Deep foundation pit open cutting construction method

A construction method and deep foundation pit technology, which is applied in excavation, infrastructure engineering, construction, etc., can solve problems such as delay in construction period and waste of manpower, and achieve the effect of saving construction costs, saving excavation costs, and reducing earthwork workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

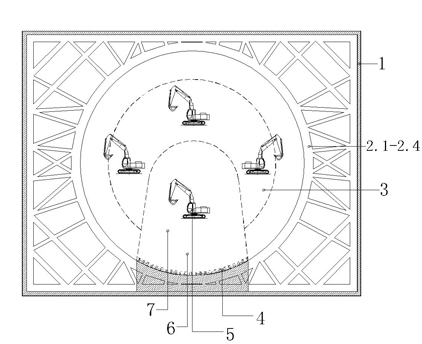

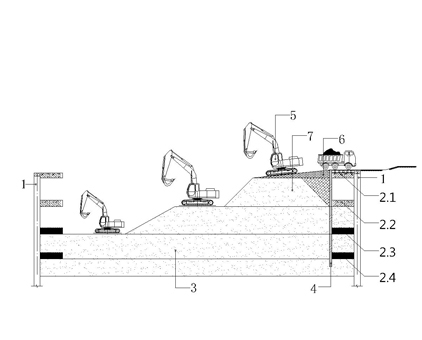

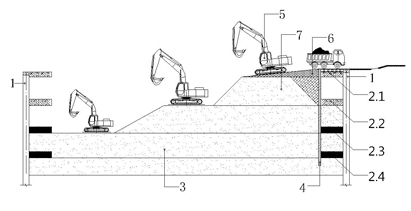

[0019] A deep foundation pit open excavation construction method is characterized in that: vertically driven steel sheet piles 4 are arranged on the inner side of each concrete ring beam 2.1-2.4 below the excavation opening 6 of the foundation pit 3, and the upper end of the steel sheet pile 4 is connected to the first The upper surface of a concrete ring beam 2.1 is even, and the lower end must exceed the lower surface of the bottom concrete ring beam by a certain length. The first step is to excavate the soil and construct the first concrete ring beam 2.1. At this time, the steel sheet pile 4 is driven in, and then Excavate the soil in the second step, keep the soil platform 7 at the excavation mouth 6 without excavating it, and use it to seat the excavator 5. For the construction of a section of concrete ring beam under the soil platform 7 of the excavation mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com