Embedding type anchoring device and anchoring method for pre-stressed anchor cable

A technology of prestressed anchor cables and anchoring devices, applied in construction, sheet pile wall, foundation structure engineering, etc., can solve the problems of application limitation of external waist beam, large construction deviation, large stress loss, etc., and achieve no anchoring structure falling. Risk, good structural reliability, and the effect of improving the compressive capacity of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0053] The invention provides a prestressed anchor cable embedded anchoring device, such as Figure 9 As shown, including stiffening structure 1, stiffening structure 1 is connected with retaining structure, retaining structure is supporting pile 2, stiffening structure 1 is welded with main reinforcement 7 of supporting pile 2, spiral reinforcement 8 or stiffening reinforcement 9 of supporting pile .

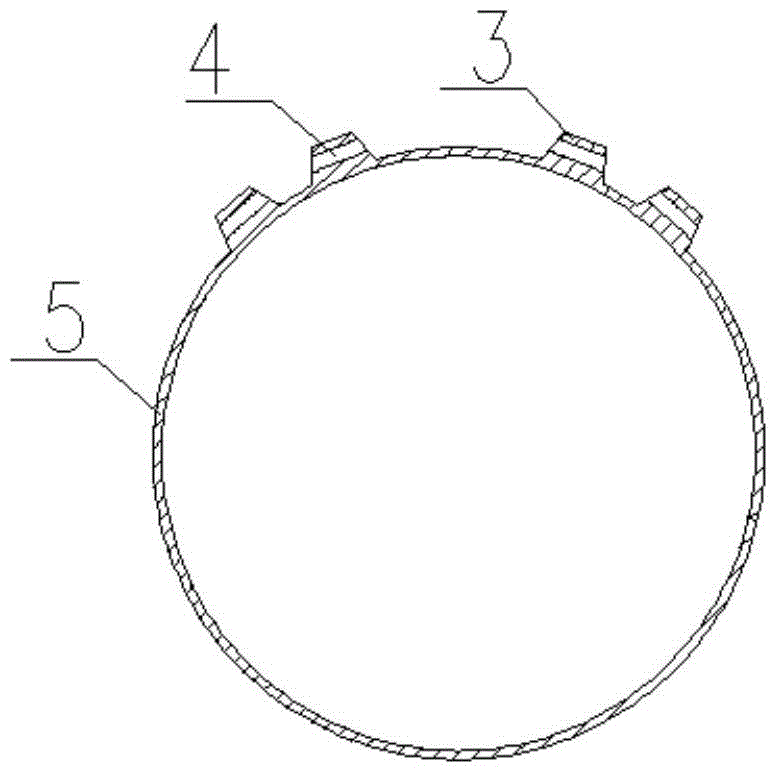

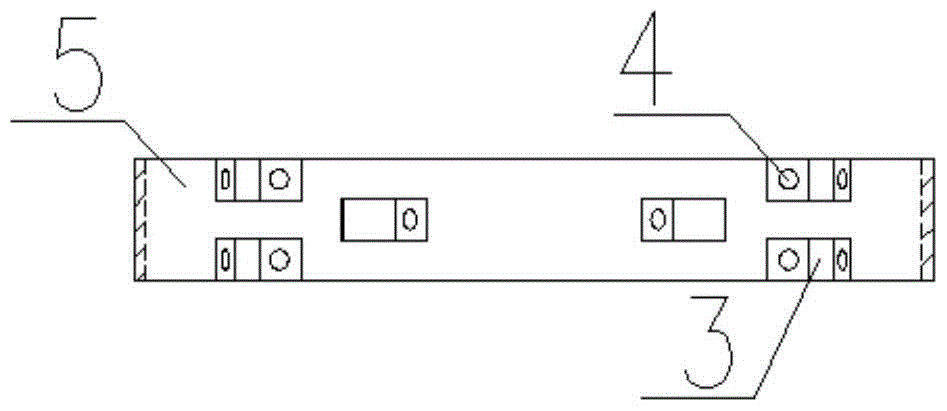

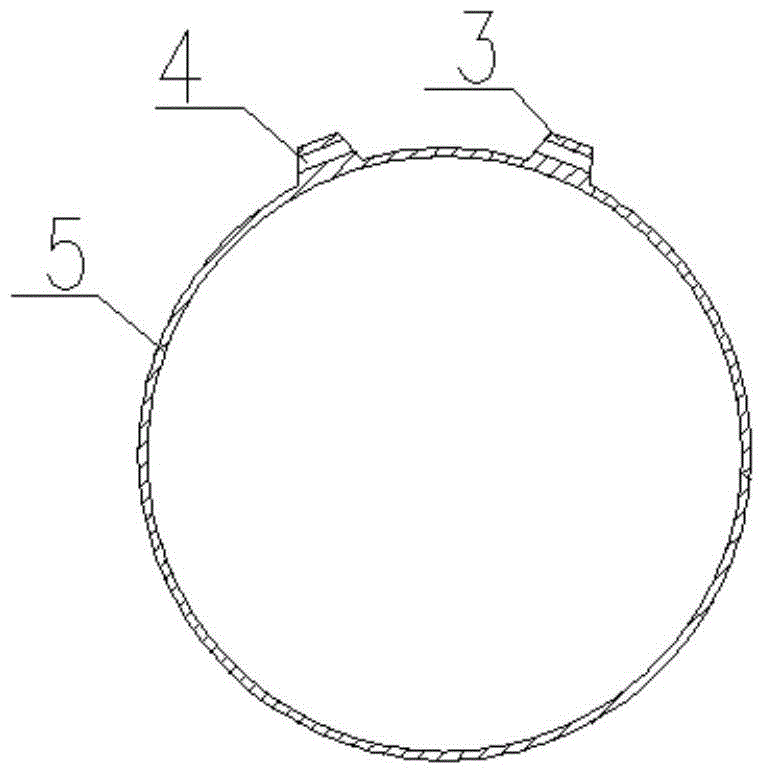

[0054] Such as Figure 1-8 As shown, the stiffening structure 1 is provided with an anchor support 3 , and the anchor support 3 is provided with a steel strand hole 4 .

[0055] The stiffening structure 1 is an annular stiffening plate 5, a square stiffening plate, a closed irregular stiffening plate, an arc stiffening plate 6, a linear stiffening plate, a groove stiffening plate, an unclosed irregular shaped stiffening plate or steel bars. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com