Excavation method of large-diameter cylindrical tailrace surge chamber

A tailwater surge chamber, cylindrical technology, applied in water conservancy projects, hydropower, hydropower stations, etc., can solve the problems of stress concentration at the intersection of caverns, complex stress state of surrounding rock, and high technical difficulty, reducing The effect of reducing the amount of engineering, reducing the amount of concrete backfill, and saving engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

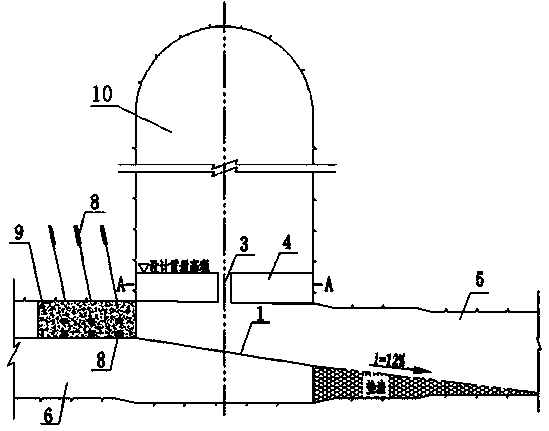

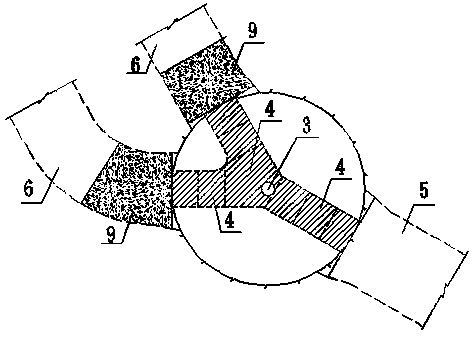

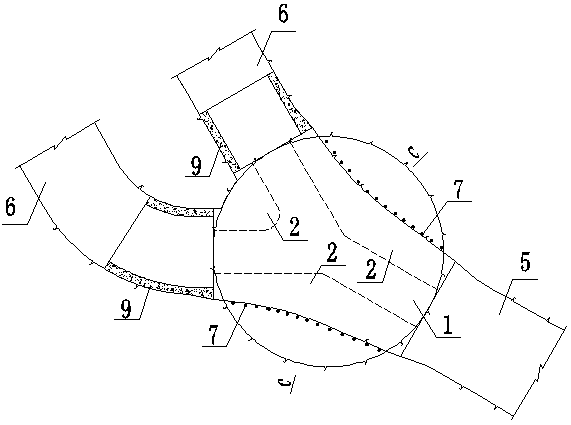

[0029] A method for excavating a large-diameter cylindrical tailwater surge chamber, comprising the following steps:

[0030] Step 1) Use the tailrace tunnel 5 as the construction channel, use the full-section drilling and blasting method to form the bottom middle pilot tunnel 1, and randomly support the bottom middle pilot tunnel 1, so as to form the mucking channel during the subsequent construction.

[0031] Step 2) After the channel of the pilot tunnel 1 at the bottom is formed, the excavation and system support of the first layer above the two adjacent draft tubes 6 on the upstream side of the tailrace tunnel 5 are completed by adopting the construction method of skip tunnel excavation. Reserved excavation stratification below the first floor.

[0032] Step 3) After the excavation and support of the first layer of draft tube 6 in step 2), concrete is poured on the excavation surface of the first layer to form the first-stage "side wall and top arch" concrete layer 9; Dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com