Predeformation support method for pipeline foundation pit

A pre-deformation, foundation pit technology, applied in excavation, infrastructure engineering, construction, etc., can solve the construction party's weak welding, installation, protection and other technologies and awareness, long foundation pit construction time, and drums and discs in the supporting structure. It can reduce the deformation resistance requirements, reduce the active earth pressure, and the process is easy to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

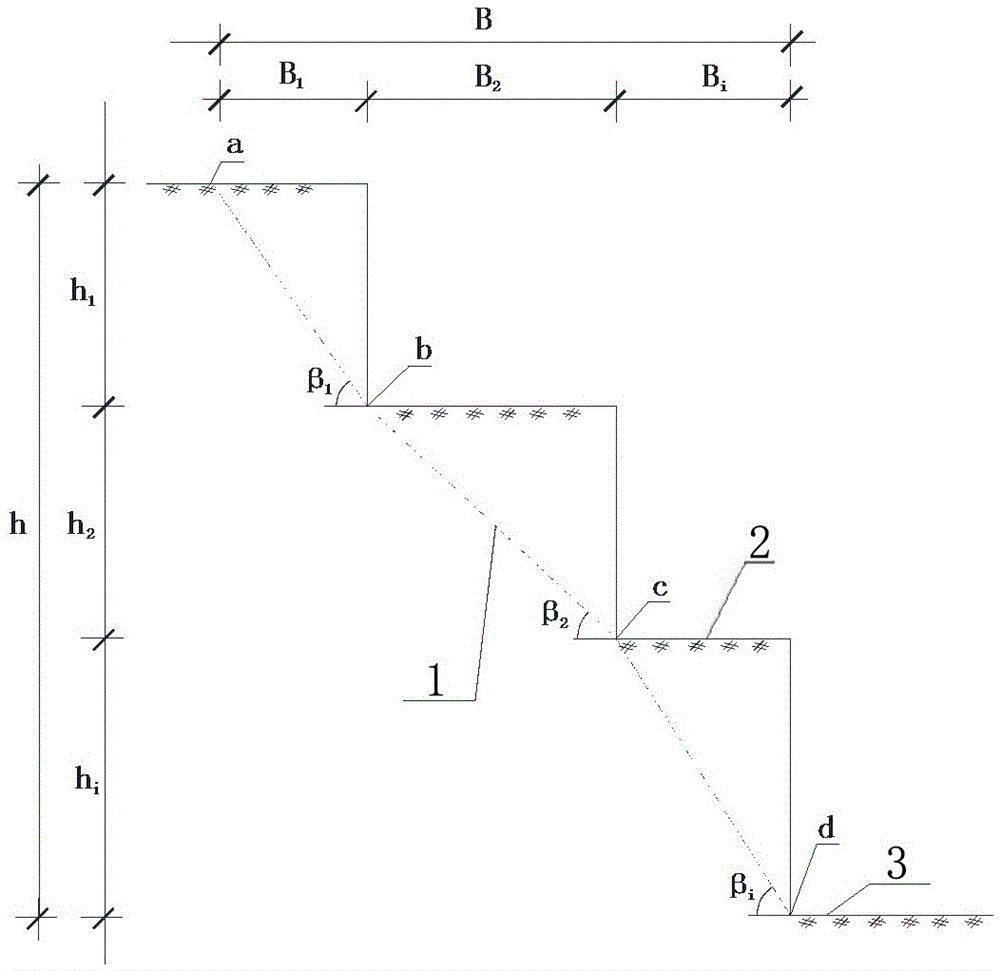

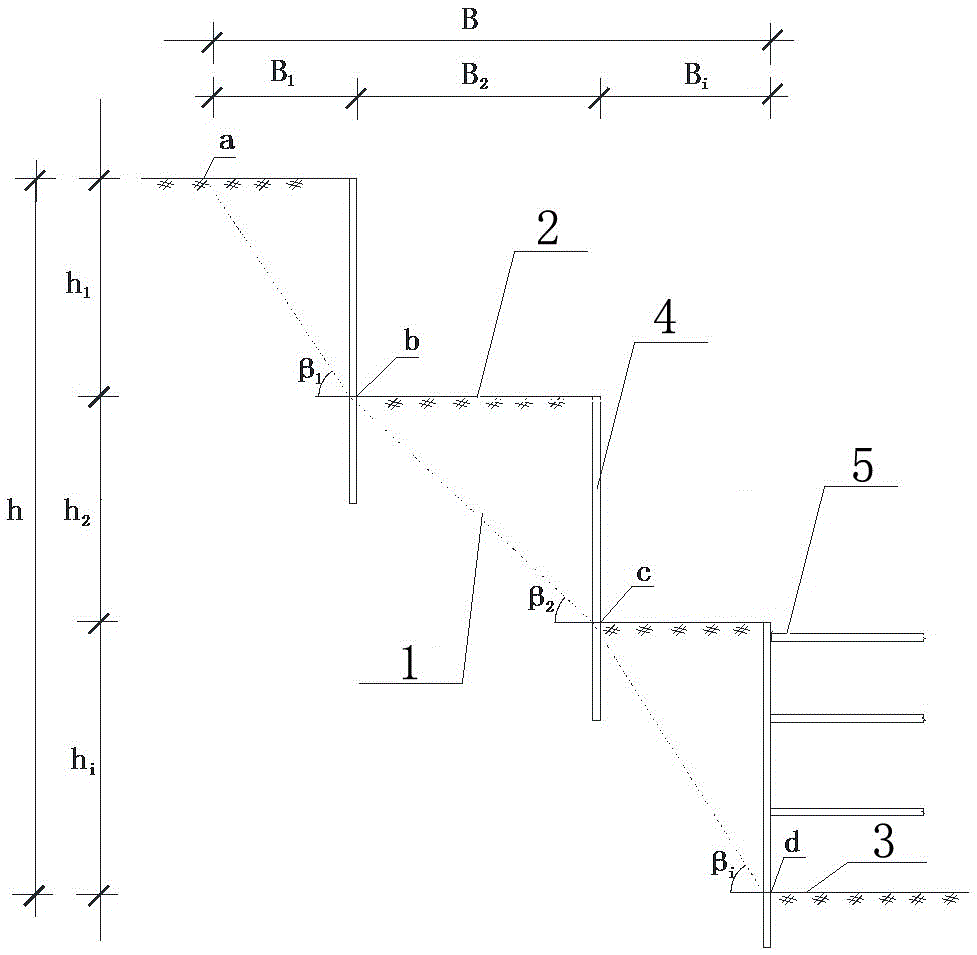

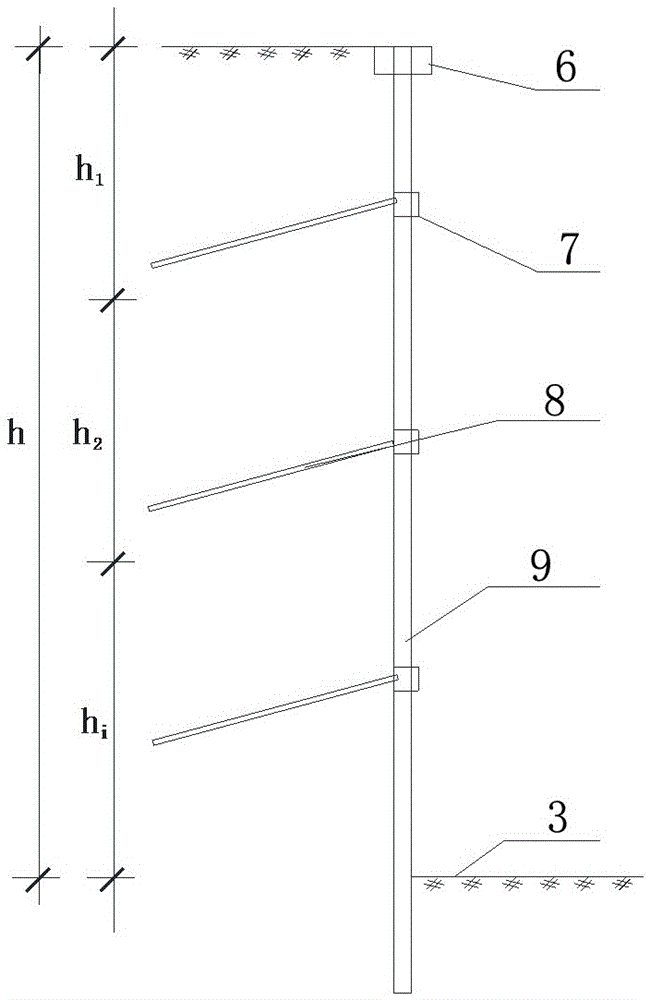

[0027] Example: see Figure 1-Figure 3 , 1-sliding surface of foundation pit, 2-step, 3-bottom of foundation pit, 4-supporting pile, 5-supporting rod, 6-crown beam, 7-waist beam, 8-anchor cable, 9-supporting column .

[0028] The pre-deformation support method for pipeline foundation pit includes the following steps:

[0029] A. Divide several steps 2 above the final step 2, remove the soil on the step surface, reduce the active earth pressure on the sliding surface of the soil and allow the sliding of the soil on the sliding surface;

[0030]B. Install steel sheet piles or cavity piles on the facade of each step 2, the force of the upper step 2 is not transmitted to the lower step 2, and the steel sheet pile or cavity pile bears the active earth pressure or sliding soil in the step 2 The maximum value of the sliding force, and its deformation meets the requirements of supporting structure materials and integrity;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com