Patents

Literature

48results about How to "Save underground space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

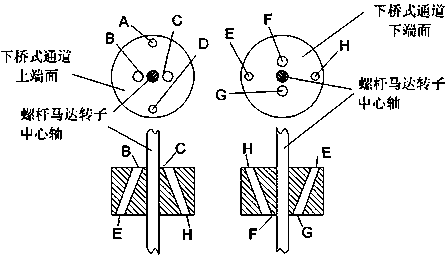

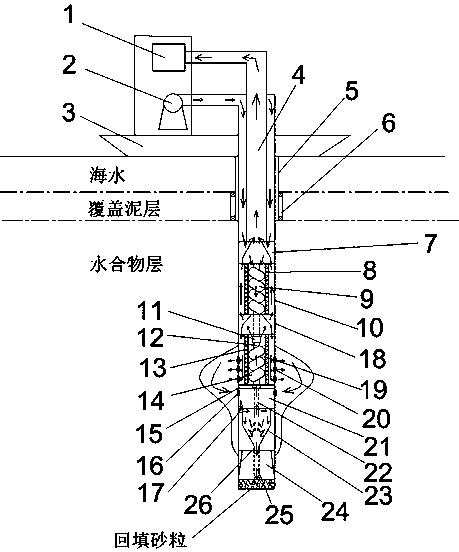

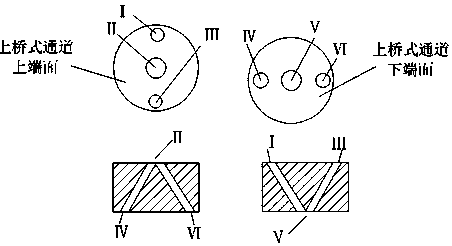

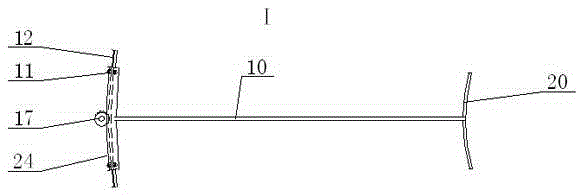

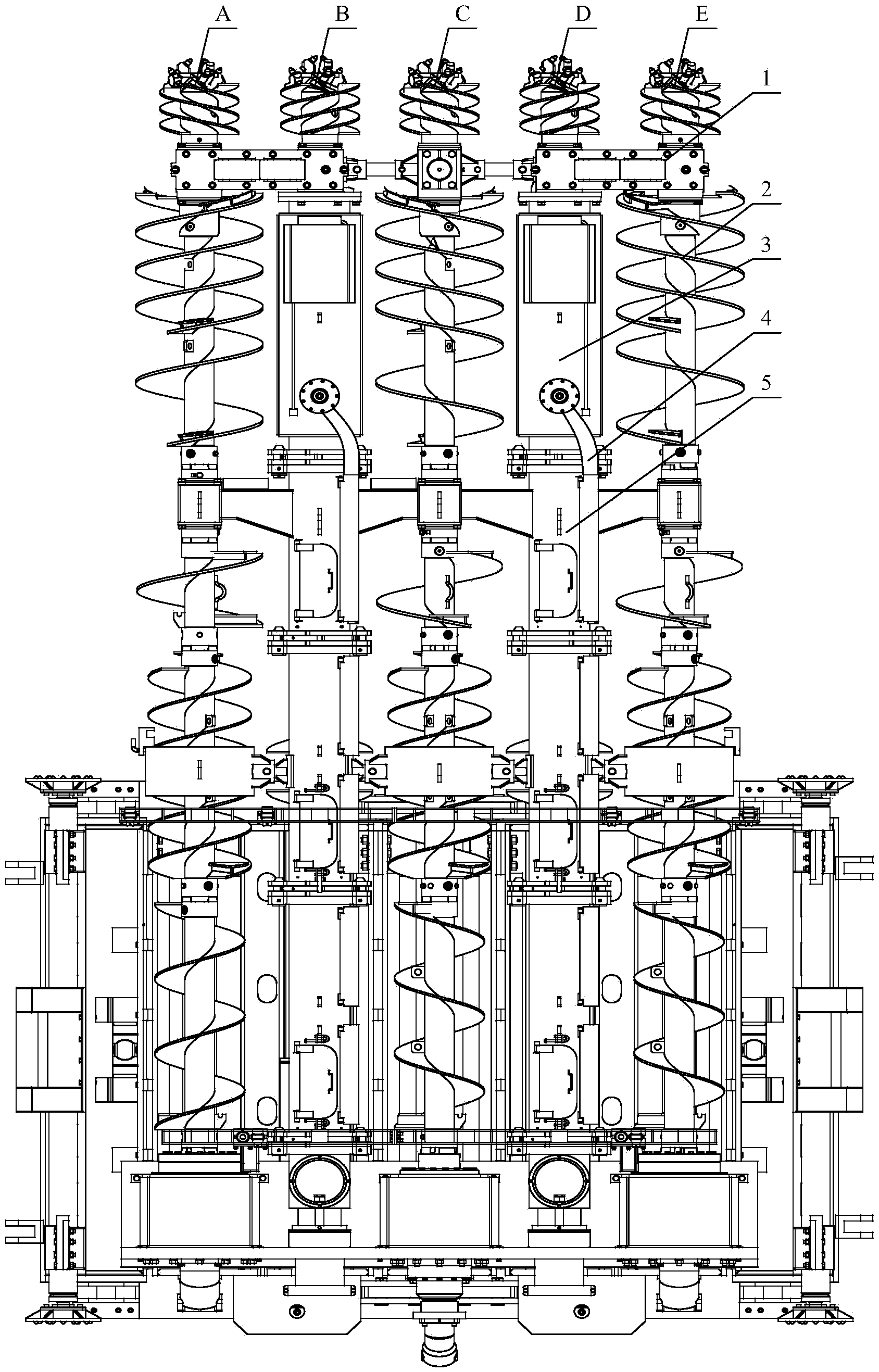

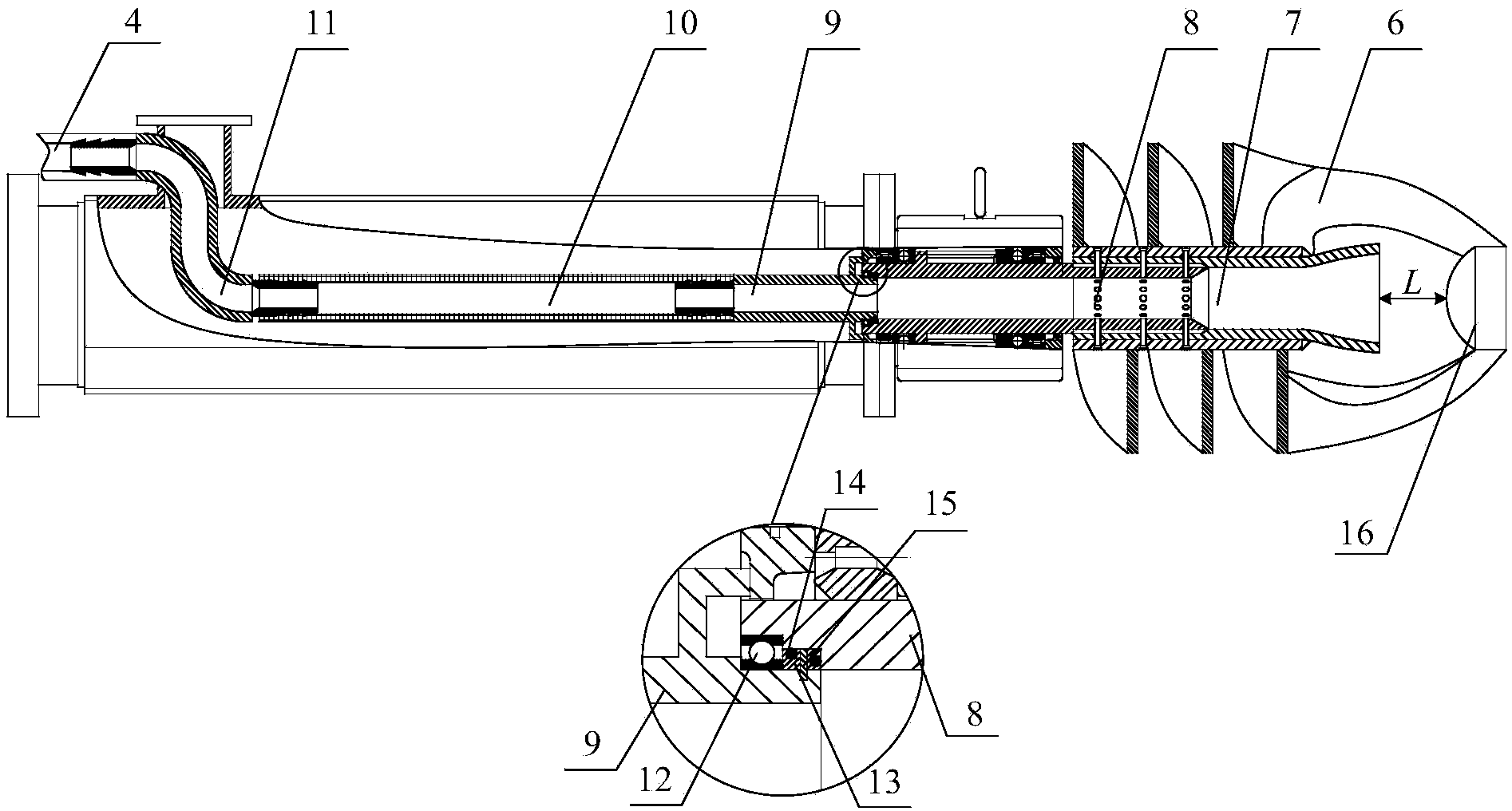

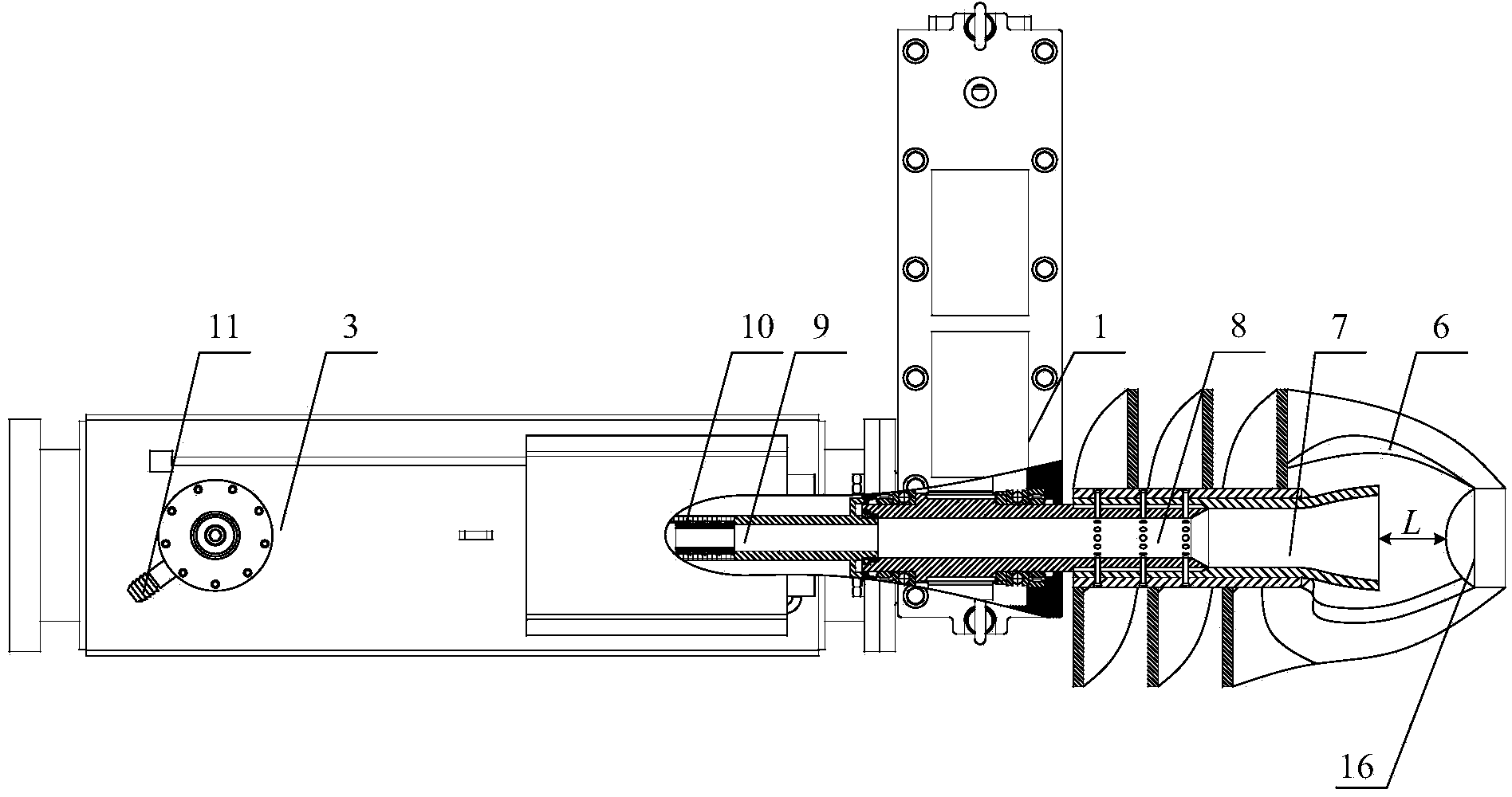

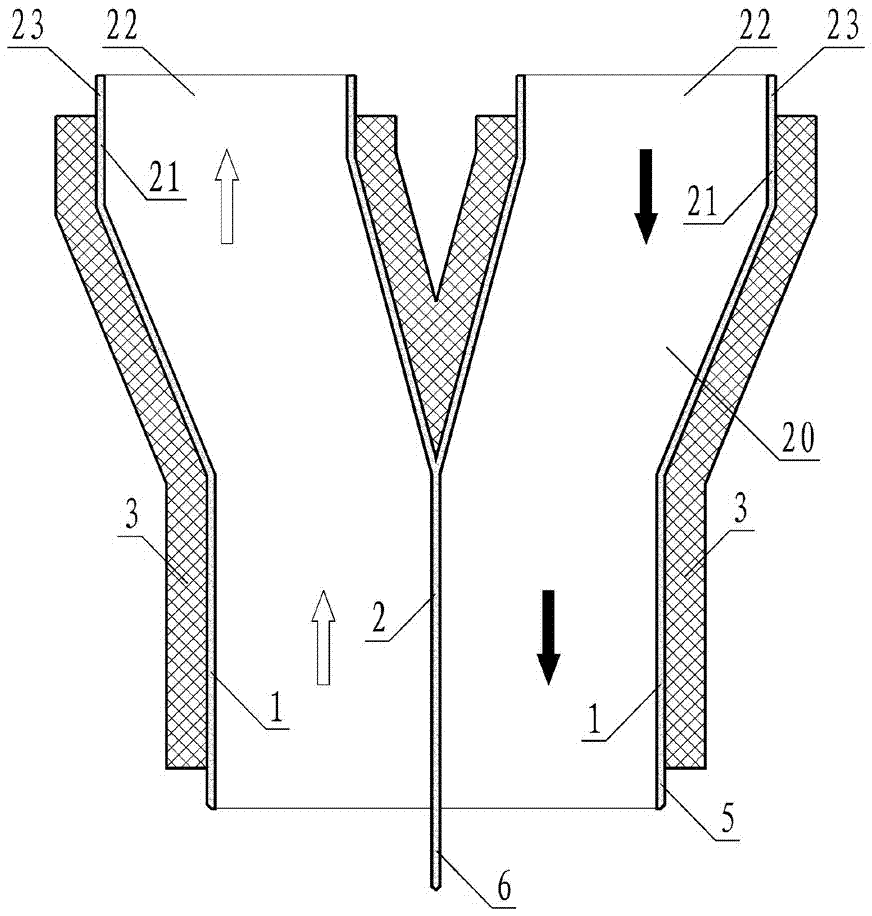

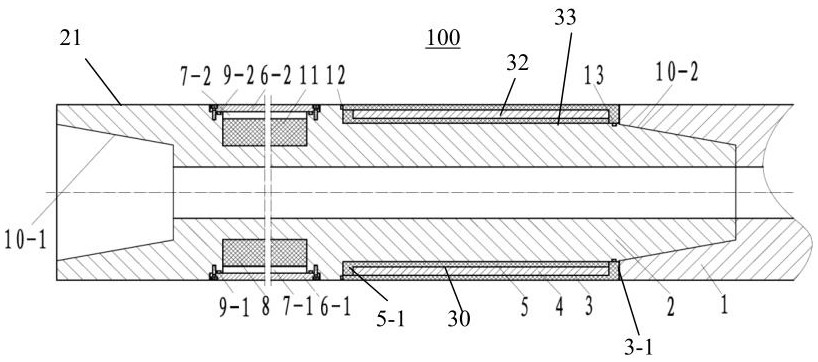

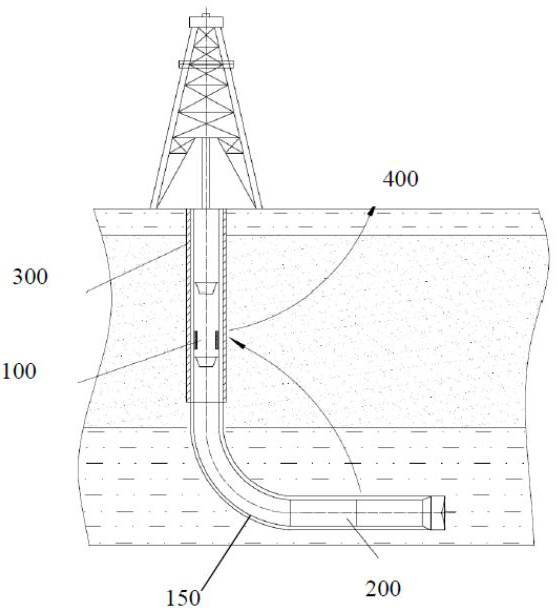

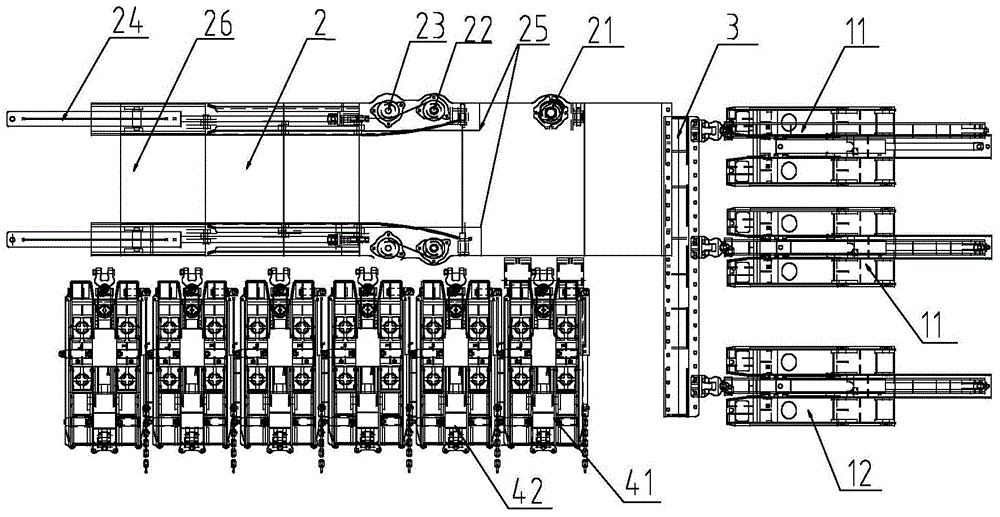

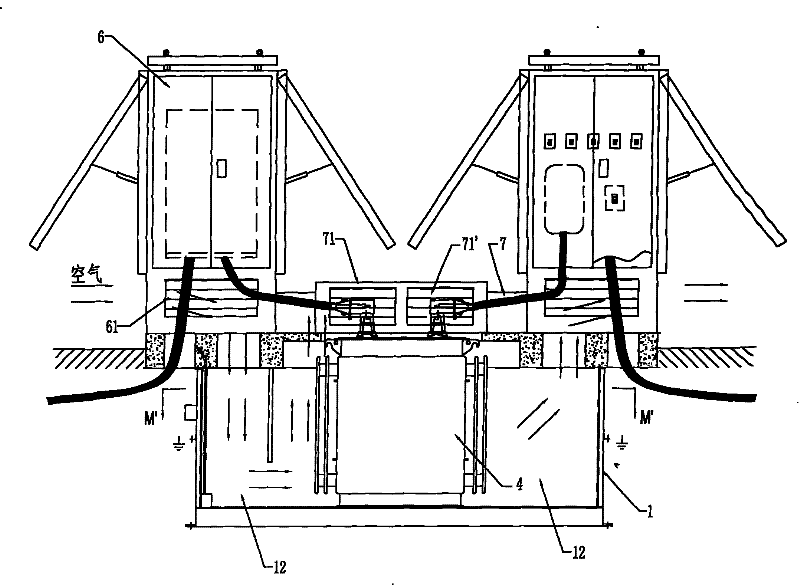

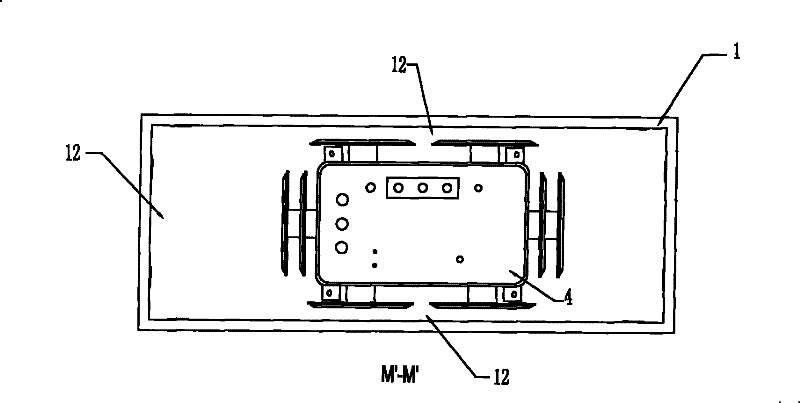

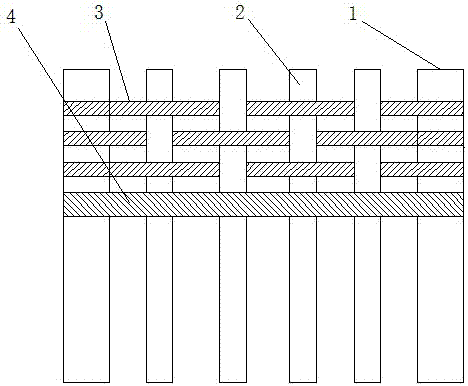

Submarine shallow-layer non-diagenetic natural gas hydrate lifting method and system

The invention discloses a submarine shallow-layer non-diagenetic natural gas hydrate lifting method and a system, which are used for lifting submarine shallow-layer non-diagenetic natural gas hydrate.A pilot hole is drilled by a drill bit, a pressure pump is started after a predetermined position is reached, high-pressure seawater drives a screw motor to rotate, and torque and rotational speed are transmitted to a screw pump by a cardan shaft; jet breaking is started by nozzles, hydrate is collected, secondarily broken and separated by collecting inlets, a secondary breaking device and a separator, separated sand is backfilled, and hydrate slurry is lifted to a solid control system on an offshore platform by the screw pump to undergo post-treatment. The invention has the following advantages: the whole process is simple, and submarine shallow-layer non-diagenetic hydrate can be effectively broken, separated and lifted; the screw pump device has the characteristics of compact structure, small size, high self-sucking capability, stable operation and long service life; and an upper bridge type passage and a lower bridge type passage ingeniously realize the pumping and lifting of seawater and hydrate slurry and save underground space.

Owner:SOUTHWEST PETROLEUM UNIV

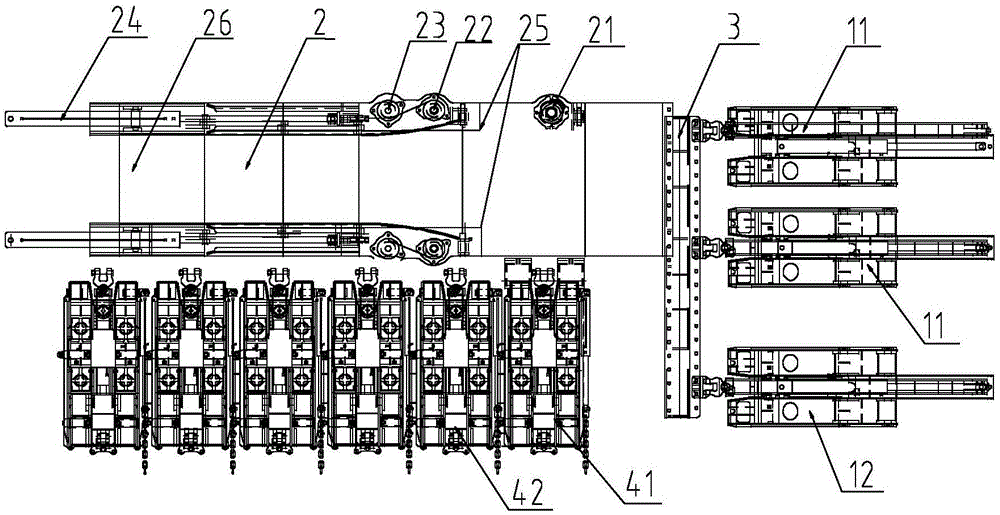

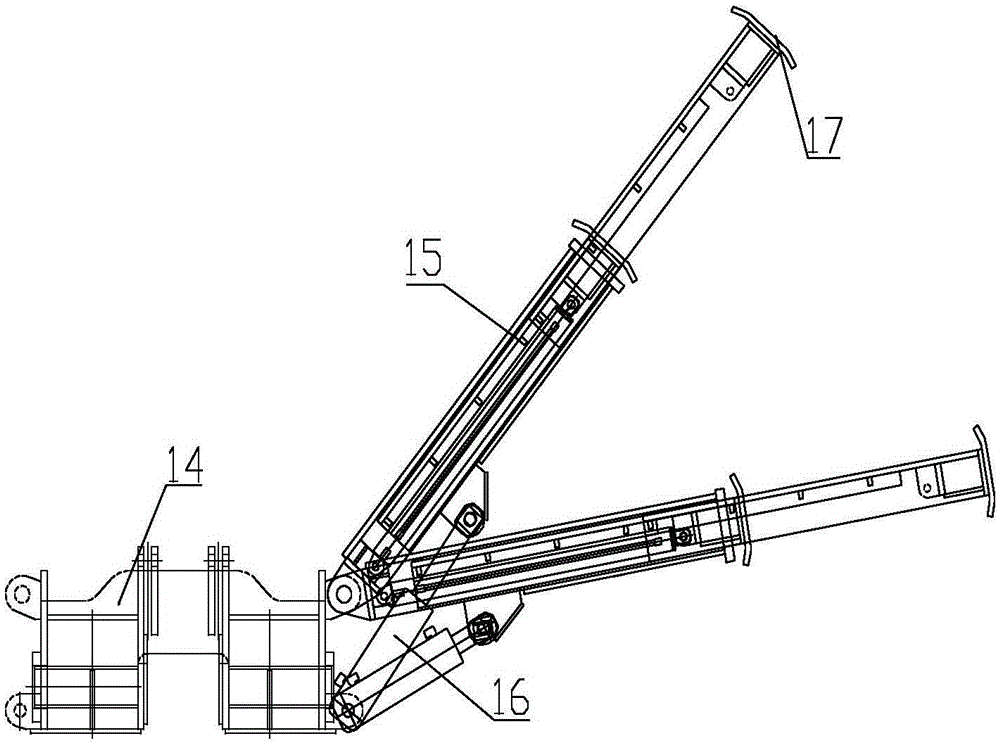

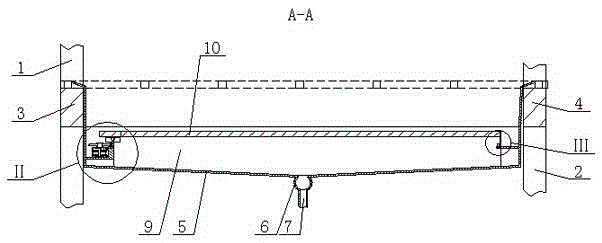

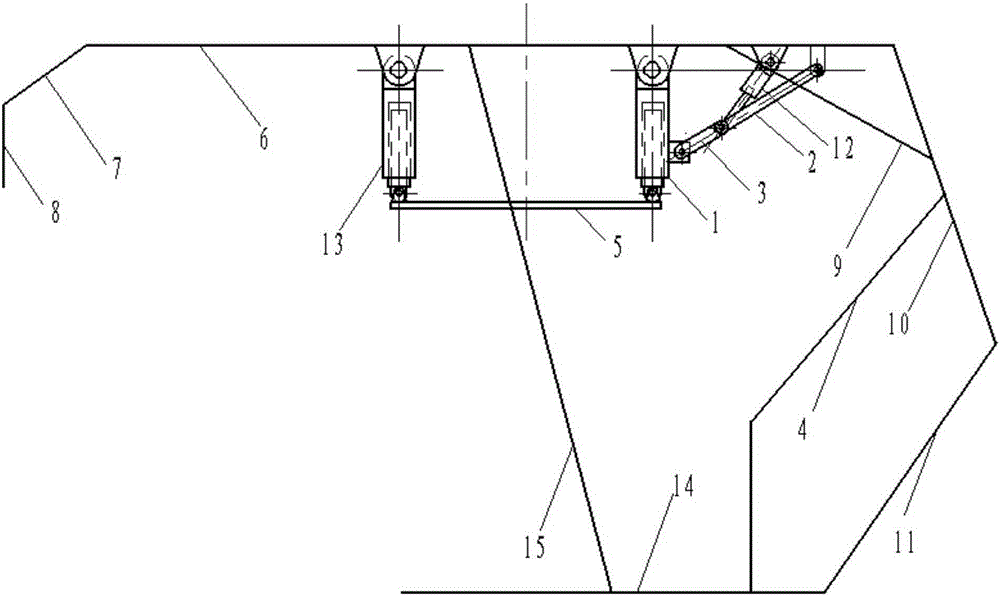

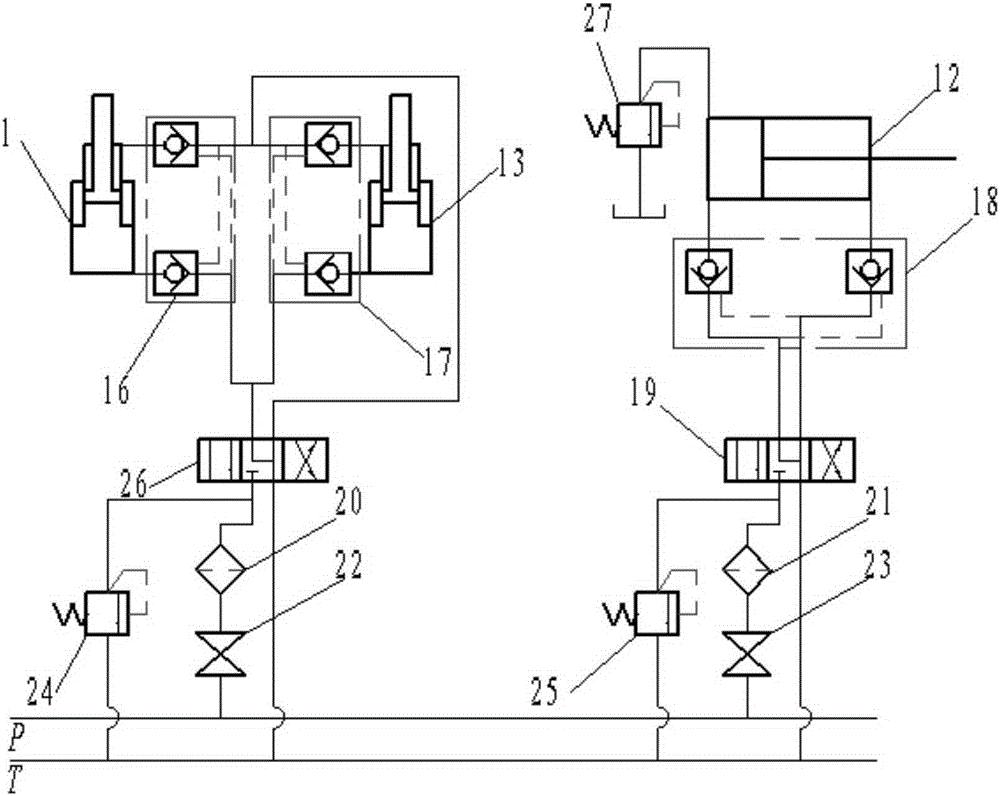

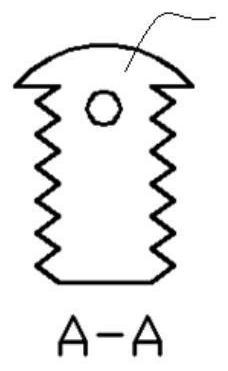

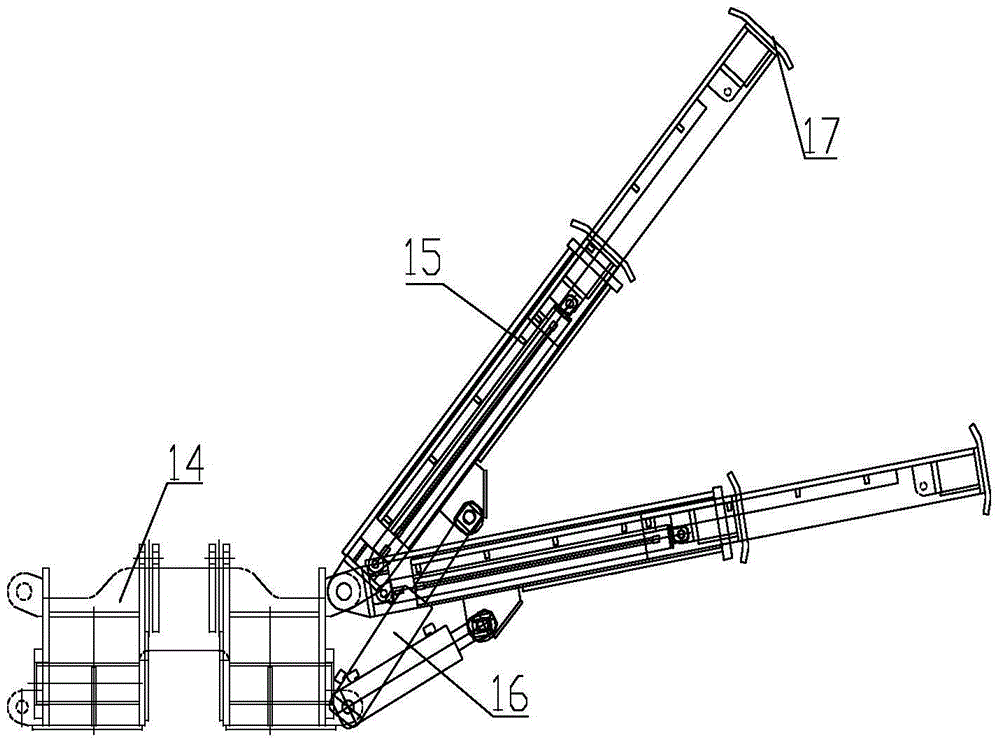

Hydraulic support withdrawing system and method

The invention discloses a hydraulic support withdrawing system and method and belongs to the technical field of hydraulic supports. The hydraulic support withdrawing system comprises at least two shield supports and a withdrawing platform. A moving beam is arranged between the shield supports and the withdrawing platform. The two sides of the moving beam are fixedly connected with a moving jack at the bottoms of the shield supports and one end of the withdrawing platform respectively. The shield supports are arranged on one side of the moving beam in parallel, and one shield support is located on the side of a hydraulic support to be withdrawn. Each shield support comprises a base and a net pushing device. The withdrawing system is high in safety coefficient, and labor is saved.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

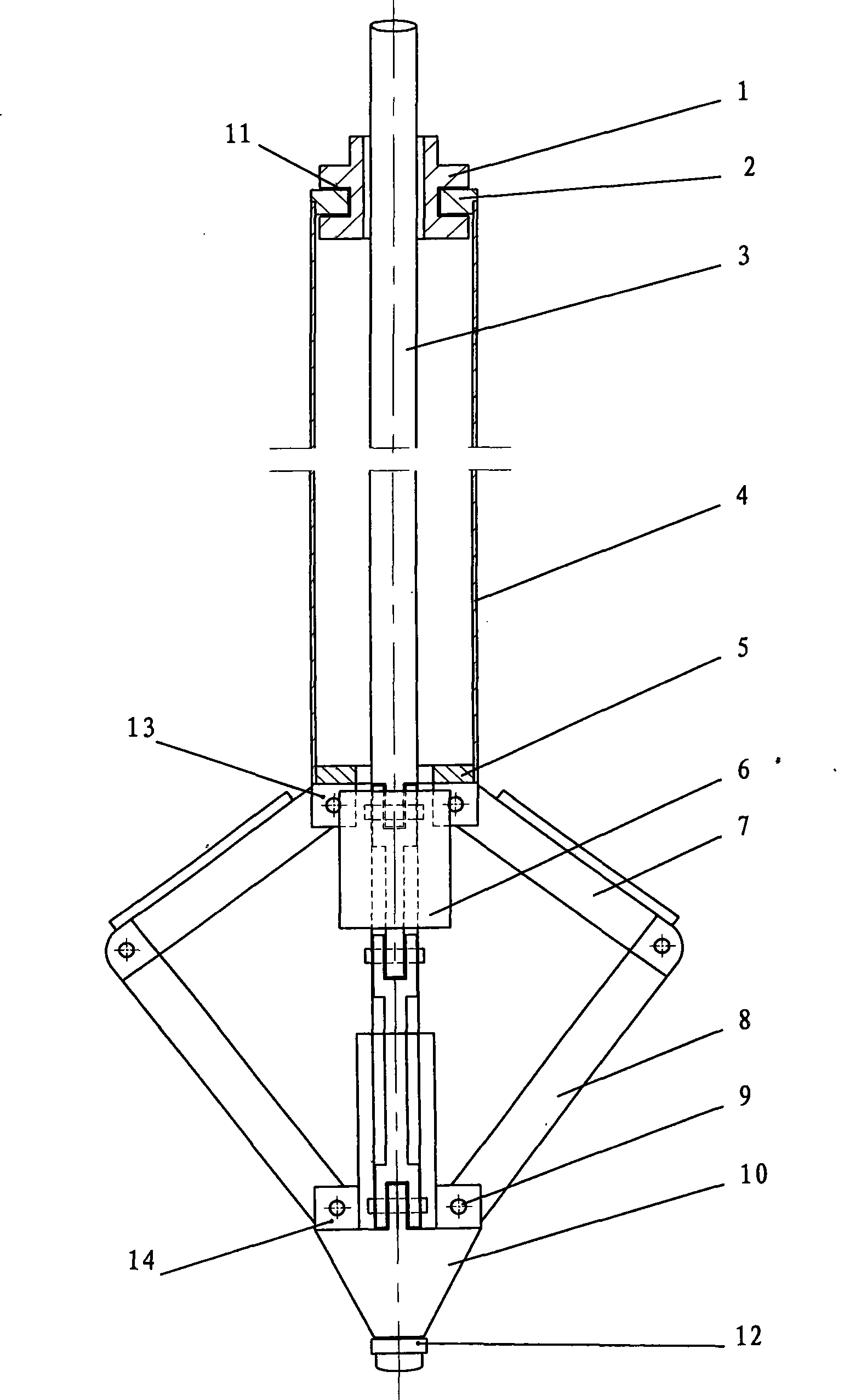

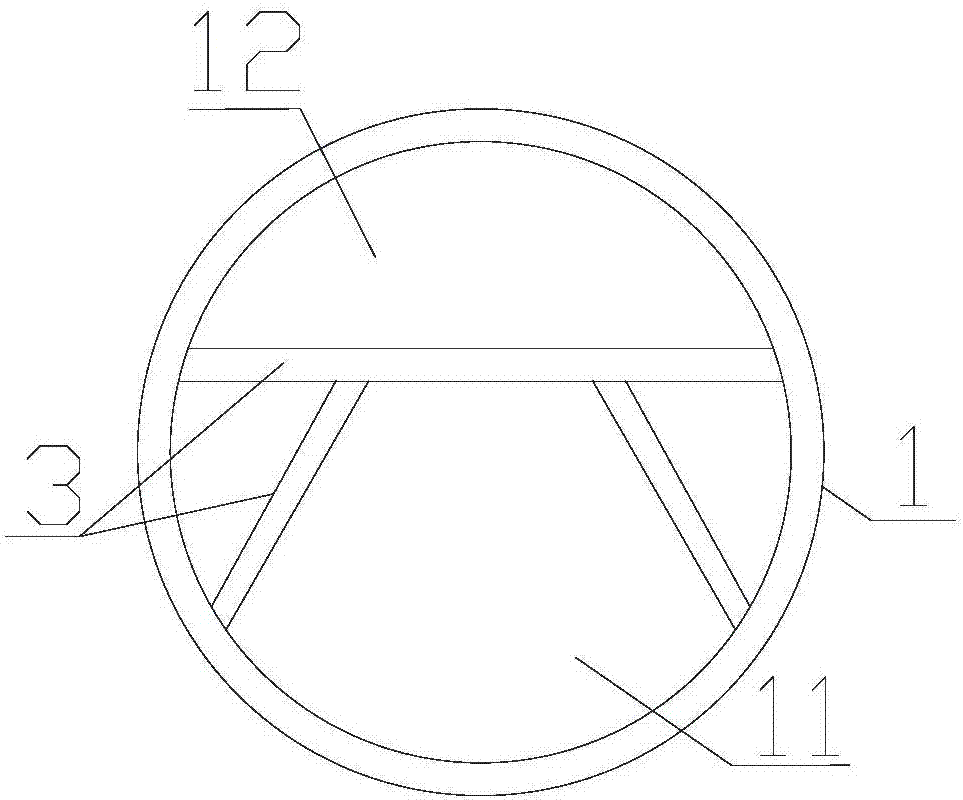

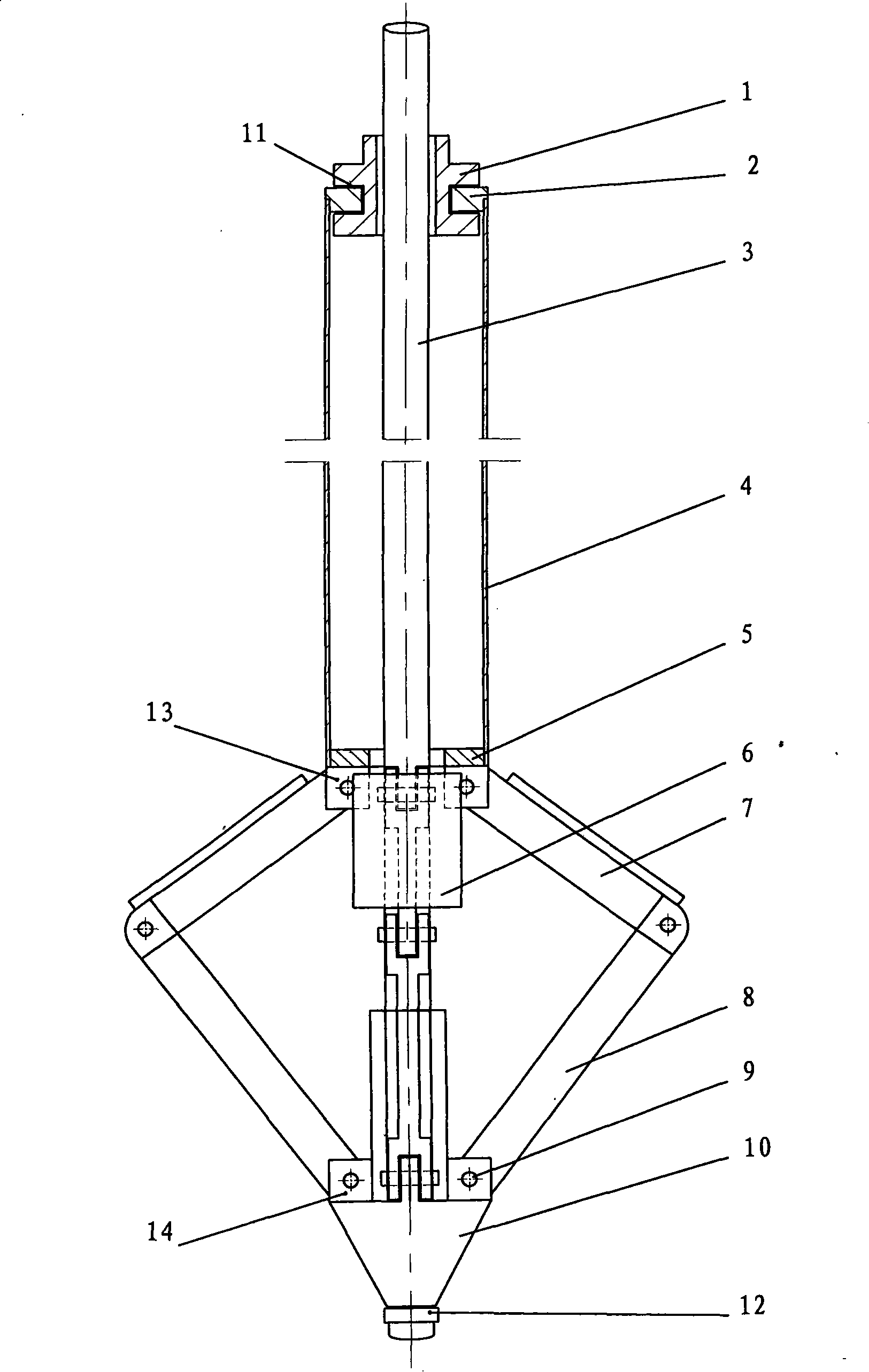

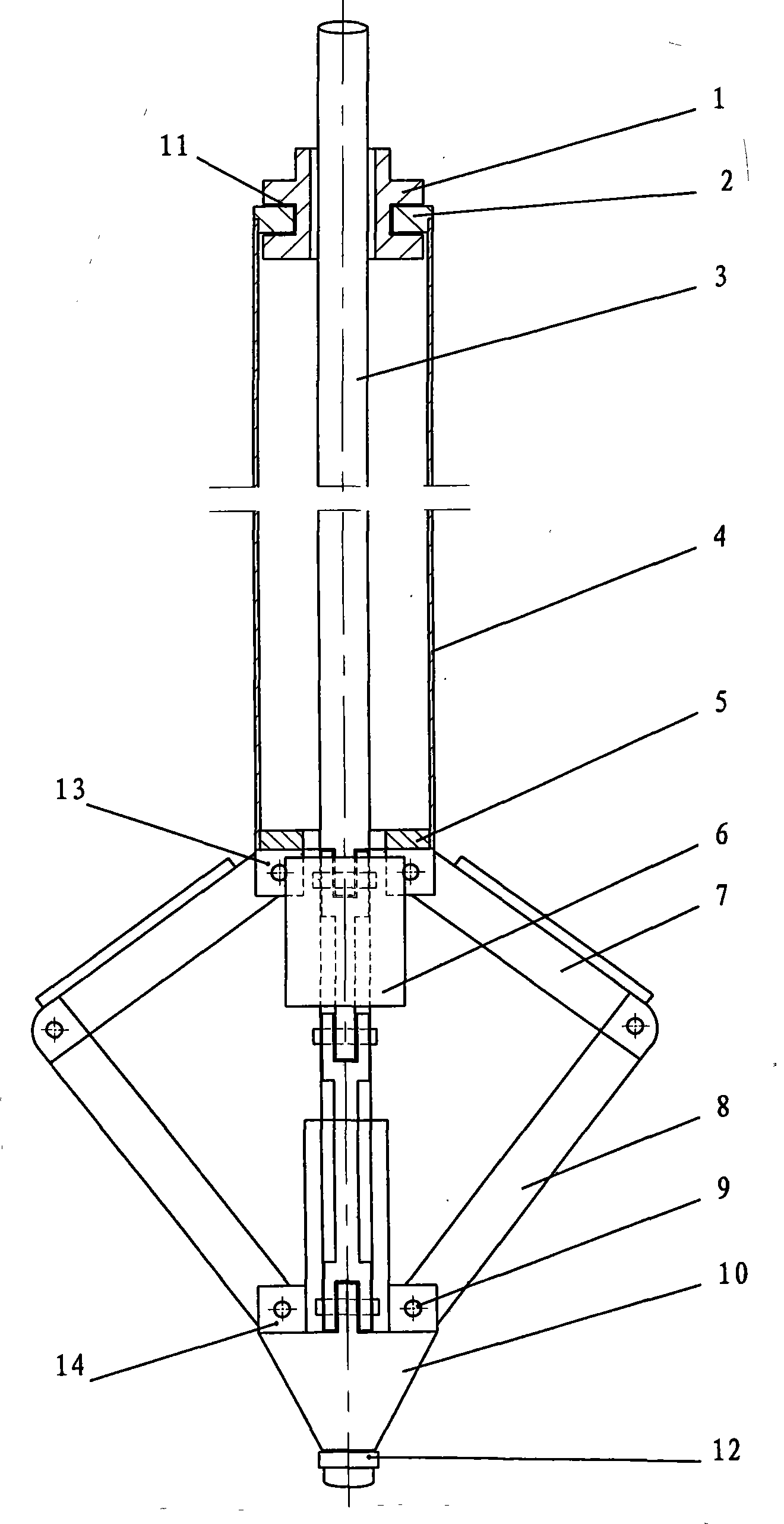

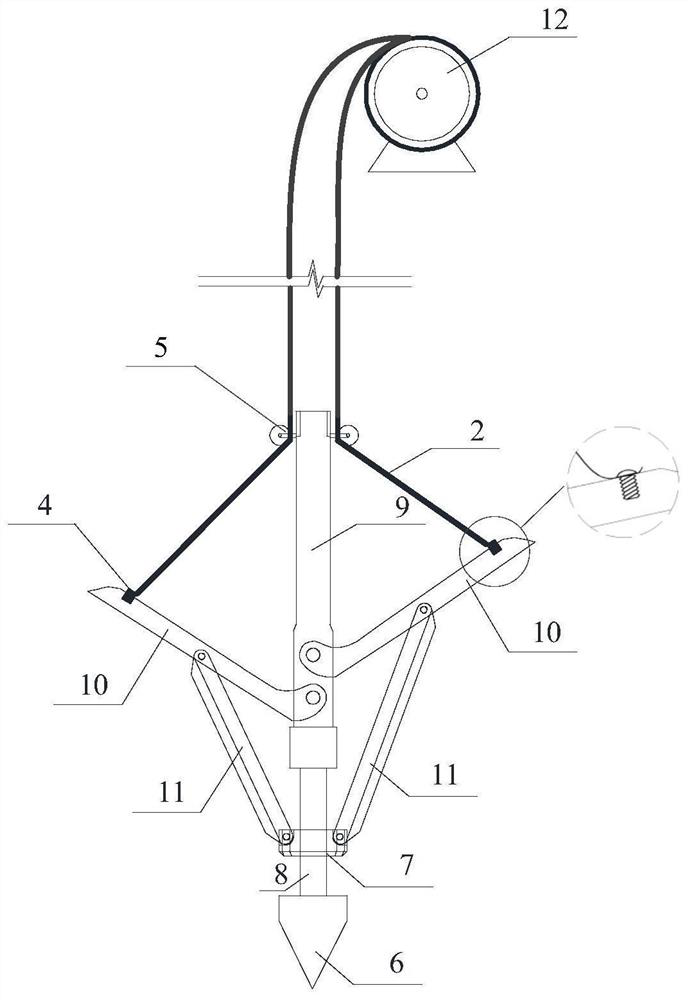

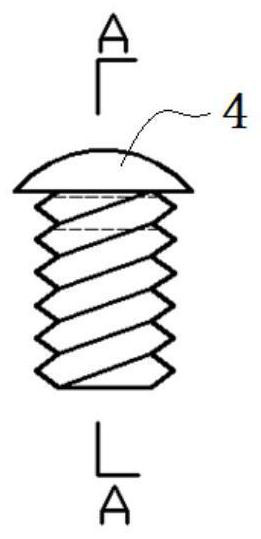

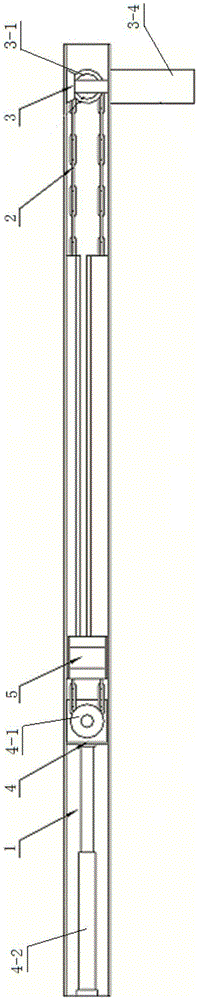

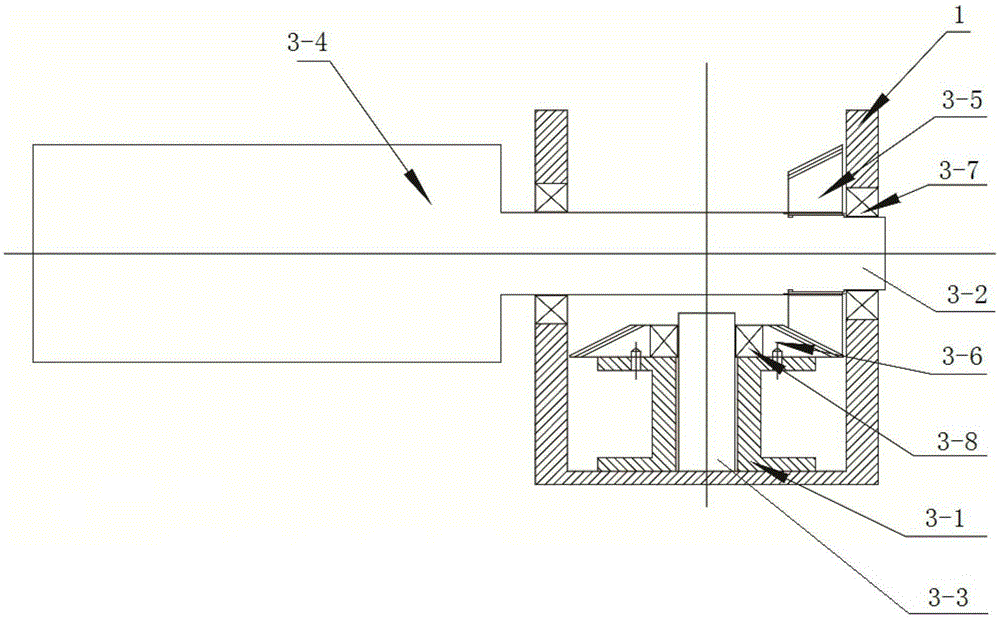

Recoverable anchor rod

InactiveCN101469541ASave underground spaceReduce underground environmental pollutionBulkheads/pilesAnchoring boltsSteel tubeUnderground space

The invention relates to a recovery type anchor bar, comprising an outer sleeve steel pipe, a screw rod disposed in the outer sleeve steel pipe along the axial direction, an upper cover board fixed on the top of the outer sleeve steel pipe, a regulation nut disposed at center of the upper cover board, a lower cover board fixing on the bottom end of the outer sleeve steel pipe, an anchor cone disposed right under the lower cover board, and a plurality of upper connection boards disposed on bottom end of the lower cover board, wherein the upper portion of the screw rod is attached to the regulation nut through a screw thread, the lower portion of the screw rod is attached to the anchor cone. Each upper connection boards is hinged to the top of an upper pulling rod, bottom end of each upper pulling rod is hinged to the top of a lower pulling rod, bottom end of each lower pulling rod is respectively attached to the anchor cone through a pin. Object of the invention is to provide a recovery type anchor bar which is high in shearing resistance capacity, underground space saving, underground environment pollution-free, and steel saving.

Owner:YANTAI UNIV

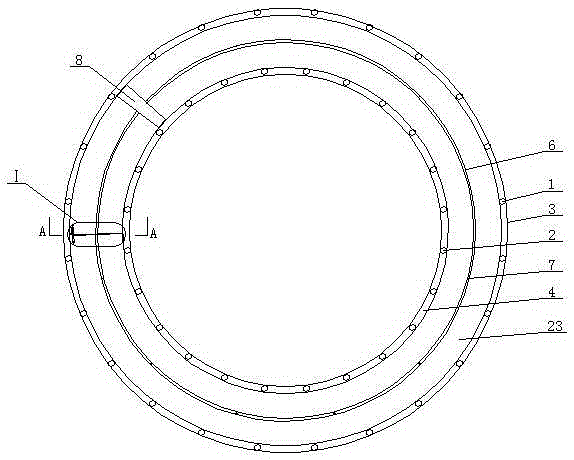

Livestock and poultry breeding solid-liquid separation excrement cleaning device

The invention provides a livestock and poultry breeding solid-liquid separation excrement cleaning device. The livestock and poultry breeding solid-liquid separation excrement cleaning device comprises an annular excrement collecting box; an excrement scraping plate is installed in the annular excrement collecting box; the excrement scraping plate is directly connected with a power driving mechanism or is connected with the power driving mechanism through a connecting piece; the excrement scraping plate is driven by the power driving mechanism to rotate around the annular excrement collecting box; the bottom plate of the annular excrement collecting box is an inclined plate; the lowest point of the inclined plate is located at the middle of the bottom plate; an urine discharging opening is formed at the middle of the bottom plate; and a solid excrement outlet is formed at the bottom plate of the annular excrement collecting box. According to the livestock and poultry breeding solid-liquid separation excrement cleaning device of the invention, after excrement falls into the annular excrement collecting box, solid-liquid separation of the excrement can be realized; solid excrement and liquid excrement are separately collected through different pipelines; the solid excrement is directly treated and is packaged; and the liquid can be adopted as secondary water after being purified; and therefore, excrement treatment procedures can be decreased, and treatment cost can be decreased, and underground space can be greatly saved. The livestock and poultry breeding solid-liquid separation excrement cleaning device of the invention is reasonable in integral design. The driving mechanism is arranged on the excrement scraping plate. The livestock and poultry breeding solid-liquid separation excrement cleaning device is especially suitable for annular comprehensive cultivation buildings and can realize fast and convenient solid-liquid separation treatment.

Owner:姜伟

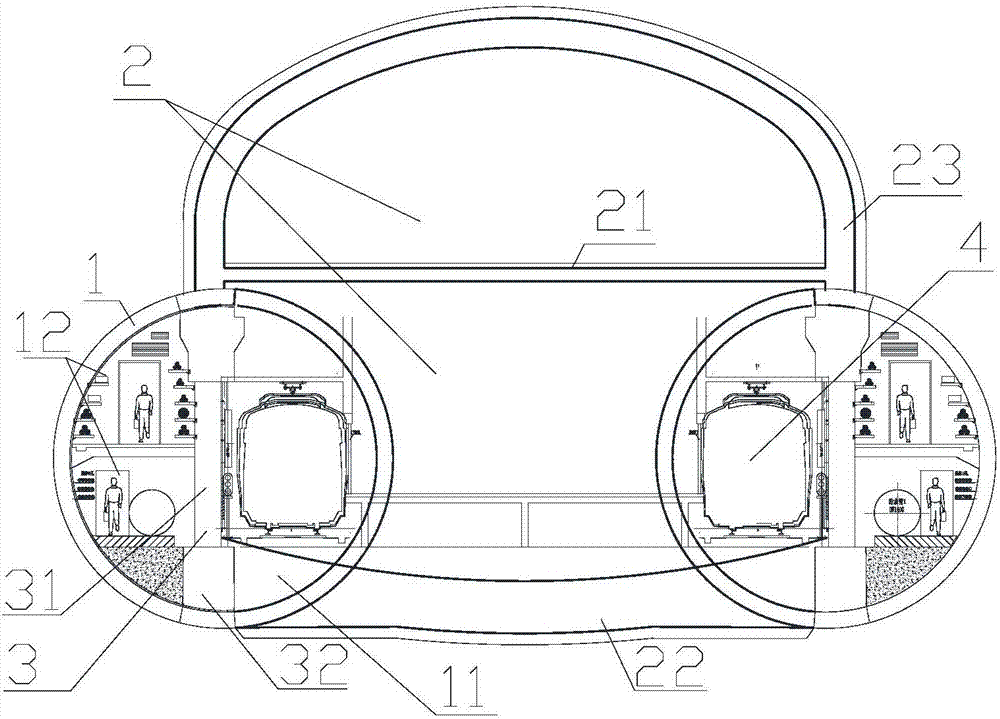

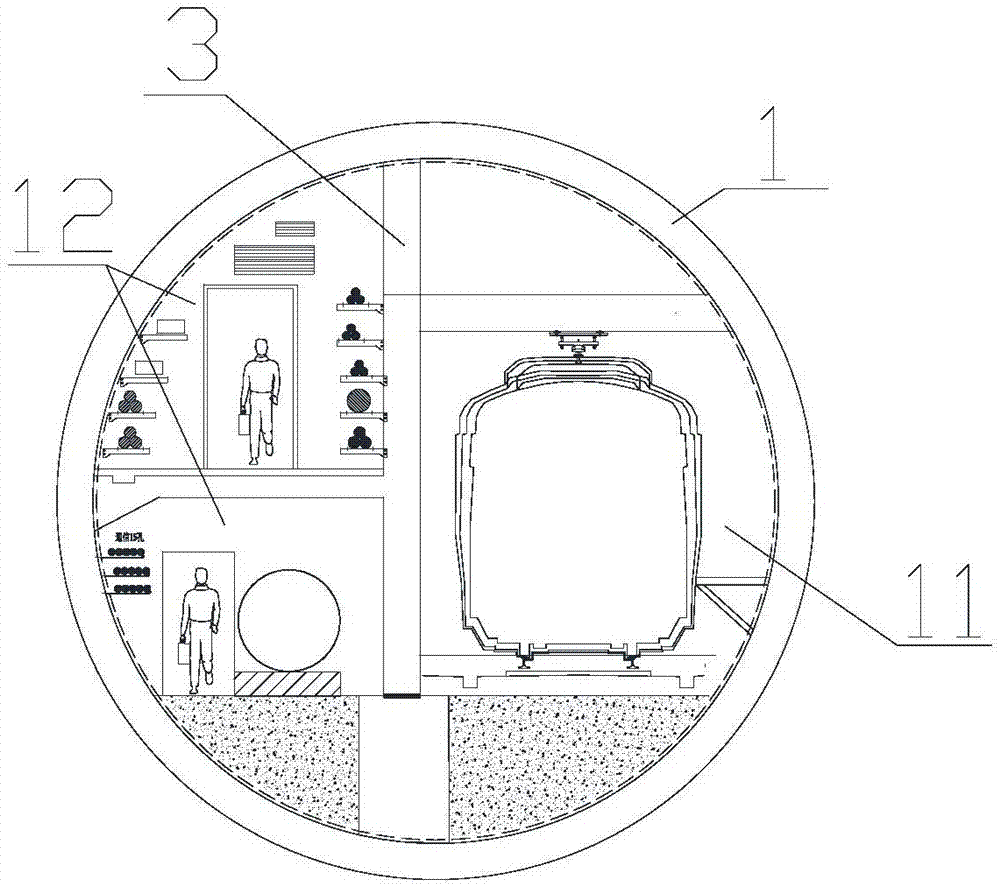

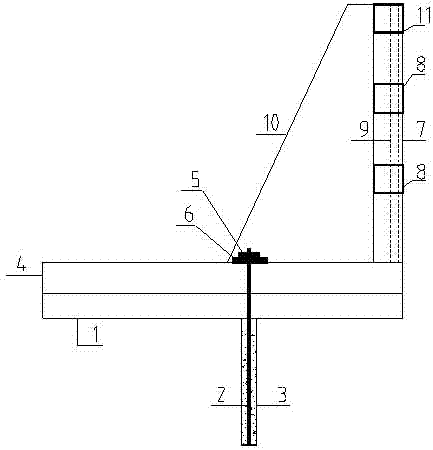

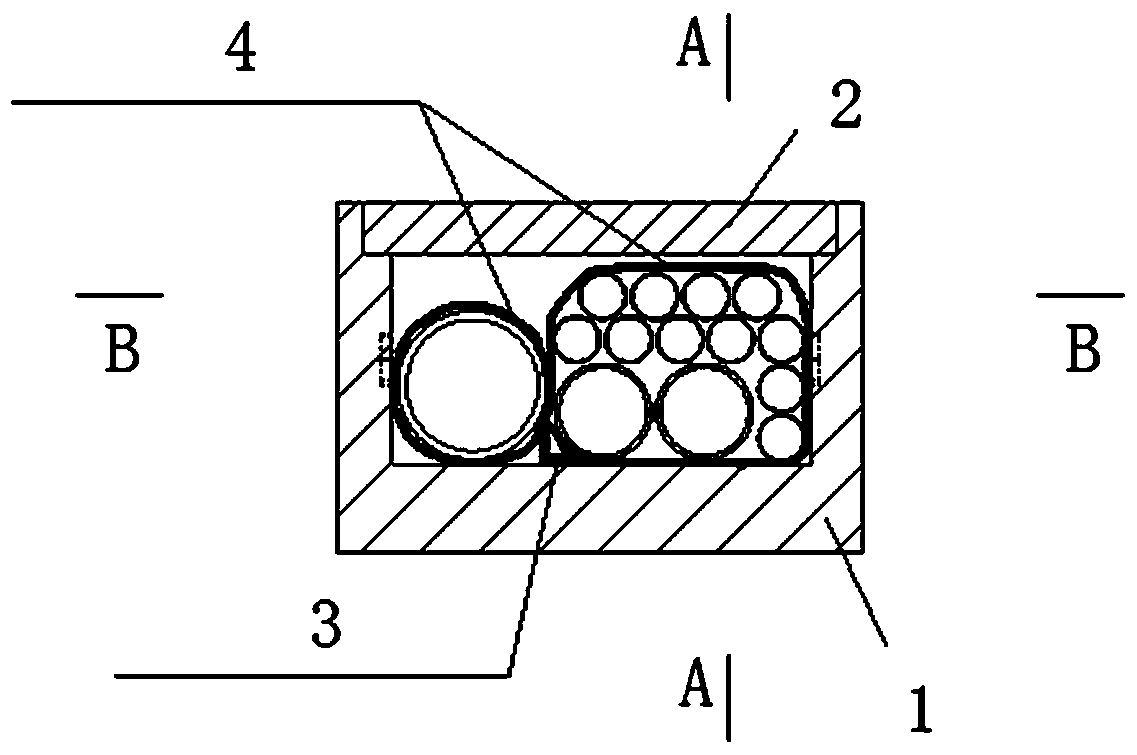

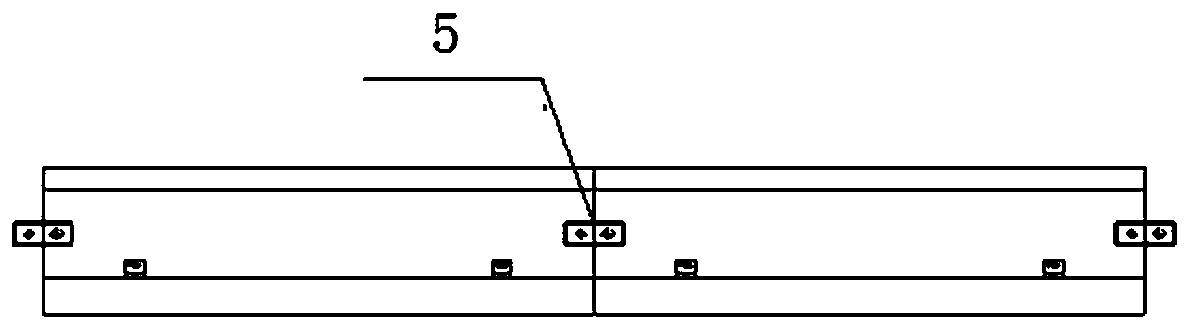

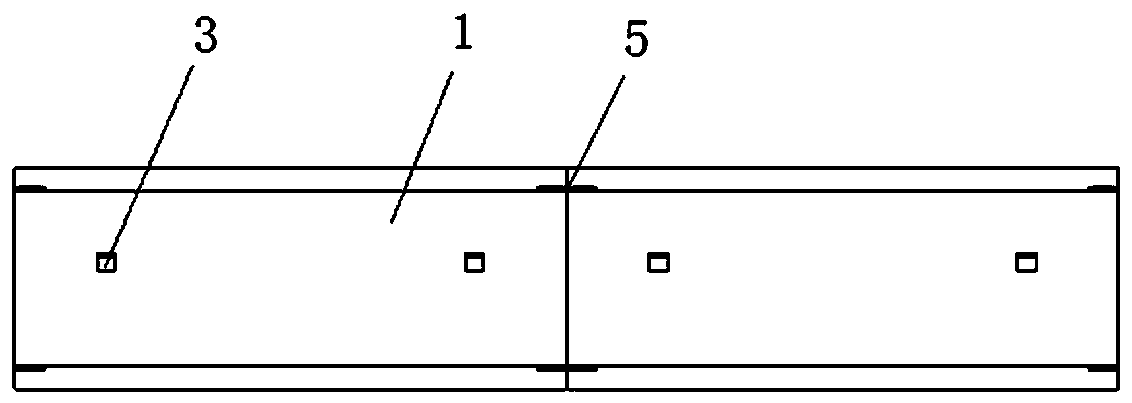

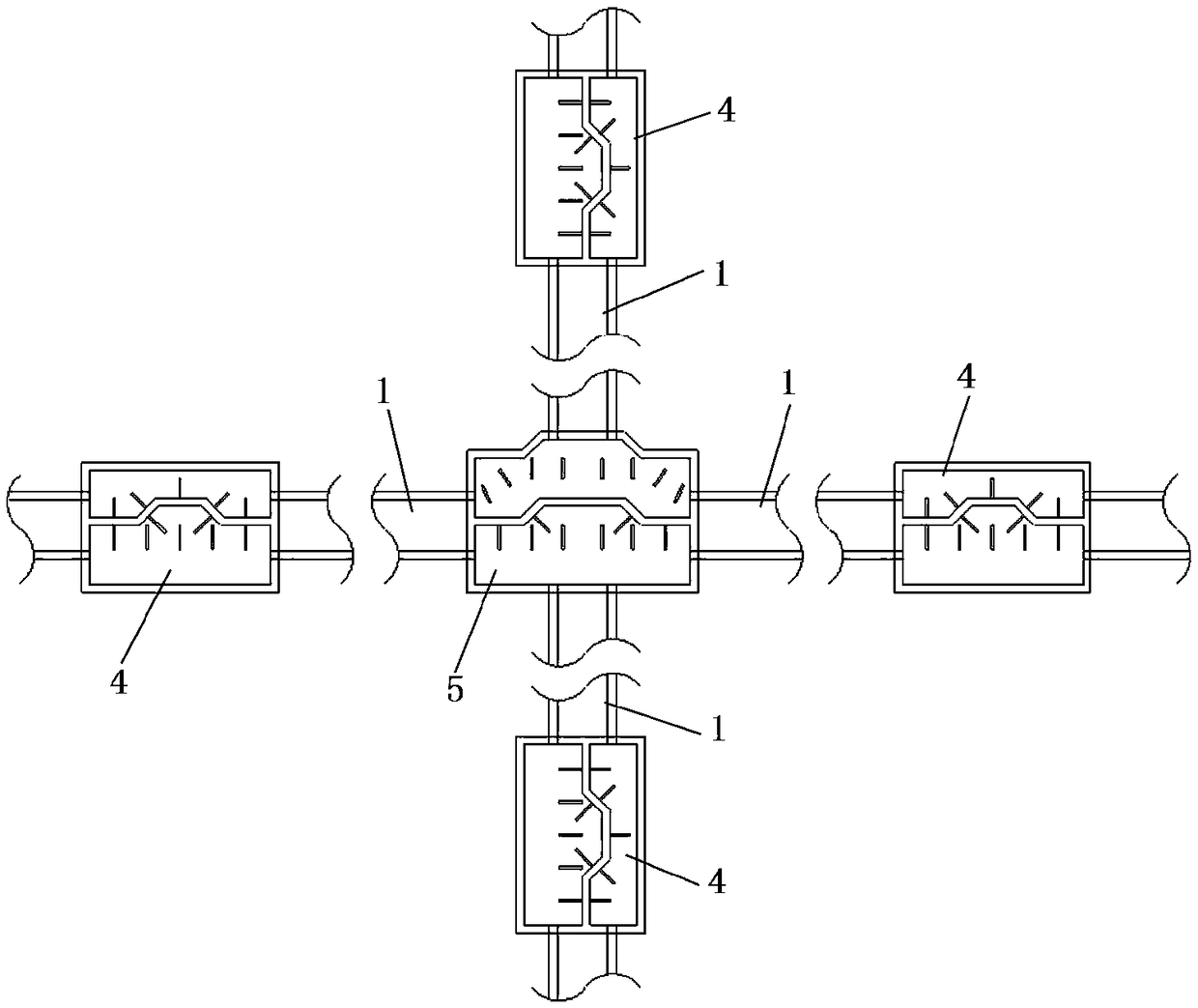

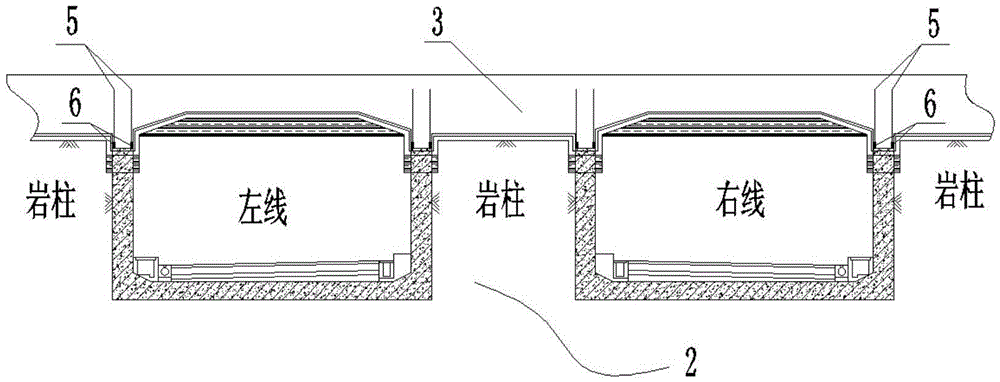

Construction method and building structure of co-construction of subways and city underground comprehensive pipe galleries

PendingCN106948834AReduce crowdingHigh space utilizationArtificial islandsUnderwater structuresUtility tunnelUrban area

The invention provides a building structure of co-construction of subways and city underground comprehensive pipe galleries. The building structure comprises section shield tunnels. An intermediate partitioning member used for dividing space in each section shield tunnel into two areas in the axial direction, wherein one of the areas serves as a subway travelling cabin, and the other area serves as pipe gallery cabins arranged continuously or at intervals in the axial direction. The invention further provides a building method of co-construction of the subways and the city underground comprehensive pipe galleries. By means of the structure and the method, the problem of building of common path sections of the large city center urban area comprehensive pipe galleries and the subways is solved, underground space is saved, construction disturbance is reduced, and the construction risk is lowered.

Owner:GUANGZHOU METRO DESIGN & RES INST

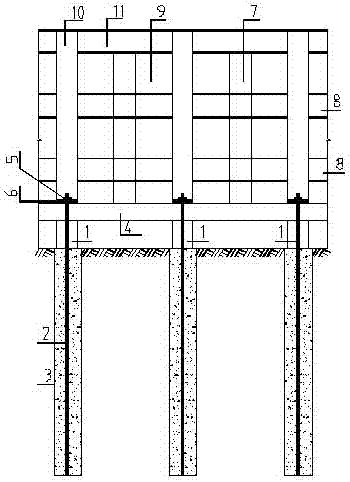

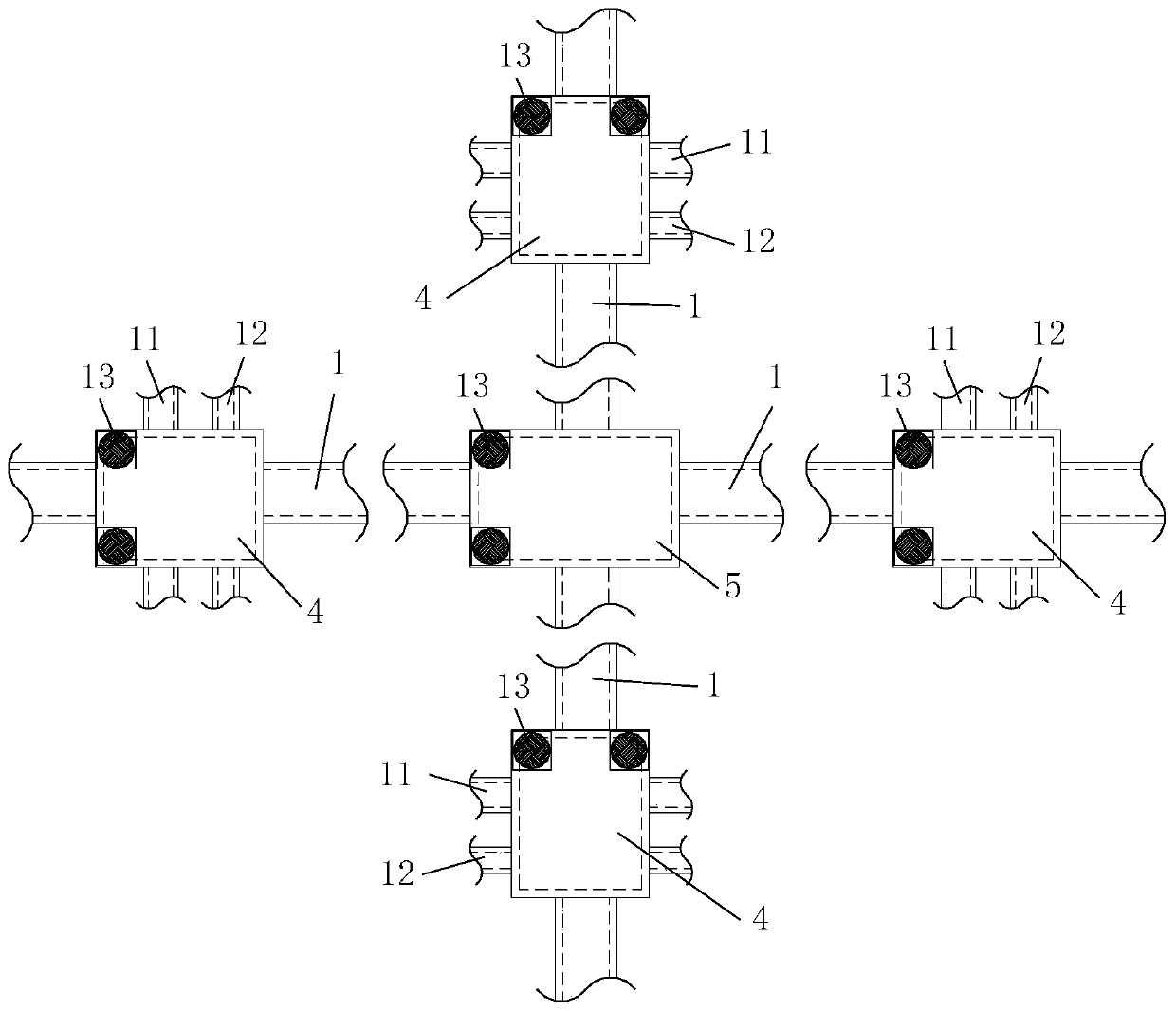

Lattice type buttress type retaining wall with ground anchor and construction method

InactiveCN107964980ASimple structureEasy constructionArtificial islandsUnderwater structuresEngineeringRetaining wall

The invention discloses a lattice type buttress type retaining wall with a ground anchor and a construction method, and belongs to the field of retaining structures. The lattice type buttress type retaining wall with the ground anchor comprises a ground beam (1), an anchor rod (2), an anchorage segment (3), a bottom plate (4), a bolt (5), a base plate (6), stand columns (7), a cross beam (8), a wall panel (9), a buttress (10) and a crown beam (11); the anchor rod (2) is anchored on the bottom plate (4) through the bolt (5) and the base plate (6), the base plate (6) is located below the bolt (5), the ground beam (1) is arranged below the bottom plate (4), the stand columns (7) and the cross beam (8) are crossed vertically to form frame cases, the wall panel (9) is located in the frame casesformed by the stand columns (7) and the cross beam (8), the wall panel (9), the buttress (10) and the bottom plate (4) are perpendicular, the lower portions of the stand columns (7) are connected with the bottom plate, and the tops of the stand columns are connected with the crown beam (11).

Owner:中国移动通信集团甘肃有限公司 +1

Filling drill bit for drilling type coal mining machine

InactiveCN104074516ADoes not affect mining operationsSolve storage problemsMaterial fill-upCutting machinesSocial benefitsSpiral blade

The invention discloses a filling drill bit for a drilling type coal mining machine. The filling drill bit comprises five drill bits, a transmission box, a ventilation box, a conveying pipe, a ventilation pipe and a matched connecting device, wherein the five drill bits are connected in parallel onto the drilling type coal mining machine; the drill bit connected with the ventilation box comprises a drill bit, a filing pipe and a hollow gear shaft; according to the actual work condition of an underground thin coal seam, a filling device is applied to the five-drill-bit drilling type coal mining machine, the drill bit cutting tooth distribution and the spiral blade installation are similar to those of a drill bit of the original drilling type coal mining machine, and the mining operation of the drill bit is not influenced; in addition, gangues generated in the thin coal seam mining and roadway construction process are filled into a goaf of the drilling type coal mining machine, so the tight connection of the mining operation and the filling operation of the drilling type coal mining machine can be realized; the occurrence of accidents such as goaf collapse and equipment damage in the rod withdrawal process of the drilling type coal mining machine due to mining span and depth increase is avoided; the safety and the efficiency of the thin and ultra-thin coal seam mining are favorably improved; and further, economic benefits and social benefits of coal mine enterprises are improved.

Owner:CHINA UNIV OF MINING & TECH

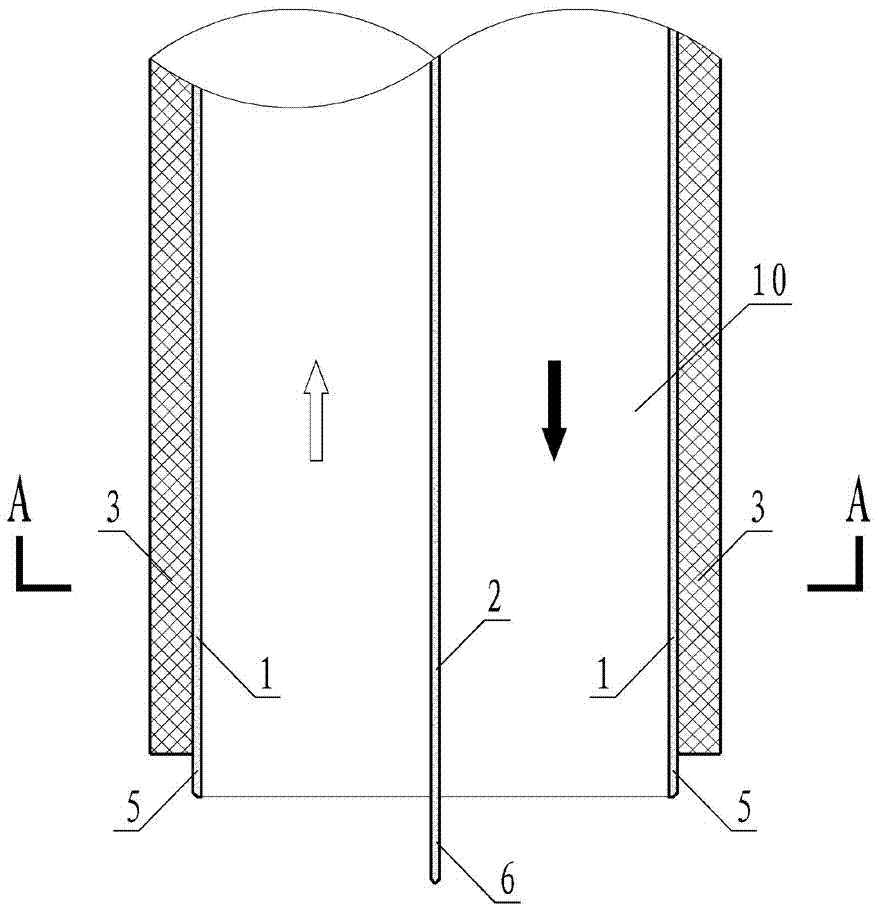

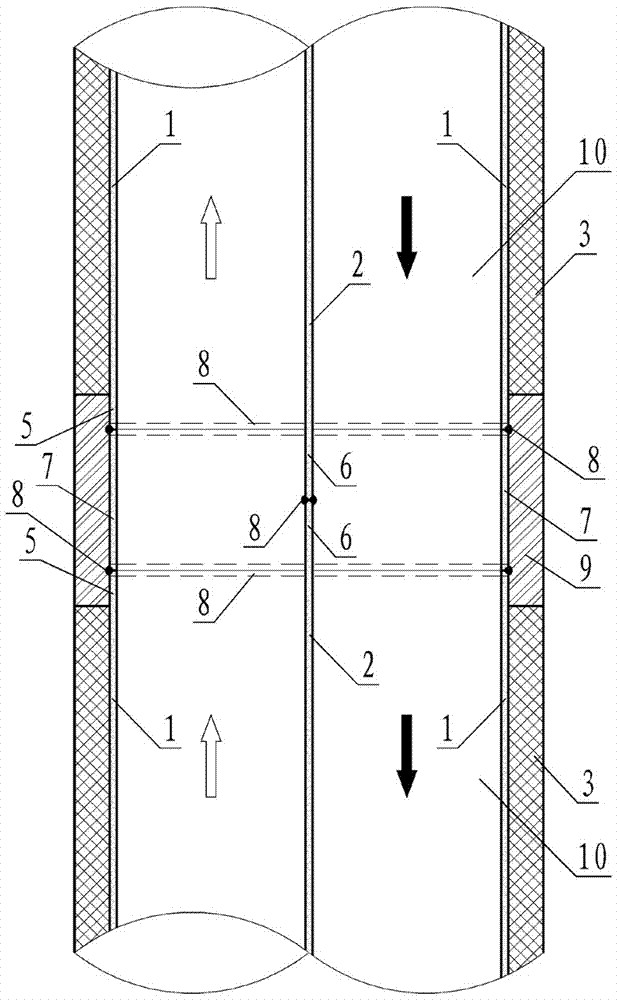

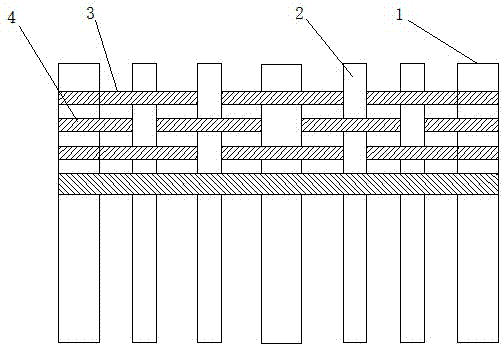

Double-hole parallel thermal power tube

ActiveCN107420652AGuaranteed cross-sectional areaReduce laying widthBranching pipesRigid pipesThermal energyLine tubing

The invention relates to a double-hole parallel thermal power tube, relates to thermal power tube network projects, and in particular relates to a tube and fittings of a thermal power tube network. According to the double-hole parallel thermal power tube, a partition plate is arranged in the middle of an elliptic tube wall of the cross section of the double-hole parallel thermal power tube, and then two horizontally parallel tube holes are formed; a heat-preservation layer is arranged on the outer side of the double-hole parallel thermal power tube; the cross section areas of the two tube holes are identical; the two tube holes are respectively used as a water supply tube and a water return tube of a thermal power tube network. On premise that the cross section areas of the tube holes are identical to those of round tubes of a same nominal diameter and the cross section areas of the water supply tube and the water return tube are ensured, the pipeline laying width is reduced, the underground space is saved, underground pipelines can be laid conveniently, the volume of earthwork of troughs is reduced, and the workload of pipeline hoisting and positioning is also reduced when being compared with that of the prior art; the outer surface area of the tube wall is smaller than those of two tubes of the prior art, so that thermal energy consumption can be effectively reduced, and the energy can be saved; the steel consumption of steel tube sections and outer heat-preservation layers is less than that of double tubes of the prior art, and materials can be saved.

Owner:广东智铭设计有限公司

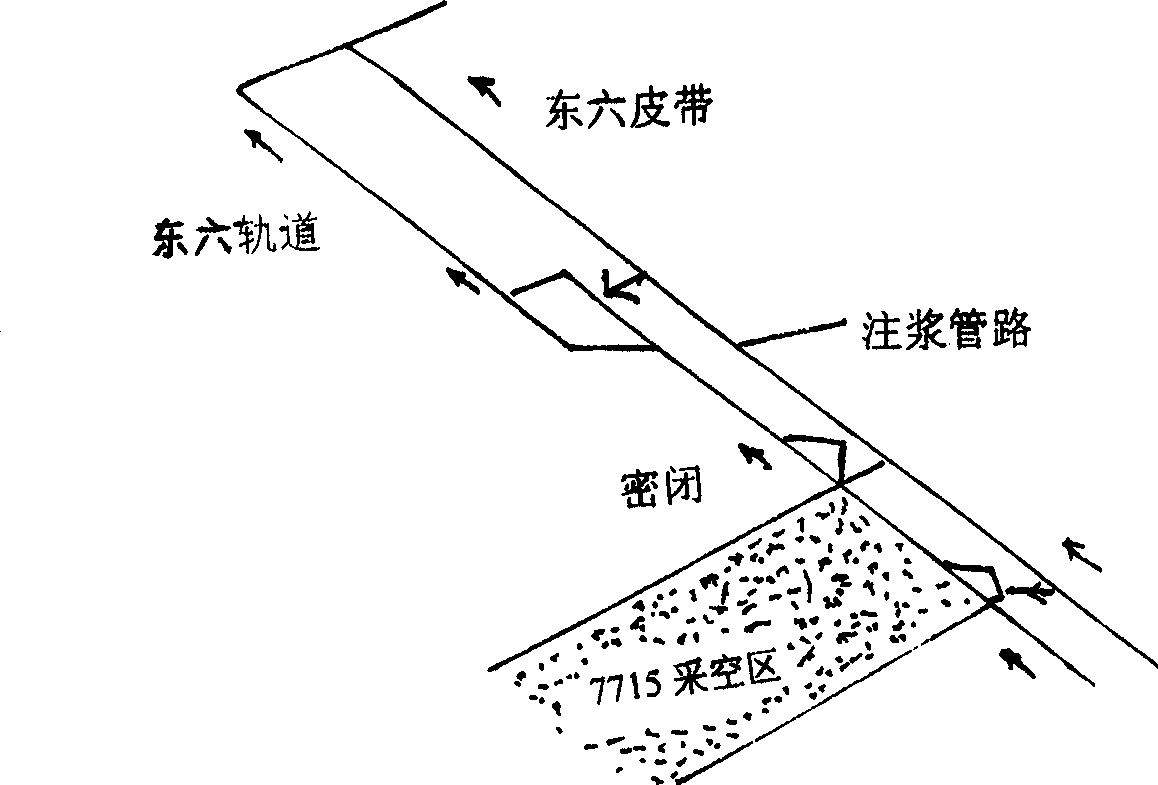

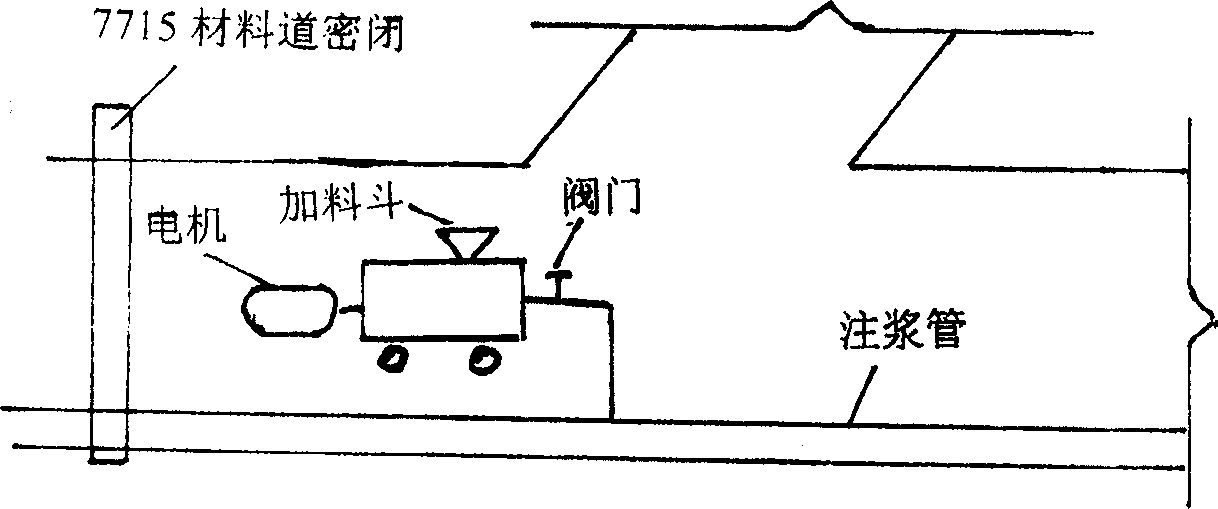

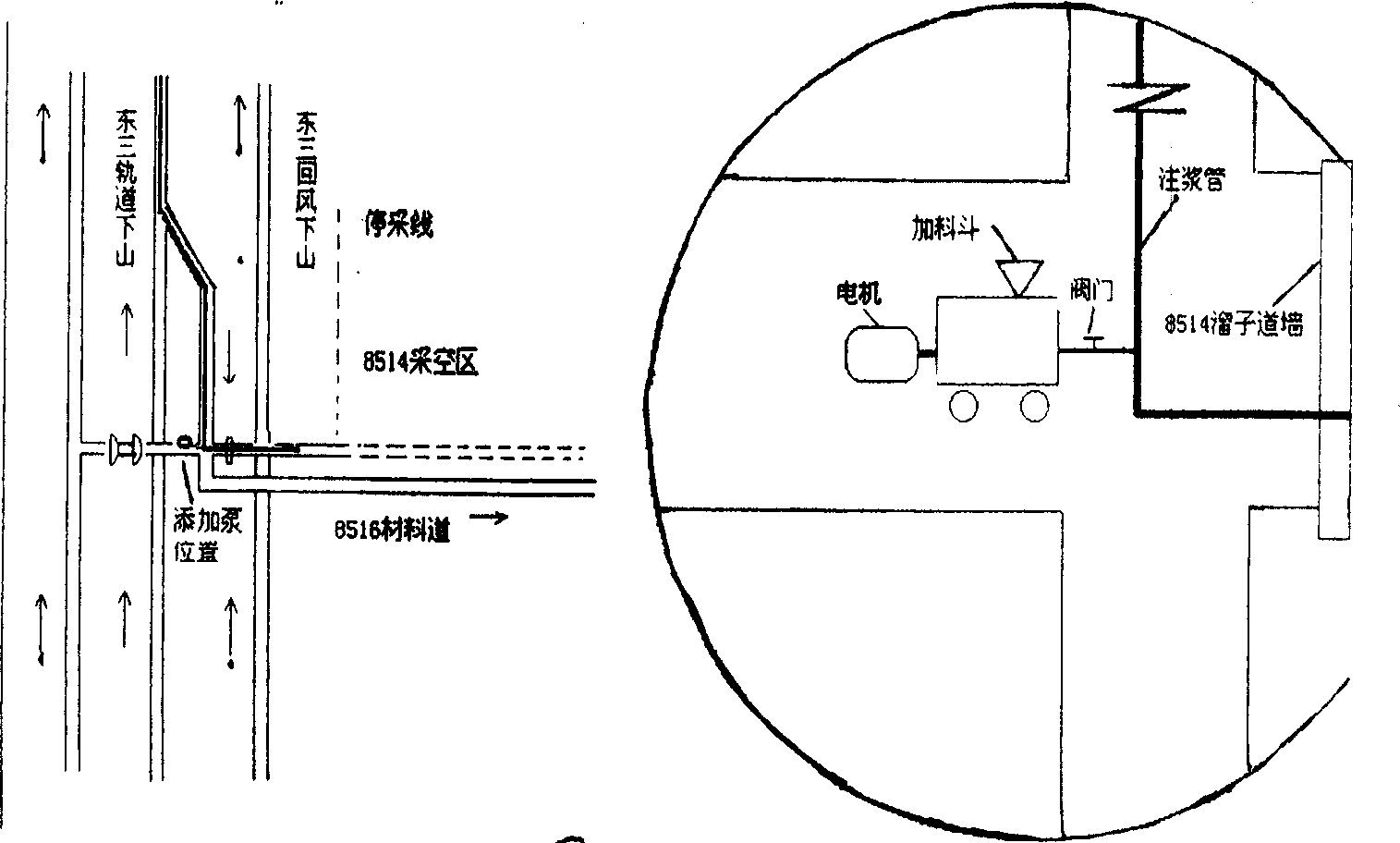

Fireproofing extinguishing materials of composite colloid of fly ash for fire in coal bed

A composite colloid for preventing and extinguishing the fire accident of coal seam is prepared from powdered coal ash and water-soluble linear high-molecular material in ratio of (40-60): 1 through mixing. It is mixed with high-concentration yellow clay sludge or powdered coal ash contained liquid before it is used.

Owner:SHANGHAI DATUN ENERGY

Recoverable anchor rod

InactiveCN101469541BReduce pollutionWill not develop impactAnchoring boltsBulkheads/pilesArchitectural engineeringScrew thread

The invention relates to a recovery type anchor bar, comprising an outer sleeve steel pipe, a screw rod disposed in the outer sleeve steel pipe along the axial direction, an upper cover board fixed on the top of the outer sleeve steel pipe, a regulation nut disposed at center of the upper cover board, a lower cover board fixing on the bottom end of the outer sleeve steel pipe, an anchor cone disposed right under the lower cover board, and a plurality of upper connection boards disposed on bottom end of the lower cover board, wherein the upper portion of the screw rod is attached to the regulation nut through a screw thread, the lower portion of the screw rod is attached to the anchor cone. Each upper connection boards is hinged to the top of an upper pulling rod, bottom end of each upper pulling rod is hinged to the top of a lower pulling rod, bottom end of each lower pulling rod is respectively attached to the anchor cone through a pin. Object of the invention is to provide a recovery type anchor bar which is high in shearing resistance capacity, underground space saving, underground environment pollution-free, and steel saving.

Owner:YANTAI UNIV

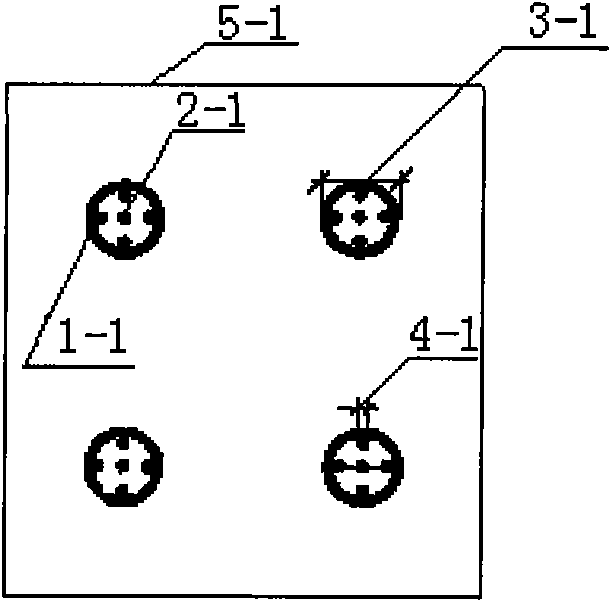

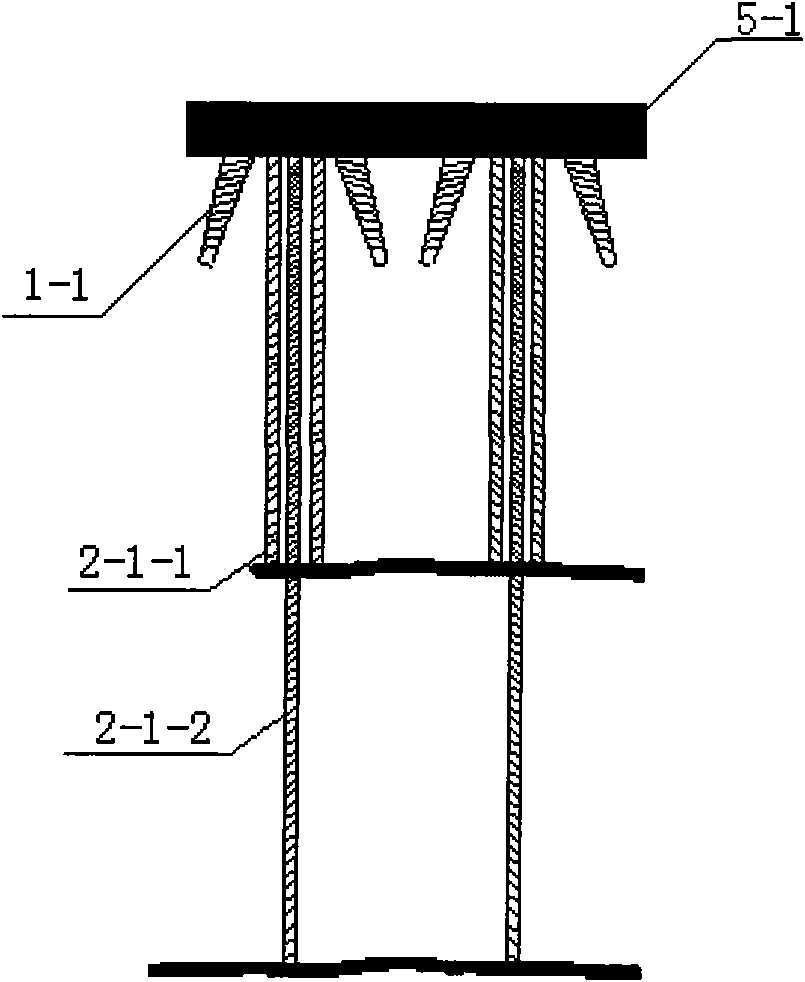

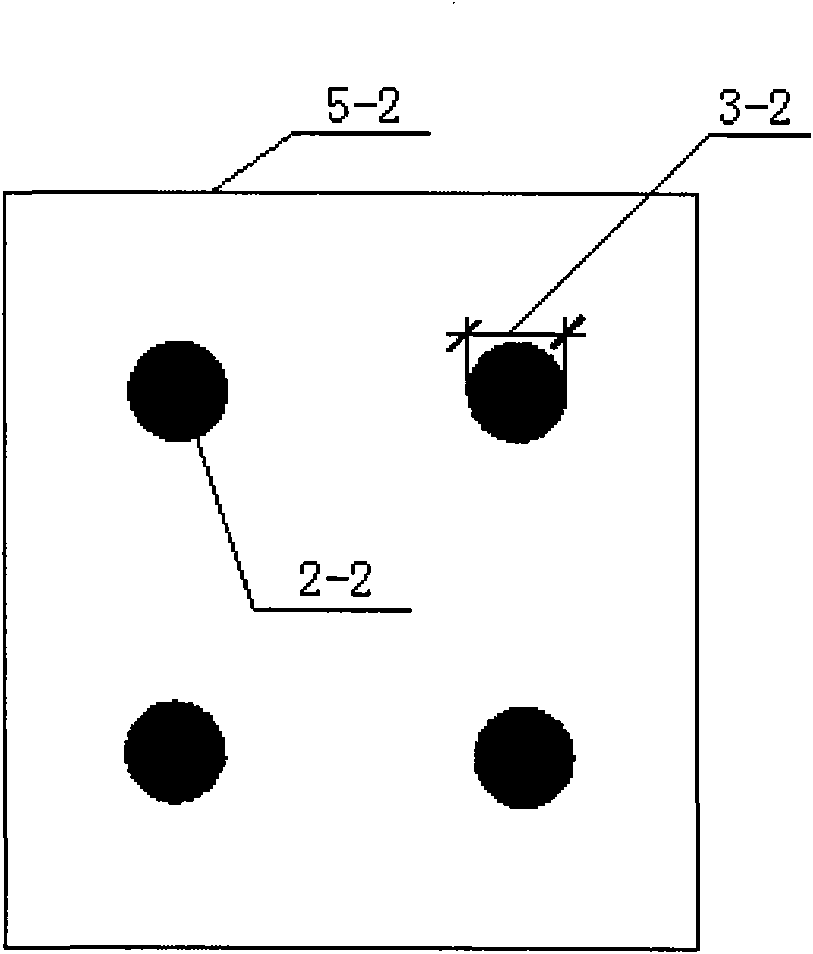

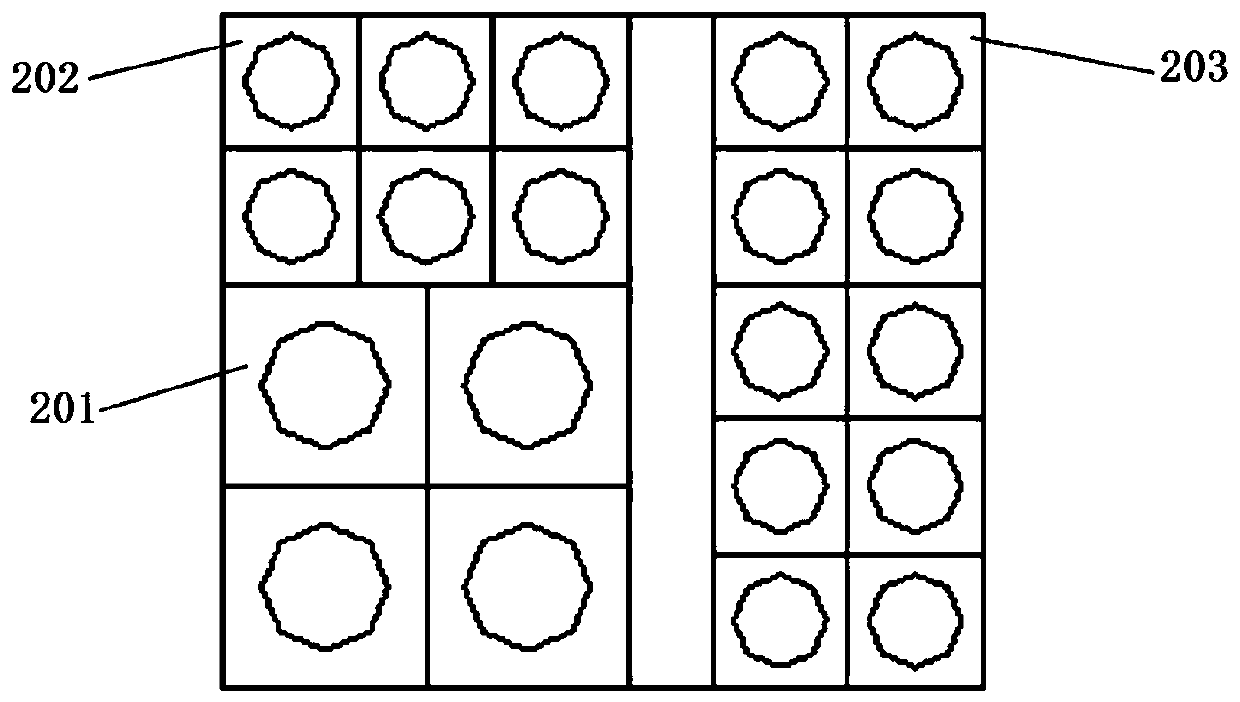

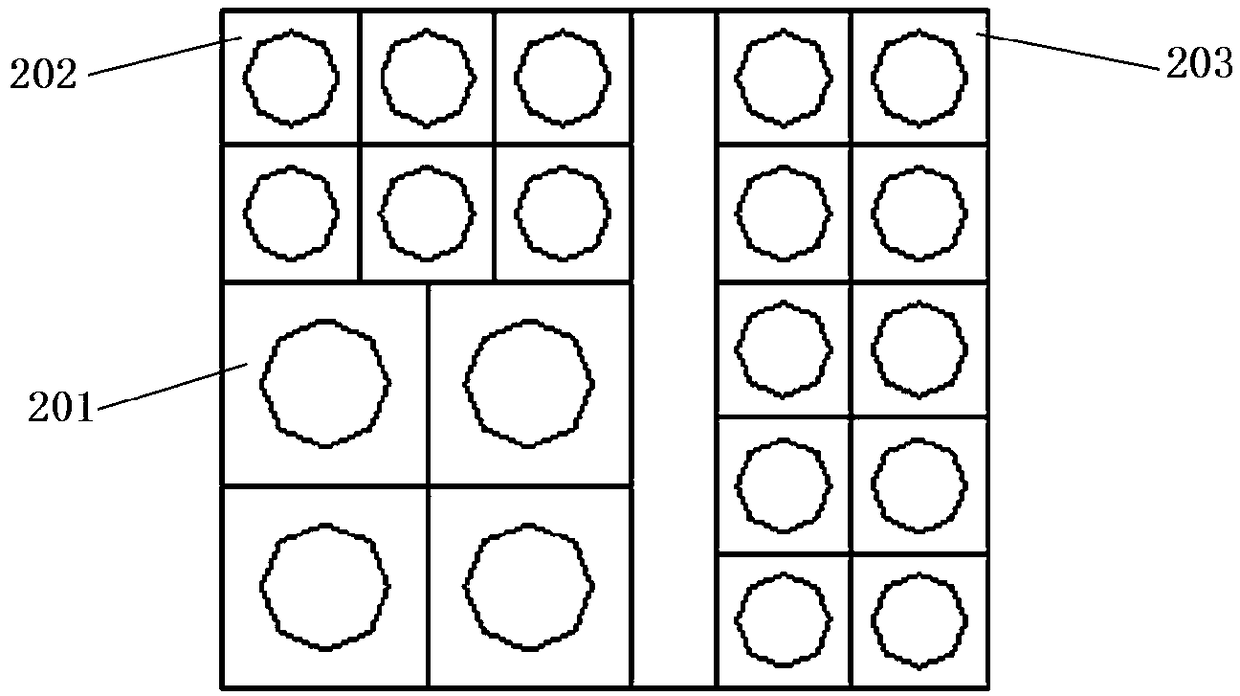

Precast perforated pipe pile and preparation method

InactiveCN101768962AImprove bearing capacityFlexible adjustment of bearing capacityBulkheads/pilesDistribution characteristicSteel tube

The invention provides a precast perforated pipe pile. A perforated pipe and concrete arranged in and out the perforated pipe form a pipe body, and the outer wall of the pipe body is provided with a self-tapping screw which is a spiral bump arranged on the outer wall of the pipe body. The bottom end of the pipe body is a flat head or a tip head, and the top end of the pipe body is a multi-face column and is externally sheathed with a side limited ring. The side limited ring is in a horn shape, and foundation soil is arranged between the pipe body and the side limited ring. The preparation method of the precast perforated pipe pile comprises the following steps: the perforated pipe is manufactured by steel pipes with different specifications, and the thickness is larger than 2 mm; the aperture of perforated holes in the perforated pipe is manufactured by a cutting mode and is determined according to the grain diameter of stone in the concrete, and the distribution of the perforated holes from the pile top to the pile end is determined according to the distribution characteristics of additional stress of the pile; the spiral bump of the outer pipe of the perforated pipe is determined according to the bearing capacity of single pile and the rotational torque; and a variety of parameters of the perforated pipe precast pile are determined according to shared building load, final foundation deformation, foundation soil conditions and conditions for affecting pile sinking.

Owner:吴保全

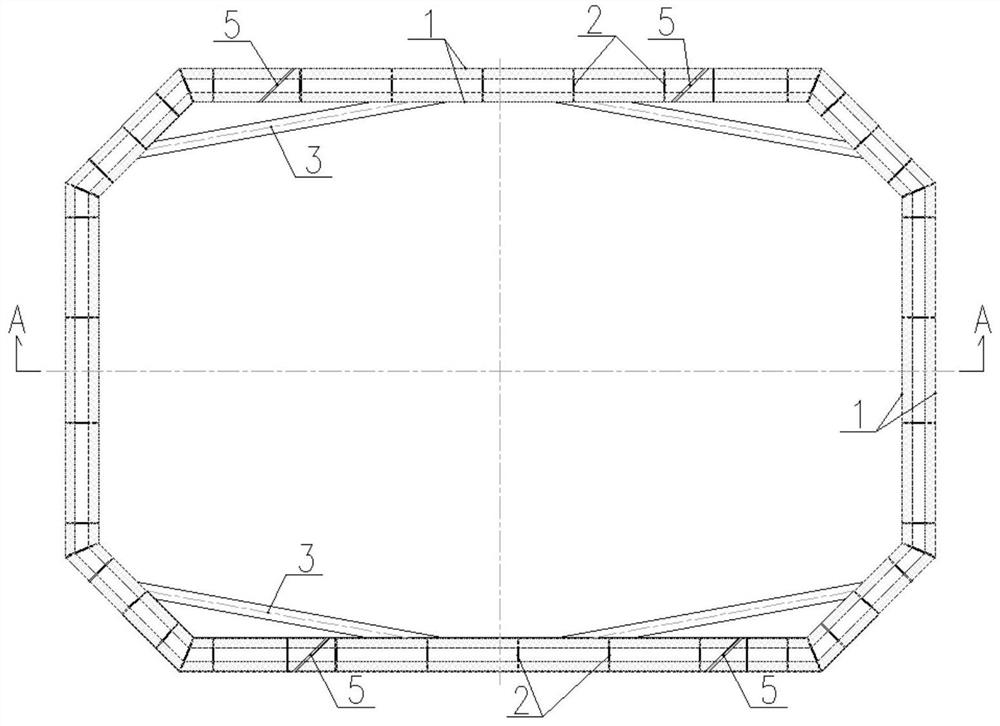

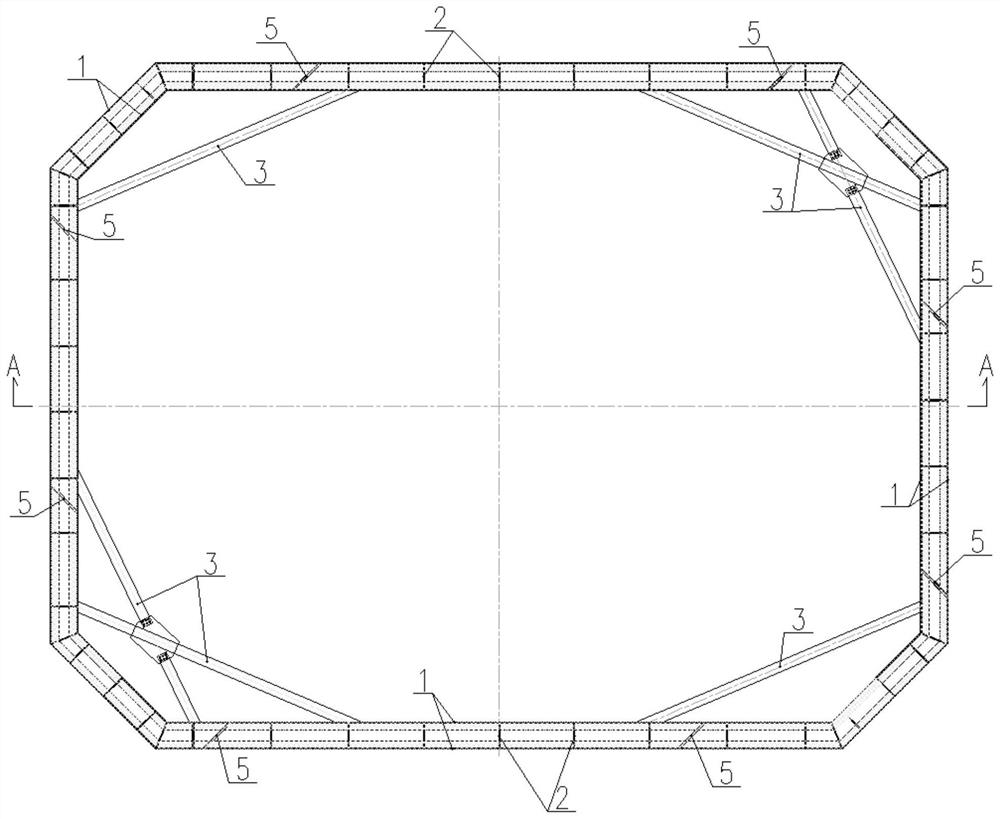

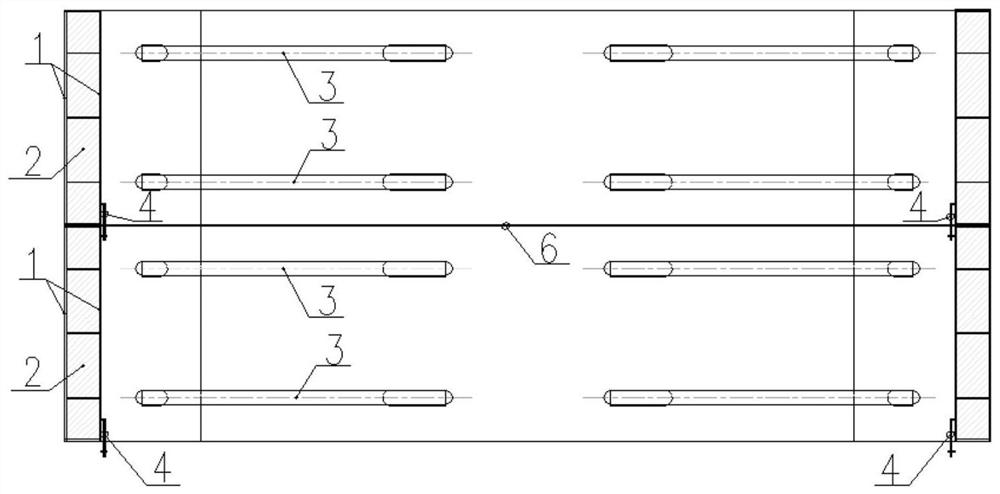

Octagonal working pit supporting member and mounting and construction method thereof

PendingCN113279414AConstruction safetyReliable constructionExcavationsSteel platesEnvironmentally friendly

The invention discloses an octagonal working pit supporting member and a mounting and construction method thereof. The octagonal working pit supporting member comprises an octagonal working pit protection wall supporting member formed by butt joint, and a frame-shaped plate and a straight plate are connected through symmetrically distributed H-shaped steel cross braces; a working pit protection wall comprises an inner layer steel plate and an outer layer steel plate which are provided with steel plate stiffening ribs, and interlayer connecting pieces connected with adjacent interlayer working pit protection walls are arranged at the bottom of the working pit protection wall; and the H-shaped steel cross braces are connected with the working pit protection wall, the adjacent octagonal supporting members are connected through the interlayer connecting pieces, and pipe jacking or directional drilling working pit layer-by-layer excavation and reverse disassembly and recovery of the excavated octagonal supporting members are implemented. The supporting structure of the working pit can be excavated downwards from the ground in a layered mode, supporting members are recycled in a reverse layered mode, waste is reduced, accident risks such as difficult sinking, sudden sinking and inclined sinking in the construction process are avoided, and the octagonal working pit supporting member has the advantages of being repeatedly used, saving space, reducing cost, reducing energy consumption and being environmentally friendly.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Cable type comprehensive pipe gallery system

PendingCN110144967AAchieve a fixed effectSmall sectionArtificial islandsUnderwater structuresPower cableEngineering

The invention provides a cable type comprehensive pipe gallery system which comprises standard sections, combination pipe pillows, sleeves, inspection leading wells, inspection cross wells and pipe line supports. Each standard section comprises a groove and a cover plate. Two or more combination pipe pillows are arranged in each standard section in the length direction. Each combination pipe pillow comprises two more pipe pillow units. The sleeves are arranged in cable pipe holes of corresponding pipe pillow units of the combination pipe pillows. Two or more pipe line supports are installed inthe inspection leading wells and the inspection cross wells correspondingly. In the same pipe line direction, the two adjacent inspection leading wells, the two adjacent inspection cross wells and the adjacent inspection leading wells and the inspection cross wells are connected through more than one standard sections. Compared with a main line comprehensive pipe gallery and a branch line comprehensive pipe gallery, electric power cables and communication cables are laid in an intensified manner, the city environment is beautified, the underground space is saved, construction is fast, the cost is low, and management is facilitated.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

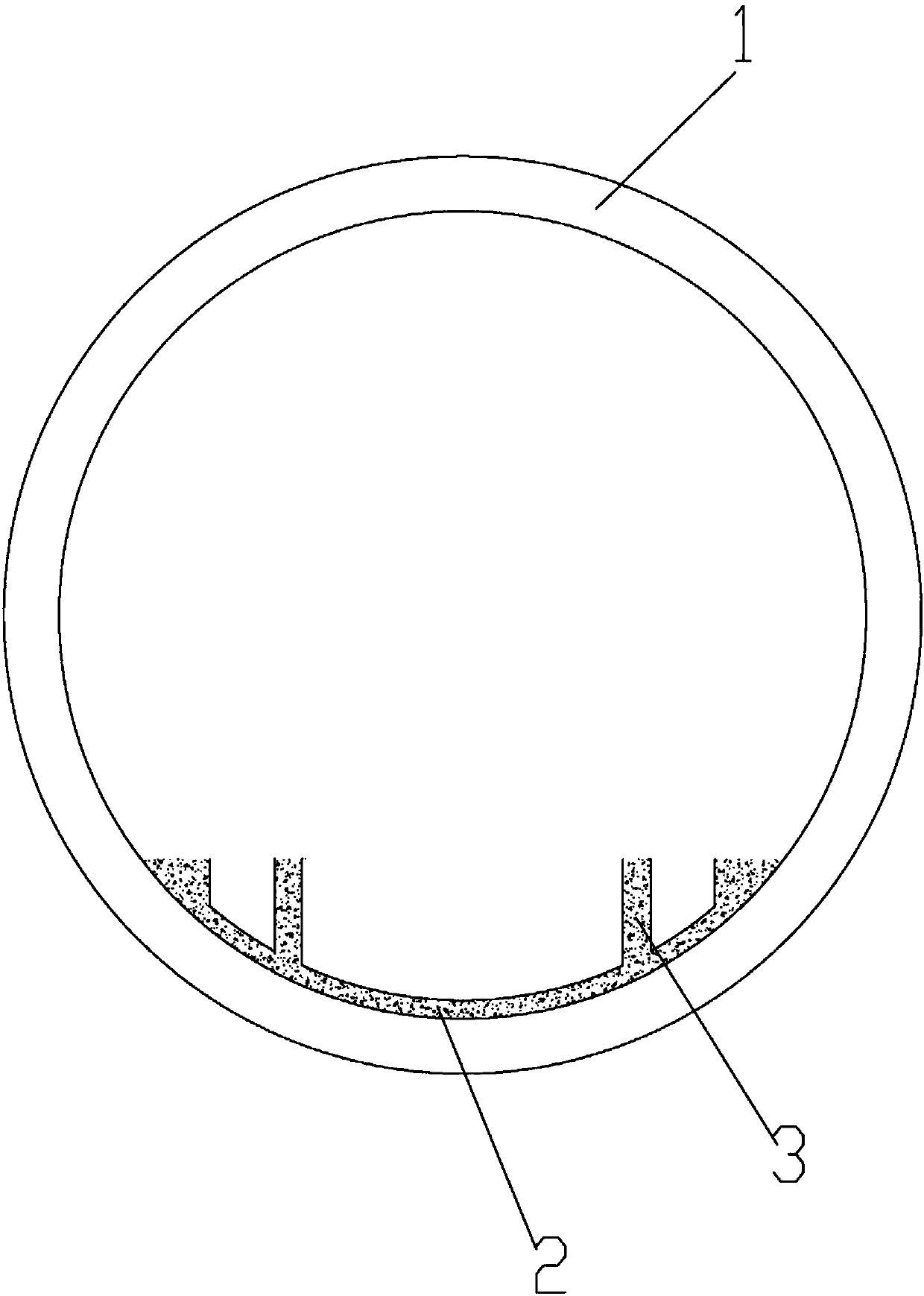

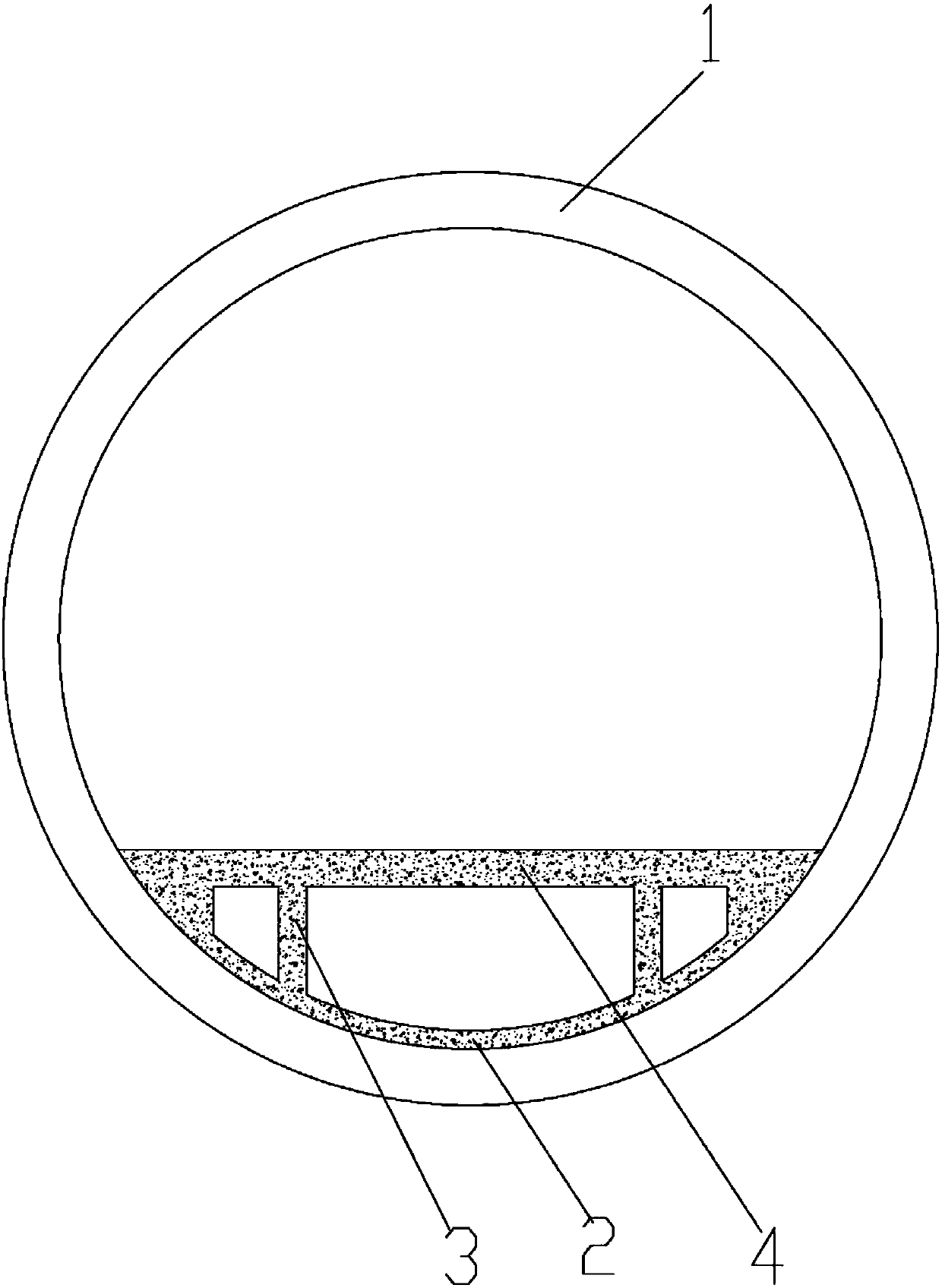

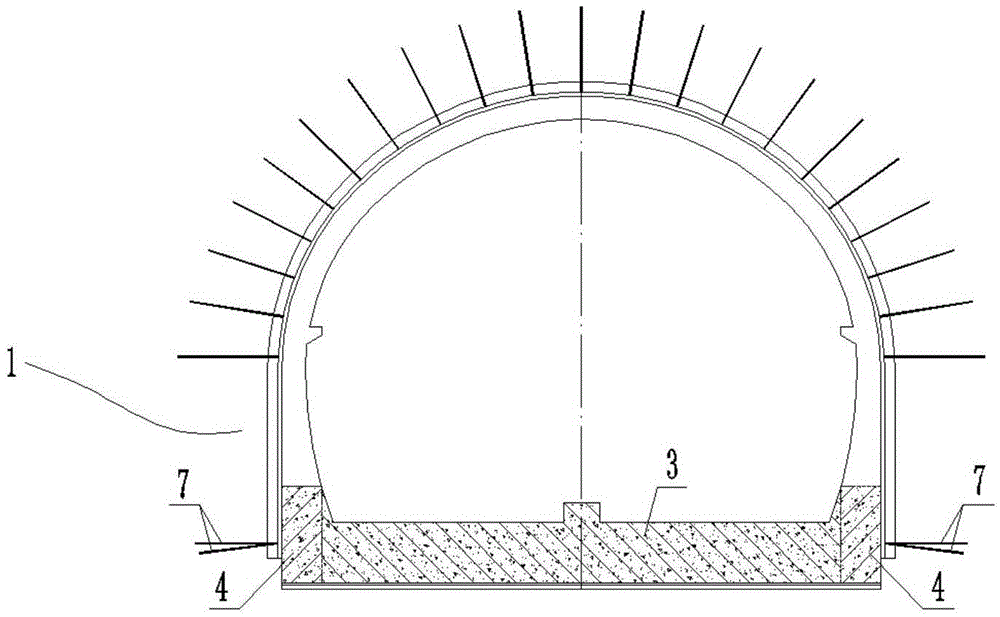

Large-diameter single-hole double-line subway tunnel and construction method thereof

The invention relates to a large-diameter single-hole double-line subway tunnel and a construction method thereof. The large-diameter single-hole double-line subway tunnel comprises a tunnel body, a bottom plate, middle partition walls, a track bed plate, tracks, an evacuation platform, line pipelines and contact nets. The bottom plate is poured at the bottom of the tunnel body; the middle partition walls are vertically poured on the bottom plate; the track bed plate is horizontally arranged on the middle partition walls inside the tunnel body; the two tracks are arranged and laid on the trackbed plate; the evacuation platform is connected to the track bed plate and is located between the two tracks; the line pipelines are laid on the side wall of the tunnel body; the contact nets are installed on the top of the tunnel body and located over the tracks. According to the large-diameter single-hole double-line subway tunnel, uplink and downlink trains are arranged in the same tunnel to reduce the occupation of the underground space by about half, the construction is convenient, and costs are reduced.

Owner:BEIJING MUNICIPAL CONSTR

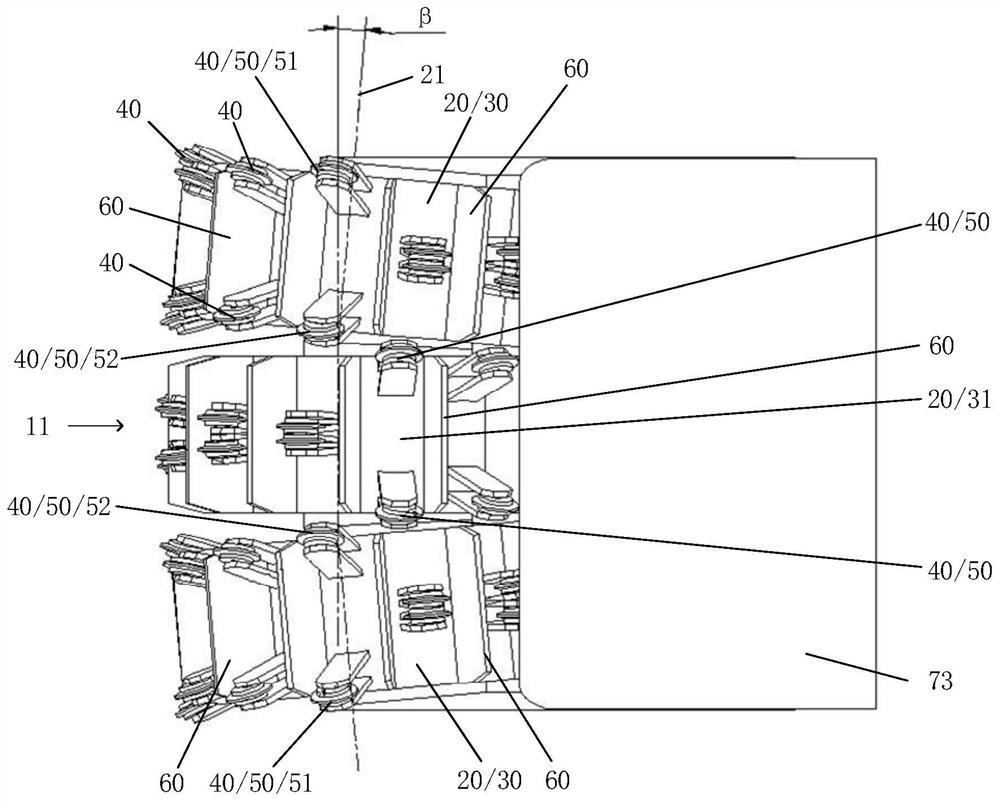

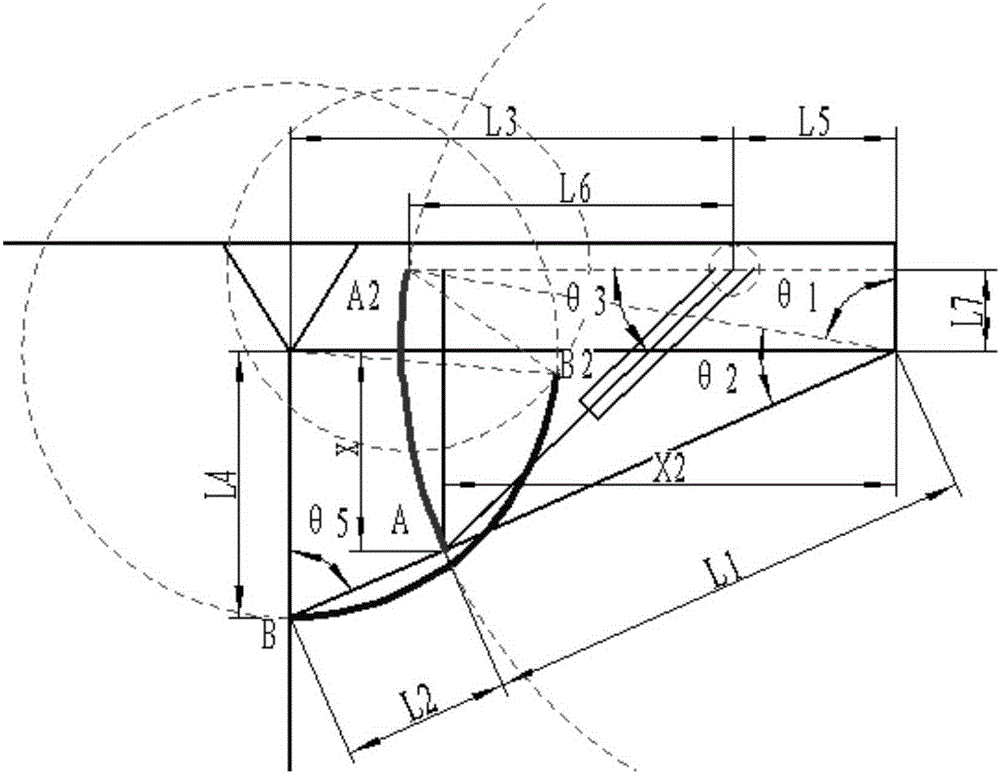

Rectangular section excavation cutterhead and heading machine

The invention provides a rectangular section excavation cutterhead and a heading machine. The rectangular section excavation cutterhead comprises a plurality of axially arranged rollers, and hobs are arranged on the periphery of each roller; the plurality of rollers comprise two outer rollers positioned on the outer side; the axis of the outer roller inclines backwards in the direction from the center of the cutter head to the outer side. The hobbing cutters of the outer roller comprise outer hobbing cutters, and at least one outer hobbing cutter extends outwards to the outside of the end face of the outer roller. By means of the method, the technical problem that it is difficult to achieve full-section excavation of the rectangular tunnel is solved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

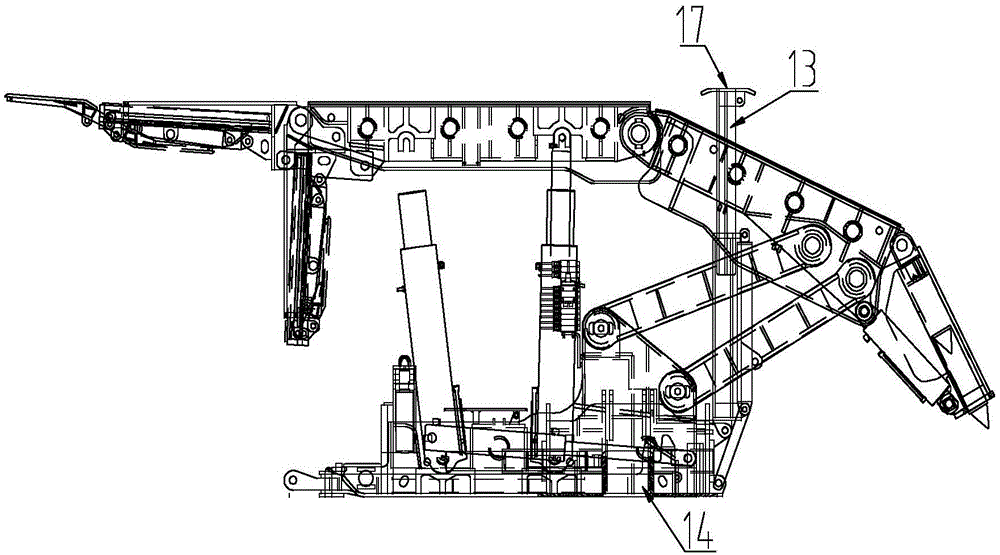

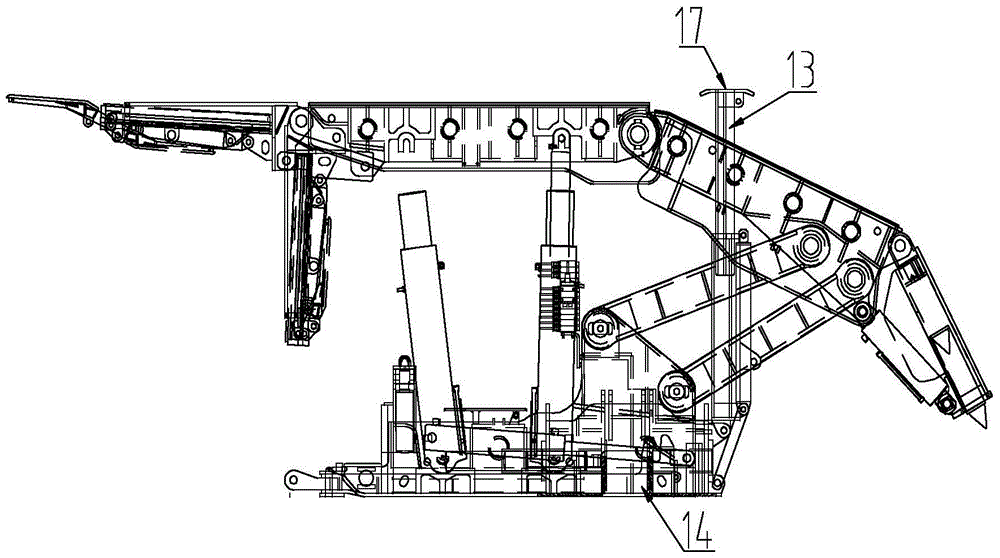

Overhaul device for top beam of hydraulic support with large mining height and application thereof

InactiveCN105201538AAvoid obstructing trafficObstructionMine roof supportsLocking mechanismJackscrew

The invention relates to an overhaul device for a top beam of a hydraulic support with large mining height and application thereof. The overhaul device comprises a lifting jack, an overhaul platform, a driving rod, a guide connecting rod and a driving jack, wherein the lifting jack is respectively articulated with the top beam of the hydraulic support and the overhaul platform, one end of the driving rod is articulated with the lifting jack, the other end of the driving rod is connected with the guide connecting rod and the driving jack, and the driving jack and the guide connecting rod are respectively articulated on the top beam of the hydraulic support. According to the invention, the current situation of difficulty in maintenance of an underground top beam valve set of the hydraulic support with large mining height is solved; a double-telescopic jack is combined with the overhaul platform and the top beam of the hydraulic support to form a parallel four-link mechanism, so that the two-dimensional rotation and lifting action of the overhaul platform are realized, the underground space can be effectively saved, and a coal mining machine is prevented from passing through; and meanwhile, a single-telescopic jack is embedded in a locking mechanism to be combined with the parallel four-link mechanism to finish the two-dimensional translation driving and locking of the overhaul platform, thereby increasing the safety.

Owner:SHANDONG UNIV OF SCI & TECH

Prefabricated groove type cable comprehensive pipe rack

PendingCN109322326ABeautify the urban environmentSave underground spaceArtificial islandsUnderwater structuresUnderground spaceRapid construction

The invention relates to a prefabricated groove type cable comprehensive pipe rack. The prefabricated groove type cable comprehensive pipe rack is characterized by being formed by splicing a pluralityof segments of prefabricated grooves; each segment of prefabricated groove comprises a U-shaped groove and a cover plate located on the U-shaped groove, a concave opening is formed in an opening of each U-shaped groove, the cover plates are directly placed on the concave openings of the U-shaped grooves, a pipe rack inner casing pipe is laid in each U-shaped groove, and the pipe rack inner casingpipes are connected with the U-shaped grooves through hoops in a manner of being spaced by a distance; the pipe rack structure can be subjected to site grooving construction, segmented splicing is achieved, operation is rapid and convenient, and the pipe rack has the advantages that a power cable and a communication cable are laid in an intensification manner, the urban environment is beautified,the underground space is saved, construction is rapid, the cost is low, rapid construction of grounding of an urban center overhead line can be achieved, and the traffic influence can be reduced.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Cable type comprehensive pipe gallery system

InactiveCN109281335AAchieve a fixed effectEasy to manageArtificial islandsUnderwater structuresPower cableUtility tunnel

The invention discloses a cable type comprehensive pipe gallery system. The system comprises standard sections, combined pipe pillows, sleeves, inspection lead-out wells, inspection cross wells and pipeline supports; each standard section comprises a groove and a cover plate, two or more combined pipe pillows are arranged in each standard section along the length direction, each combined pipe pillow comprises two or more pipe pillow units, and sleeves are arranged in cable pipe holes of the corresponding pipe pillow units of the two or more combined pipe pillows; two or more cabins are arranged in each inspection lead-out well and each inspection cross well respectively, two or more pipeline supports are arranged in each cabin; in the same pipeline direction, the two adjacent inspection lead-out wells, the two adjacent inspection cross wells, and the adjacent inspection lead-out well and the inspection cross well, are each connected through one or more standard section. Compared with atrunk line and branch line comprehensive pipe gallery, the power cable and the communication cable are intensively laid according to the cable type comprehensive pipe gallery system, the urban environment is beautified, the underground space is saved, the construction is rapid, the cost is low, and management is facilitated.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

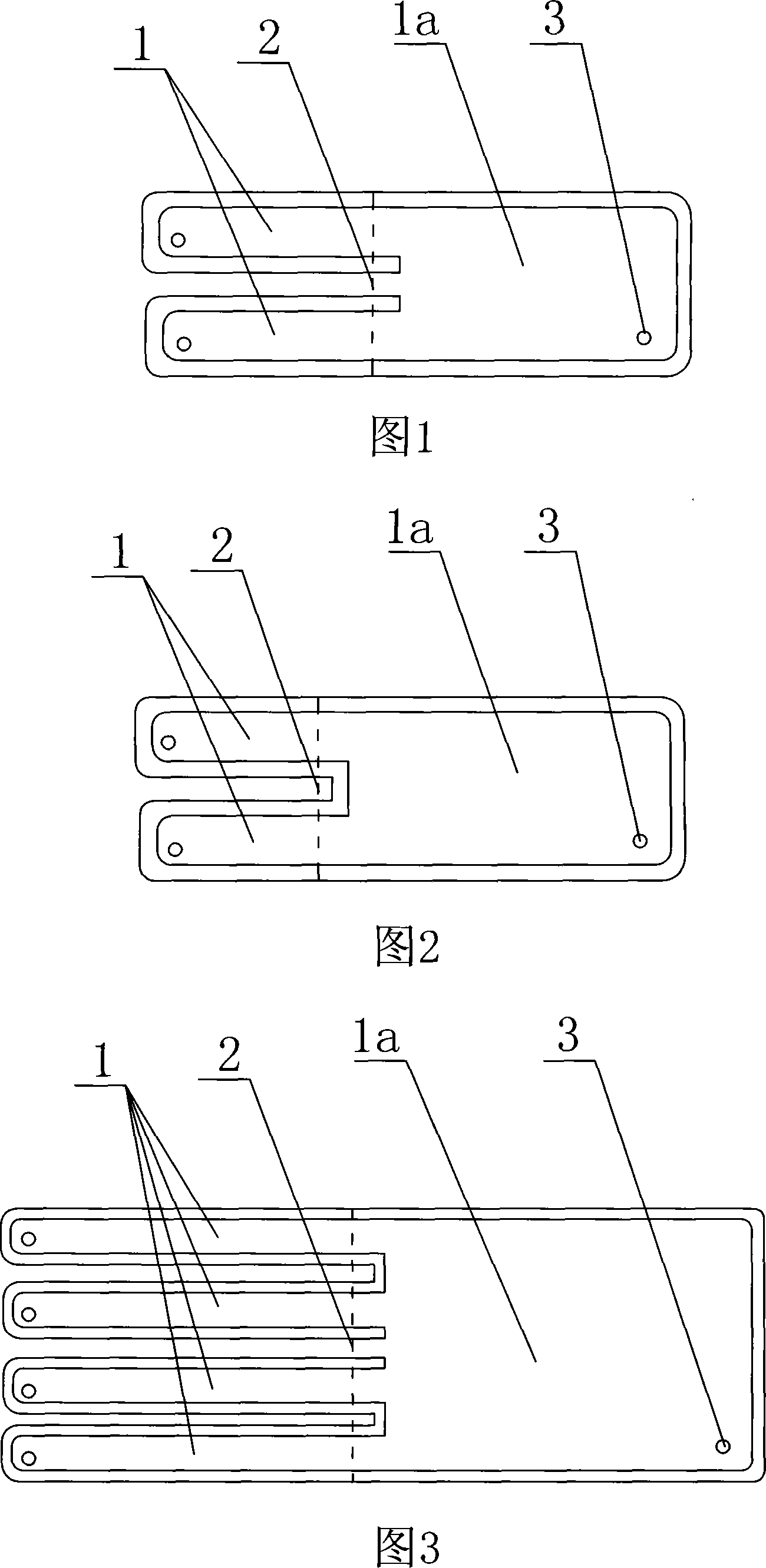

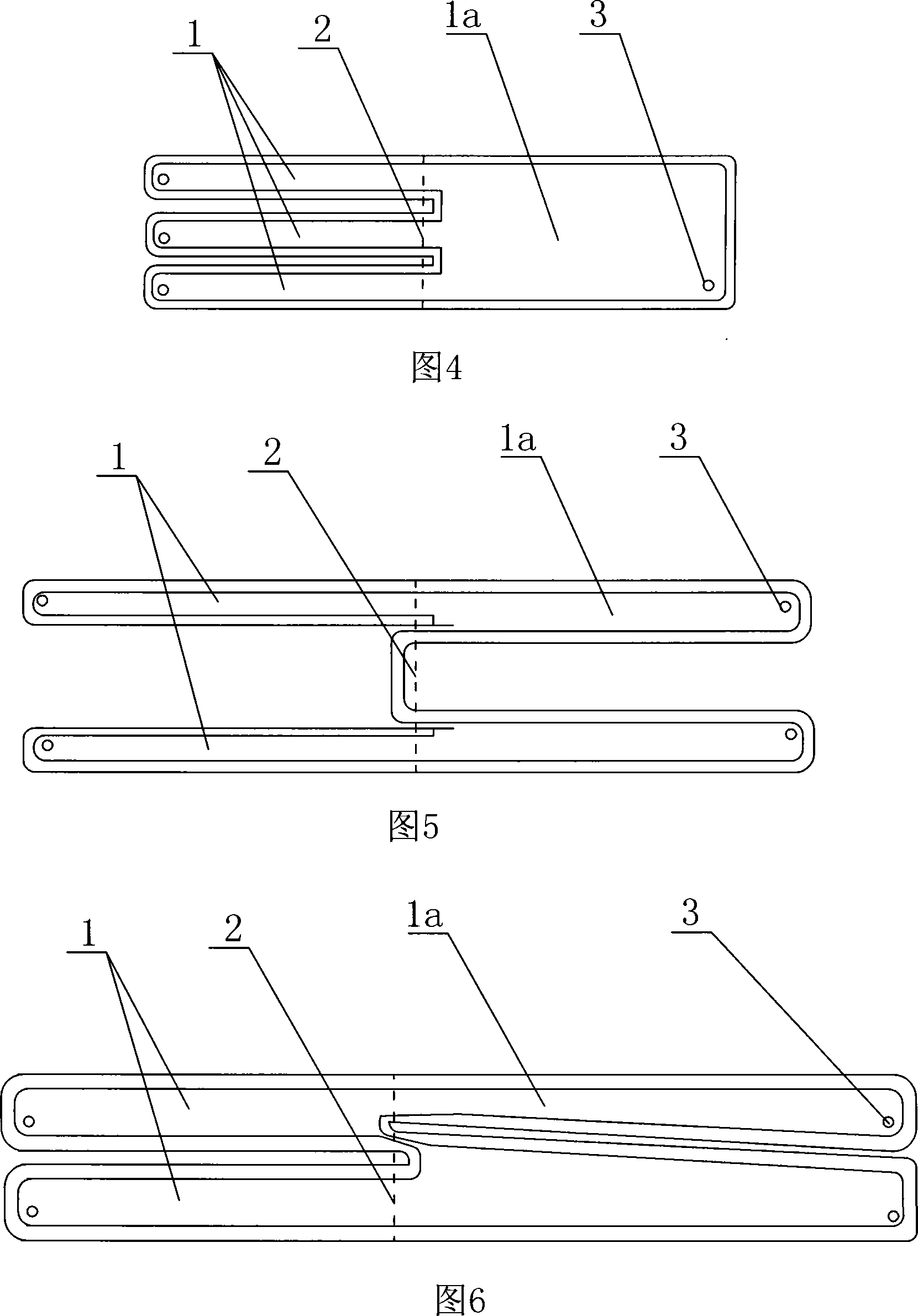

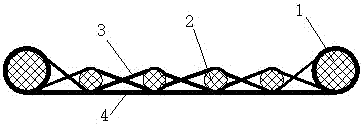

Flexible antipriming pipe

ActiveCN101179182ANovel ideaReasonable structureCable installations in underground tubesPolyesterOverlap zone

A flexible porous pipe belongs to the technical field of cable laying protection inner pipes. It is characterized in that one side of a ring-shaped polyester fabric is folded to form two or more ∩-shaped unit channels, and the other side forms a single ∩-shaped unit channel. The longitudinal length of the ∩-shaped unit channel (1) and the single ∩-shaped unit channel Infinite continuation, ∩-shaped unit channels and overlapping parts of single ∩-shaped unit channels are stitched together. The flexible porous tube has a novel concept, reasonable structure, simple process, high material utilization rate, and low manufacturing cost. The flexible porous tube disclosed in the present invention is used as the protective inner tube in cable laying, and can be applied to various cables. The laying environment can not only separate the cables that are threaded, but also reduce the friction damage on the cable surface during laying and pulling. More importantly, it can fully improve the utilization rate of pipelines, save underground space, save outer pipe resources, and reduce material costs. Effectively reduce the engineering quantity of the cable laying project, shorten the construction period, and reduce the project cost.

Owner:浙江安迪信信息技术有限公司

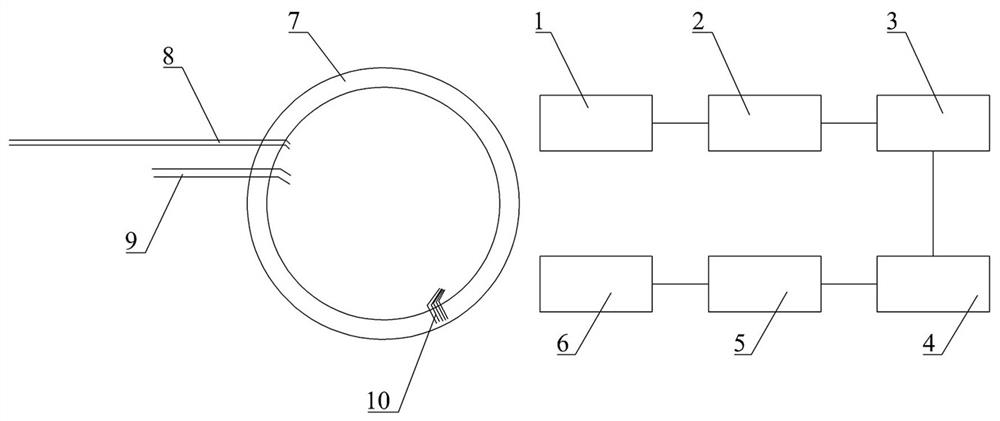

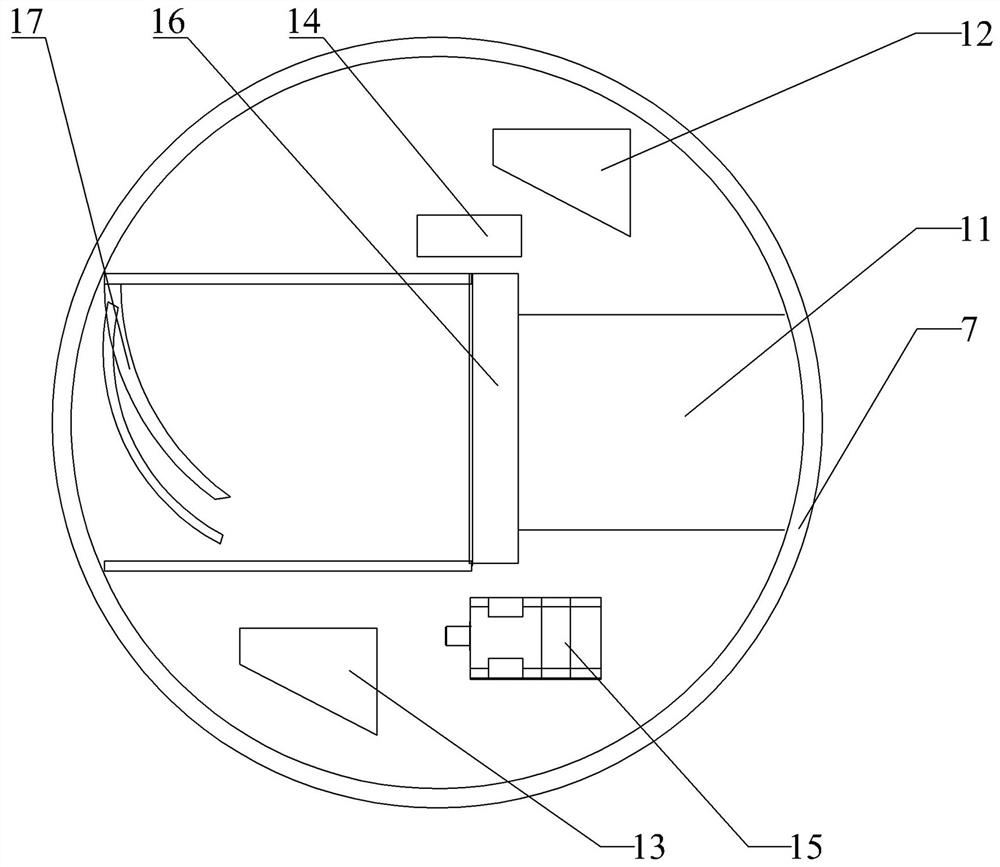

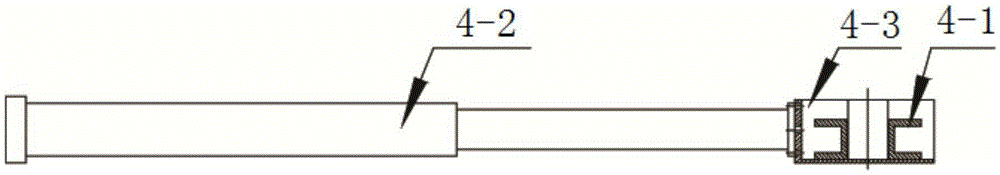

Electromagnetic measurement while drilling repeater and electromagnetic measurement while drilling system

ActiveCN109802718BHighly integratedAvoid the problem of short circuit between two polesSurveyRadio transmissionDipole antennaMechanical engineering

The invention provides an electromagnetic measurement-while-drilling repeater, and the repeater comprises a cylindrical body which is used as one pole of a dipole antenna, and the two ends of the bodyare respectively provided with a positive cone-shaped connecting buckle and a negative cone-shaped connecting buckle; The joint is connected to the regular cone-shaped connecting buckle of the body;And the step part is formed on the peripheral surface of the body, the free end of the step part is smoothly connected with the regular cone-shaped connecting buckle, and the bottom surface of the step part is radially sunken relative to the peripheral surface of the body. Wherein an antenna, which is the other pole of the dipole antenna, is arranged on the step part. The invention also provides an electromagnetic measurement while drilling system comprising the repeater.

Owner:CHINA PETROLEUM & CHEM CORP +1

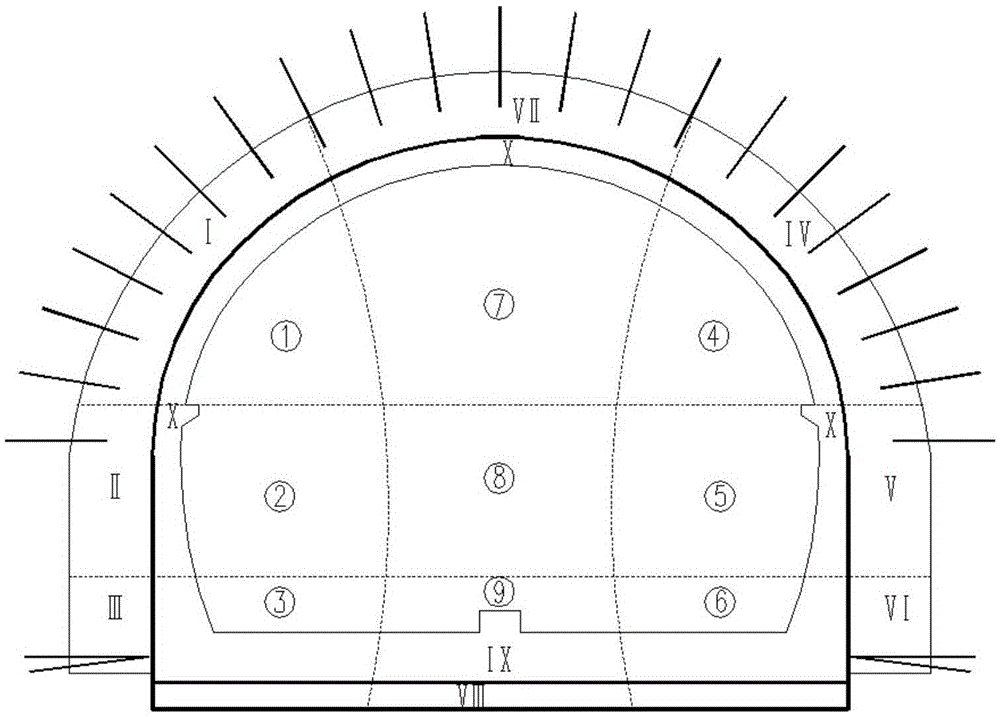

Ultra-deep narrow vertical shaft shield split launching construction method

PendingCN113982608AStart work smoothlySave underground spaceTunnelsHydro energy generationStructural engineeringMachine

The invention discloses an ultra-deep narrow vertical shaft shield split launching construction method which comprises the following steps: firstly, assembling a shield tunneling machine main machine and arranging a rear matching system and mud inlet and outlet pipe hoses under a vertical shaft, and placing shield tunneling machine rear matching trailers in a site around the vertical shaft; then, after the shield tunneling machine main machine tunnels for a certain distance, making one of the rear matching trailers transformed and then lowered into the well to be connected with the shield tunneling machine main machine, and making the rear matching system and the mud inlet and outlet pipes moved to the trailers; and finally, when the tunneling distance of the shield tunneling machine main machine reaches the length of the whole machine, withdrawing the trailers, installing all the rear matching trailers including the quitted trailer sequentially and moving the rear matching system to the corresponding trailer to finish the launching work of the shield tunneling machine. The method is high in space utilization rate, reasonable in site and space application, clear in time sequence overall planning and free of influence between procedures.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

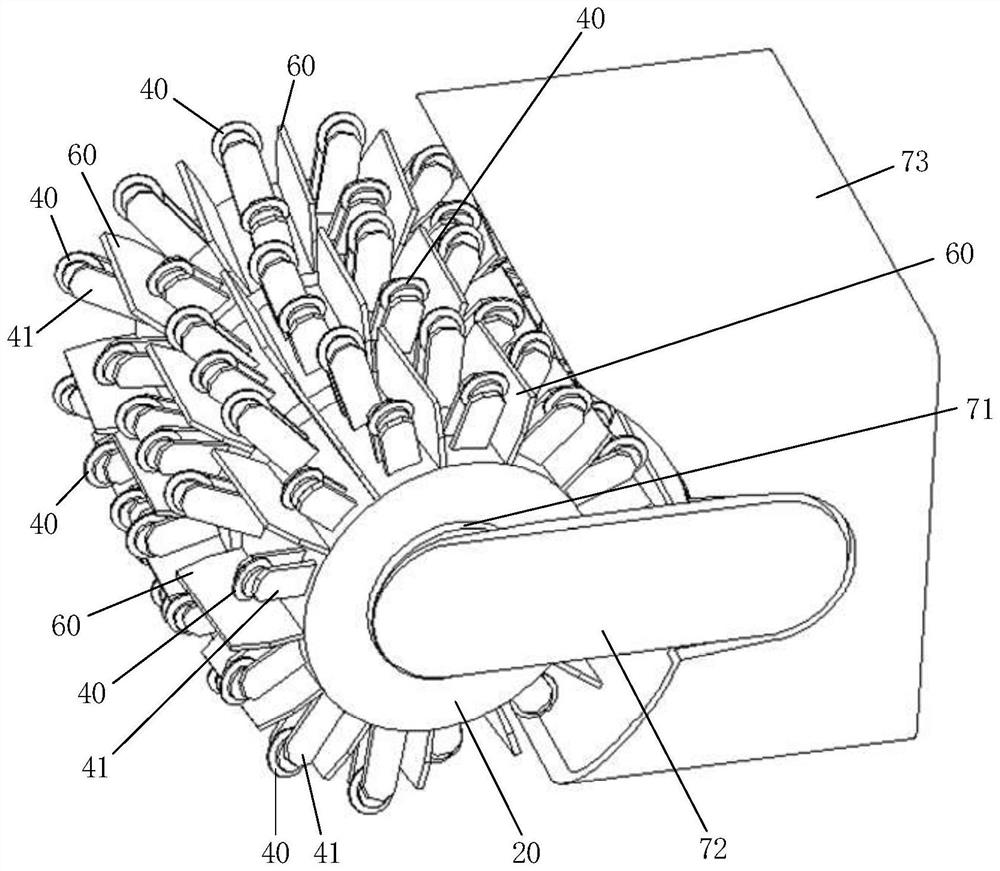

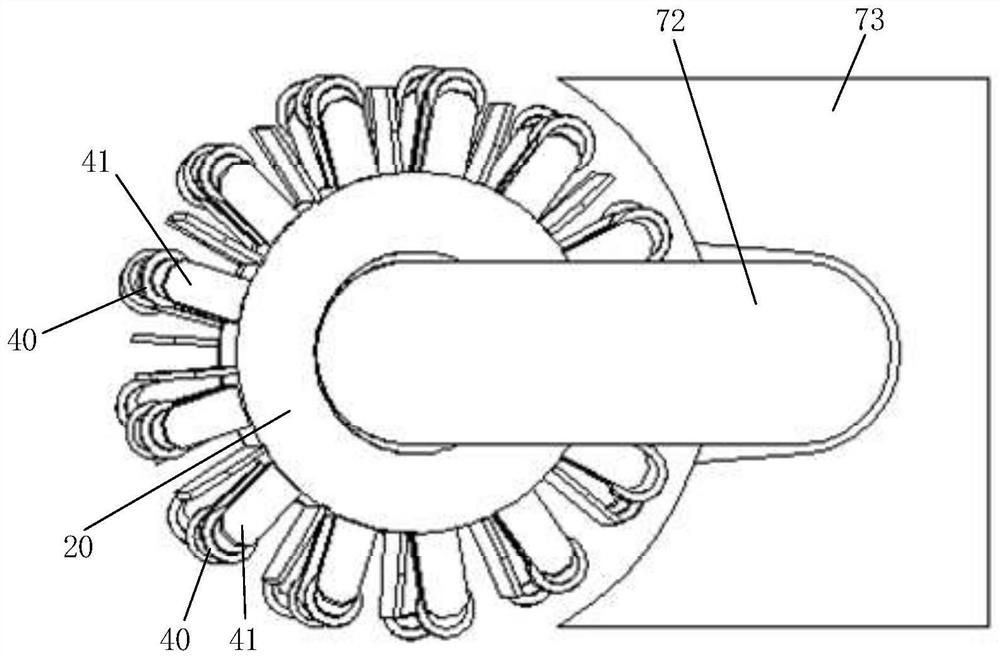

A mechanical recovery device and application method of an umbrella anchor

ActiveCN110904960BImprove integrityAvoid pollutionBulkheads/pilesArchitectural engineeringSoil resistance

The invention provides a mechanical recovery device and application method of an umbrella anchor. The recovery device includes an anchor head fixing device, a connecting rope and a top recovery device. The anchor head fixing device includes a screw with holes and an anchor fixed to the umbrella anchor. The pulleys on both sides of the main rod of the head, one end of the two anchor plates are connected to the main rod of the anchor head in rotation, the top recovery device includes a hoist and a supporting fixed bracket, and the hoist is fixed on the supporting fixed bracket; one end of the connecting rope is fixed to the umbrella by a screw with a hole On the anchor plate of the type anchor, the other end of the connecting rope is connected to the hoist of the top recovery device along the anchor rod through the pulley fixed to the main rod of the anchor head. In the present invention, by adding connecting ropes and pulleys, using screws with holes to fix the connecting ropes on the anchor plate, and using a hoist to pull the anchor plate to keep the closed state during the pull-up process, resisting the soil resistance during the dragging process, and realizing the umbrella shape The effective recycling of the anchor, the whole recycling process is very simple, the construction speed is fast and the efficiency is high.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

A hydraulic support retraction system and its retraction method

The invention discloses a hydraulic support withdrawing system and method and belongs to the technical field of hydraulic supports. The hydraulic support withdrawing system comprises at least two shield supports and a withdrawing platform. A moving beam is arranged between the shield supports and the withdrawing platform. The two sides of the moving beam are fixedly connected with a moving jack at the bottoms of the shield supports and one end of the withdrawing platform respectively. The shield supports are arranged on one side of the moving beam in parallel, and one shield support is located on the side of a hydraulic support to be withdrawn. Each shield support comprises a base and a net pushing device. The withdrawing system is high in safety coefficient, and labor is saved.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

Automatic feed and release cable clamp

Owner:上海富锲智能科技有限公司

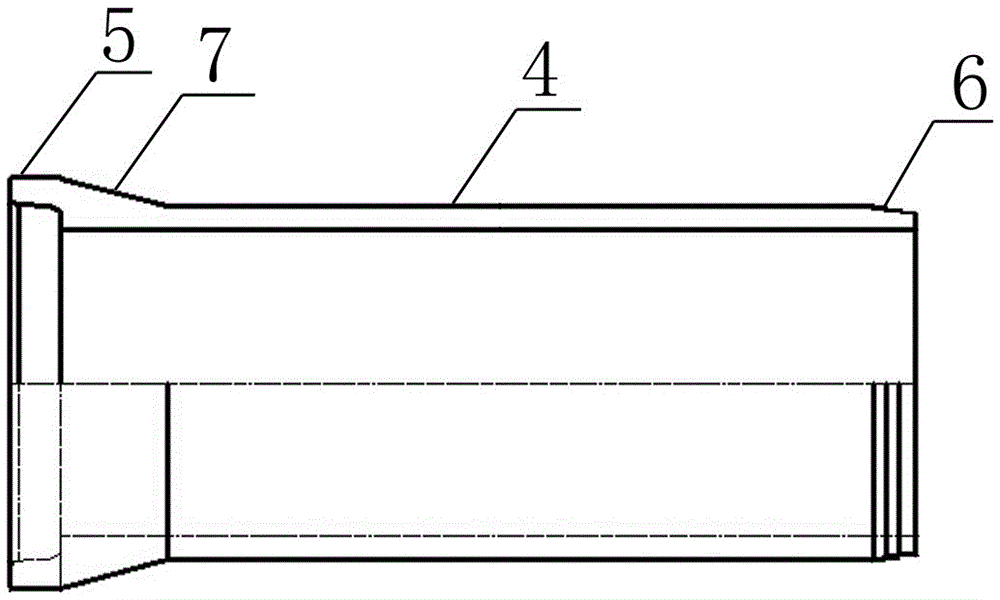

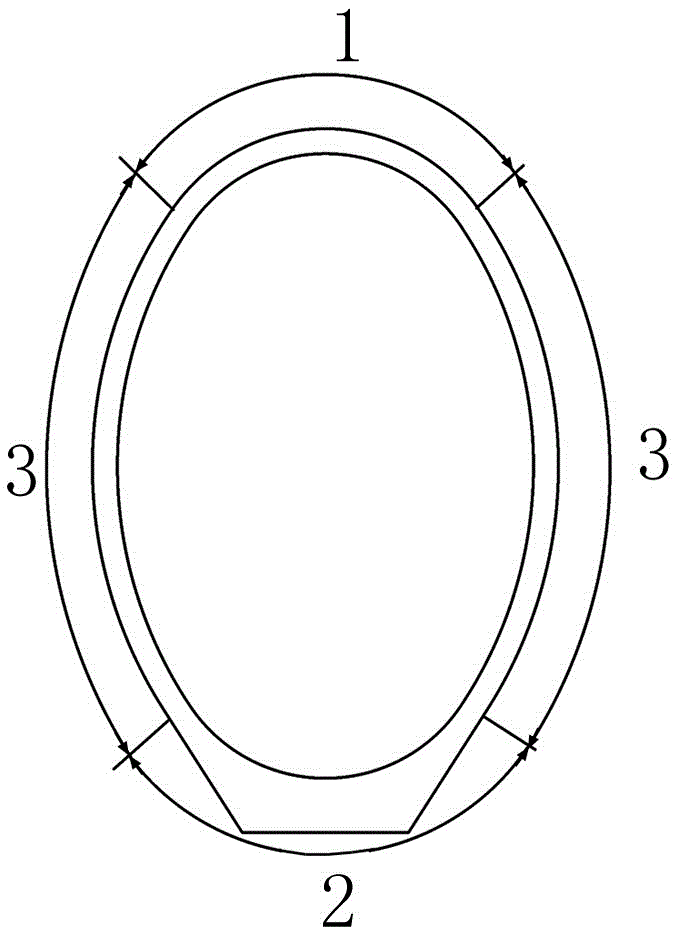

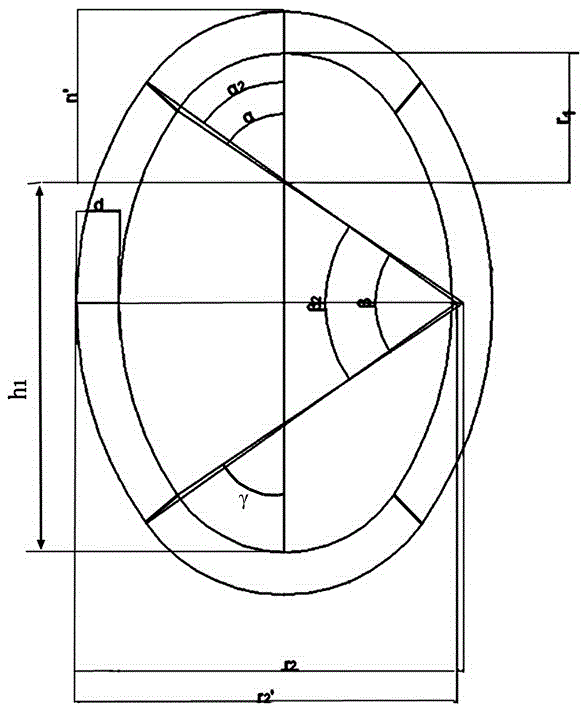

Spigot and socket type RPC thin-wall oval-cross-section pipe and construction method thereof

InactiveCN106013393AImprove stabilityImprove seismic performanceSewer pipelinesEngineeringShock resistance

The invention provides a spigot and socket type RPC thin-wall oval-cross-section pipe and a construction method thereof. The spigot and socket type RPC thin-wall oval-cross-section pipe comprises a pipe body, a socket section and a spigot section, wherein the socket section and the spigot section are arranged at the two ends of the pipe body respectively. The cross section of the pipe body is shaped like an oval ring, and the oval ring comprises a top arc section, a bottom arc section and two side arc sections located between the top arc section and the bottom arc section. According to the spigot and socket type RPC thin-wall oval-cross-section pipe and the construction method thereof, the RPC material is introduced into drain pipe design; meanwhile, on the premise that the inner width and inner height of the oval-cross-section pipe guarantee that the flow area of the oval-cross-section pipe is equal to that of a round pipe with the diameter of 1200 mm, optimization is constantly carried out through stability and mechanics calculation, and finally the inner width and inner height of the oval-cross-section pipe are determined, so that compared with oval-cross-section pipe of other sizes, the oval-cross-section pipe is better in stability and shock resistance and higher in bearing capacity.

Owner:BEIJING MUNICIPAL ENG RES INST

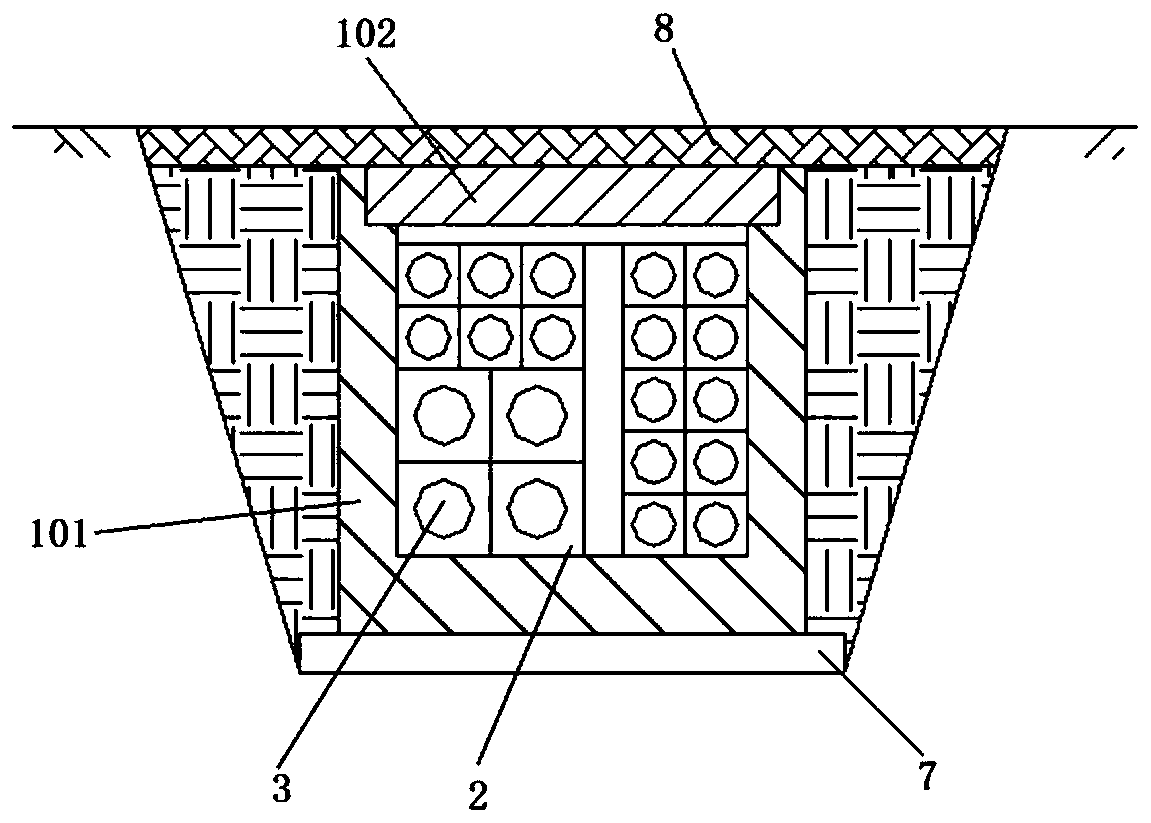

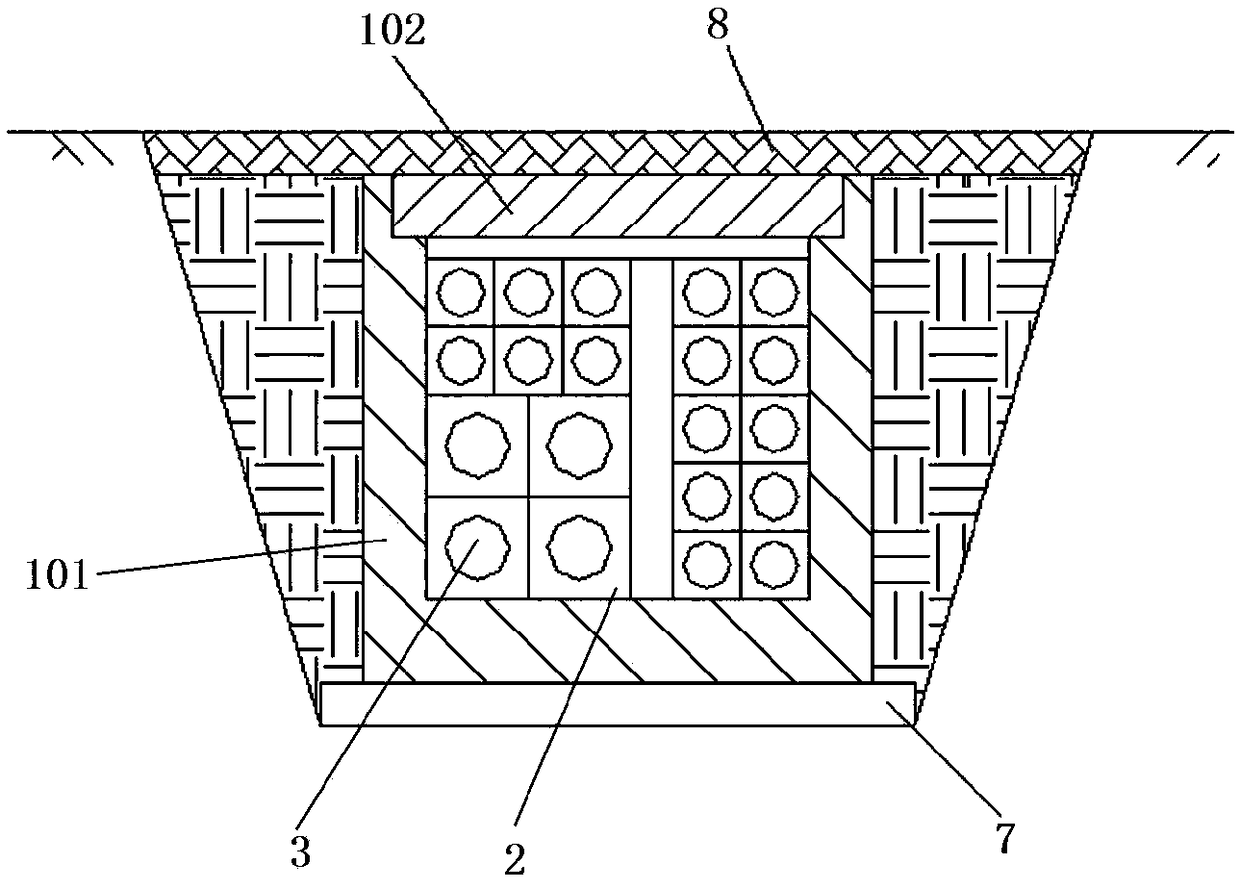

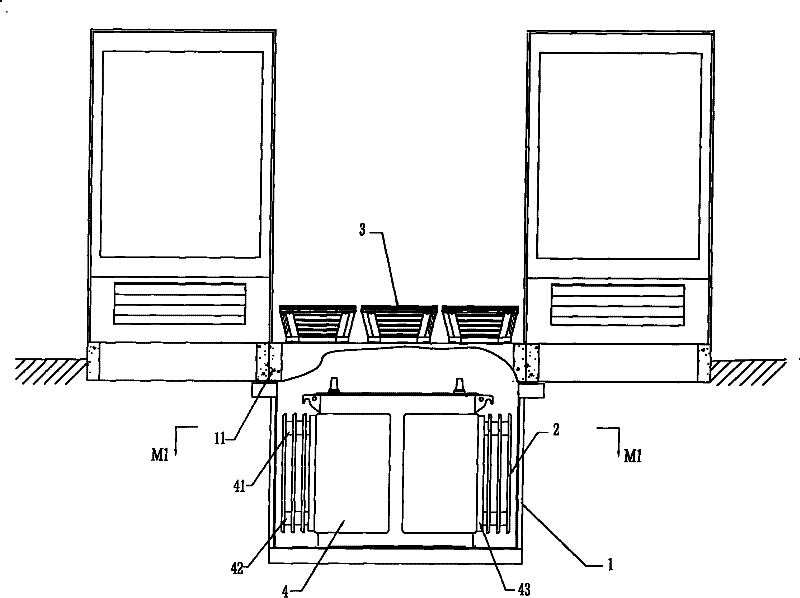

Heat dissipation system of underground box type transformer

ActiveCN101572166BSolve the defect of insufficient heat dissipationTimely cooling requirementsTransformers/inductances coolingSubstation/switching arrangement cooling/ventilationNatural ventilationTransformer

The invention discloses a heat dissipation system of an underground box type transformer, comprising a natural convection heat dissipation system mechanism formed by air chutes arranged around a transformer body in a pit box and a ventilation opening arranged on the ground. The heat dissipation system is characterized by further comprising a reinforced heat exchange mechanism which is arranged onat least one outer wall of the transformer body (4) and contacted with the inner wall of the pit box (1), so that the heat generated by the transformer body (4) is transmitted into the pit box (1) through the reinforced heat exchange mechanism, and the heat is then transferred into the surrounding stratum through the pit box. The heat dissipation system combines natural ventilation and forced ventilation, and adopts surface soil layer heat dissipation, so as to improve the heat dissipation effect and ensure lasting and stable heat dissipation; furthermore, the size of the pit box can be reduced to the utmost extent, and the pre-buried underground space is saved.

Owner:基元电气有限公司

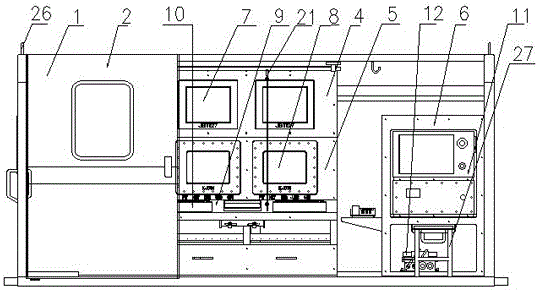

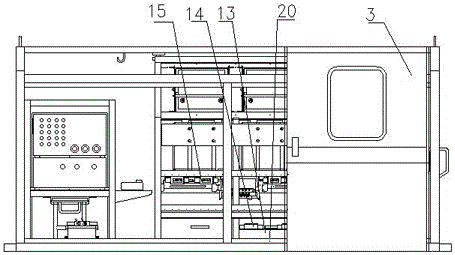

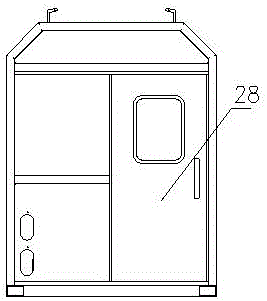

Fully mechanized mining face centralized control room

ActiveCN104074375BProtect personnel safetyProtection securityWing suspension devicesIndustrial buildingsControl systemControl room

The invention relates to a centralized control room for a fully mechanized mining face. An upper installation bracket (4) is fixedly connected to the top of the room body, and more than two explosion-proof monitors (7) are embedded in the upper installation bracket (5). The bracket (4) is connected, and more than two explosion-proof computers (8) are embedded in it, and the lower mounting bracket (5) is also provided with an operation panel (9). The keyboard (10) is embedded in the sinking groove; the main controller (11) is embedded on the upper part of the support frame (6), and the explosion-proof power supply (12) is installed on the lower part; the explosion-proof power supply (12) and the main controller (11 ), the explosion-proof monitor (7) is connected with the explosion-proof computer (8), the explosion-proof monitor (7) and the explosion-proof computer (8) are respectively connected with the main controller (11); the lower part of the lower mounting bracket (5) is provided with a mounting beam (13). The invention is arranged on the fully mechanized mining face, which not only ensures the personal safety of the personnel on the fully mechanized mining face, but also provides reliable protection for the management of the underground control system more reasonably.

Owner:SHANXI PINGYANG GUANGRI ELECTROMECHANICAL

A roof and bottom shared underground structure and its separate construction method

InactiveCN104631493BSave underground spaceReduced stabilityArtificial islandsUnderwater structuresStart timeRebar

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

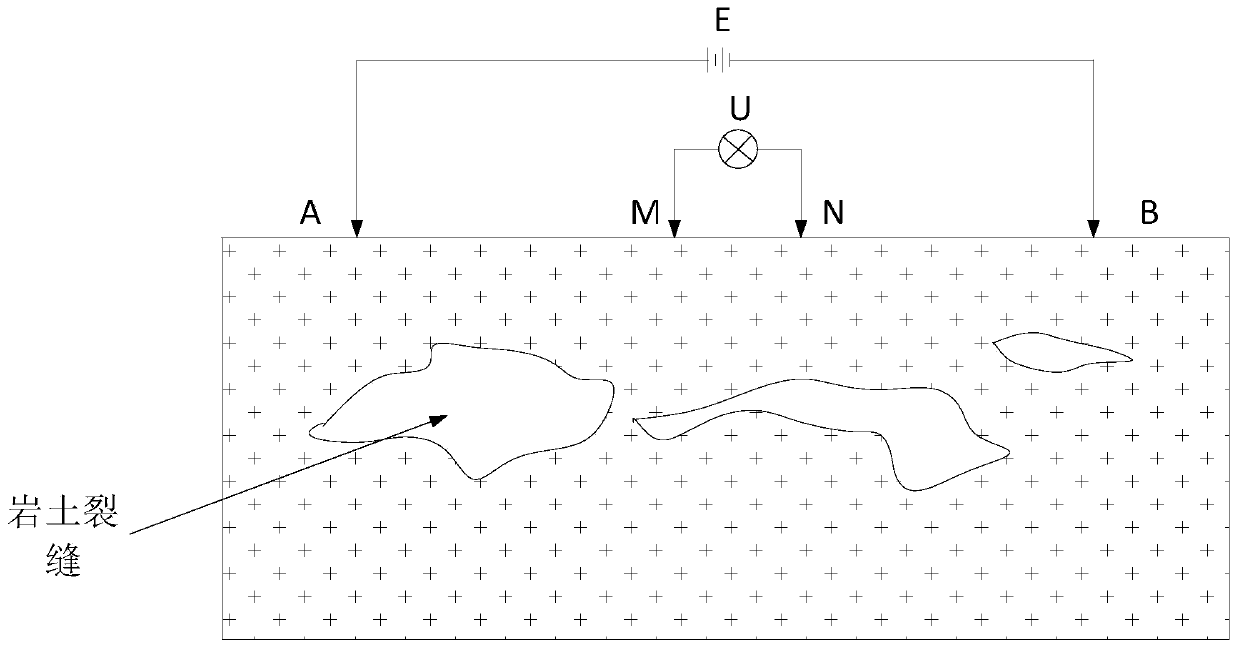

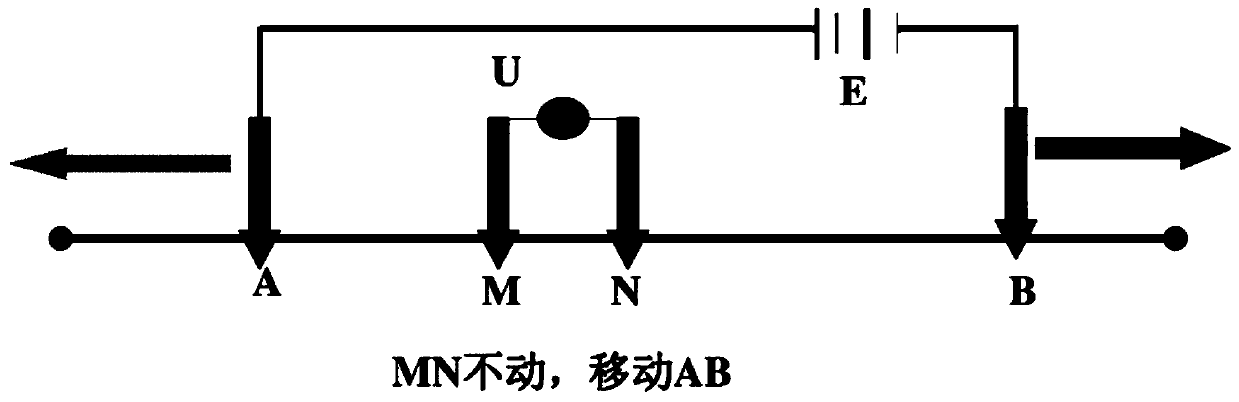

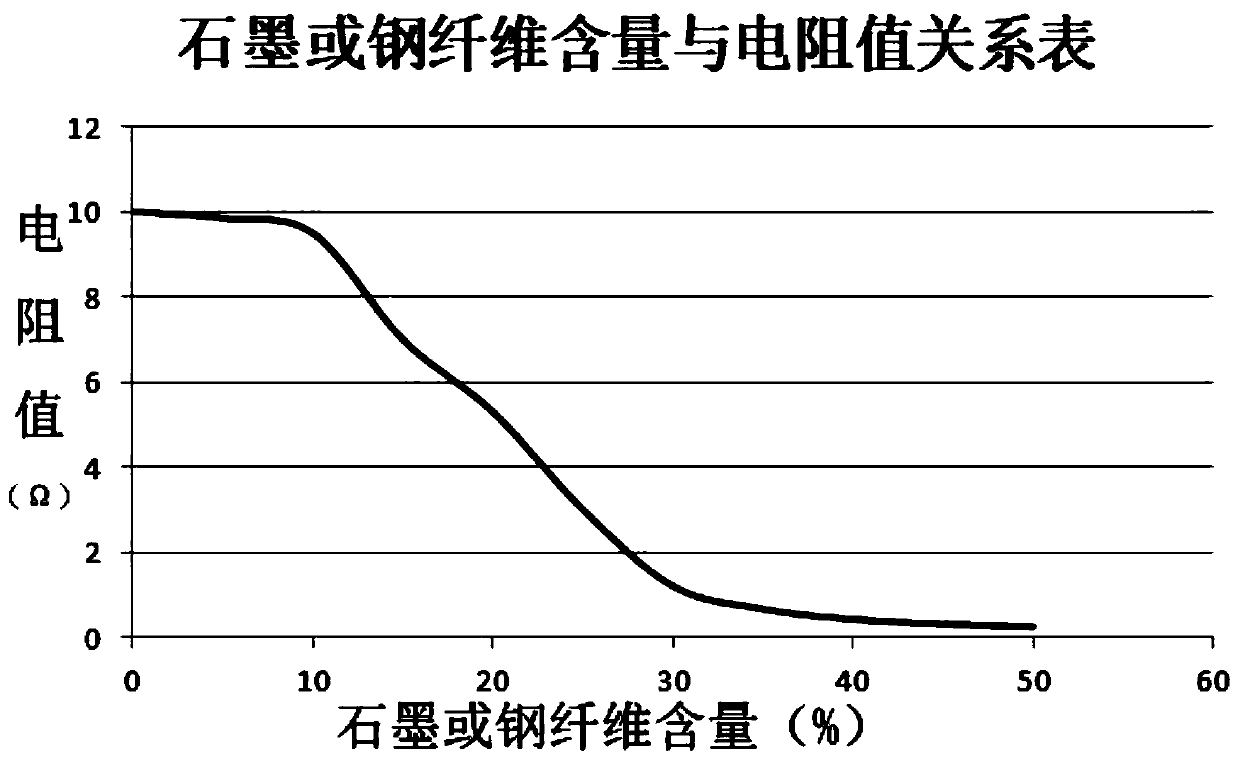

Method for detecting and monitoring grouting material by utilizing conductivity difference

InactiveCN111579597AImprove detection efficiencyReduce construction costsSolid waste managementMaterial resistanceElectrical resistance and conductanceSoil science

The invention discloses a method for detecting and monitoring a grouting material by utilizing conductivity difference. The method comprises the following steps: pre-burying a plurality of electrodesin a to-be-grouted area; solving an original resistance value of a to-be-grouted area by adopting an electrode method; according to the original resistance value, adjusting the type and the proportionof the conductive performance changing material in the grouting material, and carrying out grouting pouring on the to-be-grouted area; and obtaining the current resistance after grouting through an electrode method, if the original resistance value is the same as or infinitely close to the current resistance value, determining that no grouting material exists in the area, and otherwise, determining that the area contains the grouting material. By means of the scheme, the method has the advantages of being low in cost, high in resource utilization rate, easy and convenient to detect and the like, and has high practical value and promotional value in the technical field of grouting materials.

Owner:胡瑾 +1

A support structure of latitude and longitude foundation pit

The invention discloses a warp and weft type foundation pit supporting structure. The warp and weft type foundation pit supporting structure comprises a plurality of row piles arranged in a foundation pit, auxiliary cables and main cables for applying prestress, wherein the row piles include main piles and auxiliary piles, the main piles and the auxiliary are distributed in an I-shaped manner, a plurality of auxiliary piles are distributed between every two adjacent main piles, the auxiliary piles and the outer walls of the main piles are arranged on the same plane, the main piles and the auxiliary piles are connected with the auxiliary cables in a warp and weft weaving manner, one main cable is connected between every two adjacent main piles, and the main cable contacts with the outer walls of the auxiliary piles between the main piles. Compared with the prior art, the warp and weft type foundation pit supporting structure has the advantages that the lateral rigidity of the overall row piles is fully utilized, the normal (relative to the wall of the foundation pit) deformation of the row piles is resisted through cable force transmission, the diameters and embedding depths of the row piles are reduced, the integrity and stability of the foundation pit support structure are increased, underground space is saved greatly, and the structure is promising in application market and development prospects.

Owner:周霜林 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com