Tunnel drilling method using double-boom drill jumbo

A technology of rock drilling rig and drilling method, which is applied in drilling equipment and methods, drilling equipment, earthwork drilling, etc. Benefits, the effect of promoting efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

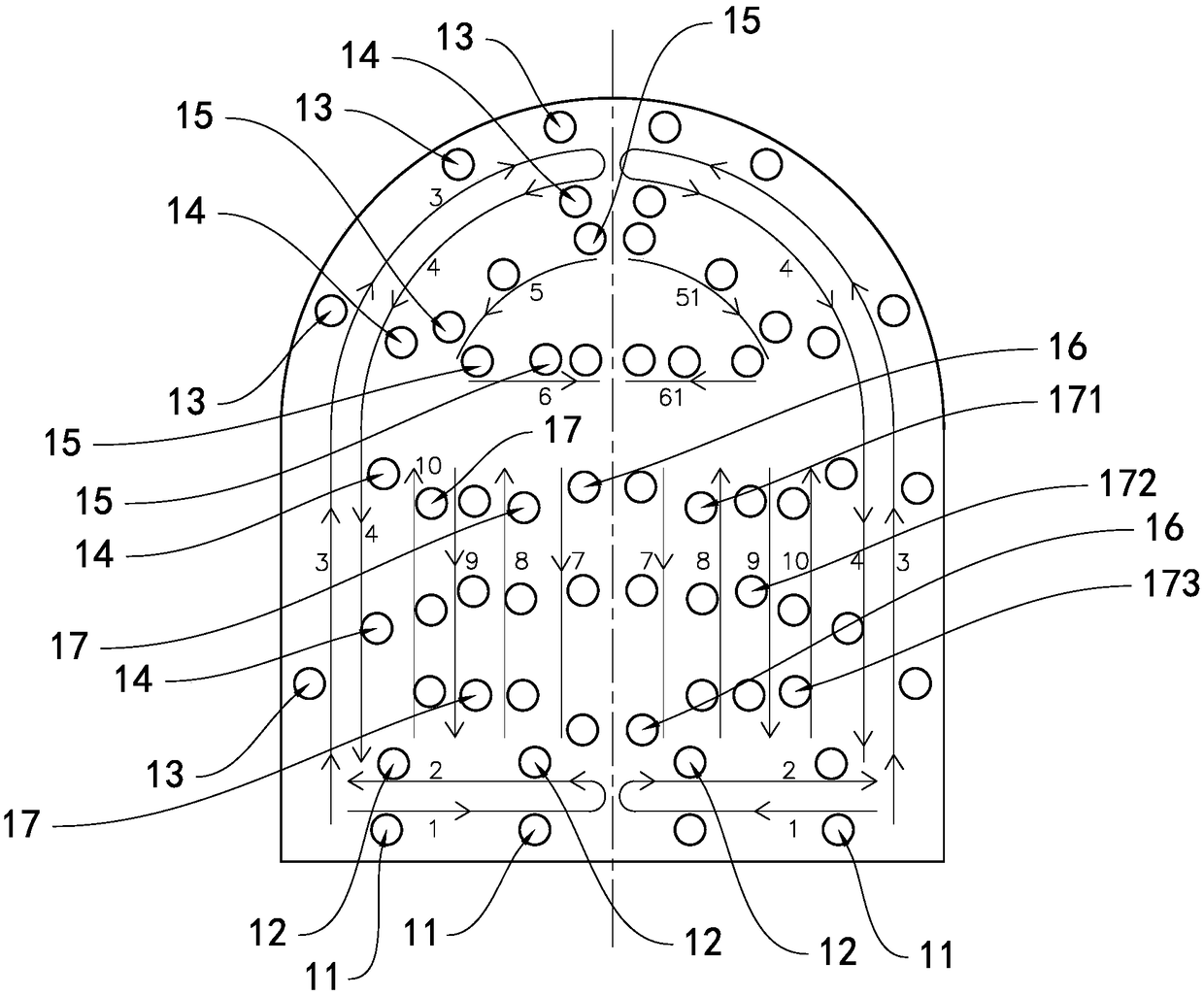

[0017] see figure 1 , the tunnel drilling method of the two-arm rock drilling jumbo provides a two-arm rock drilling jumbo, the two-arm rock drilling jumbo includes a left drilling arm and a right drilling arm, and the two-arm rock drilling jumbo tunnel drilling method is carried out according to the following steps :

[0018] S1 Drilling Bottom Hole 11: The left drill arm and the right drill arm are respectively drilled from the outer foot of the tunnel to the center of the tunnel relative to each other. The drilling direction of the left drill arm and the right drill arm is figure 1 In the direction of arrow 1;

[0019] S2 drilling and lifting gun 12: the left drilling arm and the right drilling arm respectively drill holes from the center of the tunnel to the two sides away from each other. The drilled holes are the lifting gun 12, and the lifting gun 12 is located in the bottom hole 11 along the vertical direction. Above, the drilling direction of the left and right dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com