Prefabricated ground and construction method

A technology of prefabricated assembly and construction method, applied in basic structure engineering, soil protection, construction, etc., can solve the problems of affecting normal use, large settlement after construction, large thickness of soft soil, etc., to reduce maintenance costs and on-site construction speed. Fast and improve the effect of using the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

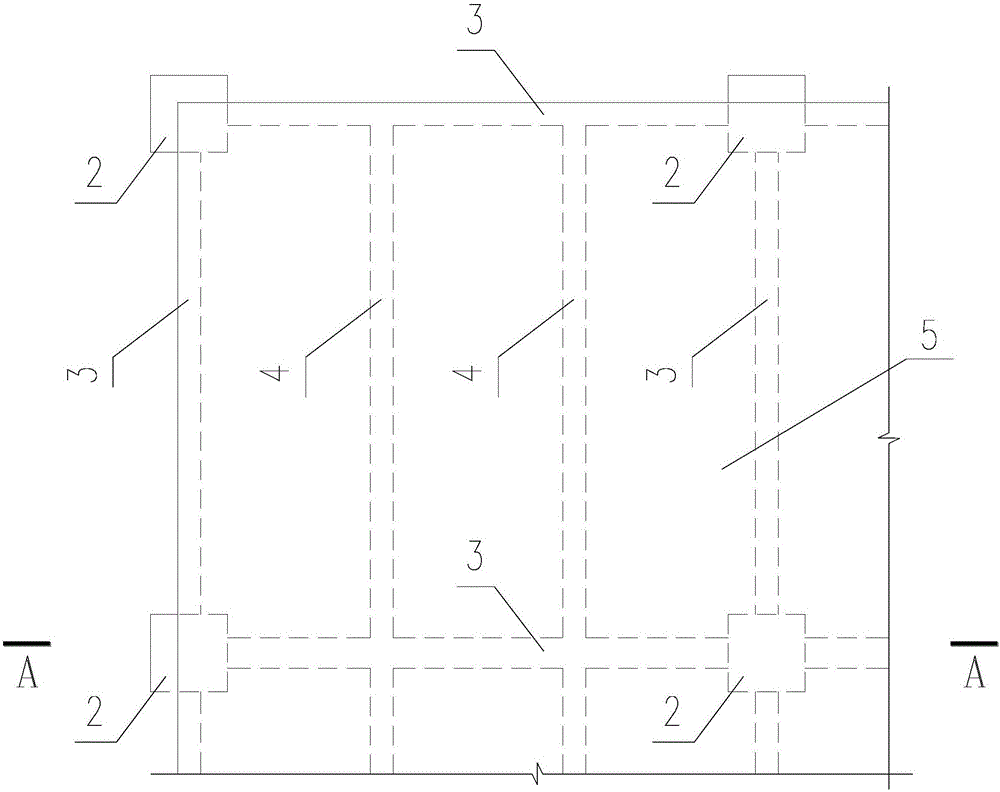

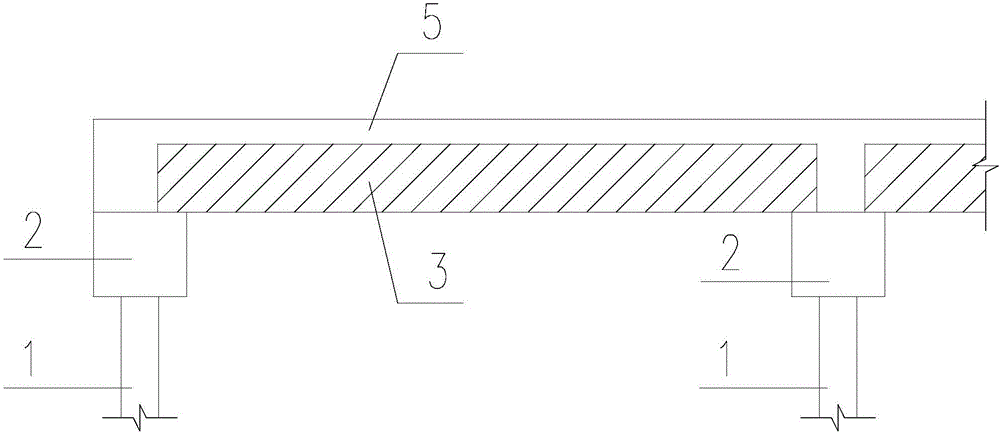

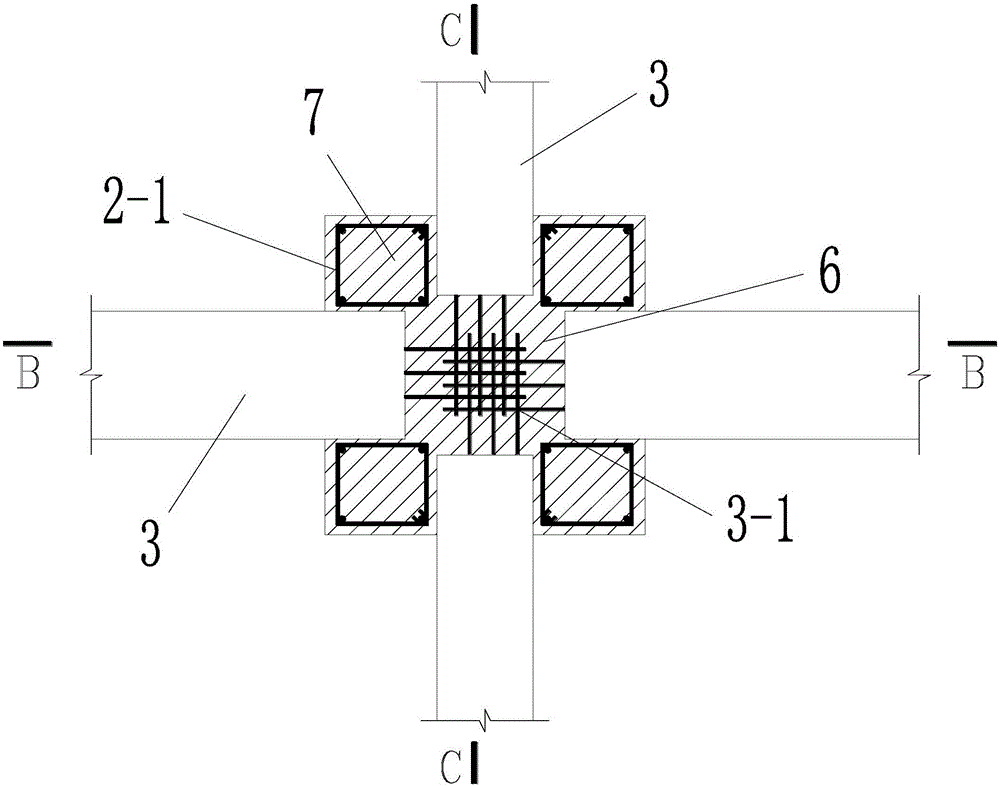

[0031] like Figures 1 to 10 Shown is a schematic diagram of an embodiment of a prefabricated floor provided by the present invention.

[0032] A prefabricated assembled ground, which includes a number of pile foundation components placed in the foundation and distributed in an array, a main beam 3 erected between two adjacent pile foundation components, and a bottom plate 5 supported on the main beam 3; The pile foundation assembly includes a prefabricated pile 1 and a cap 2 fixed on the upper end of the prefabricated pile 1 .

[0033] The main beam 3 is a prefabricated reinforced concrete main beam, and the bottom plate 5 is a prefabricated reinforced concrete bottom plate.

[0034] In order to increase the stress of the prefabricated floor, several secondary beams 4 can be arranged between corresponding side main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com