A kind of mining method of high viscosity oil

A mining method and viscous oil technology, which is applied in the fields of mining fluid, earthwork drilling, petroleum industry, etc. It can solve the problems of mining heavy oil reservoirs and high pour point oil reservoirs, difficulty in dehydration of production fluid, and high cost of water treatment. problems, to achieve the effect of improving oil displacement, enhancing oil recovery, and low equipment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

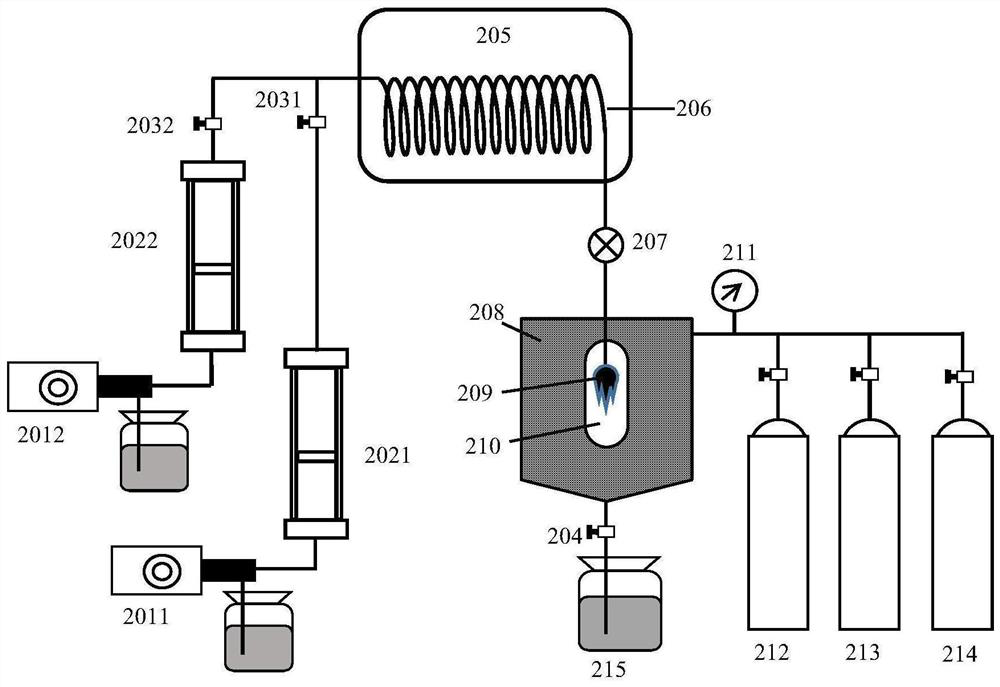

[0093] In this example, the low-viscosity oil is obtained by in-situ distillation and the safe injection temperature of the low-viscosity oil is determined by using the method of in-situ distillation of low-viscosity oil distillate huff and puff to exploit high-viscosity oil.

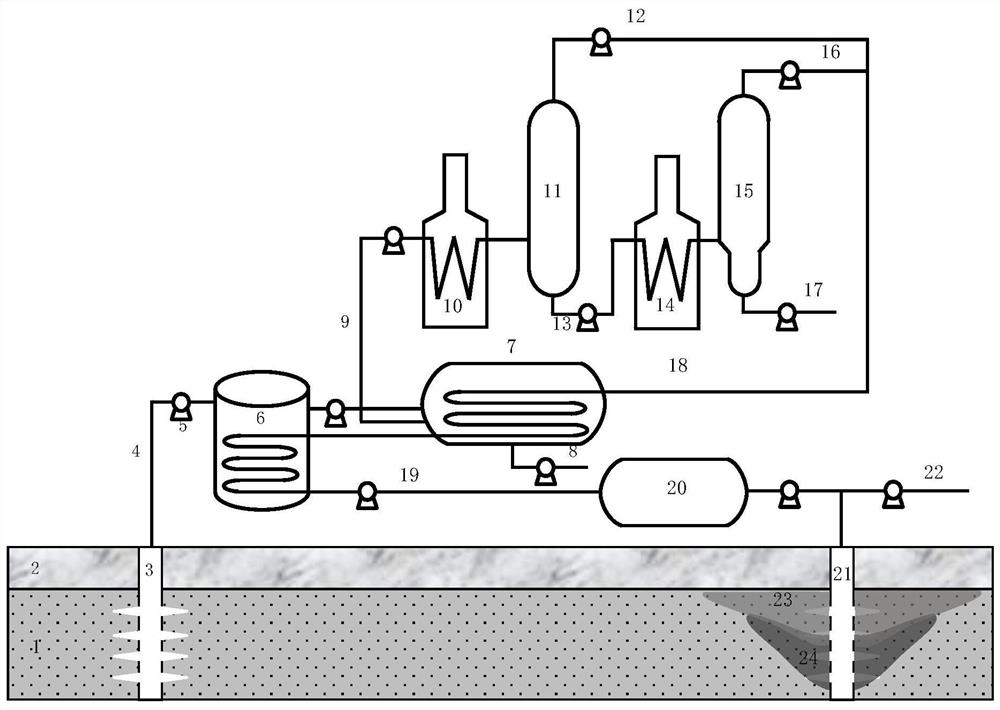

[0094] refer to figure 1 , the oil well 3 passes through the overlying rock layer 2 and enters the oil layer 1, and the high-viscosity oil produced by the oil well 3 is injected into the settling tank 6 through the high-viscosity oil pipeline 4 through the pump 5 to perform a dehydration and desanding treatment; after a dehydration and desanding process The treated high-viscosity oil is pumped into the dehydration and desalination treatment tank 7 for deep dehydration and desalination treatment, the high-viscosity oil is dehydrated to below 5%, and the brine produced by the dehydration and desalination treatment tank 7 is discharged through the brine pipeline; after dehydration and desalination treatment...

Embodiment 21

[0106] In this embodiment, the on-site distillation of low-viscosity oil fractions is used to develop thick-bed ultra-heavy oil reservoirs with horizontal wells deployed. In this example, an on-site distillation process similar to Example 1.1 was used to obtain injectable low-viscosity oil, and the light components and intermediate components obtained from the distillation were mixed to obtain viscosities of 150mPa·s, 75mPa·s and 37.5 at 50°C, respectively. mPa·s low viscosity oil.

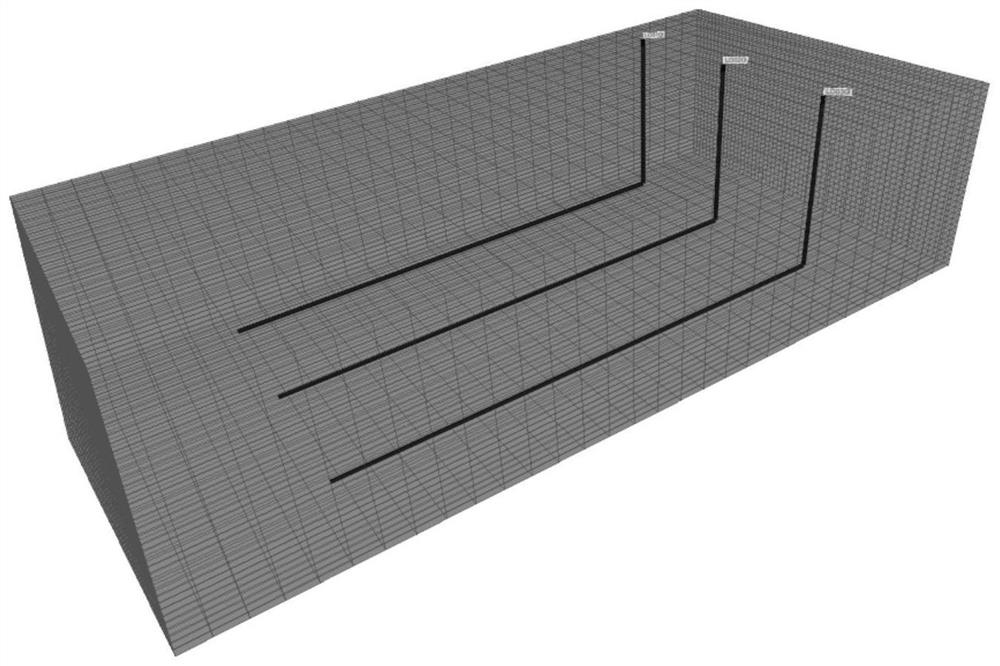

[0107] Such as image 3 As shown, a 600m×600m×30m horizontal, homogeneous and thick heavy oil reservoir has a top depth of 1000m and a thickness of 30m. Three horizontal wells are deployed in parallel. The length of each horizontal well is 400m. The position at the bottom of the oil layer is 3.5m, and the specific reservoir parameters are shown in Table 3. A homogeneous reservoir geological model with 60 × 30 × 30 grids was established. The size of the grid in the X direction is 5m, the size of ...

Embodiment 22

[0130] In this embodiment, thick-bed common heavy oil reservoirs with horizontal wells are exploited by using in-situ distillation of low-viscosity oil fraction huff and puff.

[0131] In this example, an in-situ distillation process similar to Example 1.1 was used to obtain injectable low-viscosity oil, and three viscosity grades of low-viscosity oil were obtained by mixing in different proportions. The viscosities at 50°C were 37.5 mPa·s, 75mPa·s and 100mPa·s.

[0132] The reservoir model produced is the same as in Example 2.1, except that the heavy oil is ordinary heavy oil, and the viscosity of the heavy oil is 1500mPa·s (the viscosity of degassed oil is 5260mPa·s) under formation conditions. Injection of high-temperature low-viscosity oil + nitrogen huff and puff production for 10 cycles, the injection-production cycle is 1 year, and a total of 10 years of production. In order to compare the effects, the injected low-viscosity oil temperatures were 50°C, 150°C, 180°C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com