Splicing-free composite base metal surface heat insulation decorative plate and manufacturing method thereof

A technology of thermal insulation decorative panels and metal surfaces, which is applied in building construction, covering/lining, construction, etc., can solve the problems of low flexural strength of plates, high cost of flexural strength, and low bonding strength, and achieve high cost performance, The effect of fast construction speed and high overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

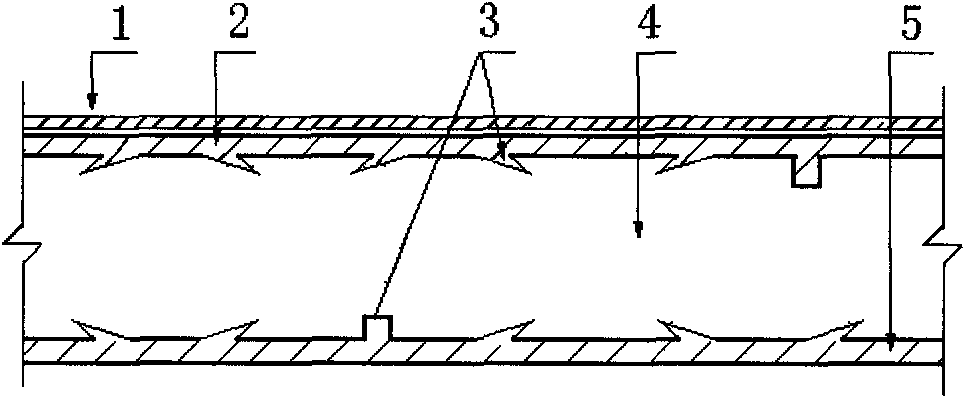

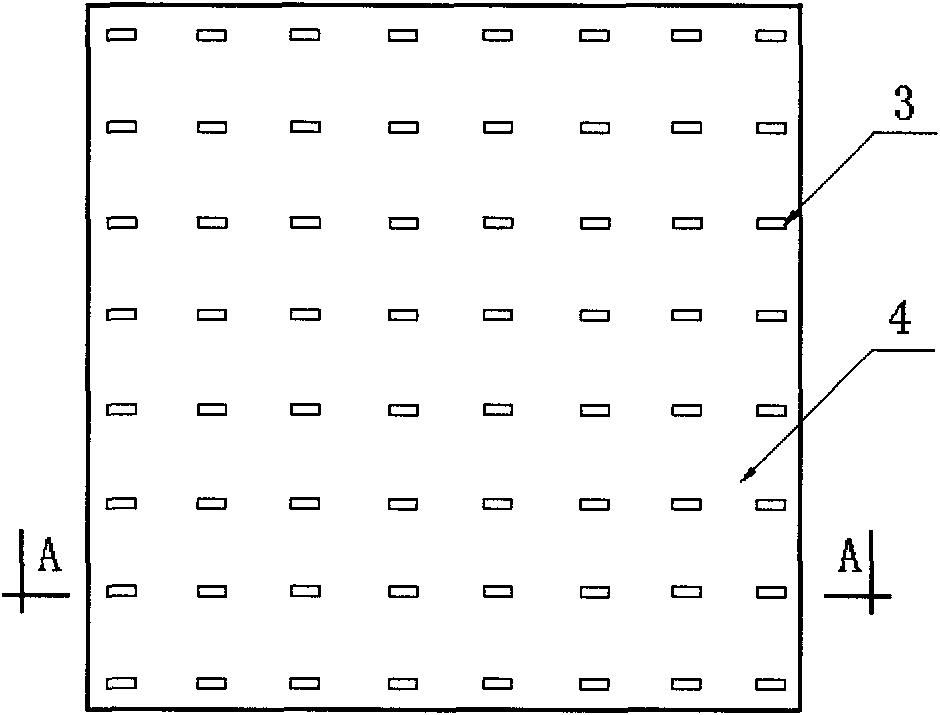

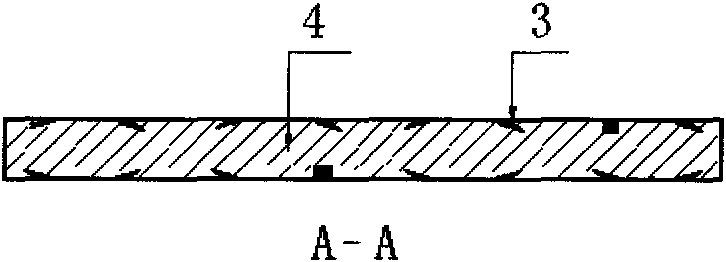

[0018] refer to figure 1 , 2 , 3, there is a foam insulation board 4 between the upper layer 2 and the lower layer 5 of the present invention, the metal decorative surface layer 1 is arranged on the upper layer 2, the helical tooth structure 3 is arranged on the upper layer and the lower layer, and the upper layer and the lower layer are cast-in-place cement or Rolled non-adhesive base layer, the foam insulation board 4 has non-penetrating holes matching the helical tooth structure on the upper and lower sides.

[0019] The thickness of the non-adhesive composite base metal surface insulation decorative board is 20-90mm, and the thickness of the foam insulation board is 10-80mm. Different thicknesses are used depending on the area of use. The foam insulation board 4 is XPS extruded board, phenolic foam board, polyurethane foam board, EPS board or foamed glass board.

[0020] The tooth structure of the bottom of the upper layer and the lower layer is a straight tooth or he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com