Side formwork structure of deep foundation and its construction method

A construction method and deep foundation technology, applied in foundation structure engineering, soil protection, construction, etc., can solve the problems that the construction quality and safety of the side formwork of the deep foundation cannot meet the construction requirements, and achieve the improvement of the cantilever force system, Ensure the construction quality and reduce the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

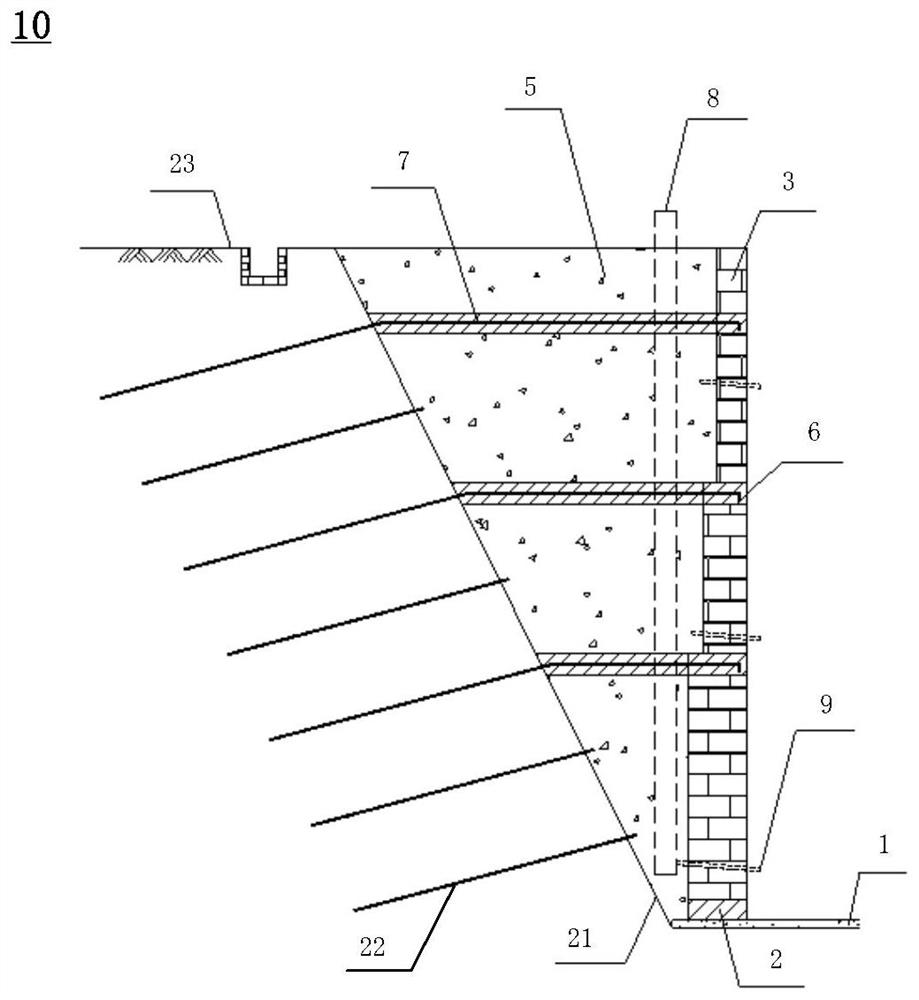

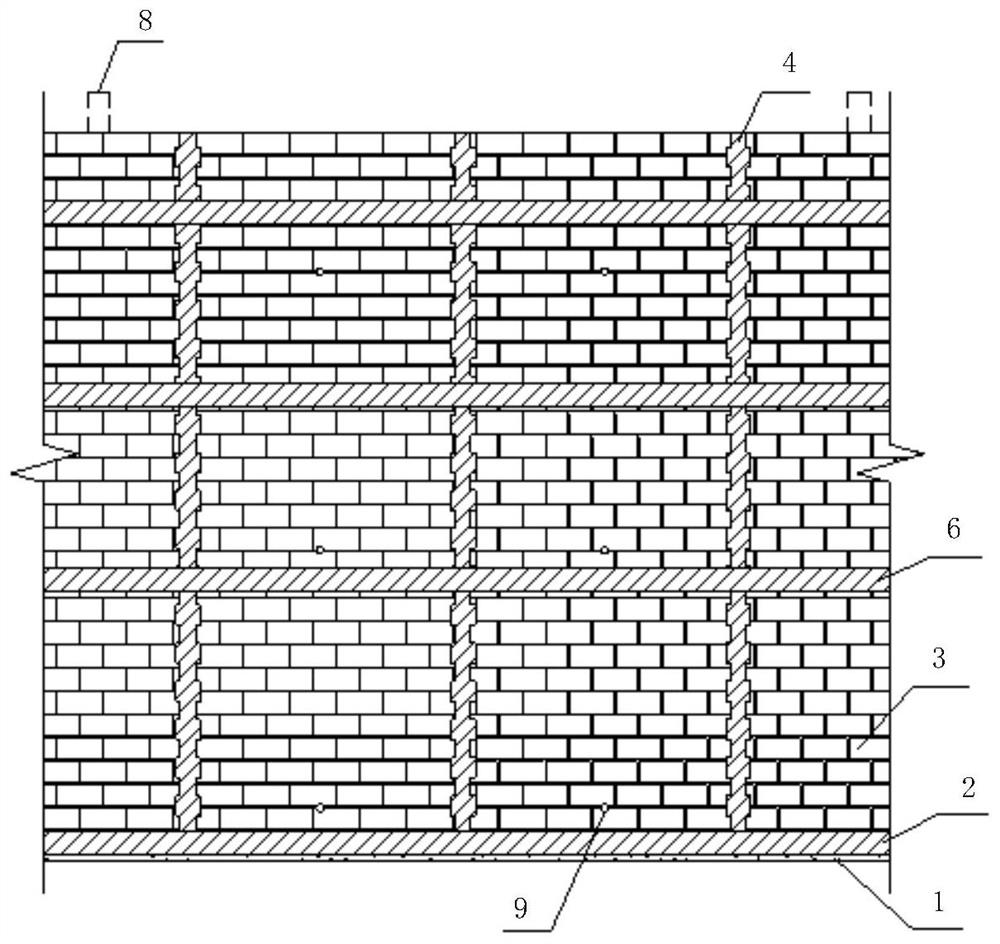

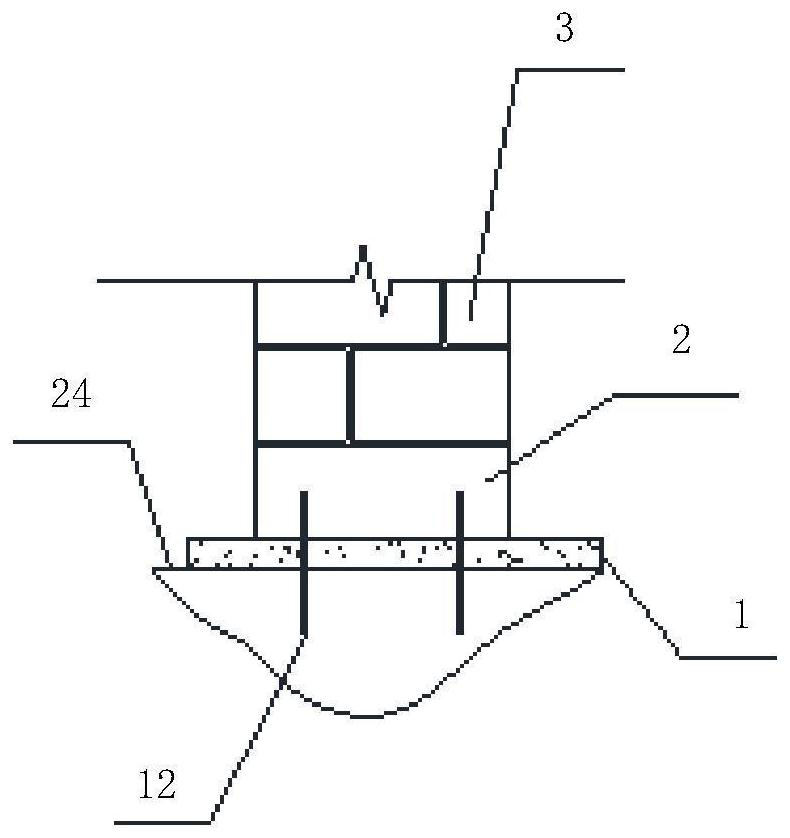

[0051] Please refer to figure 1 and figure 2 , which is a schematic structural diagram of the side mold structure of the drop-depth foundation according to the first embodiment of the present invention. like figure 1 and figure 2As shown, the side formwork structure 10 of the deep foundation includes: a concrete cushion 1, a foundation beam 2, a brick tire form 3, a structural column 4, a backfill soil layer 5, a ring beam 6 and a partition strip 7; the The concrete cushion 1 is arranged on the bottom surface of the foundation pit, the foundation beam 2 is fixed on the concrete cushion 1 and is continuously arranged along the surrounding edges of the concrete cushion 1, and the brick tire mold 3 is built on the concrete cushion 1. On the foundation beam 2, the structural column 4 is longitudinally arranged in the plane of the brick tire mold 3 and is integrated with the brick tire mold 3; the backfill soil layer 5 and the partition plate belt 7 are both It is arranged be...

Embodiment 2

[0078] Please refer to figure 2 and Image 6 , which is a schematic structural diagram of the side mold structure of the drop-depth foundation according to the second embodiment of the present invention. like figure 1 and figure 2 As shown, the side formwork structure 10 of the deep foundation includes: a concrete cushion 1, a foundation beam 2, a brick tire form 3, a structural column 4, a backfill soil layer 5, a ring beam 6 and a partition strip 7; the The concrete cushion 1 is arranged on the bottom surface of the foundation pit, the foundation beam 2 is fixed on the concrete cushion 1 and is continuously arranged along the surrounding edges of the concrete cushion 1, and the brick tire mold 3 is built on the concrete cushion 1. On the foundation beam 2, the structural column 4 is longitudinally arranged in the plane of the brick tire mold 3 and is connected with the brick tire mold 3; the backfill soil layer 5 and the partition plate belt 7 are both. It is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com