Peripheral hole arc-shaped drilling construction method for controlling tunnel overexcavation

A technology for controlling the tunnel and its surroundings. It is applied in the direction of tunnels, earthwork drilling, mining equipment, etc. It can solve problems such as delaying the construction period, affecting the safety and quality of tunnel construction, and increasing project costs, so as to enhance stability, reduce concrete backfill, Effect of reducing overbreak area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

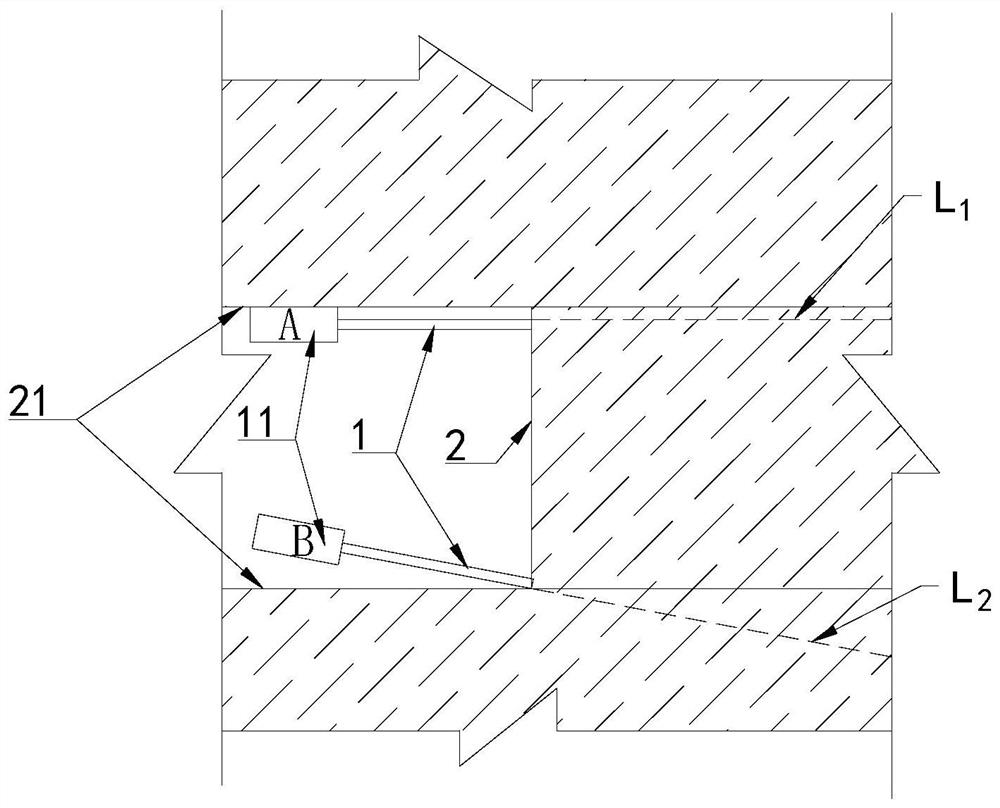

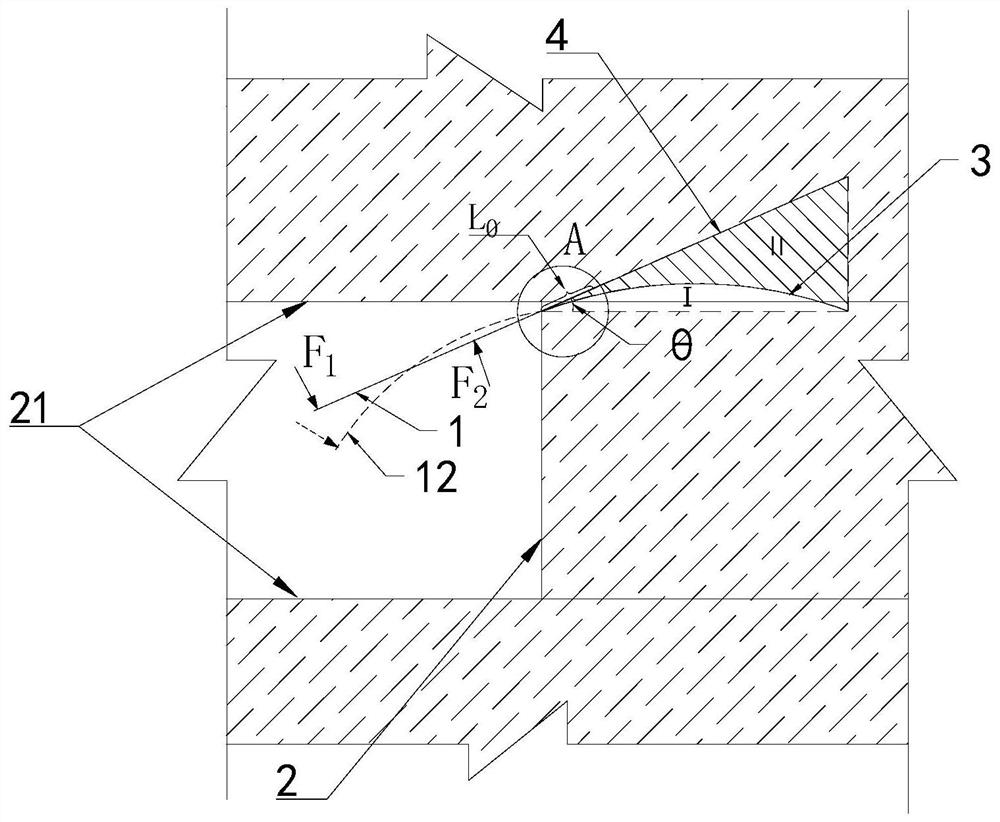

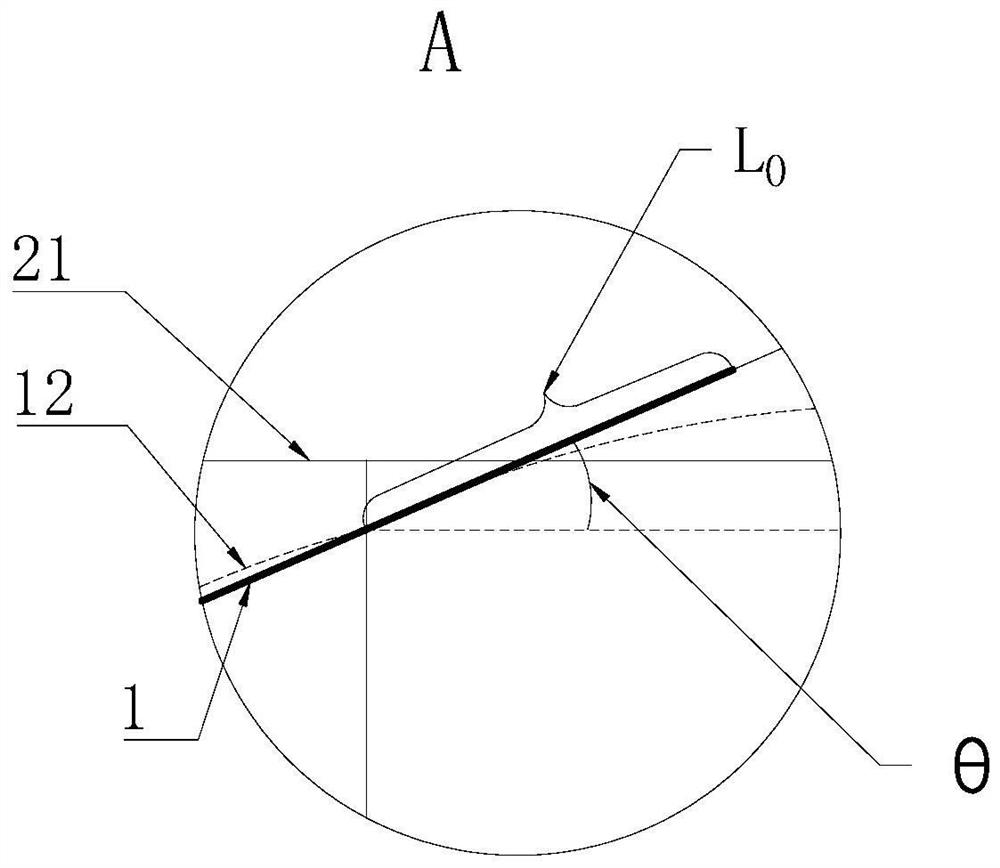

[0026] figure 1 with figure 2 Both are schematic diagrams of the cross-sectional direction of the tunnel. The rock within the excavation contour line 21 around the face 2 needs to be removed. Refer to figure 1 In the middle drilling device A, the outer diameter of the drill pipe 1 is much smaller than the outer diameter of the drill pipe seat 11 at the rear end of the drill pipe. Due to the obstruction of the drill pipe seat 11 by the inner wall of the tunnel, when drilling peripheral holes, if the drill pipe 1 If the hole is drilled parallel to the excavation contour line 21 of the tunnel, there will be a part of rock between the drill pipe 1 and the excavation contour line 21 that cannot be removed, that is, the dotted line L in the figure 1 and the part between the excavation contour line 21, so when drilling the peripheral holes, it is necessary to follow the figure 1 The middle drilling device B is provided with a drill pipe 1, that is, the drill pipe 1 drills a hole f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com