Slope support construction method combined with building main body structure

A technology that combines the main body of the building and the structure. It is applied in infrastructure engineering, architecture, underwater structures, etc. It can solve the problems of affecting the external landscape of the project, high vertical support height, and high safety risks, reducing the amount of earthwork backfill, The effect of saving project cost and reducing risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

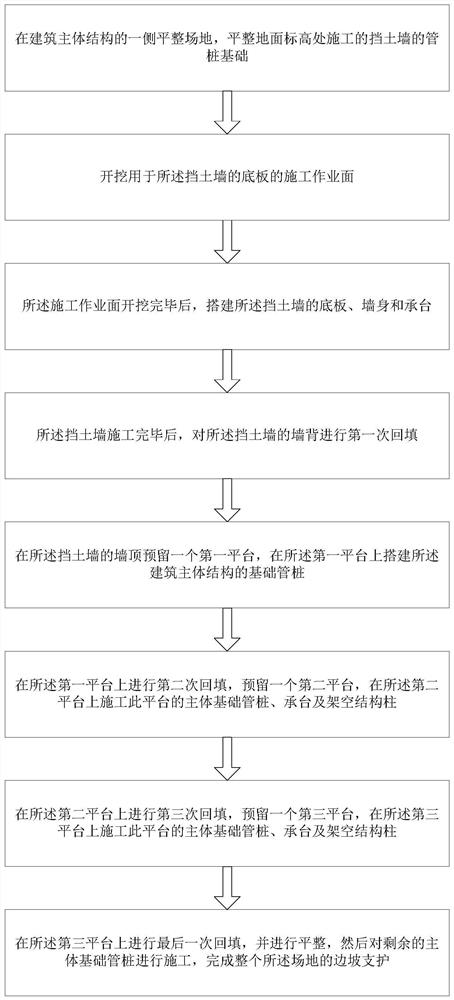

[0041] A slope support construction method combined with the main structure of the building, comprising the following steps:

[0042] S1. Level the site on one side of the main structure of the building, and level the pipe pile foundation of the retaining wall constructed at the ground level.

[0043] That is to say, when the site that needs to be constructed is uneven, the ground of the site should be leveled first on the slope side of the site, and a one-way plastic geogrid should be laid on the ground at the same time. Because it is located on one side of the slope, an L-shaped buttress-type retaining wall is adopted, and the support form of backfill graded slope is adopted to complete the pipe pile extrusion of the retaining wall.

[0044] S2. Excavating the construction work surface for the base plate of the retaining wall.

[0045] That is to say, the construction work surface is excavated, and the buttress type retaining wall is placed on the construction work surface....

Embodiment 2

[0060] A slope support construction method combined with the main structure of the building, comprising the following steps:

[0061] S1. Level the site on one side of the main structure of the building, and level the pipe pile foundation of the retaining wall constructed at the ground level.

[0062] That is to say, when the site that needs to be constructed is uneven, the ground of the site should be leveled first on the slope side of the site, and a one-way plastic geogrid should be laid on the ground at the same time. Because it is located on one side of the slope, an L-shaped buttress-type retaining wall is adopted, and the support form of backfill graded slope is adopted to complete the pipe pile extrusion of the retaining wall.

[0063] S2. Excavating the construction work surface for the base plate of the retaining wall.

[0064] That is to say, the construction work surface is excavated, and the buttress type retaining wall is placed on the construction work surface....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com