Patents

Literature

64results about How to "Simple construction work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

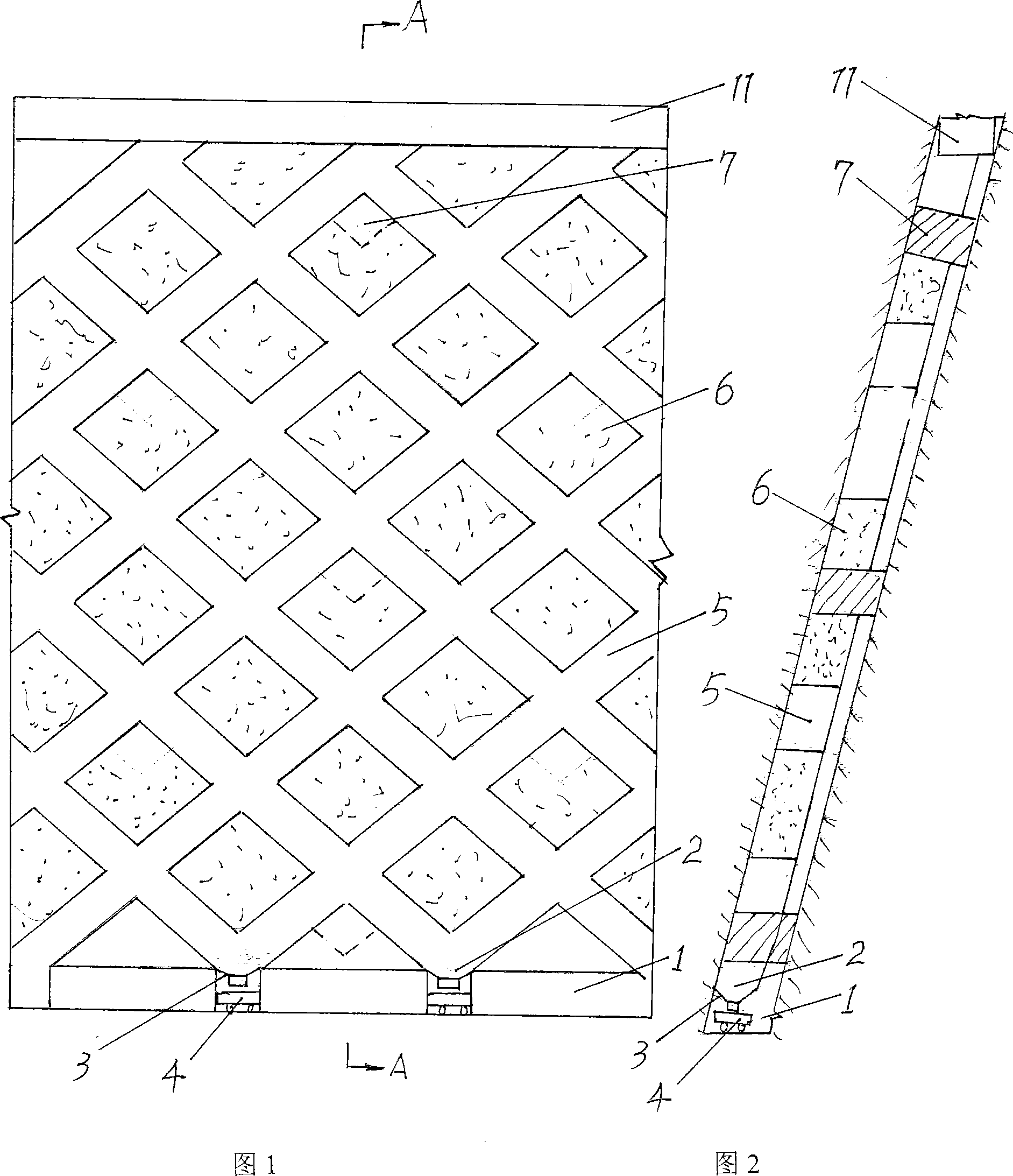

High-dipping ore block house column mining method

InactiveCN101509377AEasy to mineReduce depletion rateUnderground miningSurface miningRoom and pillar miningEngineering

The invention provides a steeply inclined ore body room-and-pillar mining method, comprising the following steps: a traveling roadway is tunneled along the trend of the ore body; broken-ore troughs are tunneled in the traveling roadway at interval with the broken-ore troughs as junctions, two inclined shafts are tunneled toward the uphill direction to the top of a quarry; a rhombic ore block formed between the inclined shafts is mined from top to bottom in sequence; ore pillars are left in the rhombic ore block at interval; ores mined in the process of tunneling slip into the broken-ore troughs along the inclined shafts depending on self weight and then put into a mine car in the traveling roadway from the broken-ore troughs to be delivered; the tunneled inclined shafts in networked cross distribution can serve as a passage and an ore chute for the miners to go up and down and as a ventilation shaft and a workplace for rock drilling, ore breaking and blasting avoiding. The method is good in ventilation effect, safe, reliable, low in cost, simple in construction operation, high in ore recovery ratio and low in dilution ratio.

Owner:KUNMING IRON & STEEL GRP CO LTD

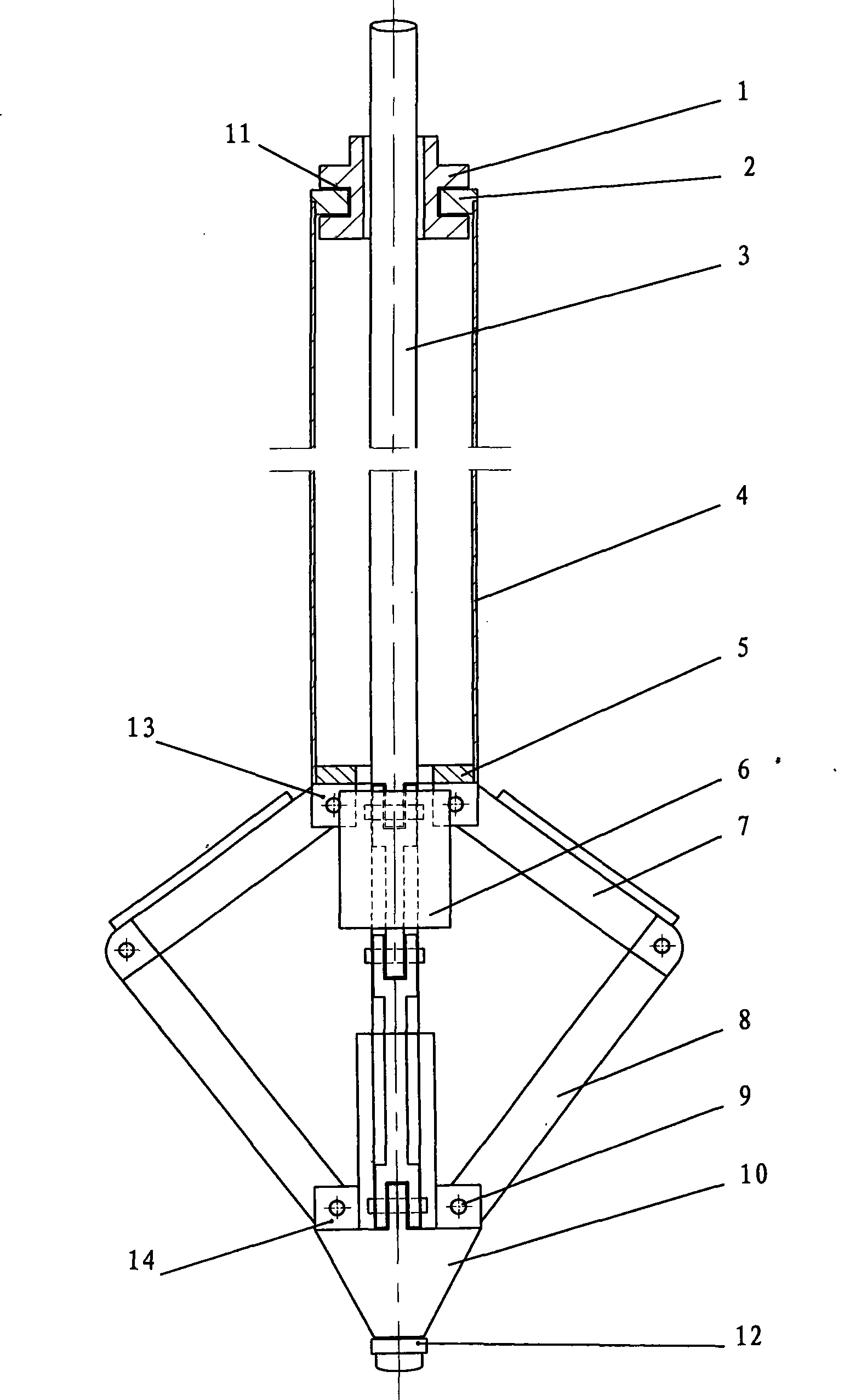

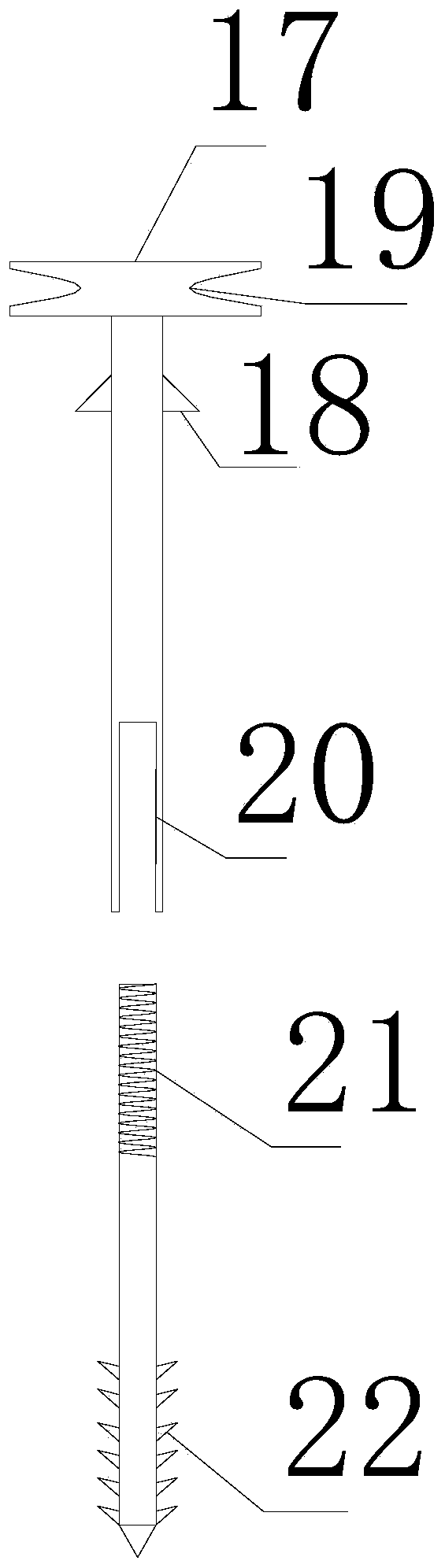

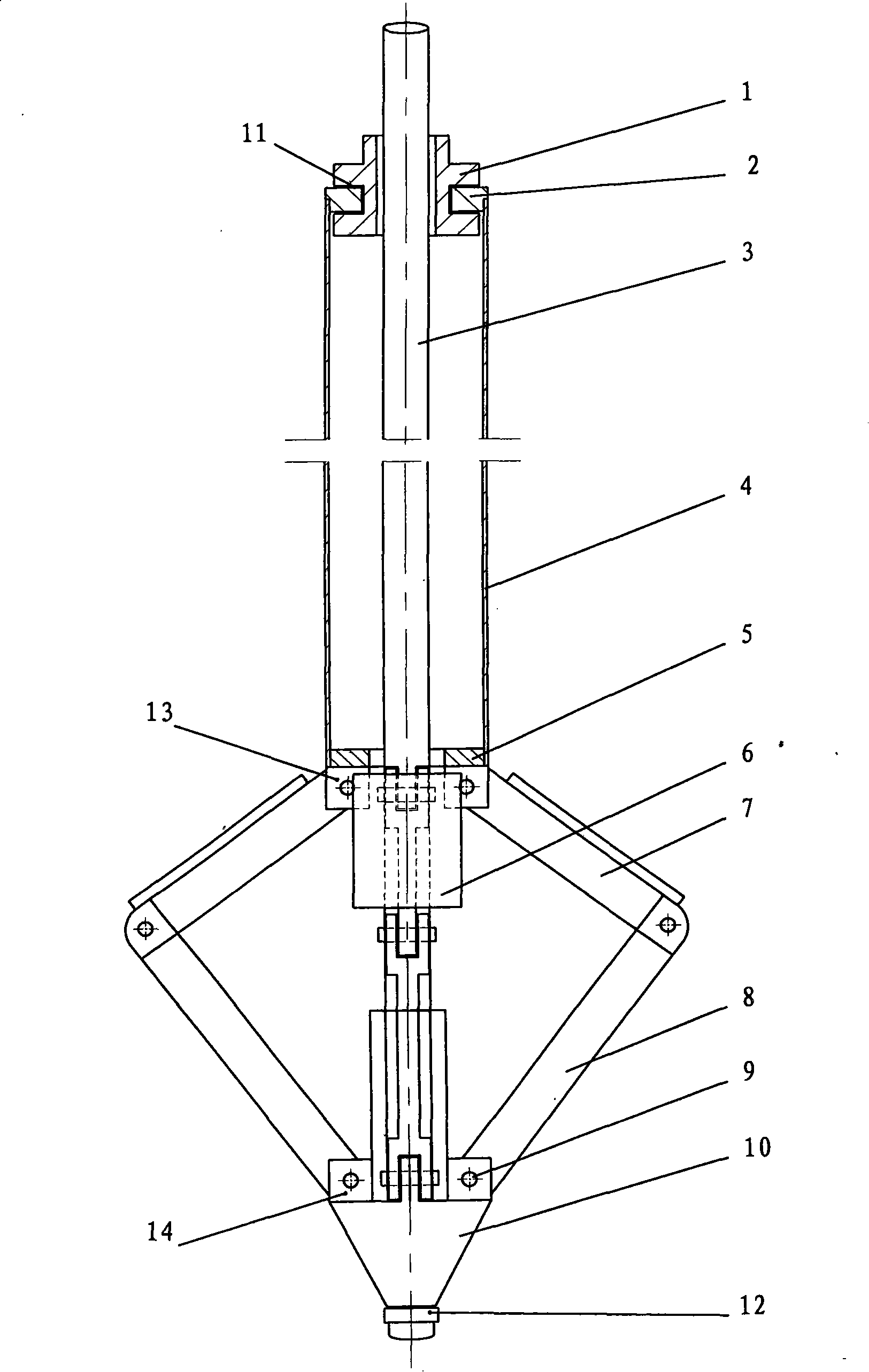

Recoverable anchor rod

InactiveCN101469541ASave underground spaceReduce underground environmental pollutionBulkheads/pilesAnchoring boltsSteel tubeUnderground space

The invention relates to a recovery type anchor bar, comprising an outer sleeve steel pipe, a screw rod disposed in the outer sleeve steel pipe along the axial direction, an upper cover board fixed on the top of the outer sleeve steel pipe, a regulation nut disposed at center of the upper cover board, a lower cover board fixing on the bottom end of the outer sleeve steel pipe, an anchor cone disposed right under the lower cover board, and a plurality of upper connection boards disposed on bottom end of the lower cover board, wherein the upper portion of the screw rod is attached to the regulation nut through a screw thread, the lower portion of the screw rod is attached to the anchor cone. Each upper connection boards is hinged to the top of an upper pulling rod, bottom end of each upper pulling rod is hinged to the top of a lower pulling rod, bottom end of each lower pulling rod is respectively attached to the anchor cone through a pin. Object of the invention is to provide a recovery type anchor bar which is high in shearing resistance capacity, underground space saving, underground environment pollution-free, and steel saving.

Owner:YANTAI UNIV

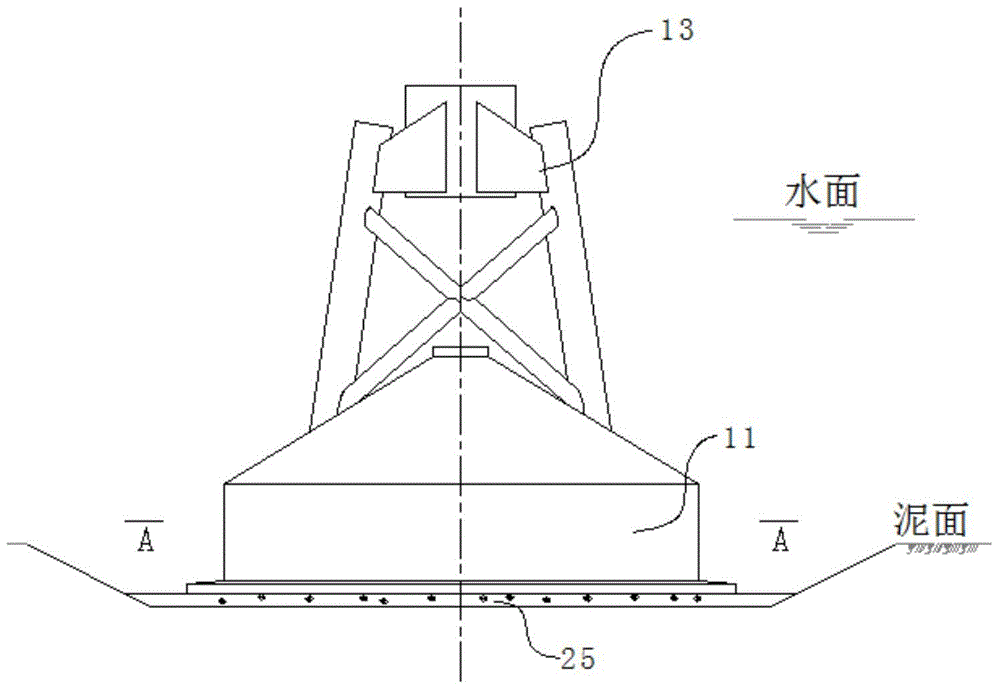

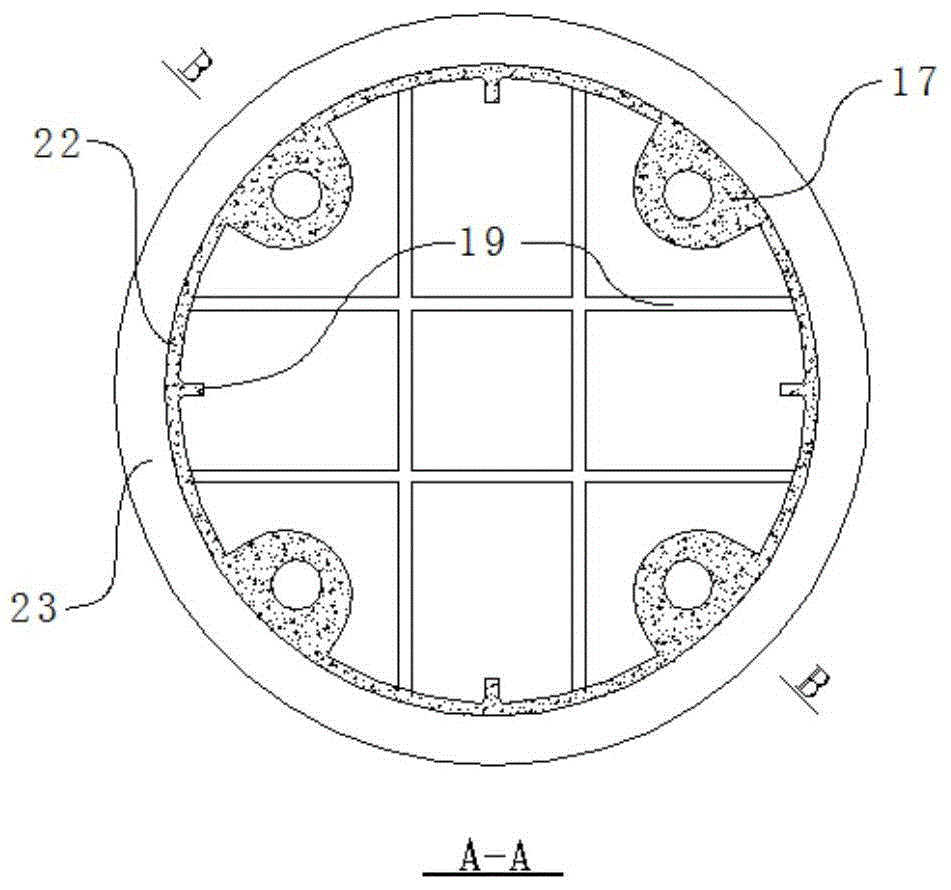

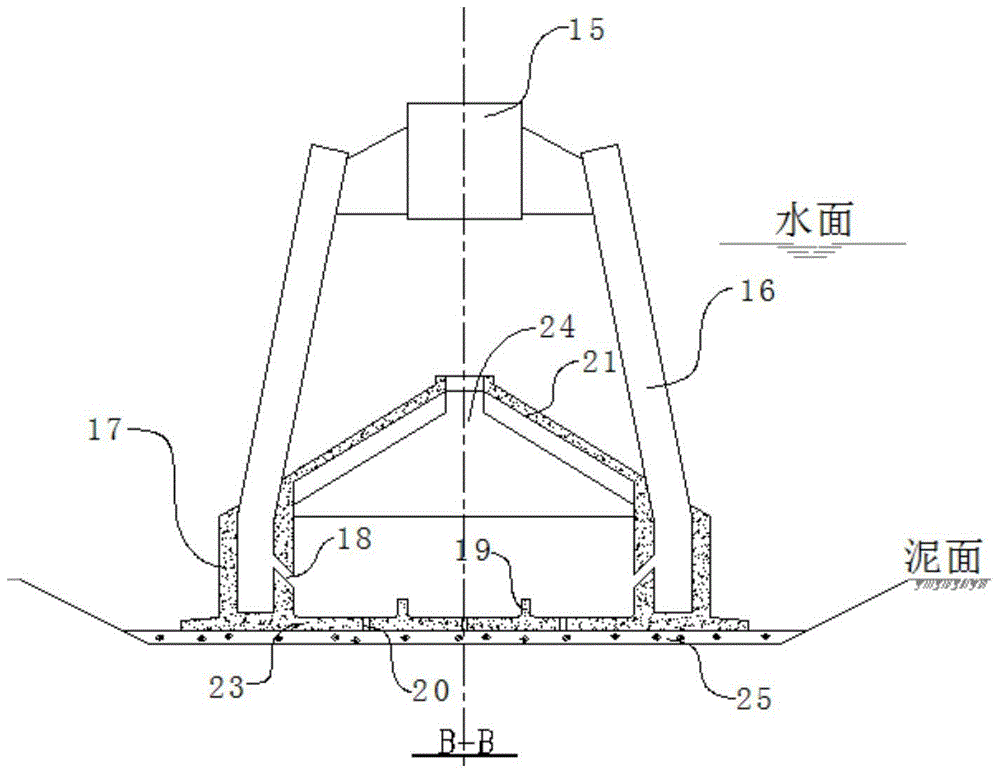

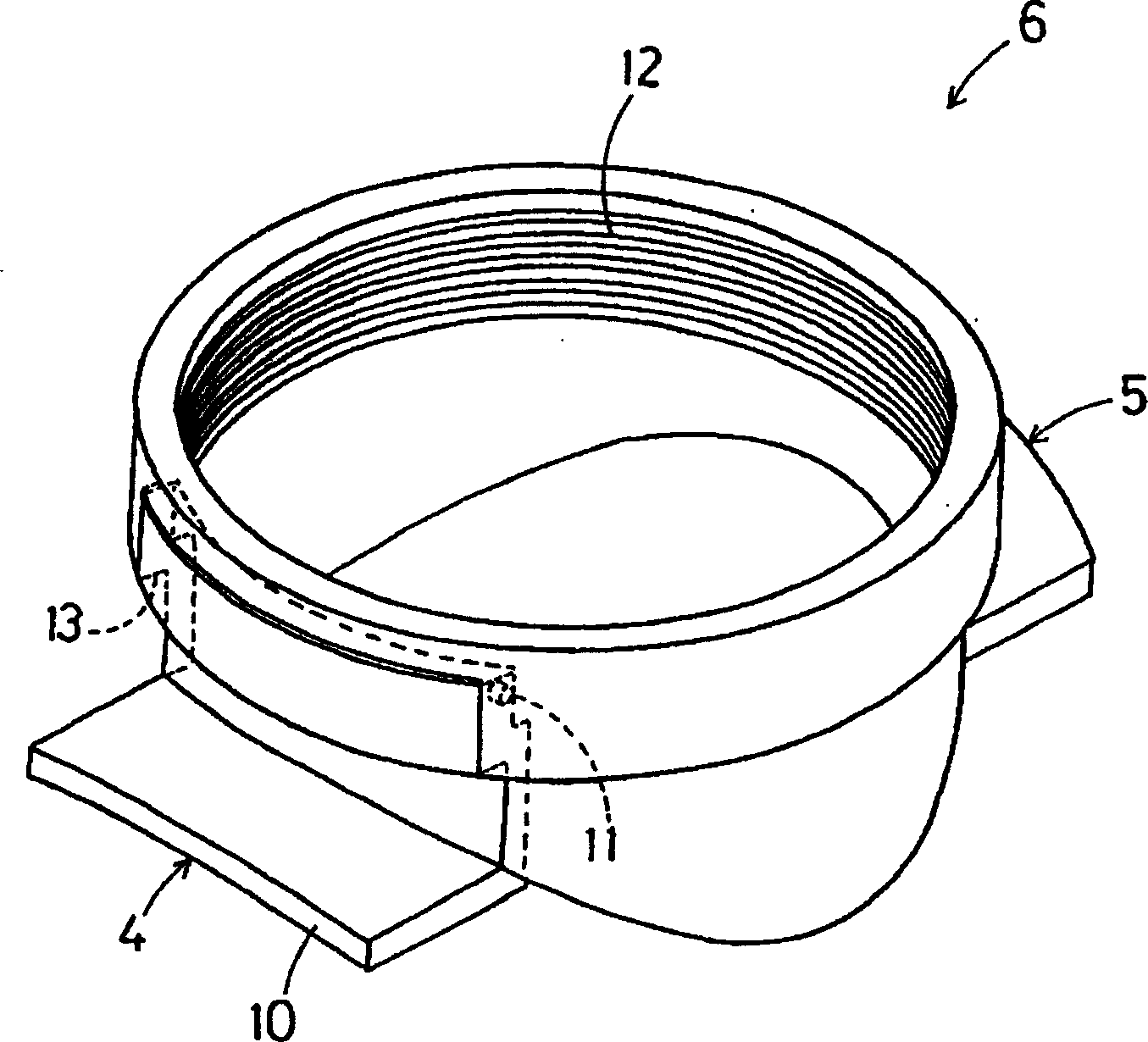

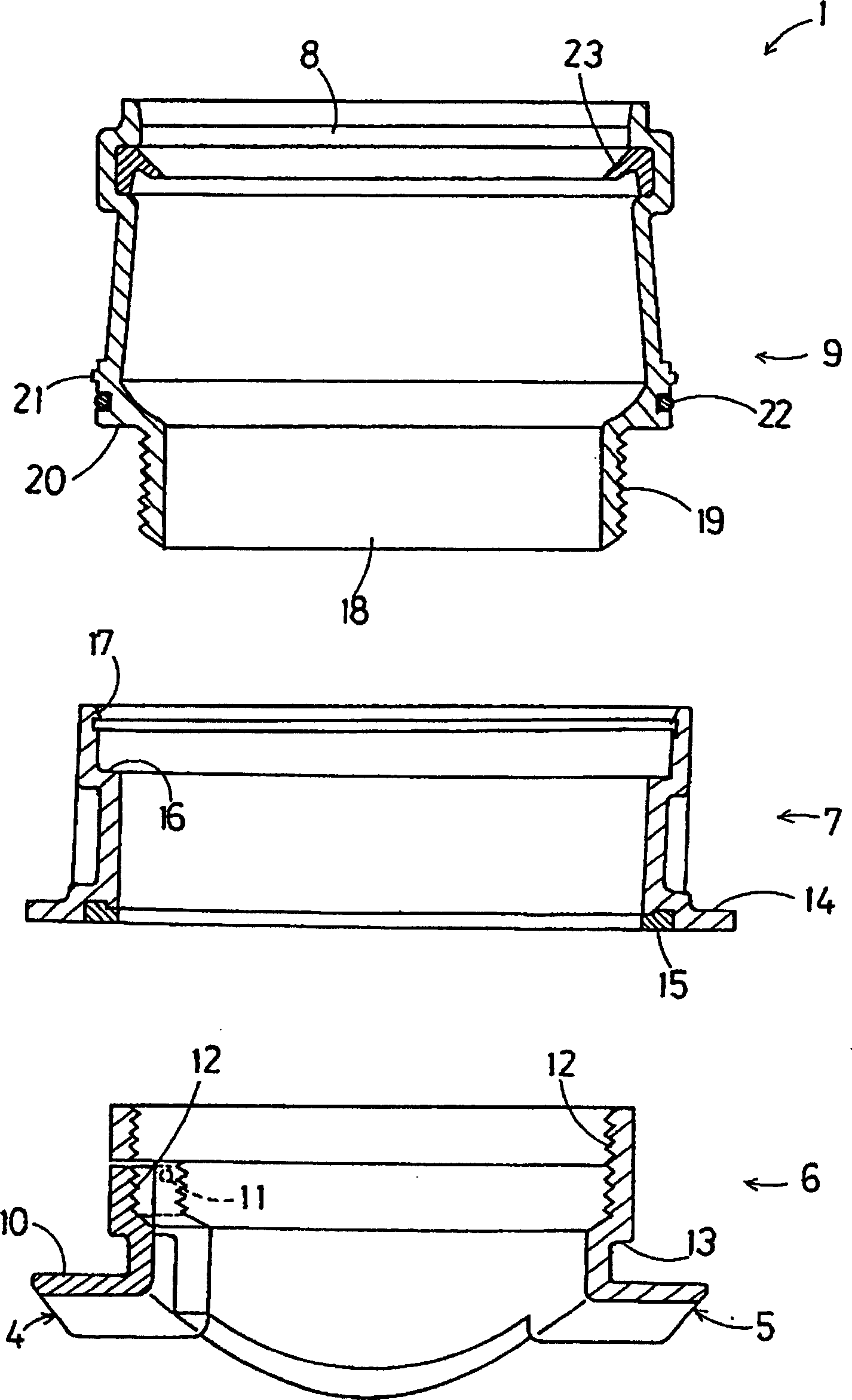

Reinforced concrete-steel structure hybrid gravity foundation for offshore wind power and construction method thereof

ActiveCN104389318ASimple and fast constructionHigh degree of factoryFoundation engineeringHybrid typeElectricity

The invention discloses a reinforced concrete-steel structure hybrid gravity foundation for offshore wind power. The reinforced concrete-steel structure hybrid gravity foundation comprises a caisson base and an upper steel support structure, wherein the caisson base has a gravity type reinforced concrete cavity structure; the steel support structure is fixed on the caisson base; the top end of the steel support structure is provided with a foundation ring which is connected with a fan tower; the caisson base and / or the steel support structure is provided with an irrigation channel which is communicated to the cavity of the caisson base. The invention further discloses a construction method of the reinforced concrete-steel structure hybrid type gravity foundation for offshore wind power. Compared with an ordinary jacket and single pile foundation, the reinforced concrete-steel structure hybrid gravity foundation has the advantages that the advantages of a reinforced concrete structure and a steel structure are combined organically; the reinforced concrete cavity structure is taken as a foundation base, and the steel structure is taken as an upper support structure; a pile foundation is not required; the foundation is made on the land, is assembled integrally, and can be transported by means of semi-submersible barge or the own buoyance. The reinforced concrete-steel structure hybrid gravity foundation is easy and convenient for construction, is shorter in the construction period, is economical, and has a wide application prospect in an offshore wind power project.

Owner:广州华申建设工程管理有限公司

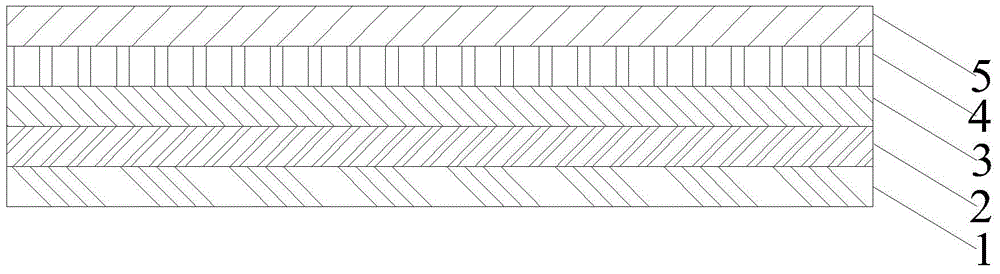

A digital printing magnetic composite sheet material with personality and an installing method

InactiveCN104589723ANo mold requiredNo feeCovering/liningsSynthetic resin layered productsEnvironmental resistancePrinting ink

A digital printing magnetic composite sheet material with personality and an installing method are disclosed. The sheet material comprises a magnetic composite material layer, a substrate layer disposed on the magnetic composite material layer, a UV pain adhering layer disposed on the substrate layer, a UV printing ink layer disposed on the UV pain adhering layer, and a UV paint protective layer disposed on the UV printing ink layer. By adoption of the structure mentioned above, the sheet material can meet personality needs on decoration styles and effects of different customers, can be customized freely regardless of the quantity, and does not has a die sinking cost or a platemaking cost. All structural components of the sheet material are environmental friendly. The sheet material has certain fireproof performance, waterproof performance, and other comprehensive performance. In the aspect of product construction, compared with construction of tradition decorative sheet materials, construction of the sheet material is environmental friendly, simple and convenient, customers can install and pave the sheet material by themselves, and matched paving materials can be recycled and reutilized, thus reducing the construction cost and reducing secondary pollution of re-decoration to the environment.

Owner:张光英

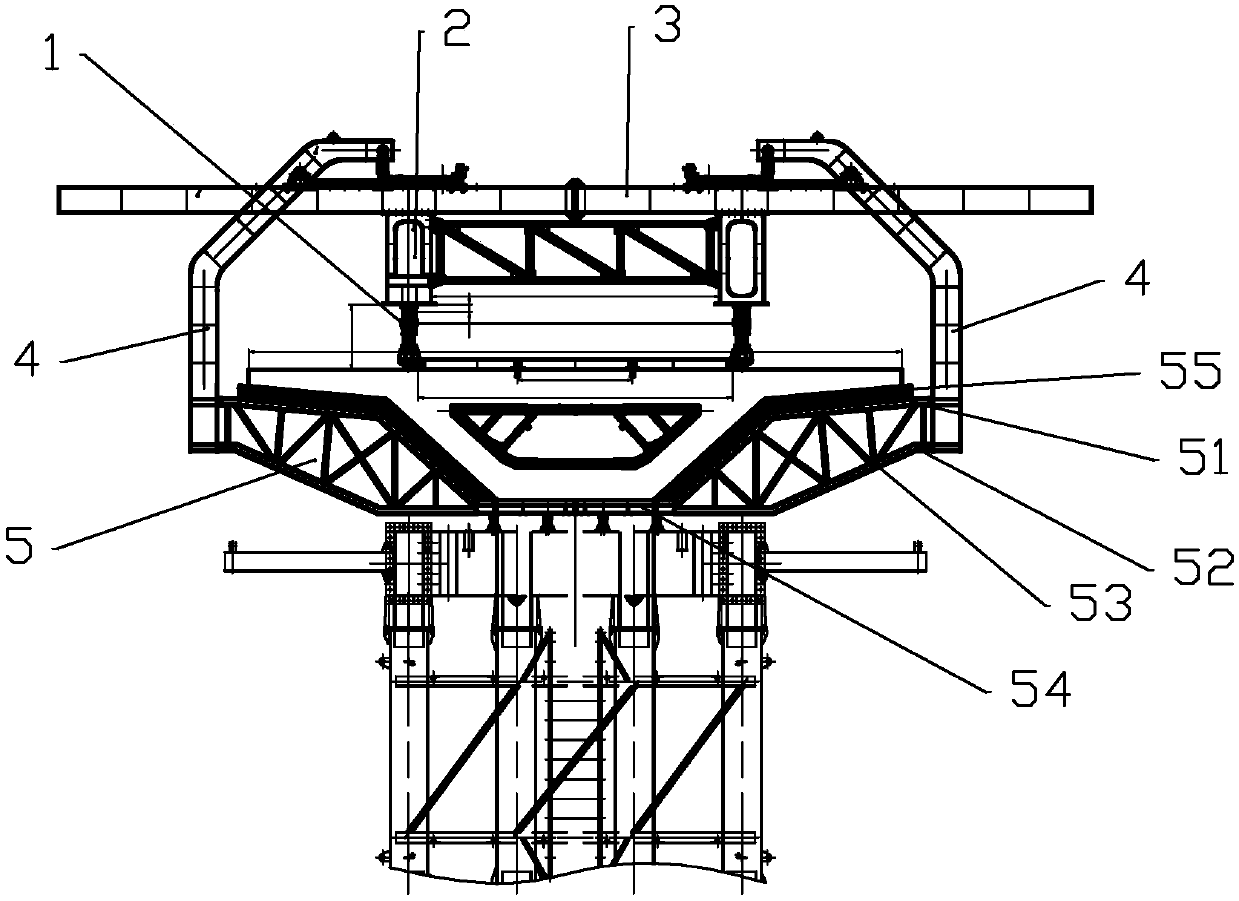

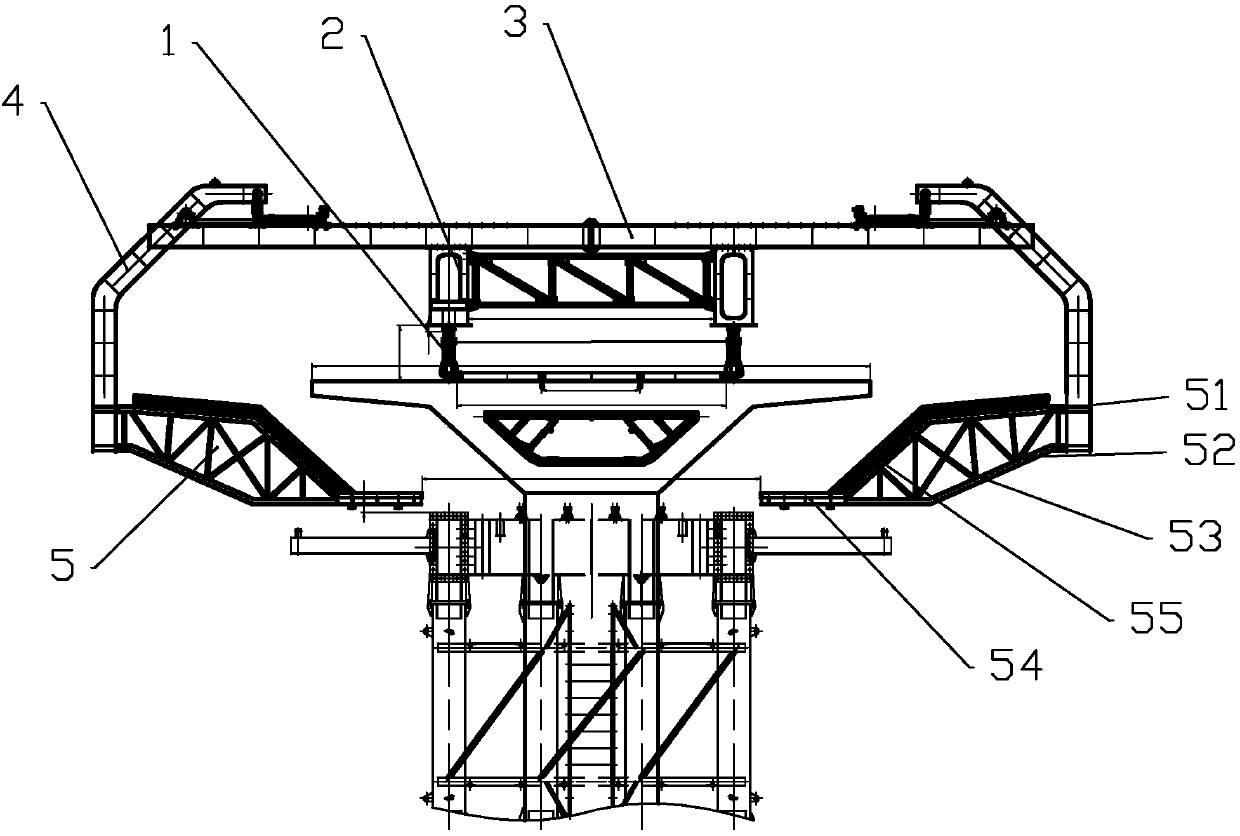

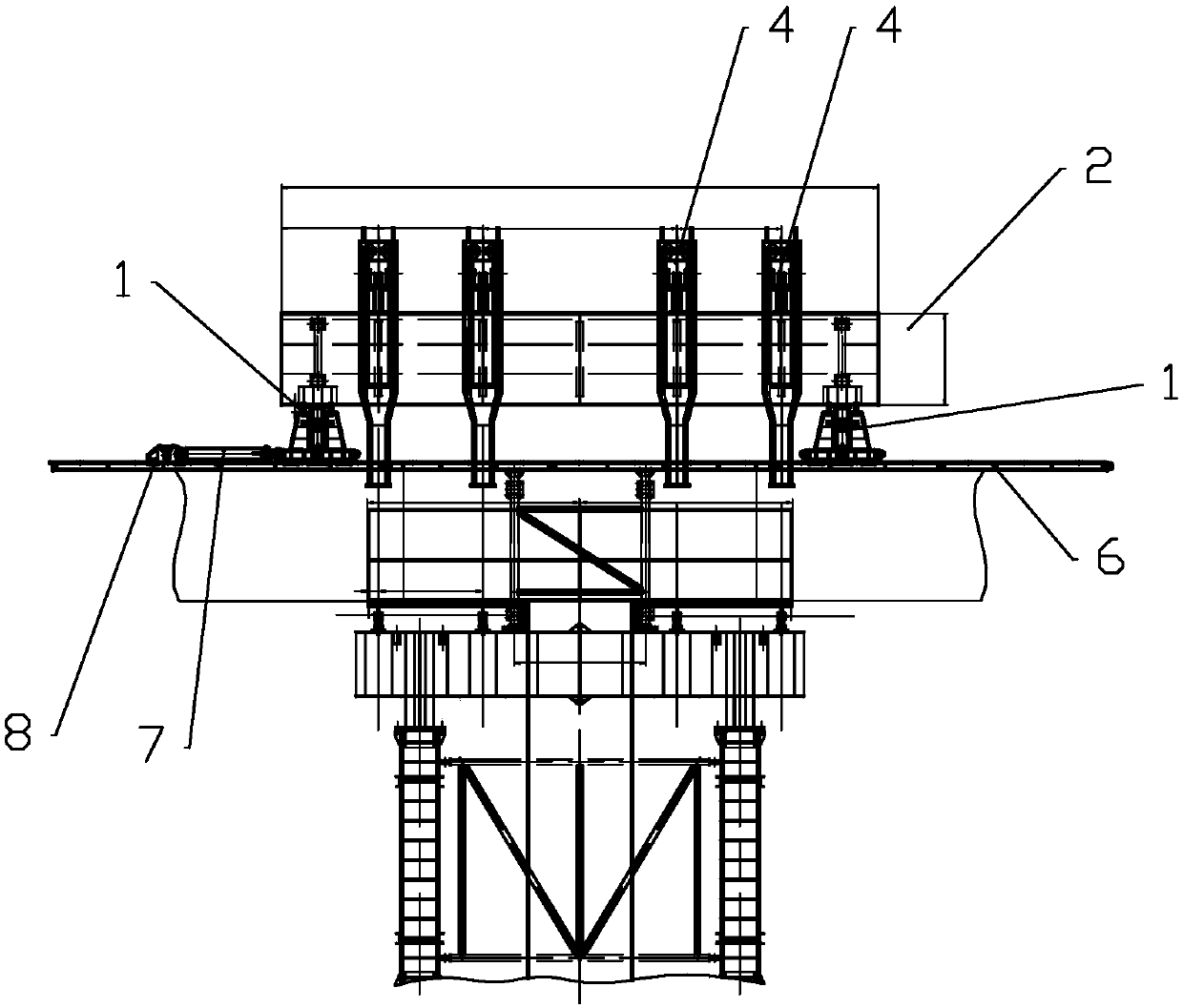

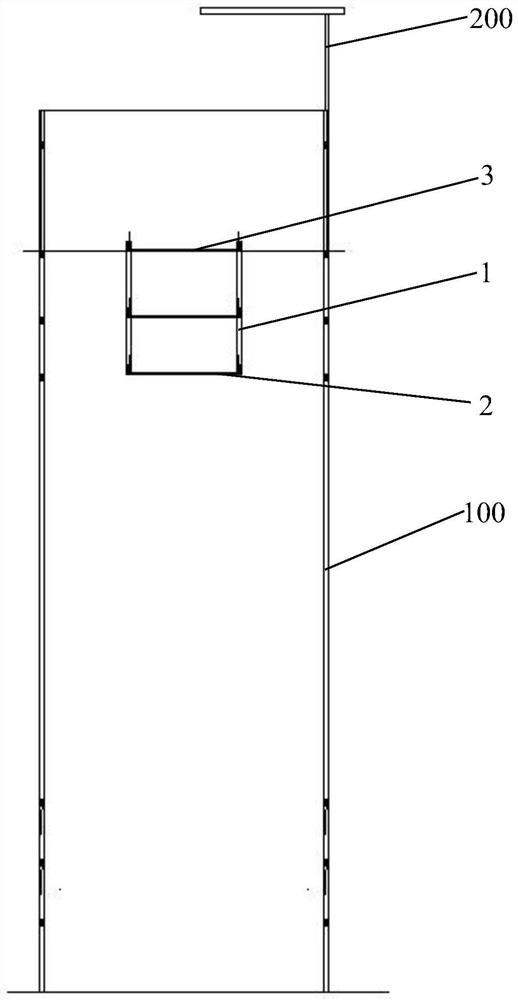

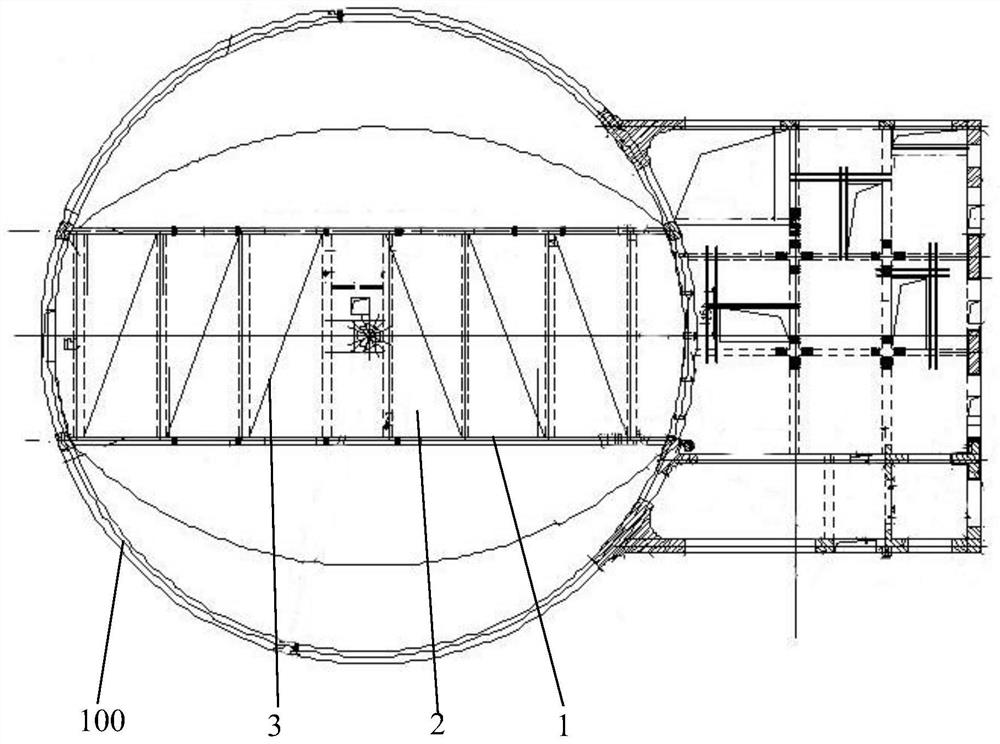

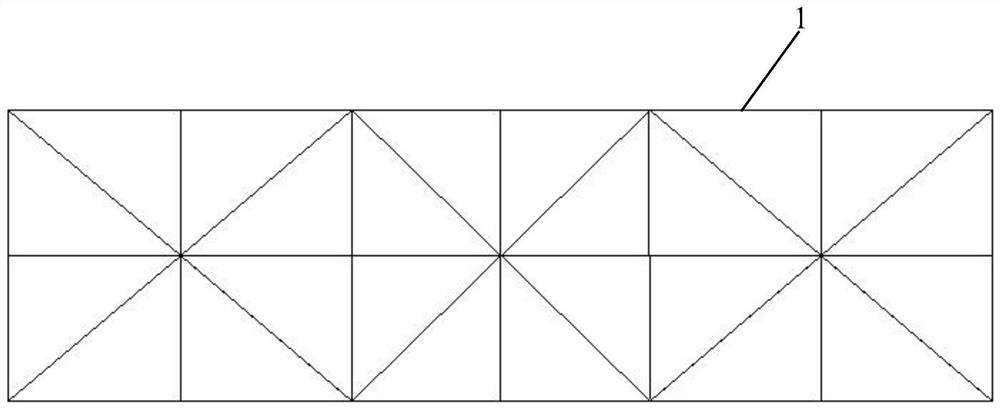

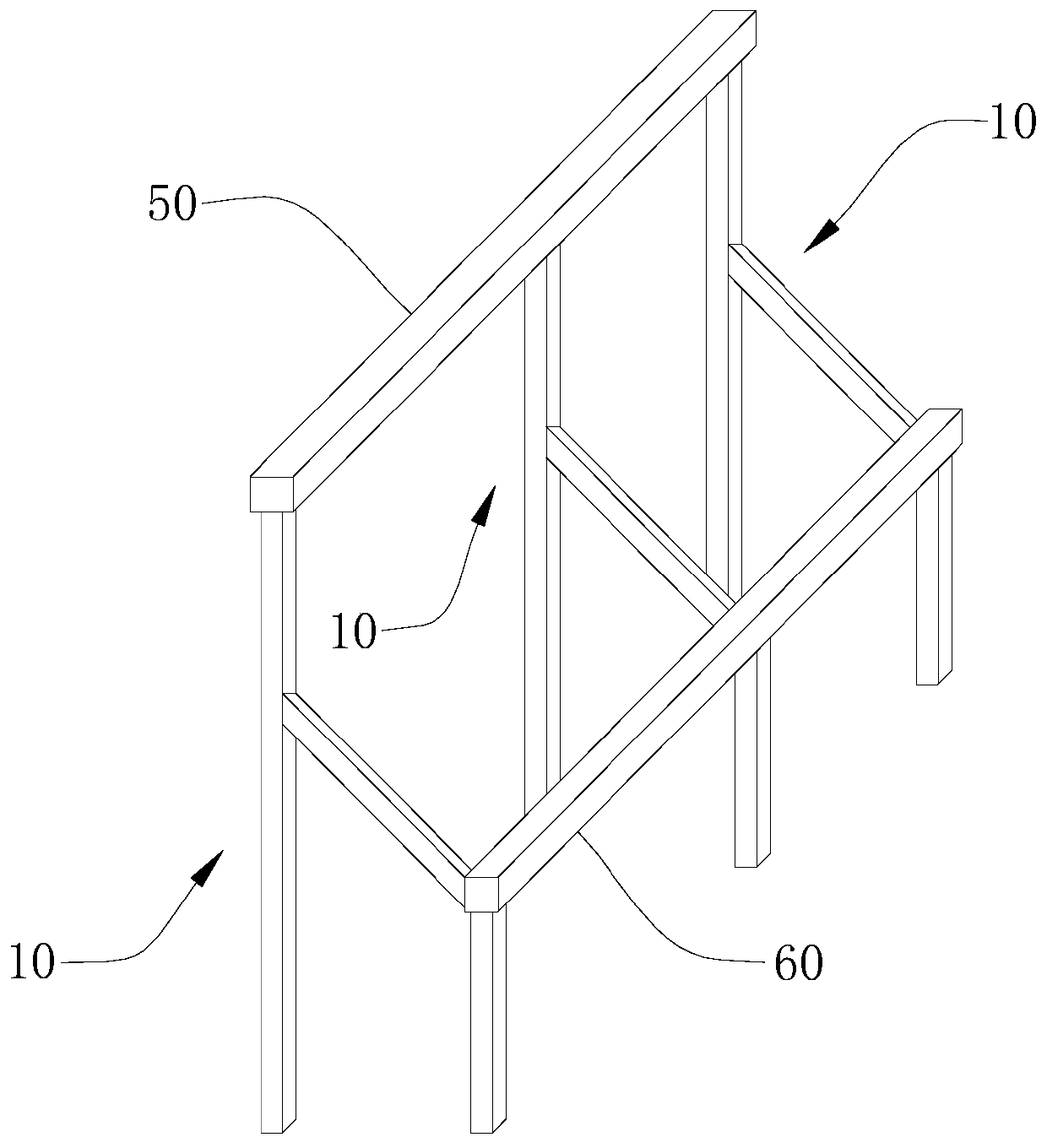

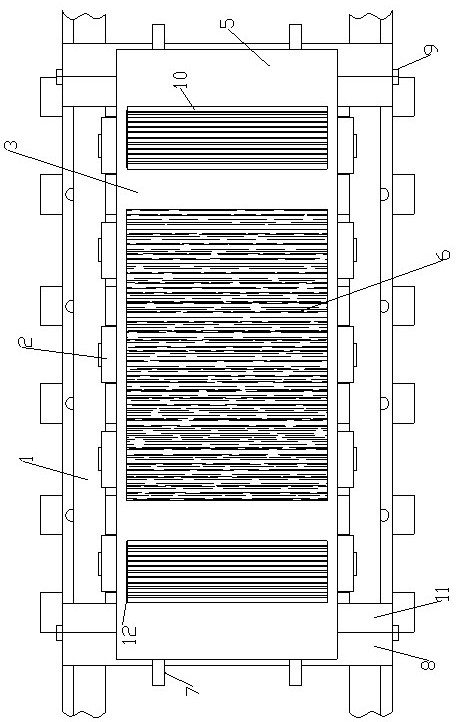

Segmented beam pier top cast-in-situ movable framework

ActiveCN110117933ASimple construction workImprove construction efficiencyBridge erection/assemblyBuilding construction

The invention discloses a segmented beam pier top cast-in-situ movable framework. The segmented beam pier top cast-in-situ movable framework comprises main beams jointly supported by a plurality of supporting columns, and a plurality of upper crossbeams, the two ends of all the upper crossbeams are suspended in midair and are symmetrically provided with lower suspended beams capable of sliding inthe length direction of the upper crossbeams, the lower ends of all the lower suspended beams are suspended in midair and are provided with outer formwork systems, and a driving device for driving thelower suspended beams to slide is further included. According to the segmented beam pier top cast-in-situ movable framework, the outer formwork systems are constructed into a complete module throughthe supporting columns and the main beams, during construction, a segmented beam pier top can be cast only by moving the constructed module to a to-be-constructed site, after casting, the segmented beam pier top cast-in-situ movable framework can be transported to the next place and continue being used, constructing work of the outer formwork systems in the construction process is simplified, theconstruction efficiency is improved, the construction cost is lowered, and the segmented beam pier top cast-in-situ movable framework is used for the field of civil engineering.

Owner:GUANGDONG FOUND ENG GRP CO LTD

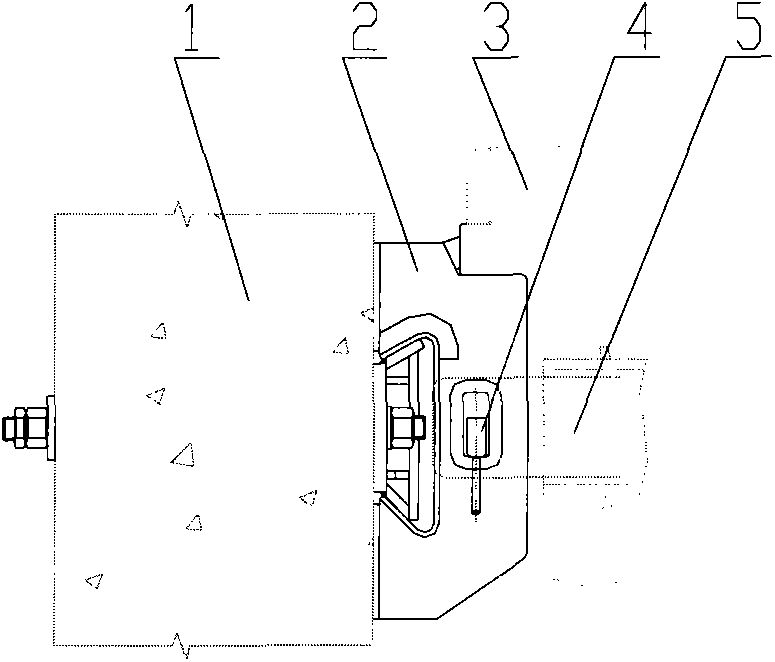

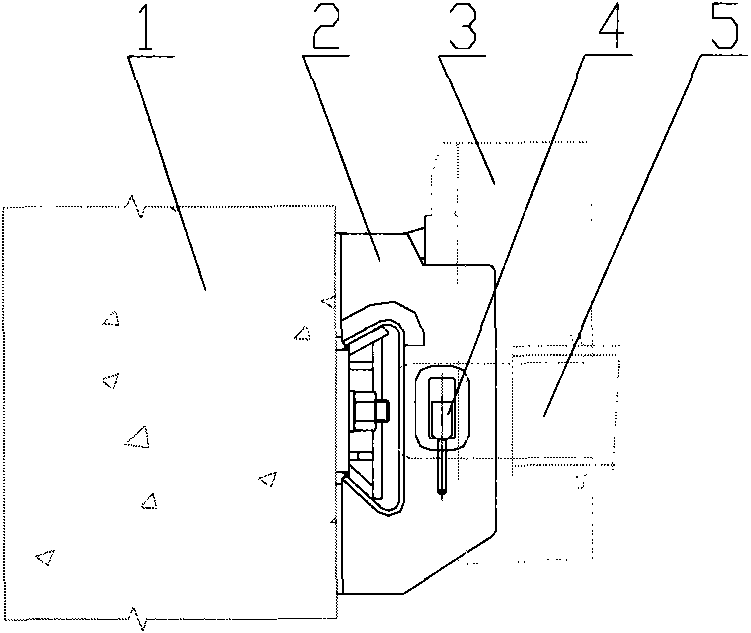

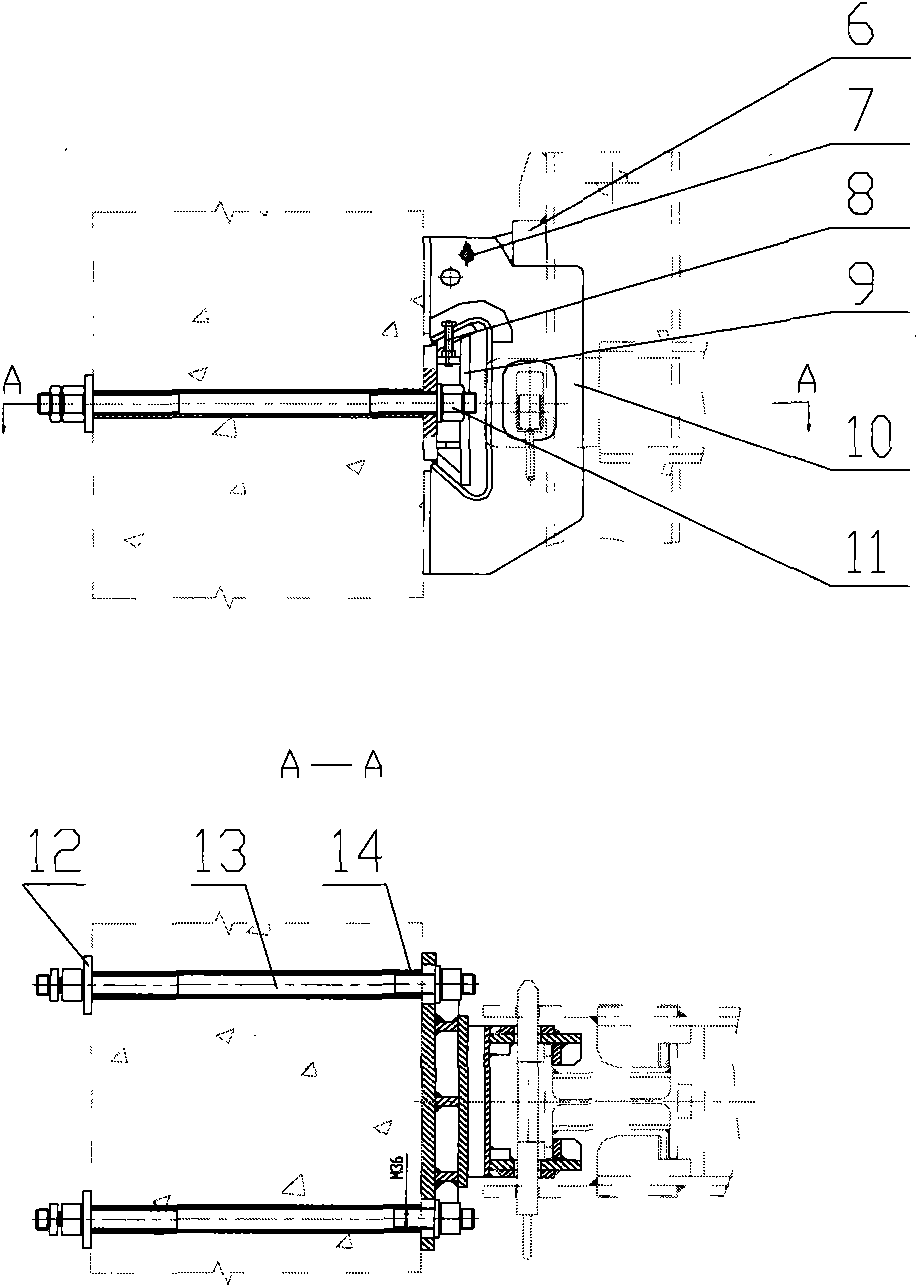

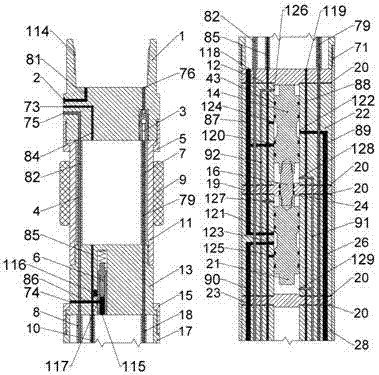

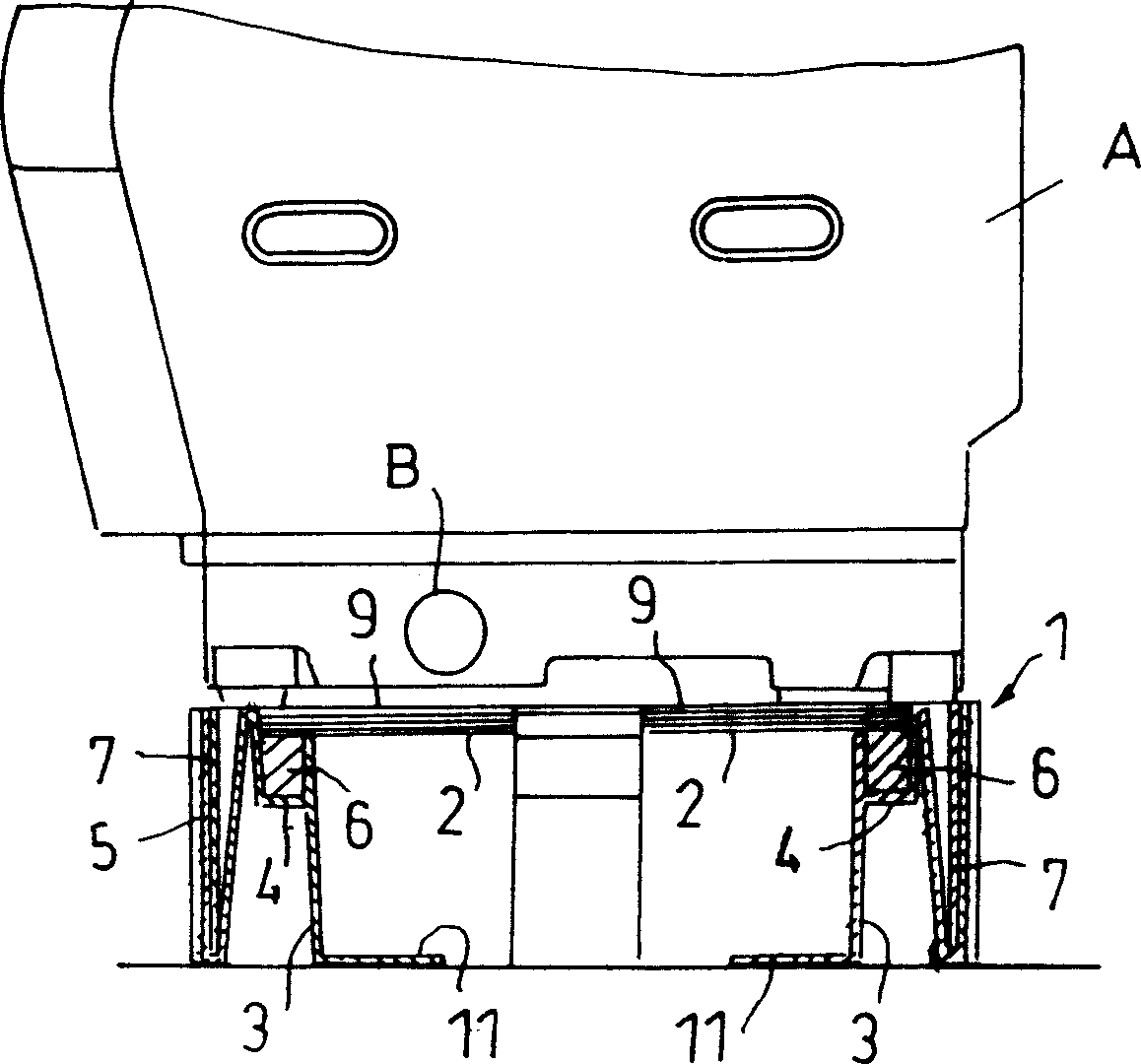

Novel shiftable through-wall (or embedded) type double-point adhering device

InactiveCN104164968ABuilding Structure Use RestrictionsImprove carrying capacityAuxillary members of forms/shuttering/falseworksEngineeringUltimate tensile strength

A novel shiftable through-wall (or embedded) type double-point adhering device is an adhering connection mechanism of a creeping formwork device and a building structure, has the functions of transferring device loads and guiding device creeping. The novel shiftable through-wall (or embedded) type double-point adhering device is composed of a bearing plate (6), a connection pin shaft (7), a positioning pin shaft (8), an adhering base (9), a fixing sleeve (10), nuts (11), through-wall base plates (12) (or embedded base plates (15)), through-wall bolts (13) (or embedded bolts (16)), and through-wall casing pipes (14) (or embedded casing pipes (17) and embedded conical sleeves (18)). The bearing plate (6) is installed on the fixing sleeve (10), and the adhering base (9) is sleeved with the fixing sleeve (10) and penetrates through the through-wall bolts (13) (or the embedded bolts (16)) to be fastened and fixed. As an open hole, allowing the through-wall bolts (13) (or the embedded bolts (16)) to penetrate through, in the adhering base (9) is designed to be in an oblong shape, and the maximum length of the open hole is 60 mm according to intensity requirements, the adhering base (9) can be adjusted on the through-wall bolts (13) (or the embedded bolts (16)), and the adhering base (9) can still be installed and used smoothly when embedment bias exists. The whole adhering device (2) is installed on a building wall (1), a creeping guide rail (3) and a creeping formwork body (5) are installed on the adhering device (2), and therefore the purpose of adhesion of the creeping formwork device is achieved.

Owner:BEIJING ACAD OF BUILDING ENG

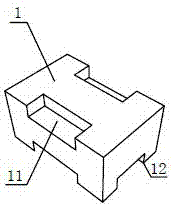

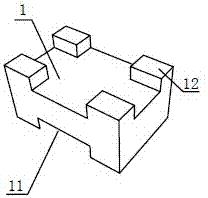

I-shaped anti-knock mortarless building block and building block wall

PendingCN107447905ASimple structureReasonable designWallsProtective buildings/sheltersShock resistanceRaw material

The invention discloses an I-shaped anti-knock mortarless building block and a building block wall, and belongs to the technical field of building blocks. The I-shaped anti-knock mortarless building block comprises a corner building block and / or a main building block, a corner building block through hole is formed in one side of the corner building block, a corner building block concave part is arranged on each of two long sides of the top surface of the corner building block, a corner building block convex part is arranged on each of two corners, away from the corner building block through hole, of the bottom surface of the corner building block, the main building block is a cuboid component, a main building block concave part is arranged on each of two long sides of the top surface of the main building block, and a main building block convex part is arranged on each of four corners of the bottom surface of the main building block. The building block wall is formed through construction of the I-shaped anti-knock mortarless building blocks. The building block wall is simple in structure, reasonable in design, simple and convenient in construction, mortar building blocks are not needed, energy and raw materials are saved, and building blocks can be constricted to the interior and exterior of the wall plane through mutual conjunction of the convex parts and the concave parts, so that the construction efficiency is improved, and the stability and the shock resistance of the wall are improved.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

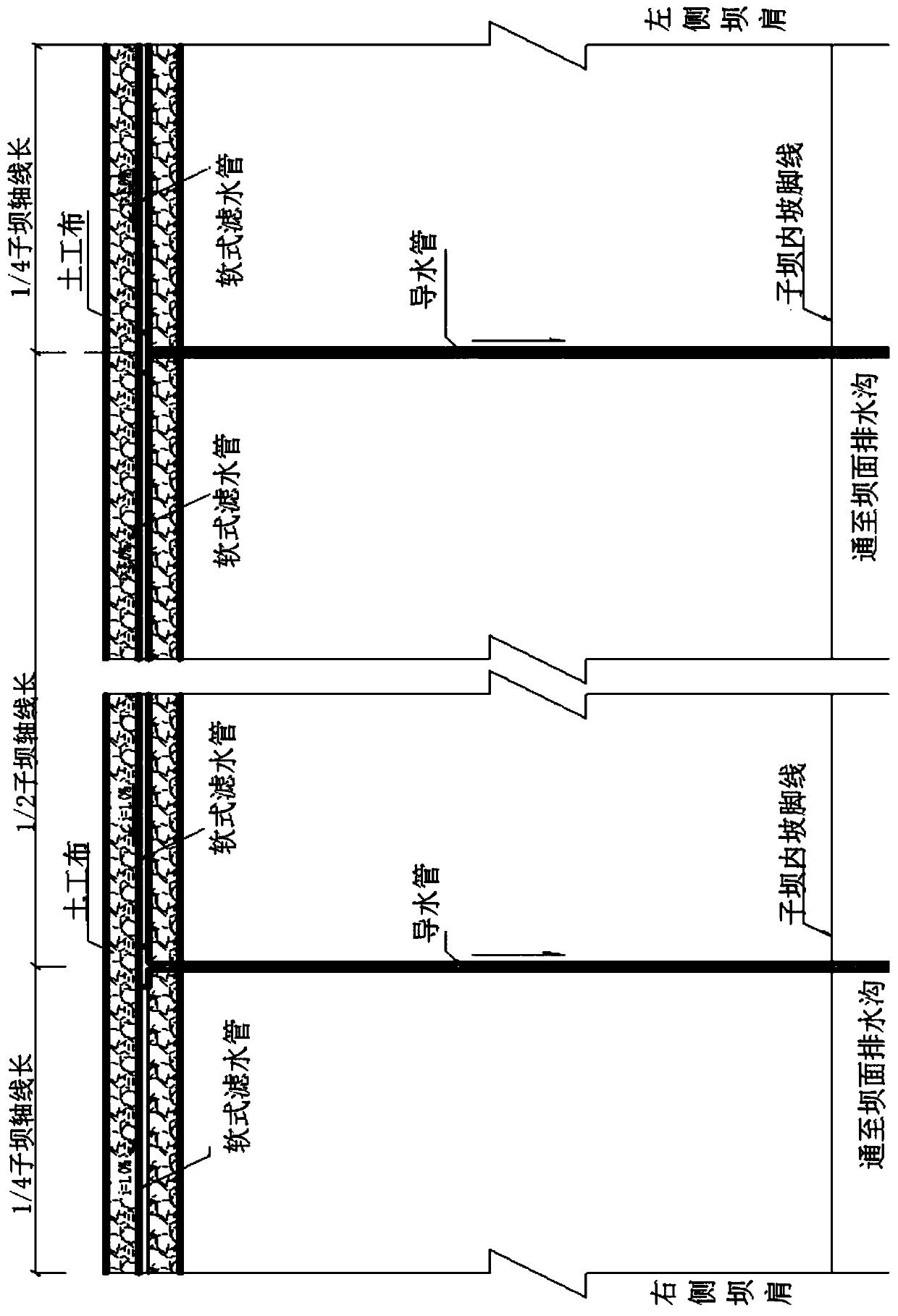

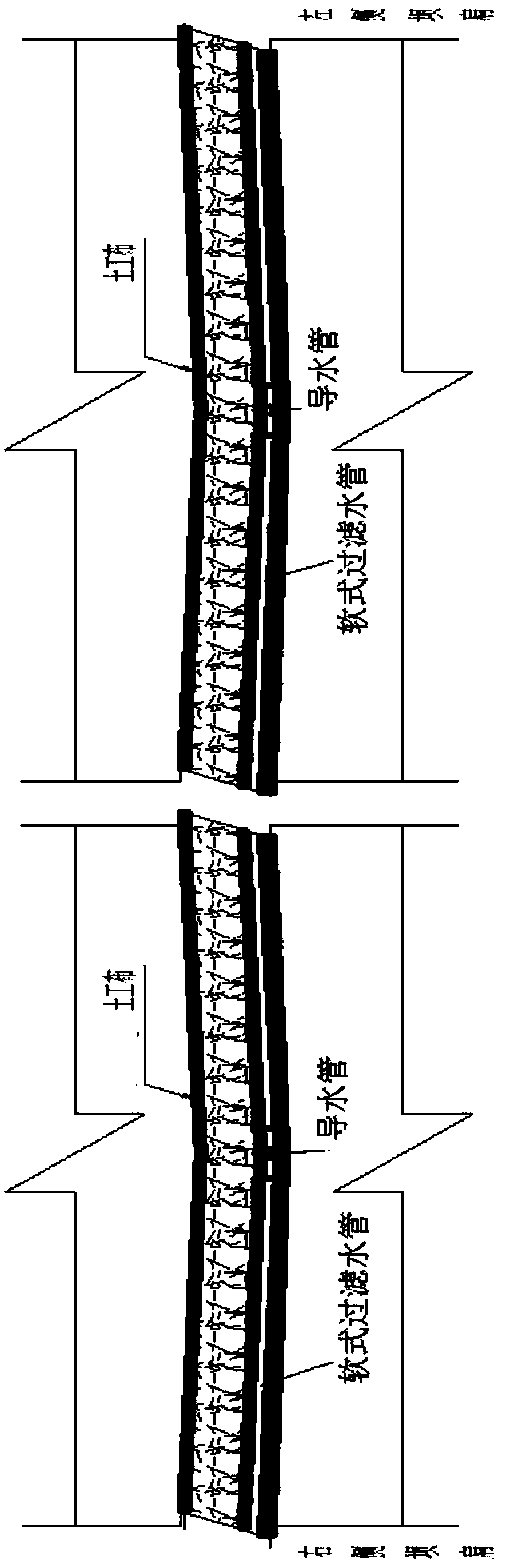

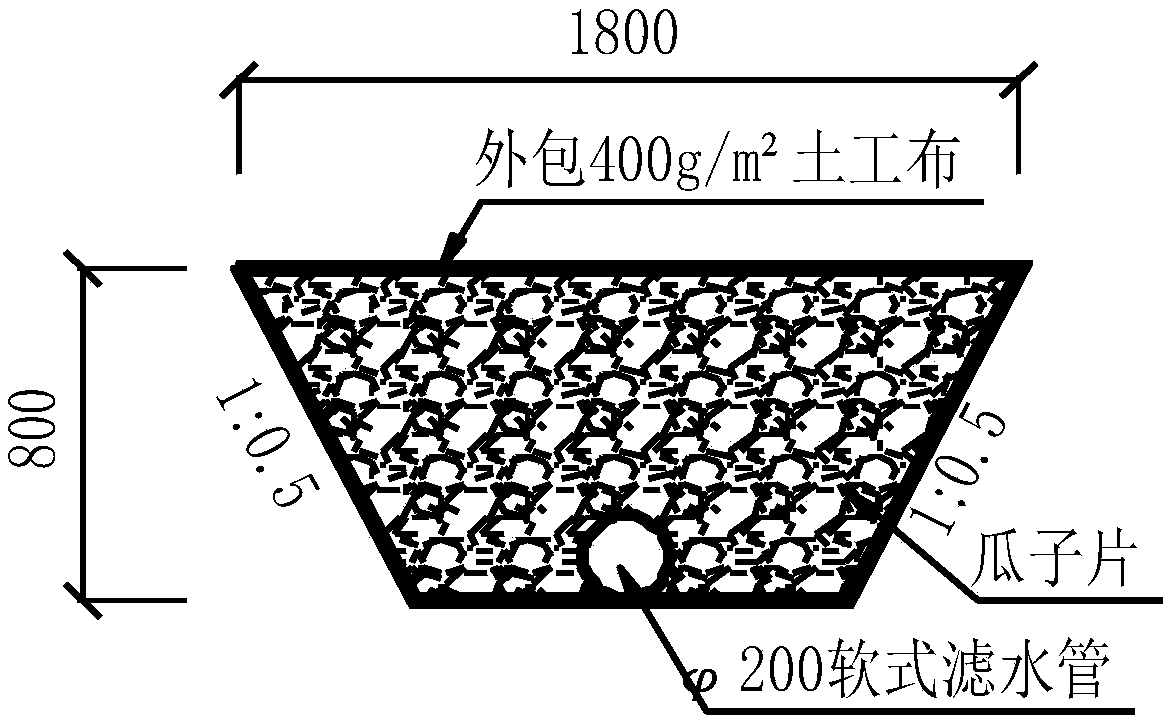

Seepage draining system layered arrangement method for decreasing seepage line buried depth of tailings reservoir

The invention relates to a seepage draining system layered arrangement method for decreasing the seepage line buried depth of a tailings reservoir. The seepage draining system layered arrangement method comprises the following steps: (1) if the initial-stage dam elevation of the tailings reservoir is N meters, according to the tailings accumulation body beach face seepage draining condition, 1 ton layers of seepage draining blind ditches are formed in a layered mode and designed at different elevations of N+H meters, N+2H meters, N+3H meters, N+4H meters... and N+nH meters of a tailings accumulation dam, and the seepage draining blind ditches are parallel to the dam axes of sub dams and are away from the dam axes of all the stages of sub dams by M meters; (2) each layer of seepage draining blind ditch parallel to the corresponding dam axis is located in front of the corresponding stage of sub dam by M meters, and composed of peastone, a soft water filter pipe and a 400 g / m<2> wrappinggeotechnical cloth; (3) one end of each layer of water guiding pipe perpendicular to the corresponding dam axis is connected with the soft water filter pipe in the corresponding seepage draining blind ditch parallel to the corresponding dam axis through a tee joint; (4) tailings drawing and seepage draining system construction are independently and alternately conducted in a zoned mode; and (5) operation of the tailings reservoir is detected and repaired. According to the seepage draining system layered arrangement method, the seepage line buried depth can be decreased, and it is guaranteed that the dry beach length of the tailings reservoir meets the design specification requirements.

Owner:NANJING MEISHAN METALLURGY DEV +1

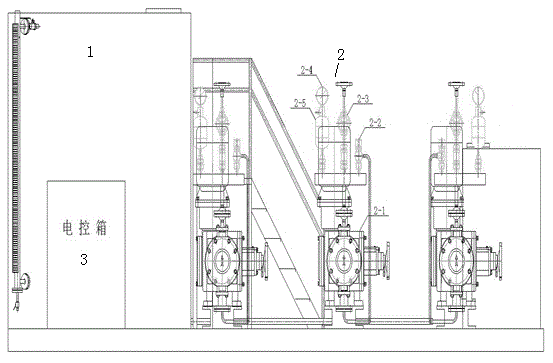

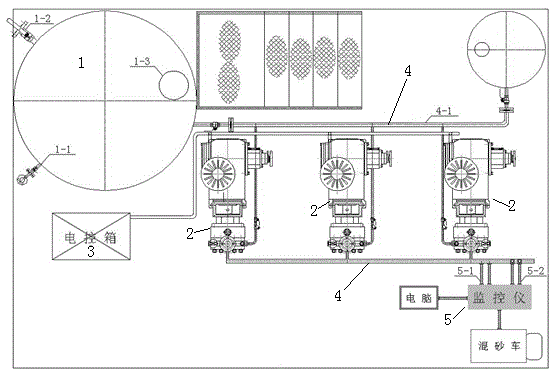

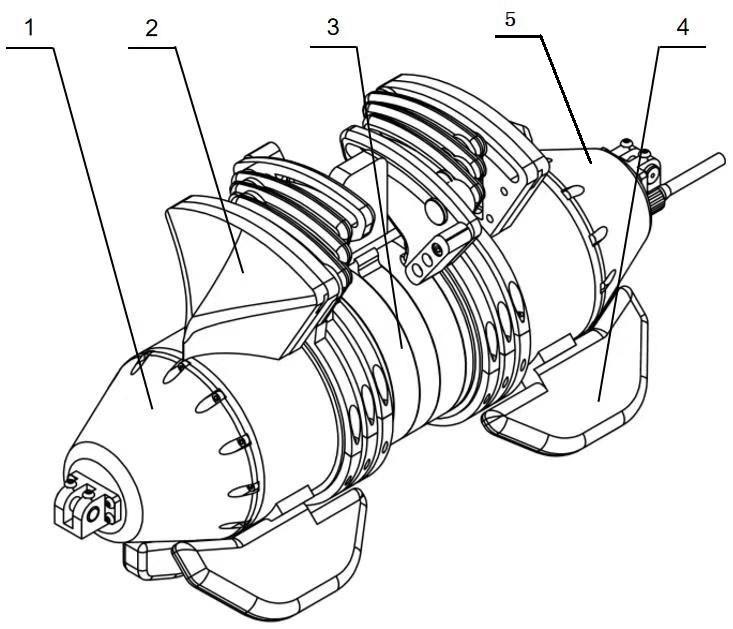

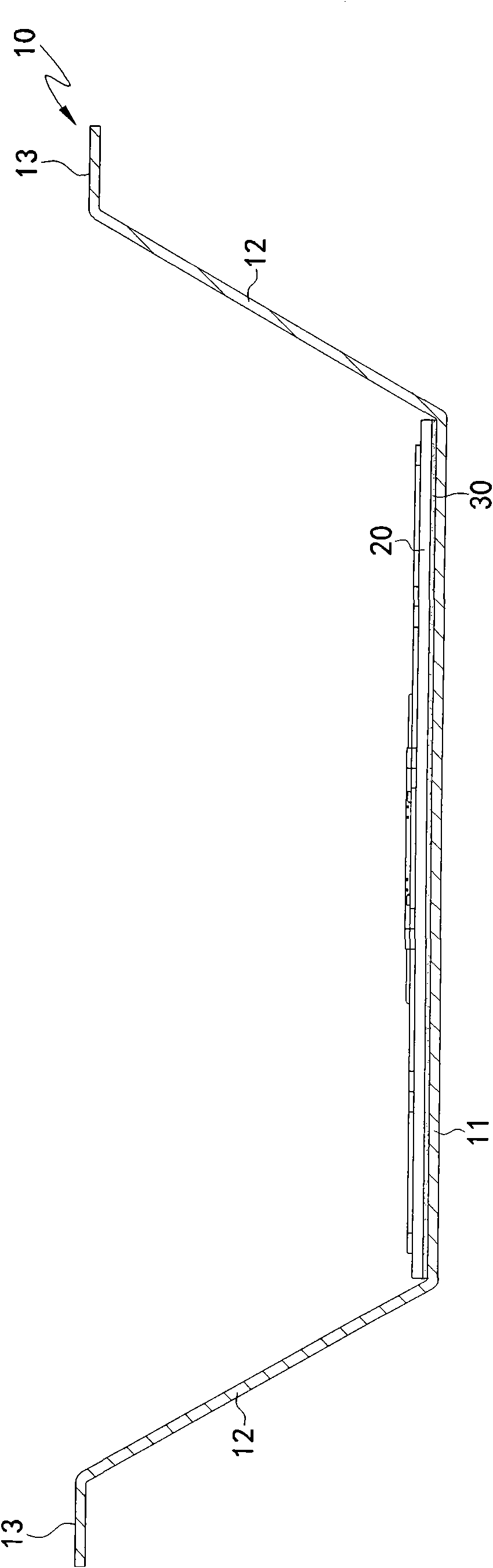

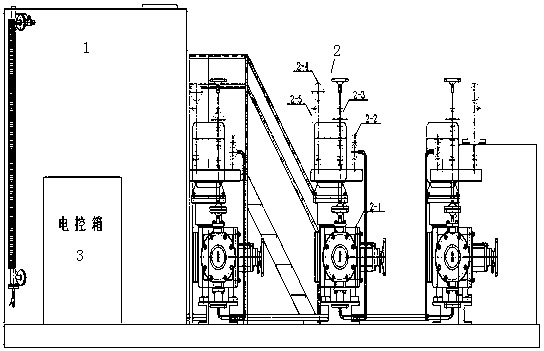

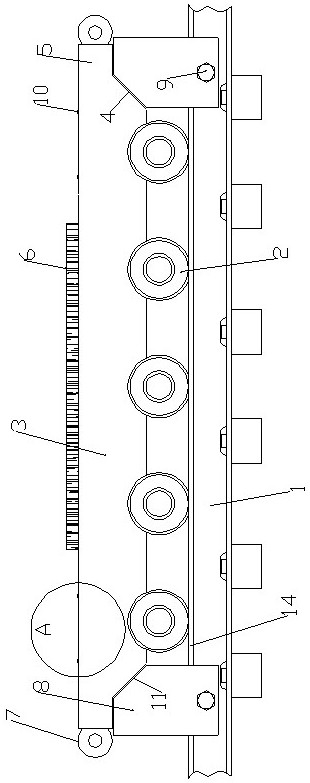

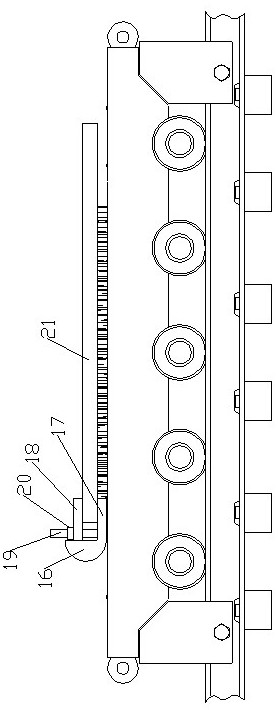

Continuous injecting and acidizing unit for water injection well

ActiveCN104879105AFast online acidizing construction workContinuous online acidizing construction operationFluid removalControl systemMonitoring system

The invention belongs to the technical field of waterflooding extraction of oilfields, and particularly provides a continuous injecting and acidizing unit for a water injection well. The continuous injecting and acidizing unit for the water injection well consists of an acid liquor storage tank (1), a hydraulic double-diaphragm metering pump (2), a control system (3), an acid liquor pipeline system (4), an online monitoring system (5) and a truck moving system, wherein the acid liquor storage tank (1) is connected with the hydraulic double-diaphragm metering pump (2); an outlet of the hydraulic double-diaphragm metering pump (2) is connected with the acid liquor pipeline system (4); the control system (3) is connected with the hydraulic double-diaphragm metering pump (2); the online monitoring system (5) is connected with the acid liquor pipeline system (4); and a shared steel base of the acid liquor storage tank (1), the hydraulic double-diaphragm metering pump (2) and the control system (3) is connected with a chassis of the truck moving system. Efficient, quick and large-scale plug removal of the water injection well is implemented, water injection pressure is reduced, and water injection amount is increased.

Owner:PETROCHINA CO LTD

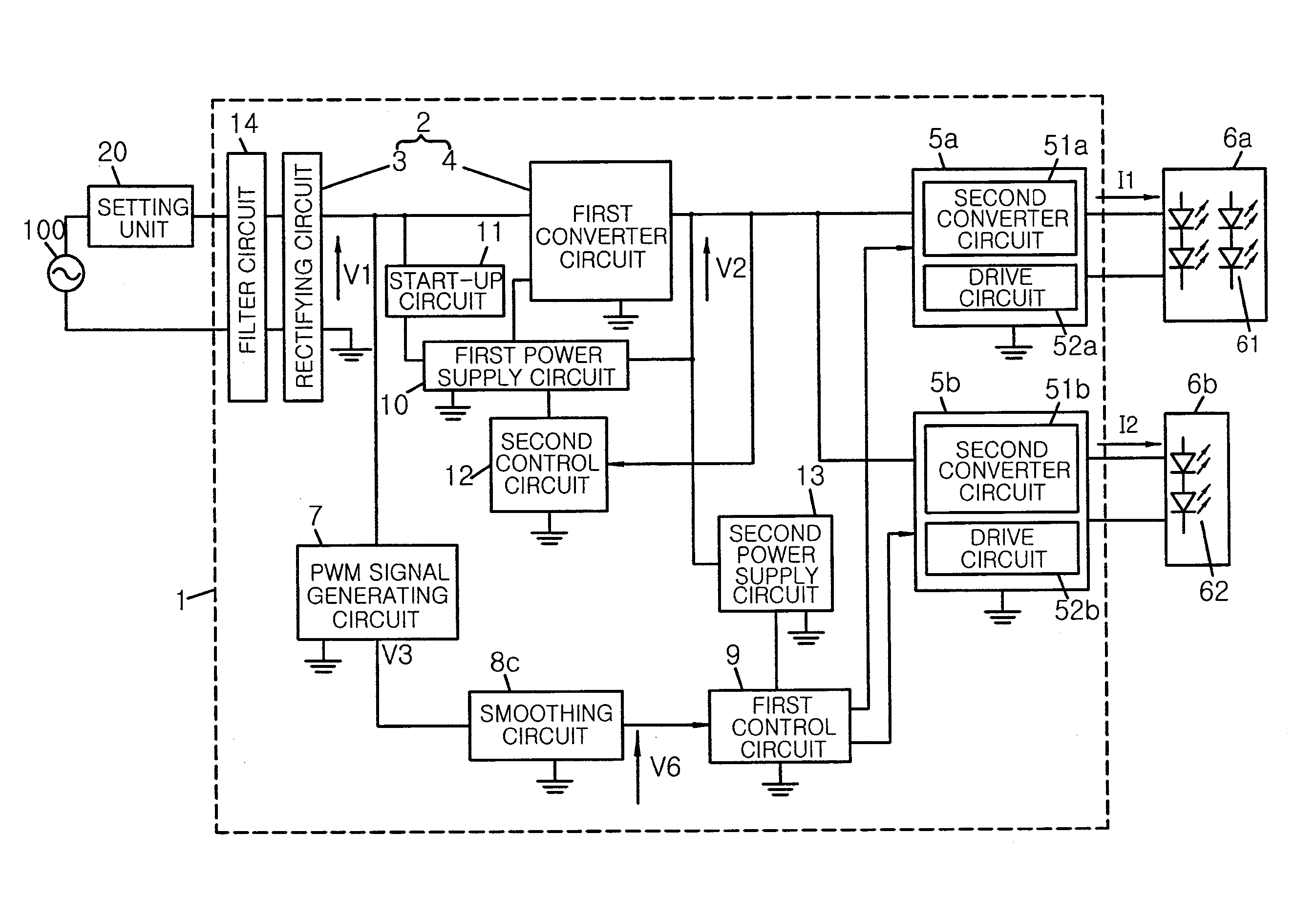

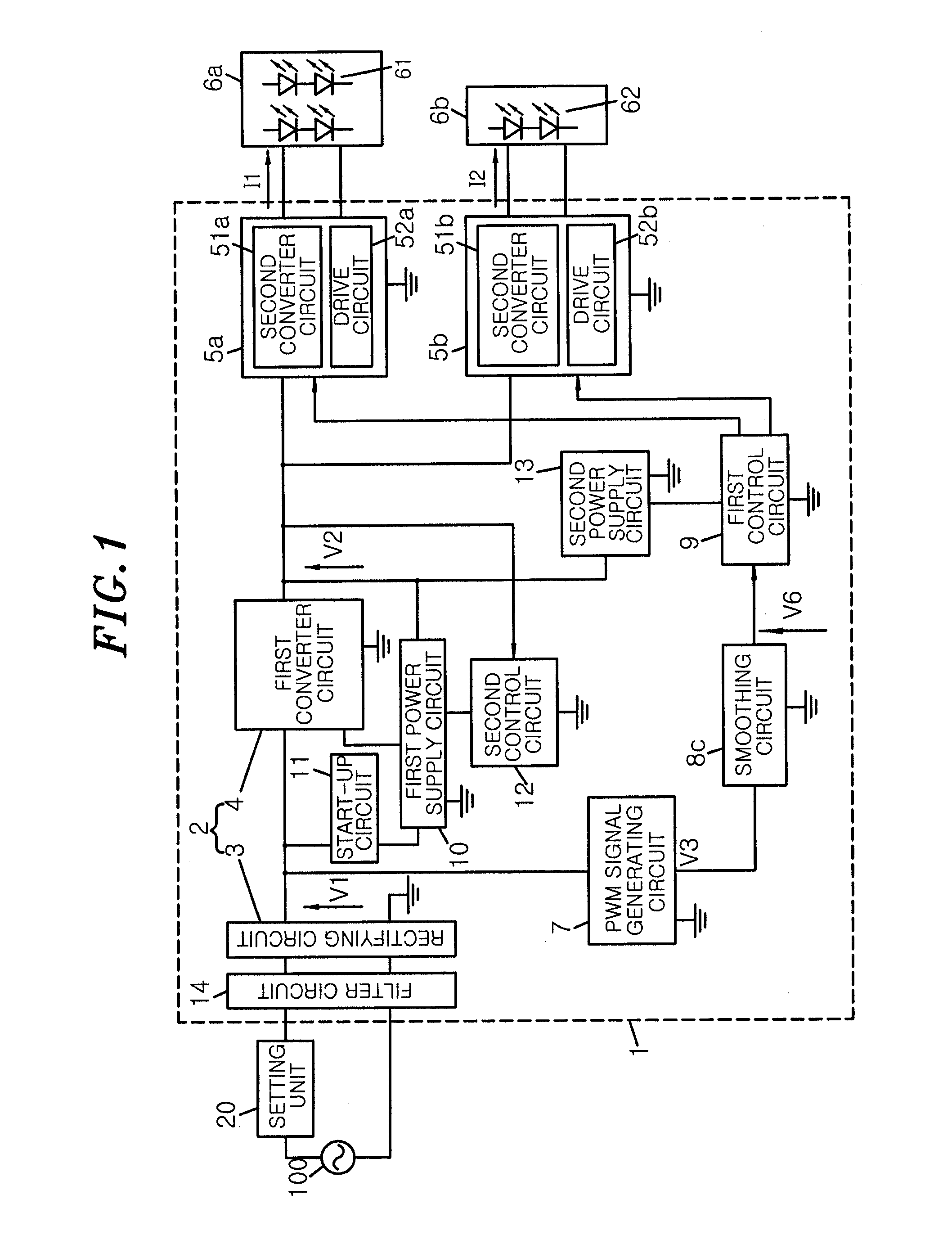

Lighting device, illumination device, illumination apparatus and illumination system

ActiveUS20150091464A1Simple construction workSimplify workElectrical apparatusElectroluminescent light sourcesEffect lightEngineering

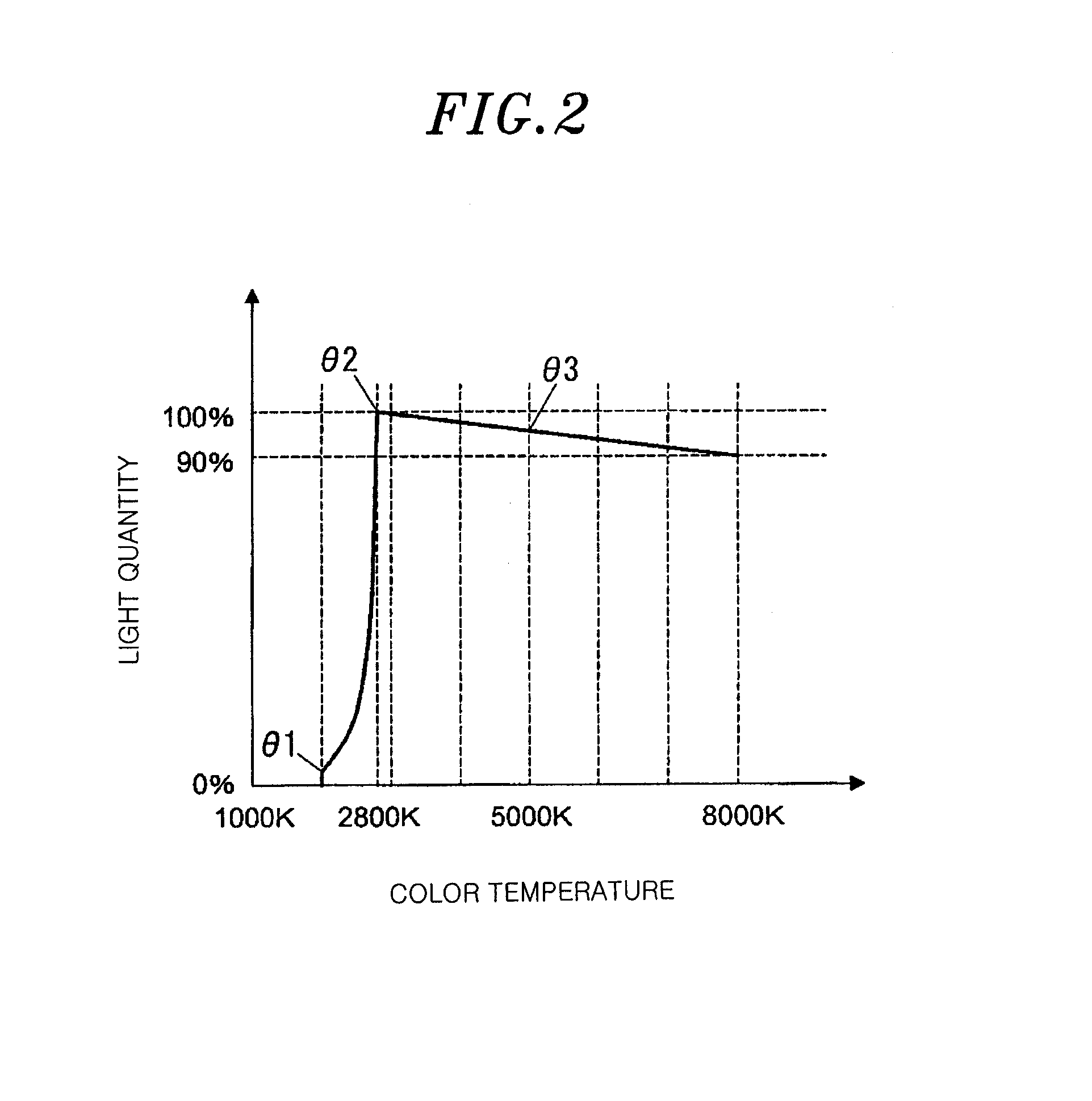

A lighting device includes an AC to DC conversion unit for receiving a setting signal and converting it into a DC voltage having a predetermined voltage, voltage conversion units for converting the DC voltage inputted from the AC to DC conversion unit and driving the light source modules according to drive signals, a PWM signal generating unit for generating a PWM signal having a duty ratio corresponding to the setting signal, and a control unit, by outputting the drive signals to the voltage conversion units based on a command value determined according to the duty ratio, for controlling output powers of the voltage conversion units such that a characteristic curve of the sum of the output powers of the voltage conversion units has the maximum or at least one inflection point within an adjustment range of the conduction angle.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

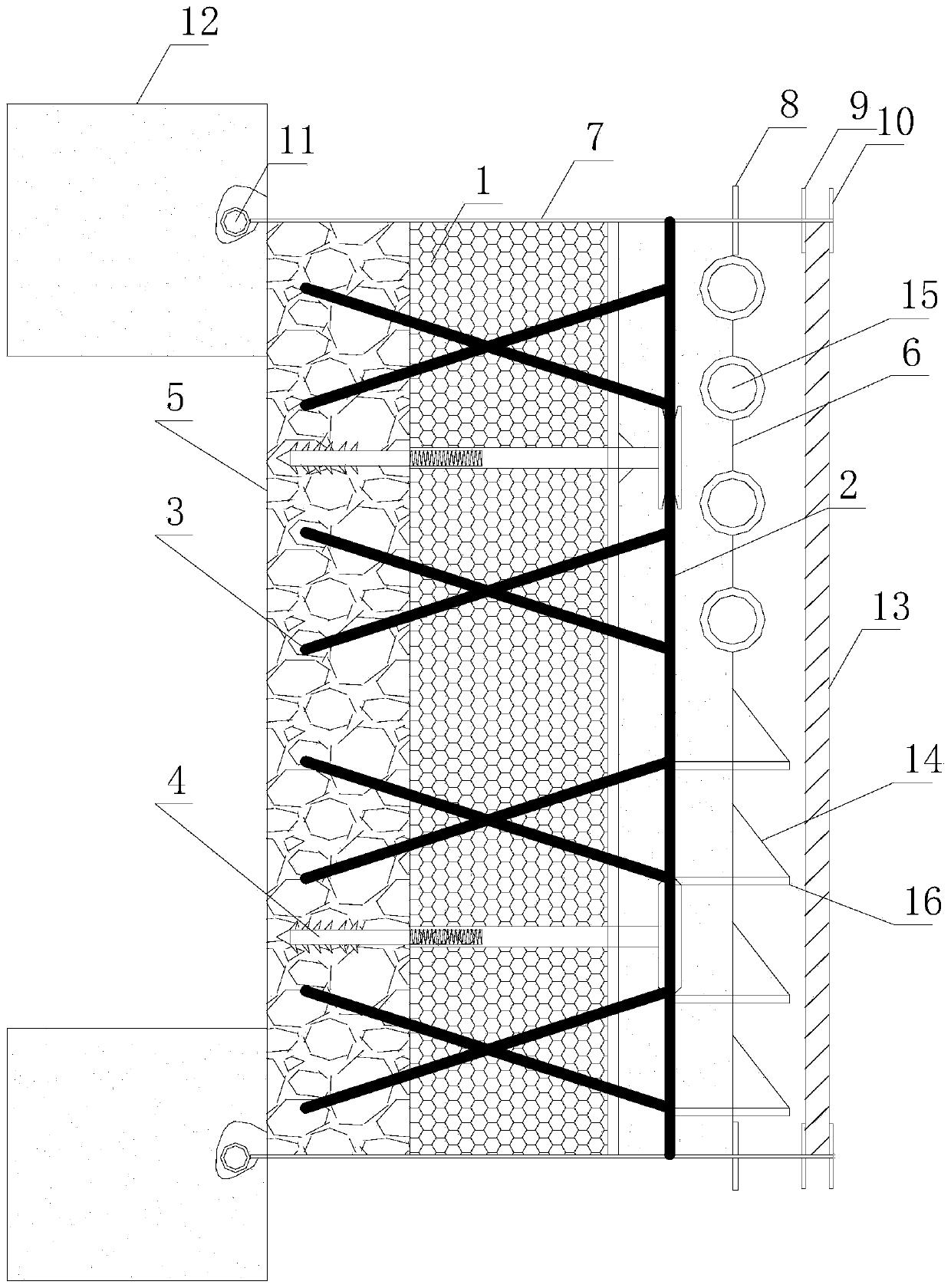

Assembly type building energy conservation and heat preservation wall and manufacturing and assembling method thereof

ActiveCN111236528AWith strengthMeet design standardsPhotovoltaic supportsSolar heating energySolar waterHeat conservation

The invention discloses an assembly type building energy conservation and heat preservation wall comprising a middle heat preservation layer, a steel wire mesh frame, split threaded rods and a fixed assembly stand. A concrete layer and a heat preservation mortar layer are arranged on the two sides of the heat preservation layer correspondingly. The steel wire mesh frame comprises inclined insertion wires and a steel wire mesh. The steel wire mesh is located in the heat preservation mortar layer. One end of each inclined insertion wire is welded to the steel wire mesh, and the other end of eachinclined insertion wire penetrates through and extends out of the heat preservation layer. The assembly type building energy conservation and heat preservation wall has the technical effect that theassembly type building energy conservation and heat preservation wall has the following advantages that the fixed assembly stand, unfilled corner structures arranged on the periphery of the heat preservation layer and dovetail groove structures arranged on the periphery of the heat preservation layer are designed, cold and hot bridges are avoided, the heat resistance is improved, the connection strength is ensured, the site hoisting construction operation is easy, and the construction period is effectively shortened; solar water pipes, solar electricity generation panels and a decoration glasslayer are arranged, and solar energy is effectively utilized to conduct water heating and electricity generation; and green energy conservation and environment protection are truly achieved.

Owner:山东乾宇建筑节能科技有限公司

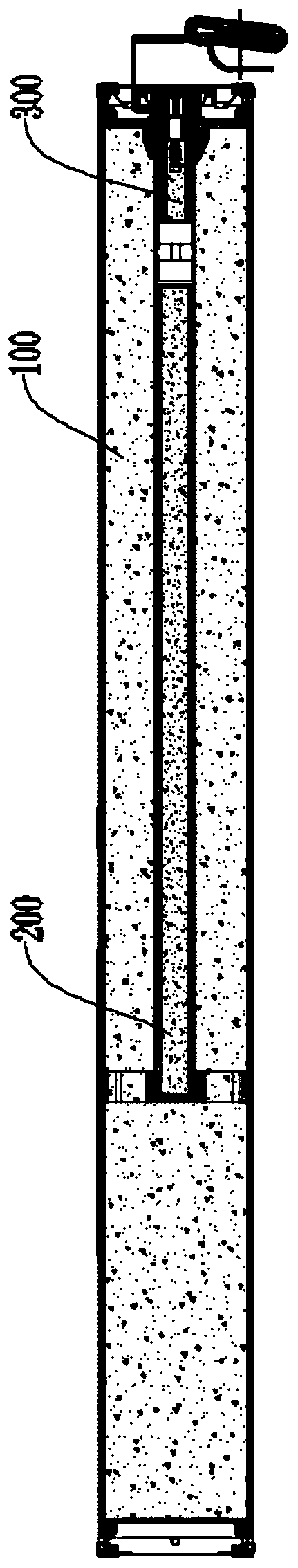

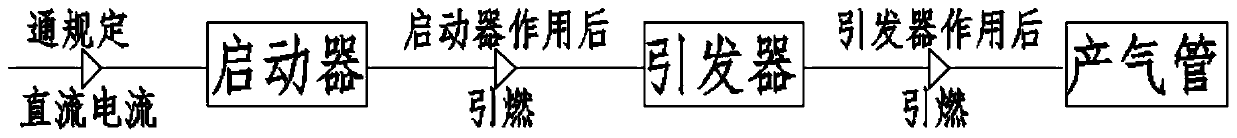

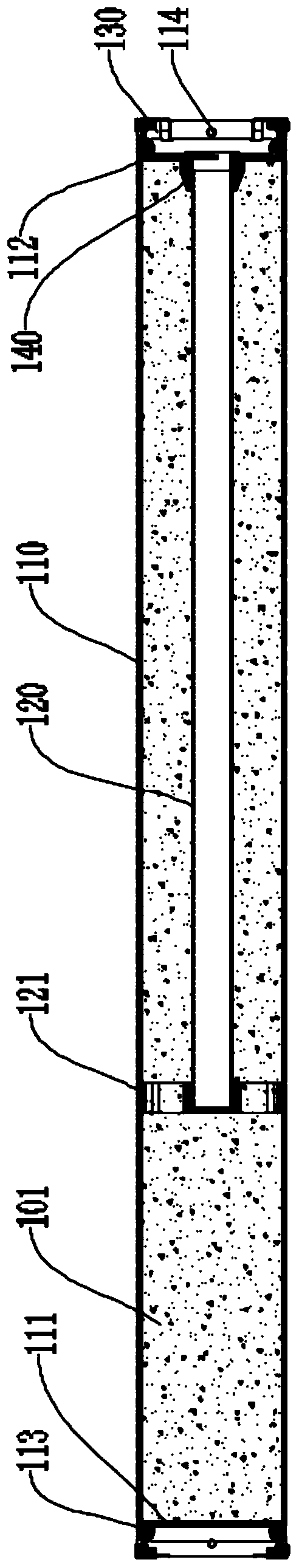

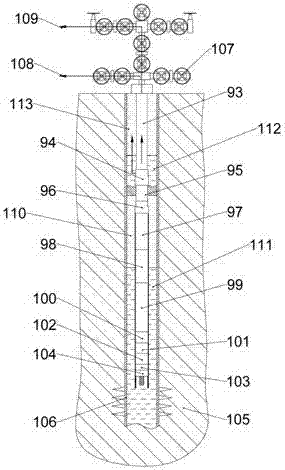

Rock breakage gas generator and gas generating agent rock breaking method

ActiveCN109813184AImprove securitySimple construction workBlasting cartridgesBlastingPower flowEngineering

The invention provides a rock breakage gas generator and a gas rock breaking method. The rock breakage gas generator comprises a gas generation pipe, a trigger device and a starter independently dismounted; the starter comprises a start pipe, a start head and an electric conducting lead; the start pipe is filled with a first gas generating agent; and direct-current starting current generated by anexternal electric exploder is started by the electric conducting lead to ignite the first gas generating agent. The trigger device is filled with a second gas generating agent, which is ignited by energy generated by the first gas generating agent; and the gas generation pipe comprises an outer cylinder, and an inner cylinder supported inside. The trigger device is positioned in the inner cylinder; and the starter at least partially extends into the inner cylinder. The gas generation pipe is filled with a third gas generating agent, which is ignited by energy generated by the second gas generating agent. Shell materials of the gas generation pipe, the trigger device and the starter all adopt low-mass paper pipe bodies or plastic pipe bodies for holding; and the gas generating agents inside are located in a non-pressure constraint state, so that the safety is high. The construction operation is simple and feasible, free of the lowest-pressure limitation and high in efficiency, and automatically adapts to the strength of construction objects.

Owner:SANMING COFFER FINE CHEM IND

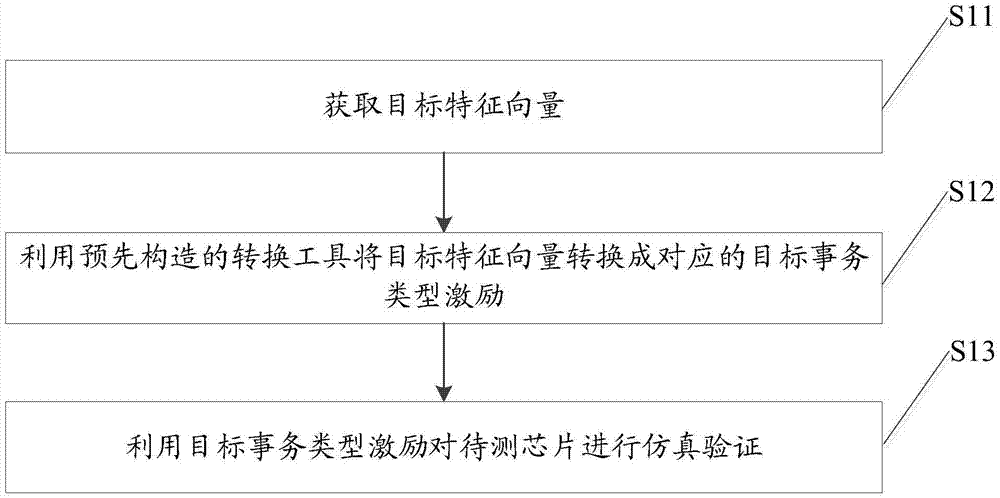

Transaction type excitation based verification method

ActiveCN105447251AReduce complexityReduce workloadSpecial data processing applicationsFeature vectorRound complexity

The invention discloses a transaction type excitation based verification method. The method comprises: obtaining a target eigenvector; converting the target eigenvector into corresponding target transaction type excitation by utilizing a pre-constructed conversion tool; and performing simulation verification on a to-be-tested chip by utilizing the target transaction type excitation. Compared with the prior art, the method has the characteristics that only the target eigenvector needs to be obtained, the target eigenvector can be converted into the corresponding transaction type excitation by utilizing the conversion tool, and the verification of the to-be-tested chip is finished without the need for manually writing the transaction type excitation, so that the complexity and workload of manual work are greatly lowered; and the eigenvector is very simple to construct relative to the transaction type excitation, so that the error rate is greatly reduced and the probability of verification failure is further reduced.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

Recoverable anchor rod

InactiveCN101469541BReduce pollutionWill not develop impactAnchoring boltsBulkheads/pilesArchitectural engineeringScrew thread

The invention relates to a recovery type anchor bar, comprising an outer sleeve steel pipe, a screw rod disposed in the outer sleeve steel pipe along the axial direction, an upper cover board fixed on the top of the outer sleeve steel pipe, a regulation nut disposed at center of the upper cover board, a lower cover board fixing on the bottom end of the outer sleeve steel pipe, an anchor cone disposed right under the lower cover board, and a plurality of upper connection boards disposed on bottom end of the lower cover board, wherein the upper portion of the screw rod is attached to the regulation nut through a screw thread, the lower portion of the screw rod is attached to the anchor cone. Each upper connection boards is hinged to the top of an upper pulling rod, bottom end of each upper pulling rod is hinged to the top of a lower pulling rod, bottom end of each lower pulling rod is respectively attached to the anchor cone through a pin. Object of the invention is to provide a recovery type anchor bar which is high in shearing resistance capacity, underground space saving, underground environment pollution-free, and steel saving.

Owner:YANTAI UNIV

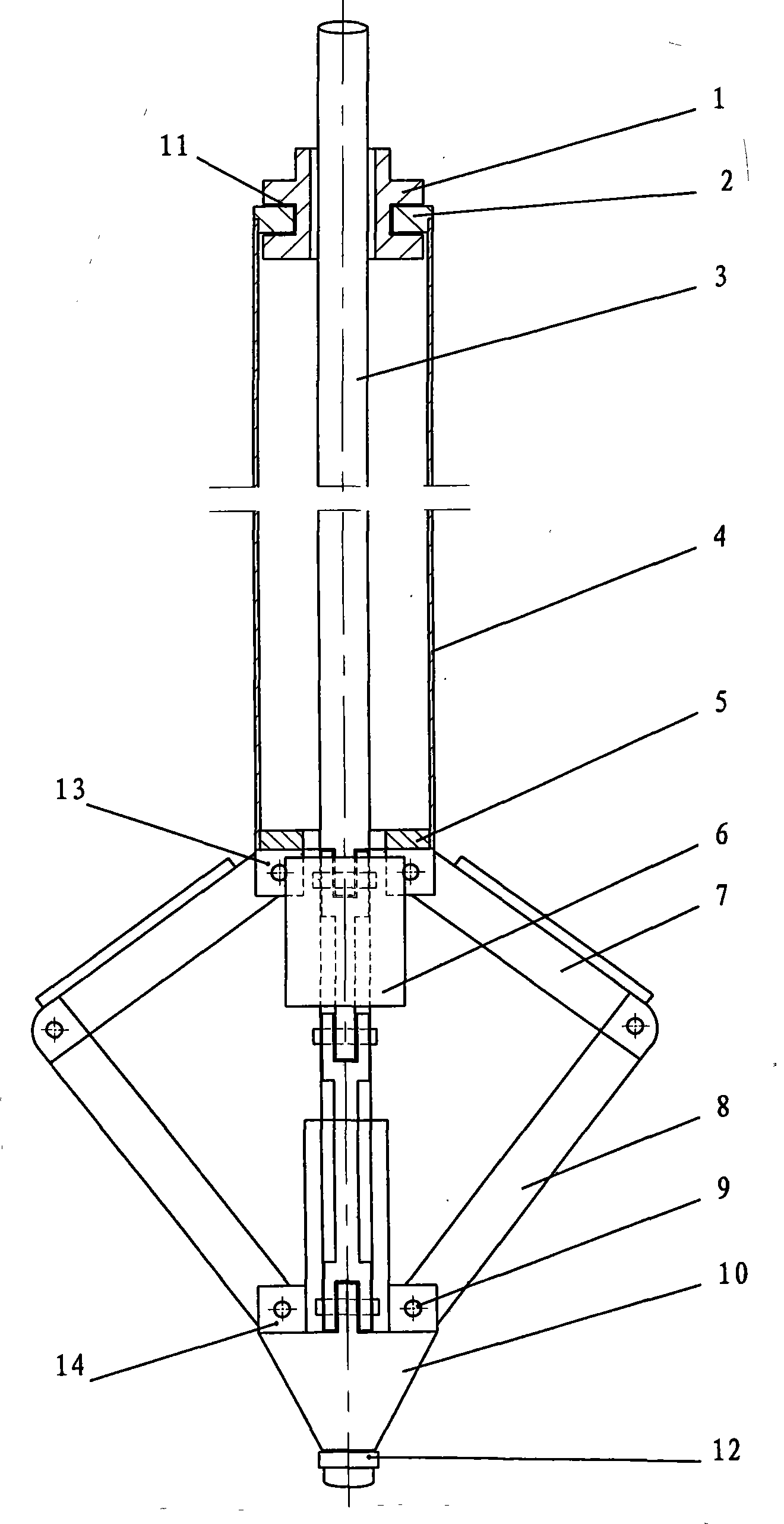

Natural caving method based surface collapse range control method

ActiveCN113338924AEffectively control the collapse rangeLow costMining devicesDisloding machinesSlagEarth surface

The invention relates to a natural caving method based surface collapse range control method. The method comprises the following steps: acquiring a conventional collapse range line, determining a controlled collapse range line, cleaning humus soil, building a water intercepting and draining ditch, constructing a joint cutting and drilling hole, piling up a slag discharging platform, piling up waste rock to strengthen collapse and respective conditions thereof, the method has the advantages that the construction operation is simple, the cost is relatively low, the effect is obvious, the surface collapse range can be effectively controlled, the influence of surface collapse on surrounding buildings or structures and the earlier-stage investment cost are reduced and the like, and the method is suitable for mining or civil buildings.

Owner:ZIJIN MINING GROUP

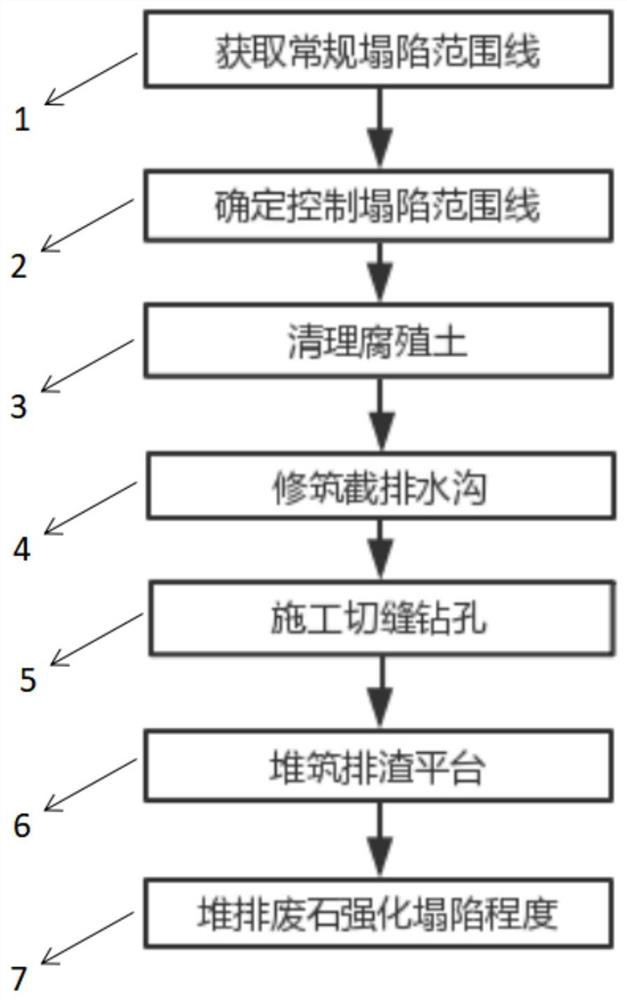

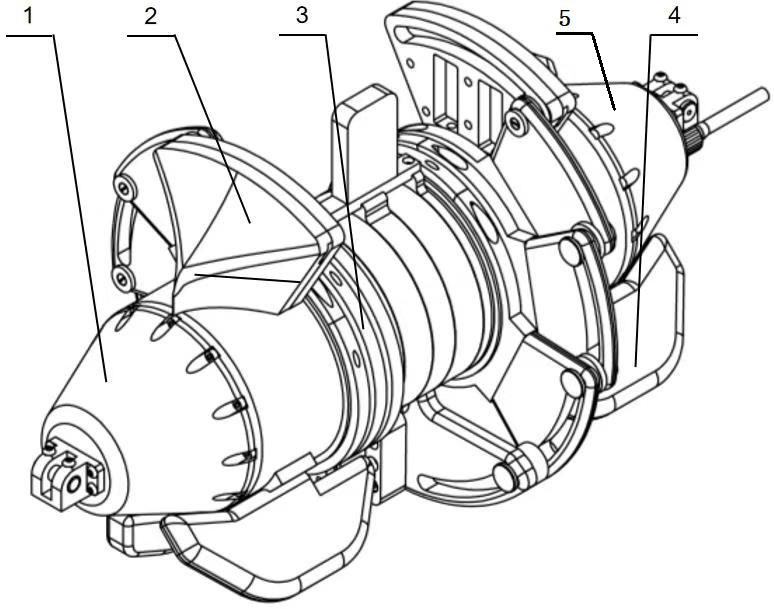

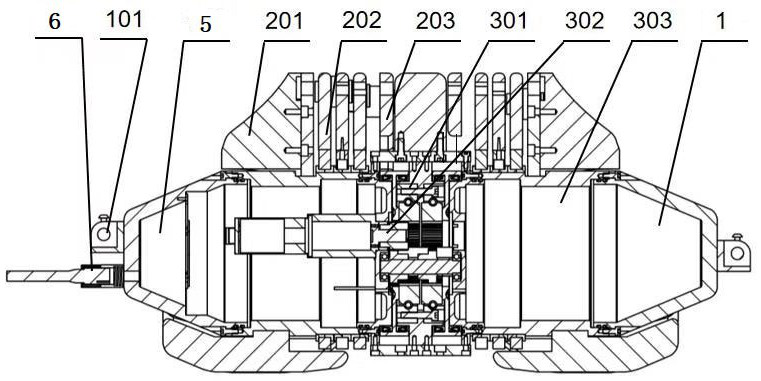

Down-hole water drainage and gas production tool

InactiveCN106968640ASimple construction workReduce operating costsFluid removalPiston pumpsOil drillingPetroleum

The invention discloses a down-hole tool used for water drainage and gas production of a natural gas well in the field of oil drilling and production. According to the technical scheme of the down-hole water drainage and gas production tool, the tool is composed of a transition connector, a packer module, an overflow valve module, a reversing valve module, a pilot valve module, an actuating module, a second pump module, a check valve short section, a first pump module, a check valve short section, a bottom end and a main outer cylinder. According to the tool, extra energy supplying is not needed, and only natural gas generated by the natural gas well self serves as a power resource. Gas enters from a gas inlet in the tool, is pressurized by multi-stage air cylinders and drives a reciprocation pump mechanism to work, and therefore accumulated liquid in the well is conveyed to the ground through an oil-line pump. The natural gas enters an oil sleeve annular space through a gas outlet in the tool and flows to a ground production pipeline. The down-hole water drainage and gas production tool can be applied to water drainage and gas production operation of vertical wells, deviated wells and horizontal wells, has the advantages of being simple in construction operation, low in operation cost and free of pollution for a stratum and is suitable for water drainage and gas production operation of low-pressure and low-gas-production wells.

Owner:SOUTHWEST PETROLEUM UNIV

Synchronous ecological repair method suitable for water front of urban river segment of mountainous river

InactiveCN110002670AGuaranteed stabilityAvoid cloggingWater resource protectionWater/sewage treatmentWater qualityEngineering

The invention relates to the field of water pollution government and body ecological repair and discloses a synchronous ecological repair method suitable for a water front of an urban river segment ofa mountainous river. The method comprises the following steps: A) constructing a wetland purification system; B) constructing an ecological permeable dike to control and guide and purify water quality; C) repairing biodiversity of a riverbed with a flat basement; and D) ecologically remolding a hard embankment. The method can improve the water environment carrying capacity and the water ecological carrying capacity of the river obviously and also can create a green gallery with a good landscape. The method of ecologically repairing the water front of the urban river segment of the mountainousriver can improve the habitat heterogeneity, the biodiversity and the landscape diversity of the urban river segment of the mountainous river and improve the water environment carrying capacity and the water ecological carrying capacity of the river so as to quickly construct and repair the ecological system of the urban river segment of the mountainous river better.

Owner:浙江融信环保科技有限公司

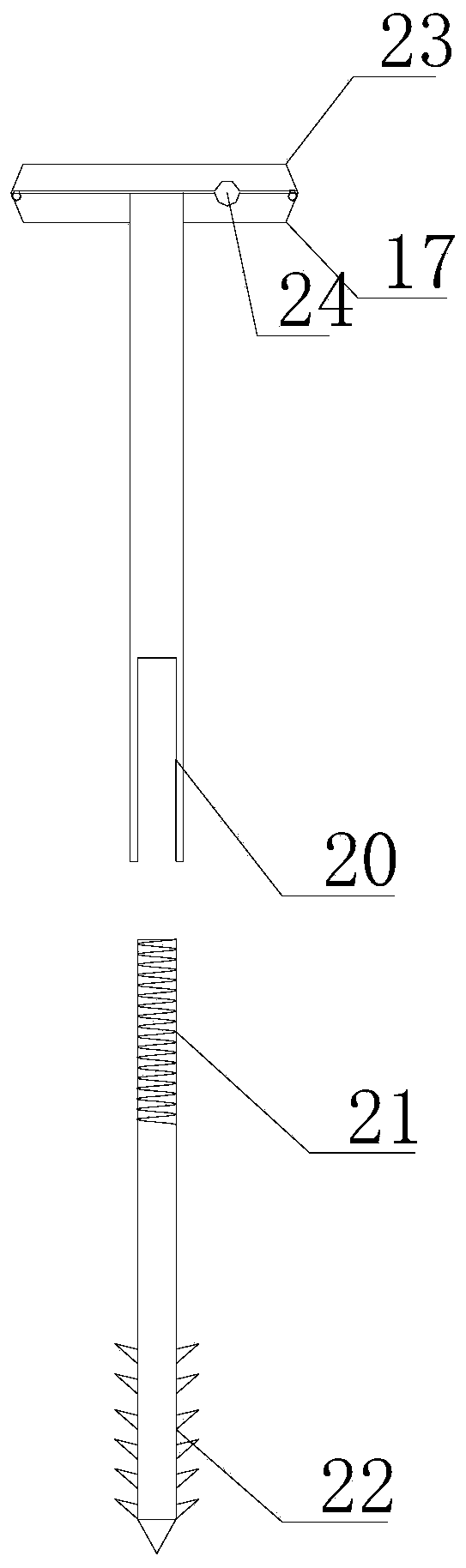

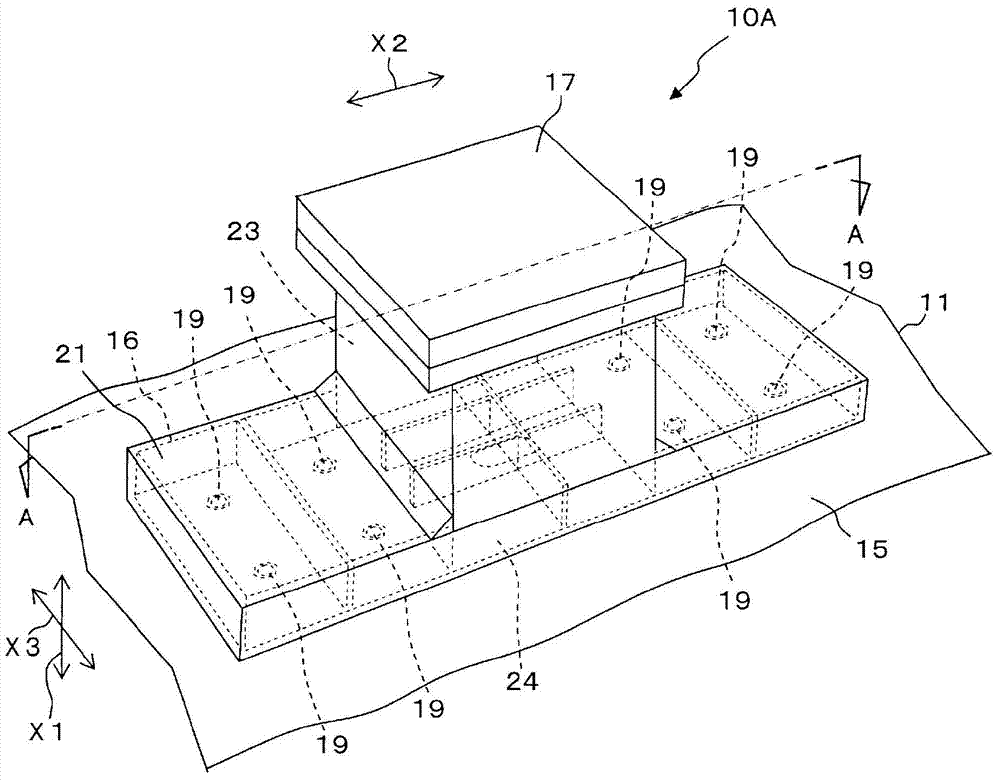

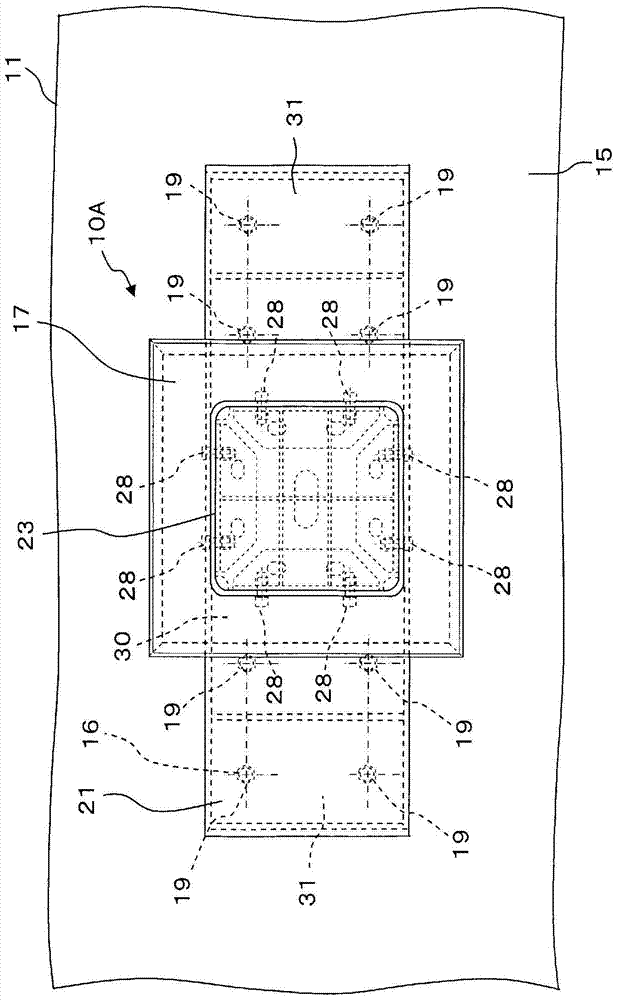

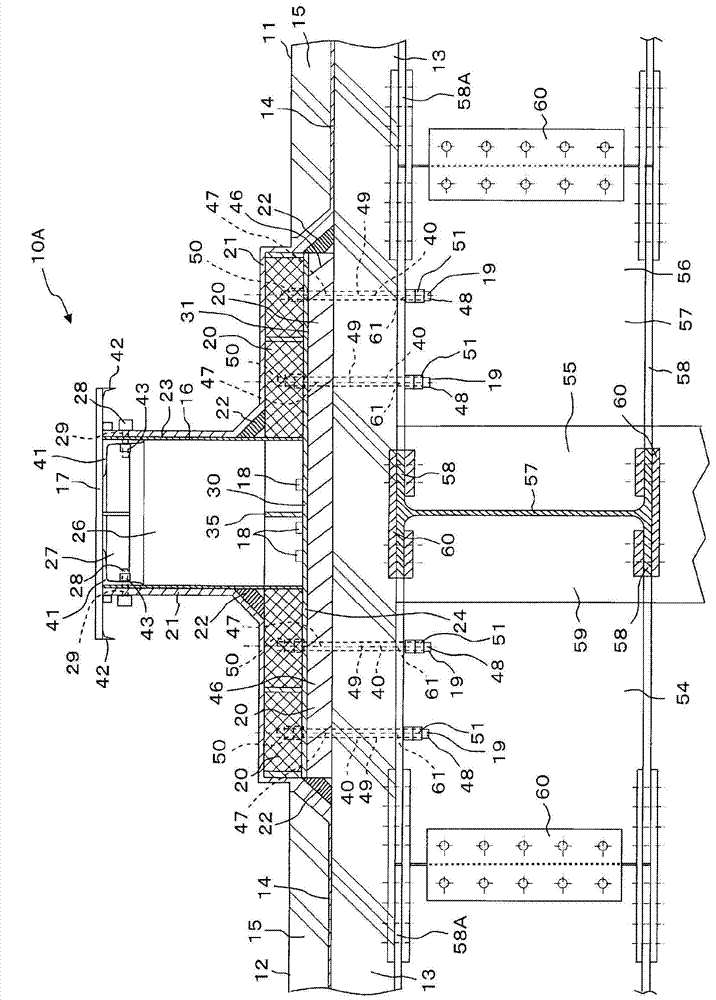

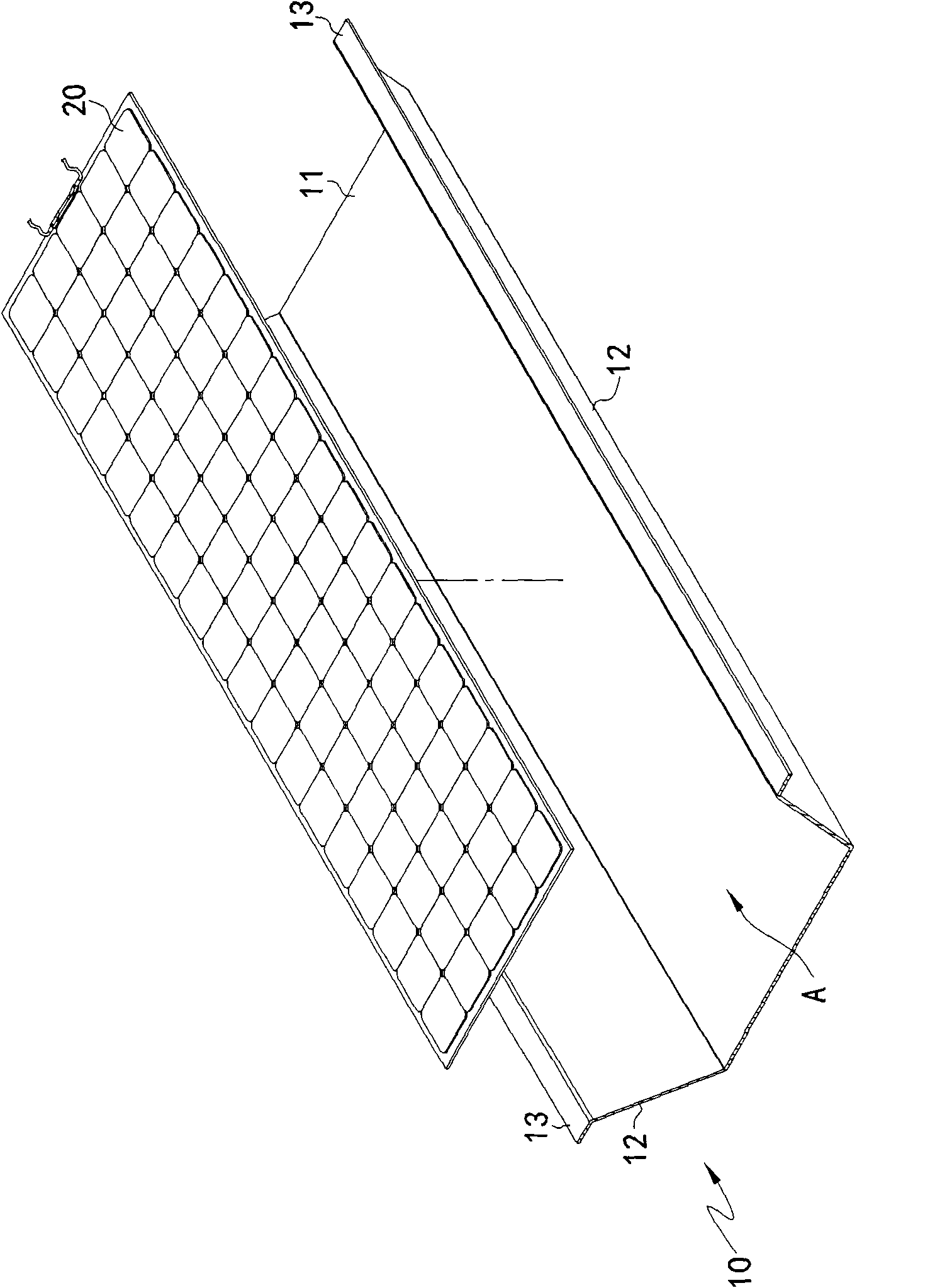

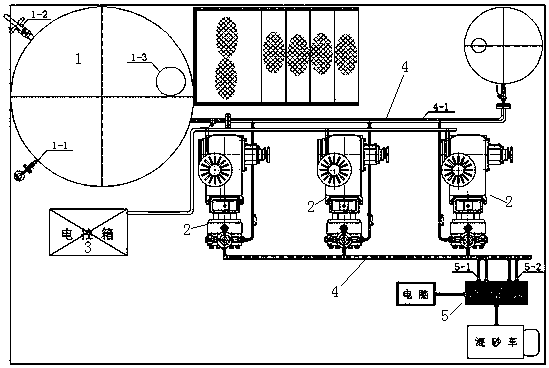

Mounting base

InactiveCN103370484AShorten the construction periodSimple construction workSolar heating energyRoof coveringBuilding construction

Problem: To provide a mounting base capable of decreasing the work and cost required for installation and capable of shortening construction time. Solution: A mounting base (10A) is formed from a metal foundation (16), height adjustment bolts (18) for adjusting the height dimension of the foundation (16), support bolts (19) inserted into support bolt insertion holes (39, 40), a metal cover (17) installed on the foundation (16), and mortar (20) filling the space (46) between the foundation (16) and the upper surface of a concrete slab (12). In the base (10A), the first fixed ends (47) of the bolts (19) are inserted into insertion holes (39) formed in a metal plate (24) and are fixed to the metal plate (24) with nuts (50), and the second fixed ends (48) of the bolts (19) are fixed to a steel beam (56) with nuts (51). The portion of the first fixed ends (47) of the bolts (19) which extends between the metal plate (24) and the top surface of the concrete floor (12) is integrated with the mortar (20) filling the space (46), and the metal cover (17) covers the opening (27) at the top of a metal tube (23) of the foundation (16).

Owner:MARUTAKA IND

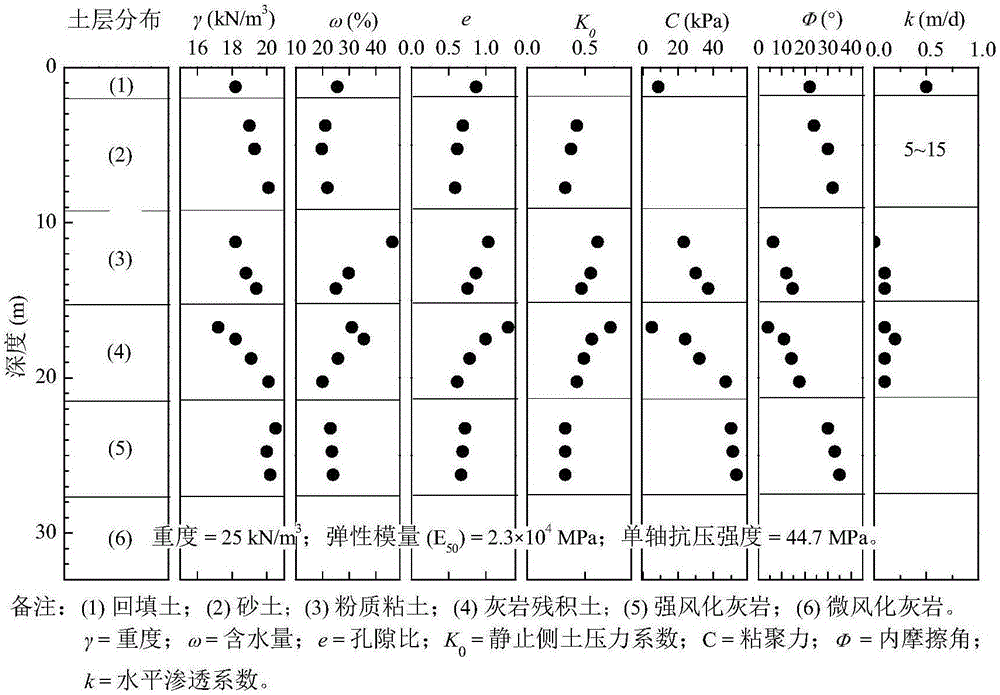

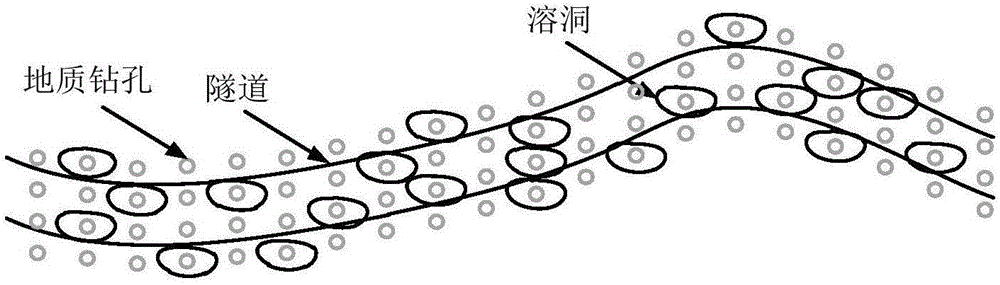

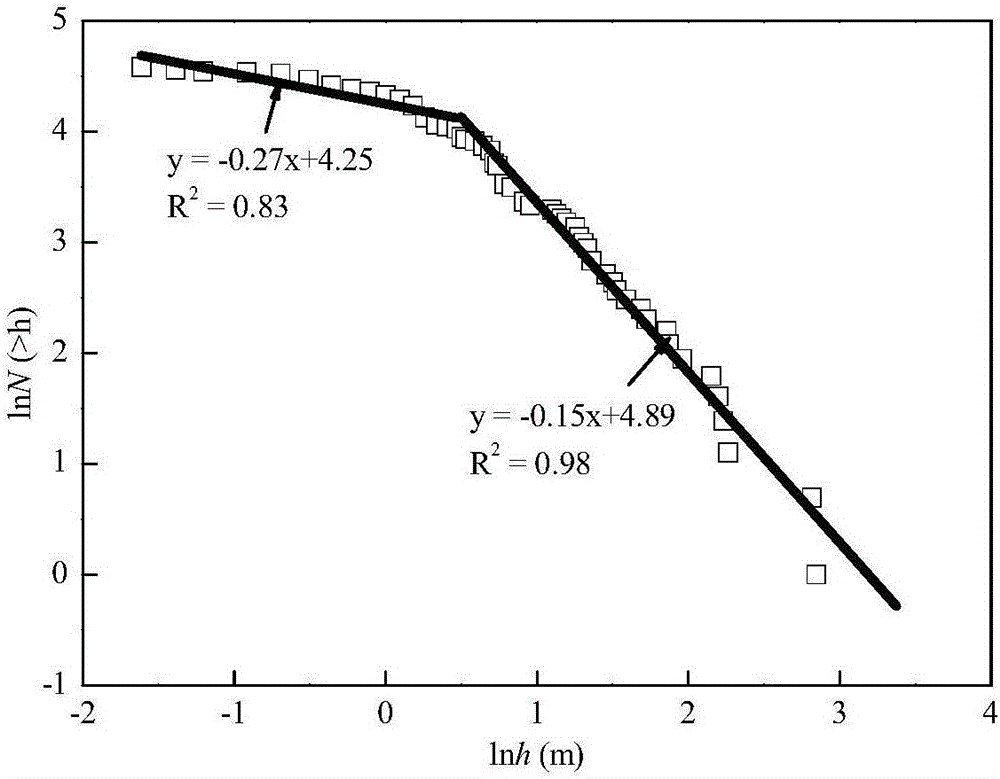

Method for determining grouting amount for filling karst caves along shield tunnel in karst stratum

The invention discloses a method for determining grouting amount for filling karst caves along a shield tunnel in a karst stratum, comprising the following steps: firstly, exploring geology of a construction site; secondly, determining a distribution condition of the karst caves along a tunnel according to a geological drilling result; thirdly, determining fractal parameters of karst cave distribution regularities; and fourthly, determining volume of the karst caves according to the fractal parameters, determining a karst cave grouting amount coefficient according to site grouting amount, and determining karst cave grouting amount of a site area. According to the method for determining the grouting amount for filling the karst caves along the shield tunnel in the karst stratum disclosed by the invention, defects of difficulty in measurement construction, long time consumption and unavailability in determining volume of karst caves in an area of an existing method are overcome, specific determining method and steps are provided, and the determination of the grouting amount for the karst caves along the shield tunnel in the karst stratum is realized.

Owner:SHANGHAI JIAO TONG UNIV

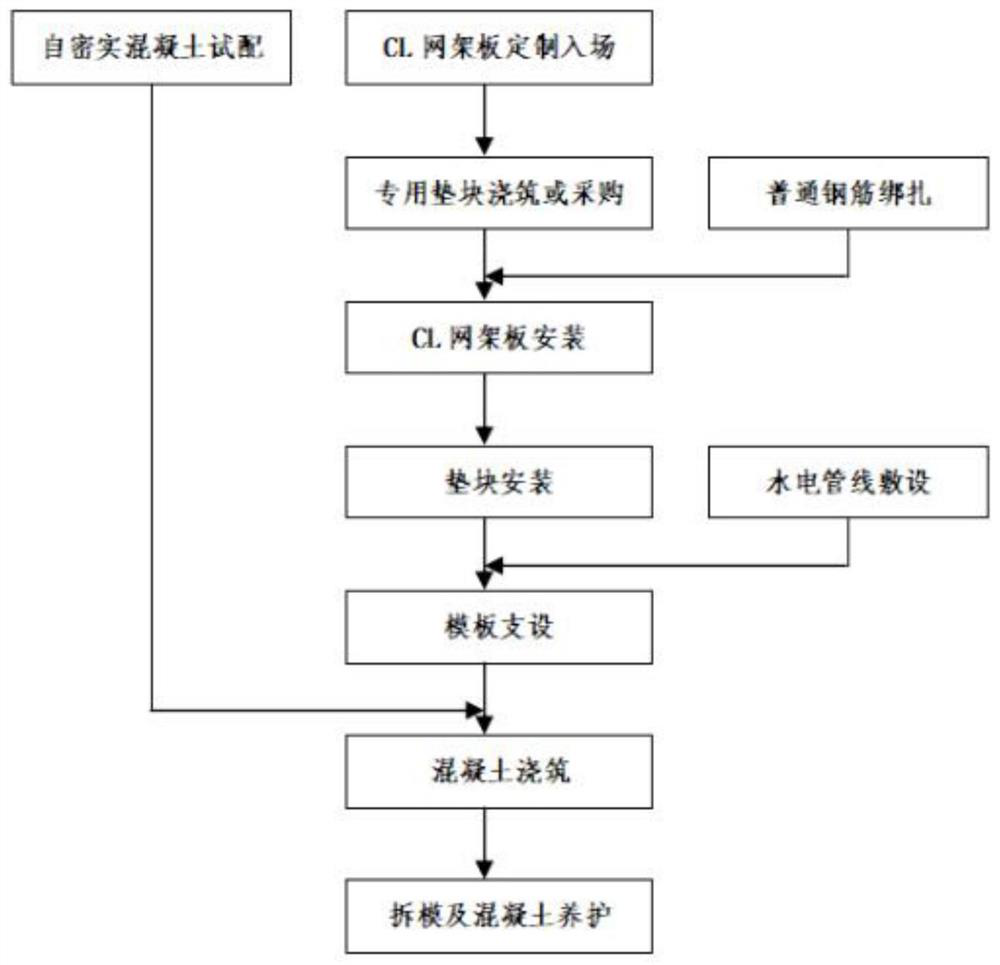

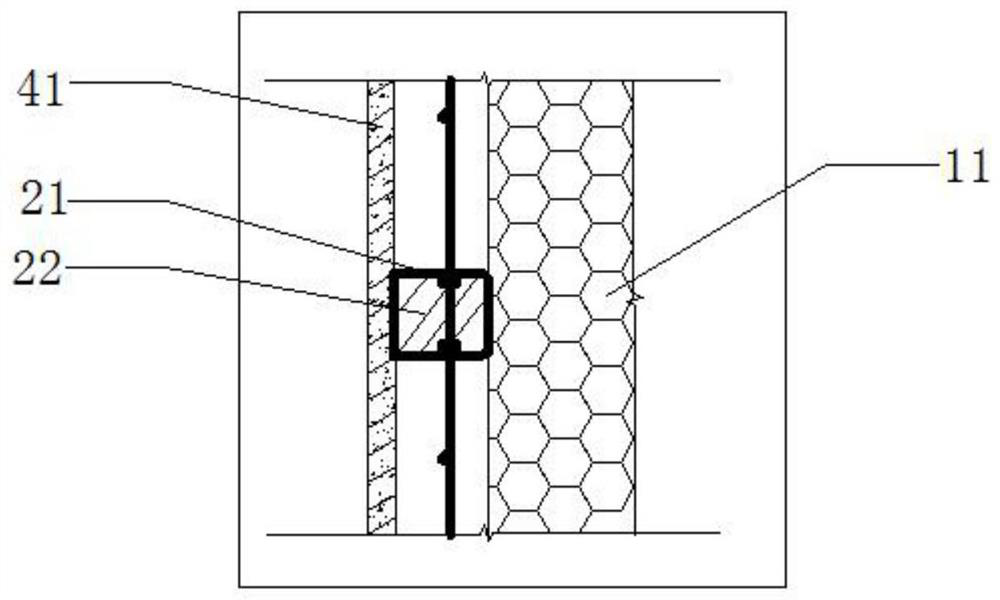

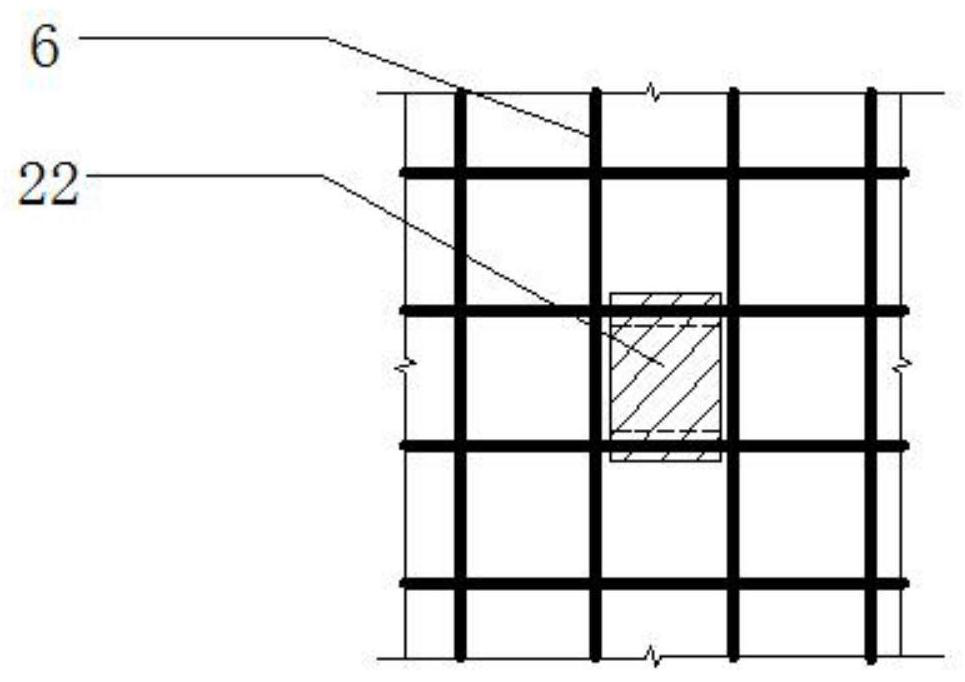

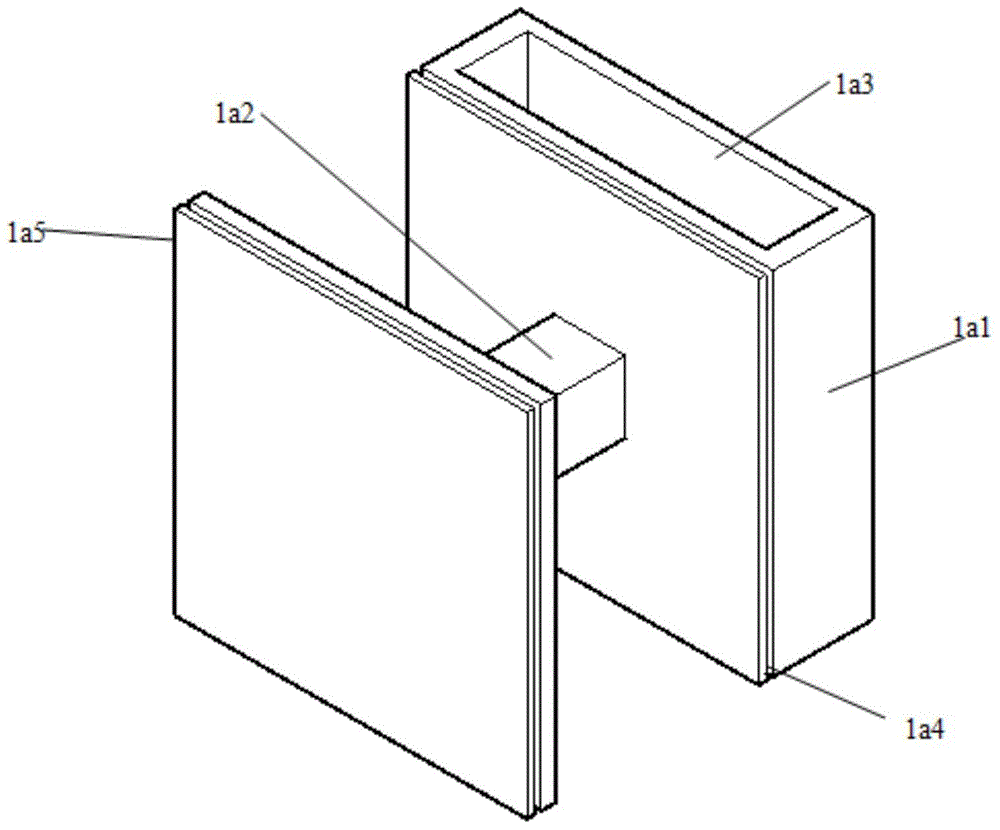

CL thermal insulation system construction method

InactiveCN112359994ASimple construction workNo lateral displacementHeat proofingBuilding material handlingThermal insulationArchitectural engineering

The invention discloses a CL thermal insulation system construction method, and belongs to the technical field of building construction. The method includes the steps that the customizing, decomposingand numbering of CL net rack plates is conducted; additional steel bars are mounted on the CL net rack plate; the CL net rack plate is installed, and the CL net rack plate is bound and fixed with fixing steel bars; a plurality of special cushion blocks are installed at the two sides of the CL net rack plate, and water and electricity pipelines are laid; a formwork used for concrete pouring is installed on the CL net rack plate, through-wall bolts are arranged on the formwork, and self-compacting concrete is matched in a trial mode; and self-compacting concrete is poured, the formwork is removed, and the concrete is maintained. According to the CL thermal insulation system construction method, the structure erecting work of a CL heat preservation system can be simply and rapidly completed,the construction process is simplified, cost is reduced, and stability and firmness are achieved; and the in-mold temperature and pouring points are controlled, the special cushion blocks are arranged at certain intervals, and the concrete pouring height difference between the two sides of the heat preservation plate is controlled, so that the situation that the CL net rack plate does not generate lateral displacement is guaranteed, the pouring requirement and pouring quality of the concrete are met, and the construction is safe and efficient.

Owner:CHINA MCC17 GRP

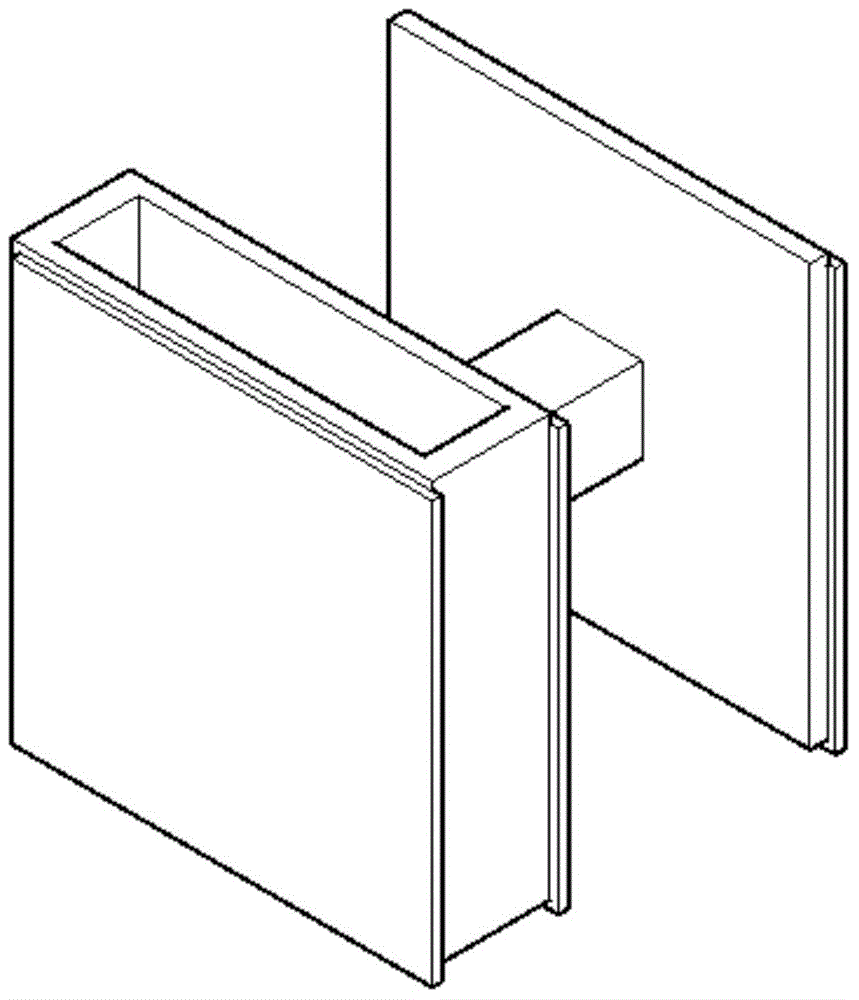

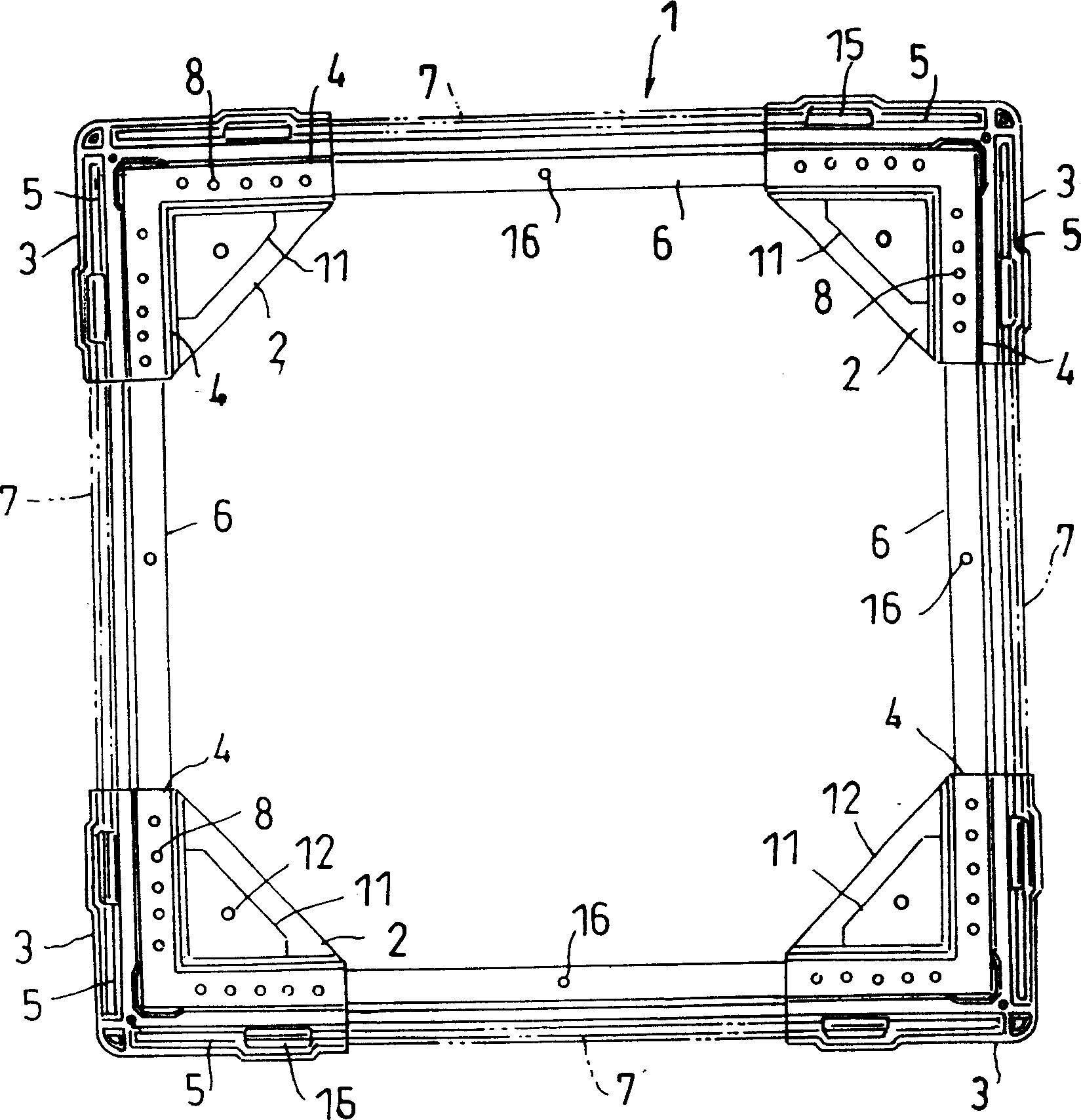

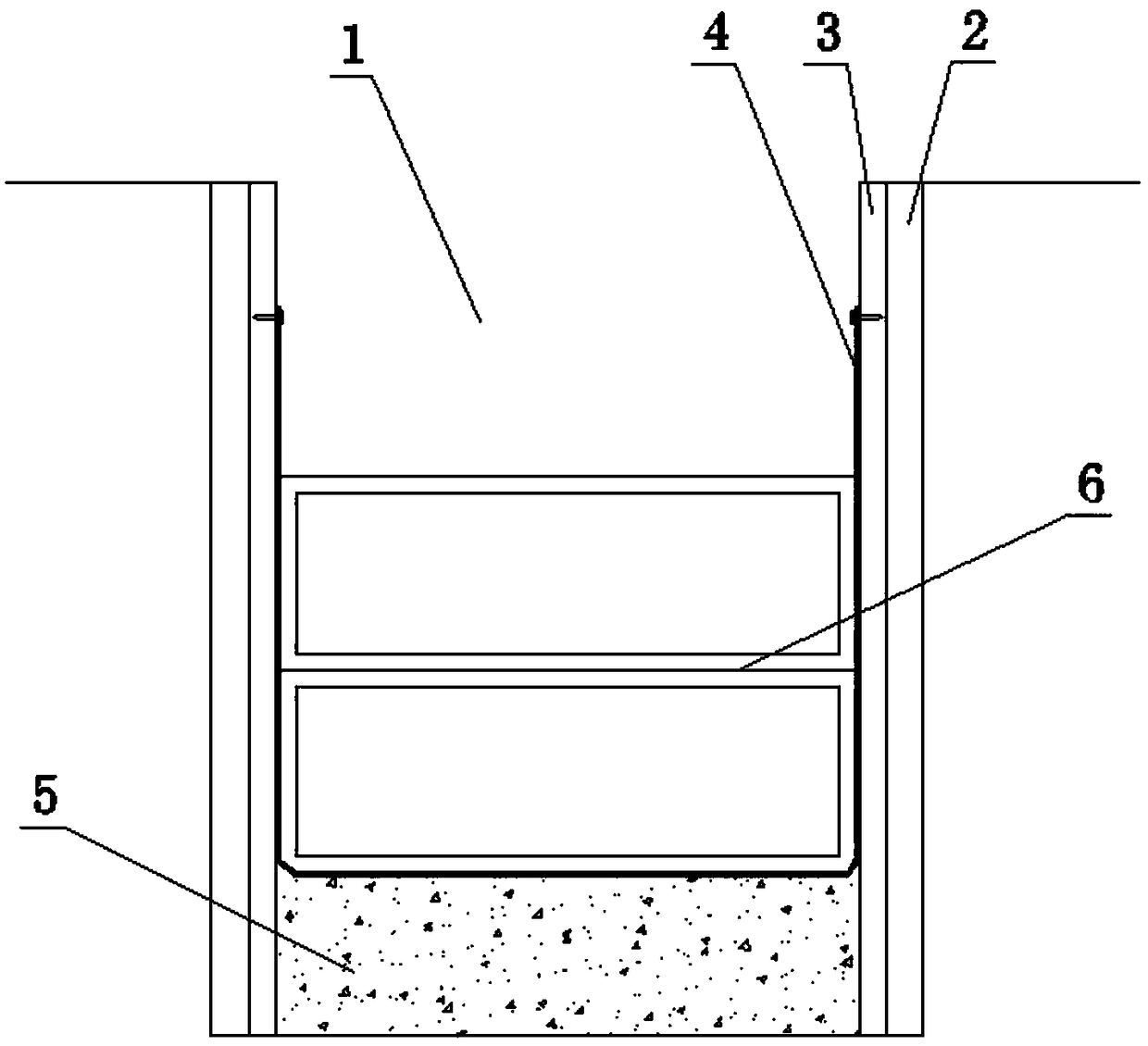

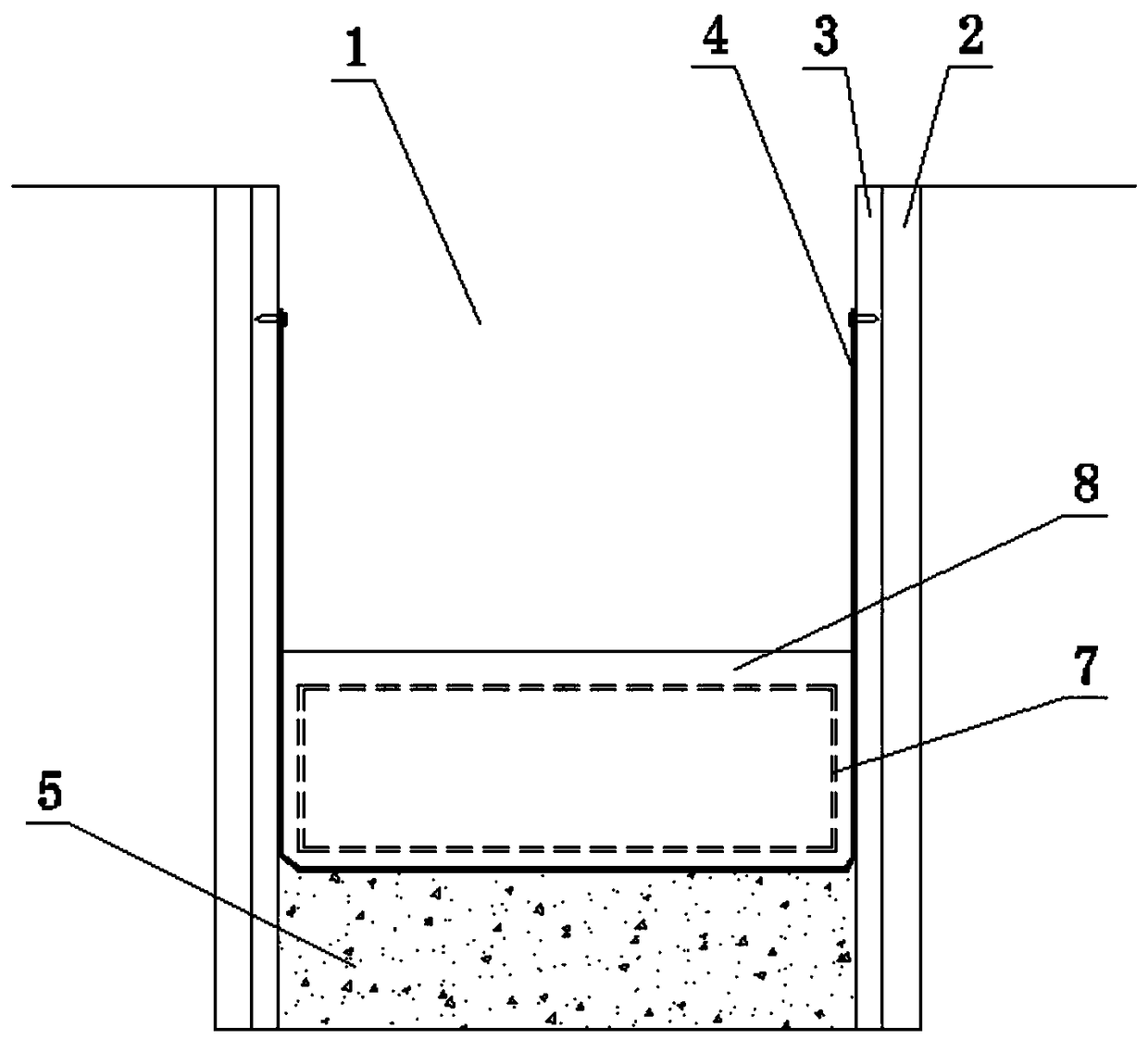

Assembling type heat preservation shear wall structure system and construction process

ActiveCN104594527ASimple construction workImprove work efficiencyWallsBuilding material handlingButt jointHorizontal and vertical

The invention discloses an assembling type heat preservation shear wall structure system and a construction process. The assembling type heat preservation shear wall structure system comprises an inner wall and an outer wall with a heat preservation function, wherein the outer wall comprises a plurality of outer wall template units which are in butt joint together; each outer wall template unit comprises two main plates which are symmetrically arranged, and a pull rod for connecting the two main plates together, one main plate is located on the inner side of a wall body and the other main plate is located on the outer side of the wall body; the main plates located on the outer side of the wall body are internally provided with heat preservation materials; the inner wall comprises a plurality of inner wall template units which are in butt joint together; each inner wall template unit comprises two main plates which are symmetrically arranged, and a pull rod for connecting the two main plates together; the assembling type template units are spliced by concave-convex rabbets; concrete can be poured into horizontal and vertical through holes, so that the whole space is fully filled with the concrete and the seepage-proof and leakage-proof effects are good.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

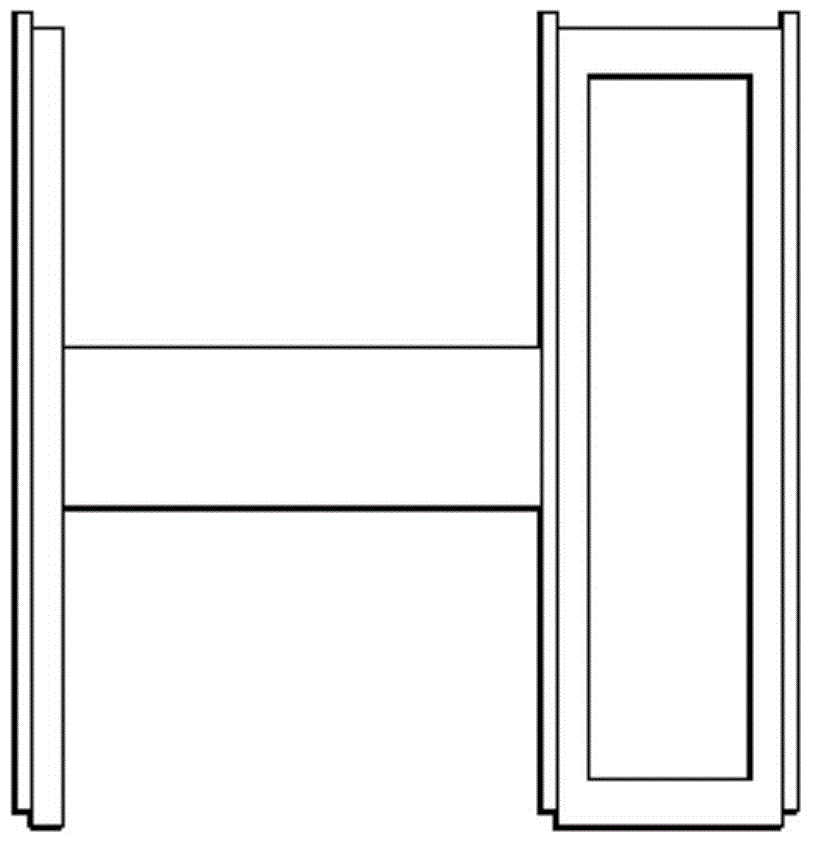

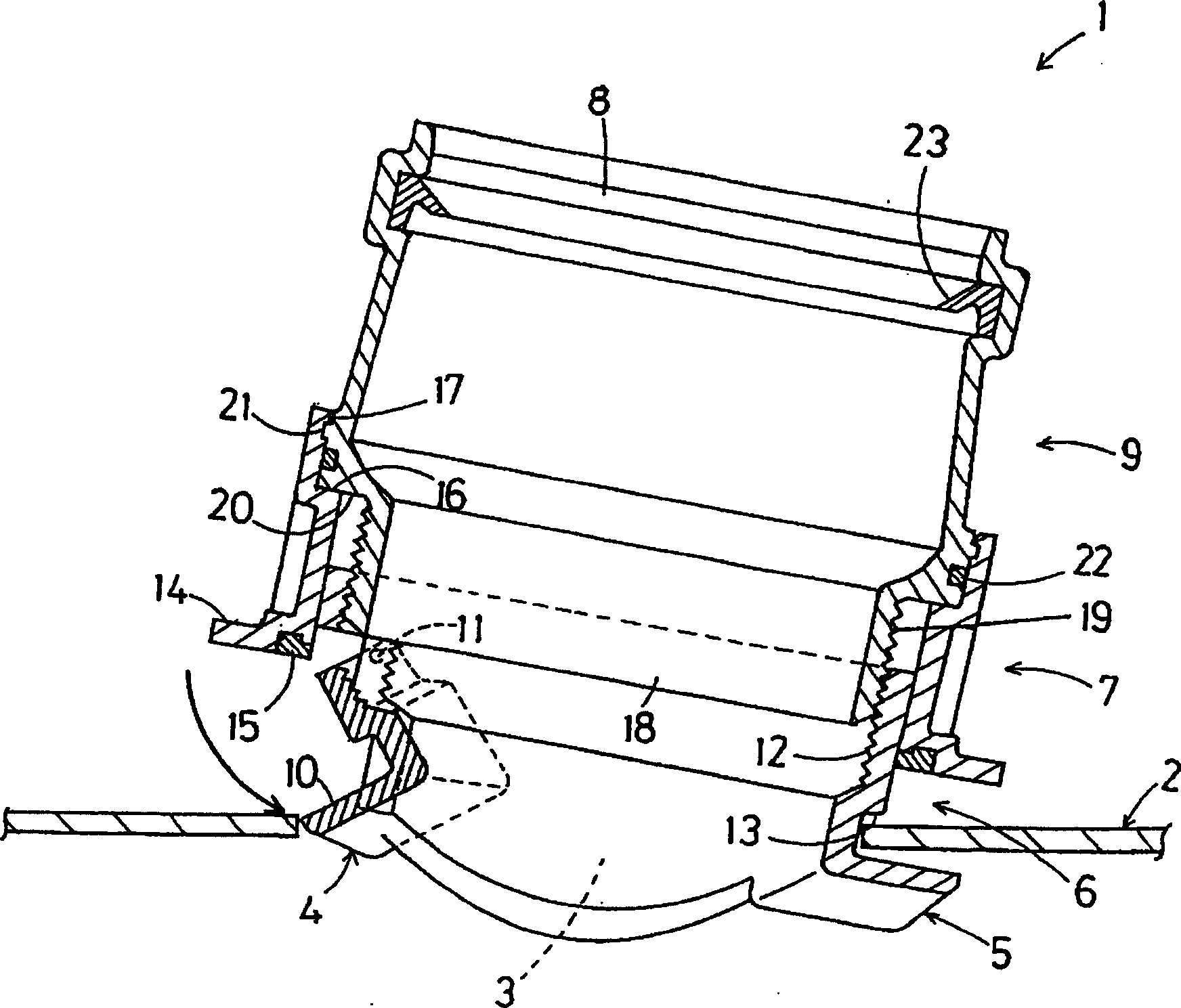

Connection branch pipe

InactiveCN1757962APrevent rotationAvoid badEngine sealsFluid pressure sealed jointsEngineeringPiping

To provide a connection branch pipe capable of improving the reliability of the execution, and achieving labor saving of the piping construction.The connection branch pipe 1 is comprised of a locking member 6 in which two locking pawls 4, 5 locked in the periphery of an opening 3 of a main drainage 2 are installed, a saddle member 7 fitted into the locking member 6 and installed on the main drainage 2, and a connecting member 9 inserted into the saddle member 7 and provided with a connection port 8 connected by an attached pipe. One locking pawl 4 is rotatably and pivotable attached to the locking member 6 via a pivot pin 11, the locking pawl 4 can pass the opening 3 of the main drainage 2 by revolving the pivotably attached locking pawl 4. The locking pawl 4 is prevented from revolving by screwing the connecting member 9 to the locking member 6, and the locking pawl 4 can not pass the opening 3 of the main drainage 2.

Owner:ARONKASEI

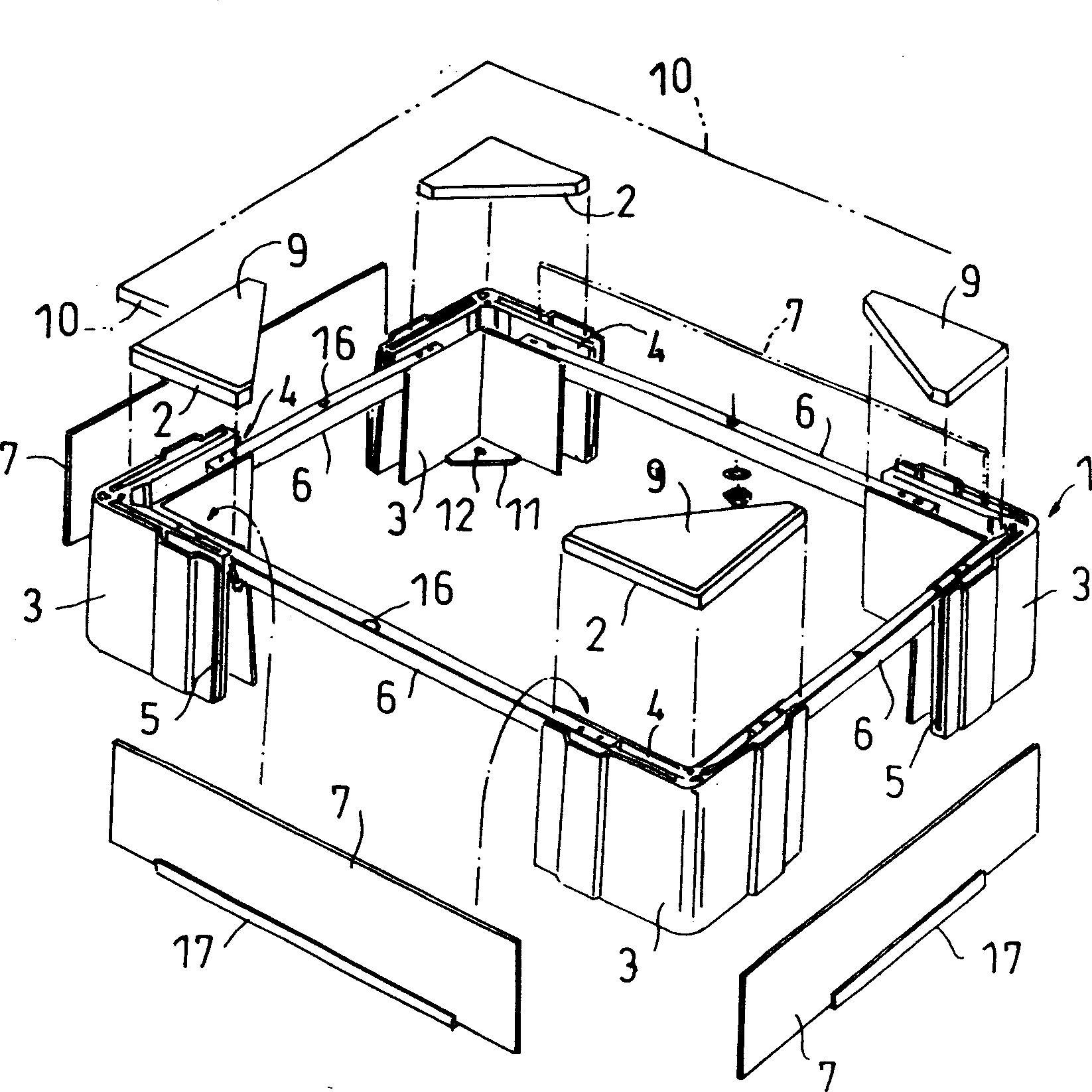

Washing machine carrier

InactiveCN1912227AEasy to set upImproved construction workabilityOther washing machinesStands/trestlesEngineeringMechanical engineering

This washing machine installation stand is constituted with pedestal members mounted with an installation plates to mount a washing machine in four corners. Connecting rod insertion parts in opposite faces of the respective pedestal members and side plate insertion parts are provided. Connecting rods are detachably connected to the connecting rod insertion parts, and side plates are detachably mounted to the side plate insertion parts. The connecting rod insertion parts are formed with attachment parts capable of varying the connecting position in the longitudinal direction of the connecting rods, and a cover plate is disposed on the mount plate via a vibration isolating rubber plate or on the pedestal members. The invention can construct an installation stand allowing flexible installation of a washing machine on a floor face such as a washing place and changing an installation area without being restricted by the dimension of the washing machine, having a compact and good external appearance without occupying a large space, facilitating the installation on the floor face, and allowing the washing machine to be easily moved or removed for inspection or cleaning.

Owner:TECHNOTECH

Pipeline dredging device

InactiveCN113026929AWide applicability to the environmentImprove construction reliabilitySewer cleaningMarine engineeringSludge

The invention discloses a pipeline dredging device, and belongs to the technical field of sludge cleaning equipment. The pipeline dredging device comprises a front end structure, a rear dredging scraper mechanism, a front dredging scraper mechanism, a machine body, a guide sliding shoe, a rear end structure and a cable system, wherein one end of the machine body is fixedly connected with the rear end structure, the cable system is arranged on the rear end structure, the other end of the machine body is fixedly connected with the front end structure, the rear dredging scraper mechanism and the front dredging scraper mechanism are symmetrically arranged on the machine body, and the guide sliding shoe is arranged below the machine body. The pipeline dredging device works in a pipeline, only one wire dragging auxiliary device is arranged on the road surface, potential safety hazards of personnel are avoided, construction operation is easy, the dredging speed is high, cost is low, and the influence on the road surface is small. The pipeline dredging device is wide in environmental applicability and high in construction reliability.

Owner:NANJING ANTOUKE INTELLIGENT SYST CO LTD

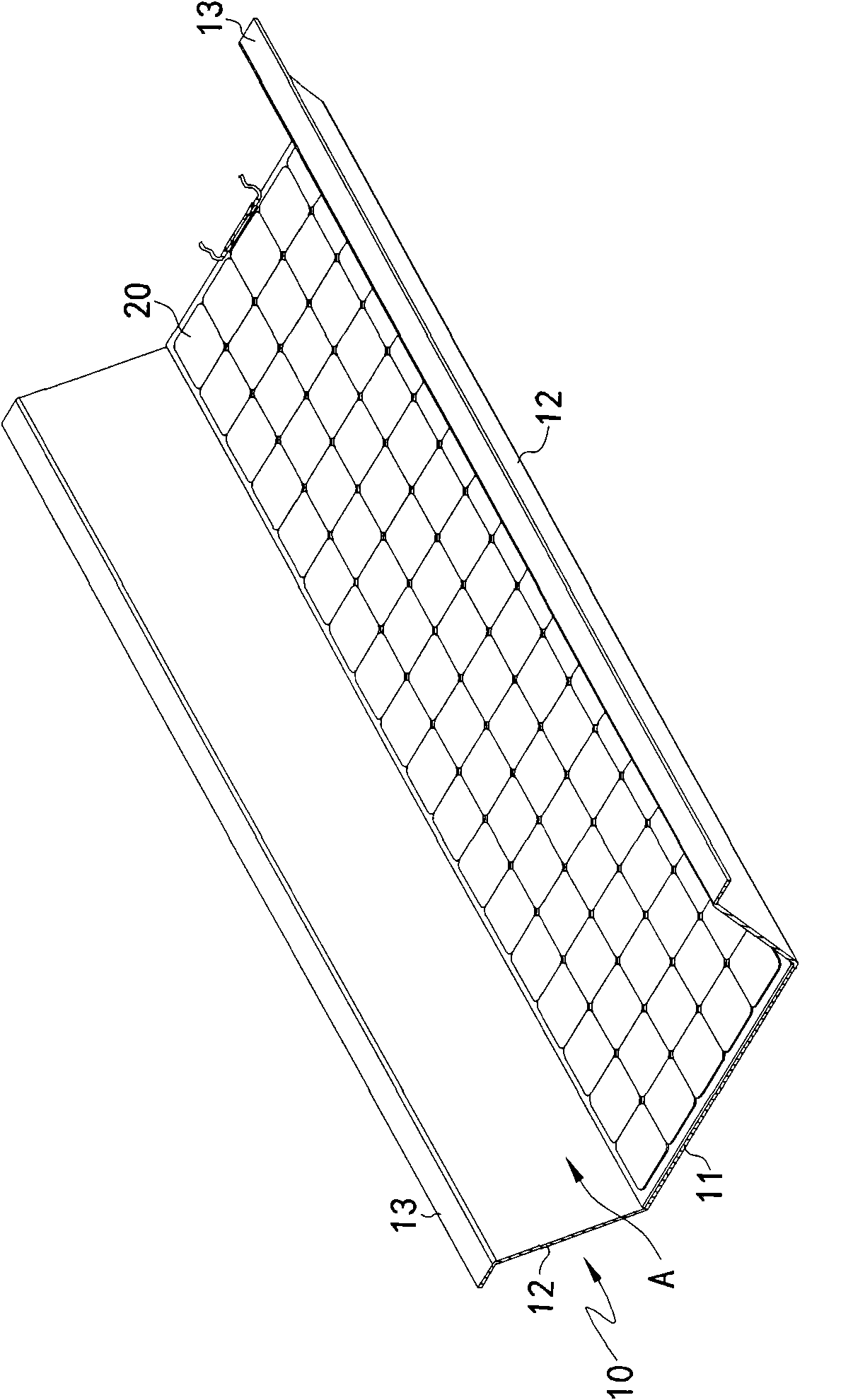

Wave plate structure with solar panel

InactiveCN102454260AWon't spoil the viewSimple construction workPhotovoltaic supportsRoof covering using slabs/sheetsAerospace engineering

Owner:A2PEAK POWER

A continuous injection acidification equipment for water injection well

ActiveCN104879105BFast online acidizing construction workContinuous online acidizing construction operationFluid removalEngineeringInjection well

Owner:PETROCHINA CO LTD

Assembly type operation platform of compound fertilizer granulation high tower and construction method of assembly type operation platform

PendingCN114135090ASimple structureLight in massBuilding support scaffoldsFertilizerAgricultural engineering

The invention discloses an assembly type operation platform of a compound fertilizer granulation high tower and a construction method thereof, the operation platform comprises: two truss side beams which are arranged in parallel at an interval, and two ends of the two truss side beams are respectively fixed on the inner tower wall of the high tower; the light prefabricated bottom plate is fixedly mounted between the bottom ends of the two truss side beams; and the multiple transverse supporting top rods are arranged at intervals, and the two ends of the multiple transverse supporting top rods are fixedly installed between the top ends of the two truss side beams correspondingly. The operation platform is simple in structure and light in weight, the truss side beams and the light prefabricated bottom plate are machined under the tower, then the machined truss side beams and the light prefabricated bottom plate are hoisted to the tower to be installed, and the operation platform has the advantages of being short in construction time, low in construction cost, high in safety and easy to construct and install.

Owner:WUHAN UNIV OF TECH

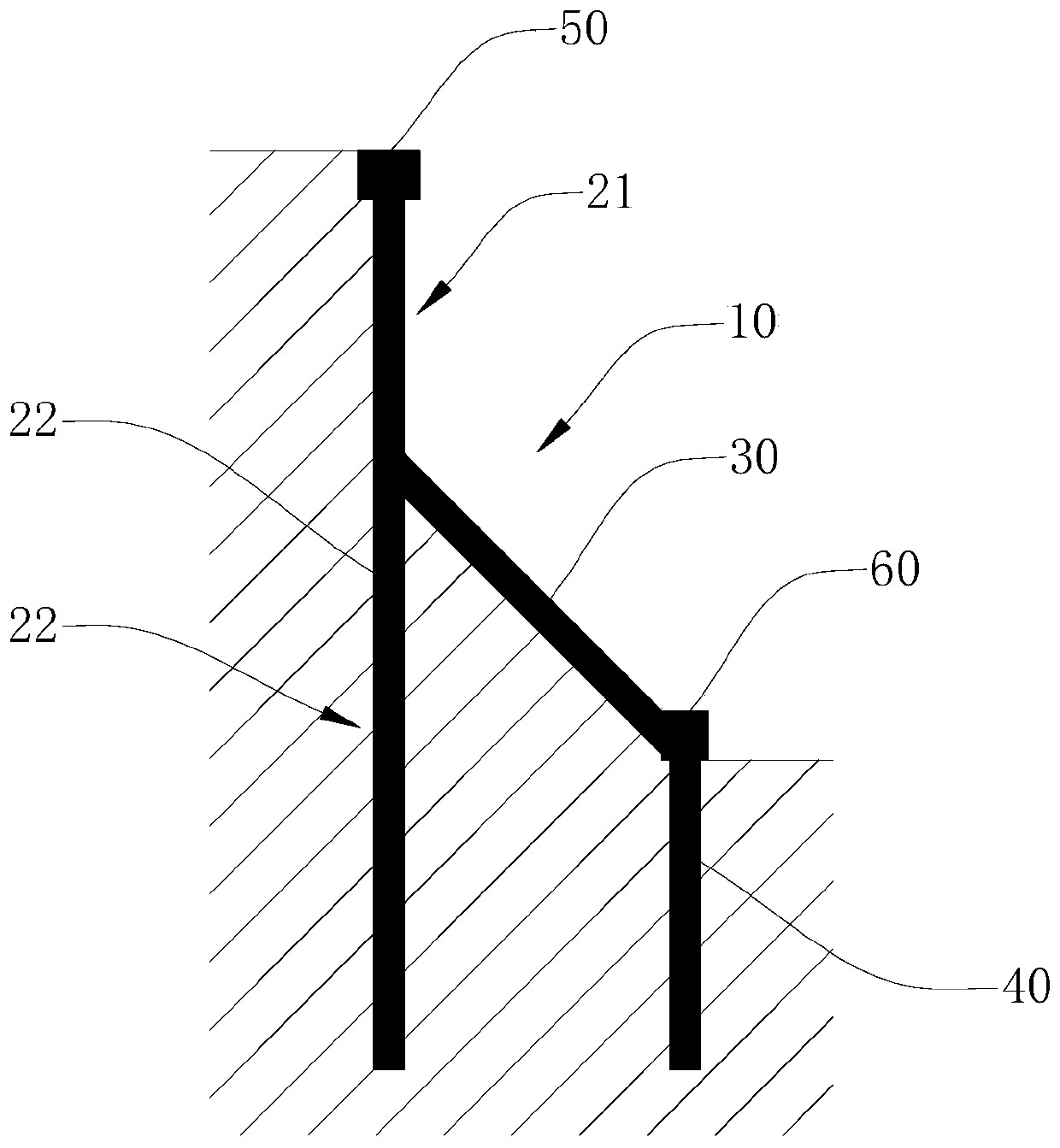

Slope supporting structure and construction method

PendingCN111305237AGive full play to the resistance to pressureAct as counter pressureExcavationsClimate change adaptationArchitectural engineeringStructure support

The invention discloses a slope supporting structure and a construction method, and belongs to the technical field of slope prevention and control. The slope supporting structure includes a pluralityof supporting units arranged at intervals. Each supporting unit comprises a vertical pile, an inclined beam and a pile foundation, wherein the two ends of the inclined beam are separately connected with the vertical pile and the pile foundation. The top ends of the adjacent vertical piles are connected through coping beams, and the adjacent pile foundations are connected through foundation beams.The slope supporting structure can effectively support a slope without need for large equipment, so that the problem that the large equipment is difficult to dispose in place or large disturbance is caused to the slope is avoided; compared with single-row or double-row micro piles, the slope supporting structure has the advantages that stress is more reasonable and the deformation resistance is higher; and compared with multi-row micro piles, the slope supporting structure has the advantages that the construction period is short and the cost is low.

Owner:CCTEG CHONGQING ENG CO LTD

Multi-layer pipe rack structure of deep pipe rack foundation pit and construction method of multi-layer pipe rack structure

InactiveCN108643229AReduce usageSimple construction workArtificial islandsUnderwater structuresWork periodShotcrete

The invention discloses a multi-layer pipe rack structure of a deep pipe rack foundation pit and a construction method of the multi-layer pipe rack structure, and belongs to the technical field of underground pipe rack construction. The pipe rack structure comprises a pipe rack foundation pit, the two sides of the pipe rack foundation pit are provided with two rows of cast-in-situ bored piles, steel plate nets are fixed to the right outer wall of the cast-in-situ bored pile on the left side of the pipe rack foundation pit and the left outer wall of the cast-in-situ bored pile on the right sideof the pipe rack foundation pit, concrete is sprayed to the steel plate nets, and a guniting layer is formed. A concrete cushion layer is poured to the bottom face of the pipe rack foundation pit, awaterproof roll is laid on the concrete cushion layer, and the two sides of the waterproof roll are overturned upwards and are closely attached to the guniting layer. The left edge position and the right edge position of the waterproof roll are fixed to the guniting layer through rivets. A multi-layer pipe rack is arranged on the waterproof roll. During construction of the multi-layer pipe rack structure of the deep pipe rack foundation pit, the guniting layer on the inner wall of the pipe rack foundation pit is utilized as a pipe rack wall plate outer template, the template usage amount is reduced, the construction cost is saved, the pipe rack template construction work is simplified, and the work period is shortened.

Owner:CHINA MCC17 GRP

A vertical wall sliding installation support device and its construction method

ActiveCN112854296BEasy to installEasy to assembleArtificial islandsUnderwater structuresSUSPENDING VEHICLEStructural engineering

The invention relates to a support device for sliding installation of a vertical wall and a construction method thereof. Inclined retaining grooves are arranged at the bottoms of both ends of the translation trolley, and a reinforced support seat is fixedly installed on the outer end of the translation trolley outside the inclined retaining groove. The center of the top surface of the supporting seat is provided with a displacement rotation groove. The displacement rotation groove is a groove structure with a semicircular cross section. Several rollers are movably installed on the inner wall of the displacement rotation groove in the length direction. The center position of the top of the translation trolley is fixedly installed with an elevated anti-slip support layer, and a rotating support device is installed on at least one side of the raised anti-slip support layer, and a bottom is clamped on at least one side of the translation trolley. The limit support block, the top of the bottom limit support block is provided with an inclined support groove that matches the inclined retaining groove; the mobile platform is used to transfer the steel frame of the vertical wall to the opening of the vertical wall, realizing the transfer without the need for a wheeled crane. The cost is greatly saved, and the installation and construction work of each vertical wall can be completed by using a crawler crane, which can save a lot of money.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com