Massive hollow concrete structures for backfilling of large cavities

A hollow concrete, large-volume technology, used in filling, earthwork drilling, shaft equipment, etc., can solve the problems of high cost and large amount of engineering, and achieve the effects of protecting the environment, reducing engineering costs, and reducing the amount of concrete backfill.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

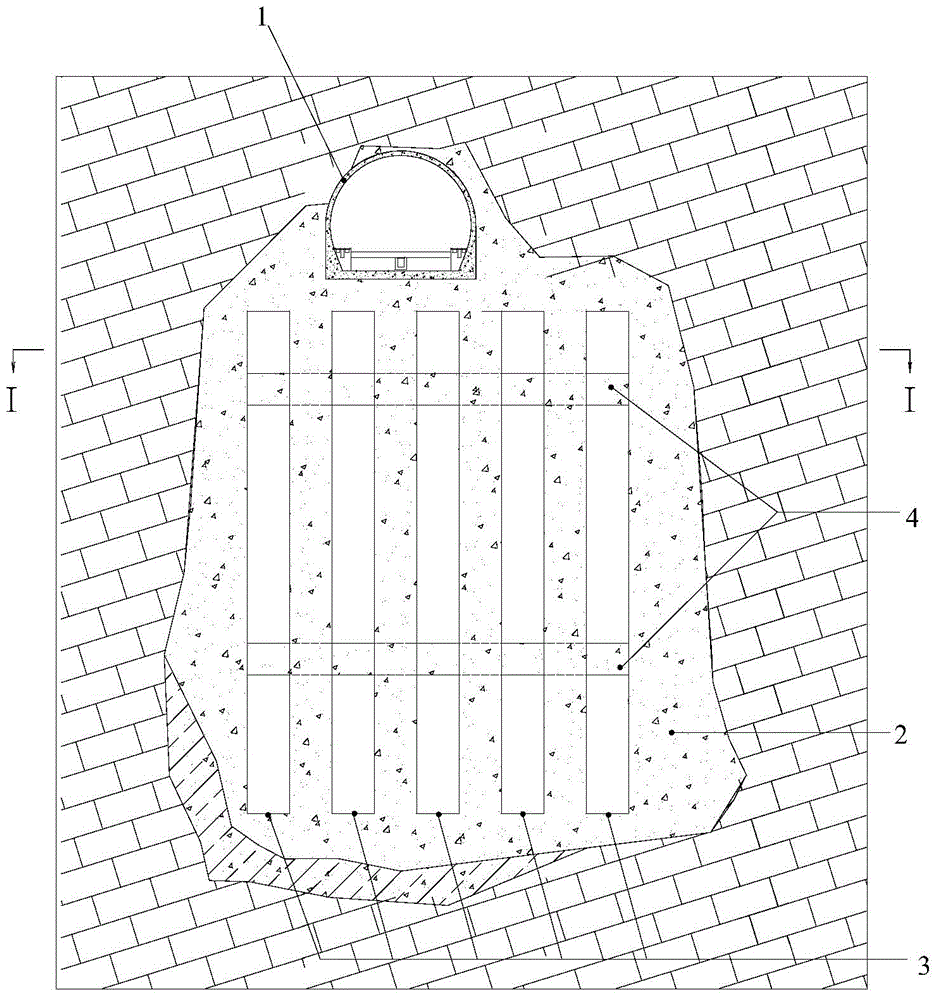

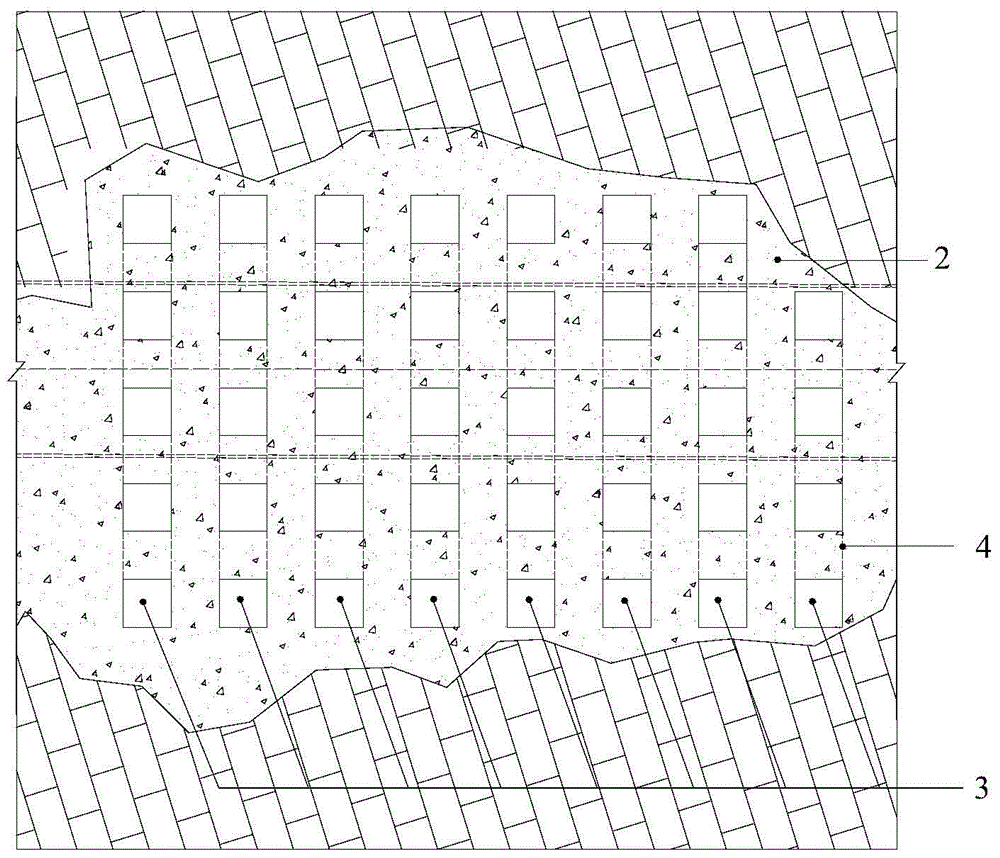

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] After safety and technical and economical comparisons, at present, large cavities without drainage requirements in the tunnel base mostly use concrete backfill structures, but the amount of concrete work is large, the cost of the project is high, and the volume deformation and cracking caused by the hydration heat of large-volume concrete cement may affect the The safety and normal use of the tunnel structure; how to solve the problem of large-volume concrete backfill safely, economically and conveniently has attracted more and more attention and attention, and the structure of reducing the large-volume concrete backfill masonry has become a key technology for the design and construction of tunnels through large cavities .

[0014] refer to figure 1 with figure 2 , the large-volume hollow concrete structure used for backfilling large-scale cavities in the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com