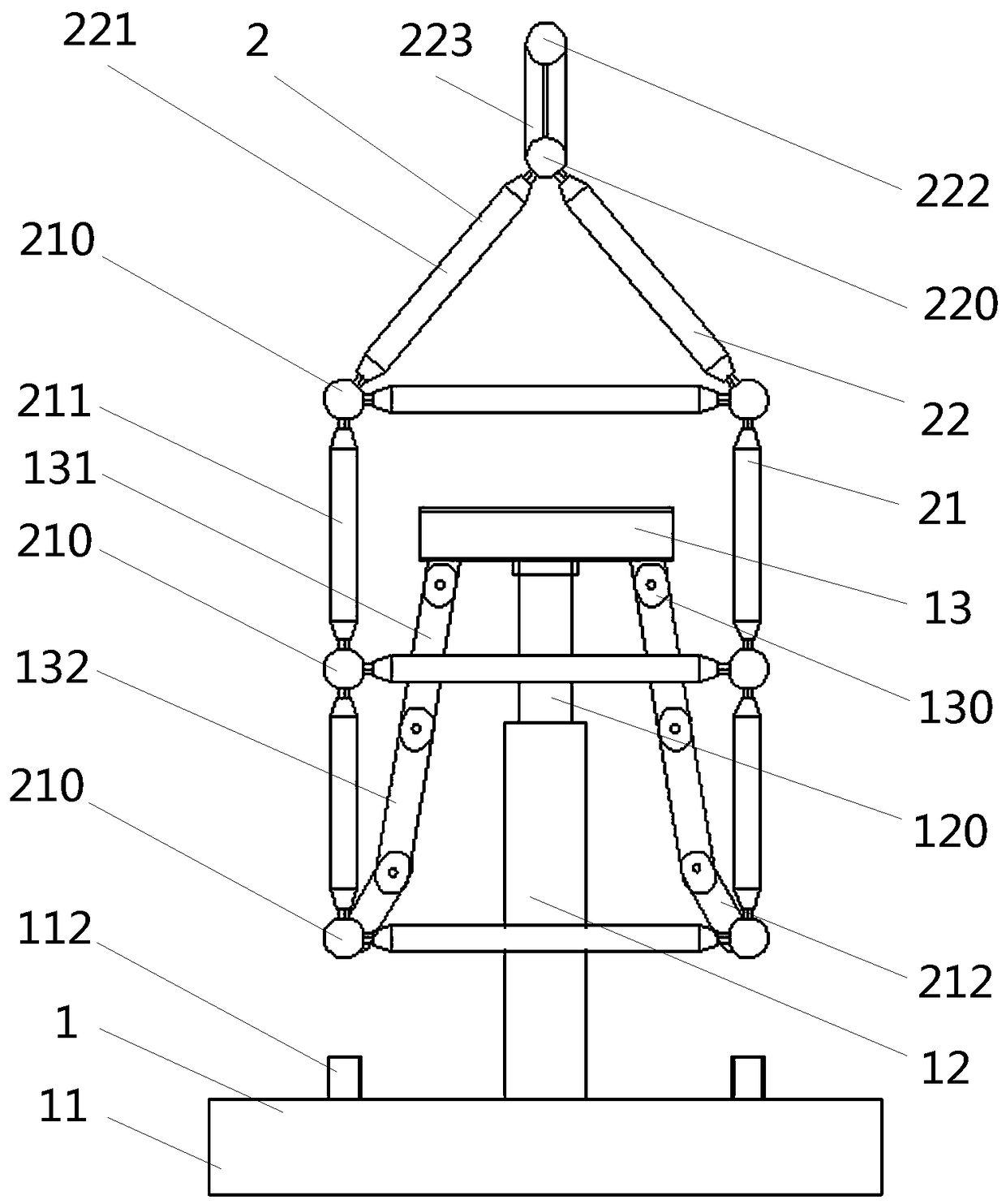

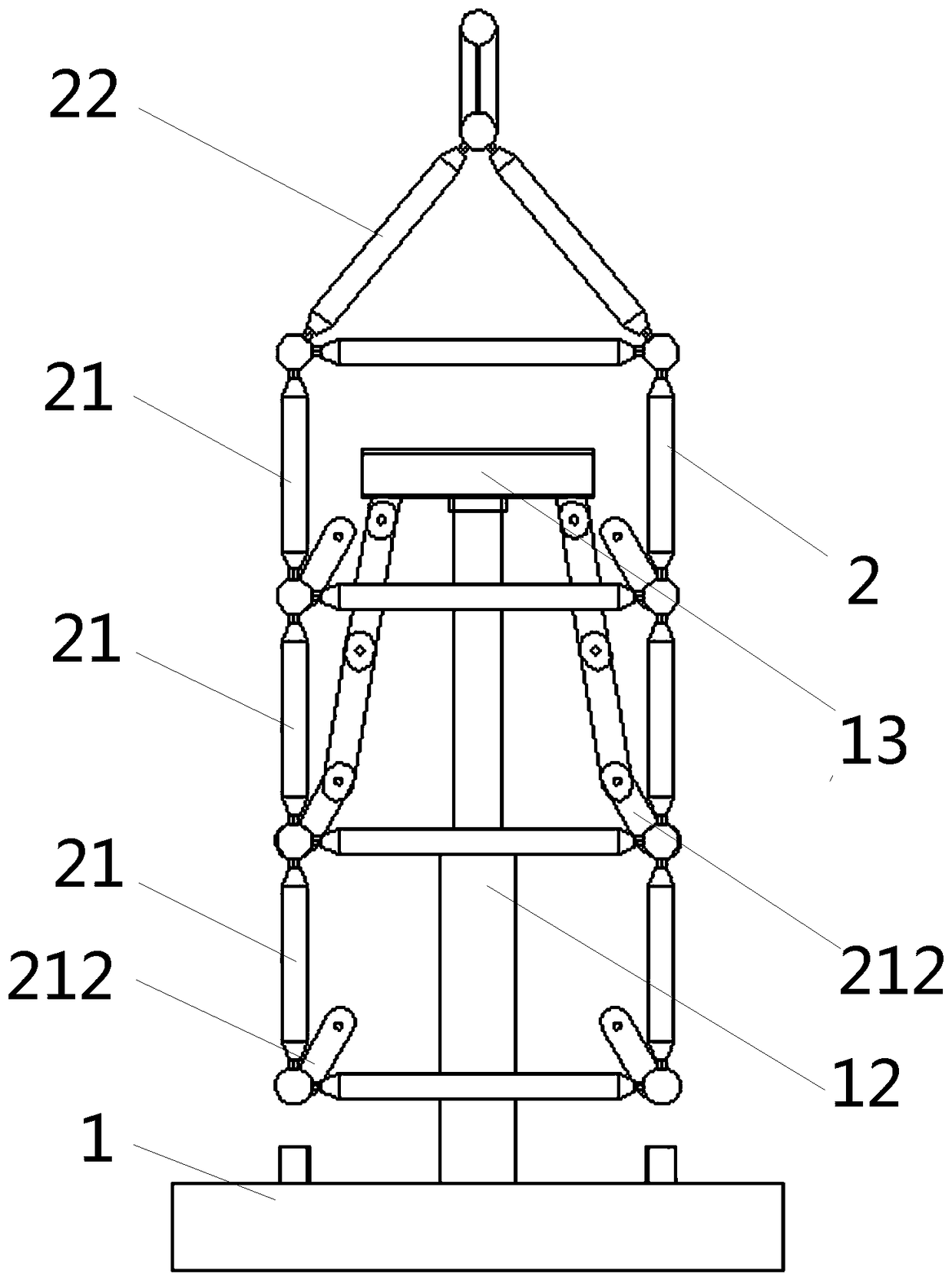

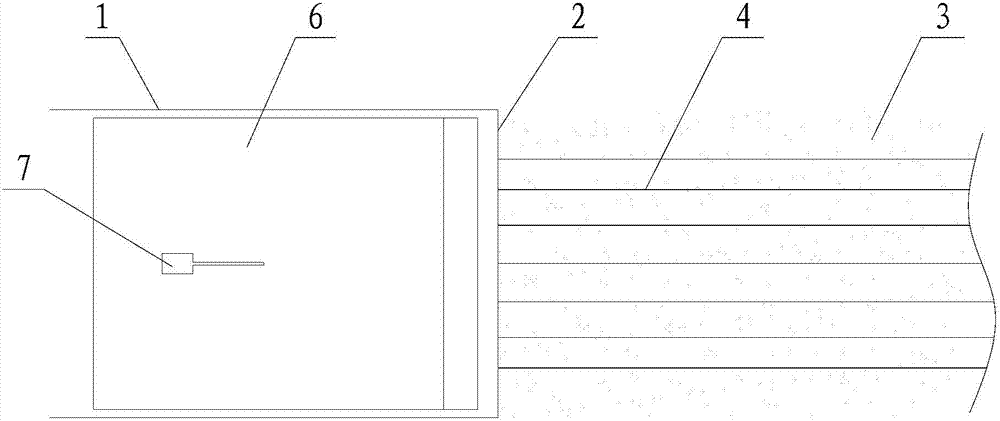

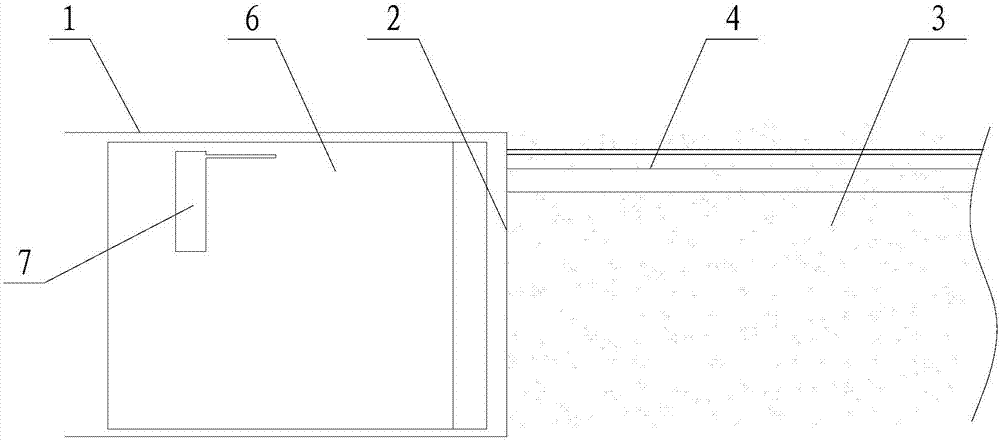

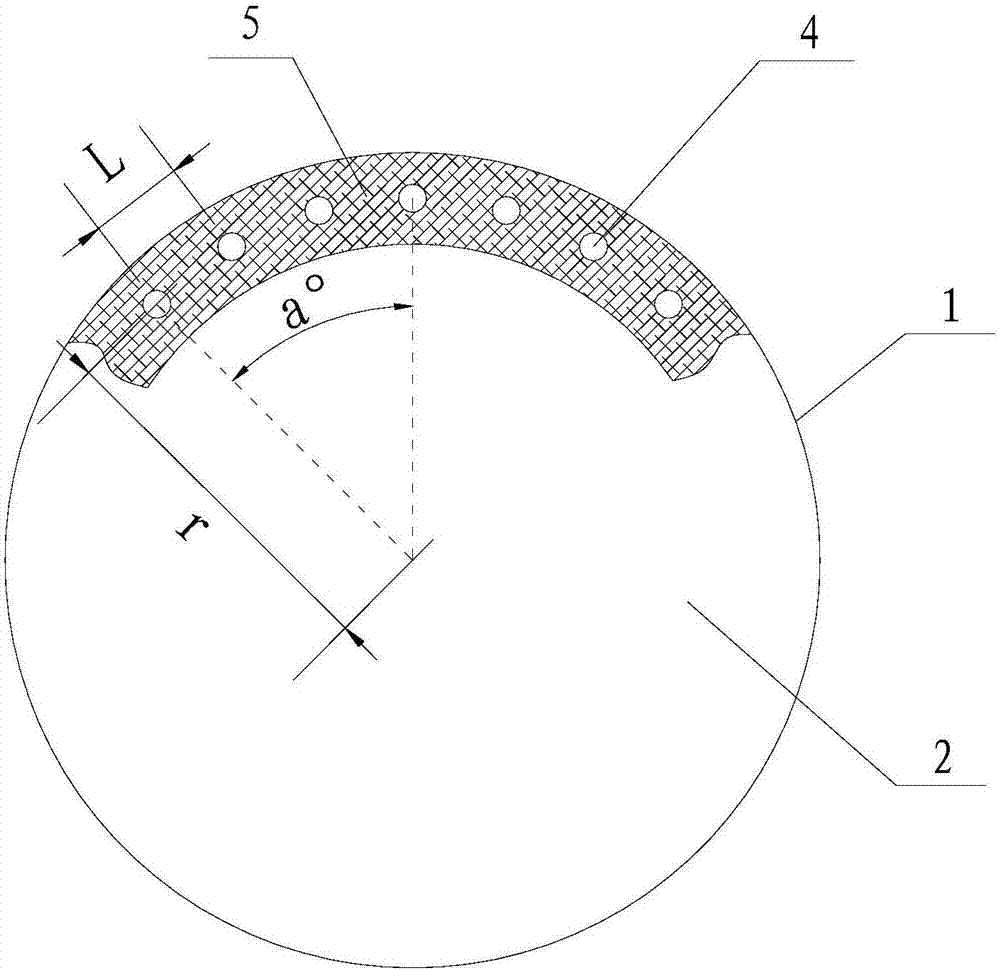

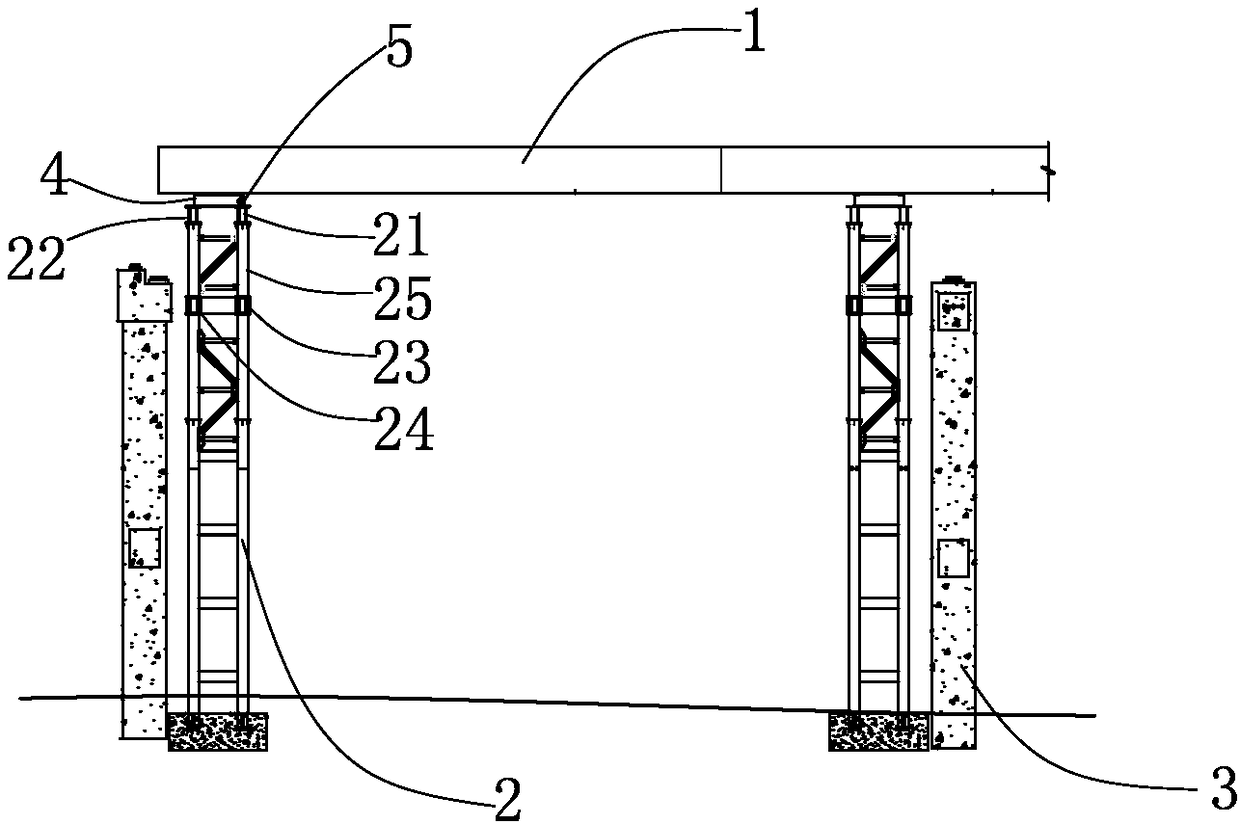

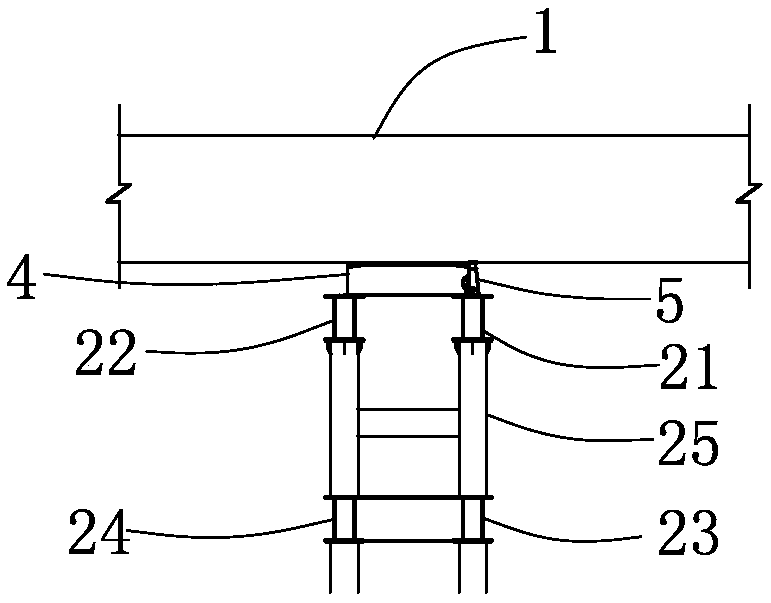

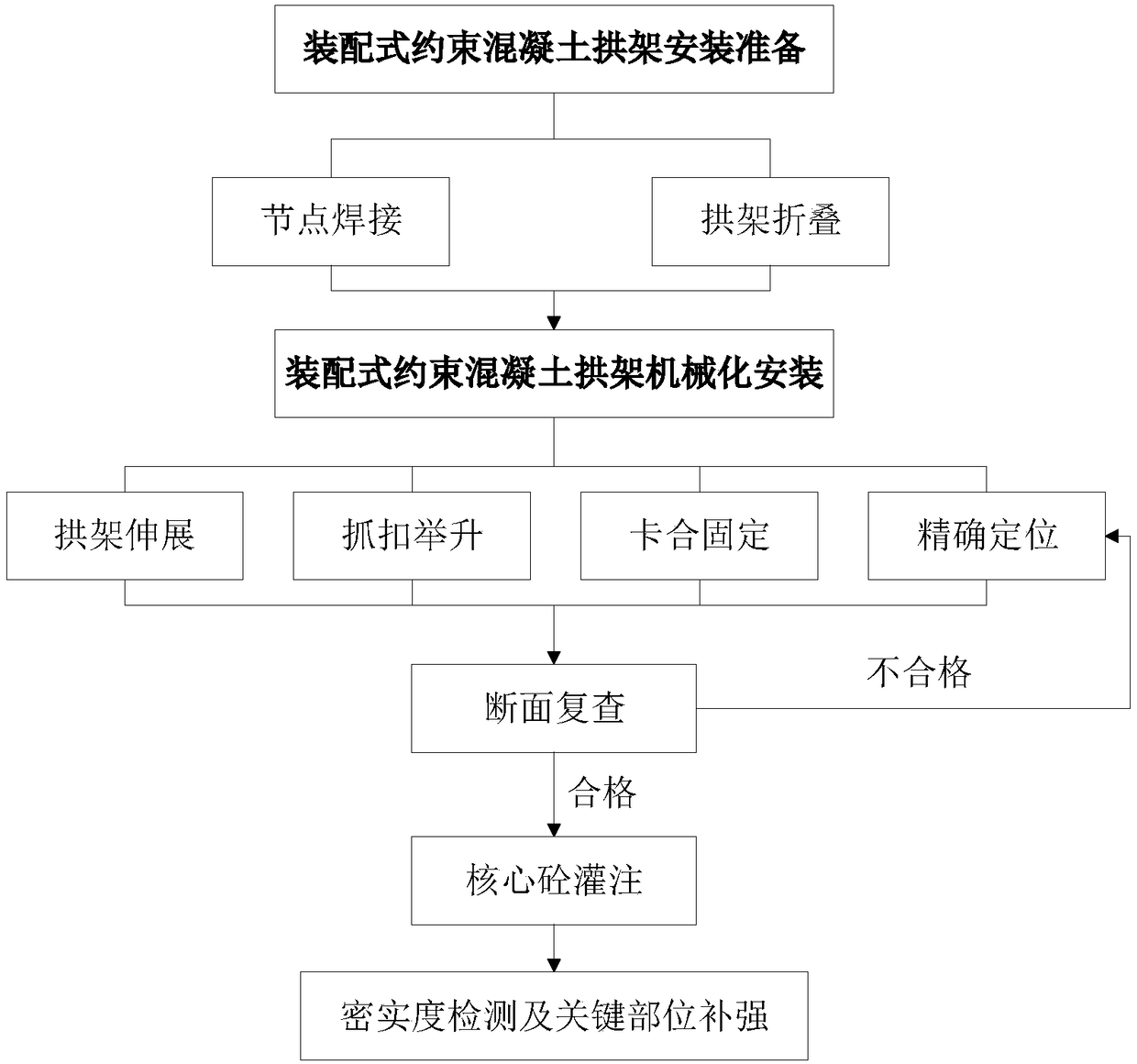

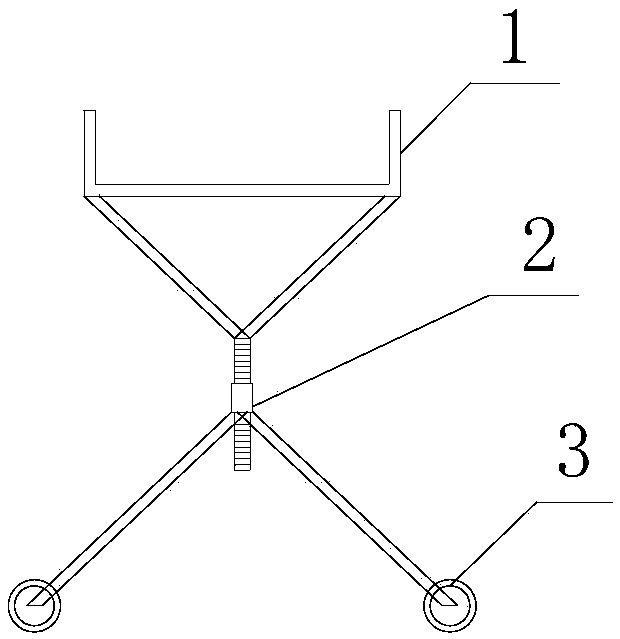

Underground construction fabricated confined concrete lagging jack and mechanized construction method

ActiveCN108104832AHigh strengthSafe and efficient constructionUnderground chambersTunnel liningEngineeringTunnel construction

The invention discloses an underground construction fabricated confined concrete lagging jack and a mechanized construction method. In order to be matched with lagging jack intelligent mounting equipment to conduct tunnel construction, the fabricated confined concrete lagging jack is researched and developed, the relevant technologies of folded hoisting, mechanized assembly, accurate positioning,fracture surface reexamination and the like of the lagging jack are broken through, the lagging jack being lifted manually to be split is not needed in the tunnel construction process, and the whole set of construction process can be conducted through a mechanized manner, and is safer and more efficient. The mechanized construction method specifically comprises the construction steps that (1), thelagging jack is folded and hoisted; (2), the lagging jack intelligent mounting equipment is utilized to conduct sequential extending on the lagging jack, fabricated joints are automatically clamped,and a longitudinal connection device is mounted in advance; (3), clamping buckle lifting, accurate positioning and clamping fixing are conducted; (4) fracture surface reexamination is conducted; (5) core concrete is poured; and (6) the compactness is detected and a key part is reinforced.

Owner:SHANDONG UNIV +1

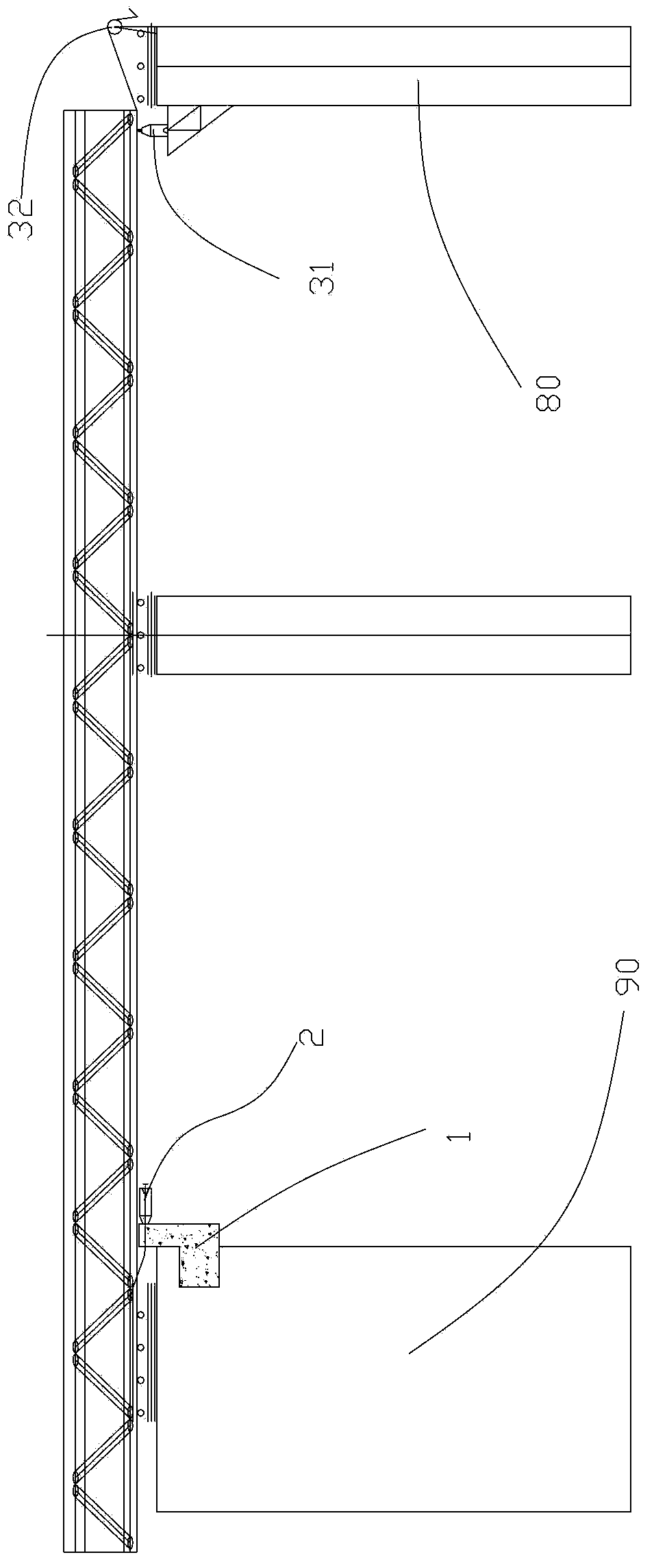

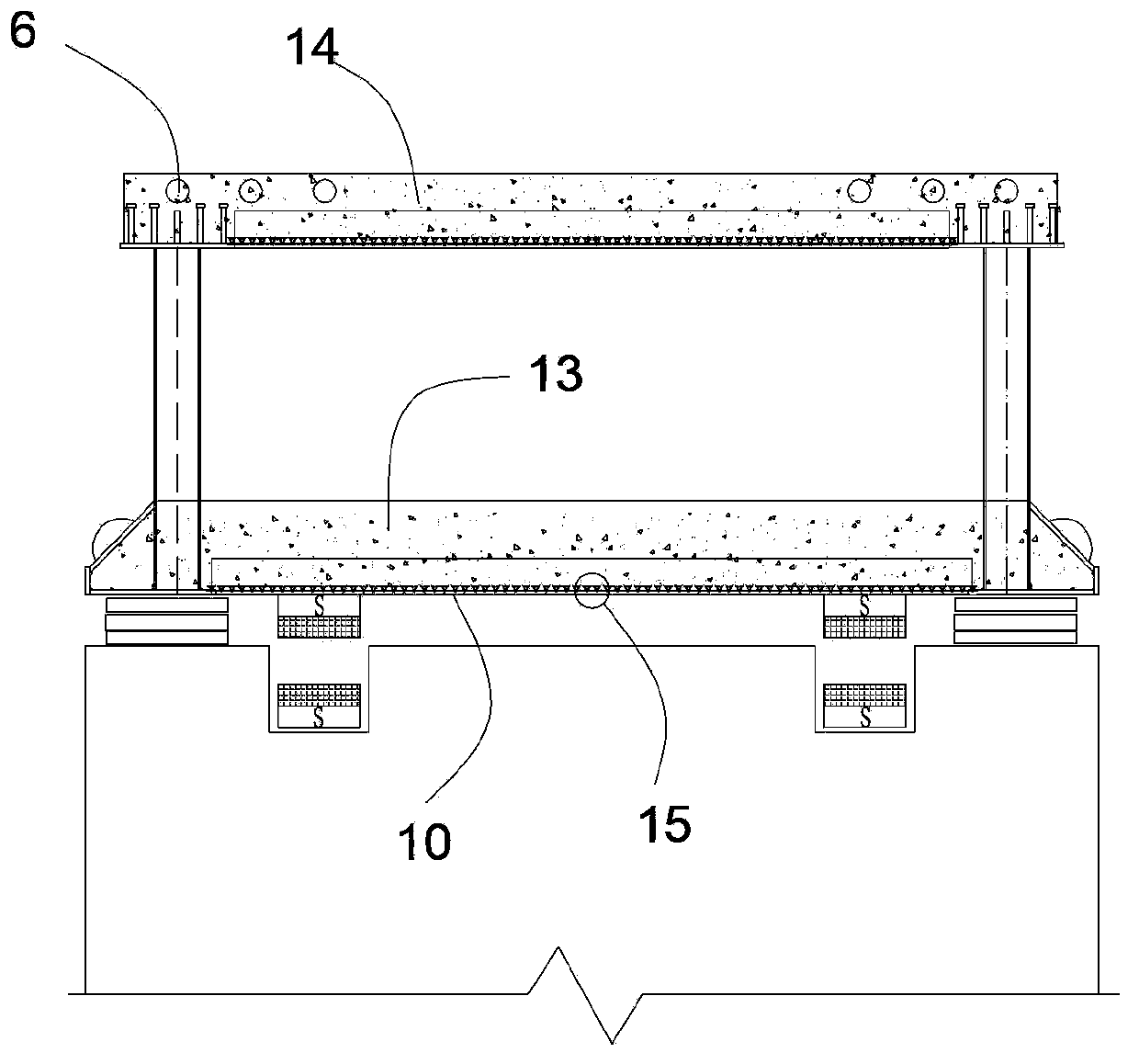

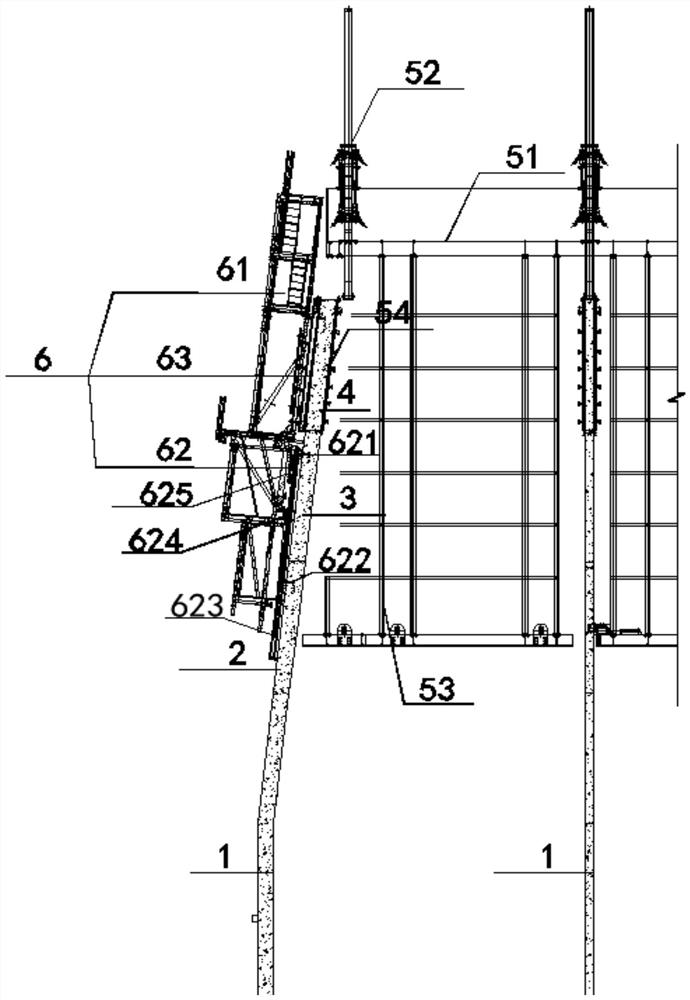

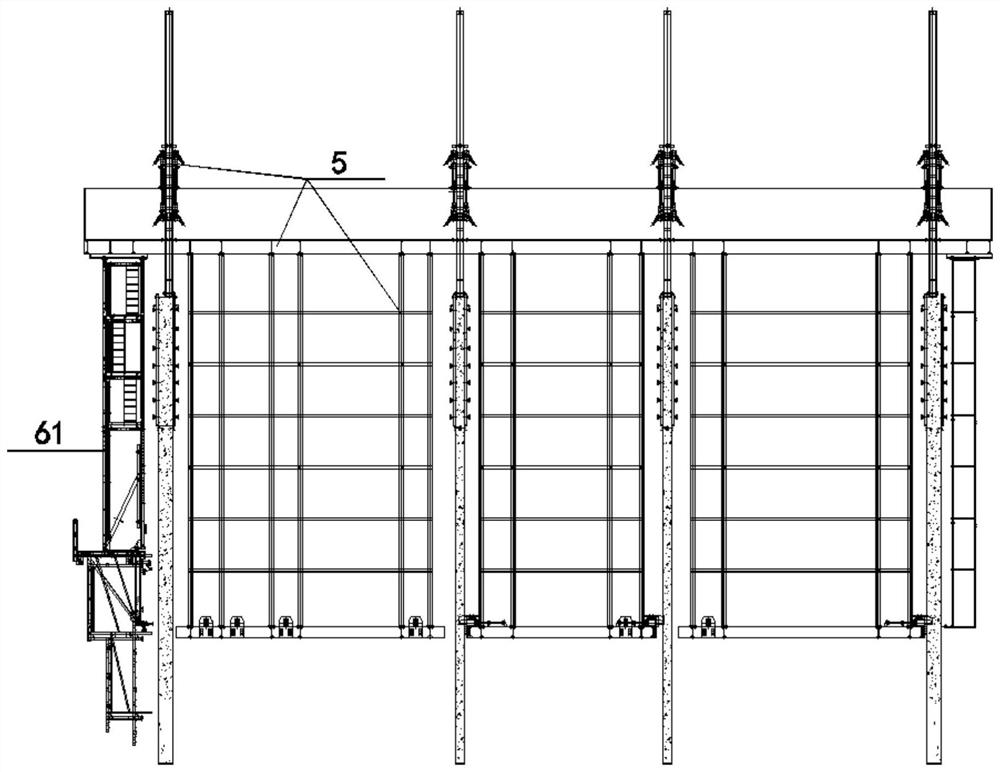

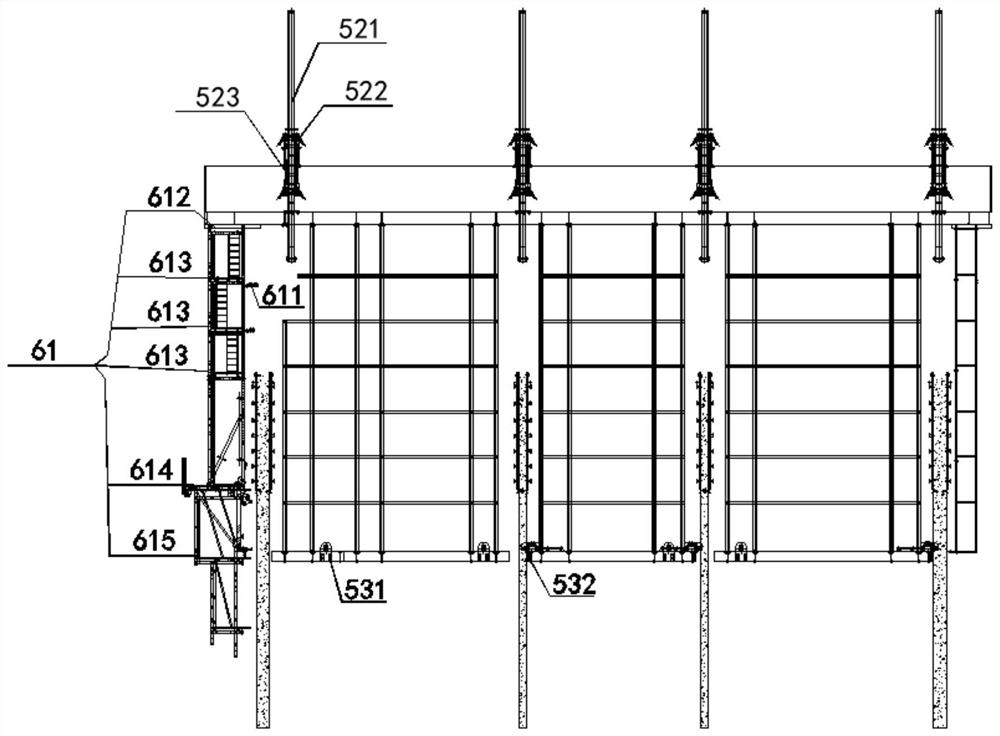

Integral steel platform formwork equipment for inclined wall construction and construction method of integral steel platform formwork equipment

PendingCN114541740ASafe and efficient constructionSolving the Difficulties in Construction of Inclined Wall StructuresClimate change adaptationForms/shuttering/falseworksSupporting systemSteel columns

The invention provides integral steel platform formwork equipment for inclined wall construction and a construction method thereof, and the integral steel platform formwork equipment comprises a main body part which comprises a steel platform system, a cylinder frame supporting system, a steel column climbing system and a main body formwork system; the slave body part comprises a slave body operation platform system, a climbing power system and a slave body template system, the slave body operation platform system is detachably connected to the lower portion of the steel platform system, the slave body operation platform system is connected with the slave body template system, and the climbing power system is connected with the slave body template system. The climbing power system is connected with the auxiliary body operation platform system and the auxiliary body formwork system, the auxiliary body formwork system is arranged on the outer side of a to-be-constructed inclined wall, and the main body formwork system and the auxiliary body formwork system are used for mold closing and concrete pouring. The problem of constructing the inclined wall structure by the integral steel platform formwork equipment is solved, and safe and efficient construction of the inclined wall structure is achieved.

Owner:SHANGHAI CONSTR NO 1 GRP

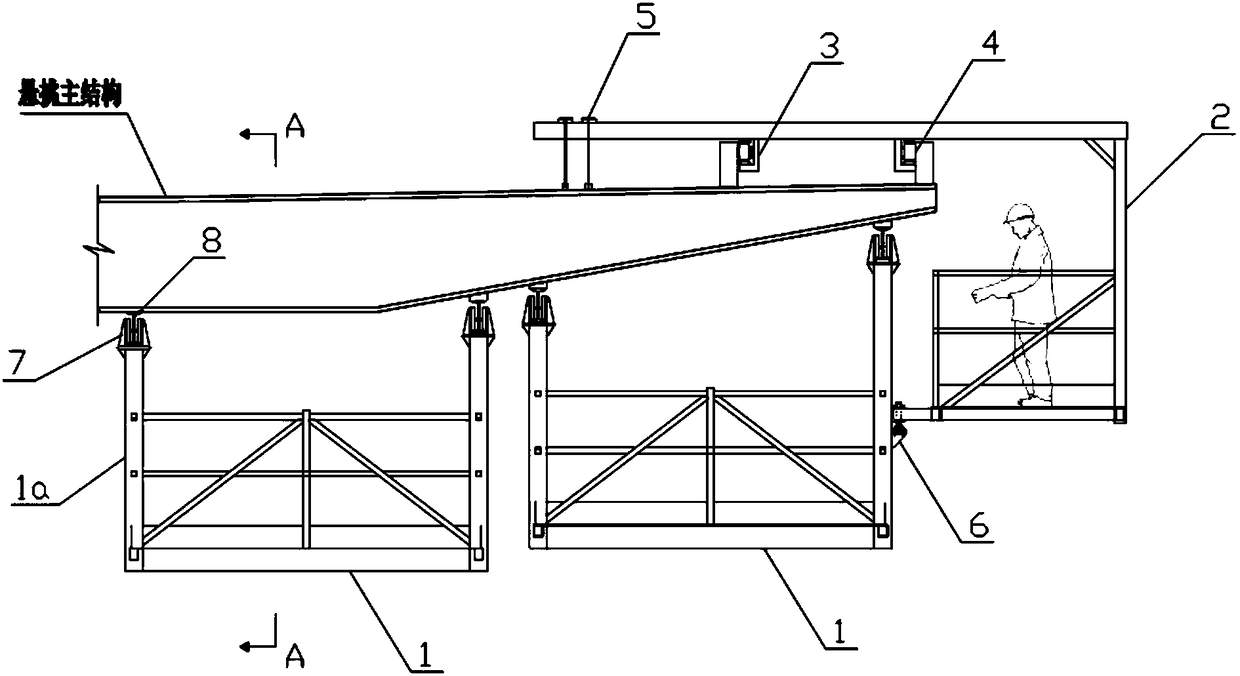

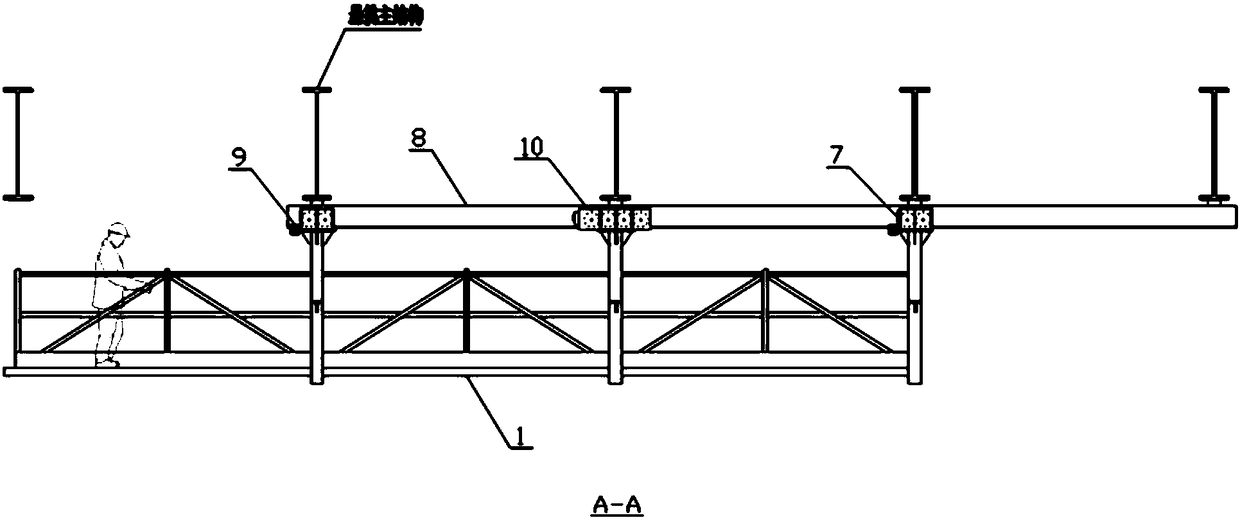

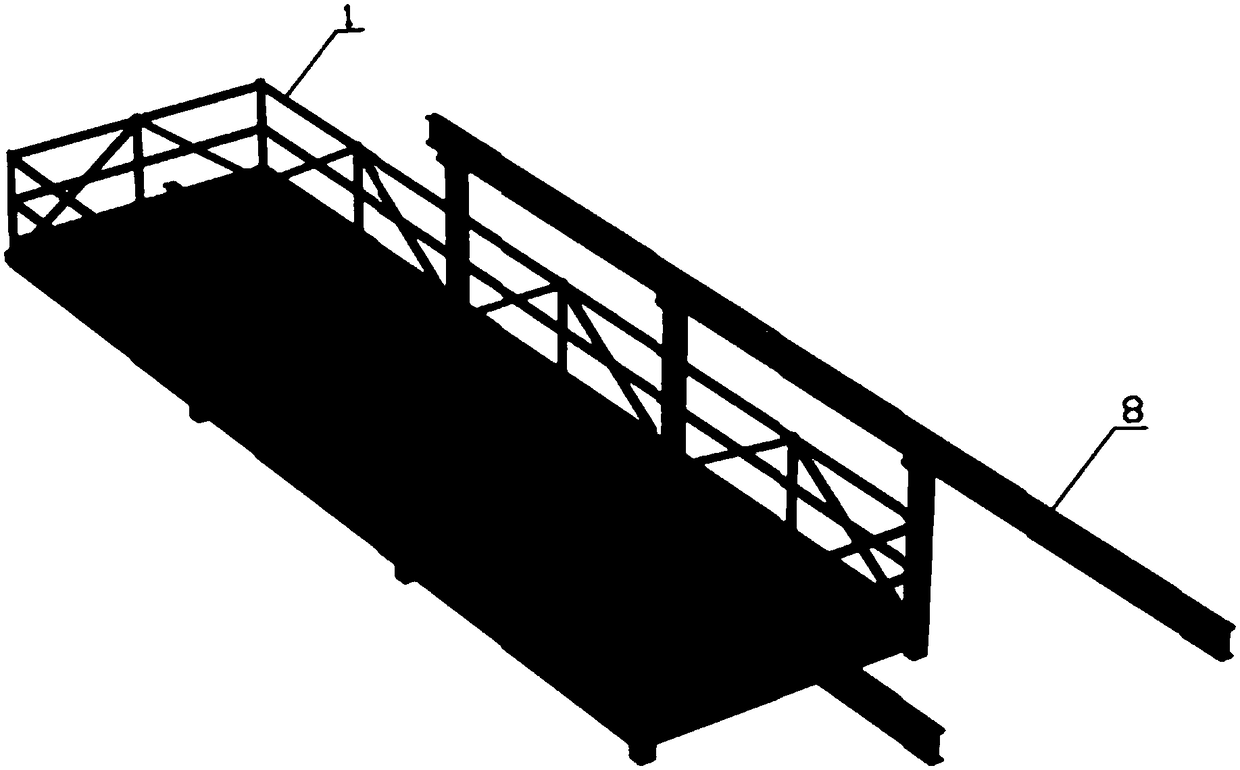

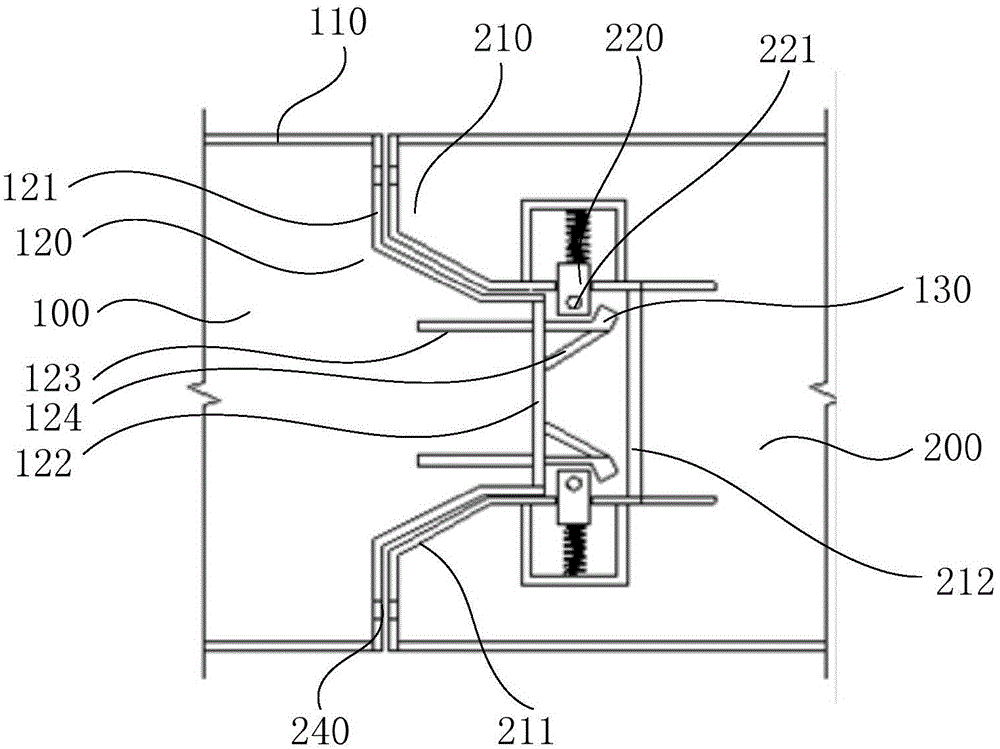

Horizontal-moving type operating platform device applied to construction of creasing curtain wall

PendingCN108277971AMeet construction requirementsConstruction safety and controllableBuilding support scaffoldsHanging basketEngineering

The invention provides a horizontal-moving type operating platform device applied to construction of a creasing curtain wall. The horizontal-moving type operating platform device comprises a modular lower-hanging type platform system and an upper-hanging type overhung platform system, the modular lower-hanging type platform system comprises an operating platform and a hanging system, and the hanging system is composed of a hanging column, a guide rail, a guiding module, a braking device and a power sliding vehicle; the operating platform is assembled through the hanging column and the guidingmodule and is hung on the guide rail, and the operating platform takes the power sliding vehicle as a power source and moves front and back in the direction of the guide rail; and the upper-hanging type overhung platform system comprises an overhung platform body, a guiding module, a guide rail, a rebar hanging ring and a fixing connecting piece, the overhung platform body and the guiding module are assembled into a whole and are buckled on the two sides of an inner edge of the guide rail, the tail end of the overhung platform body is fixed to an overhung main structure by adopting the rebar hanging ring, and the bottom end of the overhung platform body is fixed to a hanging column connecting joint of a lower-hanging type platform by adopting fixing connecting pieces. The horizontal-movingtype operating platform device makes up defects of conventional hanging basket and scaffold construction, and it is ensured that construction is safe and controllable, and the quality and the precision meet design requirements.

Owner:SHANGHAI MECHANIZED CONSTR GRP

Steel cover box cofferdam and bridge building device thereof

ActiveCN106638639AGood stitchingReduce constructionFoundation engineeringBridge erection/assemblyEngineeringWall plate

The invention relates to a steel cover box cofferdam. The steel cover box cofferdam comprises a left cofferdam side plate and a right cofferdam side plate which are connected in a tenon buckling manner. The left cofferdam side plate comprises a wall plate, a male tenon baffle and male tenon clamping grooves. The male tenon baffle is in an outwards-convex n shape and comprises a male tenon top plate part and male tenon side plate parts. The male tenon clamping grooves are located in the protruding end of the protruding side of the male tenon baffle to form a shuttle shape. The right cofferdam side plate comprises a wall plate, a female tenon baffle, female tenon clamping blocks and fixing plates, the female tenon baffle is in an inwards-concaved n shape and comprises a female tenon bottom plate and female tenon side plate parts, and the female tenon clamping blocks and the male tenon clamping grooves are matched and installed on the female tenon side plate parts through springs. The fixing plates and the female tenon side plate parts are connected, fixing holes are formed in the female tenon clamping blocks, and fixing protrusions matched with the fixing holes are formed in the fixing plates, and when the female tenon clamping blocks and the male tenon clamping grooves are clamped, the fixing protrusions can be inserted into the fixing holes to be locked.

Owner:HENAN WEIDENG CONSTR ENG CO LTD

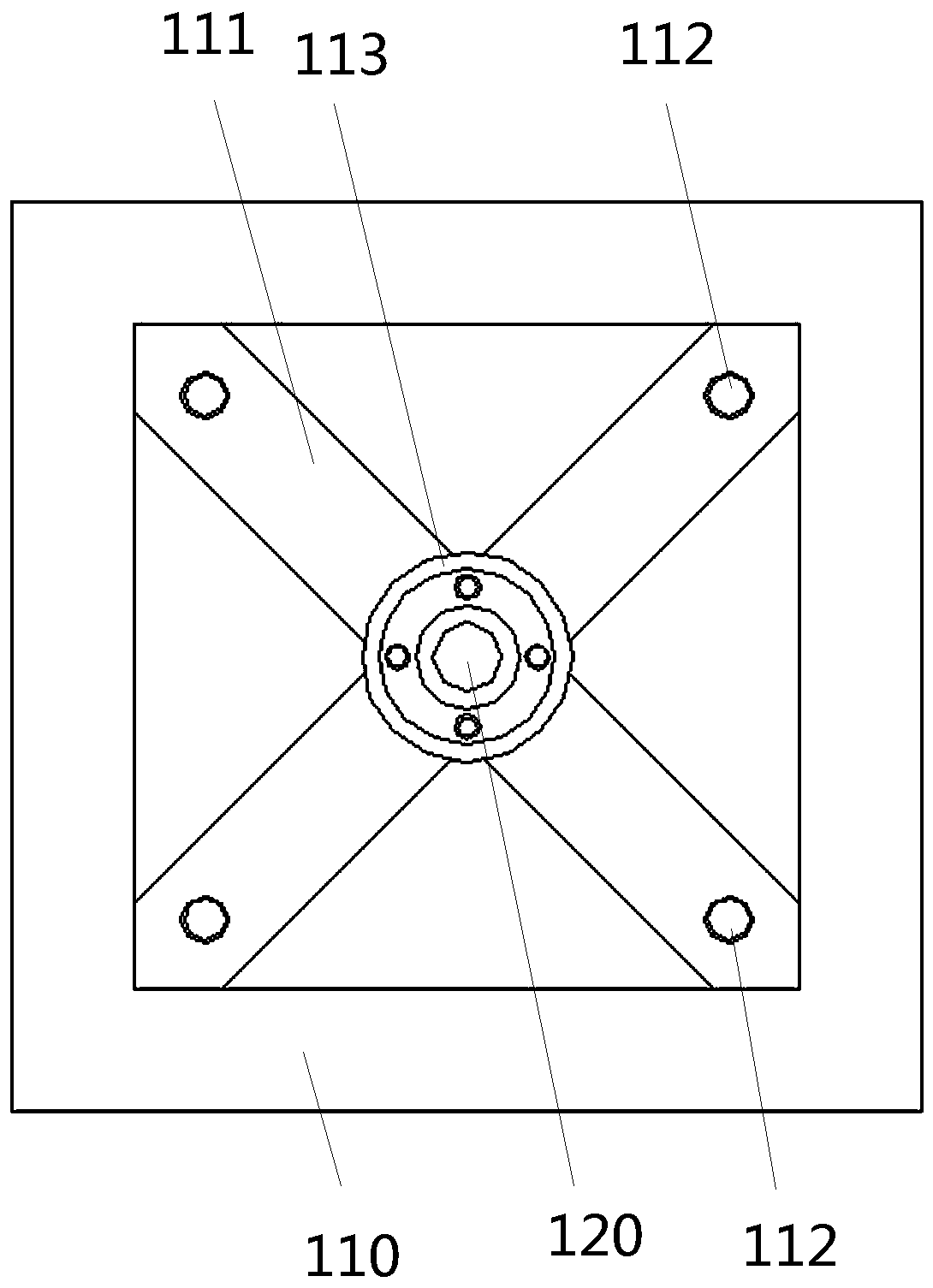

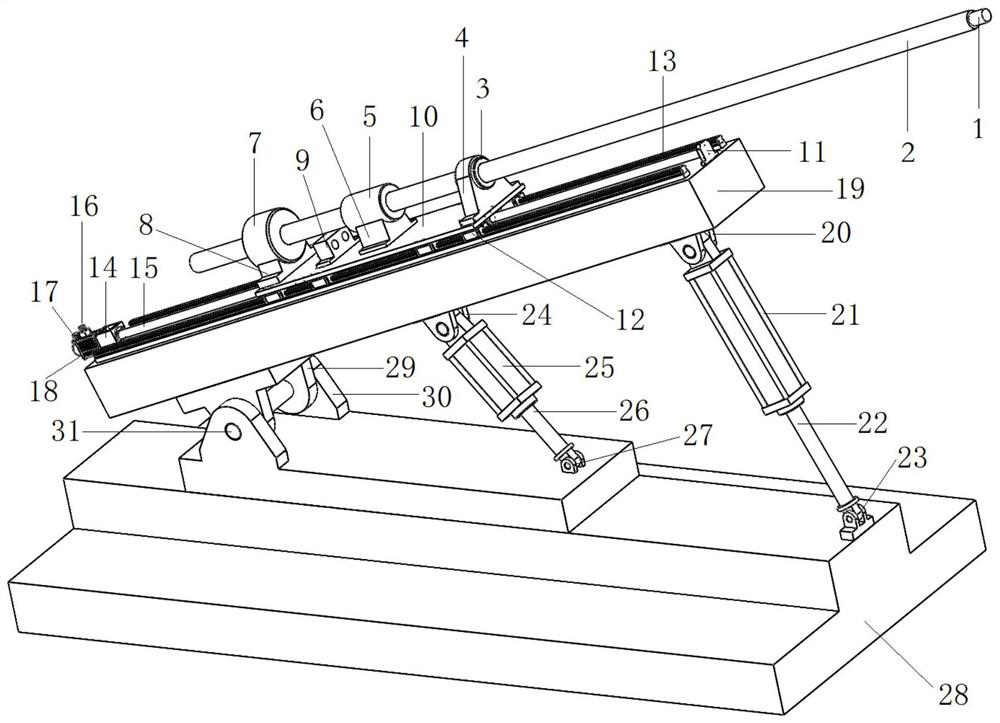

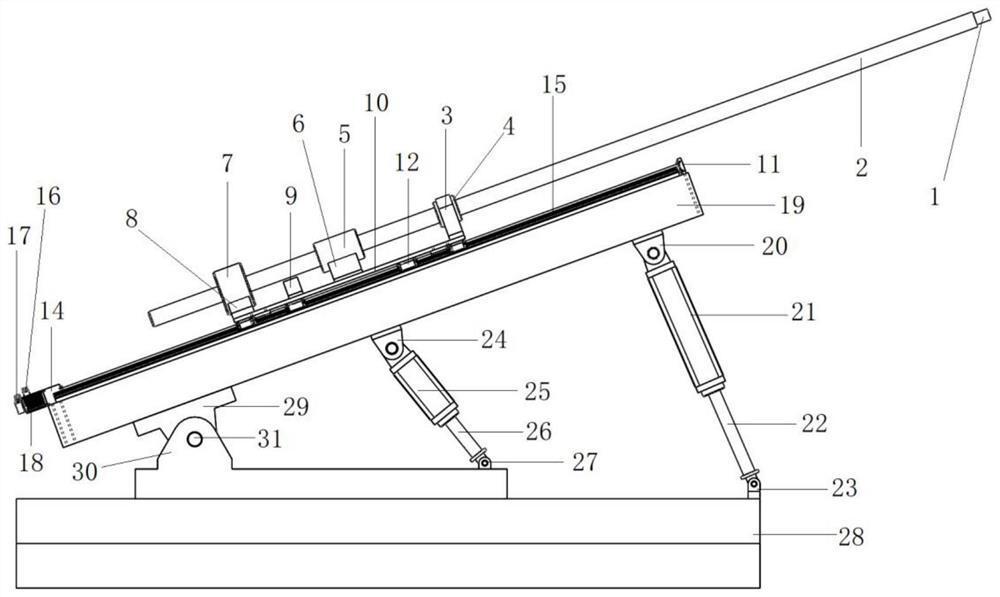

TBM tunnel face front rock mass integrity drilling device and method

ActiveCN112228095AMeet the needs of useSafe and efficient constructionMining devicesTesting machinesMining engineeringGeological survey

The invention discloses a TBM tunnel face front rock mass integrity drilling device and method. The drilling device comprises a drilling assembly, a drilling machine posture control assembly, a data monitoring assembly and a TBM drilling machine platform fixing base. The drilling assembly is connected with a TBM hydraulic system to obtain power, and the alloy drill bit rotates and horizontally moves to drill a rock mass. The drilling machine posture control assembly is used for controlling the angle, direction and position of a drill rod and keeping drilling accuracy and stability. The data monitoring assembly obtains and stores drilling mechanical response signals through a high-precision sensor and a data module so as to analyze rock mass integrity characteristics. The TBM drilling machine platform fixing base is used for achieving TBM carrying of a drilling device. The rock mass integrity parameters in front of the tunnel face of the TBM are interpreted through drilling and mechanical response information of the drilling device, the in-situ device and method are used for obtaining engineering geological survey data, and important support is provided for safe and efficient tunneling of the TBM.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

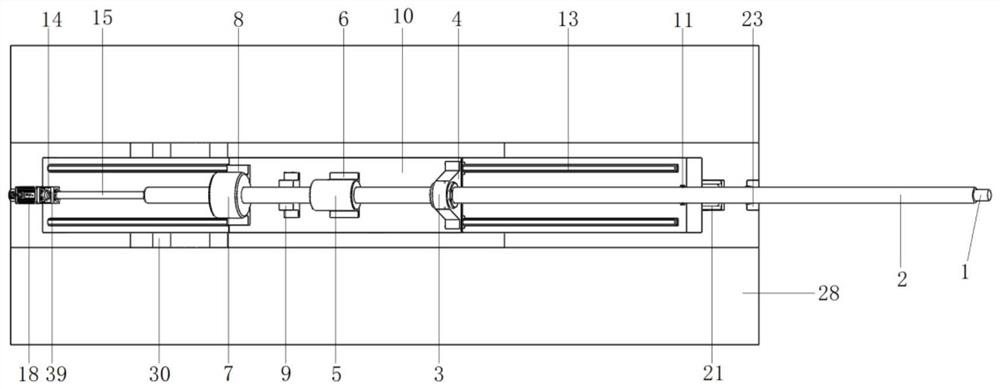

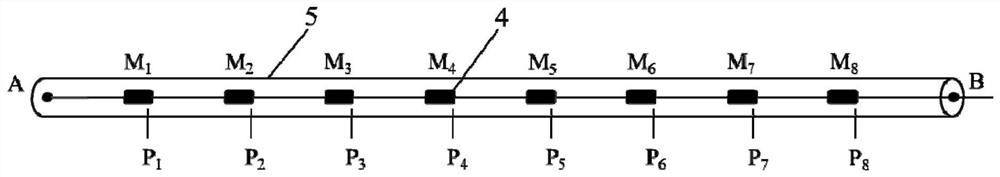

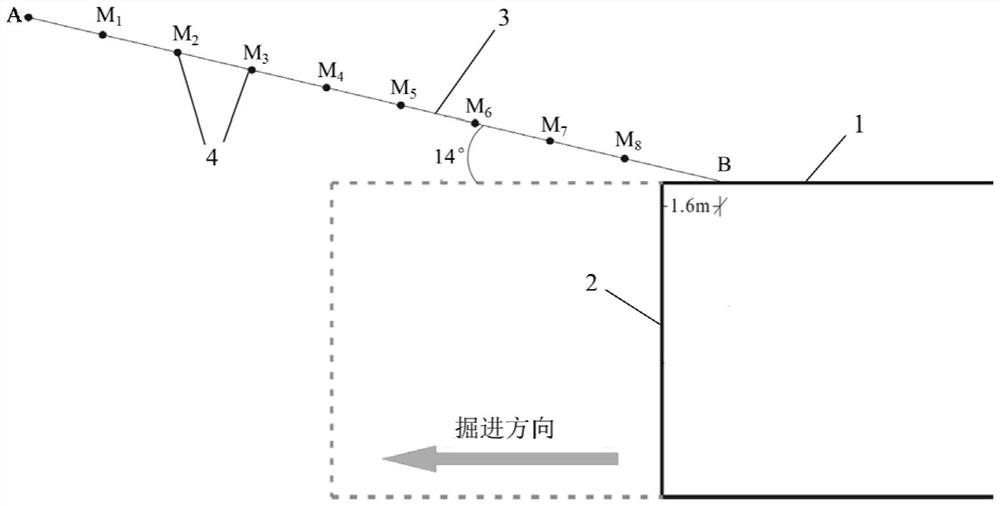

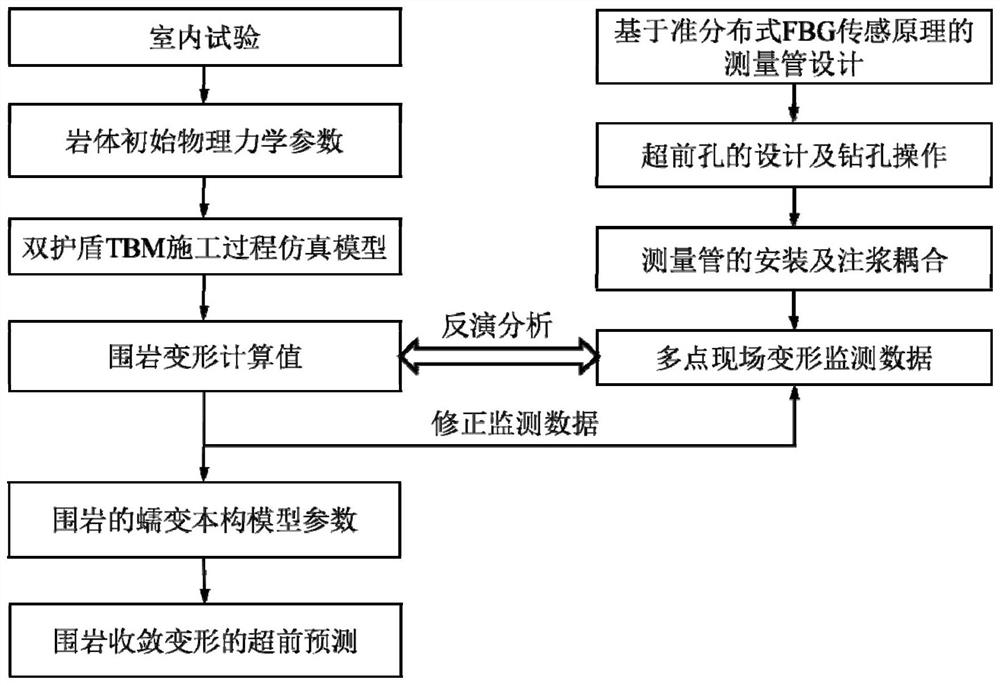

Surrounding rock deformation monitoring method and prediction method suitable for double-shield TBM

InactiveCN112833807ASurrounding rock convergence deformation monitoringForecasting trendsUsing optical meansDeformation monitoringClassical mechanics

The invention discloses a surrounding rock deformation monitoring method and prediction method suitable for a double-shield TBM. The monitoring method mainly comprises three parts of advanced borehole measuring tube design and deformation monitoring based on a quasi-distributed FBG sensing principle, monitoring value correction based on construction process numerical simulation and inversion analysis, and surrounding rock convergence deformation numerical simulation analysis and advanced prediction based on monitoring inversion parameters. The monitoring method and the prediction method have the advantages that the quasi-distributed FBG advanced drilling measurement pipe is utilized, the problem that surrounding rock deformation of a double-shield TBM tunnel is difficult to monitor due to shield and segment shielding is effectively solved, displacement correction is conducted on an imaginary fixed point of the measurement pipe through refined numerical simulation, the creep constitutive parameters of surrounding rock are inverted according to monitoring data, and advanced prediction analysis of the convergence deformation of the surrounding rock is realized based on the numerical model, so that a guidance basis is provided for construction tunneling and support design of a tunnel, and safe and efficient construction of the double-shield TBM is ensured.

Owner:TSINGHUA UNIV

Solid acid blockage remover and method for removing stratum blockage by using same

InactiveCN111621276ASolve the needs of long-distance transportationReduce riskCleaning apparatusDrilling compositionSolid acidEnvironmental engineering

The invention discloses a solid acid blockage remover and a method for removing stratum blockage by using the solid acid blockage remover. The solid acid blocking remover comprises a prepad fluid anda main treatment fluid, wherein the prepad fluid comprises the following components in percentage by weight: 8-16% of solid acid, 0.5-1.5% of a corrosion inhibitor, 0.5-1.5% of a clay stabilizer, 0.5-1.5% of an iron ion stabilizer, 0.5-1.5% of a demulsification cleanup additive and the balance of water; wherein the main treatment liquid is prepared from 5%-10% of solid acid, 4%-8% of ammonium fluoride, 0.5%-1.5% of a corrosion inhibitor, 0.5%-1.5% of a clay stabilizer, 0.5%-1.5% of an iron ion stabilizer, 0.5%-1.5% of a demulsification cleanup additive and the balance of water. The solid acidserves as main acid, most of other treating agents are solid particles, and the defects that special equipment is needed for liquid acid transportation, and long-distance transportation is high in safety risk are overcome.

Owner:PETROCHINA CO LTD

Building scaffold supporting structure

ActiveCN114439211ARaise height positionQuick assemblyScaffold accessoriesArchitectural engineeringMechanical engineering

The invention relates to the technical field of scaffolds, in particular to a building scaffold supporting structure which comprises a base, the base comprises two symmetrically-arranged second bottom rods and two first bottom rods arranged at the two ends of the two second bottom rods respectively, and a supporting part is arranged at the top of the base. Each supporting part comprises a plurality of supporting rods which are vertically arranged and detachably connected in sequence, the opposite ends of the supporting rods at the top and the supporting rods at the bottom are connected with butt joint pieces, and partition plates are arranged in the centers of the interiors of the butt joint pieces; the scaffold is reasonable in structure and flexible to use, potential safety hazards are avoided, the safety, adaptability and operation convenience in use are improved, the stability of the scaffold is improved, the ground levelness can be detected, all the components cooperate with one another and support one another functionally, the scaffold structurally has different functions and effects at different stages, the versatility is high, and the scaffold is suitable for popularization and application. The structure is stable.

Owner:HENAN JUNFEI CONSTR ENG CO LTD

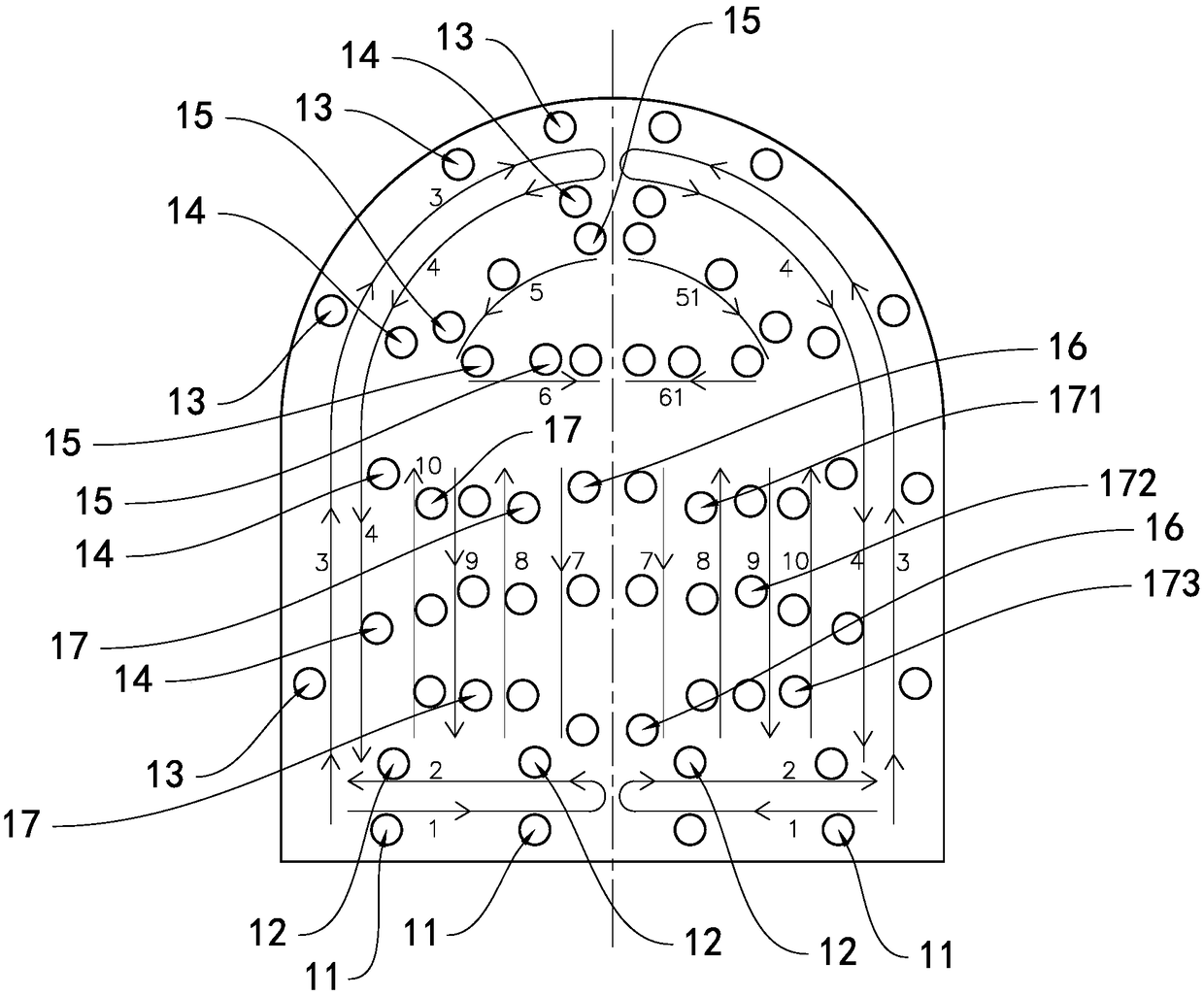

Tunnel drilling method using double-boom drill jumbo

ActiveCN108979529AGuaranteed non-interferenceIncrease maximum yieldDrilling machines and methodsDrillEnergy conservation

The invention provides a tunnel drilling method using a double-boom drill jumbo. The method using the double-boom drill jumbo which comprises a left drill boom and a right drill boom includes the steps of S1, drilling bottom holes; S2, drilling uplift blasting holes; S3, drilling peripheral holes; S4, drilling auxiliary holes; S5, drilling arch part expansion holes; S6, drilling cutting holes; S7,drilling central expansion holes, to be more specific, allowing the left drill boom and the right drill boom to perform row-by-row drilling from the center of a tunnel to the bottoms of lateral wallson two sides in an up-down-alternating manner. The method has the advantages that mutual interference between the left drill boom and the right drill boom of the drill jumbo can be avoided, the efficient use of the tunnel drill jumbo can be prompted, energy conservation and emission reduction can be achieved, safe and efficient tunnel construction can be guaranteed, and the maximum benefit of drill jumbo drilling and blasting is increased.

Owner:NO 5 ENG OF CHINA RAILWAY 19 BUREAU GRP

Bridge lifting device, bridge transformation system and bridge transformation construction method

InactiveCN112252194AReduce the impactImprove integrityBridge erection/assemblyArchitectural engineeringJackscrew

The invention relates to the technical field of bridge reinforcement, and concretely relates to a bridge lifting device, a bridge transformation system and a bridge transformation construction method.The method comprises the following steps that S1, a to-be-lifted bridge section is lifted through a lifting unit arranged at the lifting ends of two bridge lifting mechanisms and temporarily supported; S2, the two bridge lifting mechanisms are moved to the two sides of the next to-be-lifted bridge section till lifting and temporary supporting of all the bridge sections are completed; S3, two setsof semi-frame bodies are placed on the ground on the two sides of the lifted bridge section, and the lifting device is arranged above the two sets of semi-frame bodies; S4, the lifting device lifts the two sets of semi-frame bodies to the preset height and then moves to the installation position of a construction hanging bracket, and the two sets of semi-frame bodies are arranged on a pier in a sleeving mode after being spliced; and S5, connection between the lifting device and the semi-frame bodies is removed, and step S3 and step S4 are repeated to install the next construction hanging bracket. The problems that in the prior art, a hydraulic jack is adopted for pier heightening, the jacking stroke is limited, a specially-designed steel cushion block needs to be adopted, and the construction efficiency is low can be solved.

Owner:WUHAN BRIDGE SPECIAL TECH CO LTD CHINA RAILWAY MAJOR BRIDGE ENG BUREAU +1

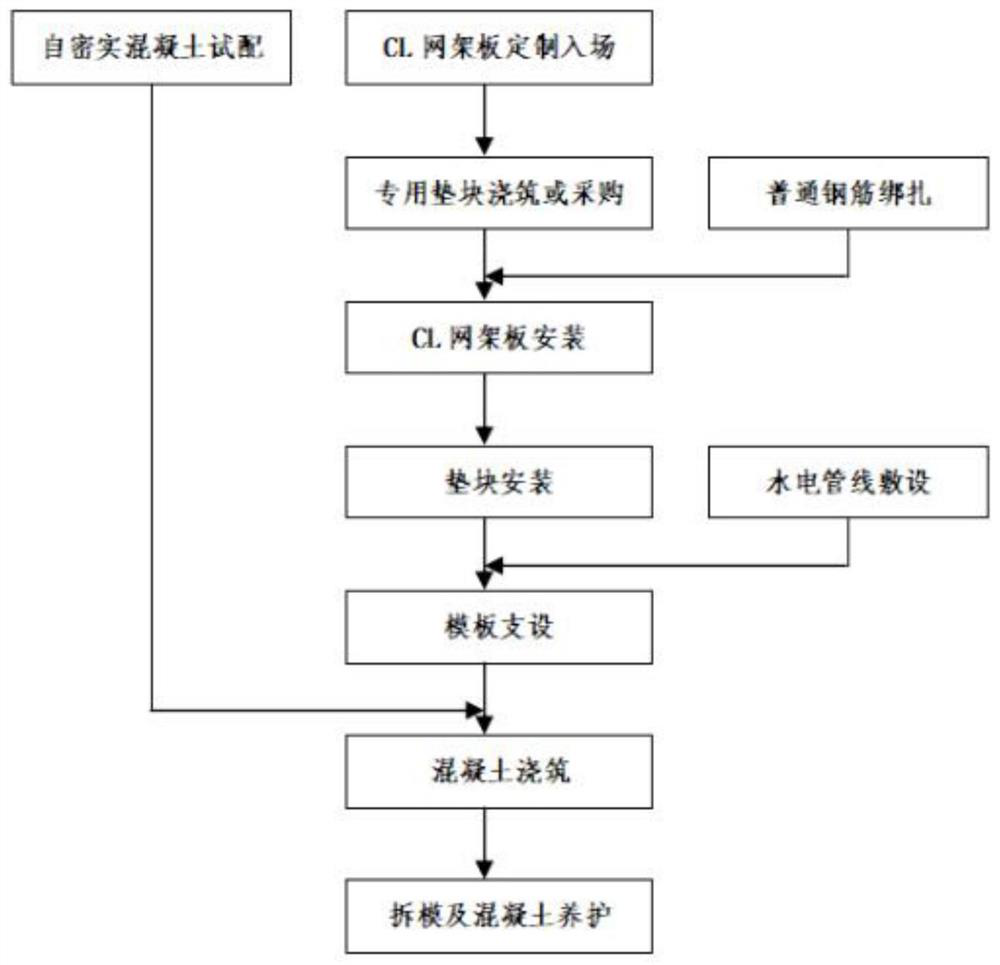

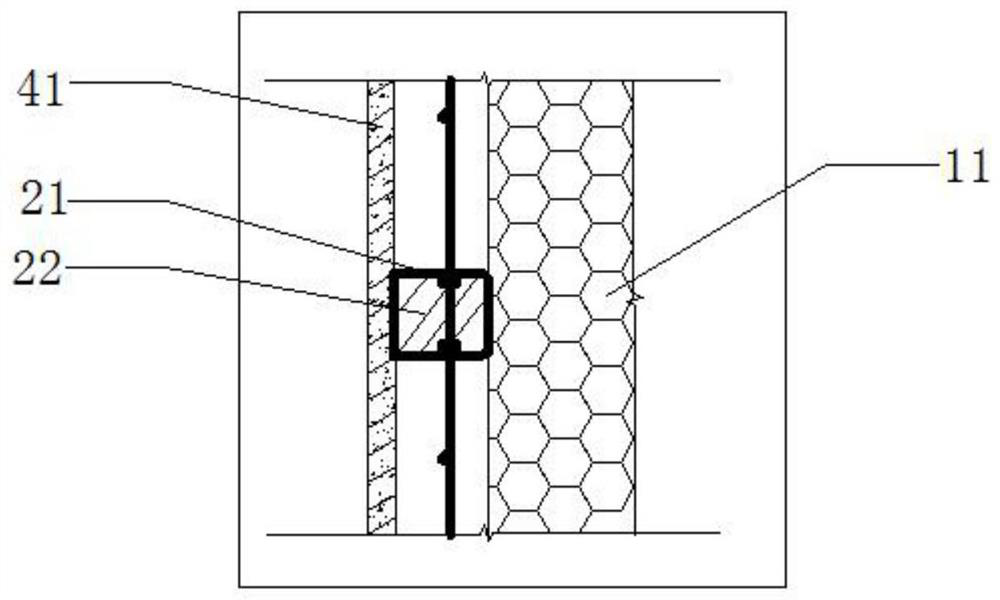

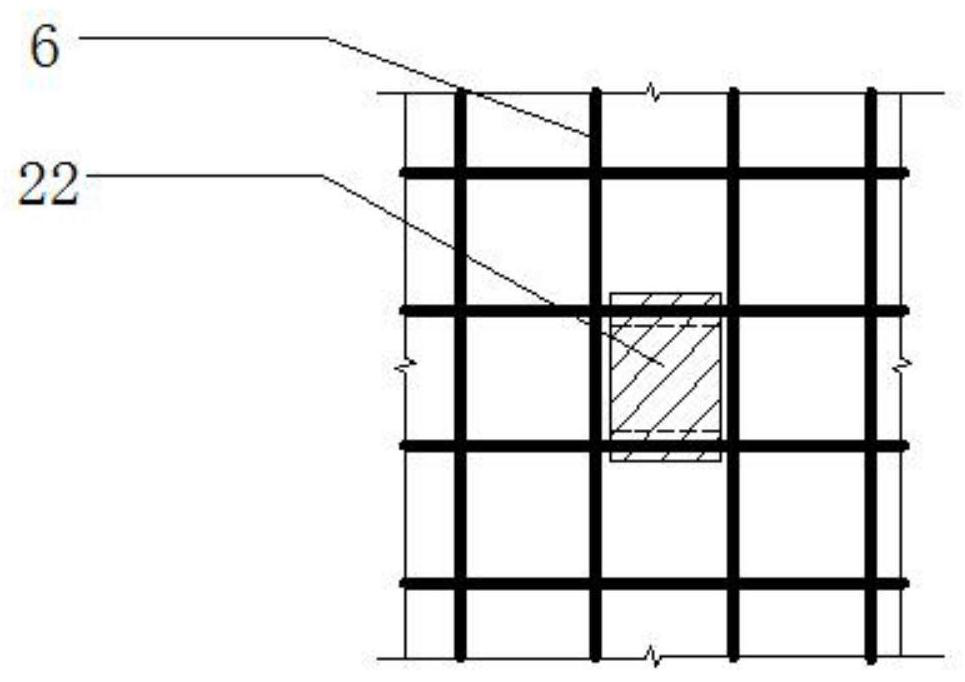

CL thermal insulation system construction method

InactiveCN112359994ASimple construction workNo lateral displacementHeat proofingBuilding material handlingThermal insulationArchitectural engineering

The invention discloses a CL thermal insulation system construction method, and belongs to the technical field of building construction. The method includes the steps that the customizing, decomposingand numbering of CL net rack plates is conducted; additional steel bars are mounted on the CL net rack plate; the CL net rack plate is installed, and the CL net rack plate is bound and fixed with fixing steel bars; a plurality of special cushion blocks are installed at the two sides of the CL net rack plate, and water and electricity pipelines are laid; a formwork used for concrete pouring is installed on the CL net rack plate, through-wall bolts are arranged on the formwork, and self-compacting concrete is matched in a trial mode; and self-compacting concrete is poured, the formwork is removed, and the concrete is maintained. According to the CL thermal insulation system construction method, the structure erecting work of a CL heat preservation system can be simply and rapidly completed,the construction process is simplified, cost is reduced, and stability and firmness are achieved; and the in-mold temperature and pouring points are controlled, the special cushion blocks are arranged at certain intervals, and the concrete pouring height difference between the two sides of the heat preservation plate is controlled, so that the situation that the CL net rack plate does not generate lateral displacement is guaranteed, the pouring requirement and pouring quality of the concrete are met, and the construction is safe and efficient.

Owner:CHINA MCC17 GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com