Assembled-type steel structural residence three-layer composite steel-column filled heat-insulation outer wall plate lifting method

A technology of thermal insulation exterior wall and hoisting method, which is applied in building construction, construction, building material processing and other directions, can solve the problems of inability to guarantee the verticality of prefabricated exterior wall panels, inconvenient adjustment, and easy cracking of the outer pages, so as to reduce the number of people. The effect of working, saving engineering costs and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in detail below with reference to accompanying drawing and embodiment:

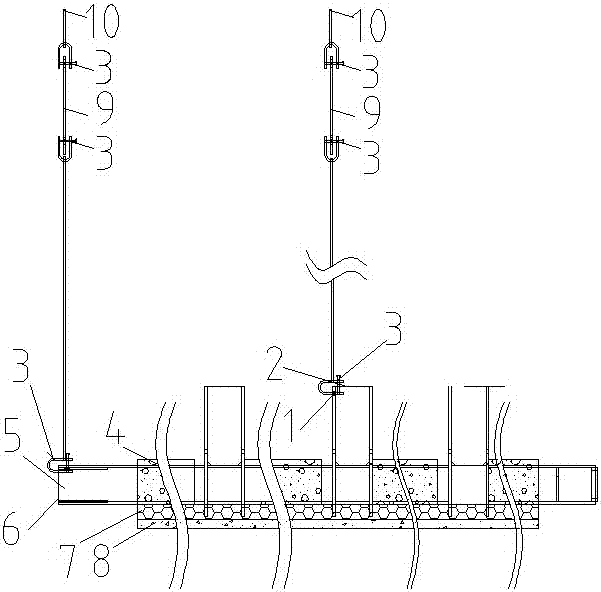

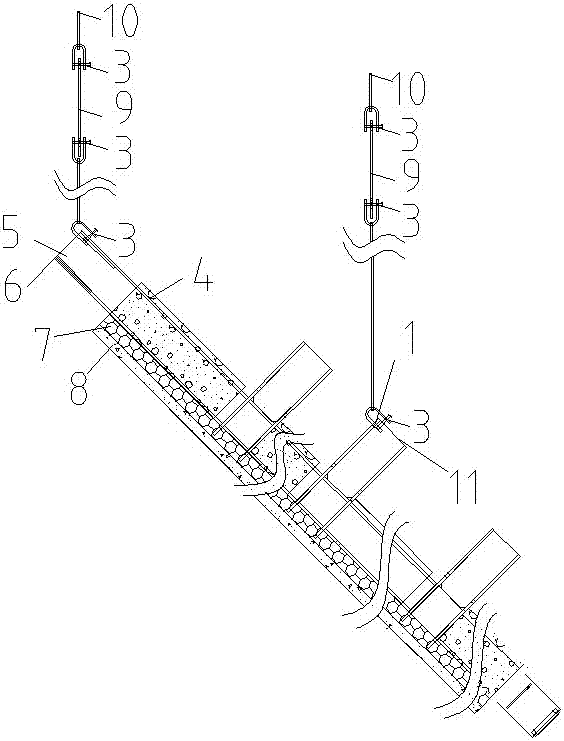

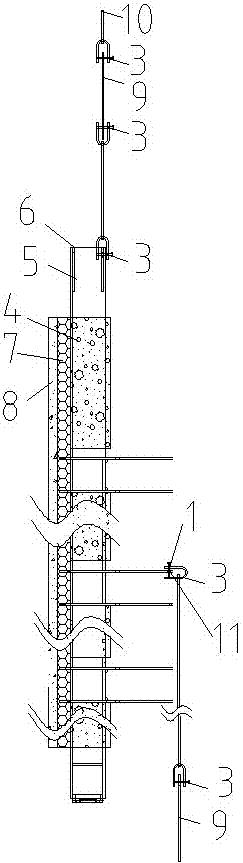

[0039] attached Figure 1-3 It can be seen that a hoisting method for a three-story composite steel column sandwich thermal insulation exterior wall panel of a prefabricated steel structure residence, the specific construction steps are as follows:

[0040] 1) Hanging point setting

[0041] The hoisting points of the multi-layer prefabricated exterior wall panels are set to 4 points for hoisting, the top of the steel column of the exterior wall panels is set at 2 points, and the middle section of the multi-layer prefabricated exterior wall panels is set with 2 hoisting points;

[0042] The top lifting point is the connecting ear plate of the outer wall panel, and the middle lifting point is the lifting hole opened on the upper flange plate of the steel beam corbel of the multi-layer platform;

[0043] 2) Spreader preparation

[0044] 2 pairs of hoisting slings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com