Method for mounting inclined shaft internal pressure steel tube

An installation method and internal pressure technology, applied in the direction of pipeline laying and maintenance, pipes/pipe joints/pipe fittings, machinery and equipment, etc., can solve the problem of no installation method, etc., and achieve the effect of safe and efficient construction

Inactive Publication Date: 2013-09-04

CHINA GEZHOUBA GROUP CO LTD +1

View PDF3 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the installation of giant penstocks (10m-13.5m in diameter) in inclined shafts of hydropower projects is becoming more and more common, but there has been no complete, comprehensive and systematic installation method in the industry, especially the installation of penstocks with diameters exceeding 10m in inclined shafts in the Three Gorges There is still a blank before the project, and a large number of technical problems need to be solved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

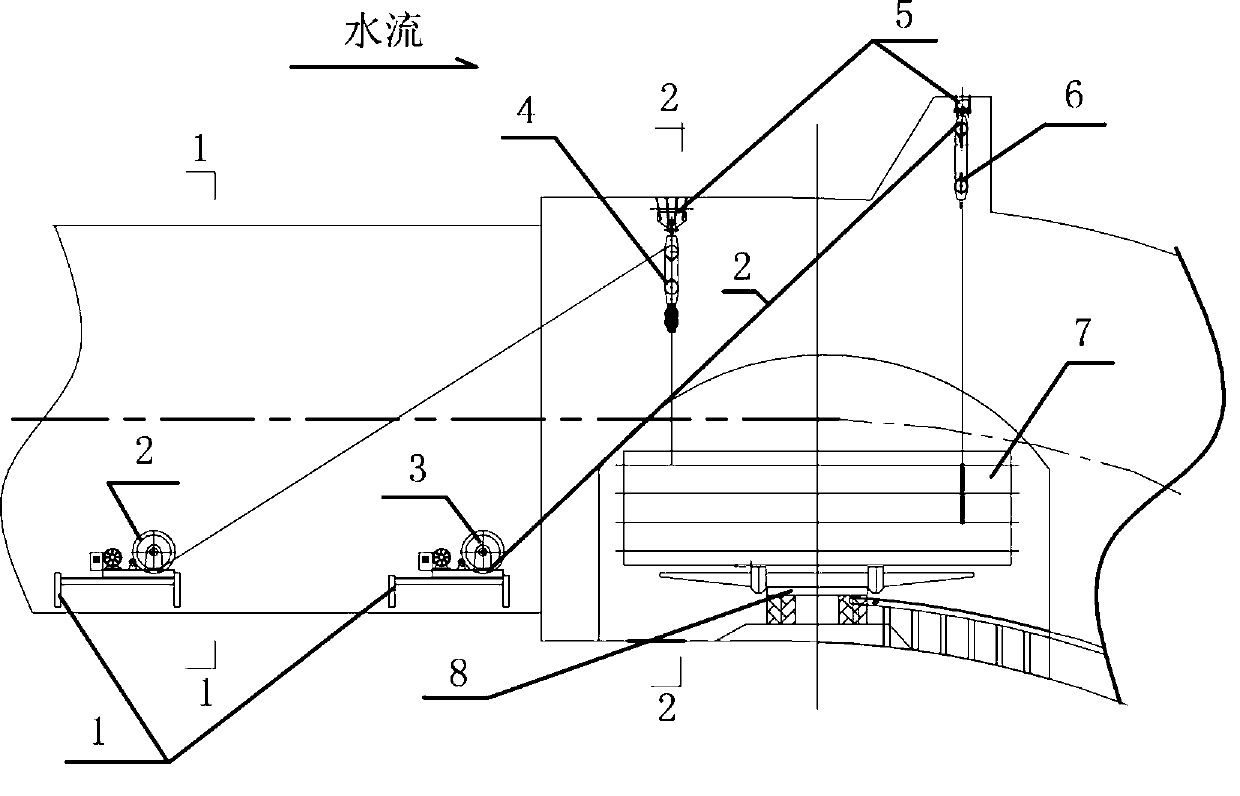

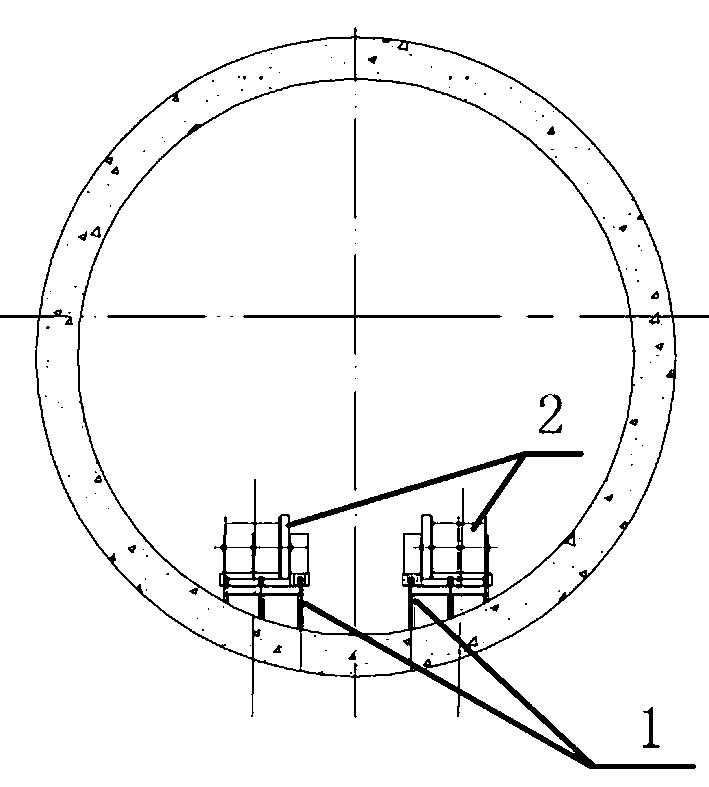

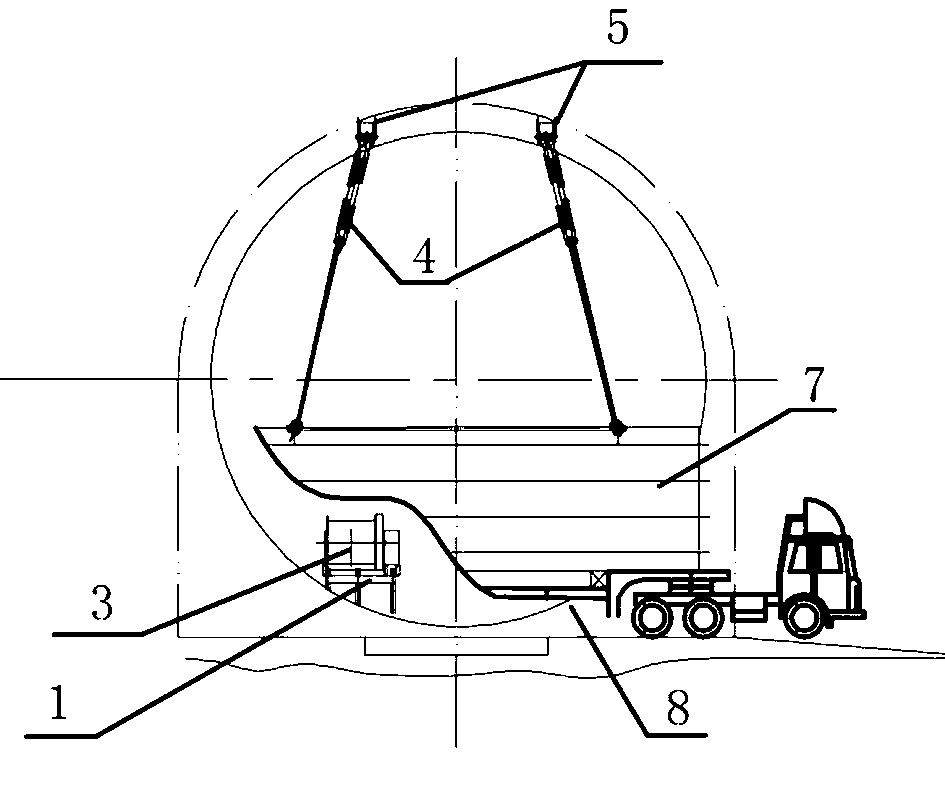

The invention relates to a method for mounting an inclined shaft internal pressure steel tube. The method comprises the steps of hoisting a hauling system, enabling a rail to slide downwards, enabling a trolley to slide downwards to complete a load test, conveying a tube coupling to be mounted of the pressure steel tube to a site, hoisting, unloading and turning over an upper slipway vehicle and a lower slipway vehicle by a winch hoisting system, tying the vehicles, connecting a gliding hauling system and the steel tube, removing a hoisting cable, enabling the hauling system to work, finishing gliding and humping of the tube coupling, unloading the tube coupling and enabling the lower slipway vehicle to reset. According to the method for mounting the inclined shaft internal pressure steel tube, a mathematical model calculation achievement which is established according to the mechanics principle is combined with a model test and a prototype test to demonstrate the feasibility of two-point towing gliding, a series of technical problems of optimizing of the structure of an anchor inside a cave chamber, rope jumping and nesting of a winch in the heavy loading process, selecting, calculating and demonstrating of a gliding towing point, designing of the structure of the trolley, synchronization balancing of double-traction, preventing abnormal abrasion of a steel wire rope of a multiplying power pulley block and gliding in-place unloading of the steel tube are solved comprehensively and systematically, and construction is safe and efficient.

Description

technical field [0001] The invention relates to a method for installing penstock steel pipes, in particular to a method for installing super-large and super-heavy giant penstock steel pipes in inclined shafts of hydropower projects that require high synchronization difference balance. Background technique [0002] At present, the installation of giant penstocks (10m-13.5m in diameter) in inclined shafts of hydropower projects is becoming more and more common, but there has been no complete, comprehensive and systematic installation method in the industry, especially the installation of penstocks with diameters exceeding 10m in inclined shafts in the Three Gorges There is still a blank before the project, and a large number of technical problems need to be solved. Contents of the invention [0003] In order to overcome the deficiencies of the existing technology, a complete, comprehensive and systematic installation method is provided, which can meet the installation requi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16L1/028

Inventor 陈群运张为明梅俊曾明程建文卫书满胡亚军黄森发

Owner CHINA GEZHOUBA GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com