Large-embedded-depth TBM construction tunnel rock burst treatment structure

A tunnel and rockburst technology, which is applied in the rockburst treatment structure and field of TBM construction tunnels with large buried depths, can solve the problems of high safety risks for drilling and blasting operators, affecting the TBM construction progress of tunnels, and difficulties in drilling and blasting operations, etc. Achieve the effect of reducing the amount of collapse and backfilling of the top arch, significant economic and social benefits, and reducing post-support and backfilling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below by accompanying drawing.

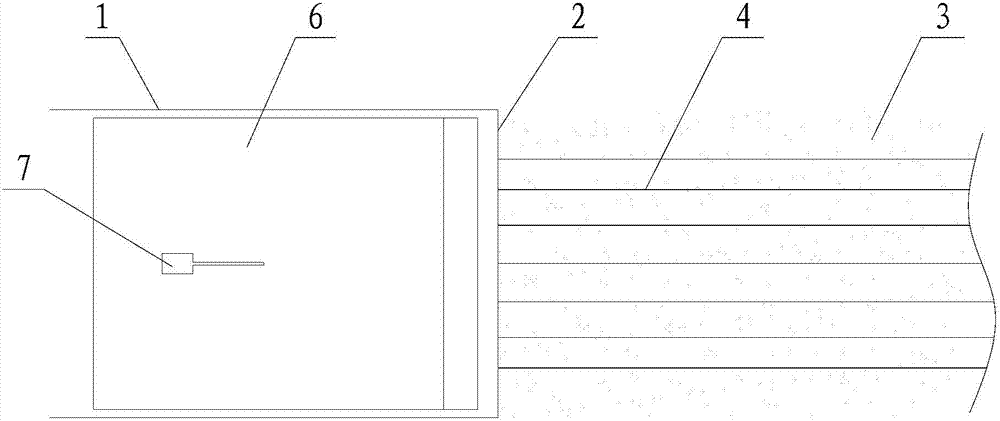

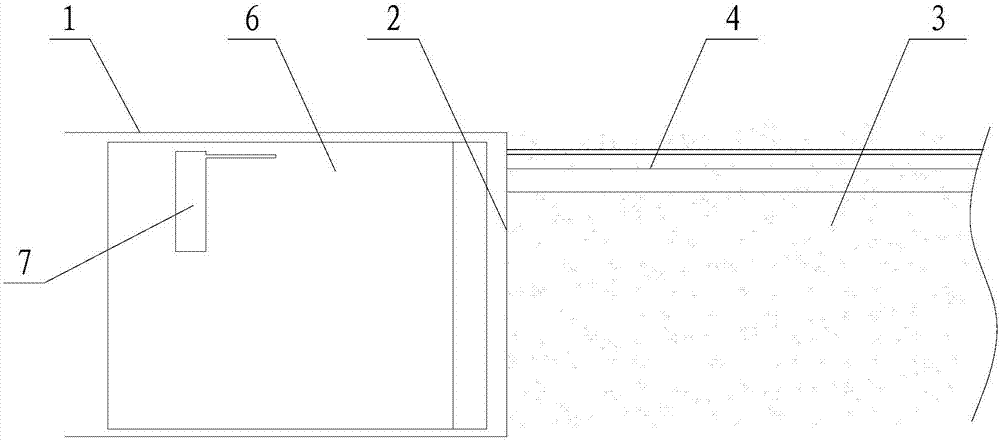

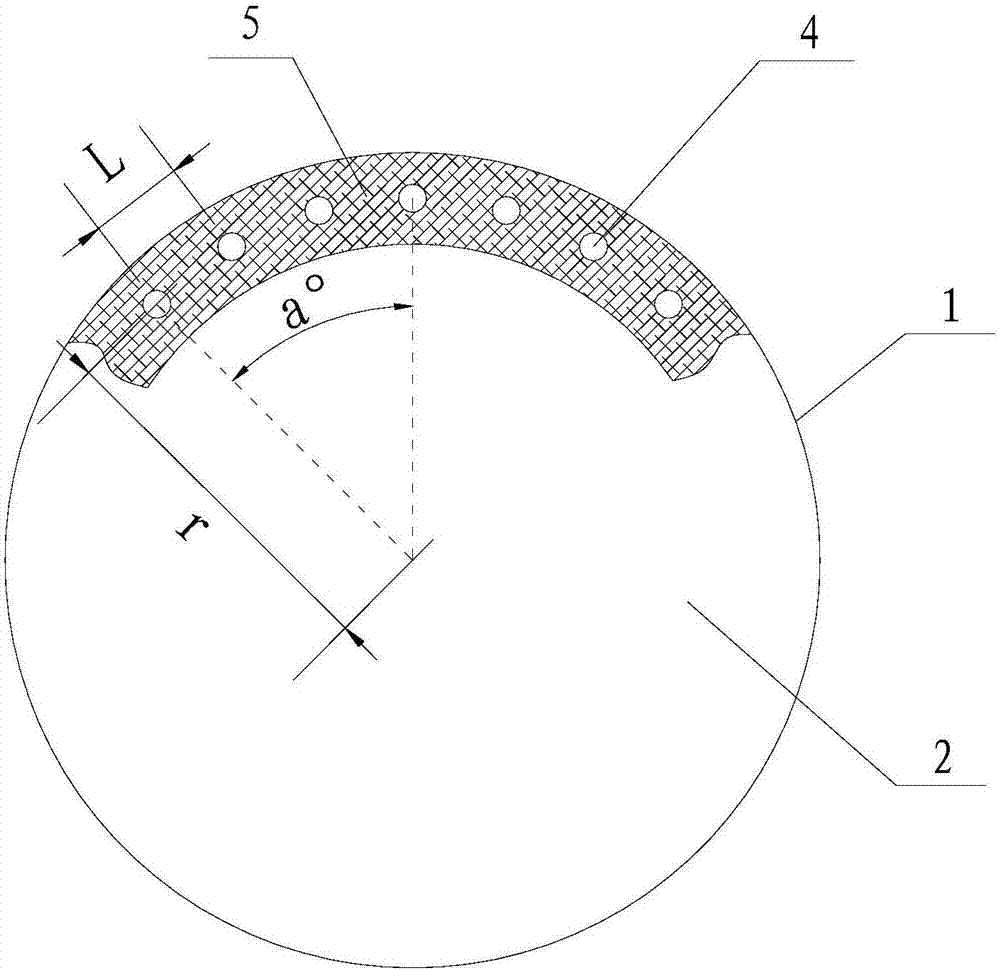

[0025] Such as figure 1 , figure 2 , image 3 As shown, the rockburst treatment structure of a TBM construction tunnel with a large buried depth includes a tunnel 1 and a rockburst area 3 in front of the tunnel face 2 where rockburst may occur. The top arch area of the tunnel face 2 is provided with multiple Advanced drilling 4, the advanced drilling 4 runs through the rockburst area 3, and each advanced drilling 4 is connected by the crack fracture zone 5 formed by the pre-splitting blasting in the drilling. In the prior art, there are generally two ways to deal with rockburst areas, one is to bypass the rockburst area by digging tunnels on the side, and perform blasting operations in front of the rockburst area, and the other is to use the drill and blast method to excavate A top arch is larger than the upper pilot tunnel of the TBM working section, and the upper pilot tunnel is supporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com