Well cementing slurry large temperature difference retarder and its preparation method

A technology of cementing slurry and large temperature difference, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve the effect of weak temperature sensitivity, promoting safety and efficiency, and better retarding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Take by weighing 60 parts of anionic monomer 2-acrylamide-2-methylpropanesulfonic acid, 25 parts of cationic monomer methacryloyloxyethyltrimethyl ammonium chloride ( DMC) and 15 parts of nonionic monomer acrylamide are placed in 330 parts of deionized water and dissolved completely, and 1.0 parts of ammonium persulfate are added as a polymerization initiator;

[0028] (2) Weigh 495 parts of white oil, 52.8 parts of Span 80 and 4.95 parts of Tween 80 according to the mass fraction of each component of the inverse emulsion system and add them to the reactor, adopt the mechanical emulsification method, and control the speed at 15000r / min~25000r / min Pre-emulsify at room temperature for 10 minutes;

[0029] (3) Weigh 330 parts of the solution prepared in step (1) according to the mass fraction of each component of the inverse emulsion system, place it in a constant pressure dropping funnel, slowly add it dropwise for 30 minutes, then stir the system at a constant tempe...

Embodiment 2

[0033] Add the cementing slurry large temperature difference retarder prepared in Example 1 into the corresponding cementing slurry system, and the mass fraction of each component of the large temperature difference cementing slurry system becomes:

[0034]

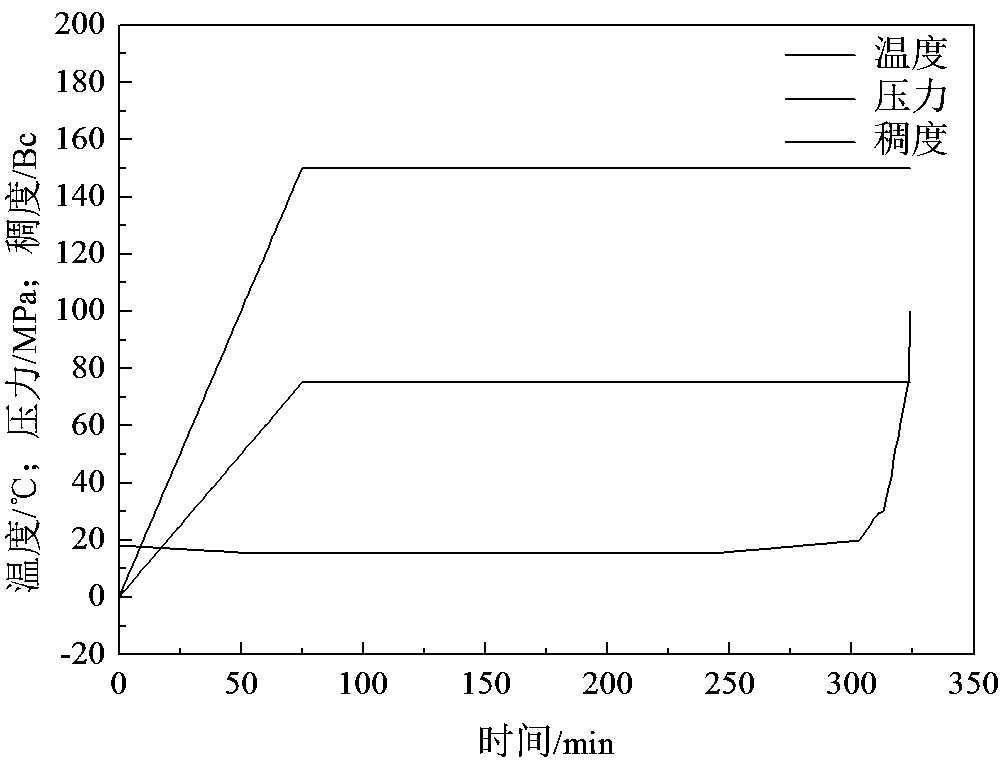

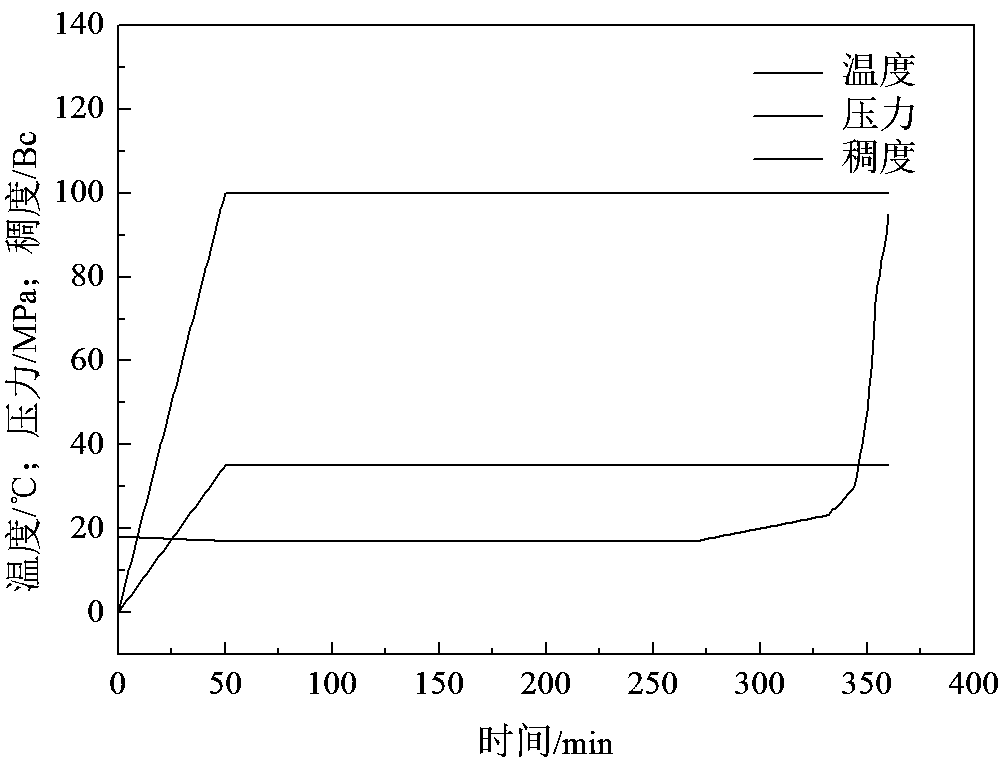

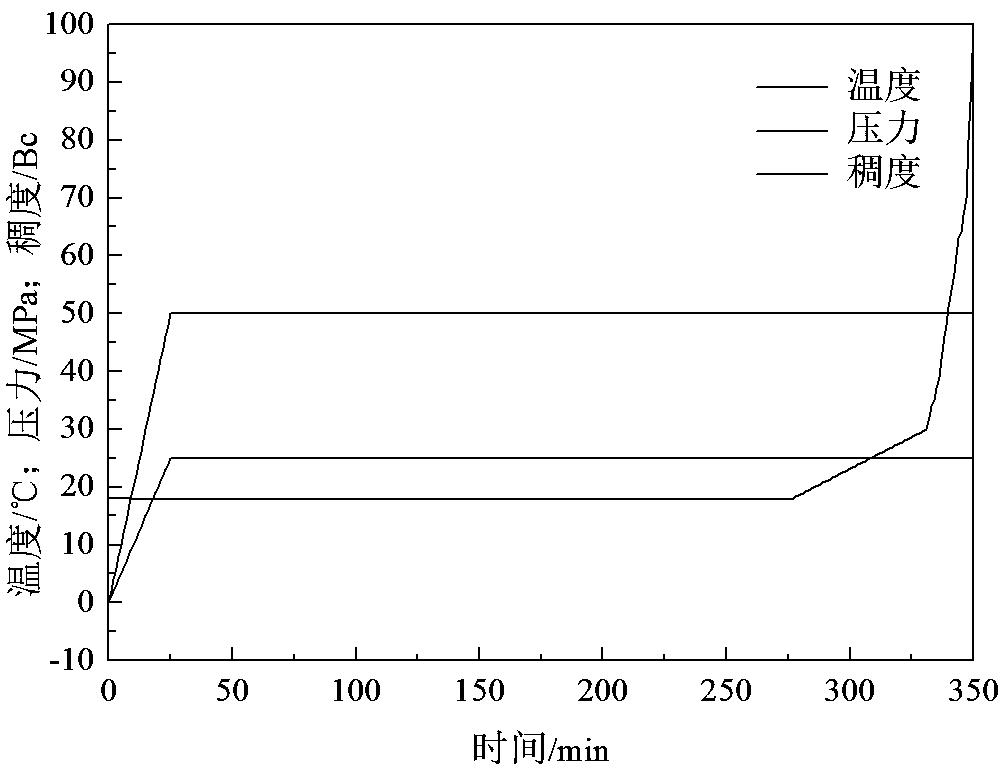

[0035] When the cementing slurry large temperature difference retarder of the present invention is added to the corresponding cement slurry system, the thickening curves under different conditions of 150°C×50MPa, 100°C×35MPa and 50°C×25MPa are as follows figure 1 , figure 2 and image 3 As shown, the experimental results show that: under the condition of 150℃×75MPa, the thickening time of the large temperature difference cementing slurry system is 324min, and the right angle thickening time is 11min, and the thickening line is good; under the condition of 100℃×35MPa, the large temperature difference cementing slurry system The thickening time of the system is 360min, the right-angle thickening time is 14min, and the ...

Embodiment 3

[0037] Add the cementing slurry large temperature difference retarder prepared in Example 1 into the corresponding cementing slurry system, and the mass fraction of each component of the large temperature difference cementing slurry system becomes:

[0038]

[0039] When the cementing slurry large temperature difference retarder of the present invention is added to the corresponding cement slurry system, under different conditions of 150°C×20MPa, 100°C×20MPa and 50°C×0.1MPa, the strength development of cement stone is as follows Figure 4 shown. Experimental results show that the large temperature difference retarder for well cementing slurry of the present invention can be used in the temperature range of 50°C to 150°C, and the strength of cement stones in both high and low temperature environments can meet the requirements of well cementing construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com