Patents

Literature

50results about How to "Reduce the amount of backfill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

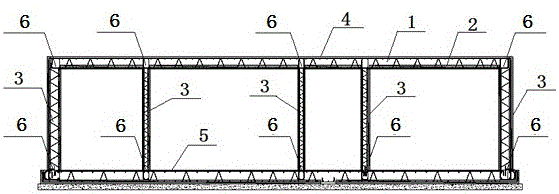

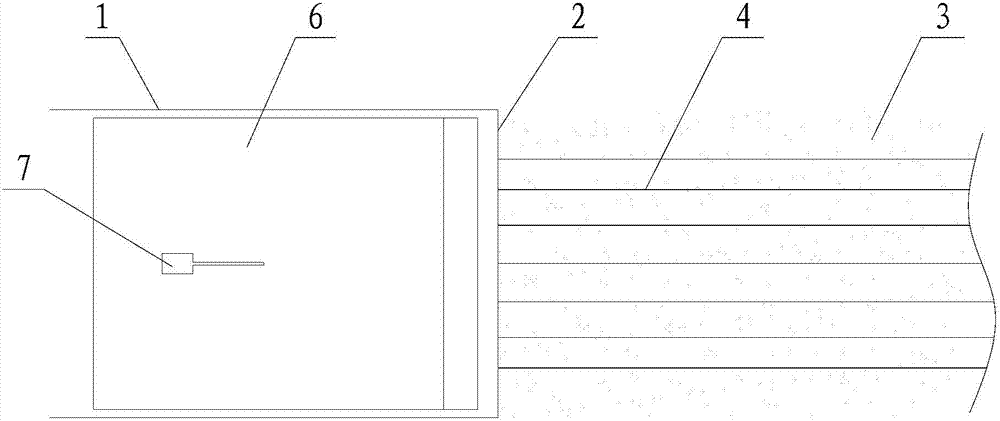

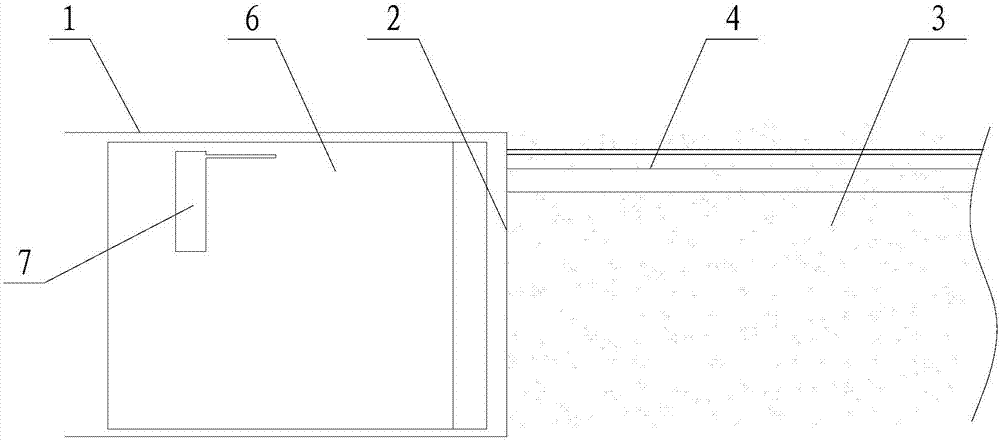

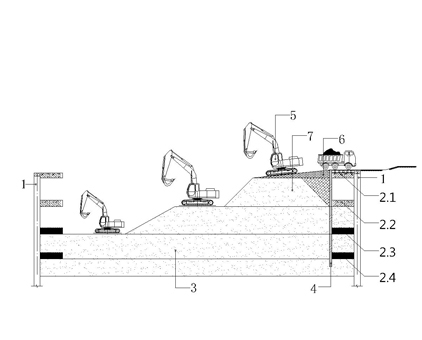

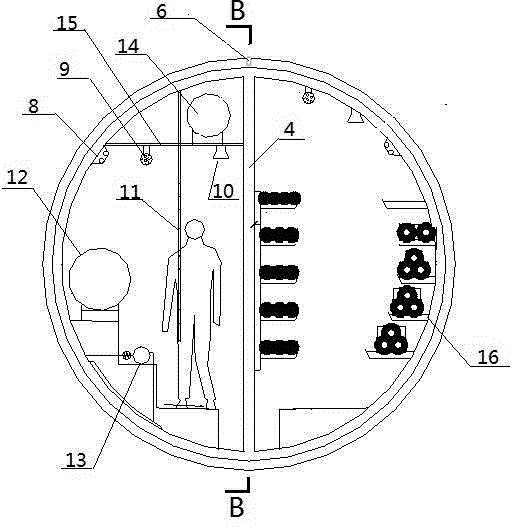

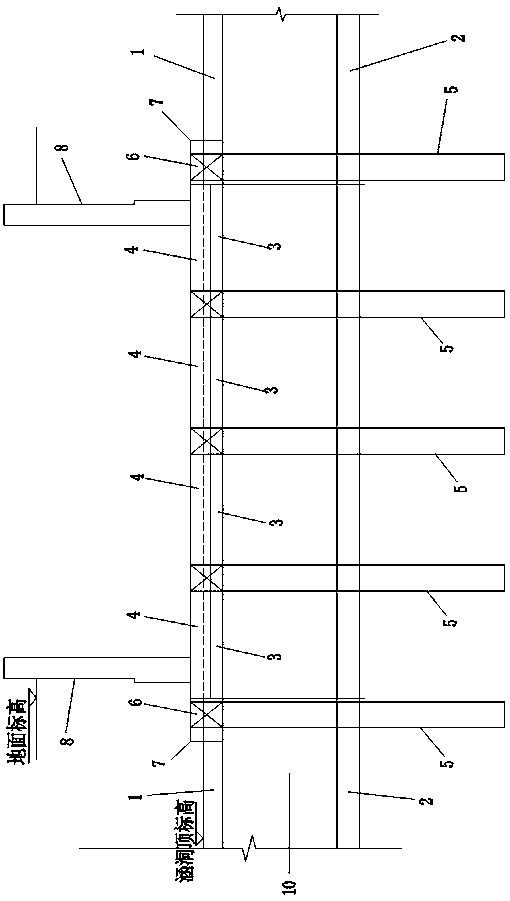

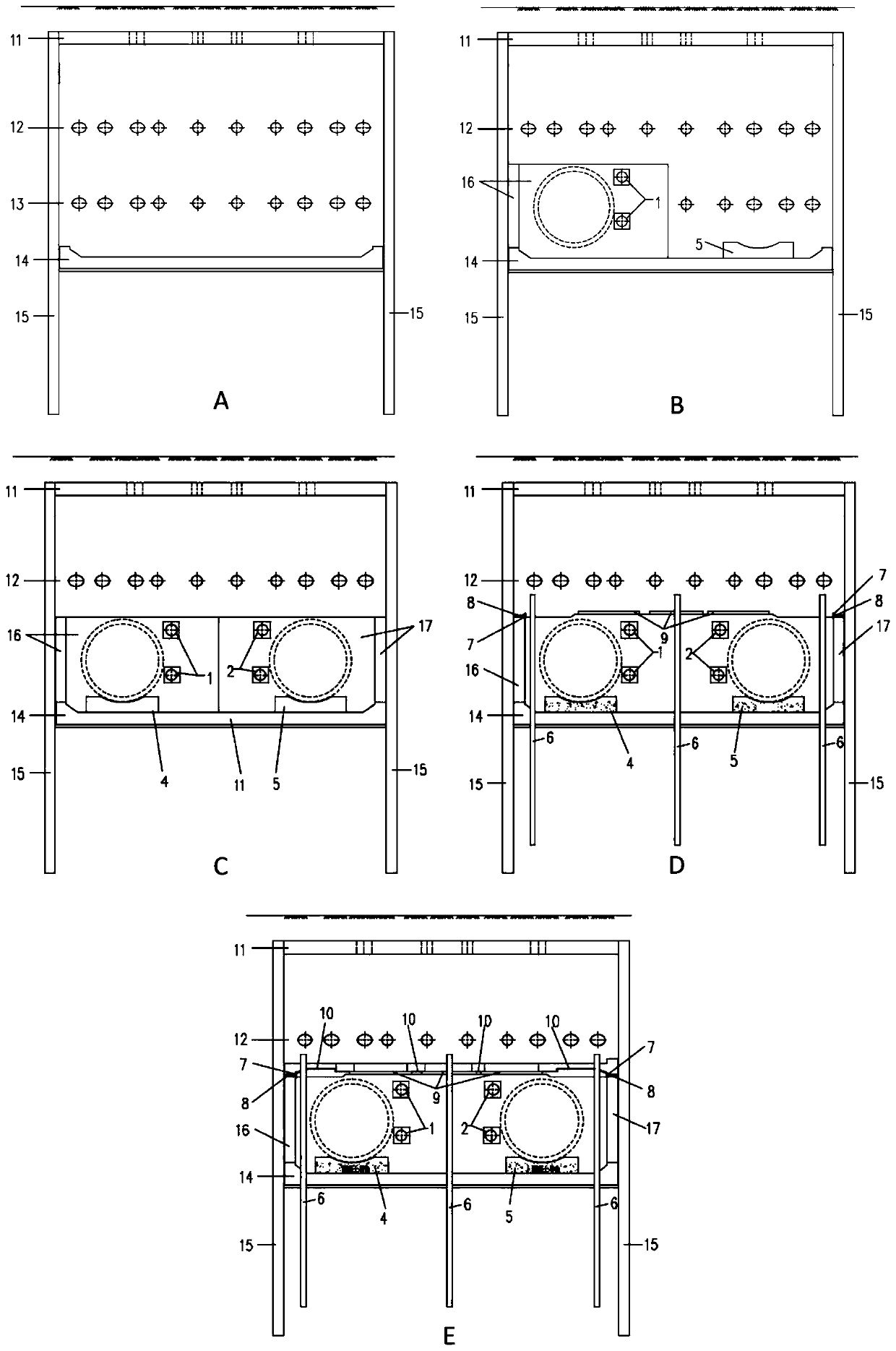

Construction and manufacturing process of total-prefabricated superimposed assembly type underground pipe gallery

ActiveCN105839667AOutstanding FeaturesHighlight significant effectArtificial islandsUnderwater structuresPrefabricationBuilding construction

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

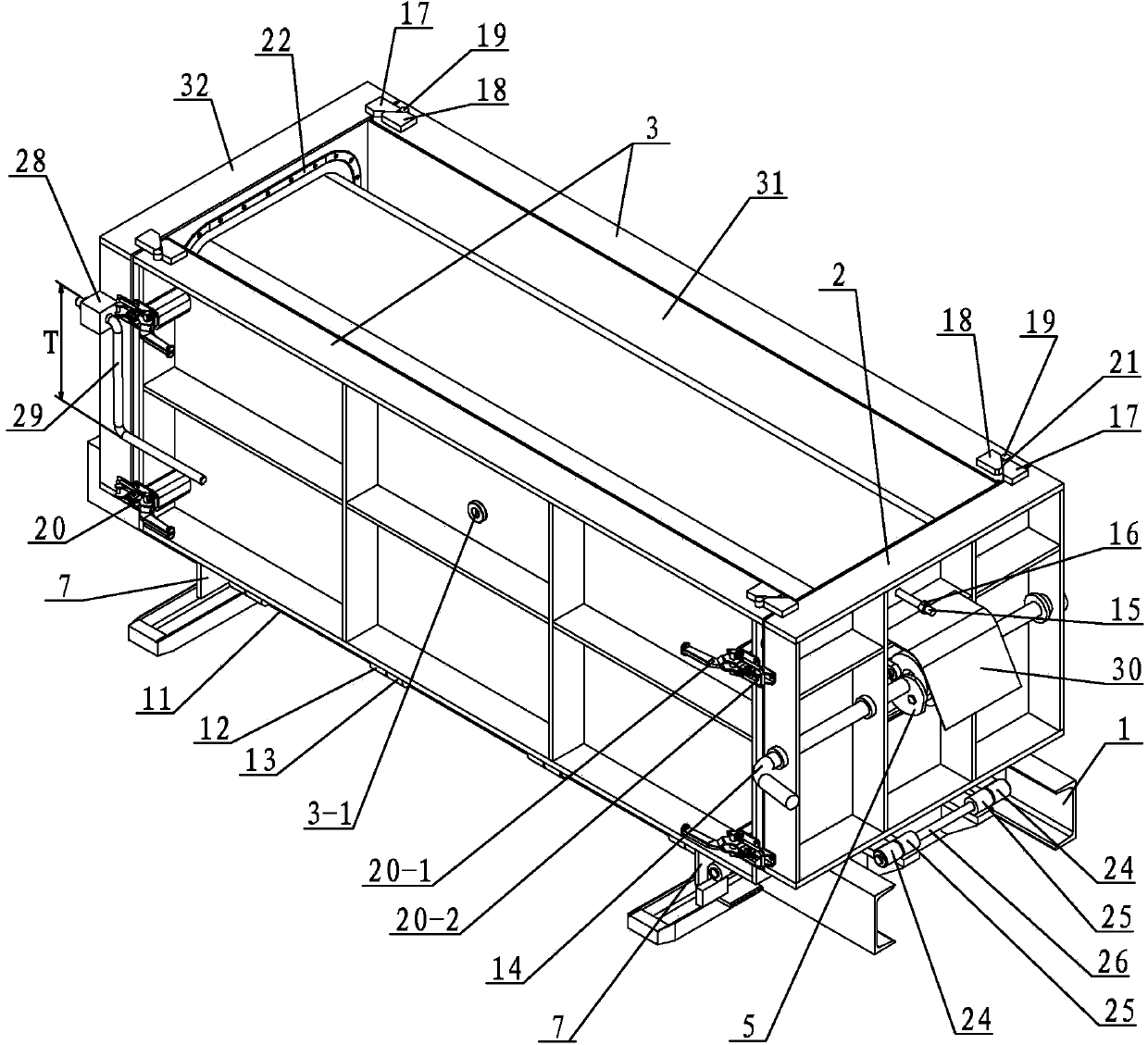

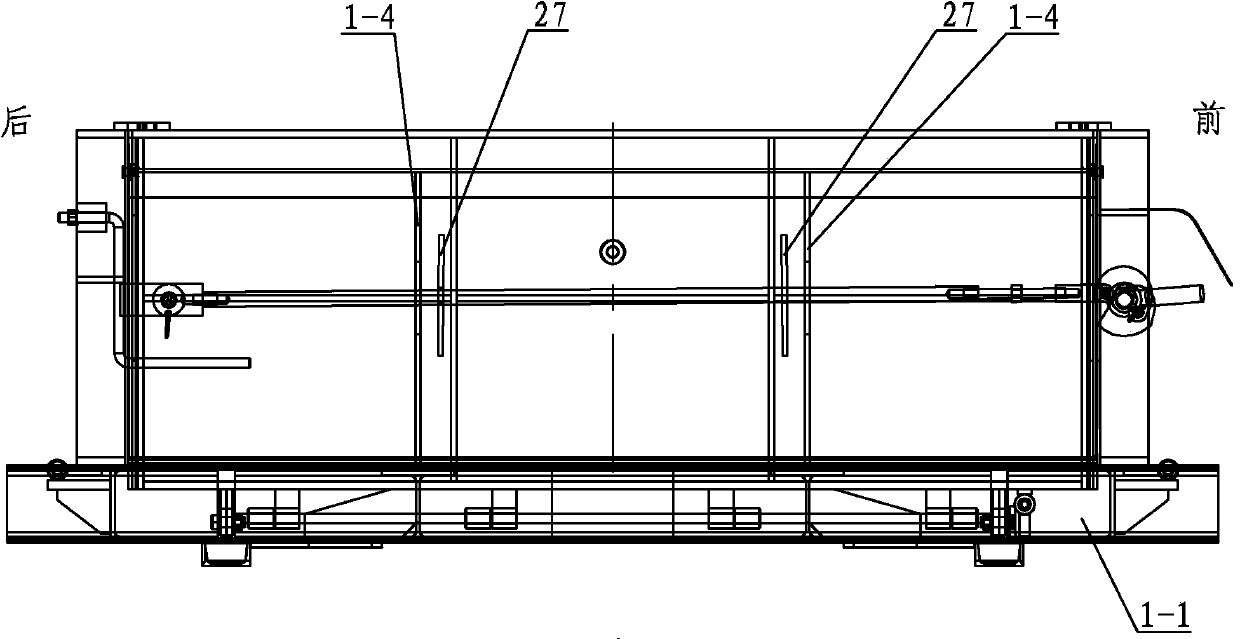

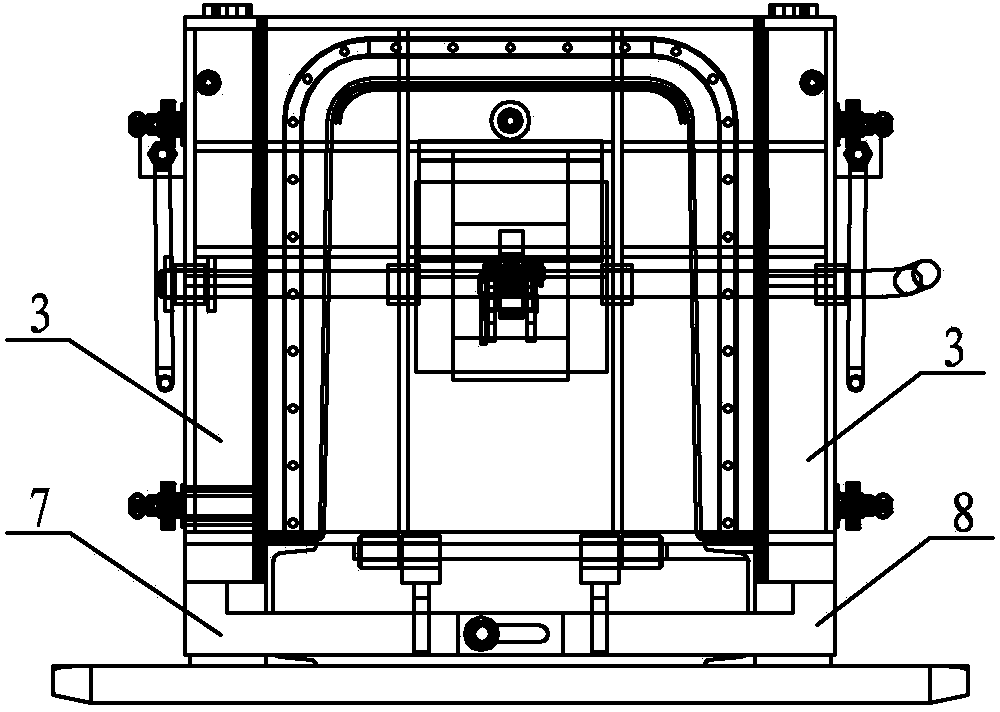

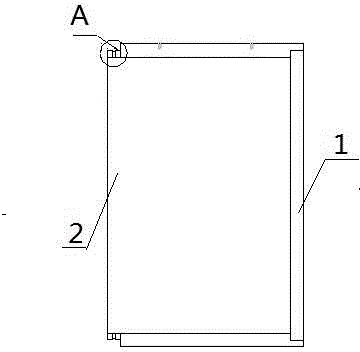

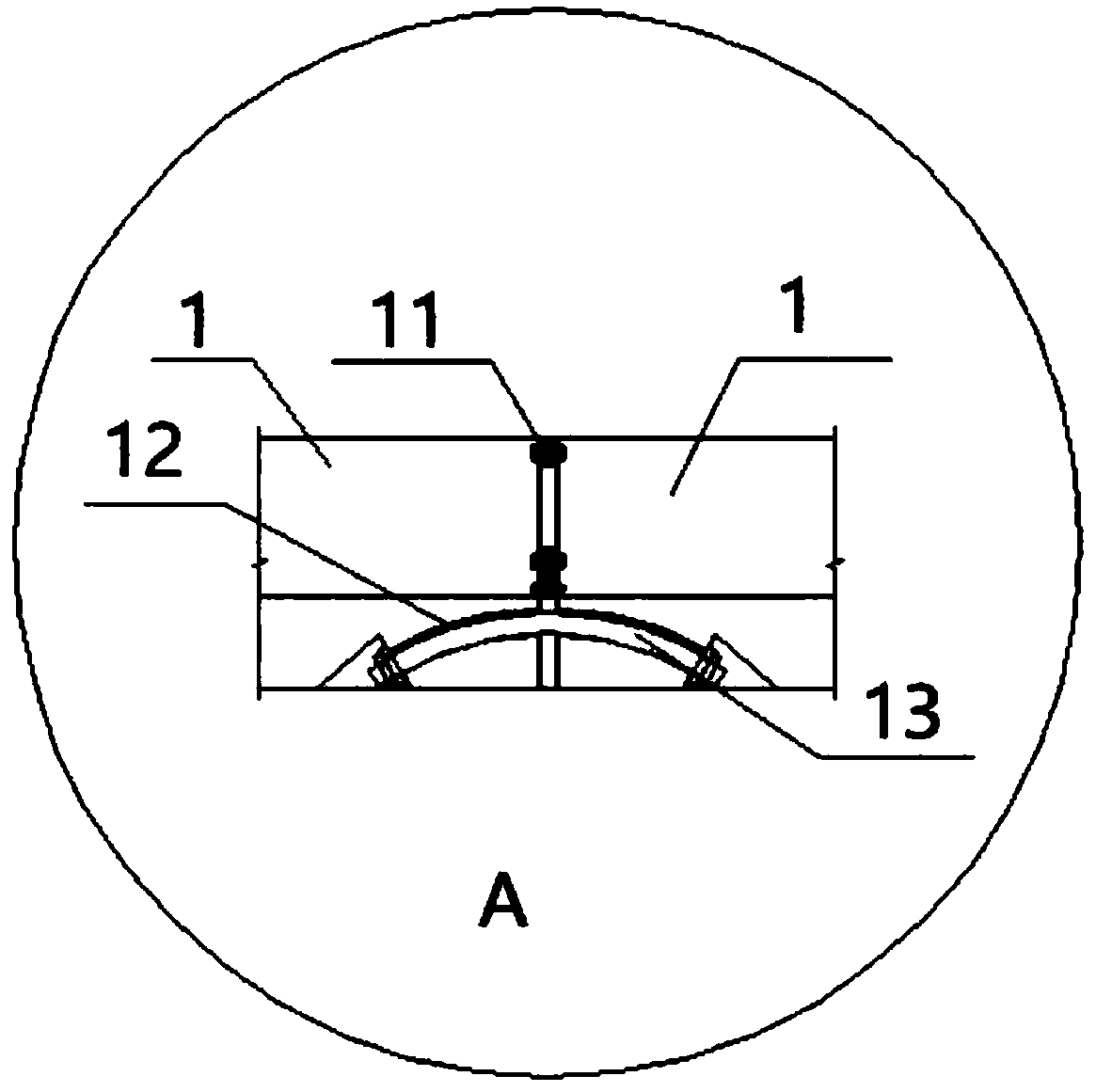

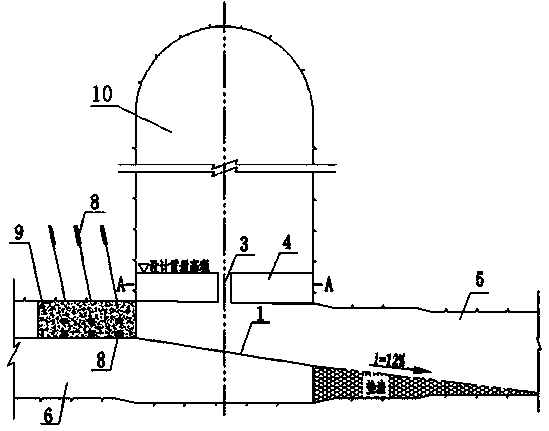

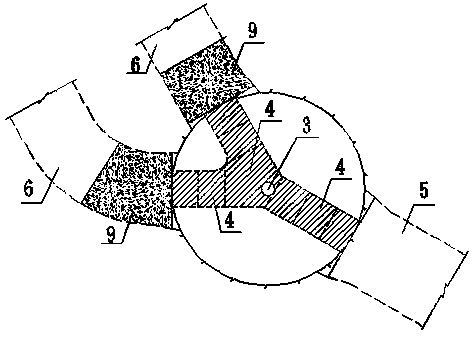

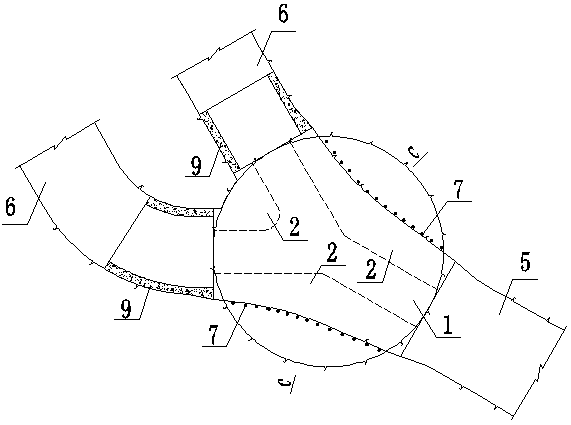

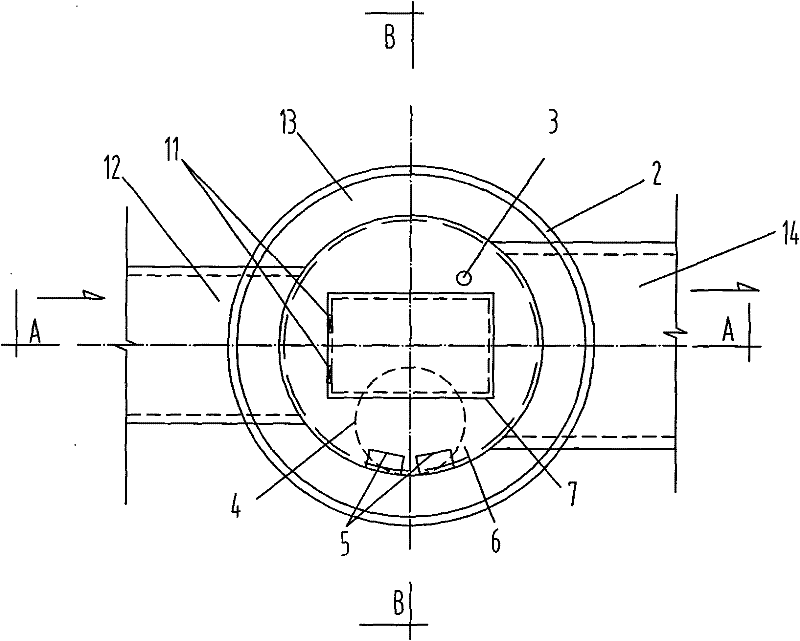

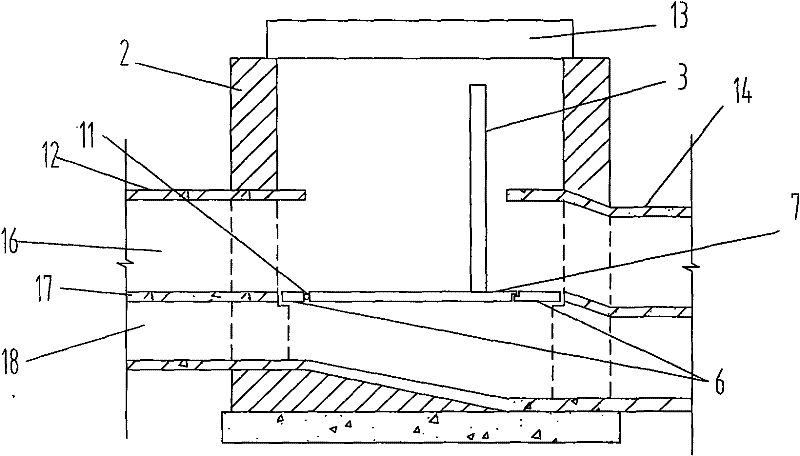

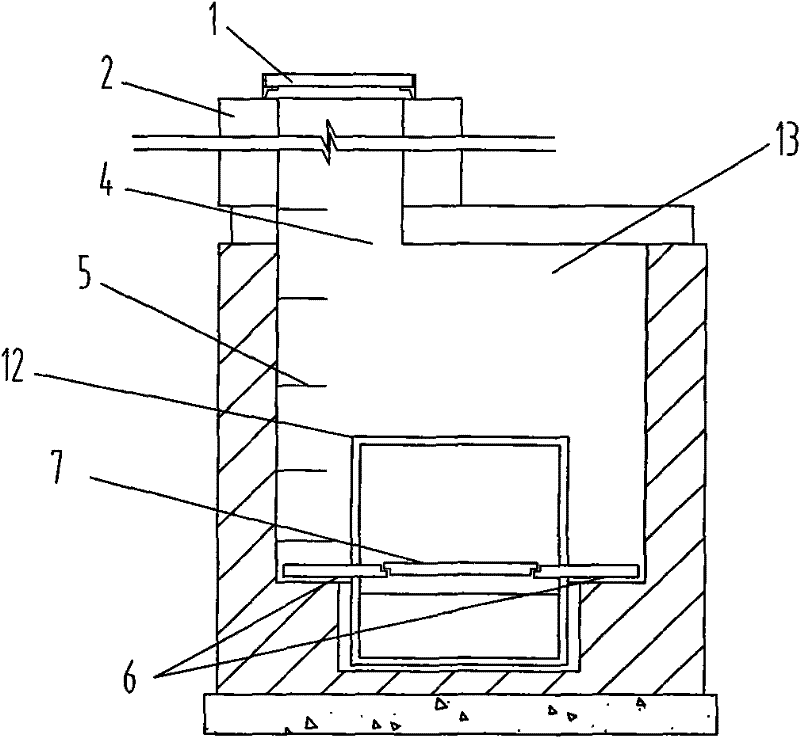

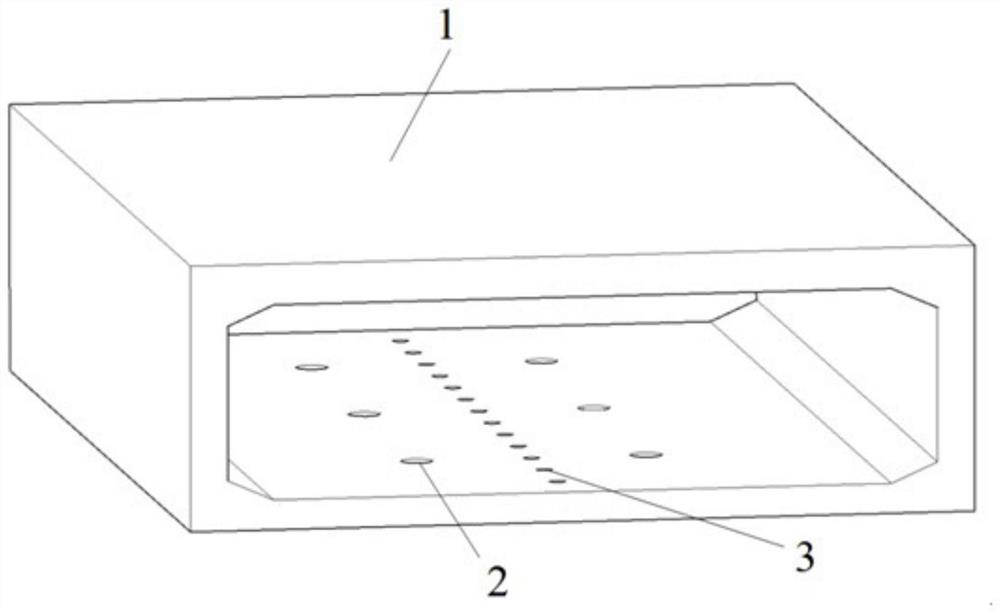

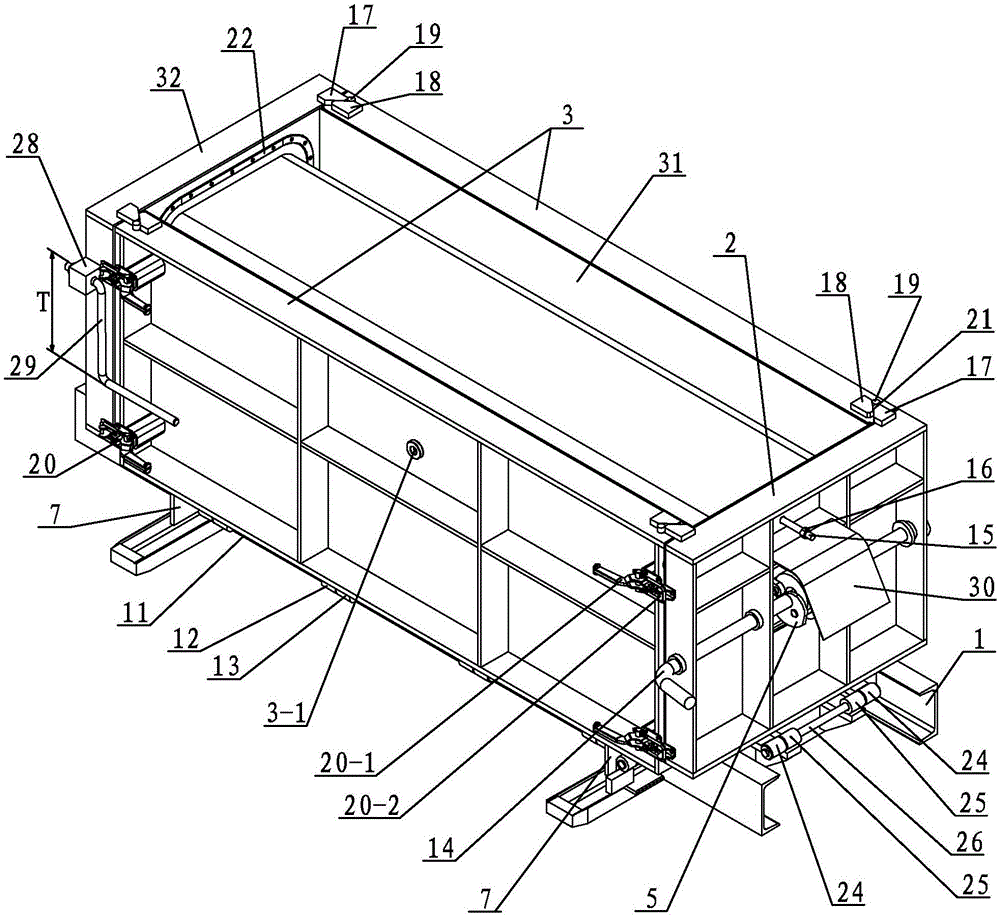

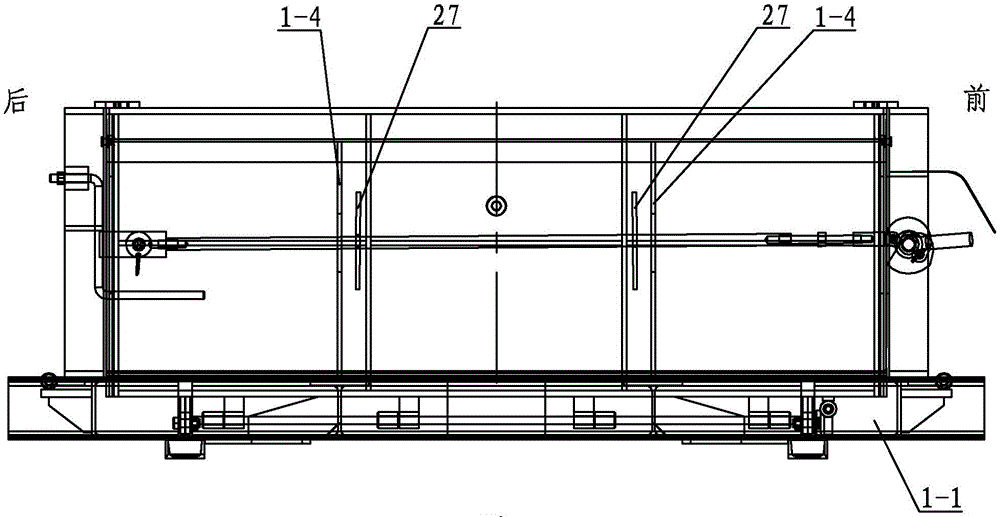

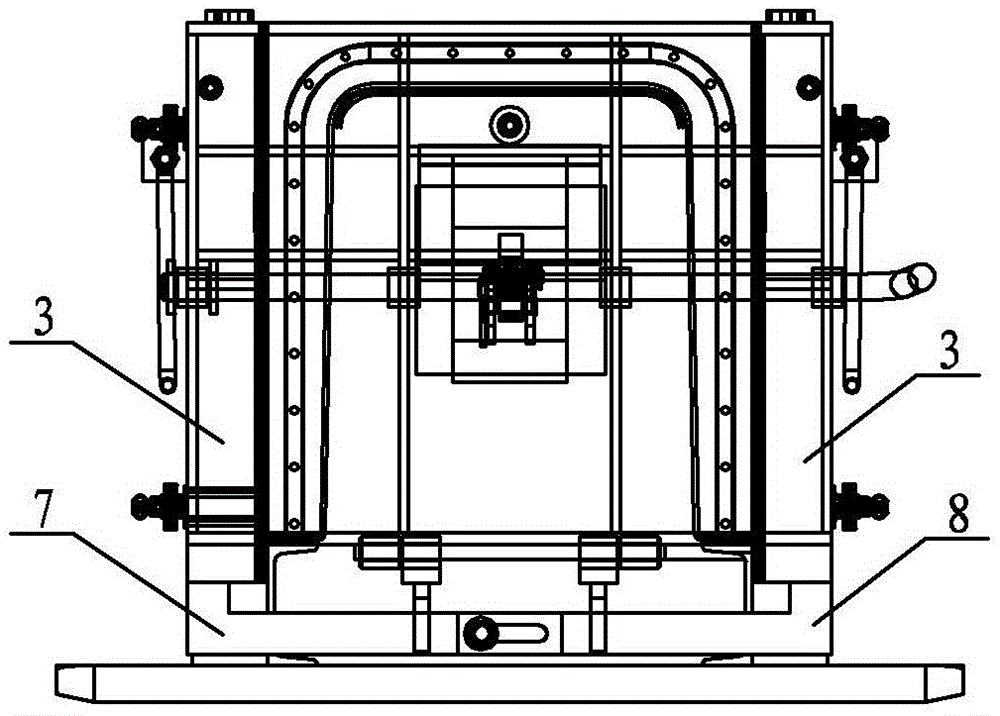

U-shaped sink machining mould

ActiveCN103770203AFlat surfaceReduce internal air bubblesMould separation apparatusMouldsStructural engineeringMachining

A U-shaped sink machining mould relates to U-shaped sink machining moulds and solves the problem that a U-shaped sink machined with an existing U-shaped sink machining mould has the length of only 500 meters as well as the problem of dimensions of cross section structures. A front end mould assembly, a rear end mould assembly and two side mould assemblies form a four-side frame, the four-side frame is arranged on a base frame assembly, both ends of the lower portion of the left side mould assembly is respectively provided with a left side mould linkage plate, both ends of the lower portion of the right side mould assembly is respectively provided with a right side mould linkage plate, the left side mould linkage plate and the right side mould linkage plate which transversely correspond to each other are hinged through a connecting member, a side hinge rod is arranged between two left side mould linkage plate, a switch shaft is mounted on the front end mould assembly, two sector connecting plates on an end mould linkage assembly are connected with the switch shaft and fixedly connected with the rear end mould assembly, and four corners of the outer side wall of each of the side mould assemblies is respectively mounted with a quick clamp. The U-shaped sink machining mould is used for machining a U-shaped sink for water channel construction.

Owner:HEILONGJIANG PROVINCIAL HYDRAULIC RES INST

Large-embedded-depth TBM construction tunnel rock burst treatment structure

The invention belongs to the technical field of tunnel TBM construction and discloses a large-embedded-depth TBM construction tunnel rock burst treatment structure and method. The large-embedded-depth TBM construction tunnel rock burst treatment structure comprises a plurality of advance boreholes formed in the vault area of the working face of a tunnel. The advance boreholes penetrate through the rock burst area. All the advance boreholes are connected through fracture crushed zones formed through presplitting blasting in the boreholes. According to the large-embedded-depth TBM construction tunnel rock burst treatment structure and method, the positions and directions of the boreholes are reasonably arranged in the working face of the tunnel through the operation space in a TBM, the crushed zones of a rock body are formed in the vault and spandrel of the rock burst area through borehole blasting, high-pressure water injection is utilized for further promoting development of crushed zone fractures and softening the rock body, high ground stress in the rock burst area is released, the rock burst risk is eliminated, the whole construction process is safe, efficient, low in cost and good in treatment effect, subsequent borehole high-pressure grouting treatment can be conducted to improve the integrity of the crushed zone fractures of the rock body, the collapse quantity and backfilling quantity of the vault during subsequent TBM excavation are decreased, and remarkable economic and social benefits are achieved.

Owner:POWERCHINA CHENGDU ENG

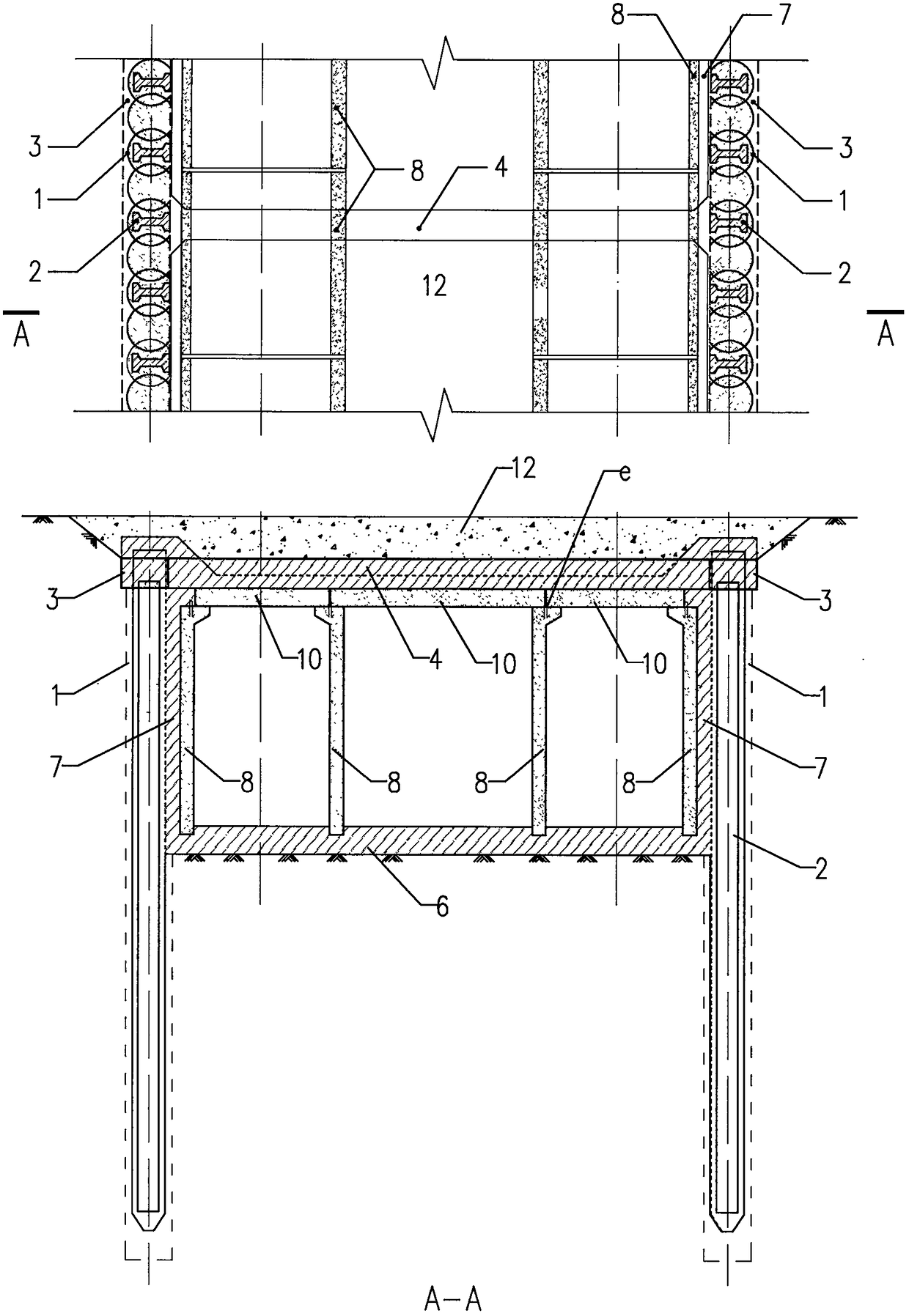

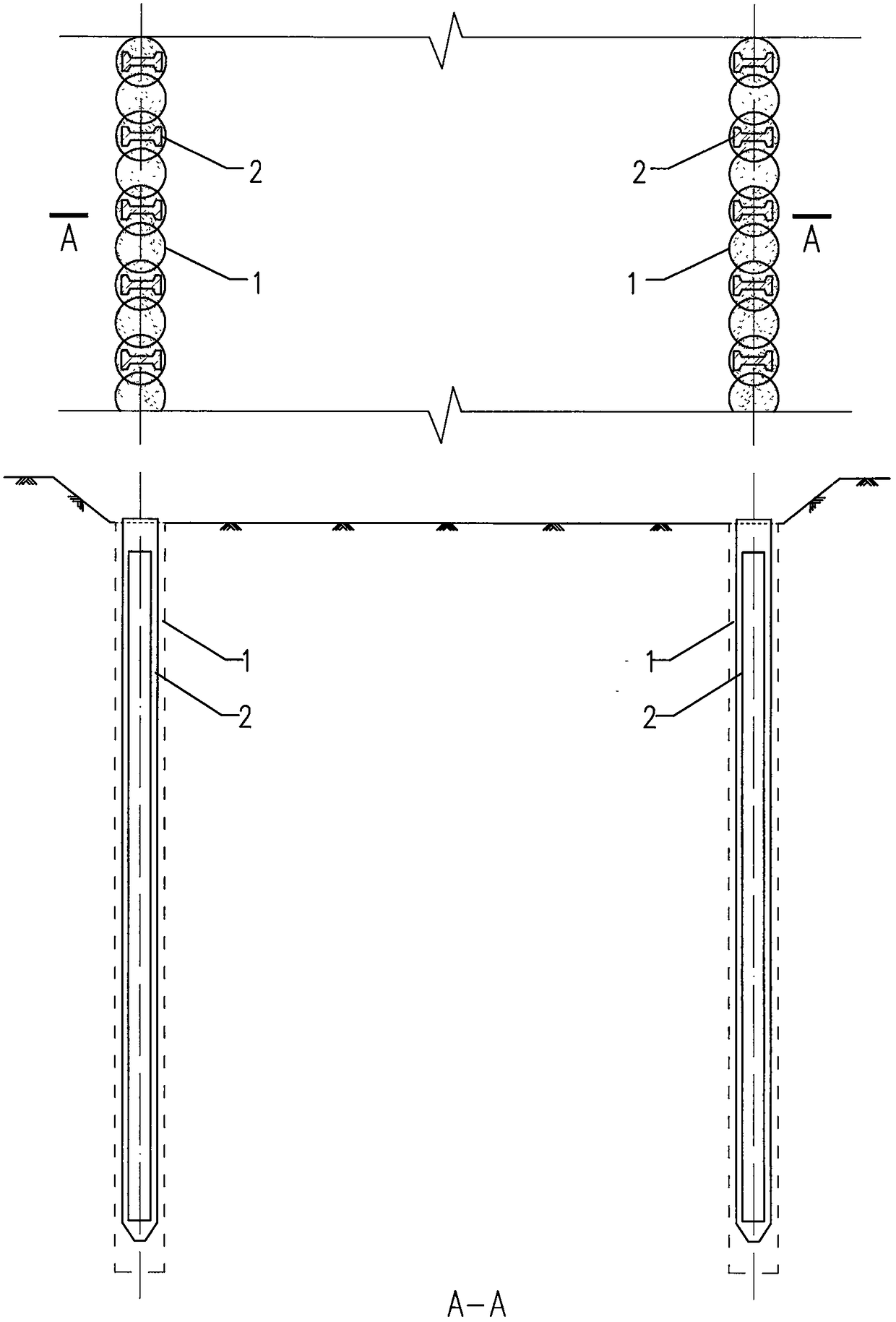

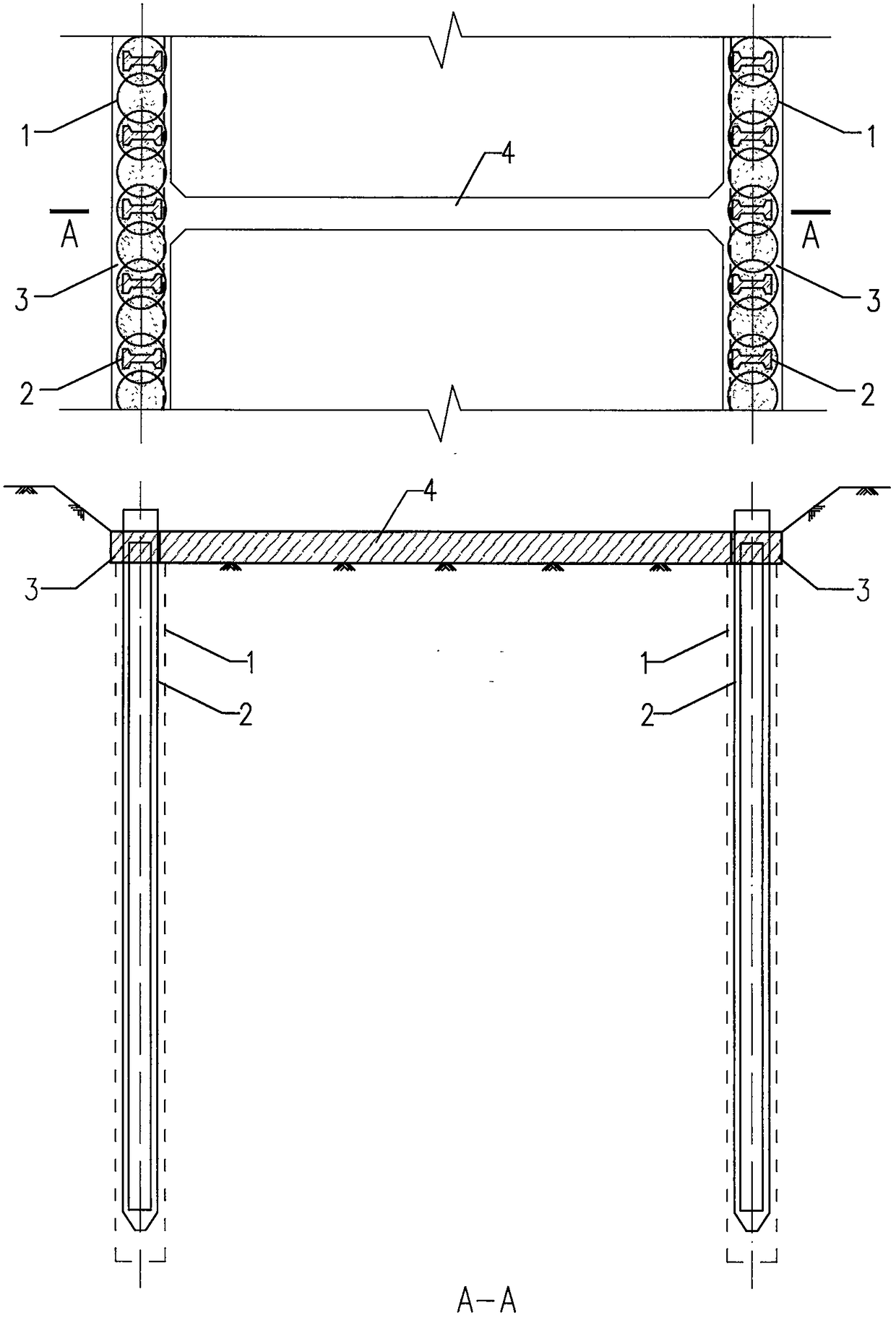

Precast plate and site-cast concrete combined underground pipe rack construction method considering structure and foundation

InactiveCN108797637ASimplify the construction processSolve the waterproof problemArtificial islandsUnderwater structuresEnvironment effectUtility tunnel

In the underground comprehensive pipe rack construction process, cement-mixed soil is put into precast I-shaped piles which are internally provided with embedded parts, and then the precast I-shaped piles are used for forming an enclosure wall; and the embedded parts of the I-shaped piles are in rebar connection with a pipe rack bottom plate. When the pipe rack bottom pack is poured, outer liningwall rebars are pre-embedded, and specified guide grooves are reserved in the pipe rack bottom plate to be used for being connected with precast concrete plates; the precast concrete plates which arewell installed serve as a template for an outer lining wall and later-poured tope plate site-cast concrete, and then the enclosure piles, supporting beams and the pipe rack structure are connected into a whole; and therefore the stiffness of the pipe rack structure can be significantly strengthened, and the settlement and anti-floating problems of the pipe rack structure are solved. Compared witha traditional pipe rack construction process, according to the construction method, the constriction procedures can be simplified, the construction progress can be accelerated, the construction cost can be reduced, the influence on the environment is small, and the construction method accords with the state-sponsored low-carbon, environmental-protection and economical green development strategies.

Owner:HANGZHOU NANLIAN CIVIL ENG TECH +1

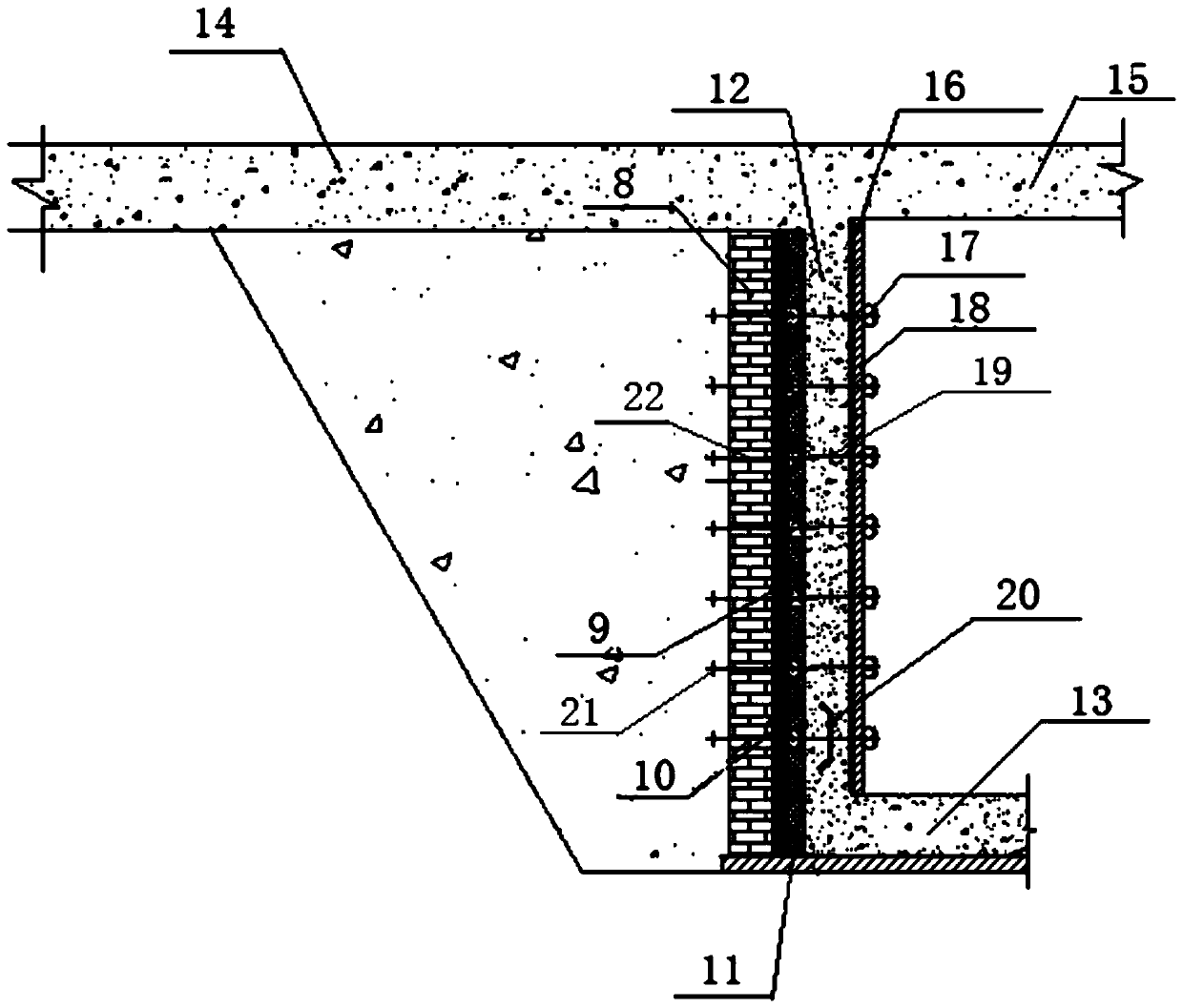

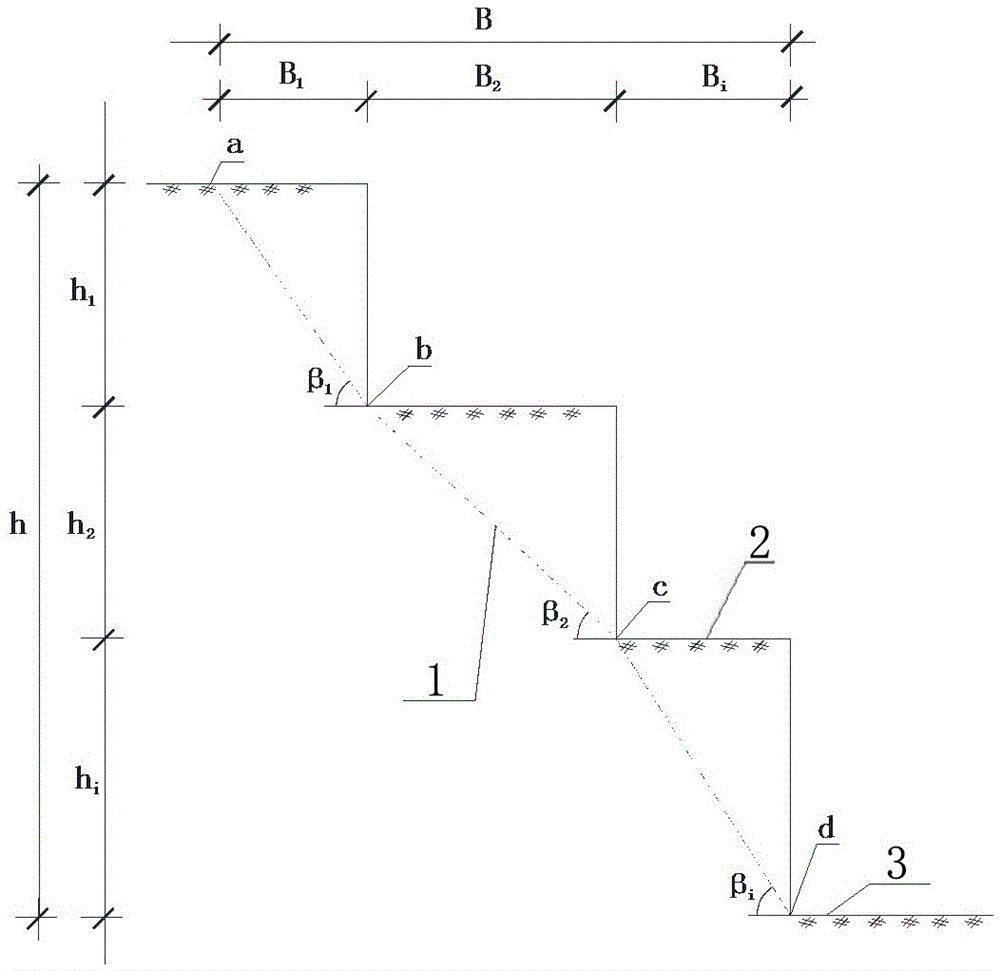

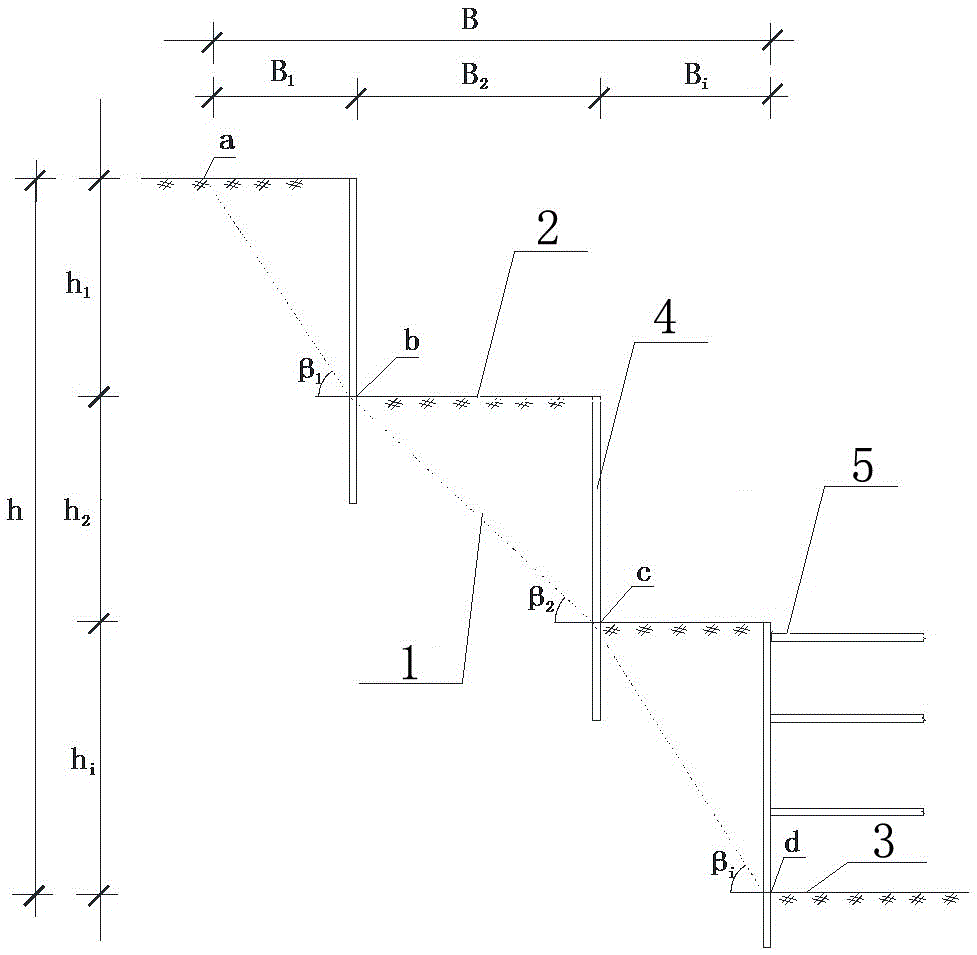

Supporting construction technology for deep foundation pit nearby road on complicated geological conditions

PendingCN110685286AReduce the amount of backfillReduce construction costsExcavationsBulkheads/pilesLithosphereDeep excavation

The invention discloses a supporting construction technology for a deep foundation pit nearby a road on the complicated geological conditions. The technology comprises the following steps of first, carrying out foundation pit excavation to the lithosphere, and carrying out slope setting construction to form a first foundation pit; second, driving first column piles on the edge of the pit bottom ofthe first foundation pit to form first batter post supporting; third, carrying out lithosphere excavation at the pit bottom of the first foundation pit to form a second foundation pit, carrying out slope setting construction, and then carrying out anchor rod supporting; and fourth, driving second column piles on the edge of the pit bottom of the second foundation pit to form second batter post supporting. According to the supporting construction technology for the deep foundation pit nearby the road on the complicated geological conditions, supporting on the deep foundation pit is implementedin the manner of arranging anchor rod supporting between batter post supporting, the problems that supporting for a deep foundation pit nearby the road on complicated geological conditions is difficult to carry out, high in construction cost, prone to having potential safety hazard, and the like are solved, supporting construction of the deep foundation pit nearby the road on the complicated geological conditions can be implemented, and the successful practice experience is provided for the field of supporting construction.

Owner:中铁八局集团第四工程有限公司 +1

Deep foundation pit open cutting construction method

InactiveCN101824825AReduce repeated excavationReduce workloadExcavationsStructural engineeringAnnular beam

The invention discloses a deep foundation pit open cutting construction method, which is characterized in that vertically knocking steel plate piles are arranged on the inner side of four concrete annular beams under a foundation pit soil outlet, the upper end of the steel plate piles is positioned at the same level as the upper surface of the first concrete annular beam, the lower end of the steel plate piles exceeds the lower surface of the lowest concrete annular beam by a certain length, first step soil digging is started, the first concrete annular beam is constructed, at the time, the steel plate piles are knocked in, then, the second step soil digging is started, and a soil table at a preserved soil outlet is maintained without being dug and is used for locating a digging machine. During the construction of a section of second concrete annular beam under the soil outlet soil table, firstly, earthwork is pulled and dug under the first annular beam, the position of a section of annular beam at the soil outlet is dug, the second concrete annular beam is completed through casting, the construction of each following concrete annular beam can be completely by parity of reasoning, and the soil is dug to the tank bottom. The method of the invention does not need to dig and fill back the earthwork platform at the soil outlet for many times, the construction program is simplified, the earthwork work load is reduced, and the construction cost is saved.

Assembly type lightweight thin wall integrated pipe gallery and production method thereof

ActiveCN104909643AOvercoming brittle structure and poor impact resistanceGood corrosion resistanceThin walledManufacturing engineering

The invention discloses an assembly type lightweight thin wall integrated pipe gallery and a production method thereof. The integrated pipe gallery is produced through casting molding of ultrahigh performance powdery concrete. The ultrahigh performance powdery concrete makes the integrated pipe gallery have a light structure, so various pipelines, cables, optical cables and other products can be safely laid.

Owner:黄贺明

Method for wastewater pollution control in waste mine shaft

A method for wastewater pollution control in a waste mine shaft is characterized in that mine solid wastes, a gelatinizing agent and water are used to prepare a sizing agent according to certain ratio, the sizing agent is conveyed into a mine shaft tunnel in a rock body, the prepared sizing agent is used to build sealed and isolated solidified bodies with a certain thickness from inside to outside according to a certain spacing distance, compartments are formed among the sealed and isolated solidified bodies, the waste mine shaft is plugged and sealed, and accumulated water in a goaf area and the compartments is blocked and sealed. In this way, the wastewater pollution control of the waste mine shaft is realized.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

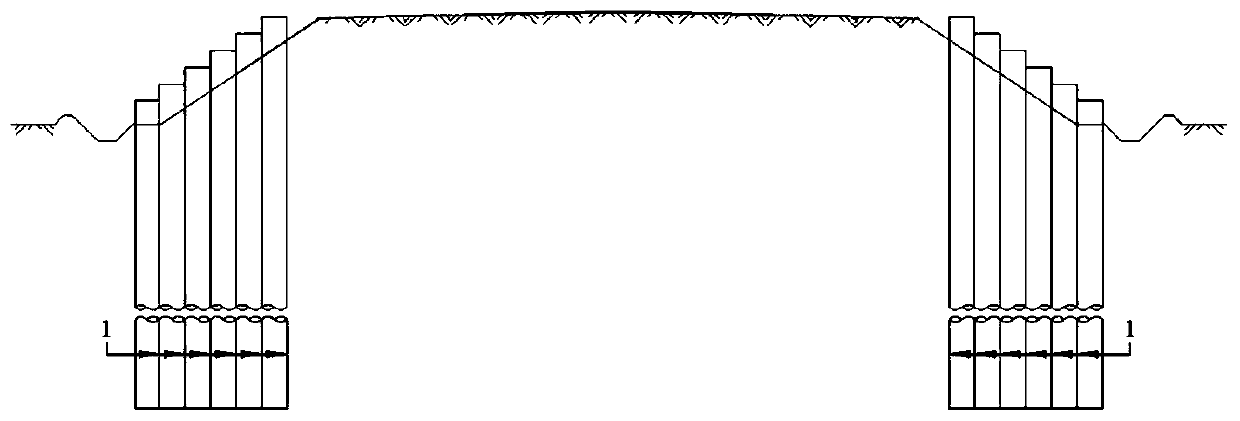

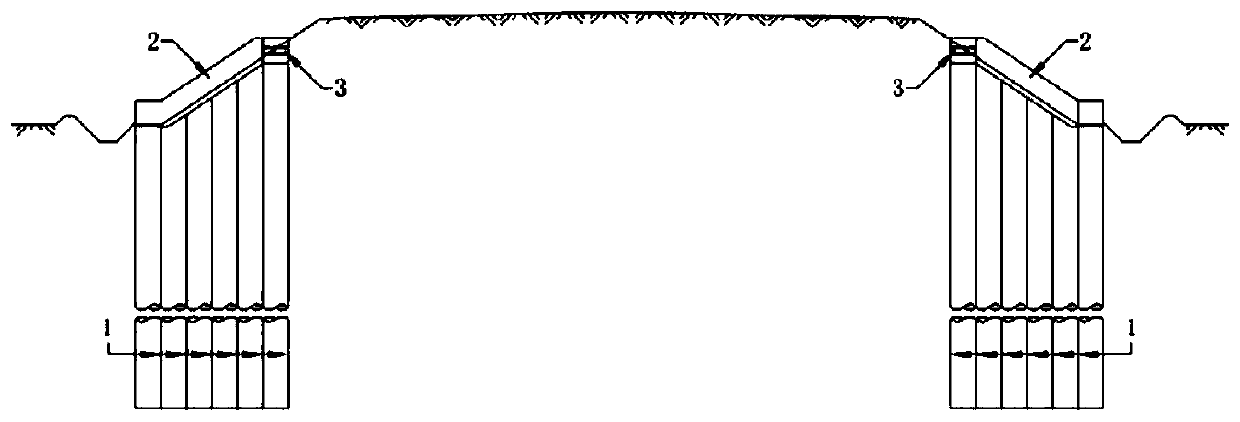

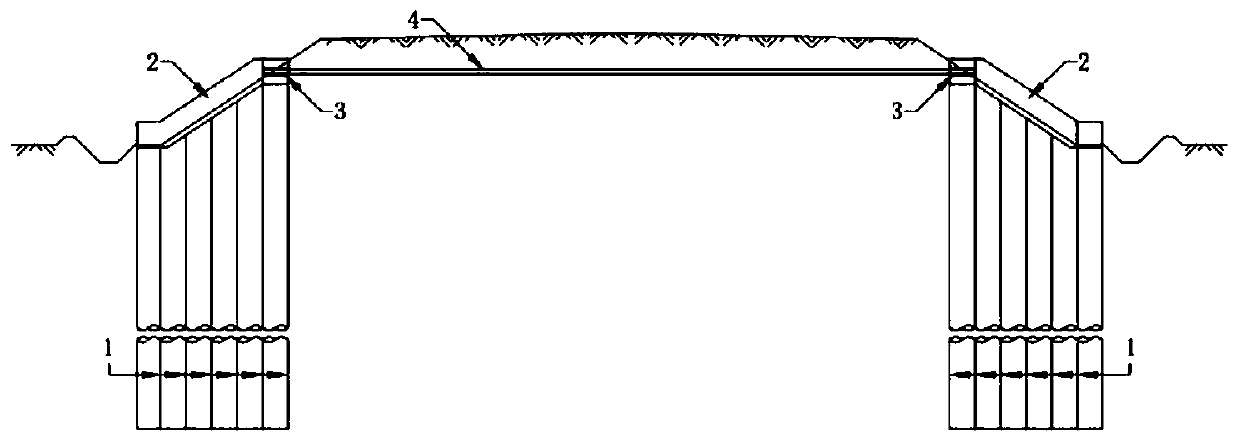

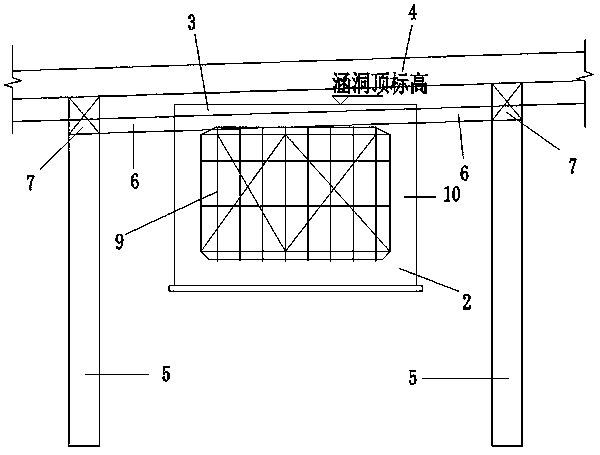

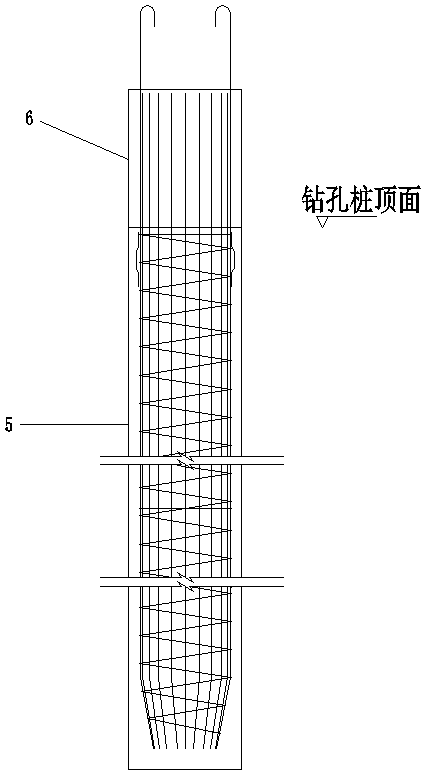

Jacking frame overpass construction method based on self-anchored prestressed overhead system

ActiveCN111485903AImprove operational safetyImprove the level of security protectionRoadwaysUnderground chambersPre stressArchitectural engineering

The invention discloses a jacking frame overpass construction method based on a self-anchored prestressed overhead system. The method comprises the following steps: constructing and arranging gate-shaped anchoring piles on roadbed slopes at two sides of a highway or a railway; arranging a cross beam on the tops of the anchoring piles, and solidifying the cross beam and the anchoring piles to forma gate-shaped frame; driving guide steel pipes into reserved positioning holes of the gate-shaped frame to the opposite sides of roadbeds; penetrating prestressed steel bundles into the guide steel pipes to form the self-anchored prestressed gate-shaped frame overhead system; prefabricating overpass frame structure segments, and jacking the segments in place within the protection range of the self-anchored prestressed overhead system; and grouting on the periphery of the overpass frame structure, and making the overpass frame structure form a permanent stressed structure to bear railway or highway loads. The construction method provided by the invention can realize that the operation is not interrupted and a road is not changed when an existing highway or railway jacking frame overpass isconstructed.

Owner:陕西铭捷交通工程有限公司

Deep foundation pit open cutting construction method

The present invention discloses a deep foundation pit open cutting construction method, which is characterized in that vertically knocking steel plate piles are arranged on the inner side of four concrete annular beams under a foundation pit soil outlet, the upper end of the steel plate piles is positioned at the same level as the upper surface of the first concrete annular beam, the lower end of the steel plate piles exceeds the lower surface of the lowest concrete annular beam by a certain length, first step soil digging is started, the first concrete annular beam is constructed, at the time, the steel plate piles are knocked in, then, the second step soil digging is started, and a soil table at a preserved soil outlet is maintained without being dug and is used for locating a digging machine. During the construction of a section of second concrete annular beam under the soil outlet soil table, firstly, earthwork is pulled and dug under the first annular beam, the position of a section of annular beam at the soil outlet is dug, the second concrete annular beam is completed through casting, the construction of each following concrete annular beam can be completely by parity of reasoning, and the soil is dug to the tank bottom. The method of the invention does not need to dig and fill back the earthwork platform at the soil outlet for many times, the construction program is simplified, the earthwork work load is reduced, and the construction cost is saved.

Owner:TIANJIN SANJIAN CONSTR ENG

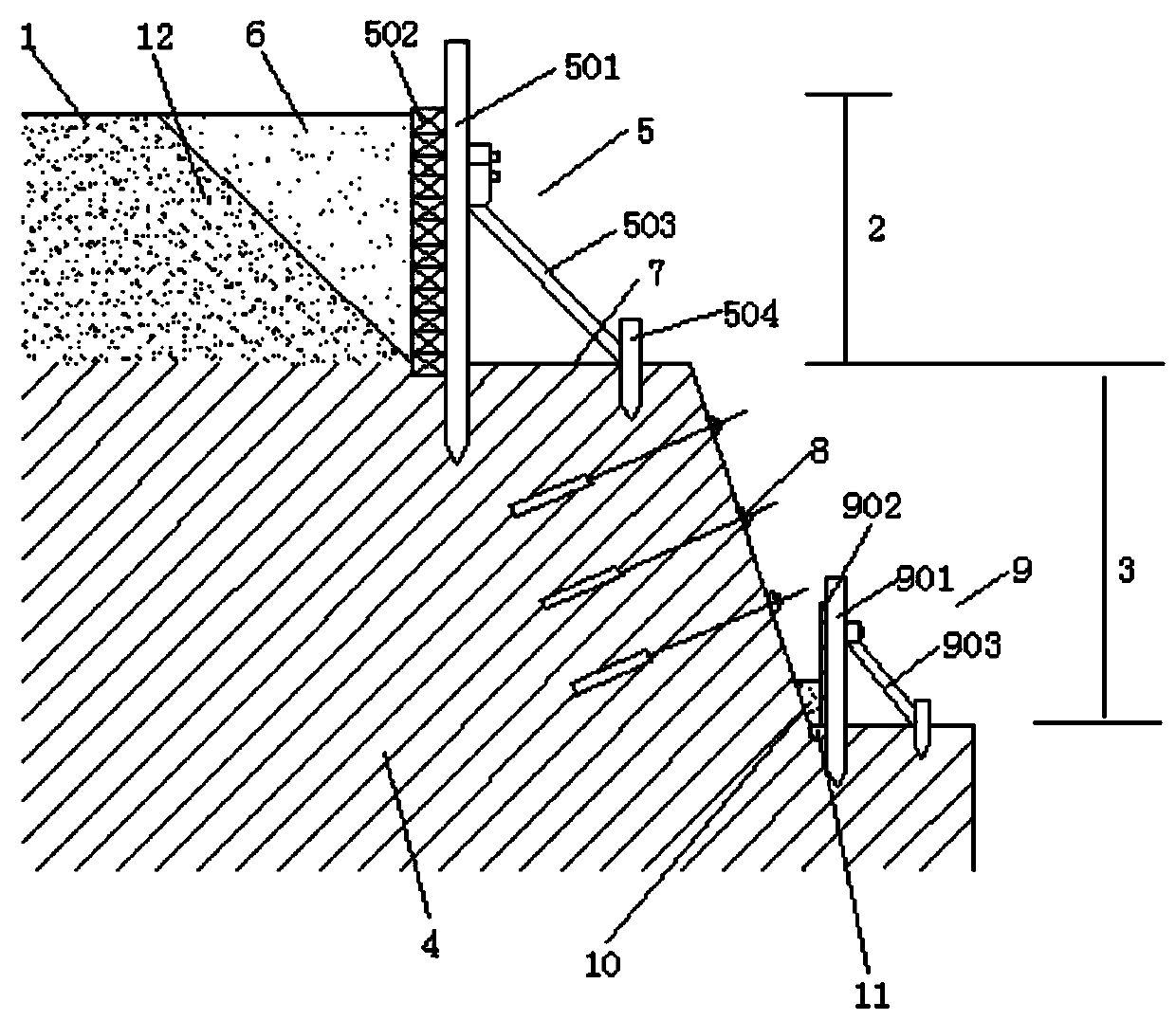

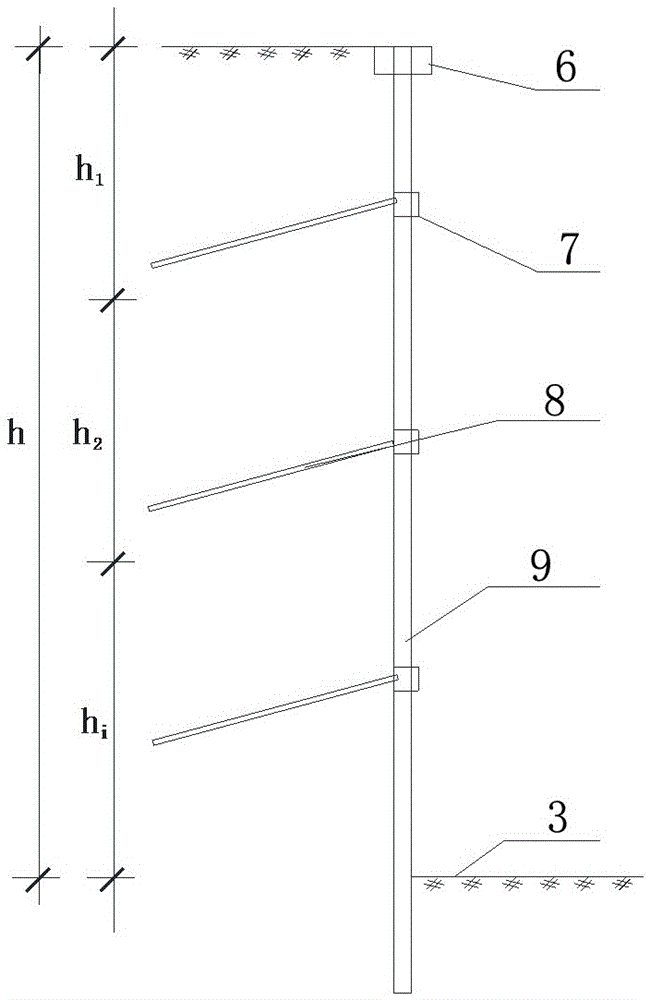

Embedding type anchoring device and anchoring method for pre-stressed anchor cable

The invention discloses an embedding type anchoring device for a pre-stressed anchor cable. The embedding type anchoring device comprises a strengthening structure connected with a soil blocking structure steel bar framework. The strengthening structure is provided with anchor supports. The anchor supports are provided with steel strand holes. According to the device, the anchor cable and soil blocking structures are directly connected. An anchoring method comprises the following specific steps that firstly, the soil blocking structure steel bar framework is manufactured, and the embedding type anchoring device for the pre-stressed anchor cable is fixed to the soil blocking structure steel bar framework; secondly, the soil blocking structure steel bar framework is hung in a preformed soil blocking structural hole, and concrete is poured in the soil blocking structure steel bar framework so as to form the multiple soil blocking structures; thirdly, after the concrete of the soil blocking structures is solidified, a concrete protection layer at the anchor supports is chiseled at the anchor cable elevation position to expose the steel strand holes; and fourthly, the free end of a steel strand of the anchor cable penetrates the steel strand holes, and tensioning and locking are achieved through an anchor. According to the method, construction is convenient, and the falling risk of the anchoring structure is avoided.

Owner:徐传召

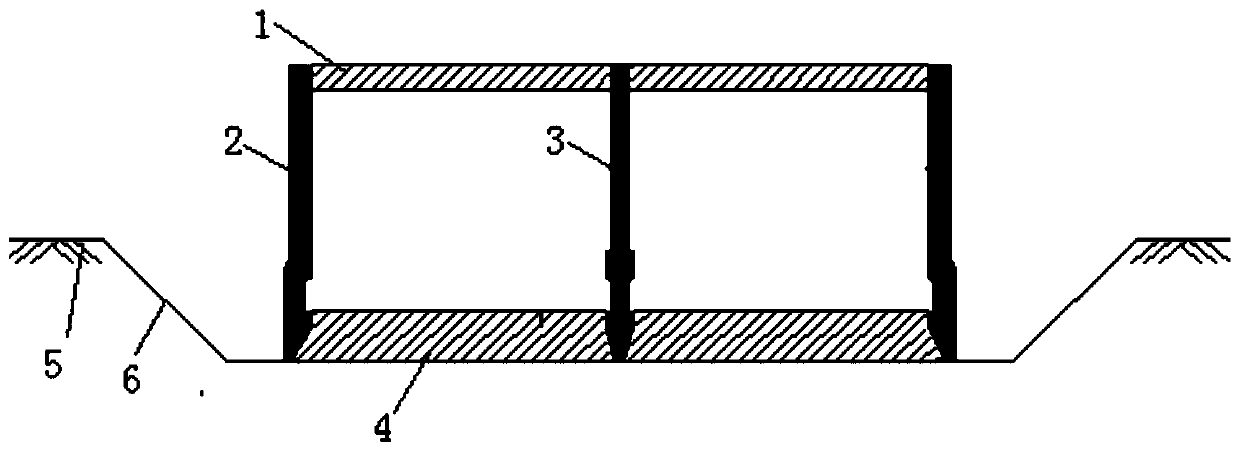

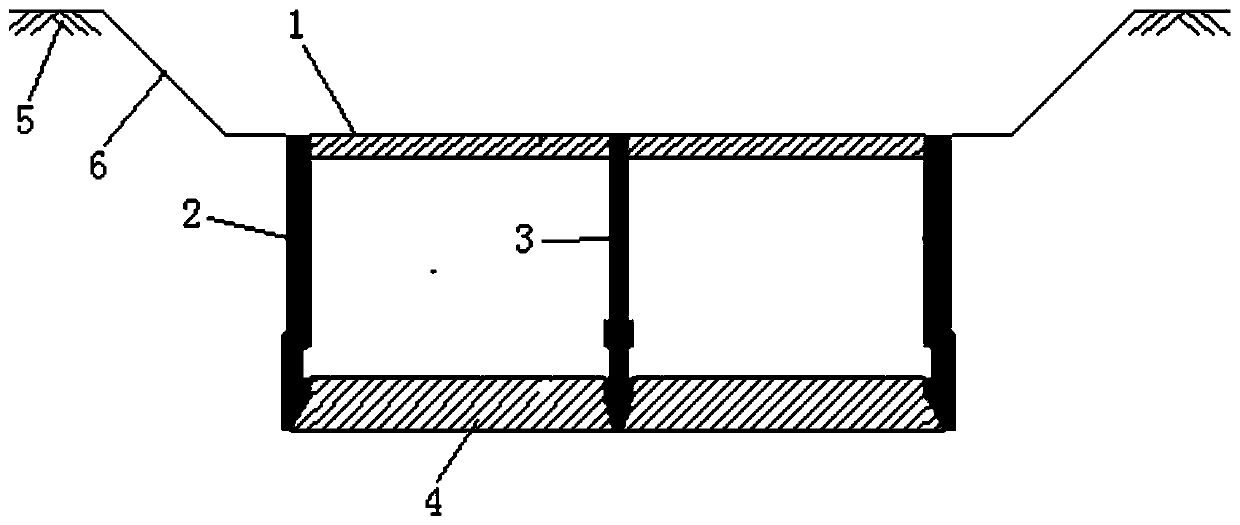

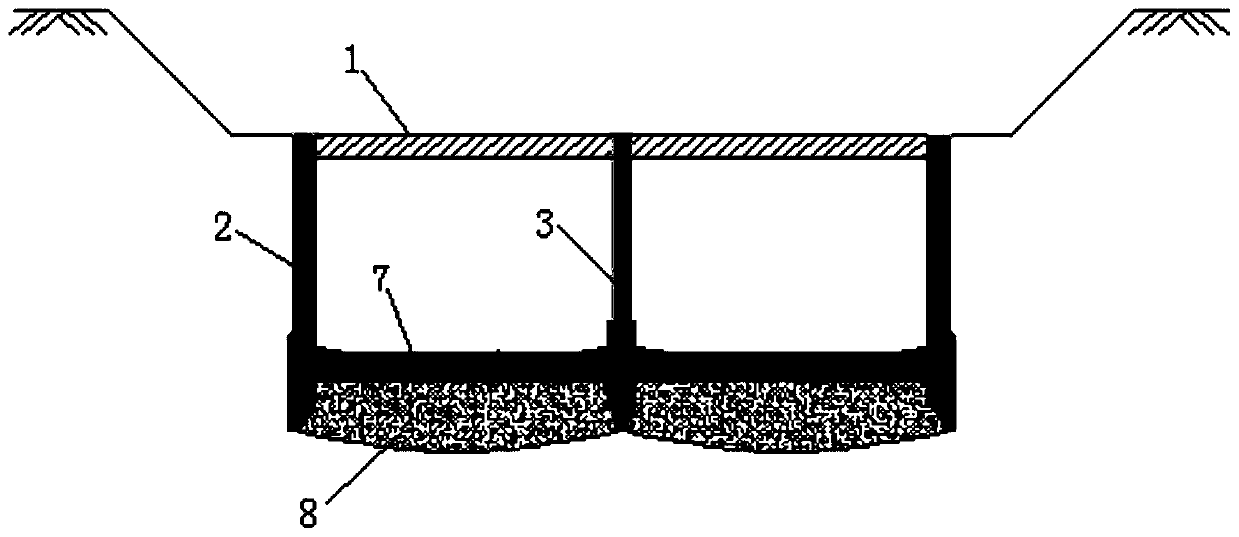

Underground integrated pipe corridor structure and sinking type construction method

InactiveCN109898556AStop landslideImprove construction safetyArtificial islandsUnderwater structuresBuilding construction

The invention relates to an underground integrated pipe corridor structure and a sinking type construction method. The underground integrated pipe corridor structure comprises side walls and a middlewall, the tops of the side walls and the middle wall are separately and fixedly connected with a roof, the bottoms of the side walls and the middle wall are separately and fixedly connected with a bottom plate, a back cover is arranged on the lower part of the bottom plate, a roof frame beam is arranged in the roof, and a bottom plate frame beam is arranged in the bottom plate. The underground integrated pipe corridor structure and the sinking type construction method can omit the process of excavation and support of a foundation pit, reduce the construction procedure, reduce the constructioncost, and reduce the construction period.

Owner:JINAN MUNICIPAL ENG DESIGN & RES INSITITUTE GRP

Outside-pit rescue emergency well construction method

InactiveCN110616728AReduce the amount of backfillImprove water qualityFoundation engineeringWellheadEngineering

The invention discloses an outside-pit rescue emergency well construction method, and relates to the technical field of infrastructure construction. The technical aim of foundation pit emergency rescue can be achieved. The method comprises the steps that a protection casing is tripped in a well hole, and the protection casing is used for forming supporting on the wall of the well hole; an emergency well tube is tripped into the protection casing, the middle tube segment of the emergency well tube is a dual-layer filter tube internally containing filter materials, and the upper tube segment andthe lower tube segment are waterproof solid tubes; the filter materials are backfilled into the annular space between the emergency well tube and the protection casing, and the top face of the backfilled filter materials is higher than the middle tube segment of the emergency well tube; the protection casing is lifted to the position which is higher than the middle tube segment of the emergency well tube and lower than the top face of the backfilled filter materials; a fixing clamp is used for fixing a well opening of the emergency well tube and the protection casing; and rescue water drawingcan be implemented; after emergency rescue is finished, the emergency well tube, and the protection casing are sequentially drawn out upwards; and the backfilled clay is used for filling and levelingup the well hole. The method can achieve rapid well sinking and rapid recycling.

Owner:SHANGHAI GUANGLIAN ENVIRONMENTAL & GEOTECHNICAL ENG CO LTD

Rapid construction method for U-shaped groove crossing existing culvert

The invention provides a rapid construction method for a U-shaped groove crossing an existing culvert, and belongs to the technical field of culvert U-shaped groove construction. The rapid construction method comprises the following steps that a U-shaped groove foundation pit is dug; supporting piles are applied; a U-shaped groove section culvert structure top plate is broken, the pile tops of theconstructed supporting piles are removed, and pile top anchoring crown beam steel bars are reserved; full-hall supports are erected in the culvert; a pile top crown beam, a structural distribution beam and co-building structure steel bars of a U-shaped groove bottom plate and the culvert top plate are applied; and after the co-building structure of the U-shaped groove bottom plate and the culverttop plate is cast and formed at a time by adopting C35 concrete, wall bodies on both sides of the U-shaped groove are constructed through pulling a vertical formwork in opposite, and a U-shaped groove wall rear soil body is backfilled after the strength is achieved. According to the rapid construction method, on the premise of ensuring the normal using function of the existing culvert and reducing the influence of peripheral pipelines, the construction efficiency of the U-shaped groove is improved to the greatest extent, and the construction process is simplified.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

Environment-friendly prefabricated integral comprehensive pipe gallery and assembling method thereof

PendingCN109469103AImprove waterproof performanceGuaranteed drynessArtificial islandsProtective foundationRebarWall plate

The invention discloses an environment-friendly prefabricated integral comprehensive pipe gallery and an assembling method thereof. The environment-friendly prefabricated integral comprehensive pipe gallery comprises multiple pipe gallery units which are sequentially arranged in the length direction of the comprehensive pipe gallery, and each pipe gallery unit comprises a prefabricated bottom plate, a first cast-in-situ wall plate, a second cast-in-situ wall plate, a prefabricated bin separating plate and two prefabricated C-shaped outer wall plates; each prefabricated C-shaped outer wall plate comprises a main wall plate extending in the height direction of the comprehensive pipe gallery and two auxiliary wall plates which are oppositely arranged at the two ends of the main wall plate; anchoring reinforcement bars used for stretching into the first cast-in-situ wall plates are embedded into the first auxiliary wall plates; anchoring reinforcement bars used for stretching into the second cast-in-situ wall plates are embedded into the second auxiliary wall plates; and the prefabricated bin separating plates partition a pipe gallery channel into a plurality of independent pipe gallery subchannels. According to the environment-friendly prefabricated integral comprehensive pipe gallery and the assembling method thereof, all the prefabricated parts are small in section area, low inweight, simple in structure, low in comprehensive cost and excellent in structural strength and shear resistance, and site construction pollution is low.

Owner:SHANGHAI JOHNSON ARCHITECTURAL & ENG DESIGN CONSULTANTS

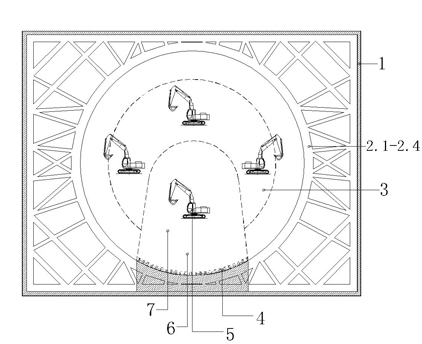

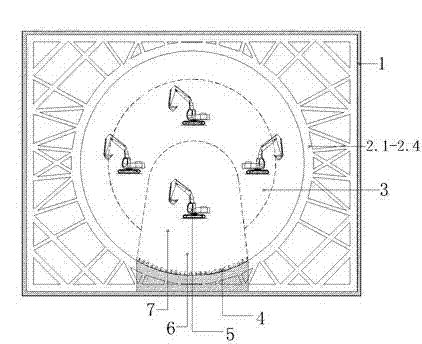

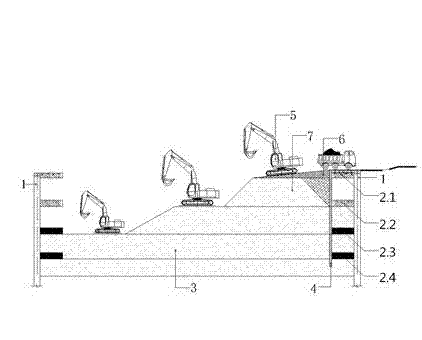

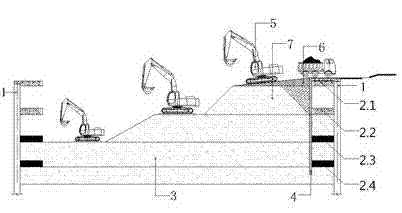

Excavation method of large-diameter cylindrical tailrace surge chamber

ActiveCN108755622AEnsure safetyReduce the maximum spanWater-power plantsHydro energy generationStress concentrationCarrying capacity

The invention relates to an excavation method of a large-diameter cylindrical tailrace surge chamber and belongs to the technical field of water conservancy and hydropower underground engineering construction. The excavation method adopts the technical scheme that firstly, middle drift penetrating and reserved protection layer stage excavation are performed, partitioning penetrating is conducted from inside to outside, and thin-layer excavation and layer-by-layer supporting are adopted; stage adjustment and releasing of surrounding rock stress are achieved, and stress drastic adjustment aftersurrounding rock excavation decompression caused by deep-hole-bench large-charge blasting is avoided; fork segment tailwater pipes adopt pre-stressed anchor cable reinforced supporting and first-stageside wall and vault concrete pouring which are are combined, and the two adjacent tailwater pipes adopt the comprehensive excavation construction scheme of drift vertical excavation and layer-by-layer supporting, and the carrying capacity of a bottom fork reserved rock partition wall is remarkably improved. Since the two adjacent tailwater pipes adopt the comprehensive excavation construction scheme of drift vertical excavation and layer-by-layer supporting, the problems that the surrounding rock stress state after practical engineering construction excavation is implemented is complex, driftintersection positions have stress concentration and large plastic zones, and the construction technical difficulty is high are solved.

Owner:SINOHYDRO BUREAU 14 CO LTD

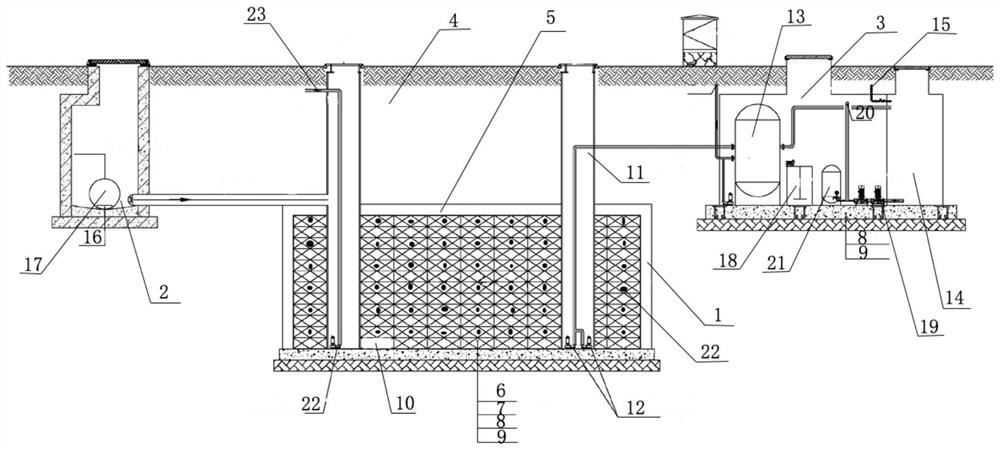

Buried integrated rainwater recycling system and construction method thereof

PendingCN113638481AReduce usage intensityMeet load requirementsFatty/oily/floating substances removal devicesSewerage structuresWater storageMicroorganism

The invention discloses a buried integrated rainwater recycling system and a construction method thereof. The buried integrated rainwater recycling system comprises a rainwater collecting pool, a safety flow dividing well and a rainwater recycling and utilizing device, and the rainwater collecting pool is correspondingly connected with the safety flow dividing well and the rainwater recycling and utilizing device; the rainwater collecting pool sequentially comprises vegetation soil, a medium sand protection layer, a water storage module framework, composite waterproof geotechnical cloth, a concrete foundation and plain soil from top to bottom; a microbial carrier ball and an aeration device are arranged in the water storage module framework, and a microbial flora is adhered to the microbial carrier ball; and a sewage discharging well is arranged in the water storage module framework, a rainwater lifting pump is arranged in the sewage discharging well, and the rainwater lifting pump is connected with the rainwater recycling and utilizing device through a pipeline. The rainwater recycling efficiency is improved, urban inland inundation is relieved, and the ecological environment is protected.

Owner:JIANGSU SHANSHUI ENVIRONMENT CONSTR GRP

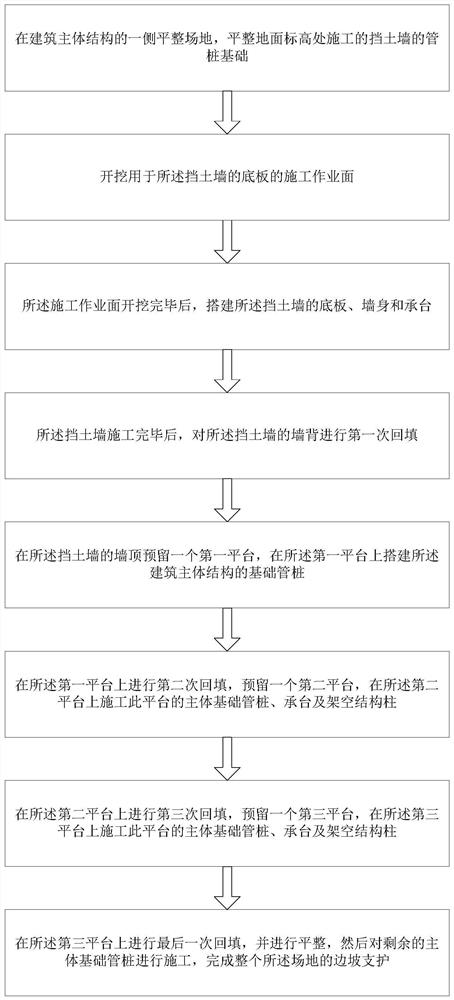

Slope support construction method combined with building main body structure

InactiveCN113417301AReduce riskReduce the amount of backfillArtificial islandsExcavationsArchitectural engineeringRetaining wall

The invention provides a slope support construction method combined with a building main body structure. The method comprises the following steps of leveling a site, excavating a construction working surface of a bottom plate of a retaining wall, building the bottom plate, a wall body and a bearing platform of the retaining wall, carrying out primary backfilling, reserving a first platform on the wall top of the retaining wall, building a foundation pipe pile of a building main body structure, performing secondary backfilling, reserving a second platform, constructing a main body foundation pipe pile, a bearing platform and an overhead structure column of the platform, performing third backfilling, reserving a third platform, constructing a main body foundation pipe pile, a bearing platform and an overhead structure column of the platform, performing final backfilling, flattening, constructing main body foundation pipe piles and finishing slope support. By flexibly adopting a combined form of vertical support and step-slope support with different heights, the building main body structure is overhead for graded step-slope, so that the aims of reducing the vertical support height, reducing the risk of an ultrahigh retaining wall, reducing the earthwork backfilling amount and saving the construction cost are fulfilled.

Owner:广东佰业泰建设工程有限公司

A kind of construction method of rapid trough on high and steep slope

ActiveCN110607784BReduce the amount of backfillReduce traffic safety risksBlastingArtificial water canalsSlagSteep slope

The invention belongs to the technical field of water conservancy and hydropower construction engineering, and relates to a construction method for excavating rapid flow troughs on high and steep slopes. The trough and the slag chute are excavated in reverse from bottom to top, and the cross-section is an inverted trapezoid; before excavation of the slag chute, the main air supply pipeline is arranged from bottom to top along the downstream direction of the rapid flow chute, and reserved every 8-10m One branch pipe interface, the main air pipe pipe adopts φ108mm steel pipe; (2) Excavate the protective layer from the top to the bottom; (3) The slag body slides to the bottom of the trough along the slag chute, forming a slag accumulation platform at the bottom of the trough. The slag accumulation platform is used to clean the slag body; this construction method can avoid the excavation slag body from collapsing completely during the excavation of the rapid flow trough, which can reduce the construction environmental protection risk, reduce the construction safety risk, relieve the pressure of the construction period, and ensure the smooth flow. Reduce temporary road traffic safety risks.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

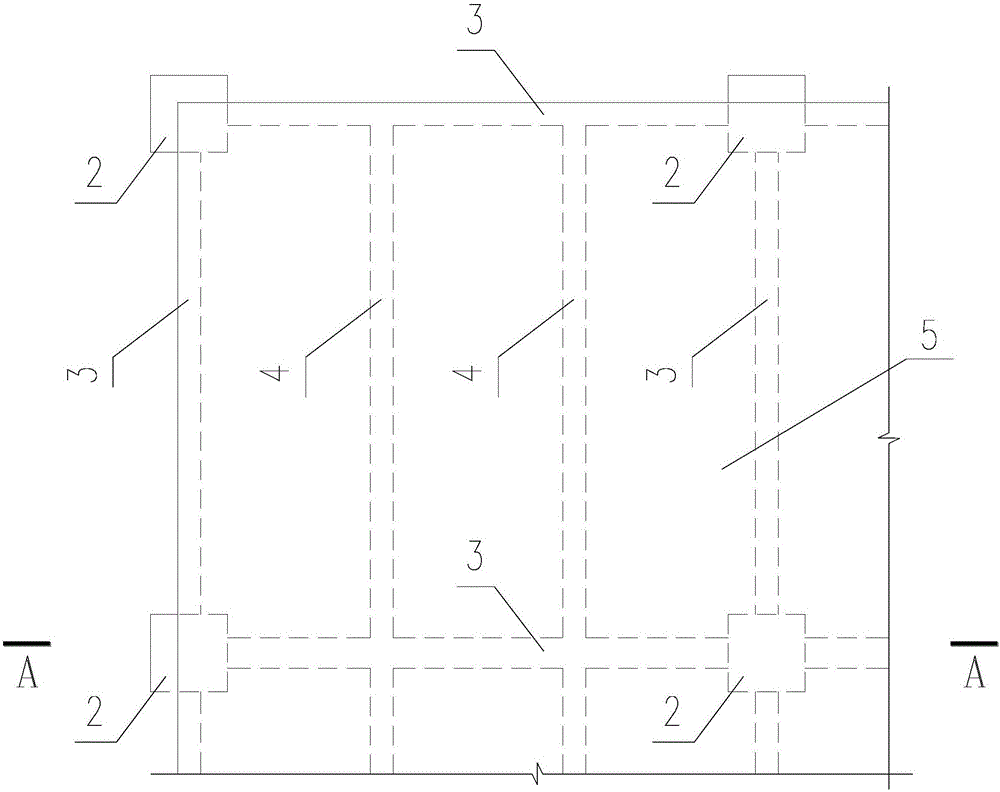

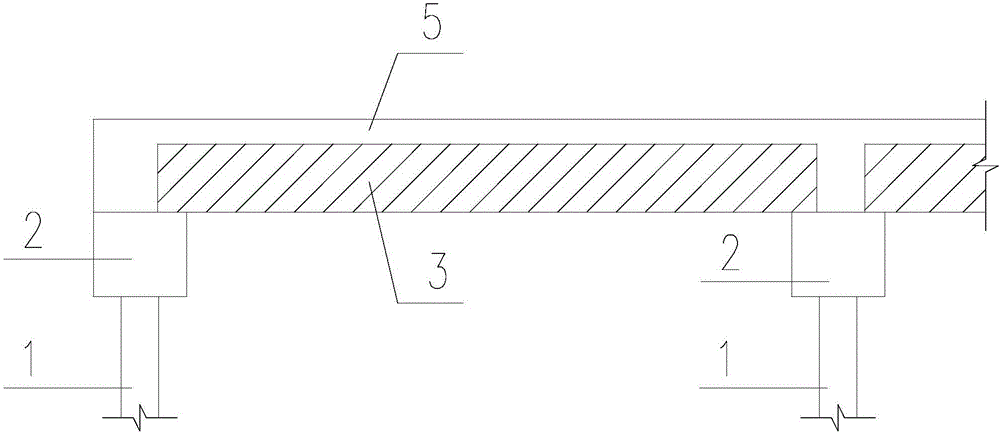

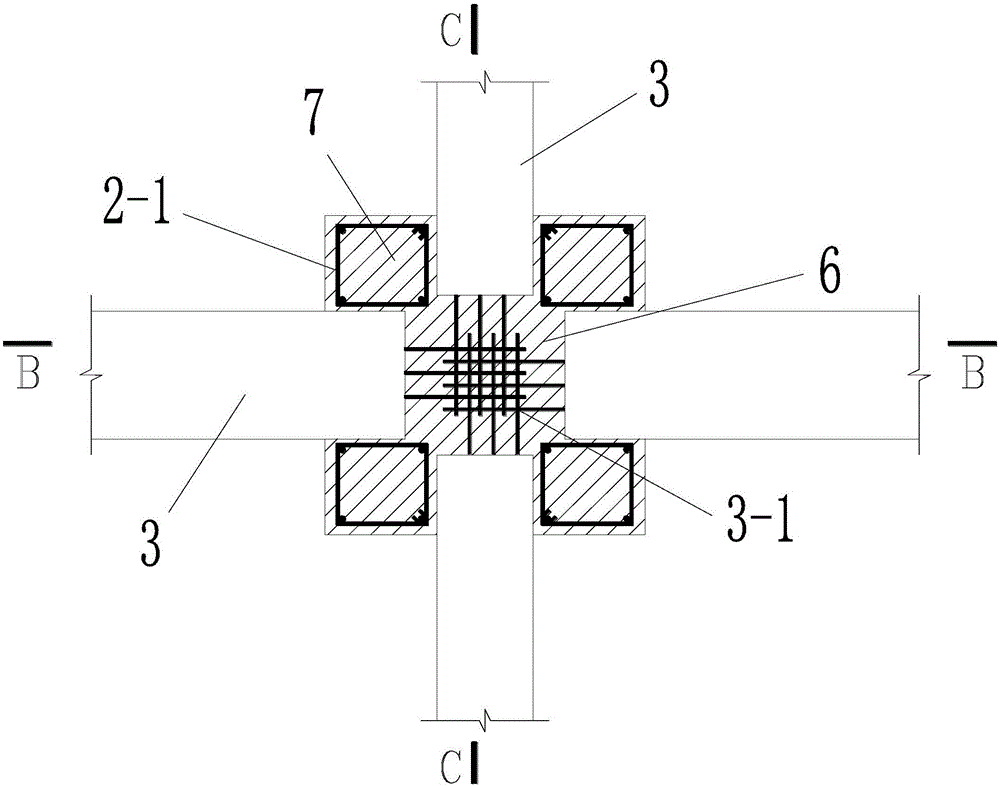

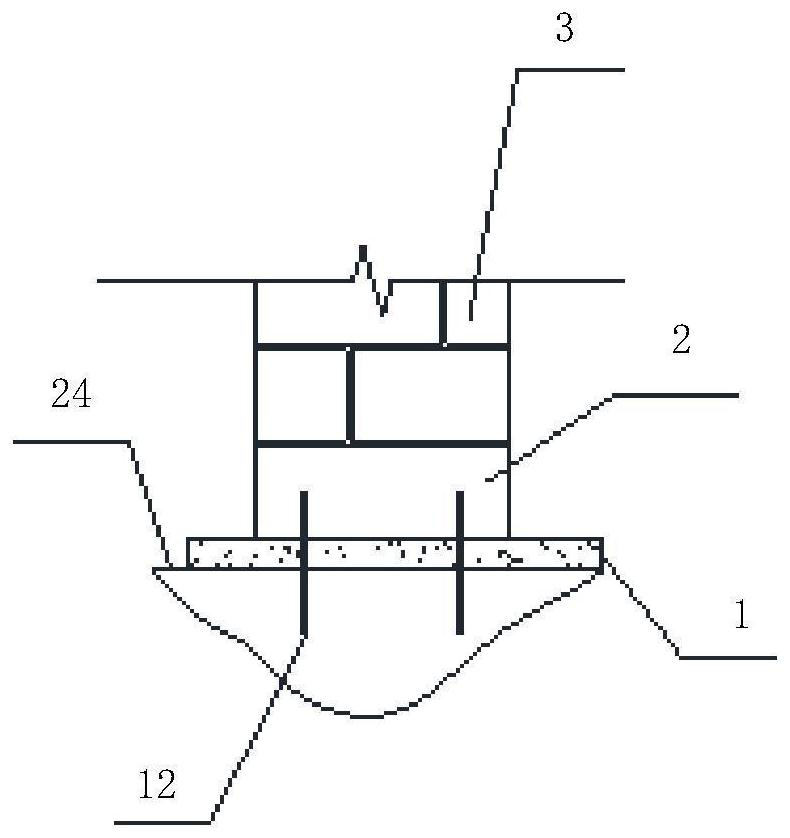

Prefabricated ground and construction method

InactiveCN106677202AFast construction on siteShort payback periodSoil preservationEconomic benefitsHouse building

The invention relates to a prefabricated ground. The prefabricated ground comprises a plurality of pile foundation assemblies arranged in a foundation and distributed in an array manner, main beams each erected between two corresponding adjacent pile foundation assemblies and a bottom plate supported on the main beams. Each pile foundation assembly comprises a preformed pile and a bearing table fixedly arranged at the upper end of the preformed pile. One aim of the prefabricated ground is to provide the prefabricated ground capable of increasing the engineering construction speed and quality. The prefabricated ground has the beneficial effects that the site construction speed of the prefabricated ground is high and is one few hundredth of the time needed for a conventional foundation treatment scheme, and therefore the investment recovery period is shortened, the overall cost input is reduced, and remarkable economic benefits are achieved; and deformation of the prefabricated ground in the using period is remarkably reduced relative to that of the conventional foundation treatment scheme, and the maintenance cost of house buildings in the using period can be reduced.

Owner:ARCHITECTURAL DESIGN INST FUKIEN PROV

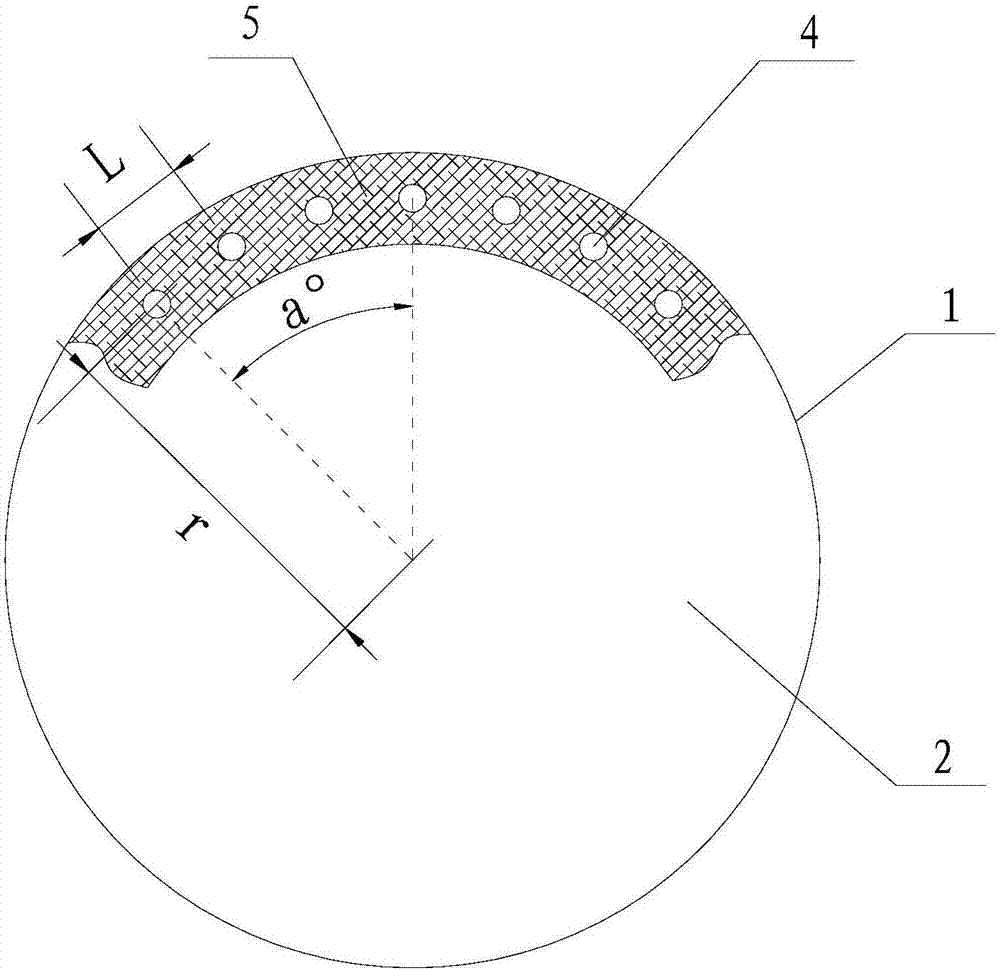

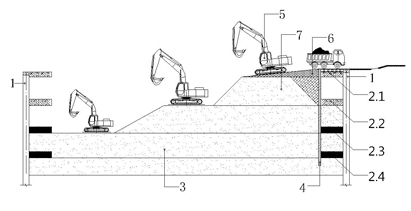

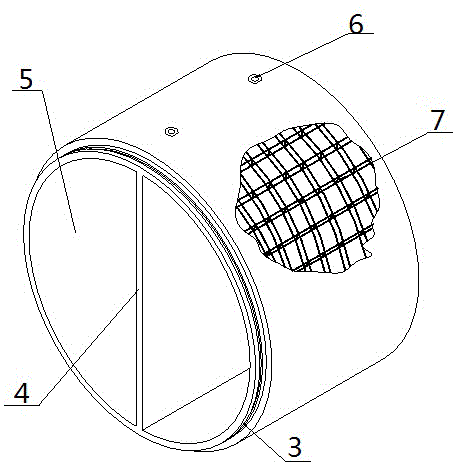

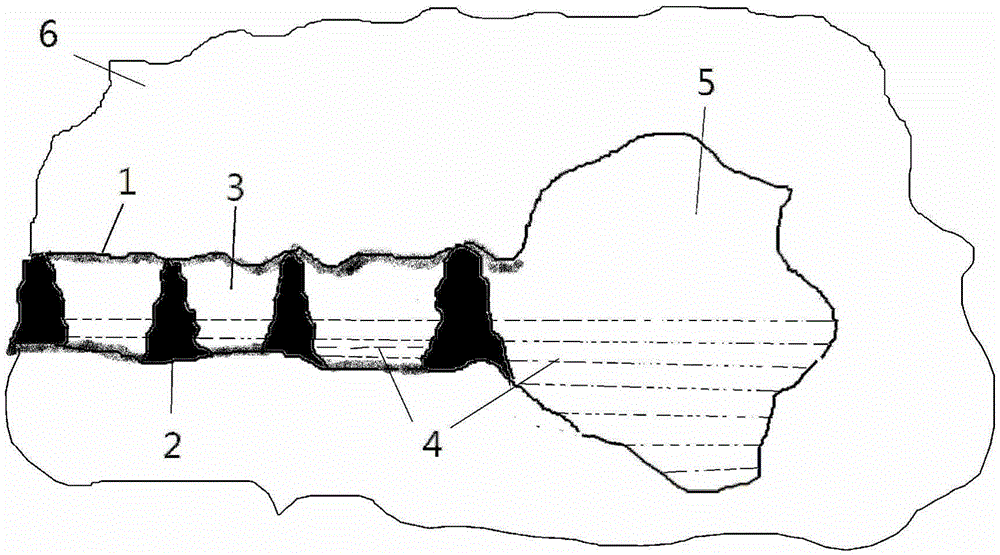

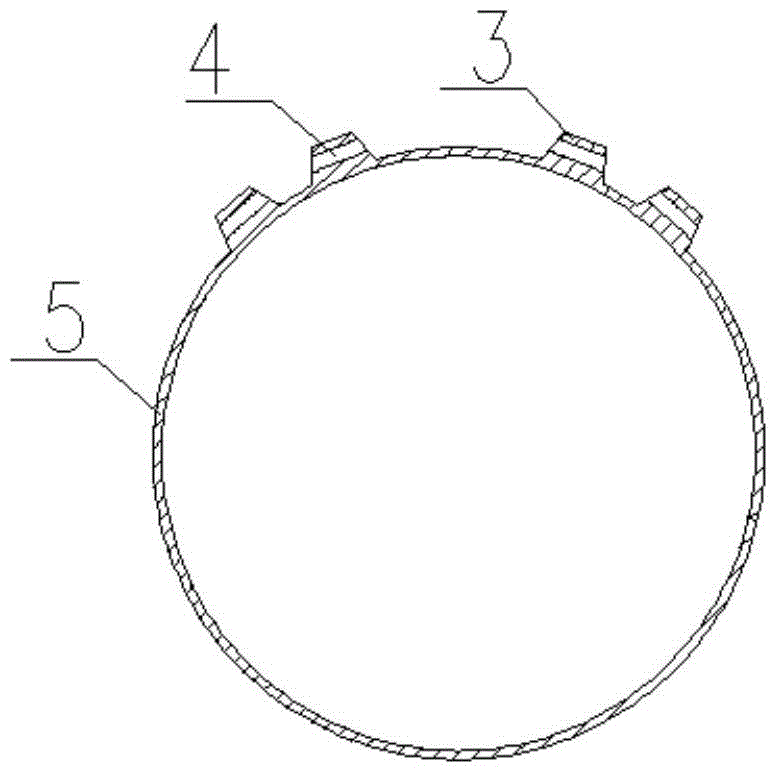

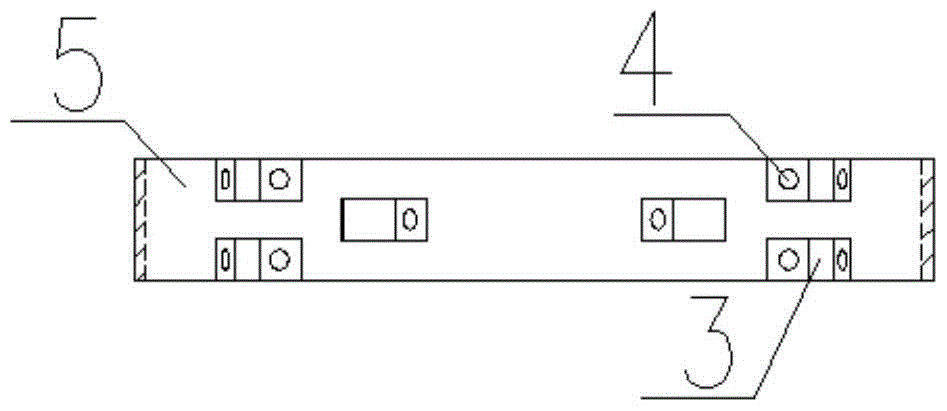

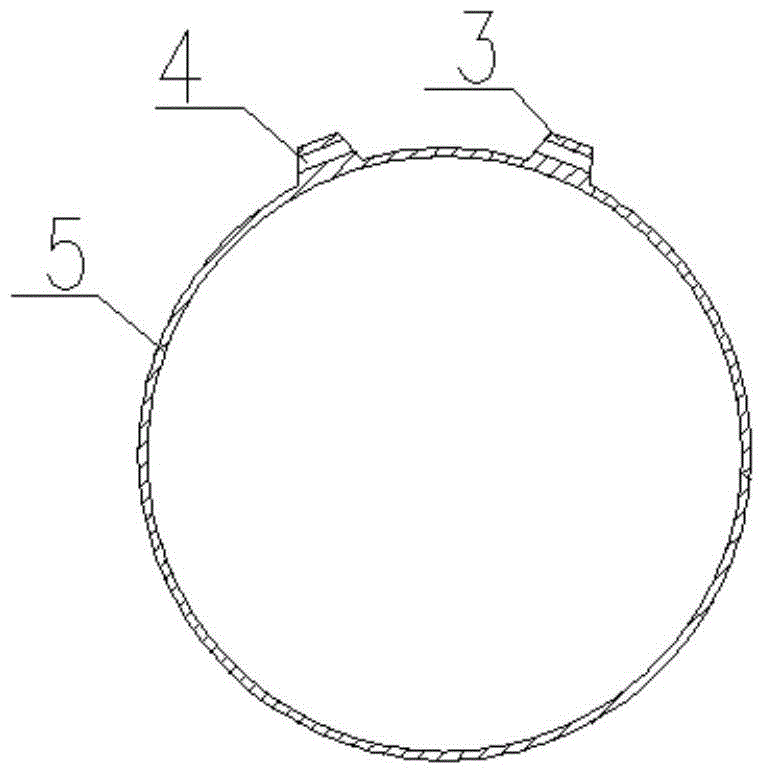

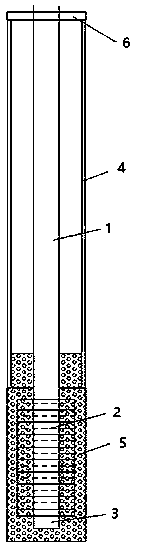

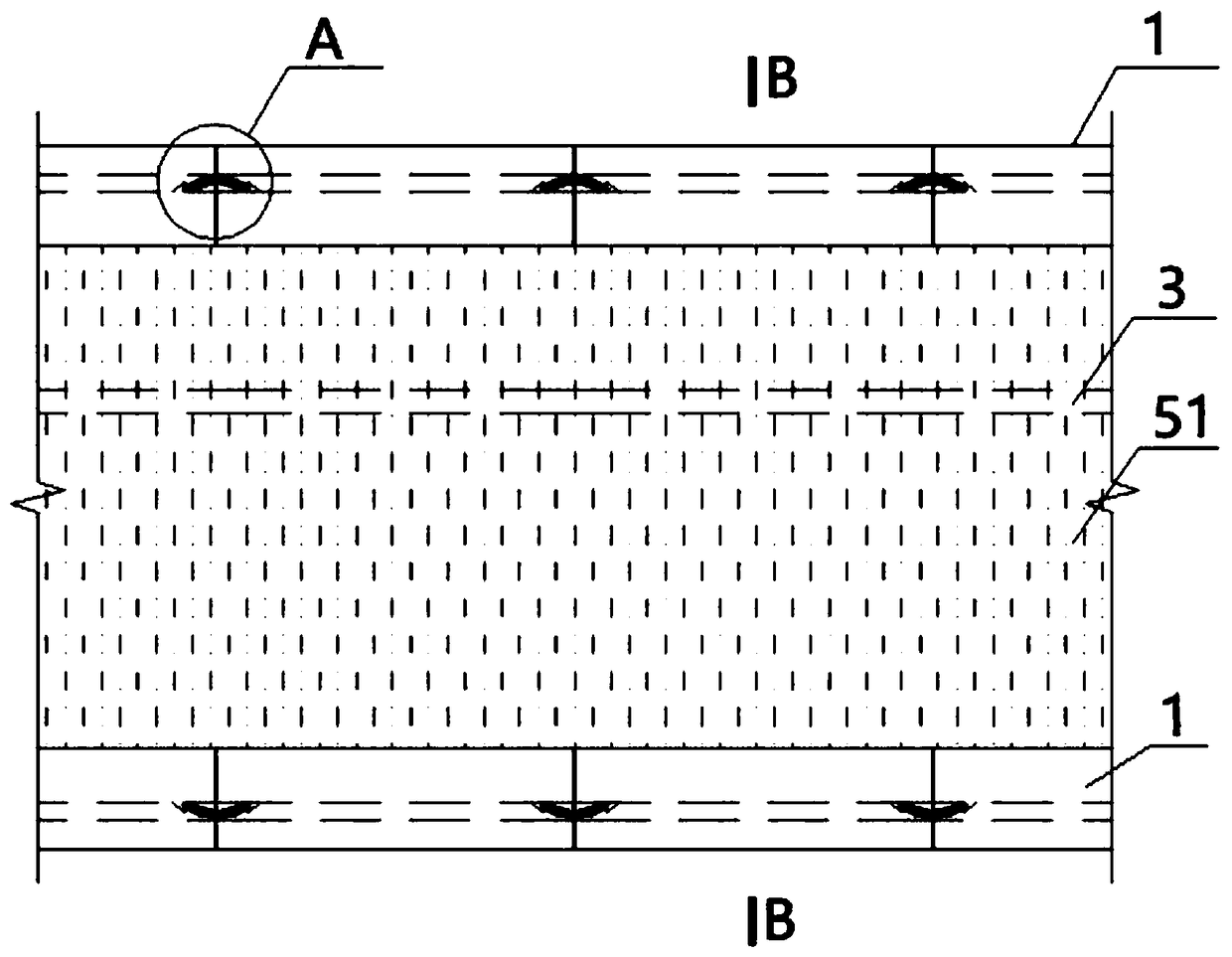

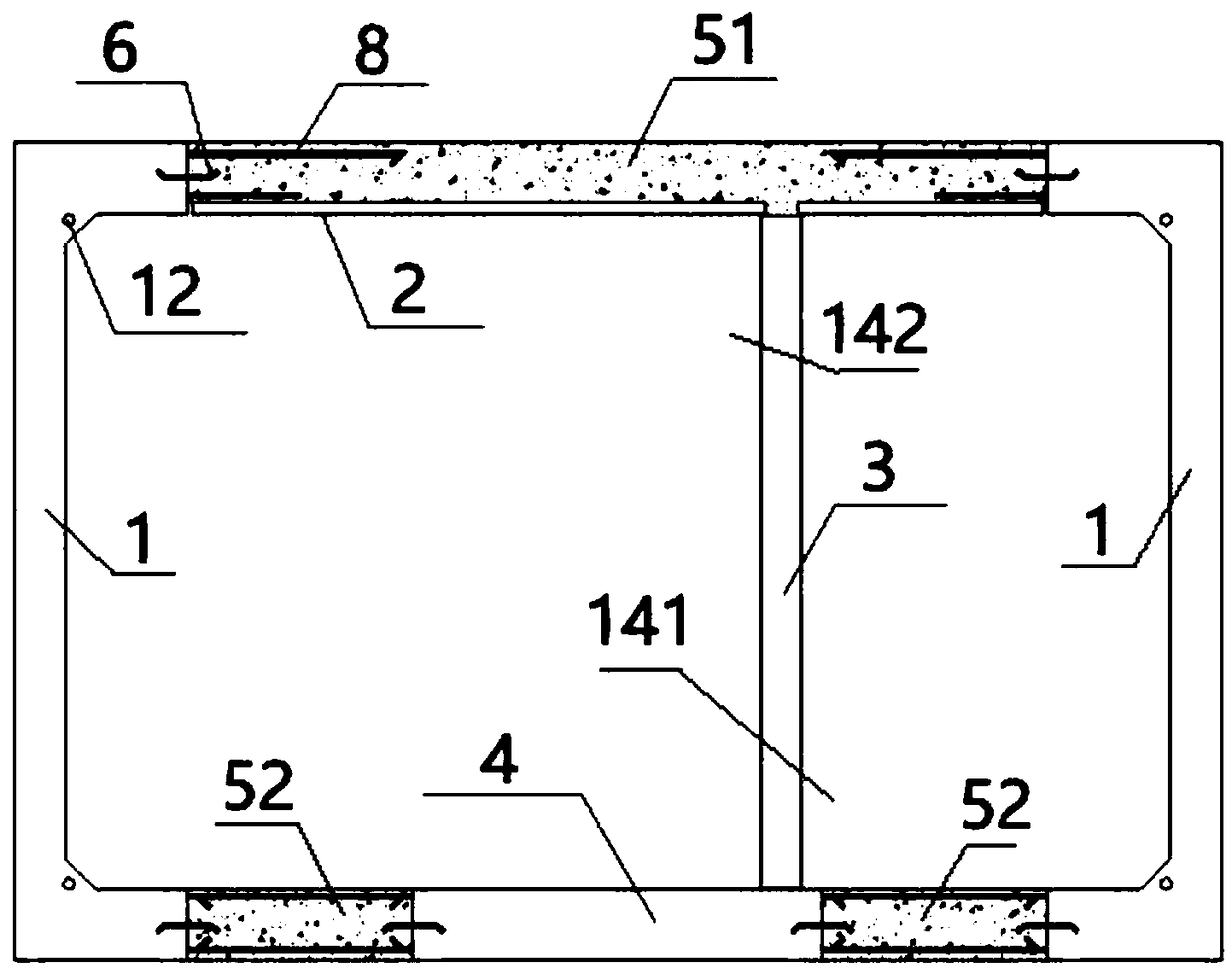

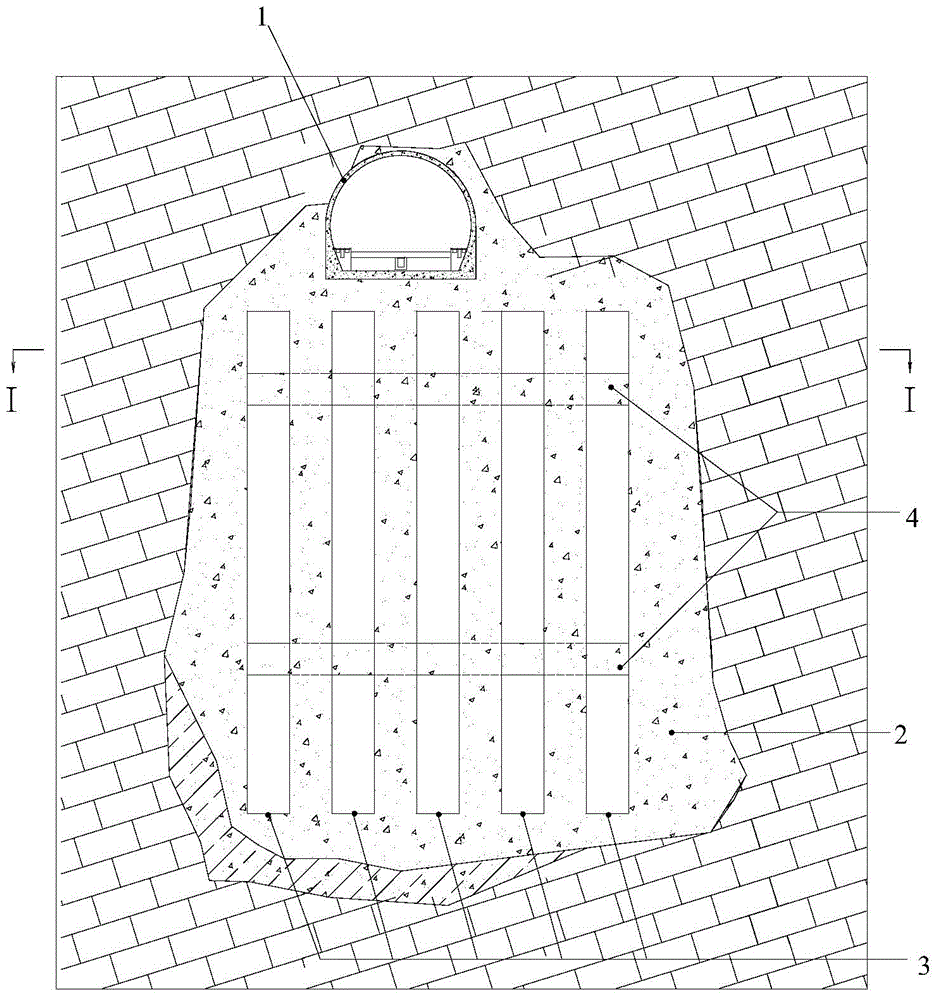

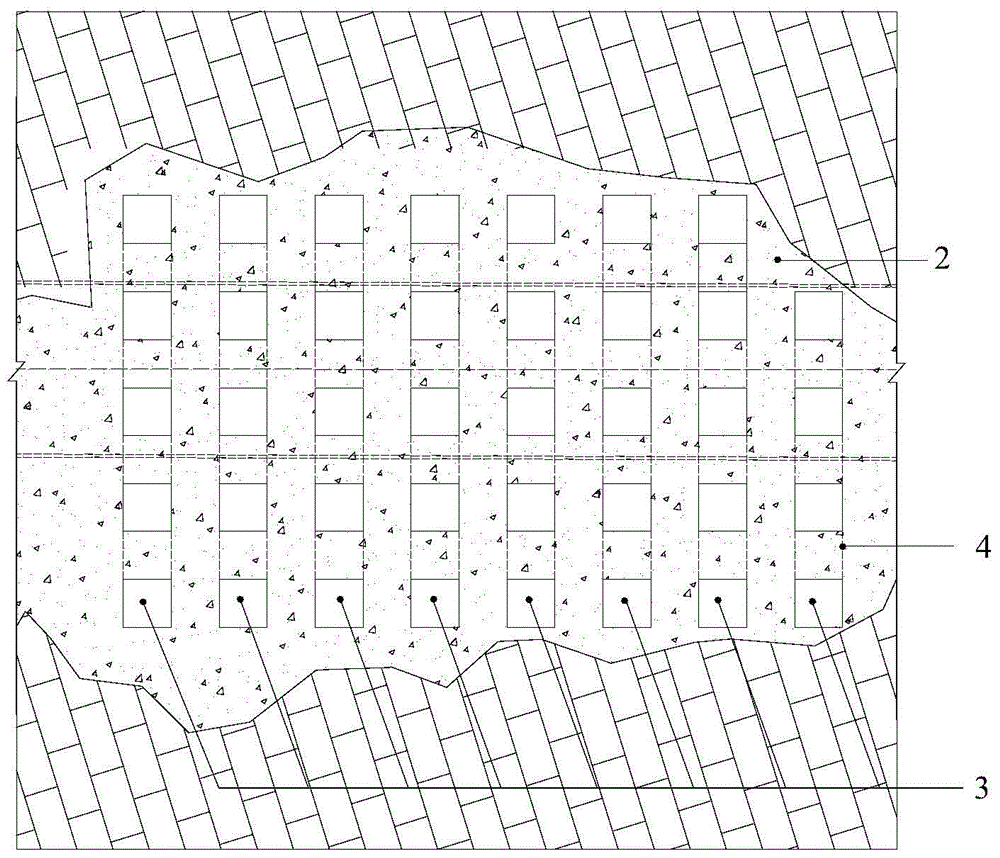

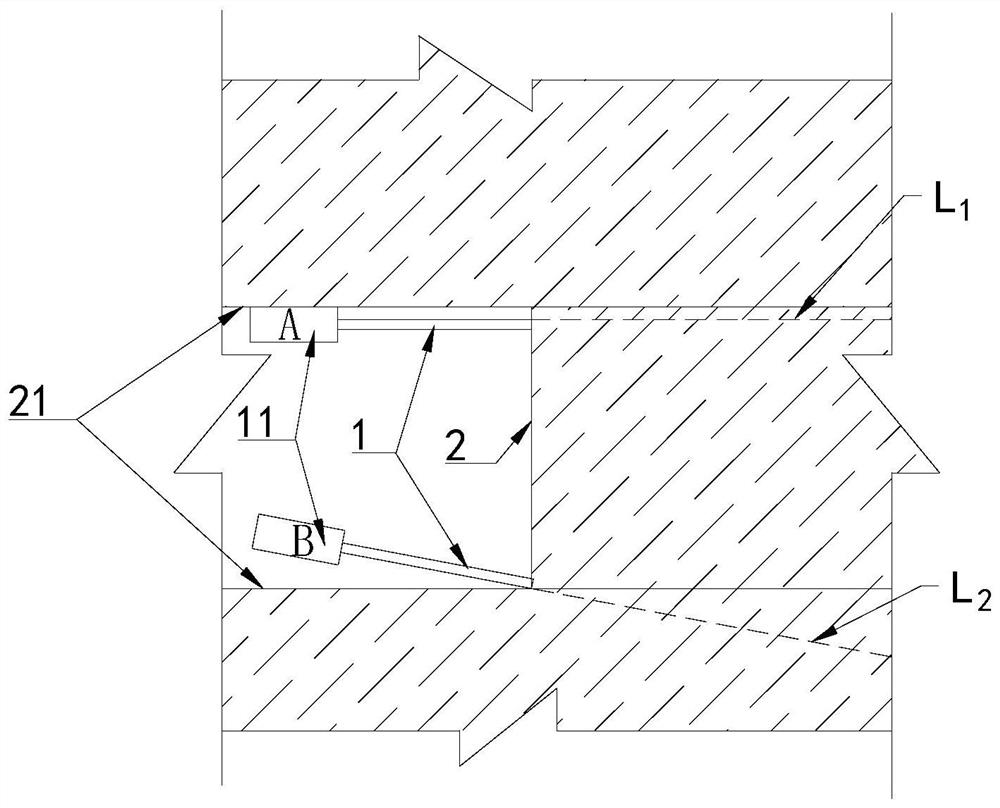

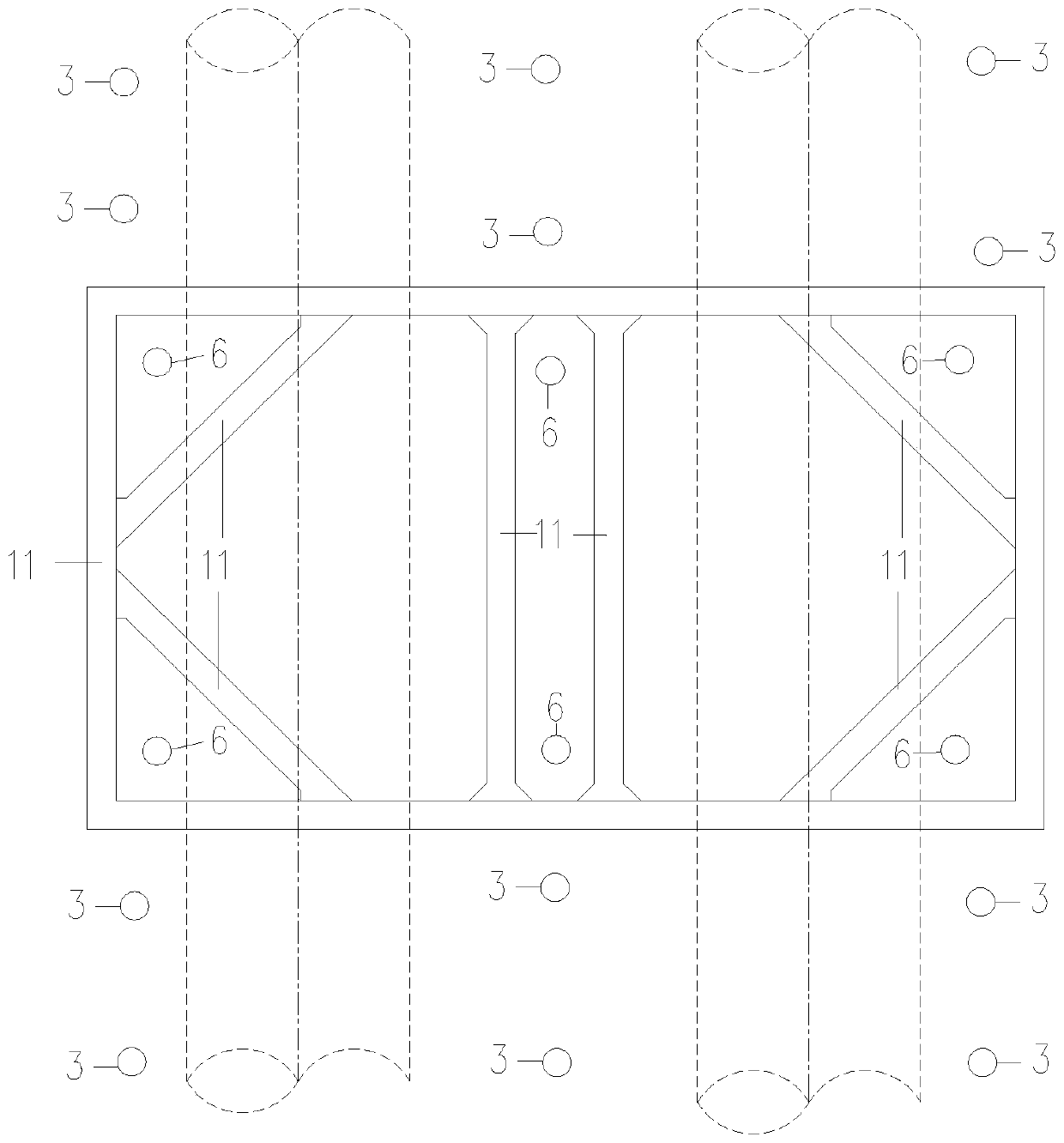

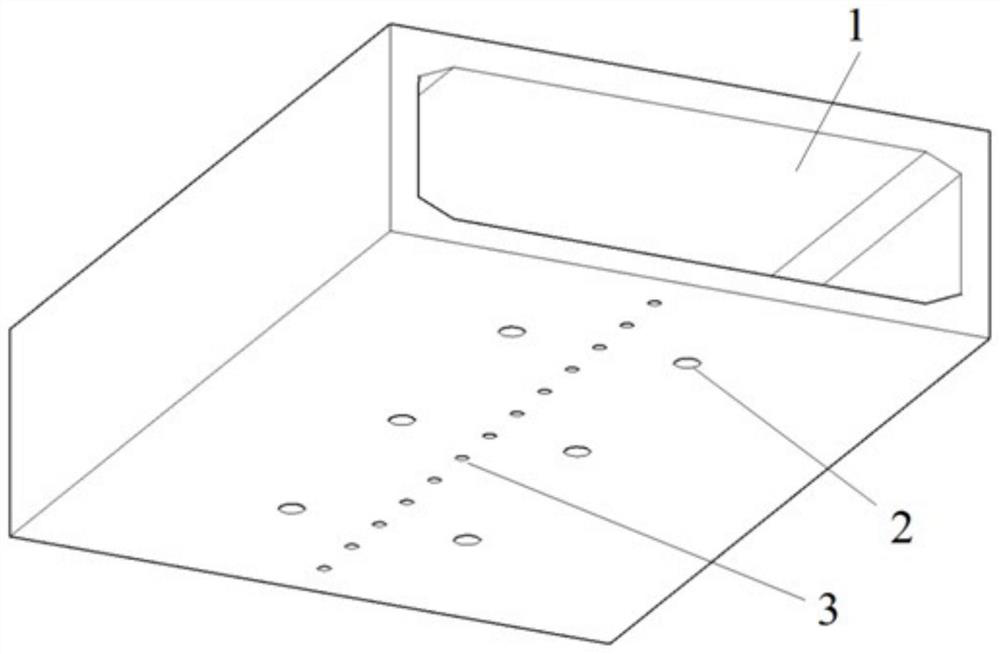

Massive hollow concrete structures for backfilling of large cavities

ActiveCN103498477BReduce the amount of backfillLow costUnderground chambersEmbankmentsEngineeringHollow core

The large-volume hollow concrete structure used for backfilling large-scale cavities can minimize the amount of concrete while ensuring the safety and reliability of the structure. It includes a backfill concrete body (2) filled between the outer wall of the tunnel lining (1) and the rock wall of a large cavity. Vertical holes (3) are laid out in the backfill concrete body (2) along the horizontal and vertical intervals. Concrete transverse connecting plates (4) are arranged at vertical intervals toward the holes (3).

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

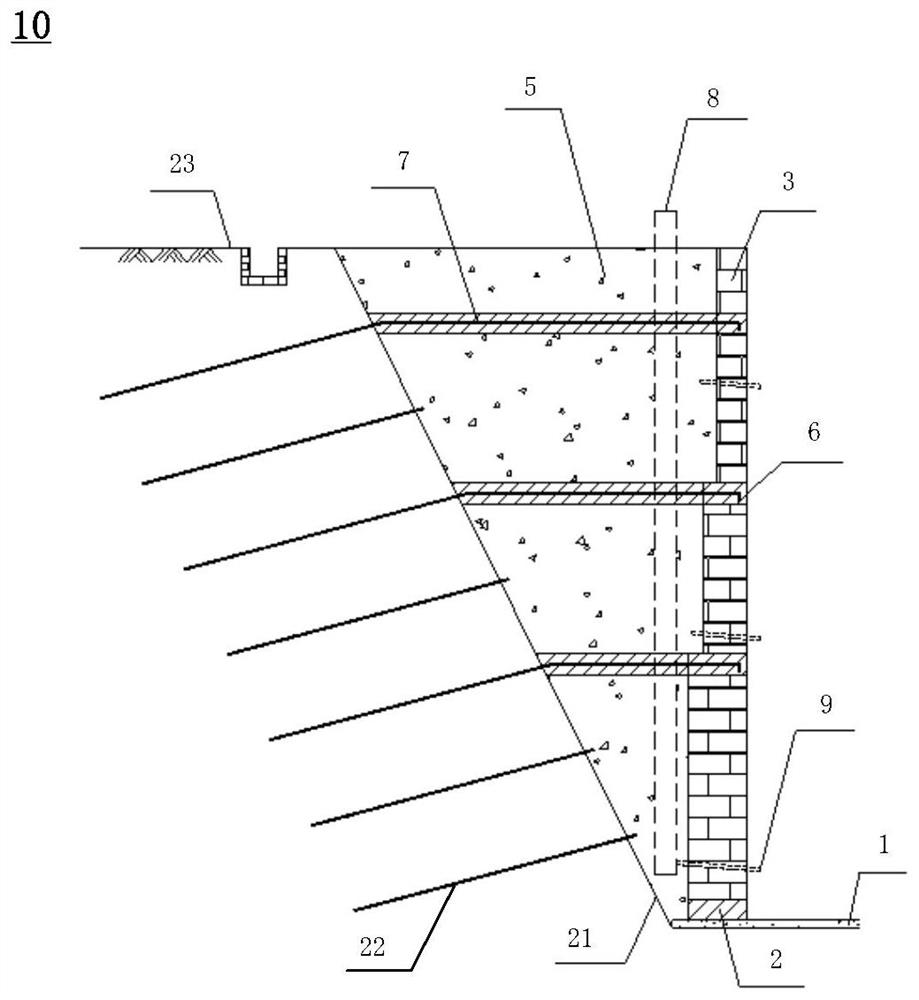

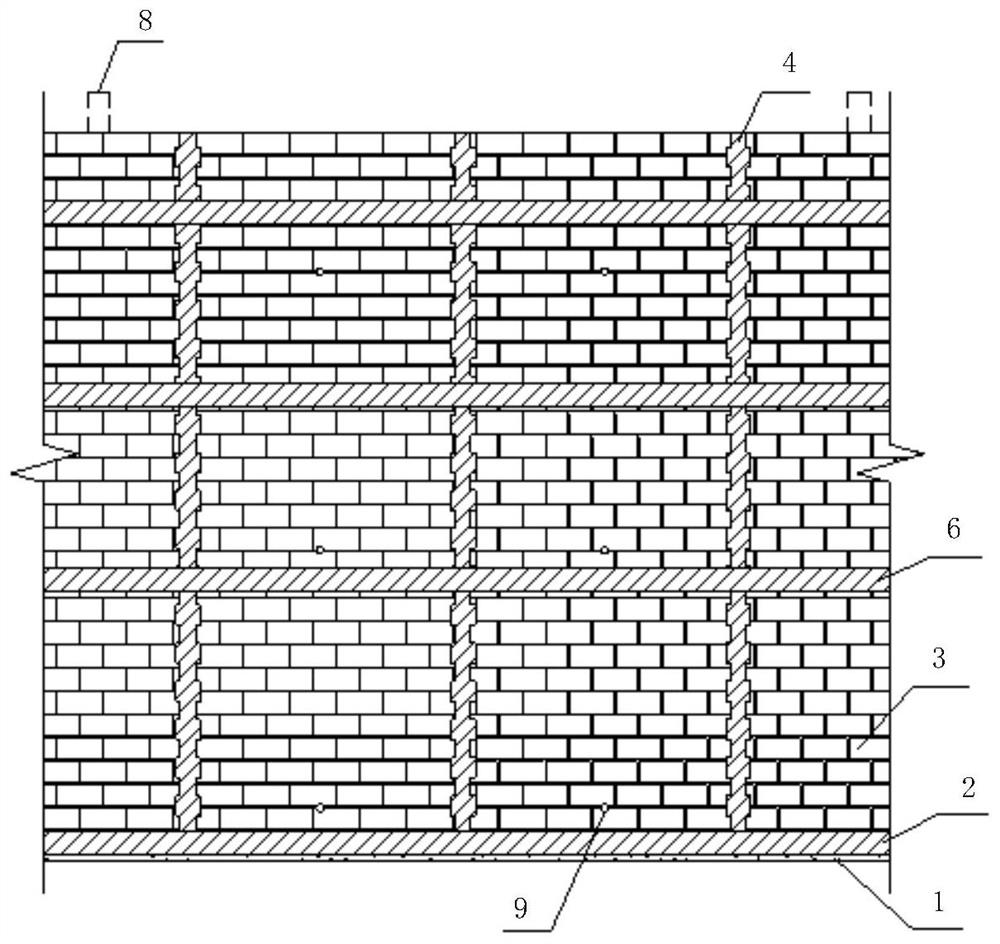

Reverse Construction Method of Adjacent High and Low Floors (Spans) of Basement

ActiveCN105714849BSmall amount of workReduce the amount of backfillArtificial islandsProtective foundationBasementBrick

The invention provides a reverse construction method for adjacent high and low floors (bays) of a basement. The reverse construction method comprises the following steps: S1, performing slope excavation to a high-floor (bay) area along a boundary of the high and low floors (bays); S2, after the excavation is over, moving the outer edge line of a to-be-cast boundary wall through a distance of the sum of the thicknesses of a waterproof layer and a waterproof protection layer to form a brick form edge line, and laying a brick form along the brick form edge line; S3, after laying of the brick form is over, backfilling the high-floor (bay) side of a slope-excavated part of a boundary area with cyclopean concrete; S4, after backfilling of the cyclopean concrete is over, performing waterproof construction on the low-floor (bay) side of the brick form; S5, after the waterproof construction is over, constructing a low-floor (bay) foundation slab; and S6, simultaneously performing casting construction of the boundary wall and a high-floor (bay) foundation slab. According to the reverse construction method, no slope support construction is needed, the work amount and backfilling amount of earth rock excavation are reduced, the cost of waterproof steel plates is lowered, the construction period is shortened, and the construction cost is lowered.

Owner:CHINA HUAYE GROUP

Drainage system used in cities, towns and communities

ActiveCN101666116BEffective interceptionNo pollution in the processSewerage structuresSewage drainingEngineeringSewage

The invention requests to protect a drainage system used in cities, towns and communities, which is formed by connecting at least a co-line divided-flow dual-layer drainage pipe and channel or a common drainage pipe and channel with a rainwater-sewage compound dual-layer manhole. An intercepting rainwater-sewage compound dual-layer drainage manhole can be arranged on the drainage system accordingto the requirement so as to realize that the initial surface runoff is intercepted into a sewage pipe and channel and is delivered to a sewage treatment plant to be treated, and a non-intercepting rainwater-sewage compound dual-layer drainage manhole can be arranged according to the requirements of direction change, gradient change, connector change, pipe and channel intersection, examination andrepair of linear pipes and channels every certain distance and other special purposes. The drainage system can realize individual delivery and drainage of the rainwater and sewage by layers on the same pipeline and has the characteristics of simple pipelines, few manholes, low investment, operation and maintenance cost, capability of reducing the pollution effects of first rain runoff in an economic and effective manner, and no rainwater-sewage interflow and overflow water pollution, etc.

Owner:CHONGQING UNIV

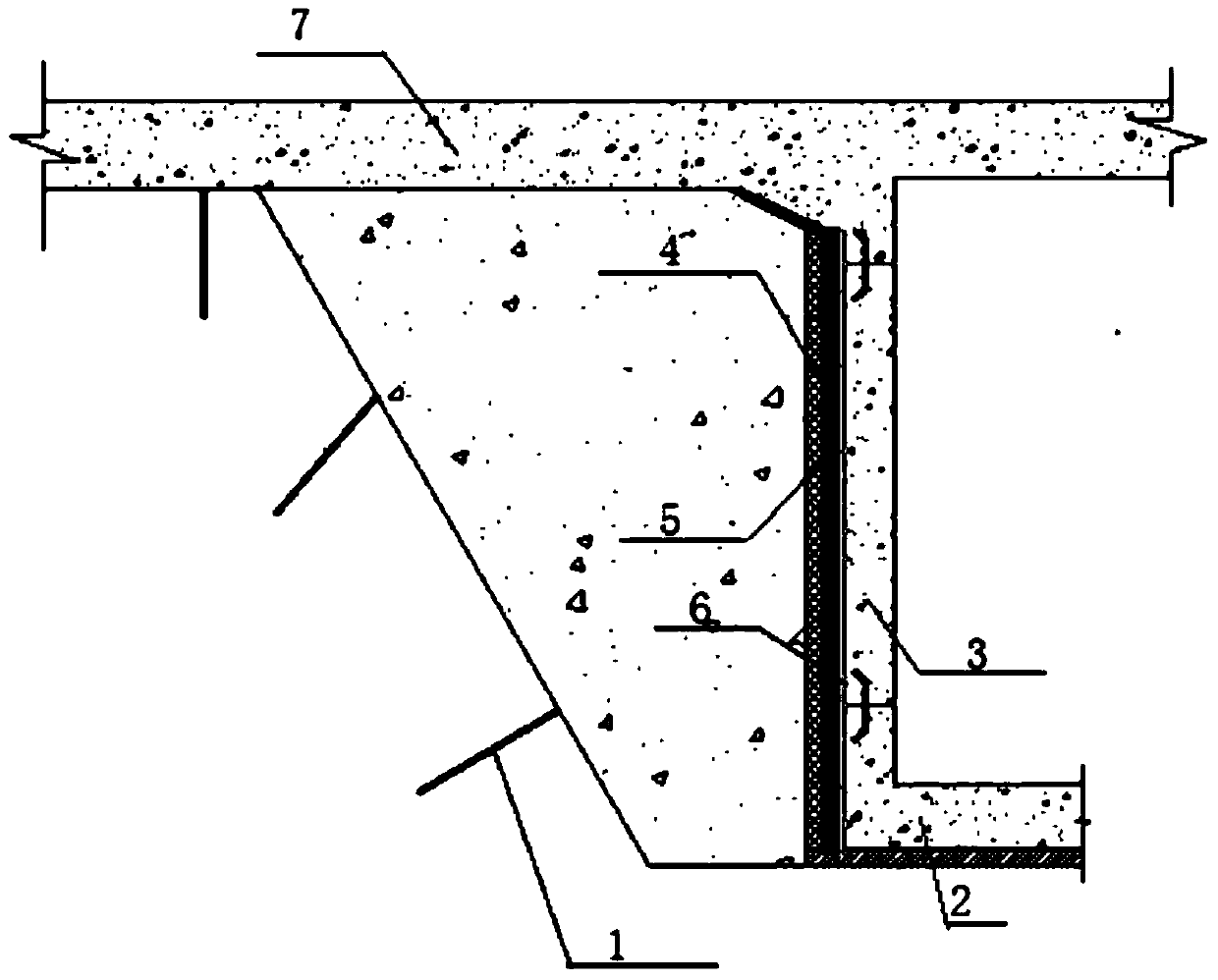

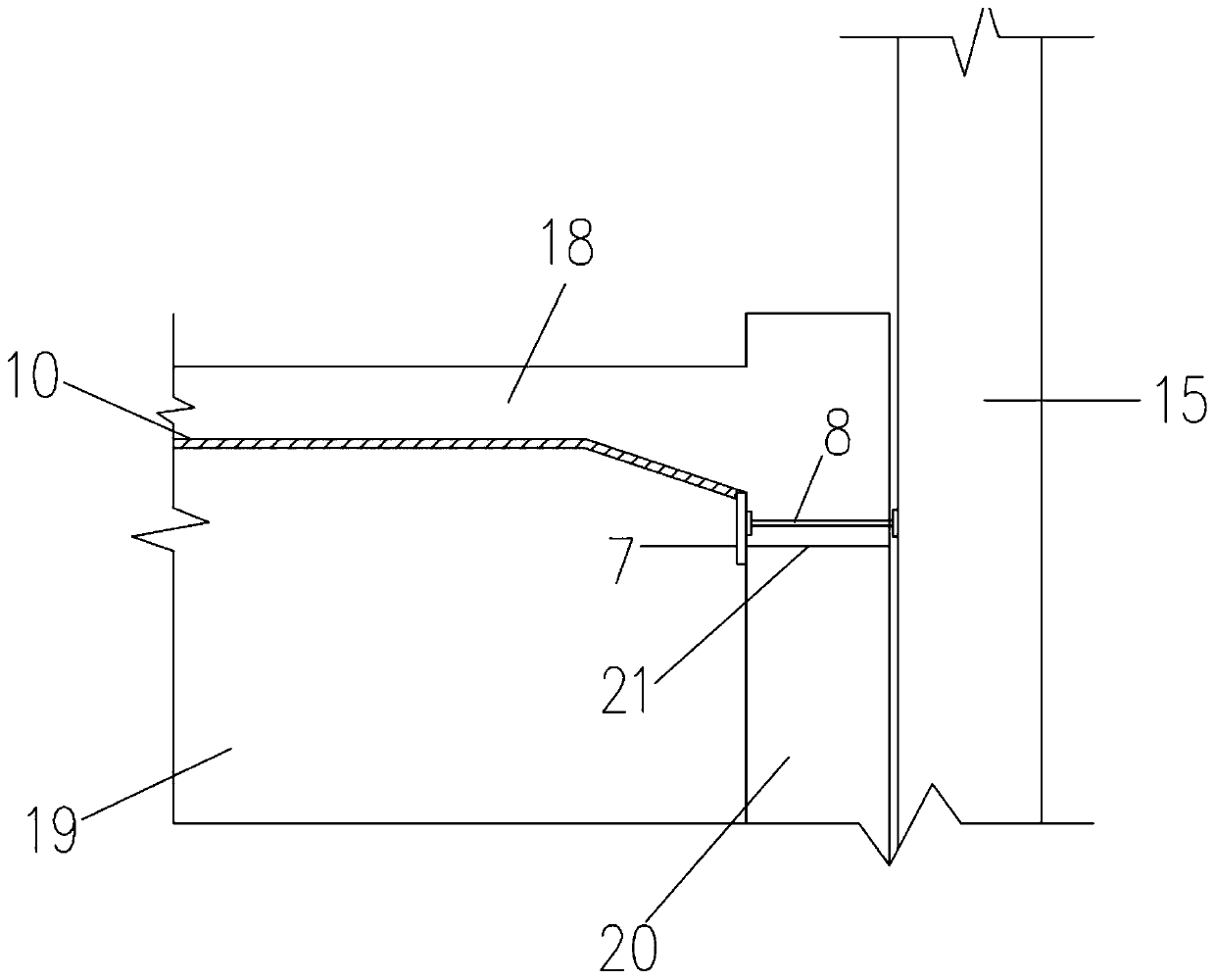

Side formwork structure of deep foundation and its construction method

ActiveCN113073670BImproved cantilever force systemImprove carrying capacitySoil preservationReinforced concreteBrick

Owner:SHANGHAI NO 4 CONSTR

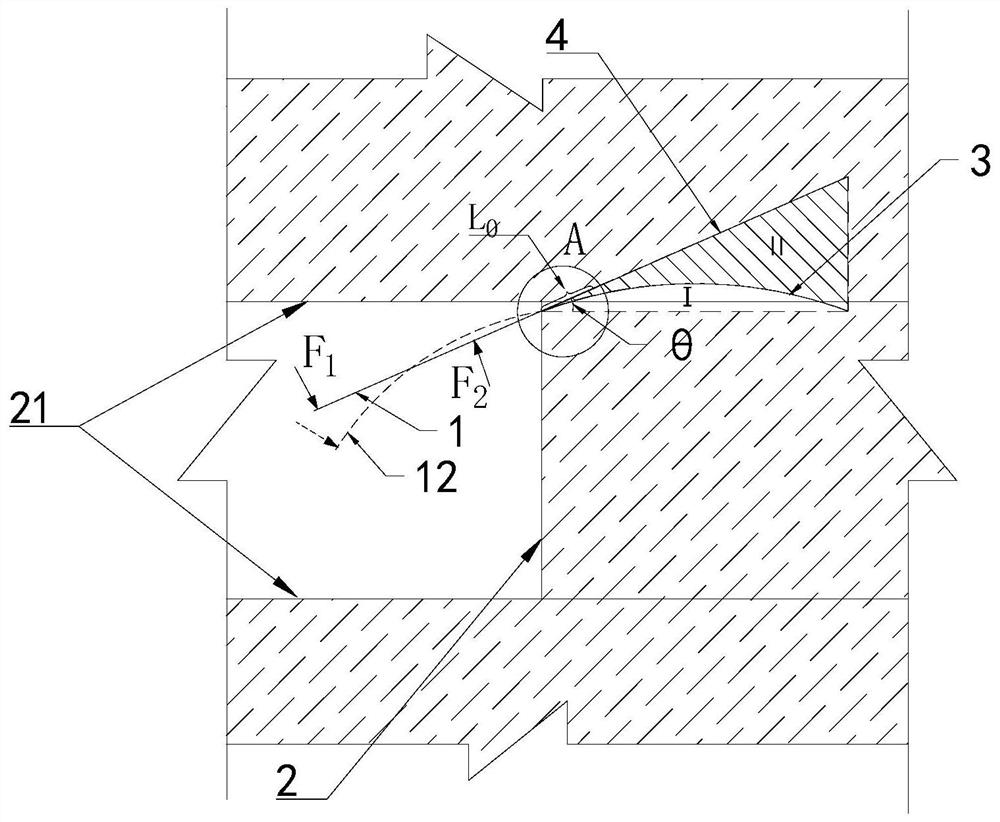

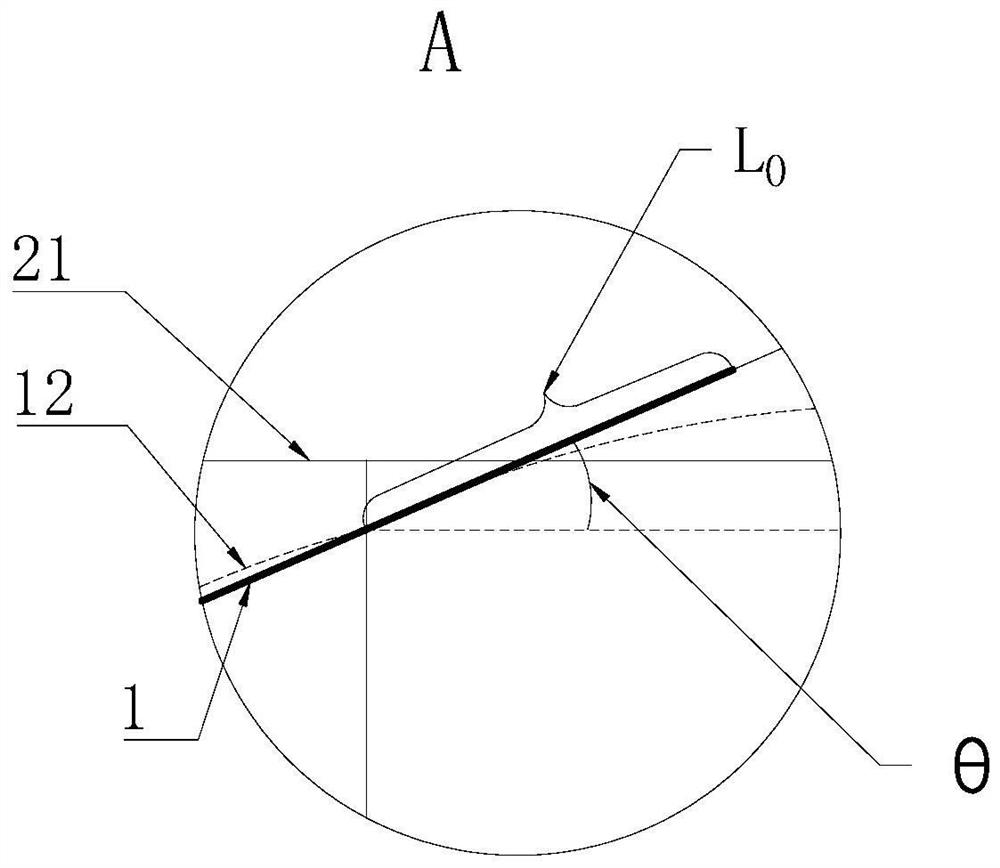

Peripheral hole arc-shaped drilling construction method for controlling tunnel overexcavation

The invention discloses a peripheral hole arc-shaped drilling construction method for controlling tunnel overexcavation, and relates to the technical field of tunnel construction. The method comprises the following steps that S1, a drill rod is used for drilling towards the front of a tunnel in the direction forming an outer included angle 22 with the axis of the tunnel at the position close to the excavation contour line of the tunnel face, and the drilling length is L0; and S2, external force F1 facing the inner side of the tunnel and external force F2 facing the outer side of the tunnel are continuously applied to the tail end of the drill rod and the position close to a hole opening, so that the drill rod generates deformation protruding towards the inner wall of the tunnel and continuously drills holes, and the straight holes can be changed into arc-shaped holes through drilling in the state. According to the construction method, the arc-shaped tunnel drilling and blasting peripheral holes can be drilled, and compared with linear peripheral holes with the same footage length, the tunnel overexcavation amount can be effectively reduced.

Owner:龚伦

Irrigation and water conservancy construction method

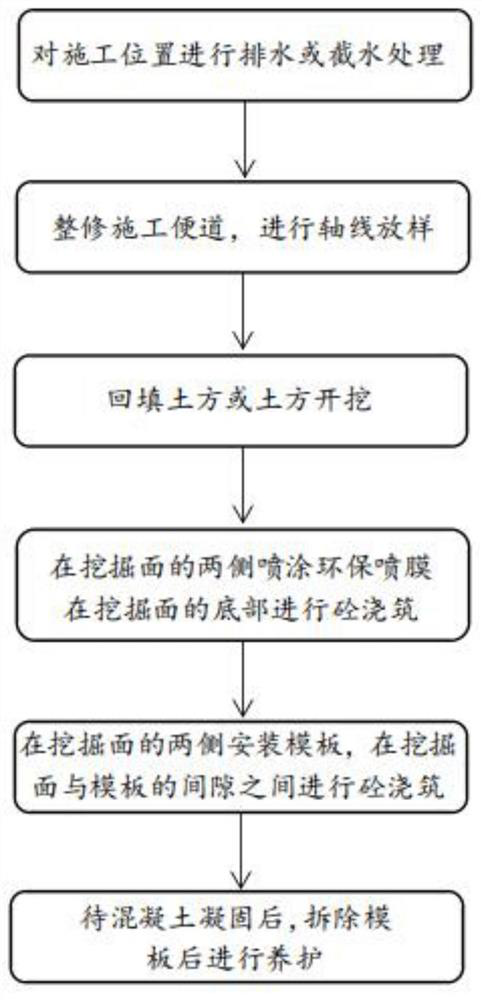

InactiveCN113550268AReduce excavationReduce the amount of backfillArtificial water canalsSurface cleaningStructural engineering

The invention relates to an irrigation and water conservancy construction method. The irrigation and water conservancy construction method comprises the following specific steps that a construction position is determined, and drainage or interception treatment is conducted on the construction position; a construction road is repaired, and after surface cleaning and impurity cleaning are conducted on the construction position, construction lofting is conducted; if the original channel exists in the construction position, when the size of the original channel is larger than or equal to that of the new channel, backfilling and compacting are conducted in the original channel, and then earthwork excavation is conducted; when the size of the original channel is smaller than that of the new channel, earth excavation is conducted on the original channel; if the original channel does not exist at the construction position, earth excavation is conducted according to the size of the new channel; after excavation is completed, environment-friendly spraying films are sprayed to the two sides of the excavation face, and concrete pouring is conducted on the bottom of the excavation face; after concrete at the bottom of the excavation face is solidified, formworks are installed on the two sides of the excavation face, and concrete pouring is conducted in gaps between the excavation face and the formworks; and after the concrete is solidified, the formworks are dismantled, and then maintenance is conducted. The method is convenient to construct, and has the advantages of shortening the construction period and saving the cost.

Owner:广东洋晟建设工程有限公司

Predeformation support method for pipeline foundation pit

The invention discloses a pipe foundation pit predeformation support method. The method comprises the following steps: (A) a part above a final step is divided into multiple steps; and soil bodies on the step surfaces are removed, so that the active soil pressure on the sliding surfaces of the soil bodies is reduced, and the sliding of the soil bodies on the sliding surfaces is allowed; (B) steel plate piles or cavity piles are arranged on the vertical surfaces of all the steps; the acting force of the previous steps is not transferred to the later steps; the steel plate piles or the cavity piles bear the biggest value of the active soil pressure in the steps or the sliding force in the sliding soil bodies; and the deformation of the steel plate piles or the cavity piles satisfies the material and integrity requirements of a support structure; and (C) measuring points are preset on all the steel plate piles or the cavity piles, and are directly measured; the parts with the deformation exceeding a normal limit state are reinforced; and the generation of unstable state is controlled timely. The method allows the soil bodies on all the steps above the final step to generate large deformation, even the deformation exceeding dozens of centimeters, so that the construction process is simple, the procedures are easily realized, and the construction cost is far lower than that of the foundation pit support design controlled according to small deformation.

Owner:HENAN UNIVERSITY

Simultaneous Construction Method of Shield Crossing Piston Air Duct and Upper Structure of Piston Air Duct

ActiveCN109162741BProtection securityReduce the amount of backfillUnderground chambersFoundation engineeringSupporting systemClassical mechanics

The invention relates to the technical field of subway construction and particularly relates to a method for synchronously constructing a shield crossing piston air duct and a piston air dust upper structure. The segmented flow construction is employed by a second floor underground, the conversion of an inner support force system is reasonably completed, and a reliable reaction support system is provided for the passing of a shield. During the construction of a soil mold, a pit precipitation well is introduced out, and the stability of a piston air duct bottom plate structure in construction is ensured. After the construction of a middle plate, a middle plate hole is blocked by using a hole blocking plate, therefore, piston structure upper and lower structures are completely isolated, a closed space is provided for the shield crossing piston air duct, an effective reaction support is formed, an end reinforcement process is avoided, and the construction of the piston air dust upper structure is carried out simultaneously. According to the method, the problem that the shield crossing piston air duct and the piston air dust upper structure cannot be synchronously constructed is effectively solved, and the method has the advantages of reasonable operation, high safety and reliability, the effective avoidance of slow work, and the effective shortening of a construction period.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

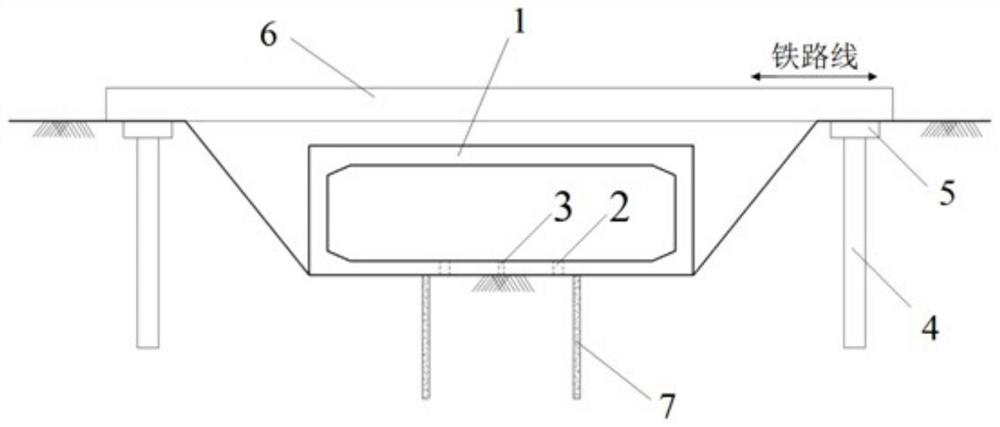

Construction method for underground pipe gallery located at bottom of frame bridge below railway line

PendingCN114396076AImprove support stabilityDoes not affect trafficArtificial islandsProtective foundationSupporting systemSlurry

The invention discloses a construction method for an underground pipe gallery located at the bottom of a frame bridge below a railway line. The construction method mainly comprises the following construction steps that the frame bridge is jacked in place; backfilling the railroad bed to recover the original railway line; constructing horizontal steel pipes at the bottom of the frame bridge; steel piles are driven into soil at the bottom of the frame bridge; soil at the bottom of the frame bridge is excavated to the designed elevation; laying a cement leveling layer; assembling and constructing each section of underground pipe gallery; and slurry is injected into the periphery of the underground pipe gallery. The method has the following advantages: the construction of the underground pipe gallery has no influence on the construction period of a railway line, and the influence on the existing railway line can be ignored; a supporting system formed by the cement-soil stirring walls, the steel pipes and the steel piles has high strength, and a safe and stable space is provided for construction of the underground pipe gallery. Slurry is injected into the periphery of the underground pipe gallery based on the grouting holes, so that the space between the underground pipe gallery and the surrounding soil body is filled with the grouting, and the construction quality is guaranteed.

Owner:安徽铁建工程有限公司

A mold for processing U-shaped water tank

ActiveCN103770203BFlat surfaceReduce internal air bubblesMould separation apparatusMouldsEngineeringMachining

A U-shaped sink machining mould relates to U-shaped sink machining moulds and solves the problem that a U-shaped sink machined with an existing U-shaped sink machining mould has the length of only 500 meters as well as the problem of dimensions of cross section structures. A front end mould assembly, a rear end mould assembly and two side mould assemblies form a four-side frame, the four-side frame is arranged on a base frame assembly, both ends of the lower portion of the left side mould assembly is respectively provided with a left side mould linkage plate, both ends of the lower portion of the right side mould assembly is respectively provided with a right side mould linkage plate, the left side mould linkage plate and the right side mould linkage plate which transversely correspond to each other are hinged through a connecting member, a side hinge rod is arranged between two left side mould linkage plate, a switch shaft is mounted on the front end mould assembly, two sector connecting plates on an end mould linkage assembly are connected with the switch shaft and fixedly connected with the rear end mould assembly, and four corners of the outer side wall of each of the side mould assemblies is respectively mounted with a quick clamp. The U-shaped sink machining mould is used for machining a U-shaped sink for water channel construction.

Owner:HEILONGJIANG PROVINCIAL HYDRAULIC RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com