A mold for processing U-shaped water tank

A mold and water tank technology, applied in the field of molds for processing U-shaped water tanks, can solve the problems of large floor space, many internal bubbles, low product strength, etc., and achieve the effect of saving floor space, less internal bubbles, and high product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

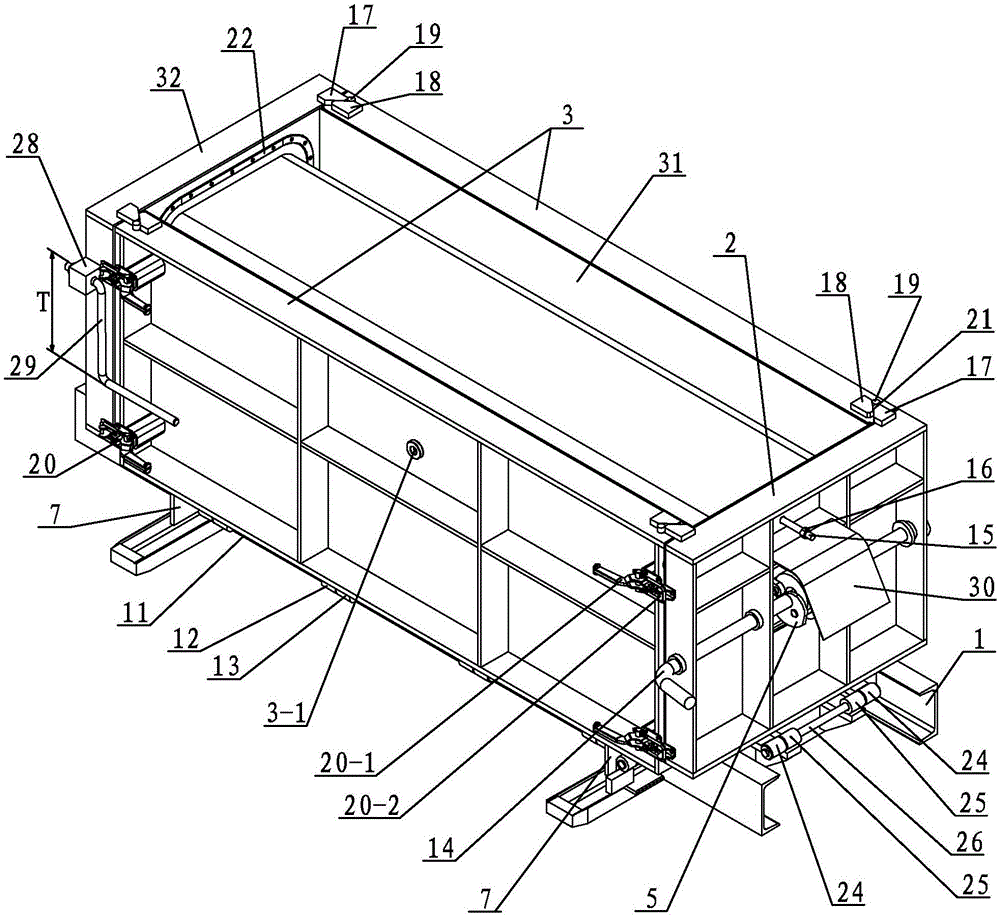

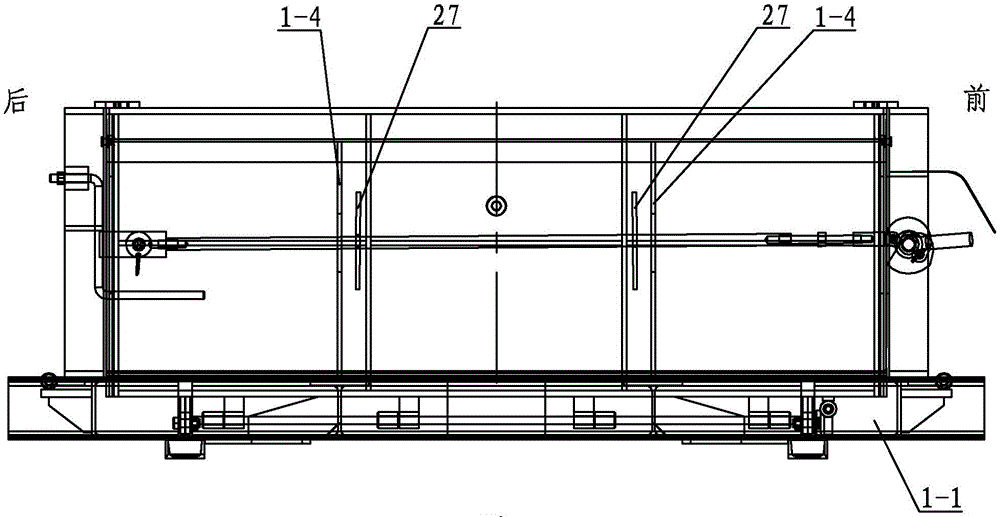

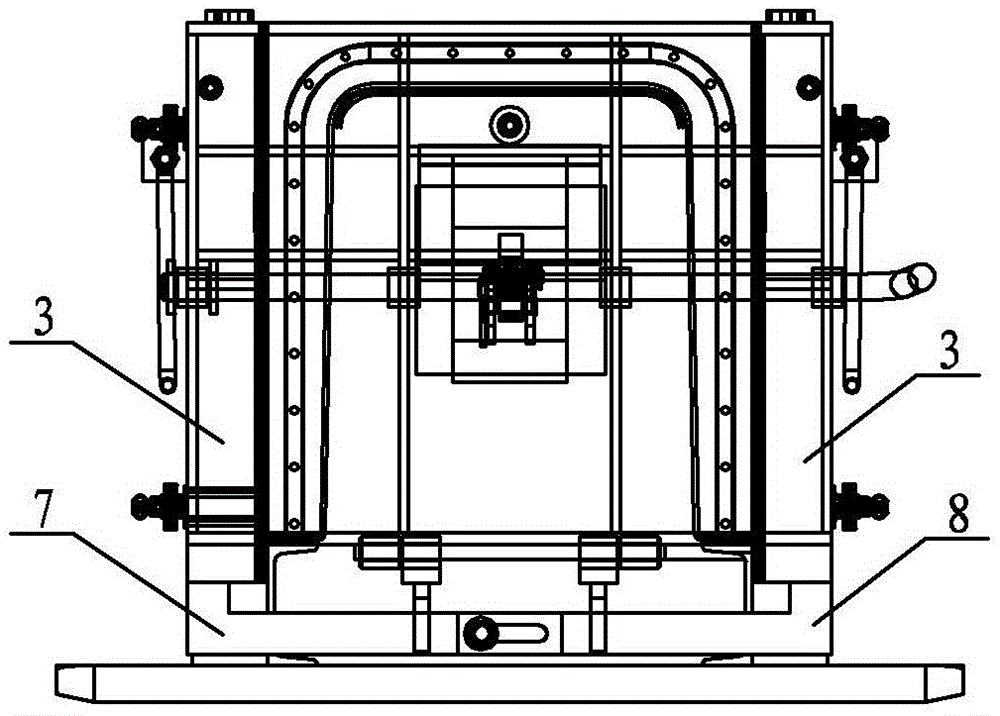

[0023] Specific implementation mode one: combine Figure 1 to Figure 12Describe this embodiment. This embodiment includes a chassis assembly 1, a front mold assembly 2, a rear mold assembly 32, an end mold linkage assembly 5, a switch shaft 14, two side mold assemblies 3, and two left mold assemblies. Linkage plate 7, two right side mold linkage plates 8, two connecting elements 9, two side hinge bars 11, two inverted U-shaped gaskets 22, two end hinge bars 26, four end mold positioning obliques Plate 17, four side mold positioning inclined plates 18, four positioning shafts 19, four bottom frame end hinged sleeves 24, four end mold assembly hinged sleeves 25, eight quick clamps 20, several bottom frame side hinged sleeves 12 and several side mold assembly hinge sleeves 13, the chassis assembly 1 includes an inverted U-shaped plate 1-2, two longitudinal beams 1-1, two inverted U-shaped end plates 1-3, and two inverted U-shaped ribs Plate 1-4 and two beams 1-5, two longitudina...

specific Embodiment approach 2

[0024] Specific implementation mode two: combination figure 1 Describe this embodiment, the hasp 20-1 on the quick clamp 20 of this embodiment is installed on the side mold assembly 3, and the snap hook 20-2 on the quick clamp 20 is installed on the corresponding front mold assembly 2 and the rear end On the mold assembly 32. Quick clamp 20 makes front end mold assembly 2 and rear end mold assembly 32 and two side mold assemblies 3 realize fast locking, makes front end mold assembly 2 and rear end mold assembly 32 and two side mold assemblies 3 form a solid whole. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1 This embodiment is described. The difference between this embodiment and the specific embodiment 1 or 2 is that it also adds an opening and closing clamping rod 15 and a clamping nut 16. The opening and closing clamping rod 15 is arranged on the front-end mold assembly 2, and One end of the opening and closing clamping rod 15 is fixedly connected with the U-shaped end plate 1-3, and the other end of the opening and closing clamping rod 15 passes through the front-end mold assembly 2 and is threadedly connected with the clamping nut 16. The opening and closing position pull rod 15 is used to limit the opening angle of the front mold assembly 2 . Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com