Patents

Literature

94results about How to "Strong self-priming ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

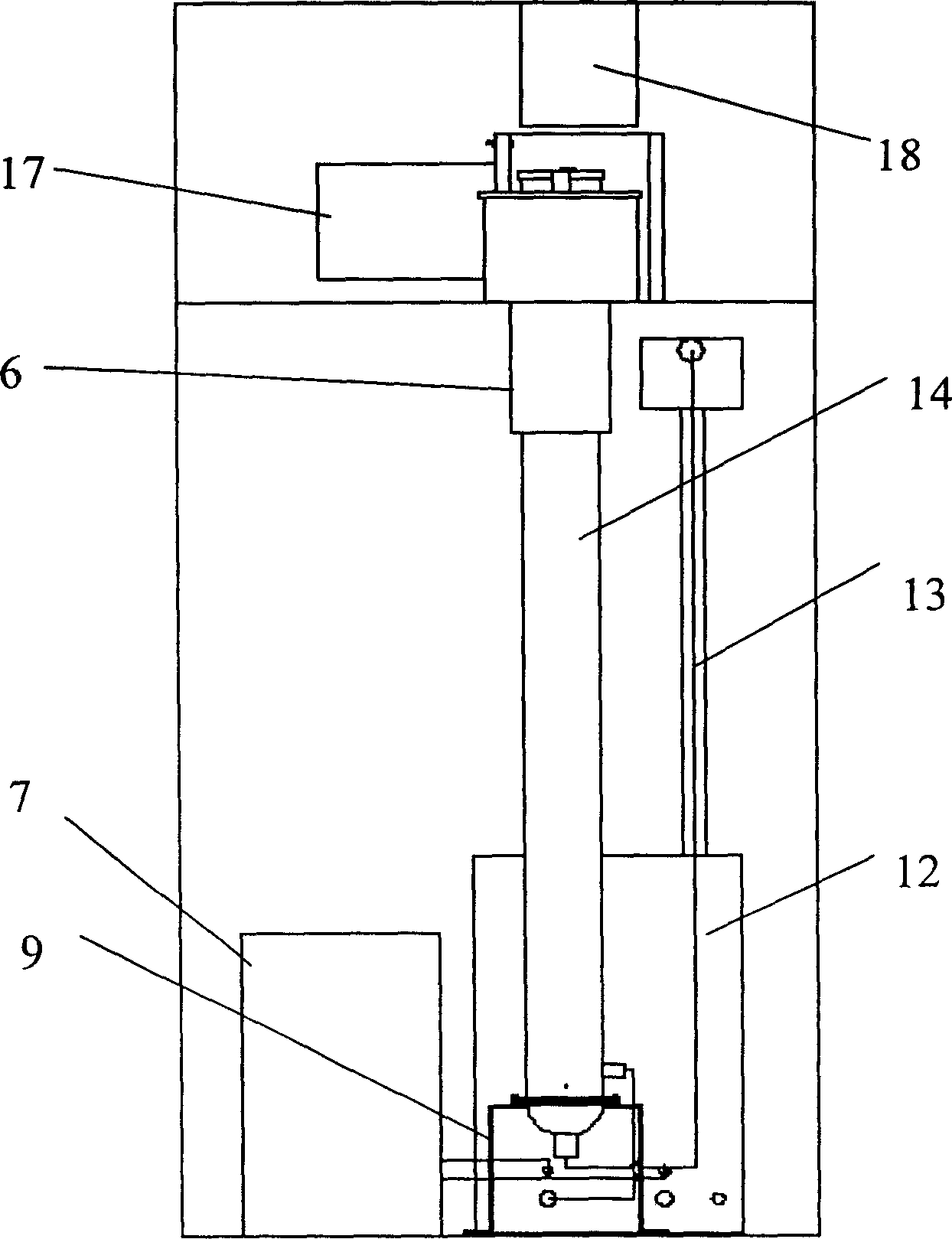

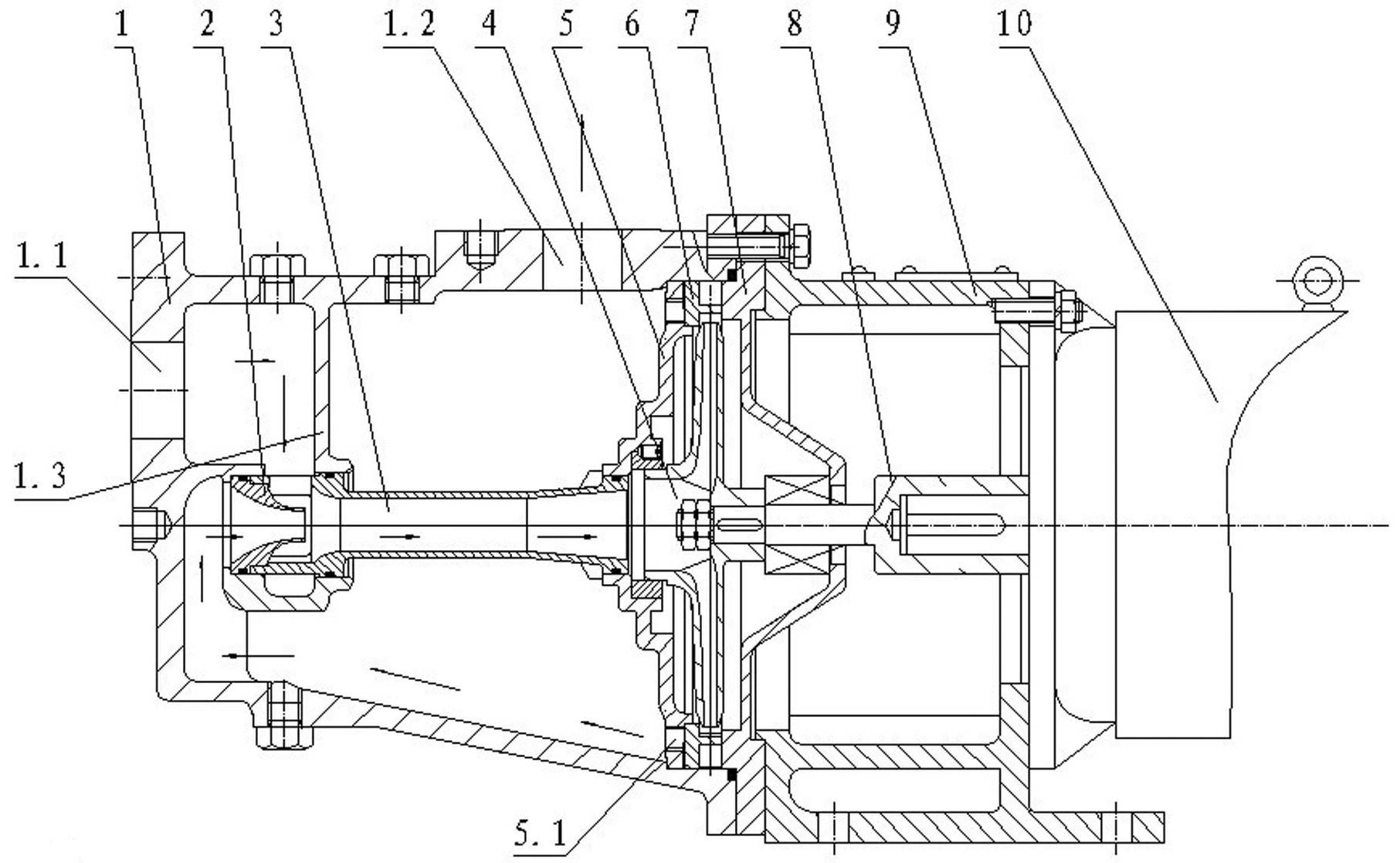

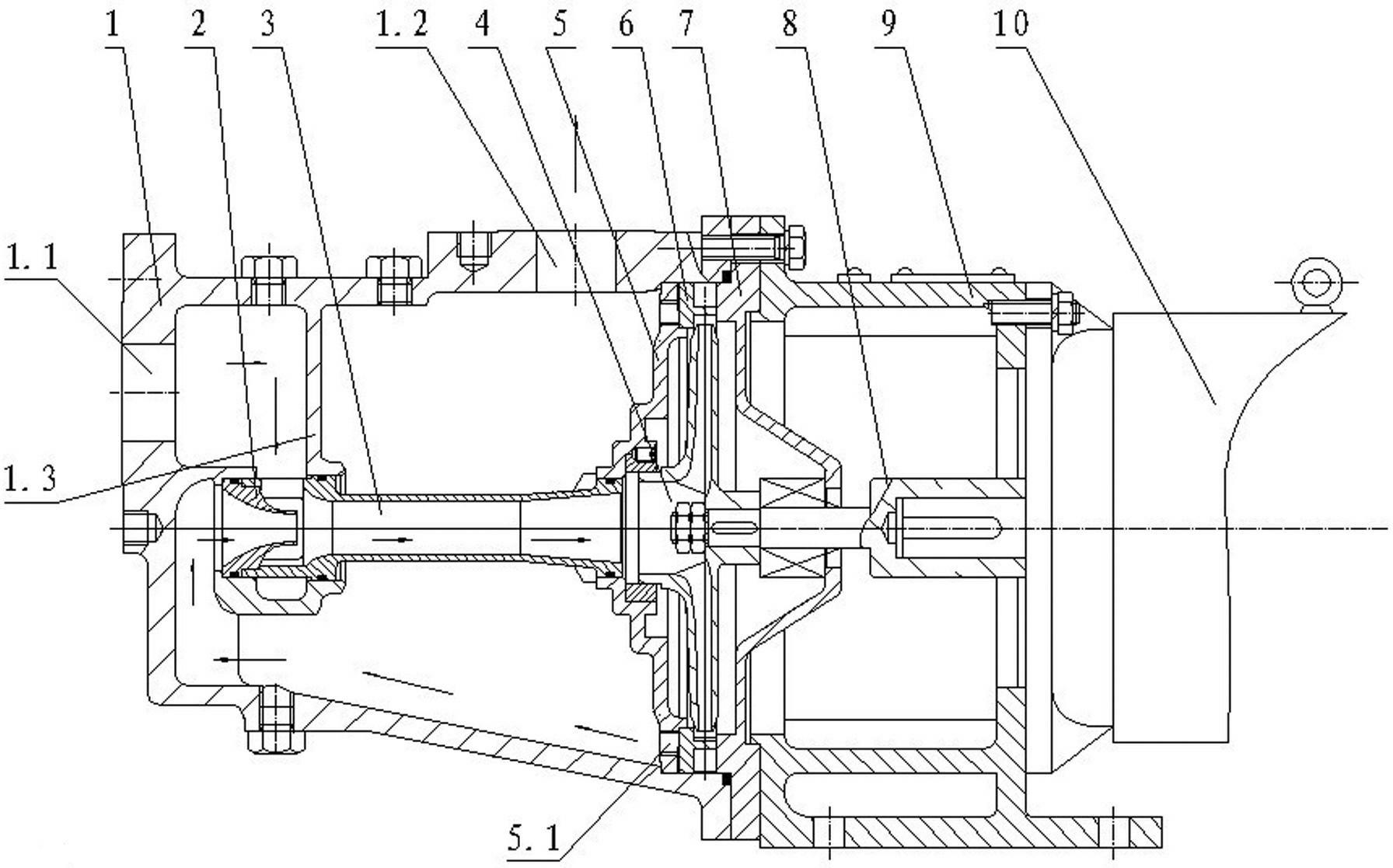

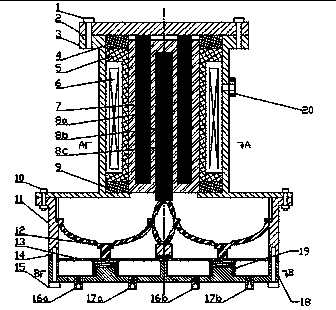

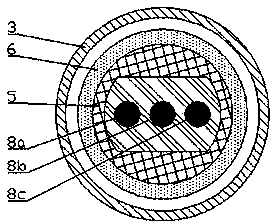

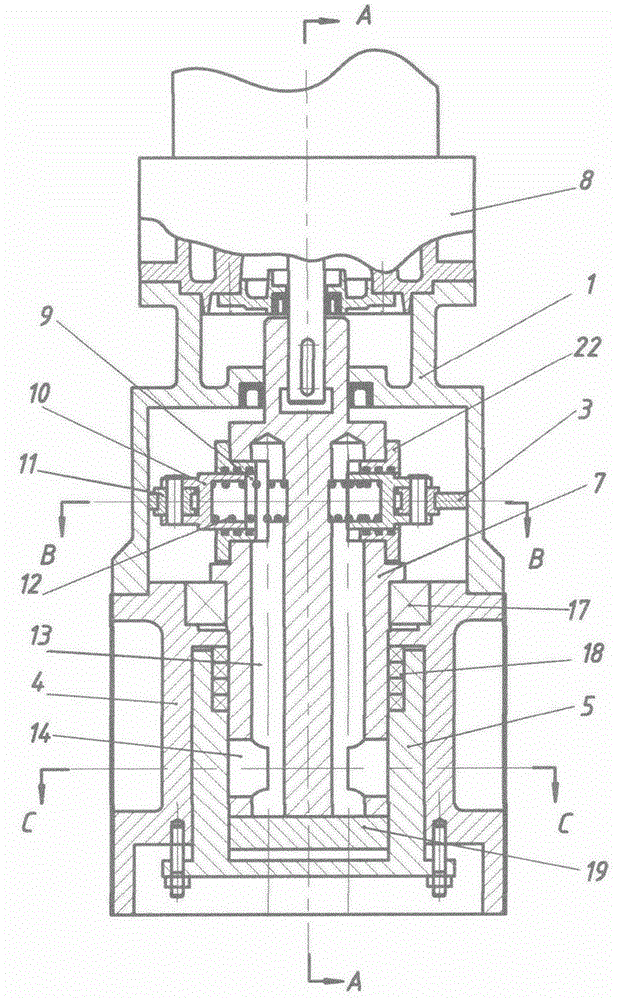

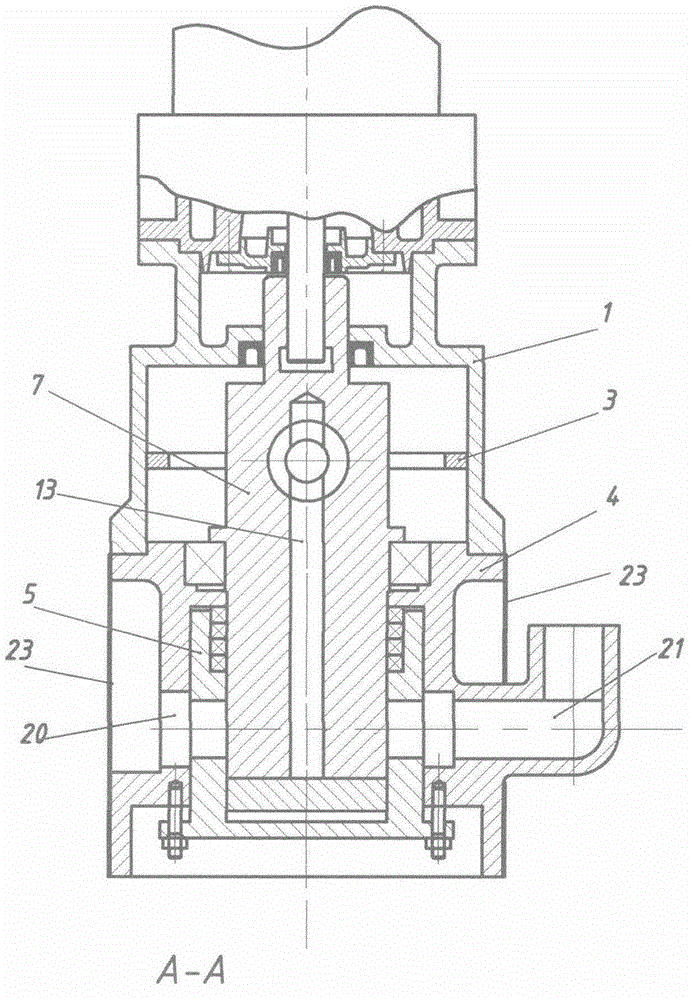

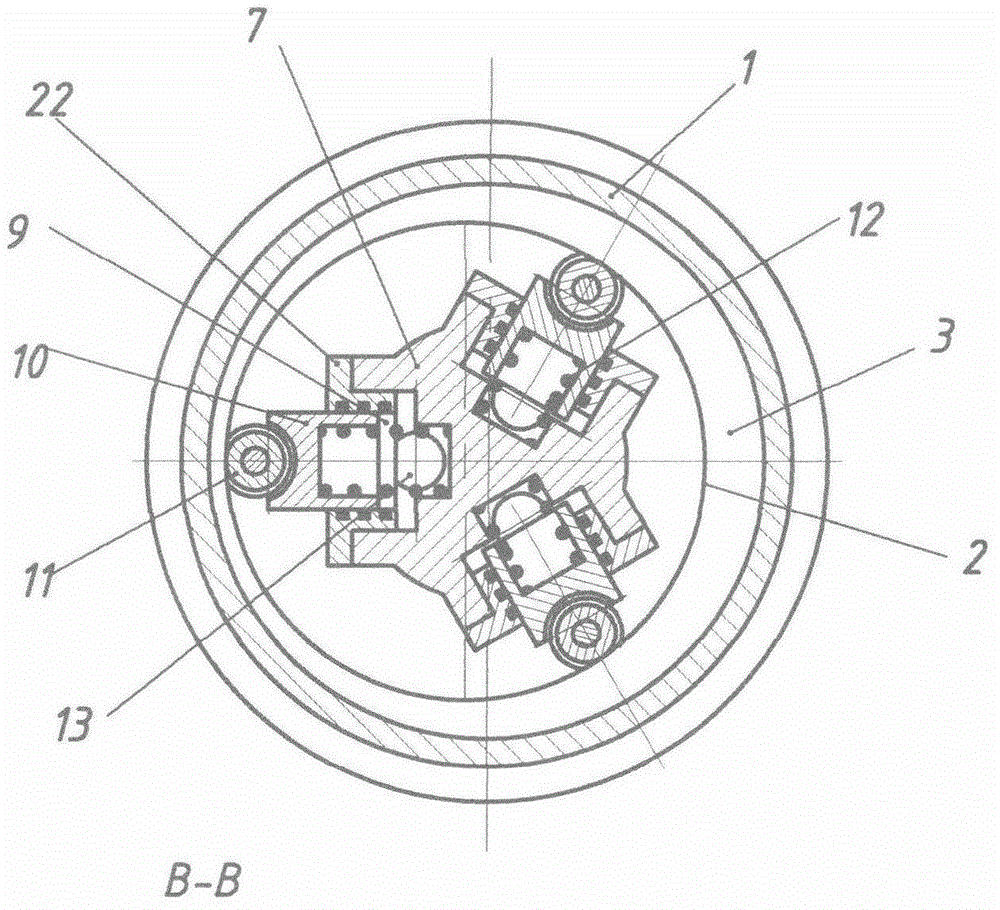

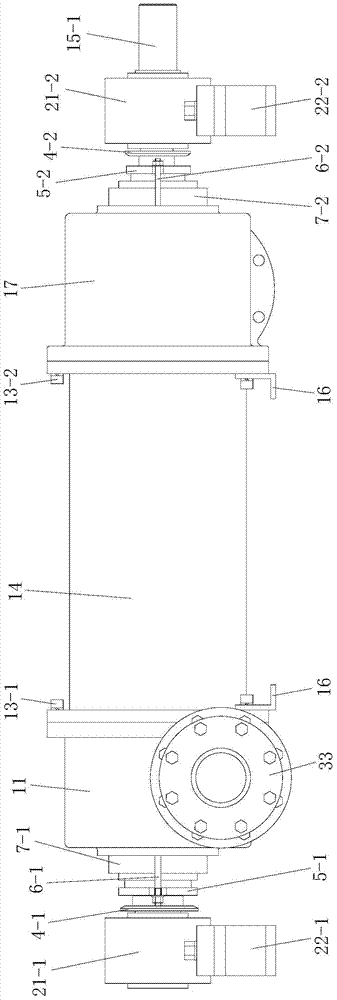

Submarine shallow-layer non-diagenetic natural gas hydrate lifting method and system

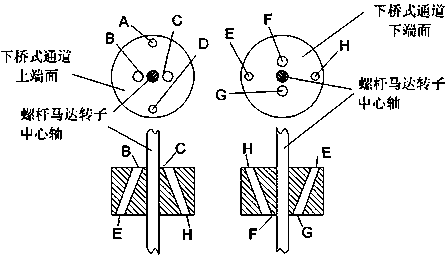

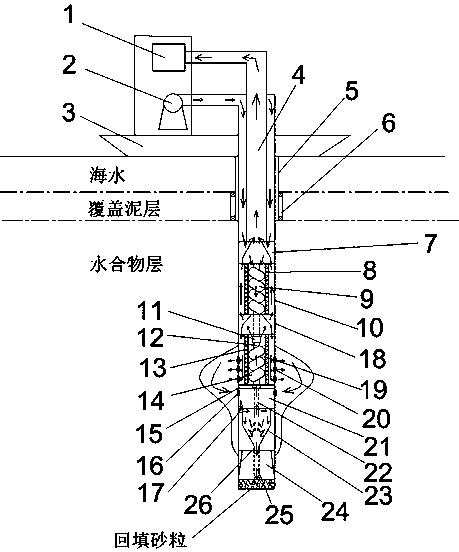

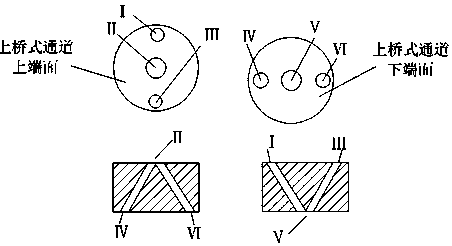

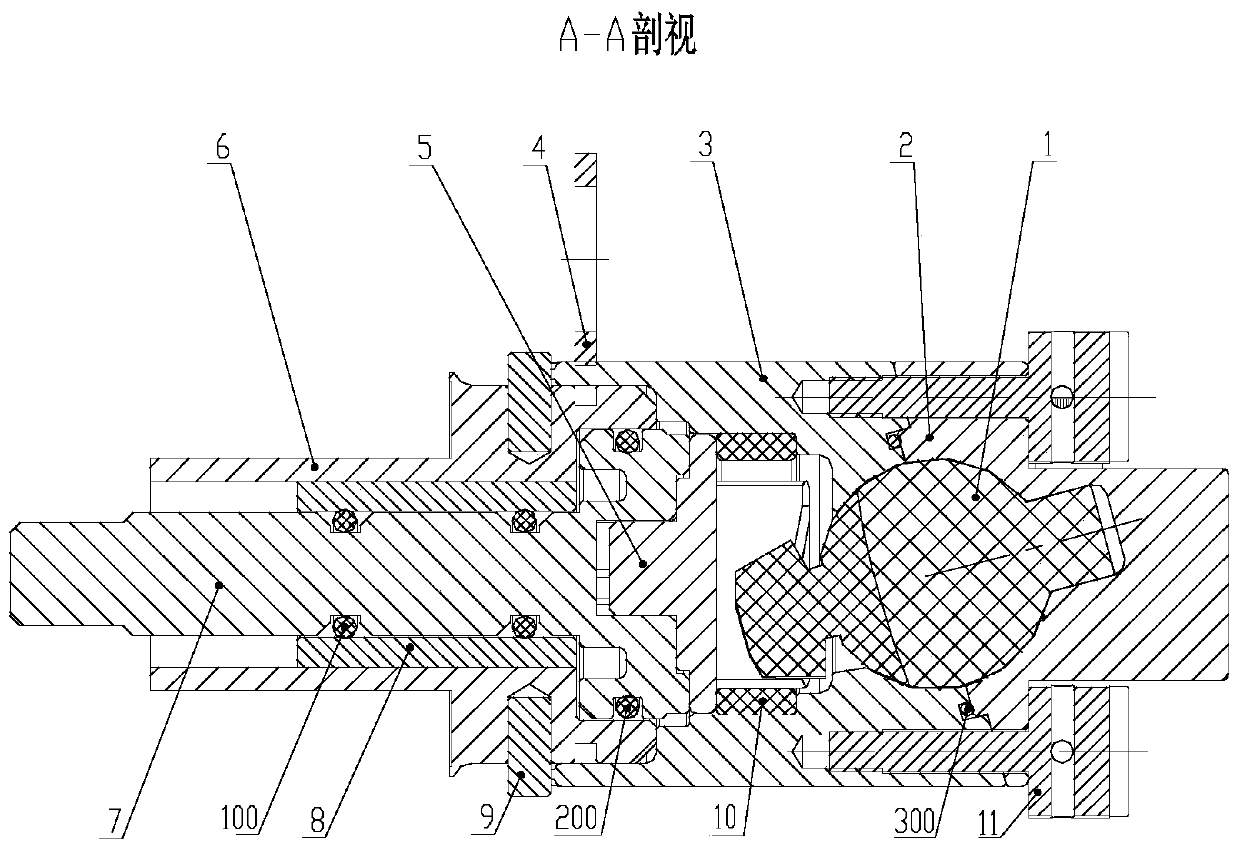

The invention discloses a submarine shallow-layer non-diagenetic natural gas hydrate lifting method and a system, which are used for lifting submarine shallow-layer non-diagenetic natural gas hydrate.A pilot hole is drilled by a drill bit, a pressure pump is started after a predetermined position is reached, high-pressure seawater drives a screw motor to rotate, and torque and rotational speed are transmitted to a screw pump by a cardan shaft; jet breaking is started by nozzles, hydrate is collected, secondarily broken and separated by collecting inlets, a secondary breaking device and a separator, separated sand is backfilled, and hydrate slurry is lifted to a solid control system on an offshore platform by the screw pump to undergo post-treatment. The invention has the following advantages: the whole process is simple, and submarine shallow-layer non-diagenetic hydrate can be effectively broken, separated and lifted; the screw pump device has the characteristics of compact structure, small size, high self-sucking capability, stable operation and long service life; and an upper bridge type passage and a lower bridge type passage ingeniously realize the pumping and lifting of seawater and hydrate slurry and save underground space.

Owner:SOUTHWEST PETROLEUM UNIV

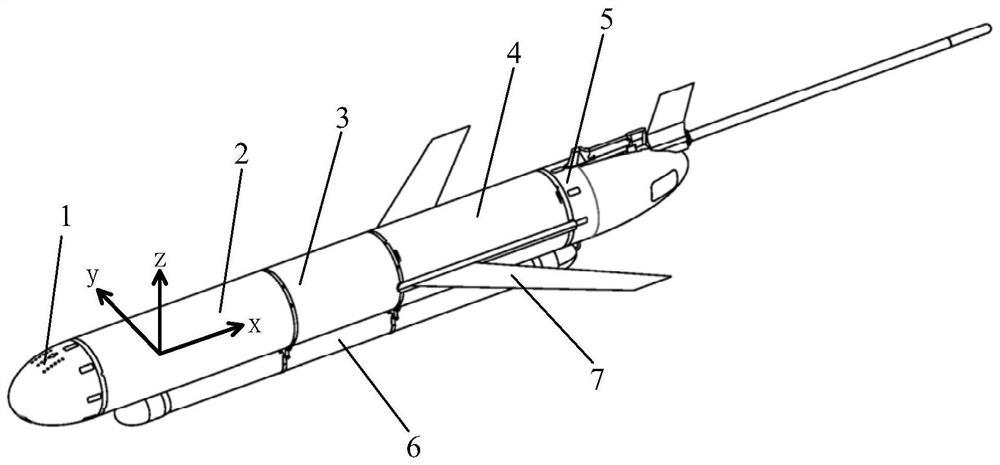

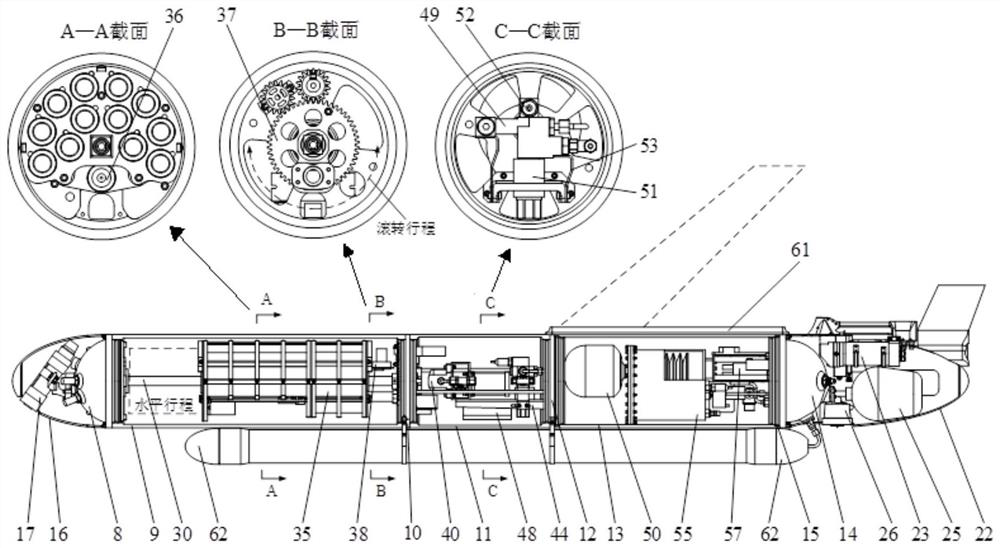

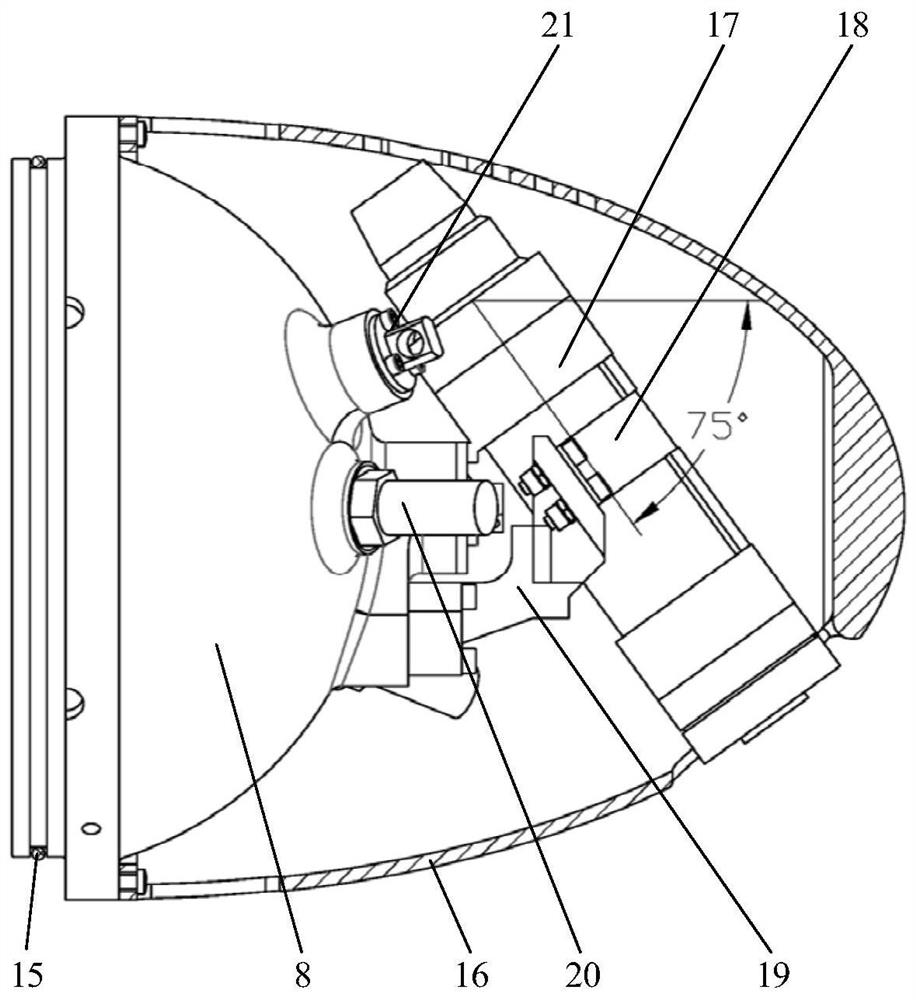

Hybrid power underwater glider using battery electric energy and ocean temperature difference energy

ActiveCN111634396AImprove energy self-sufficiencyImprove battery lifePower plants using propulsion unit combinationsPropulsive elementsElectrical batteryMarine engineering

The invention discloses a hybrid power underwater glider using battery electric energy and ocean temperature difference energy. The hybrid power underwater glider comprises a front immersion cabin section, a front pressure-resistant cabin section, a middle pressure-resistant cabin section, a rear pressure-resistant cabin section, a rear immersion cabin section, heat exchangers and horizontal wings, wherein the cabin sections are fixedly connected in sequence along a cylindrical rotation axis to form a hybrid power underwater glider body part, the heat exchangers are externally hung on a bellypart of the body, the horizontal wings are horizontally arranged on two sides of the rear pressure-resistant cabin section, the hybrid power underwater glider battery pack has two degrees of freedom of translation and rotation, and can be used for adjusting a pitching attitude angle and a course angle of the underwater glider; a hydraulic device in the main machine body and the heat exchangers form a hydraulic oil path, and in the diving preparation stage of the hybrid power underwater glider, an oil return path works, in the diving gliding stage, a solidification oil path works, in the floating conversion stage, the energy release oil way and the oil pumping oil way work, and in the floating gliding stage, the energy storage oil way works, and the buoyancy driving process is completed bycompounding two forms of energy, namely battery electric energy and ocean temperature difference energy.

Owner:TIANJIN UNIV

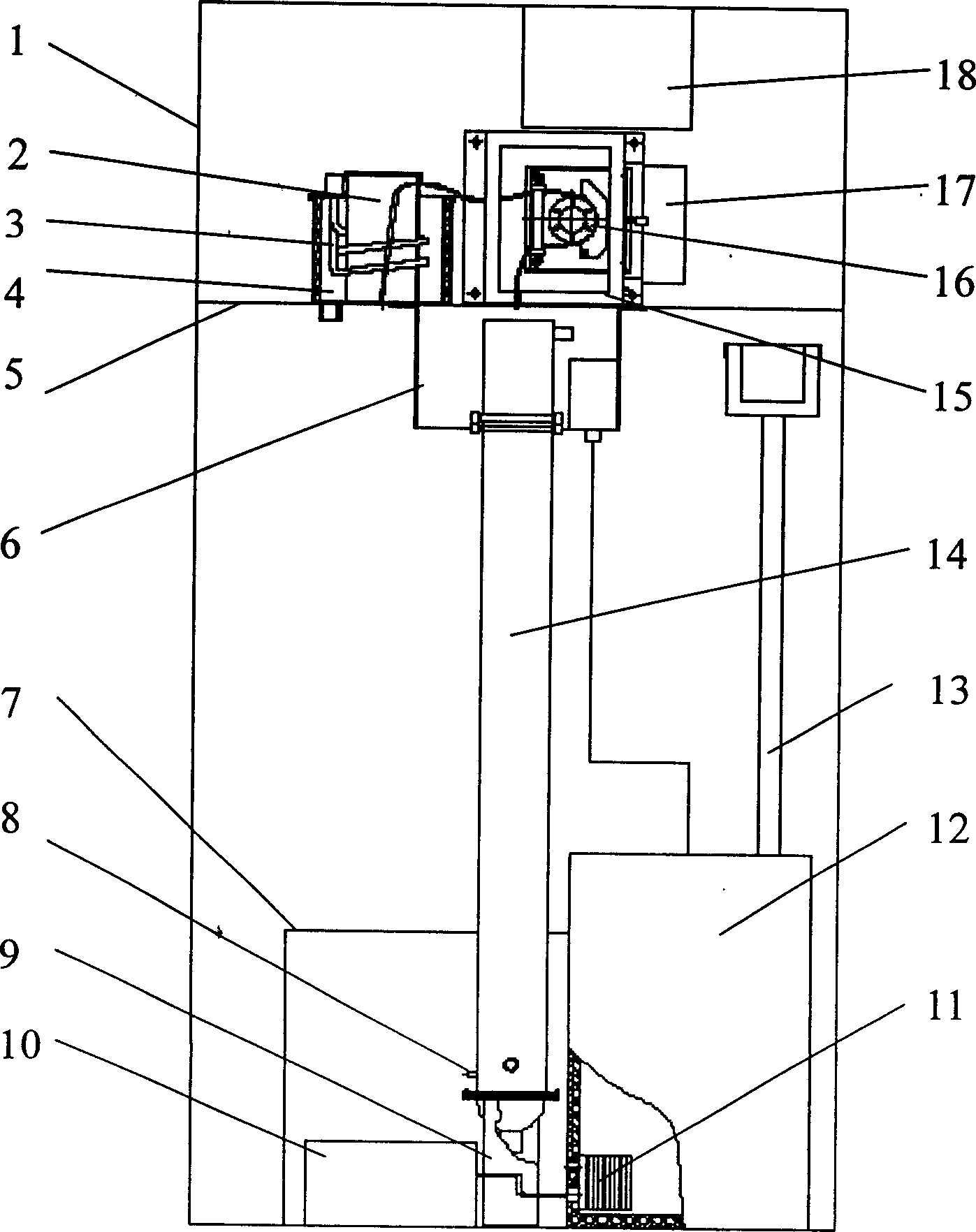

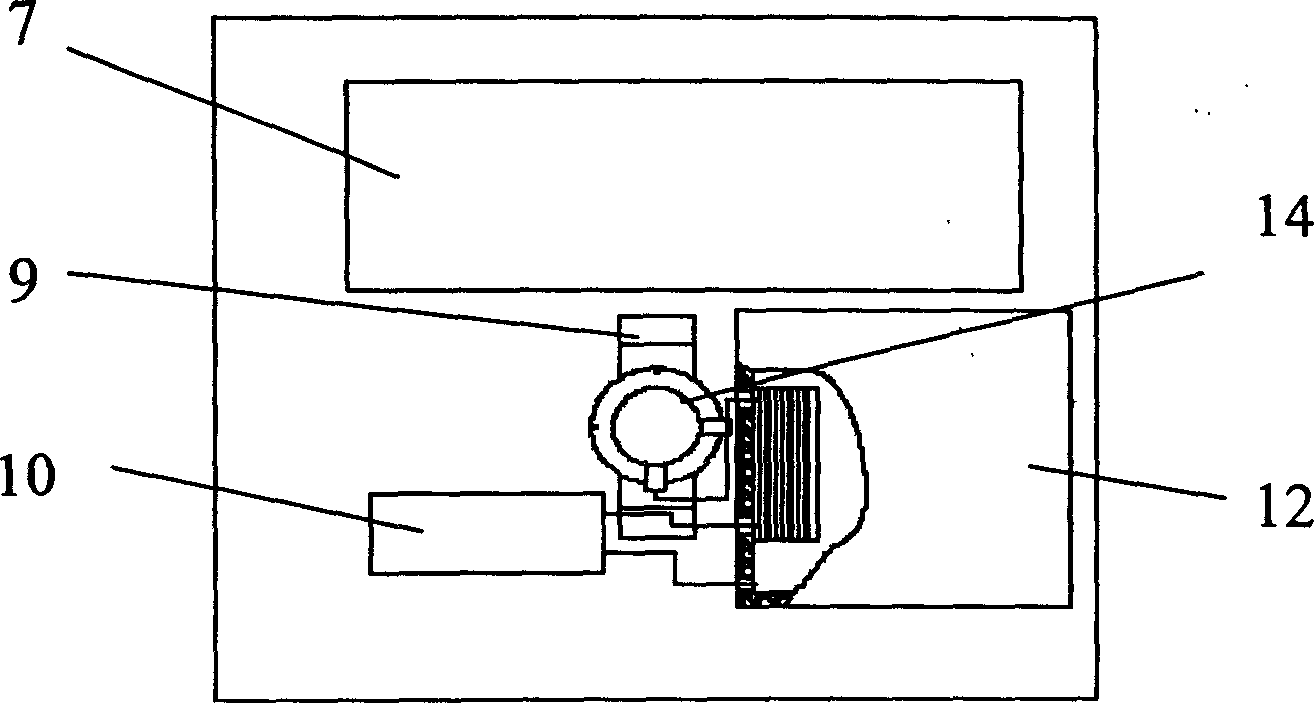

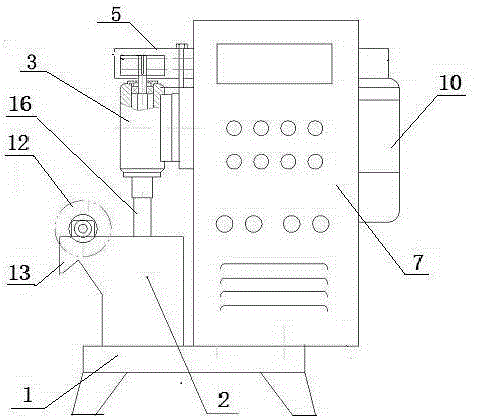

Automatic medicinal dropping pill machine

InactiveCN1775204AChange drip rateEasy to cleanPharmaceutical product form changeSolid materialControl systemBiochemical engineering

The present invention relates to an automatic liquid medicine dripping pills making machine. It includes the following several portions: machine frame with table plate, quantitative pump pills-dripping system, condensate circulation system and micro-control system and its correspondent program. The quantitative pump pills-dripping system fixed on the table plate includes medicine tank component and quantitative pump component which are connected by means of hose, said medicine tank component includes medicine tank and oil tank, the interior of oil tank is equipped with an electro-heating device, and its exterior is equipped with a heat-insulating layer, and the bottom portion of the medicine tank is equipped with a temperature sensor. Besides, said invention also provides the concrete structure of quantitative pump component and table plate, and provides its working principle.

Owner:HEBEI UNIV OF TECH

Injection pump and suction method thereof

InactiveCN102345648AIncrease vacuumStrong vacuumJet pumpsMachines/enginesHigh concentrationSelf-absorption

The invention discloses an injection pump and a suction method thereof. The injection pump comprises a suction pipe, a nozzle, a choke inlet section, a choke, a diffusing pipe and an annular nozzle, wherein the caliber of a discharging hole of an inner cavity of the nozzle is more than that of a feeding hole of the inner cavity of the nozzle, the discharging hole of the inner cavity of the nozzle is sequentially communicated with the choke inlet section, the choke and the diffusing pipe, the caliber of the inlet end of the choke inlet section is more than that of the outlet end of the choke inlet section, the caliber of the outlet end of the diffusing pipe is more than that of the inlet end of the diffusing pipe, an annular air chamber is arranged on the outer side of the nozzle and communicated with an air inlet pipe, a ventilating annular gap is arranged between the inner wall of the annular nozzle and the nozzle, one end of the gap is communicated with the inlet end of the choke inlet section, and the other end of the gap is communicated with the air chamber. The invention has the advantages that the injection pump has high vacuum degree by completely using an air medium as power, strong self-absorption capacity, high suction stroke, no blockage and low cost, is suitable in environments with high temperature, high pressure, deep water, strong radiation, strong corrosion and the like, and can be used for sucking fluid with higher concentration and larger-particle solid materials.

Owner:芜湖天远生物科技有限公司

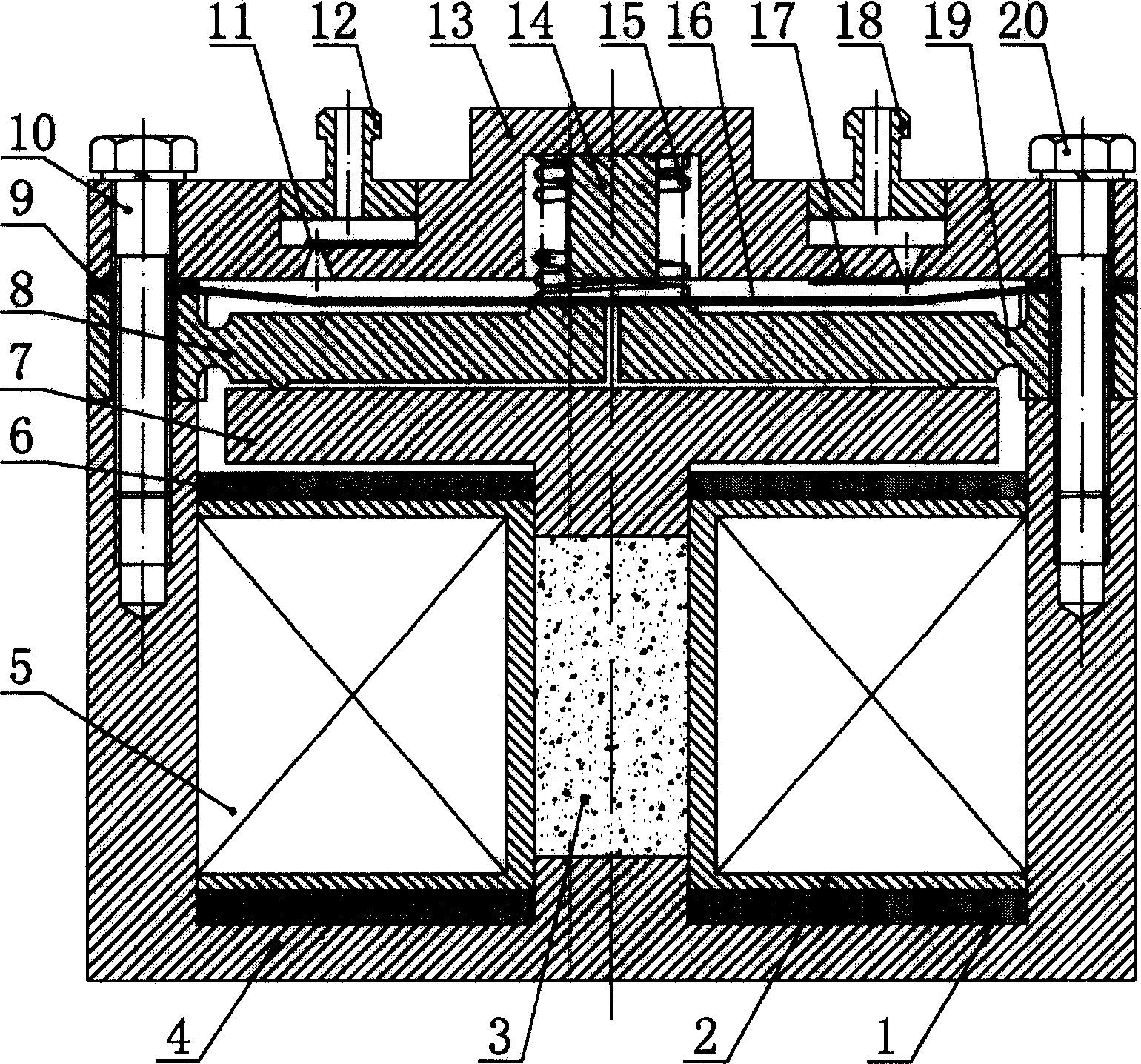

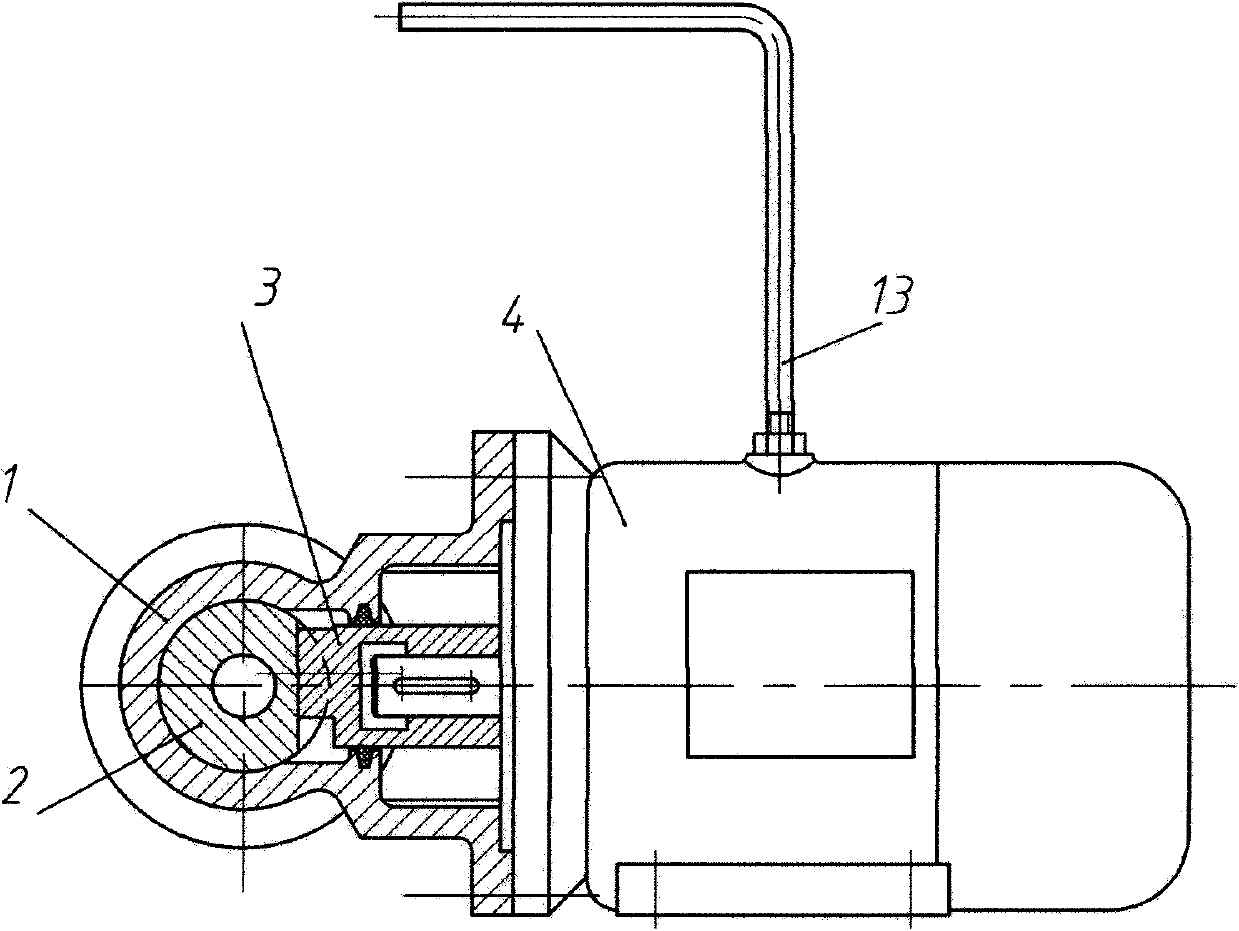

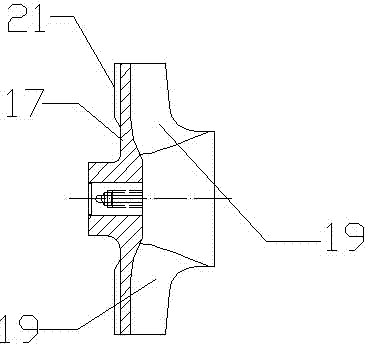

Over-magnetostriction rod drive membrane pump

InactiveCN1908431ANo impactReduce noiseFlexible member pumpsPositive-displacement liquid enginesLow voltageInlet valve

The invention relates to a film micro pump driven by ultra magnetic deformation rod, wherein one flexible film (16) is mounted between the pump (4) and the pump cover (13); the flexible film (16) and the pump cover (13) form sealing working chamber; inside the chamber, the left-displacement amplifier (8), the right-displacement amplifier (19), the top disc (7), the upper permanent magnet (6), the coil skeleton (2) coiled with driving winding (5), and the lower permanent magnet (1) are arranged from up to down; the through hole at the middle of skeleton (2) is mounted with ultra magnetic deformation rod; the spring (15) is mounted between the pump cover (13) and flexible film (16) to form pre-compressor with the pump cover (13); the pump cover (13) is mounted with water inlet tube (18) and water outlet tube (12), to connect the working chamber and outer space via inlet valve (17) and outlet valve (11). The invention can be used in the condition that demands high power and low-voltage driving.

Owner:卢全国

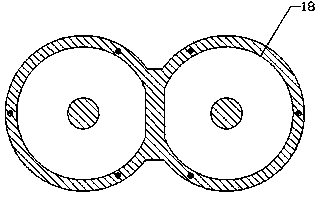

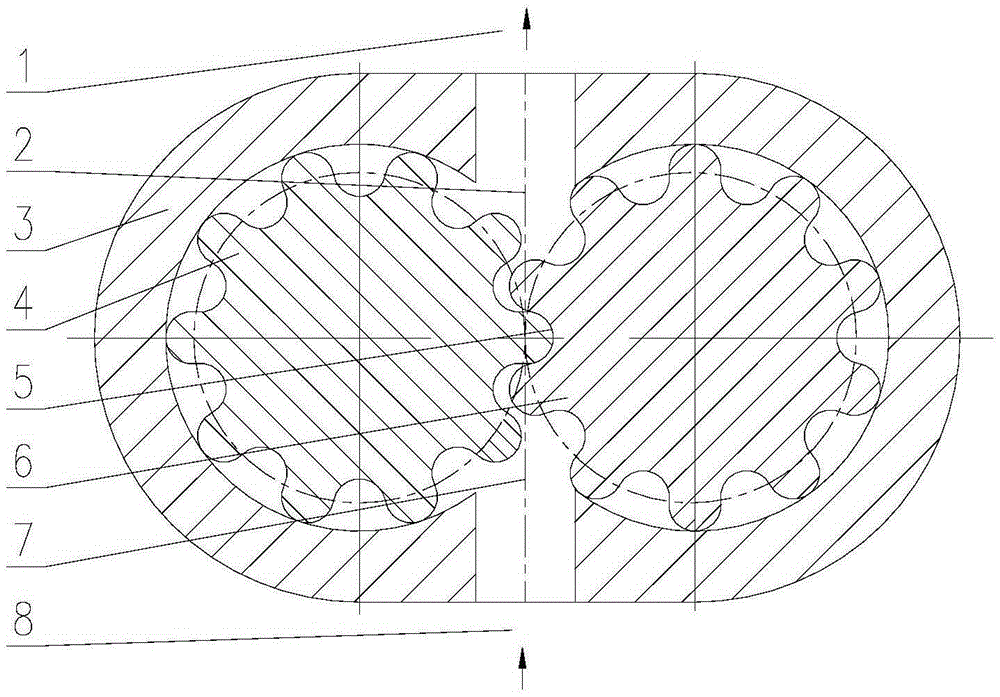

Triangular rotor hydraulic pump

InactiveCN1851271AIncrease contactGood sealingRotary piston pumpsRotary piston liquid enginesIsoetes triquetraHydraulic pump

The invention relates to triangle rotor hydraulic pump. It includes stator and rotor. The stator is set oil inlet and outlet. They are respectively connected to oil-in and oil-out grooves. The inner cavity of the stator is formed '8'shape. The rotor is formed equilateral triangle. Thus its three angles can keep good touch with the stator inner cavity while turning. It has good leakproofness, and little noise. And it has better efficiency because of six times oil extraction and pressing per rotation for rotor.

Owner:SHAANXI UNIV OF SCI & TECH

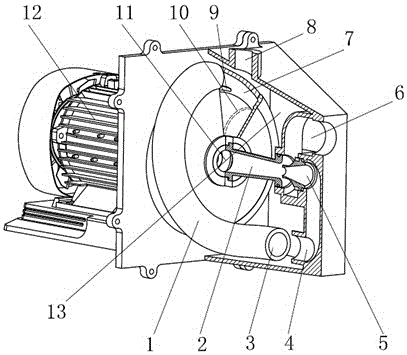

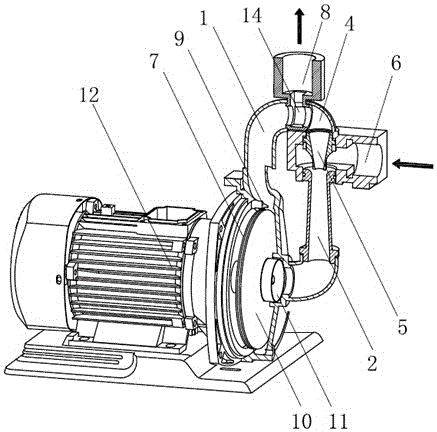

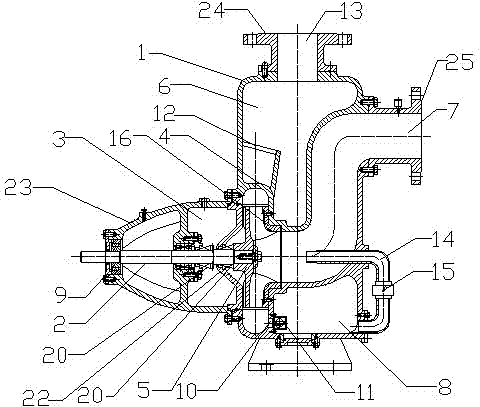

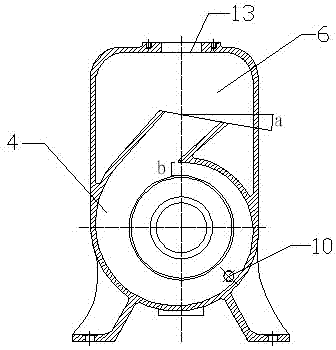

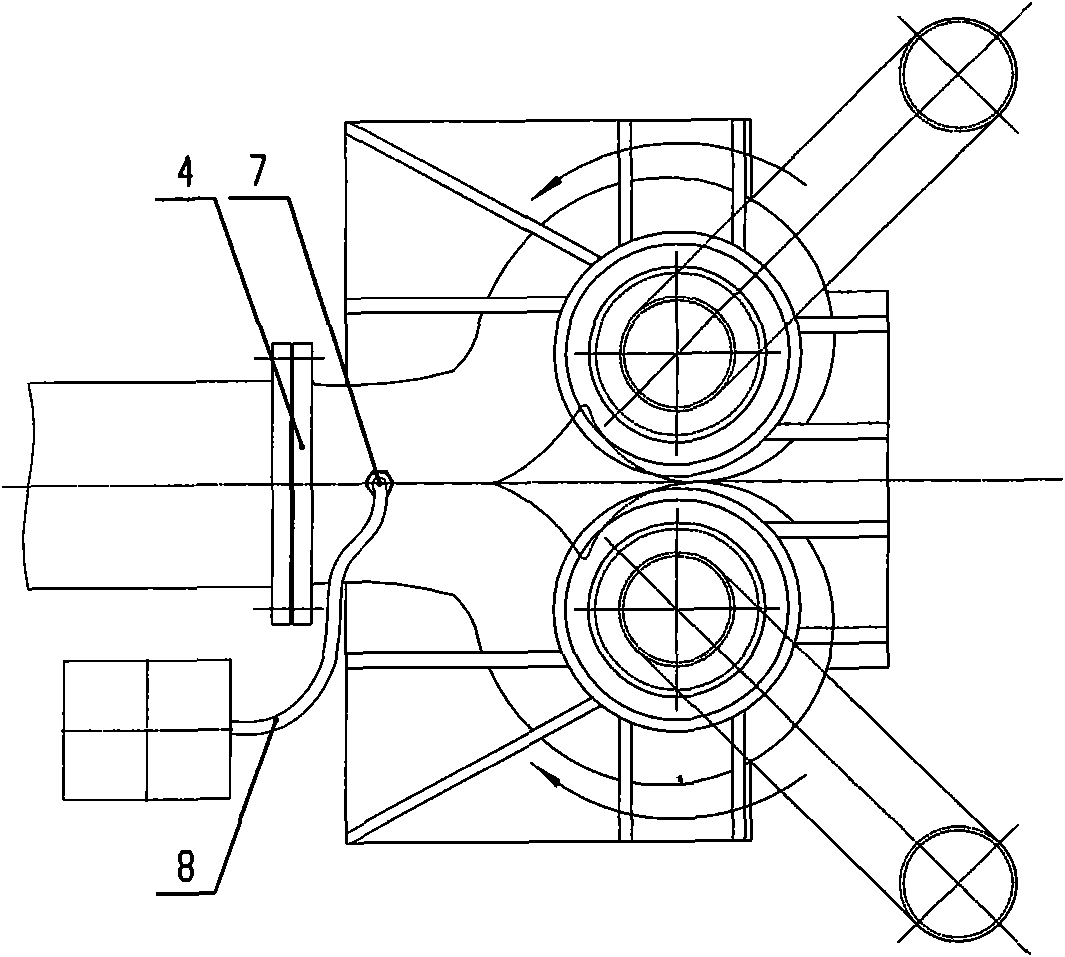

Low-noise self-priming combined pump

ActiveCN106224249AReserve large trafficKeep high headPump componentsPriming pumpLow noiseWorking fluid

The invention discloses a low-noise self-priming combined pump. According to the low-noise self-priming combined pump, diffusion guide vanes and a guide disc of a traditional self-priming jet pump are removed, a single-baffle-tongue single-outlet centrifugal vortex chamber or a multi-baffle-tongue multi-outlet centrifugal vortex chamber which is higher in hydraulic performance and efficiency is adopted, a single entry type runner is designed, centrifuged and accelerated fluid is reasonably guided into a distribution pumping chamber or a distribution tee joint, scraping among the guide vanes, the guide disc and a centrifugal impeller and strong impact of the high-speed fluid to the guide vanes and the guide disc are eliminated essentially, transitional flowing between the centrifugal vortex chamber and the distribution pumping chamber or the distribution tee joint is more smooth, and the flowing losses and flowing noise are lower. Through the reasonable arrangement of the single entry type runner, continuous supply of the working fluid at the inlet section of a spray nozzle can be guaranteed, so that negative pressure is maintained, and strong self-priming capacity is obtained. The traditional large-sized distribution pumping chamber can be replaced with the distribution tee joint, and thus the structure is more compact.

Owner:ZHEJIANG SINCONTROL PUMP IND

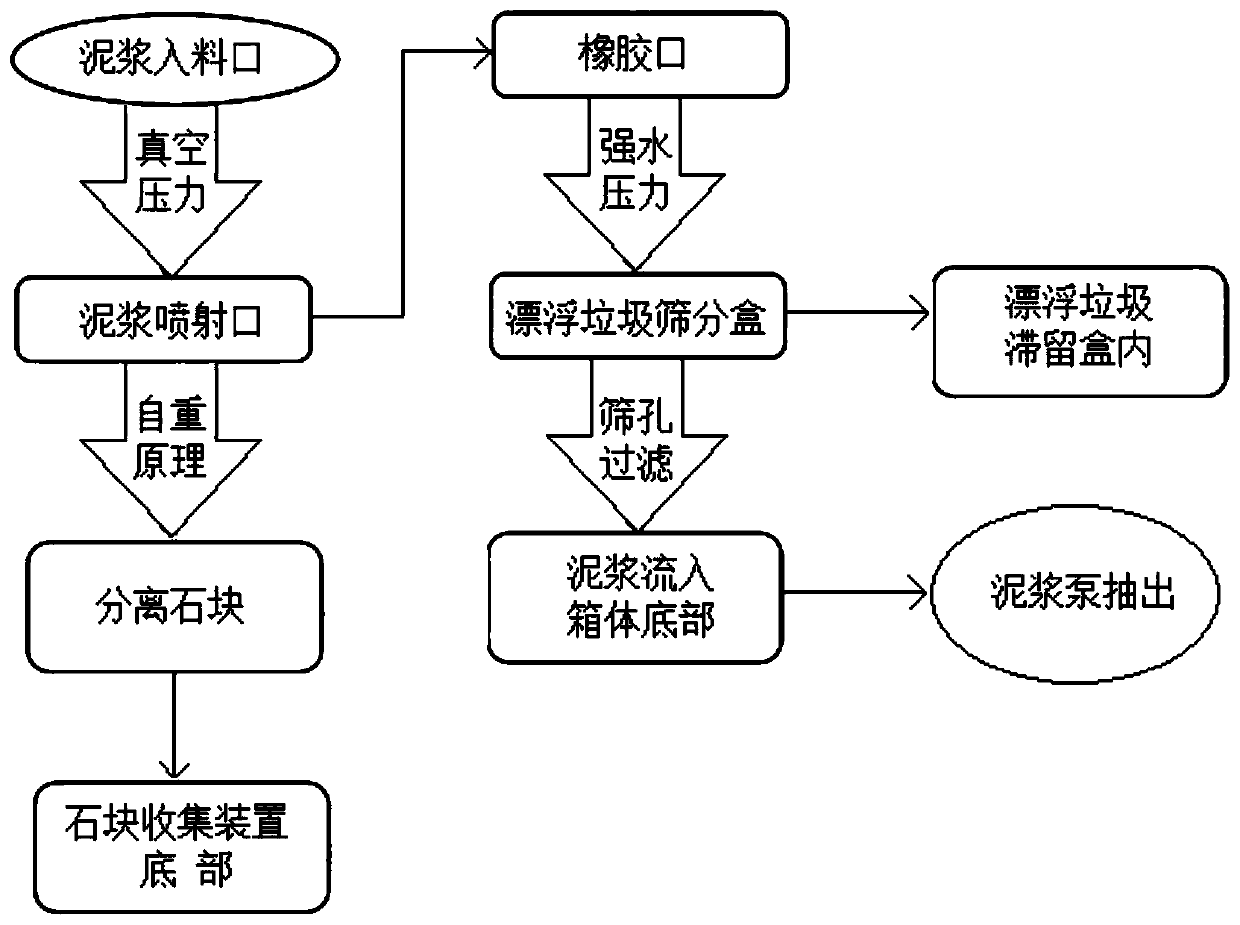

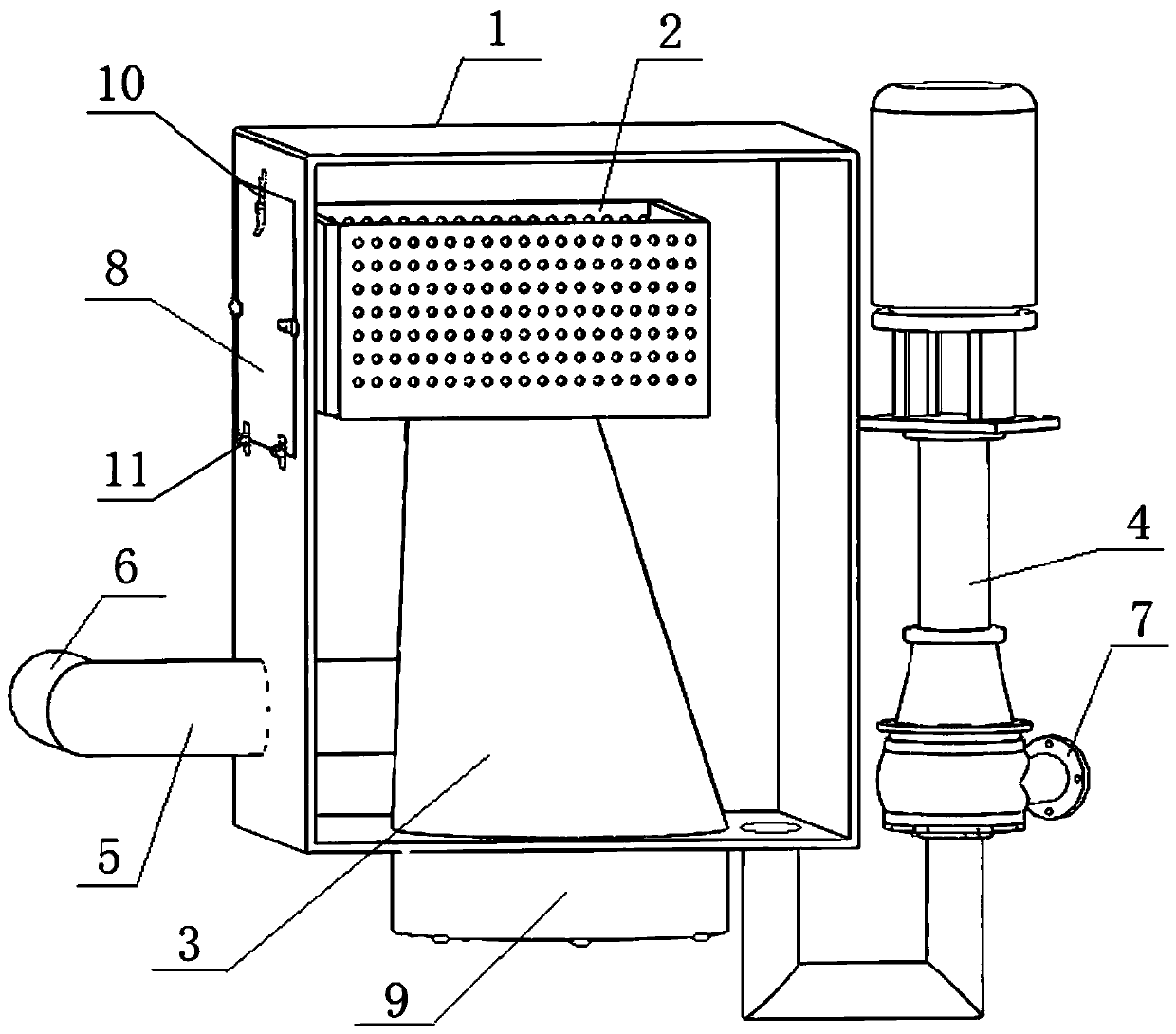

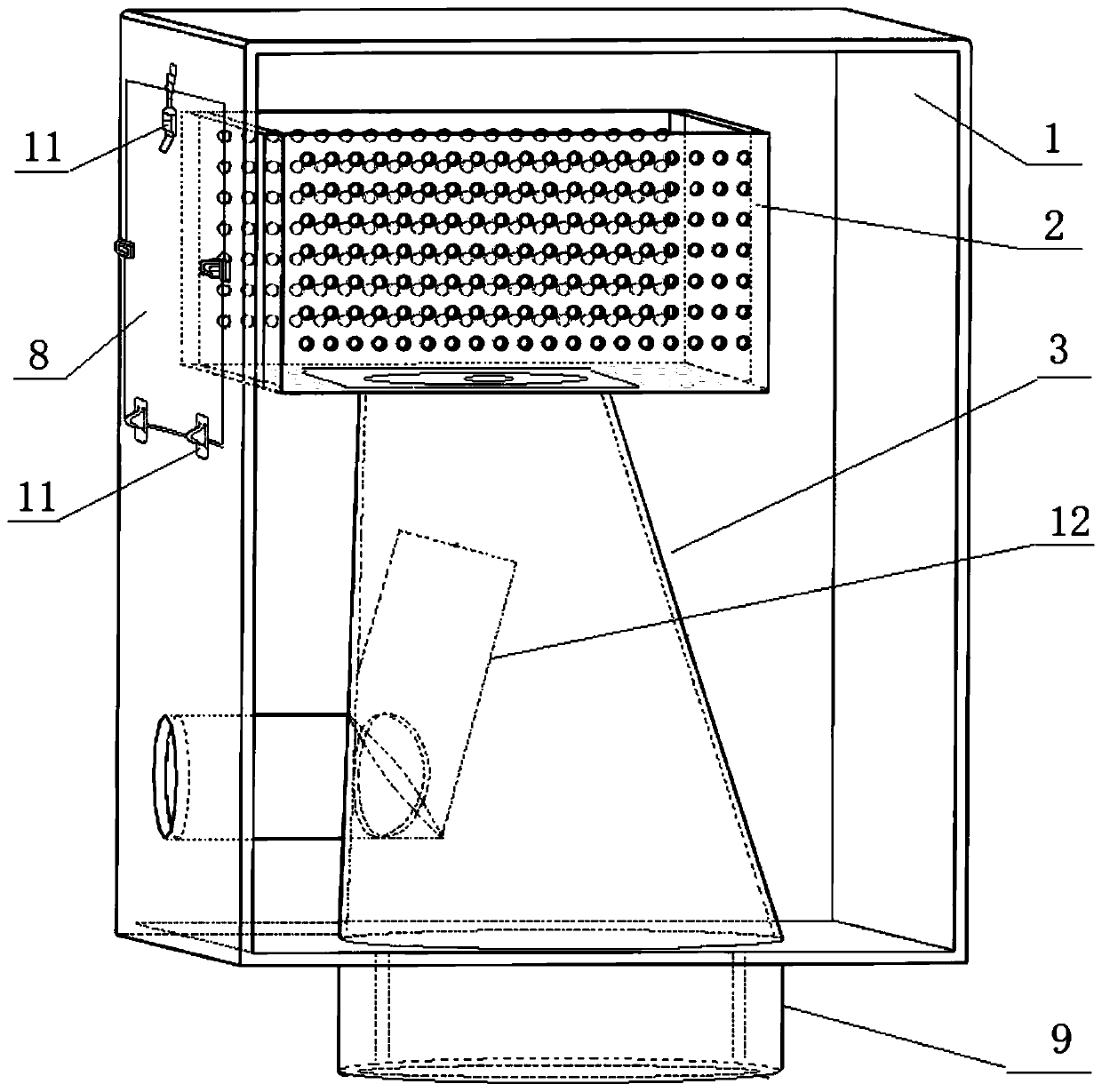

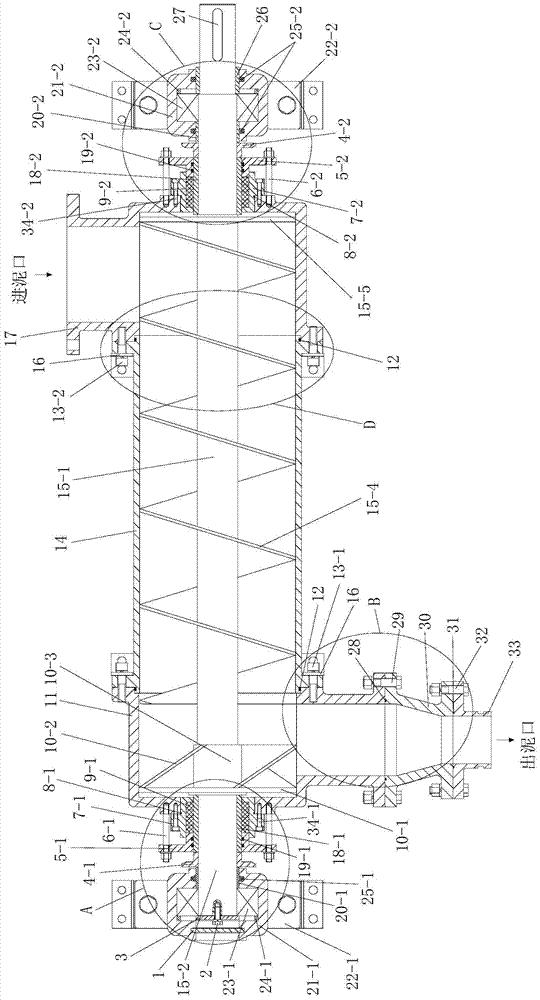

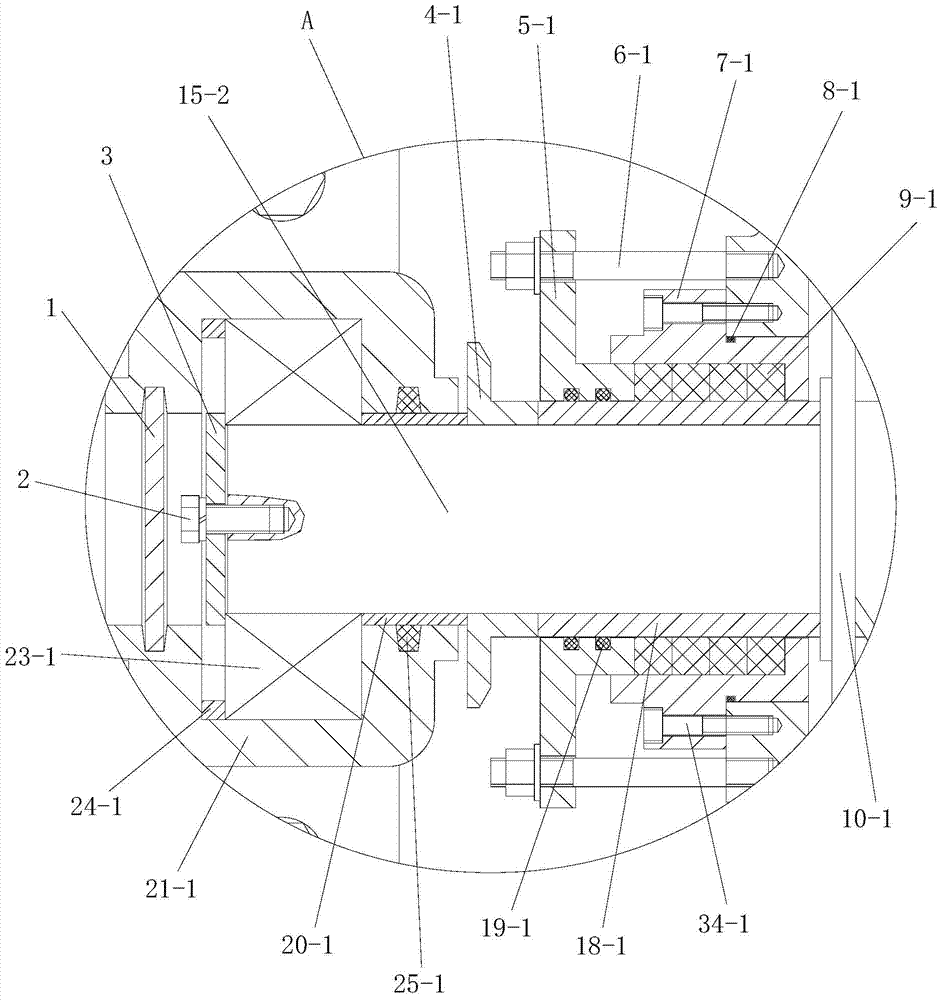

River channel dredging, screening and mud-cleaning method and equipment

PendingCN110512674AAddress diversityAddress mechanical propertiesMechanical machines/dredgersEngineeringMud pump

The invention provides a river channel dredging, screening and mud-cleaning method and equipment. A combined lifting structure operating under action of negative pressure is adopted, stone with a large density and floating rubbish with a small density are screened out by means of dead load from rubbish mixed with mud and are respectively collected. A mud pump (4) is installed on one side of a boxbody (1). The lower portion of the other side of the box body (1) is provided with a mud pipe (5). The inner end of the mud pipe (5) communicates with a stone collecting device (3) vertically installed in the box body (1) through a mud jet opening (12). A floating rubbish screening box (2) is installed on the top of the stone block collecting (3). The problems that rubbish in small and medium-sized river channels are complicated and diversified, and mechanical operation is difficult are solved. The interception ratio of the stone and the floating rubbish reaches 90% or over. The river channeldredging, screening and mud-cleaning equipment is high in self-suction capacity, stable in conveyance and operation, simple and compact in structure and convenient to assemble, disassemble and maintain. The dredging construction efficiency is significantly improved, labor is liberated, mechanization of dredging of the small and medium-sized river channels is facilitated, and the river channel dredging, screening and mud-cleaning equipment is suitable for use and popularization.

Owner:袁晓宇

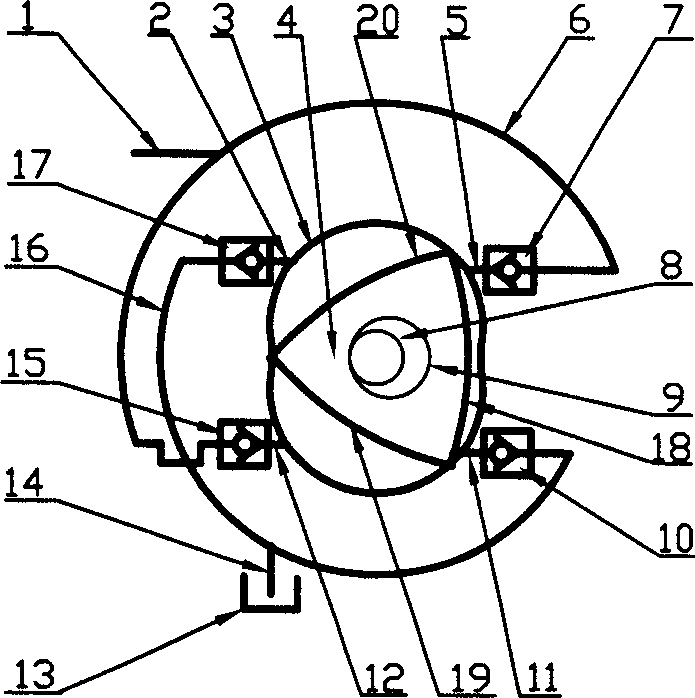

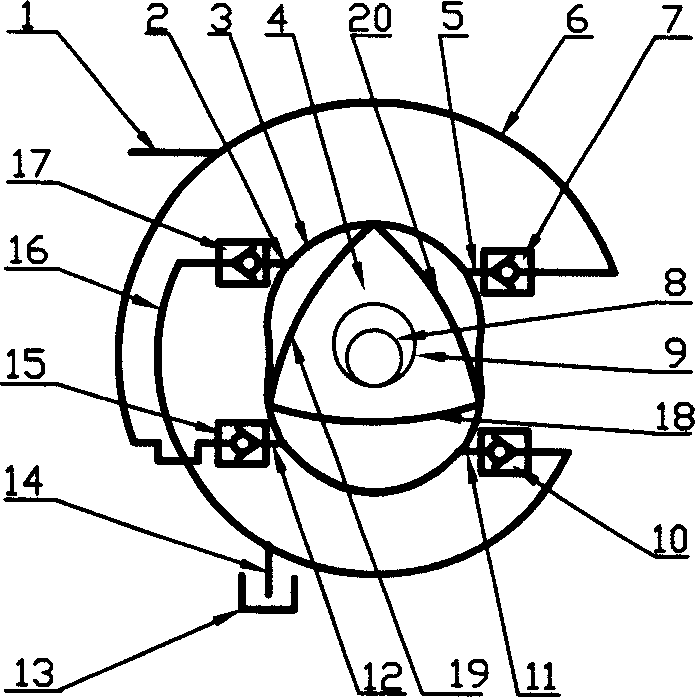

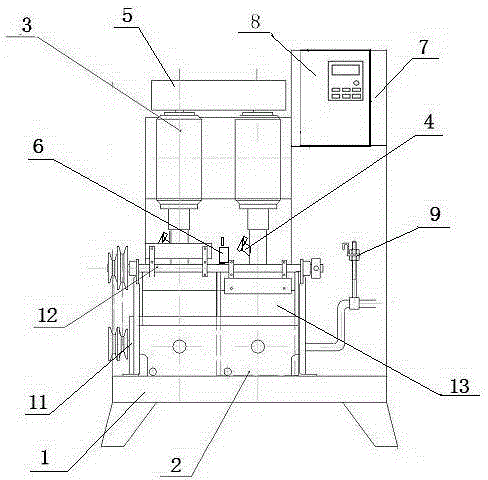

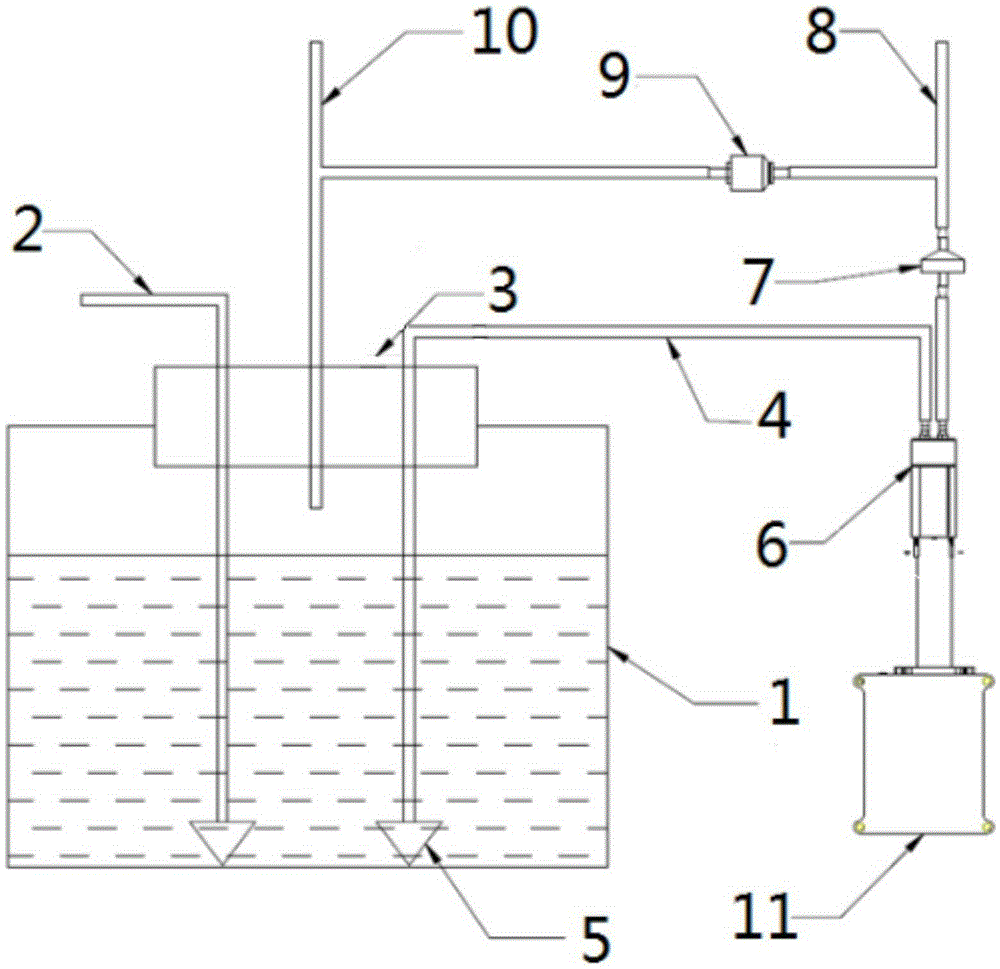

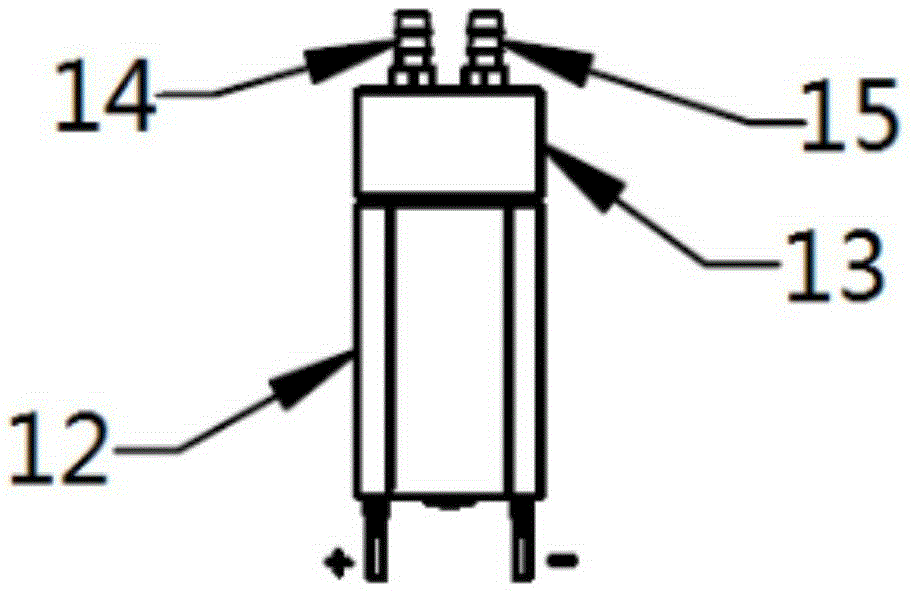

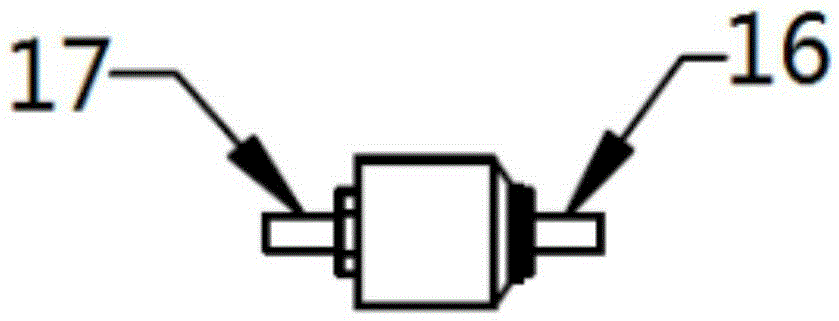

Micro closed-circuit continuous flotation machine

InactiveCN104307643AStrong self-priming abilityInflatable volumeFlotationFrequency changerFoaming agent

The invention provides a micro closed-circuit continuous flotation machine, relating to a flotation machine for a beneficiation experiment. A continuous flotation experiment is carried out by using a small amount of representative sample ores, the result of the experiment can represent the results of small closed-circuit experiments and pilot-scale tests in a single machine of a laboratory, and laboratory or industrial beneficiation indicators can be provided in a shorter period of time. The micro closed-circuit continuous flotation machine mainly comprises a slurry storage barrel, a stirring barrel, a trace reagent feeder rubber hose pump and a flotation machine; the flotation machine comprises a main motor, a flotation tank, a suction regulating valve, a scraping plate motor, a scraping plate, a foam tank, a liquid level regulating tube, a frequency converter, an electric control cabinet, a stirring shaft and an impeller, wherein the slurry storage barrel is connected to the stirring barrel, the stirring barrel is connected to a trace reagent feeder, the rubber hose pump is connected to the flotation tank, the frequency converter is connected to the main motor and controls the main motor, and the liquid level regulating tube is mounted on the flotation tank; the reagent feeder is connected to the stirring barrel so as to supply auxiliary absorption agent foaming agent and regulating agent for flotation; the machine is mainly used for beneficiation laboratories.

Owner:JIANGXI SOC MACHINERY MFG

Handheld flushing pump

InactiveCN103775301AReduce volumeCompact structurePumpsPositive-displacement liquid enginesElectricityStopped work

The invention discloses a handheld flushing pump, mainly comprising a pump body, a piston, an eccentric shaft, a motor, an input check valve and a drainage check valve, wherein the eccentric section of the eccentric shaft is inserted into a groove at the waist part of the piston, and when the motor drives the eccentric shaft to rotate, the piston moves to and fro so as to suck and drain off water. The pump body and the eccentric shaft are both directly mounted on the micro motor, so that handheld flushing pump is compact in structure, light in weight, small in size and convenient to move, and can be used at all sites with civil electricity; according to the character of pumps, the handheld flushing pump belongs to displacement pumps, has higher self-suction capacity, can perform flushing by only inserting a suction pipe into a water bucket, does not need to stop working even water in the water bucket is used up, and still can suck water for flushing by filling water into the water bucket, thus providing the capability of self-restoring after running out of water; furthermore, the pump has very high efficiency which generally can reach more than 70%. The handheld flushing pump has the advantages of compact structure, light weight, convenience to move, strong self-suction capacity, self-restoring after running out of water, and utilization of civil electricity.

Owner:余文凌

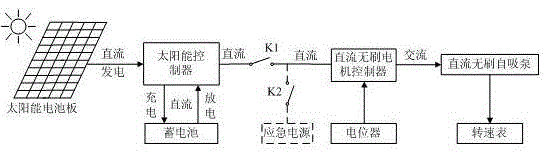

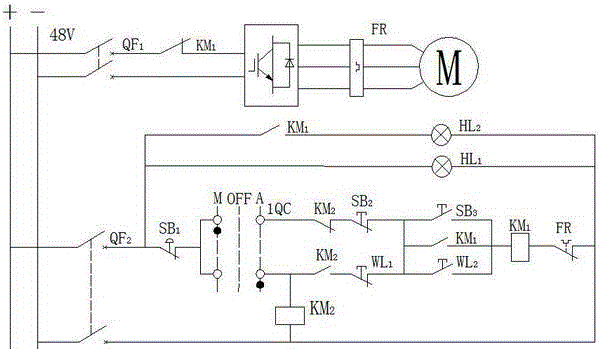

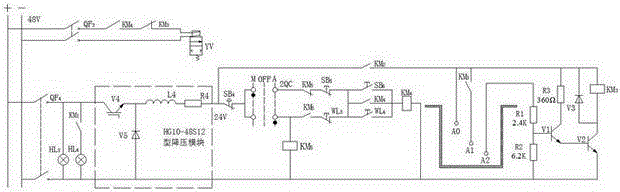

Water taking and pressurizing control system of solar sprinkler

InactiveCN104381098AEasy to operateOperational securityWatering devicesRenewable energy machinesBrushless motorsWireless control

The invention discloses a water taking and pressurizing control system of a solar sprinkler. The system comprises a solar photovoltaic power generating module, a direct-current brushless motor control circuit and a water source constant water level automatic water replenishing control circuit. The solar photovoltaic power generating module respectively powers the direct-current brushless motor control circuit and the water source constant water level automatic water replenishing control circuit. The direct-current brushless motor control circuit controls the power supply of a water pump. The control system has the advantages that the system uses clean solar energy to supply power, wireless control is used, convenient operation is achieved, remote on and off control of units is achieved, remote transmission indication and alarming of a system fault state unit can be achieved, a high-performance brushless direct-current motor is used to drive a self-priming pump, high system reliability and low energy loss are achieved, the water pump is started in a convenient and labor saving manner, automatic irrigation can be achieved conveniently, universality and flexibility of sprinkling irrigation units are increased effectively, and the irrigation requirements of farms, pastures, crops, economical crops and forage grass are satisfied.

Owner:NORTHWEST A & F UNIV

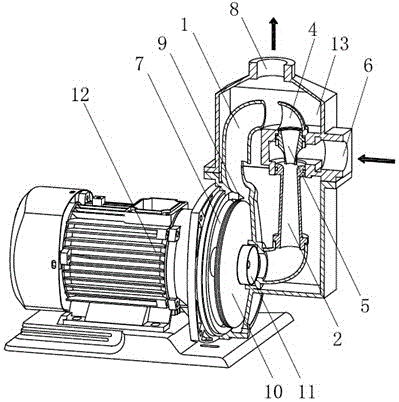

Jet self-sucking centrifugal water pump

ActiveCN102322424ACombination structure is simple and feasibleEasy to manufacturePriming pumpNon-positive displacement fluid enginesPump chamberEngineering

The invention discloses a jet self-sucking centrifugal water pump. The pump comprises a pump body, a nozzle, a diffuser, an impeller, an inner pump cover, a guide blade, an outer pump cover, a pump shaft, a bracket and a motor, wherein the motor is directly connected with the bracket; the pump shaft is coaxially connected with the motor; the impeller is arranged at the end of the pump shaft; two sides of the impeller are provided with a centrifugal pump chamber structure through matching of the outer pump cover, the guide blade and the inner pump cover; the opened end of the pump body is connected with the outer pump cover in a sealed mode, so that a centrifugal pump chamber is accommodated in the pump body; axial through holes are uniformly distributed on the end face of the inner pump cover and communicated with a water outlet cavity of the pump body; the diffuser is connected between the inner pump cover and a clapboard in the sealed mode; the end of the diffuser, which is positioned at one end of a water sucking port, is coaxially provided with the nozzle to form a jet pump structure; and the outlet of the diffuser is positioned at the inlet of the impeller. A jet pump and a centrifugal pump are integrated to achieve performance complementation; the jet pump helps the centrifugal pump to self-suck, the self-sucking process is short, and self-sucking capability is high; andthe pump has an integrated structure and is not required to be additionally provided with a self-sucking device, so that matching cost is saved, and the pump is particularly suitable to be used as a marine pump.

Owner:JIANGSU WANFENG MARINE EQUIP MFG

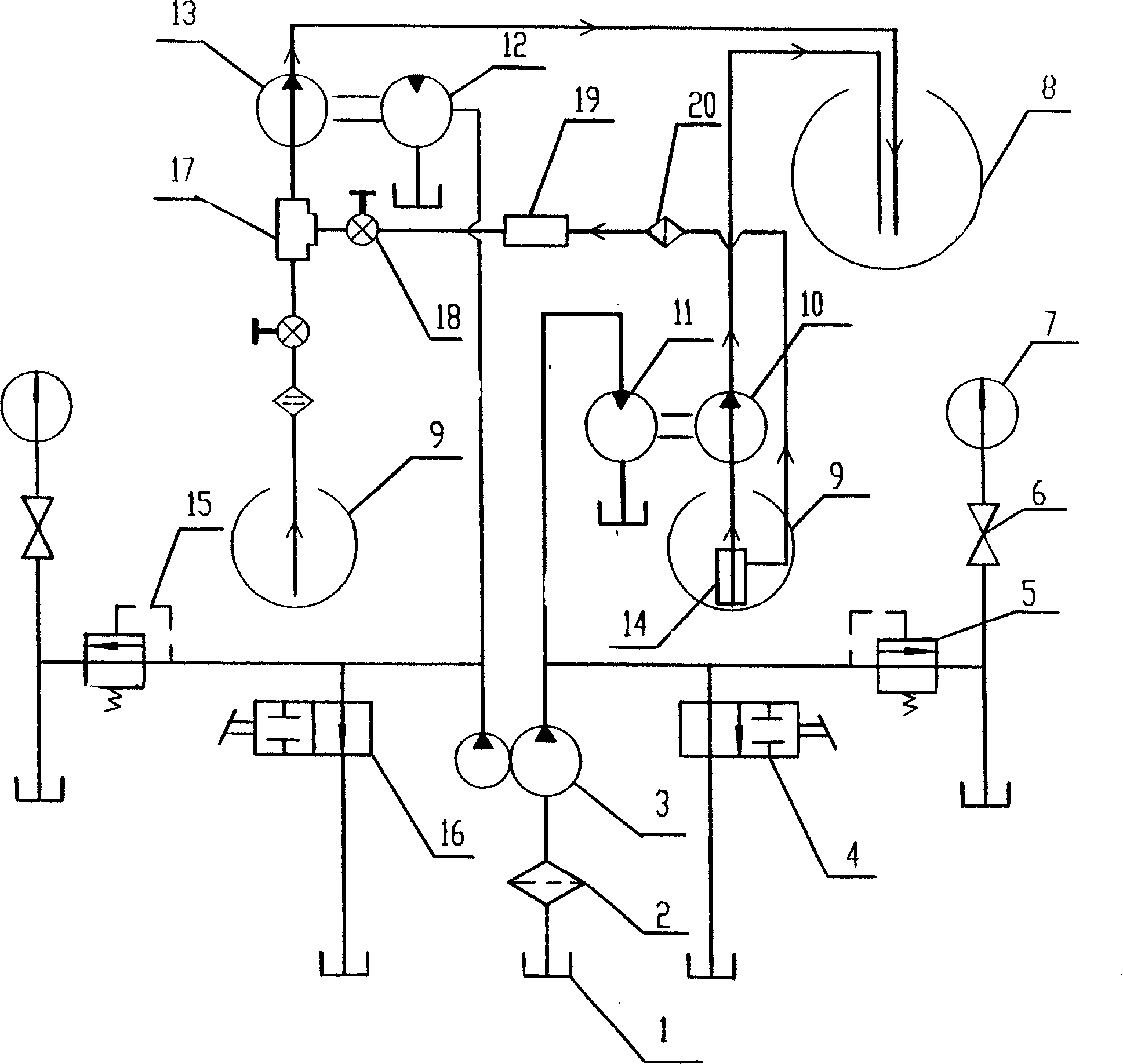

Unloading and cleaning system for hydraulic unloading imersion pump oil filling riser

InactiveCN1613748ANo air resistance, cavitation phenomenonImprove oil unloading speedLiquid flow controllersLiquid transferring devicesFuel tankAir temperature

An oil unloading and emptying system for the hydraulic dumping oil tank is composed of pitching tube module, submerged oil pump module, hydraulic station and tank-emptying system. Said hydraulic station has a hydraulic power output unit consisting of antiexplosion motor and duplex pump in oil tank. Said submerged oil pump module consists of submerged oil pump, fork pipe, plunger motor, said hydraulic station and pressure delivering pipeline. Sadi tank-emptying system comprises said duplex pump, emptying pump, fork pipe, three-way and valves.

Owner:株洲市自强油气储运设备制造有限公司

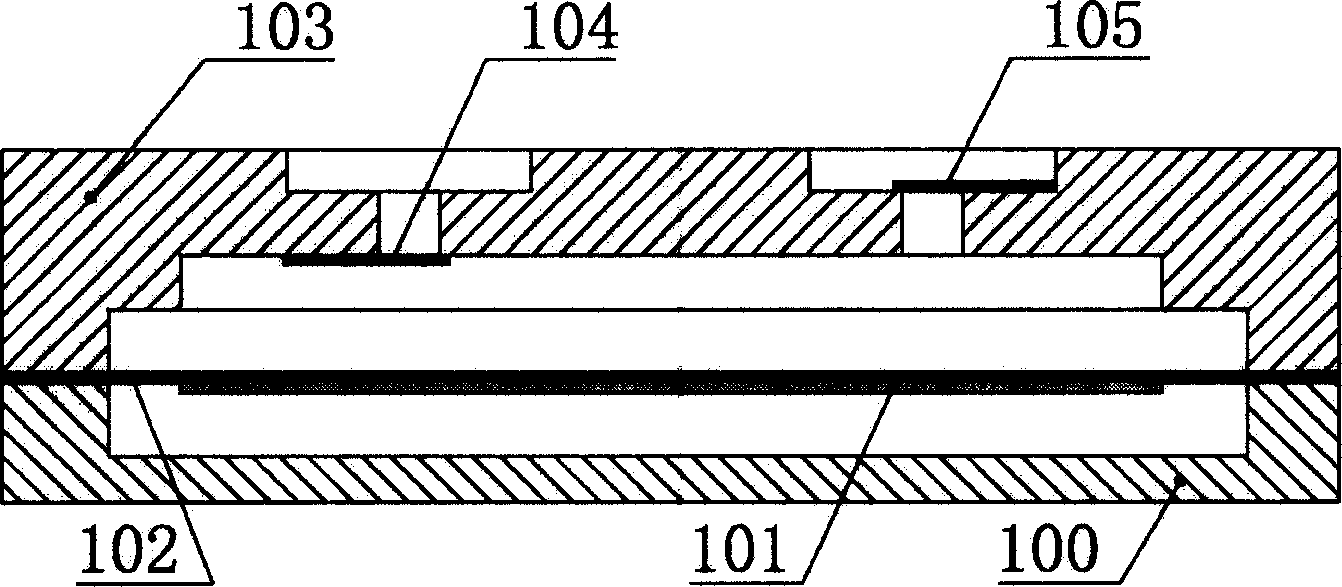

Magnetostriction type dual-cavity membrane type micropump

ActiveCN103629090AStrong elastic deformation recovery abilityRealize mixed conveyingFlexible member pumpsPositive-displacement liquid enginesFluid controlEngineering

The invention discloses a magnetostriction type dual-cavity membrane type micropump, and belongs to the field of micro fluid control. The magnetostriction type dual-cavity membrane type micropump mainly comprises a magnetostriction rod set, a sleeve, a permanent magnet, a coil rack which a coil is wound around, a displacement amplifying mechanism, elastic membranes and a pump case. An upper polarity rod and a lower polarity rod are arranged at corresponding positions inside the sleeve respectively. The sleeve is arranged in a center through hole of the coil rack which the coil is wound around. After a control current flows into the coil, an external magnetic field is changed to cause magnetostriction rods to deform; the displacement amplifying mechanism deforms elastically, wherein a left kind semiellipse elastic deformation amount and a right kind semiellipse elastic deformation amount of the displacement amplifying mechanism are different; the displacement amplifying mechanism extrudes the elastic membrane on a left cavity and the elastic membrane on a right cavity of a pump body respectively through column heads, different deformation amounts of the elastic membranes cause different changes in the volumes of the two airtight cavities, and therefore it can be realized that micro fluids inside the two cavities are conveyed according to a fixed ratio. The magnetostriction type dual-cavity membrane type micropump has the advantages of being small in size, low in flow, capable of being driven at a low voltage, and capable of conveying two fluids in a hybrid mode according to a fixed ratio.

Owner:JIANGSU UNIV

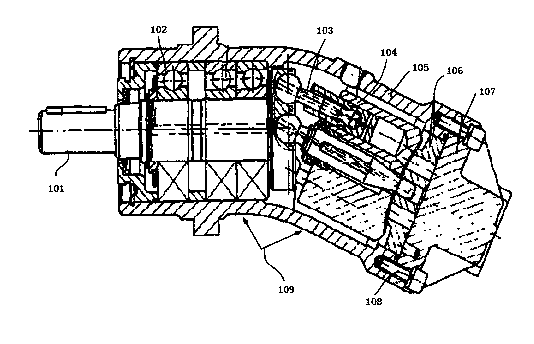

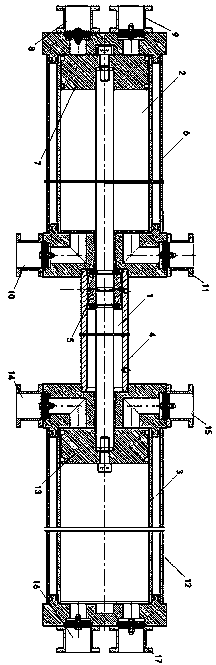

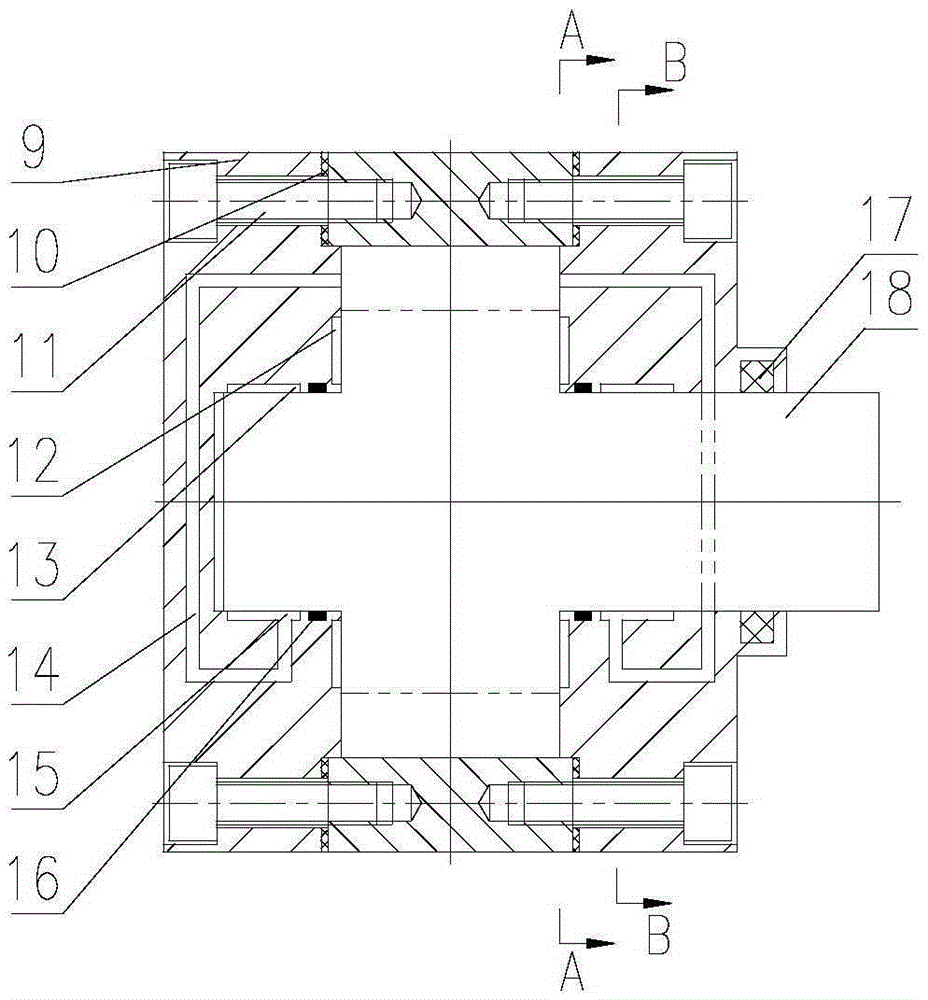

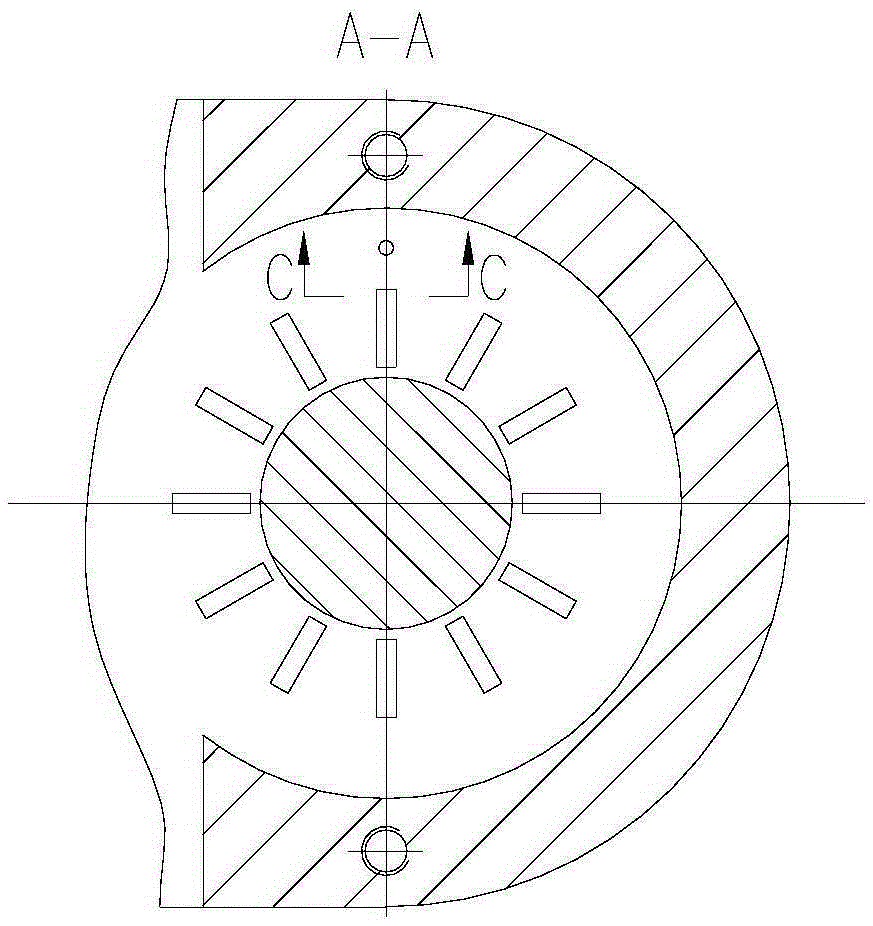

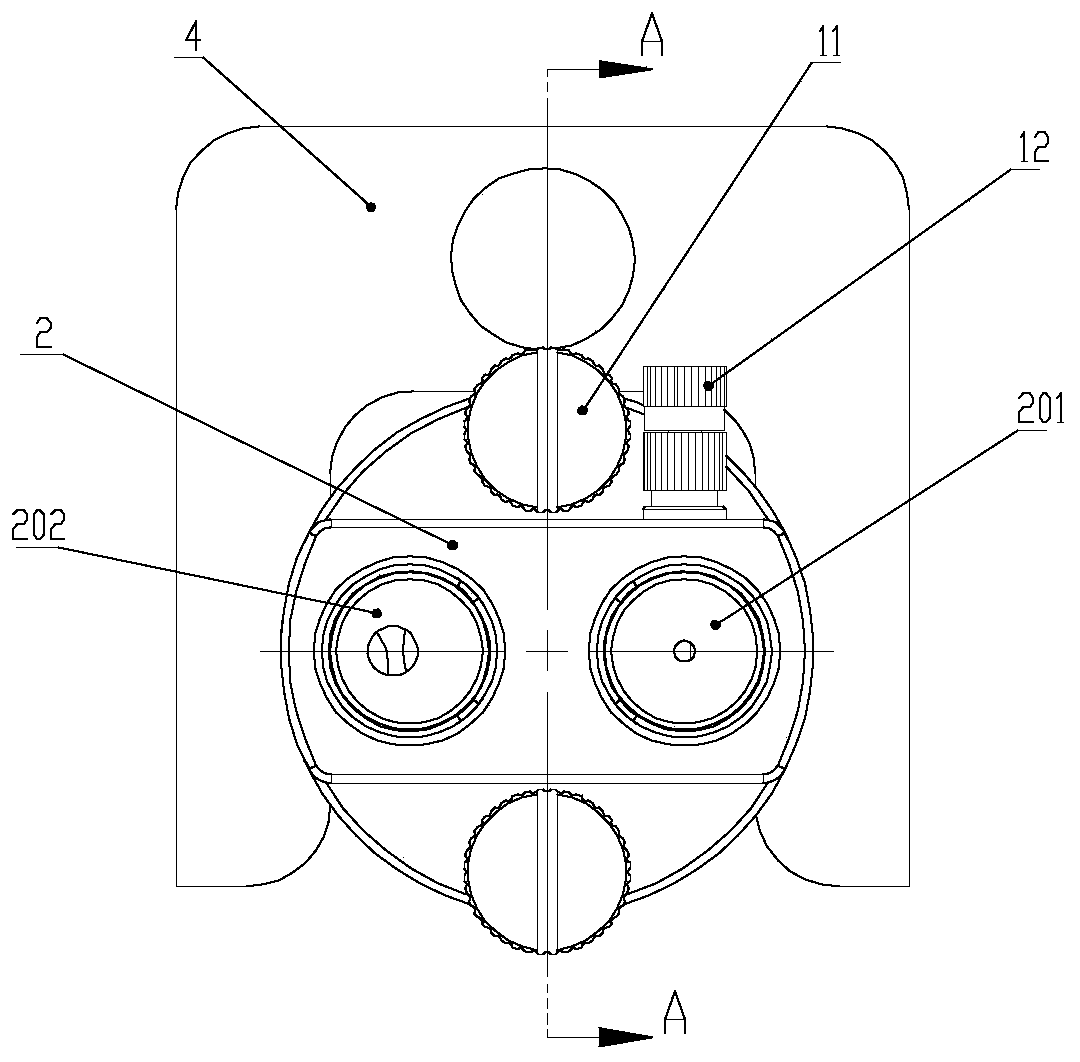

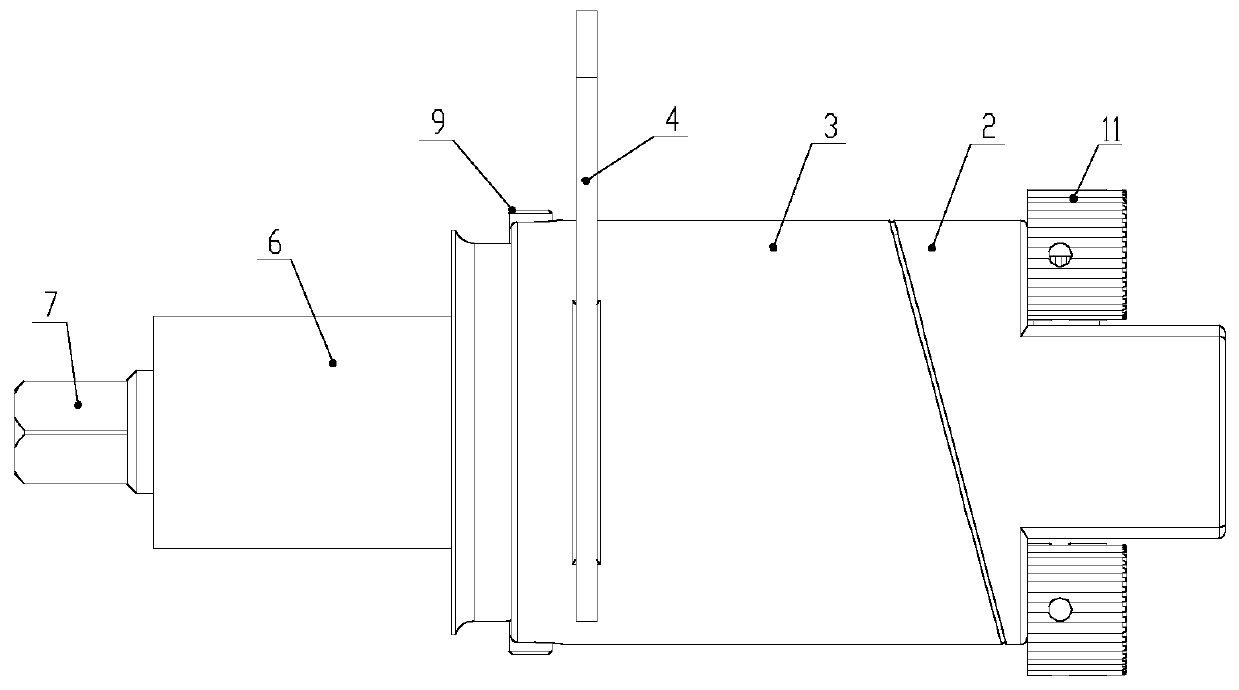

Inclined shaft type plunger pump device

InactiveCN104234959AFirmly connectedReduce friction lossPositive-displacement liquid enginesMulti-cylinder pumpsEngineeringMechanical engineering

The invention discloses an inclined shaft type plunger pump device. The inclined shaft type plunger pump device comprises a main shaft, a bearing, a connecting rod plunger pair, a cylinder, a shell, a valve plate and a back cover, wherein one end of a rotating shaft is connected with the inner wall of one end of the shell through the bearing; the shell is bent; one end of the rotating shaft in the shell is connected with the connecting rod plunger pair; the connecting rod plunger pair is connected with the cylinder; the cylinder is connected with the valve plate; the back cover is arranged at the other end of the shell; and the connecting rod plunger pair, the cylinder and the valve plate are sealed in the shell through the back cover. In the inclined shaft type plunger pump device, the lateral force of the plunger is smaller than the lateral force of the plunger of a straight shaft type pump, so that the frictional loss caused by the lateral force is low; and the connection between a connecting rod bulb and the main shaft is firm, so that the self-priming capacity is stronger.

Owner:龙勇军

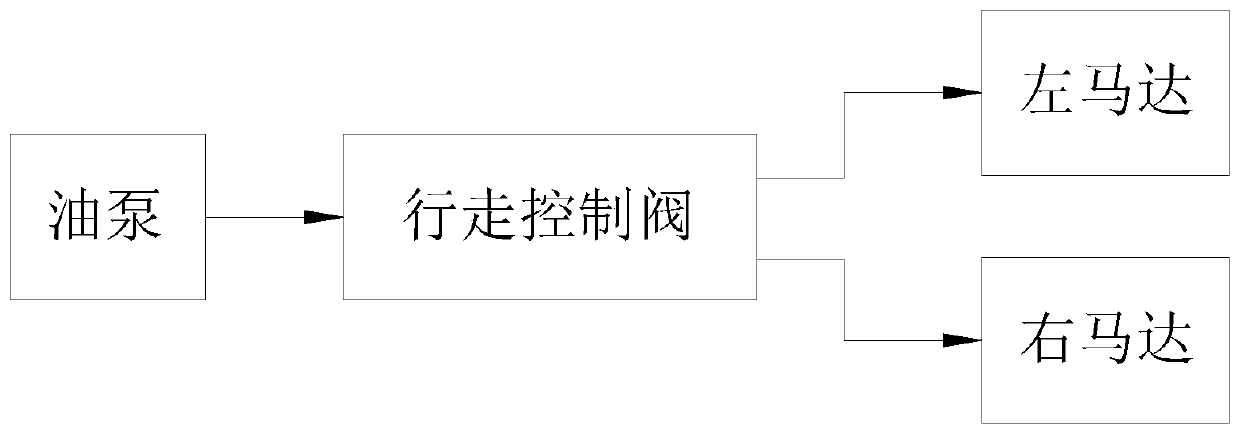

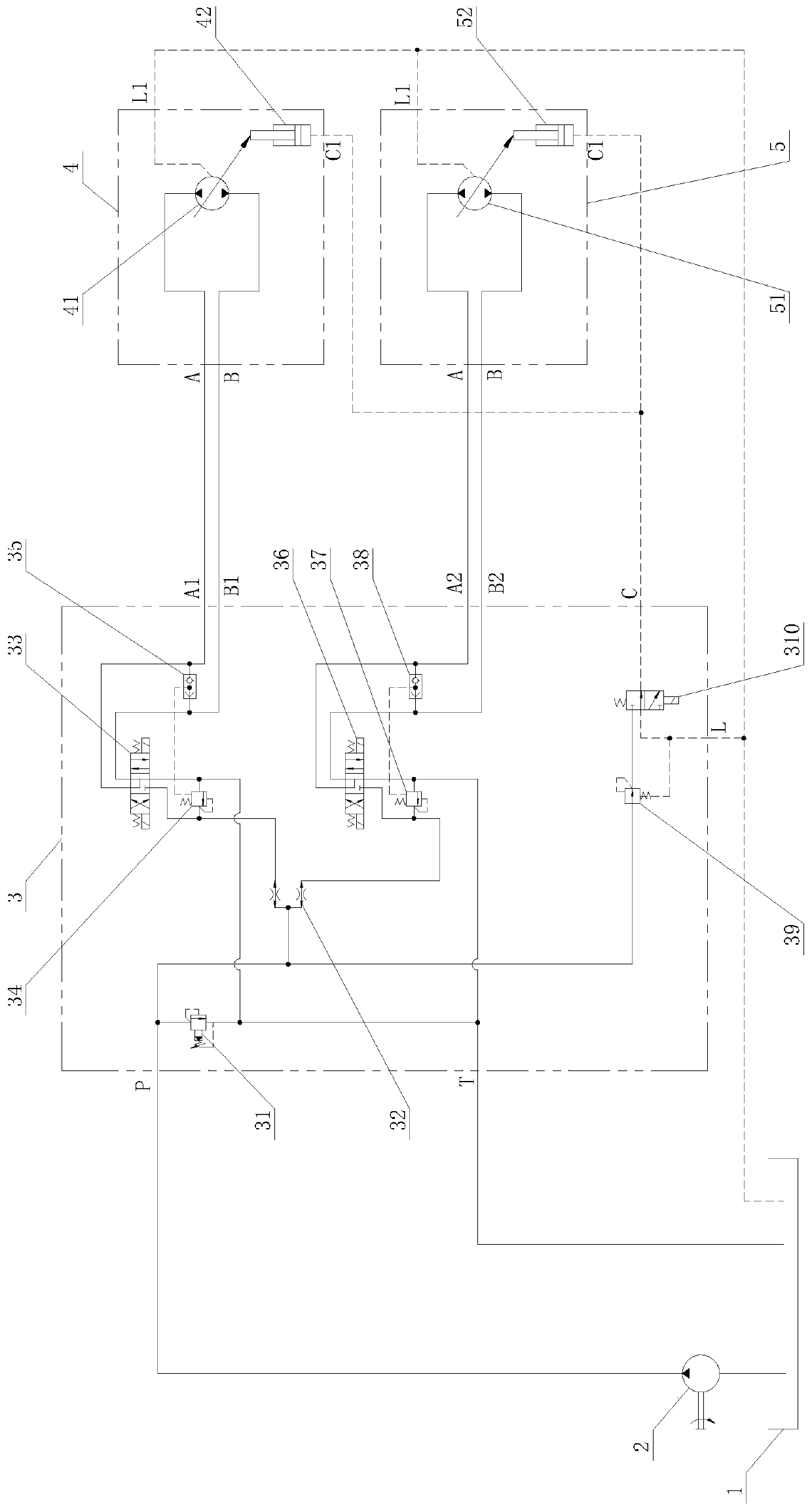

Travelling control valve of crawler-type hydraulic travelling system and travelling system

PendingCN110131226AStrong self-priming abilitySimple structureServomotorsServometer circuitsControl valvesControl theory

The invention discloses a travelling control valve of a crawler-type hydraulic travelling system and the travelling system. The travelling control valve comprises a flow dividing valve, shuttle valves, normal-off type pressure compensators and three-position four-way electromagnetic proportional reversing valves, wherein an quantitative pump output oil path is divided into two paths through the flow dividing valve, one path flows to a left travelling motor through the first three-position four-way electromagnetic proportional reversing valve, and the other path flows to a right travelling motor through the second three-position four-way electromagnetic proportional reversing valve; the pressure difference between the two ends of the first three-position four-way electromagnetic proportional reversing valve is determined by the first normal-off pressure compensator through the first shuttle valve; and the pressure difference between the two ends of the second three-position four-way electromagnetic proportional reversing valve is determined by the second normal-off pressure compensator through the second shuttle valve. According to the valve, the influence of two-side different loads on flow is effectively avoided, the synchronous precision of the motors on the two sides is improved, and differential driving is stabler and more flexible; the displacement of the two variable motors is controlled by the two-position three-way electromagnetic valves and pressure reducing valves correspondingly so as to achieve high-low-speed switching of vehicles.

Owner:徐州海伦哲特种车辆有限公司

Self-priming non-clogging sewage pump

InactiveCN103925222ASimple structureReduce manufacturing costPriming pumpNon-positive displacement fluid enginesEngineeringSewage

A self-priming non-clogging sewage pump comprises a pump block, a rotating shaft, an impeller, a pump cover, and a hanger. The pump block comprises an oil chamber, a volute, a gas-liquid separation chamber, an inflow pipe, a liquid storage chamber and a front cover plate. The pump cover is connected with the left side of the volute. The hanger is fixed to the left end of the pump block. One end of the rotating shaft is connected with the impeller; the other end of the rotating shaft penetrates the pump cover, the oil chamber and the hanger and is connected with a bearing at the left end of the hanger. The impeller is disposed inside the volute. The front cover plate is fixed to the inner wall of the volute through bolts. The right side of the lower end of the volute is provided with a reflow hole which is communicated with the liquid storage chamber through a one-way inflow valve. An outlet in the upper end of the volute is arranged in the gas-liquid separation chamber. The self-priming non-clogging sewage pump is simple in structure, low in production cost and convenient to popularize; clogging can be avoided effectively; maintenance costs are lowered; the service life of the pump is prolonged. The self-priming non-clogging sewage pump has high self-priming capacity, self-priming time is shortened and operating efficiency is improved.

Owner:XINXIANG UNIV

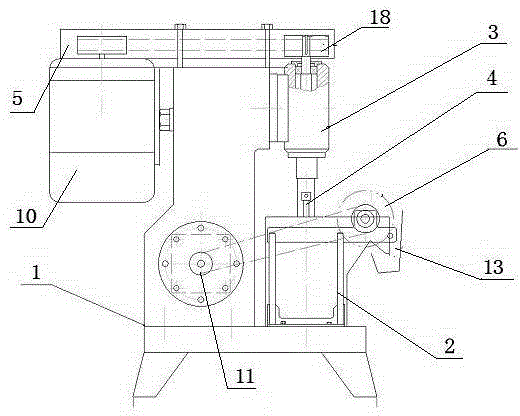

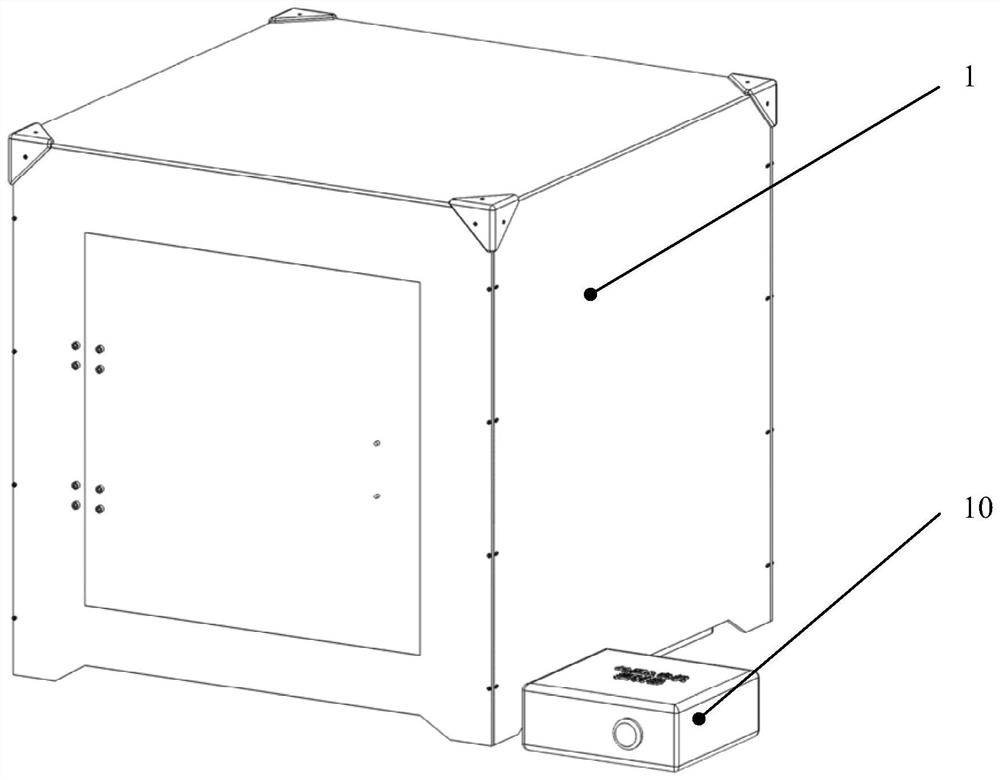

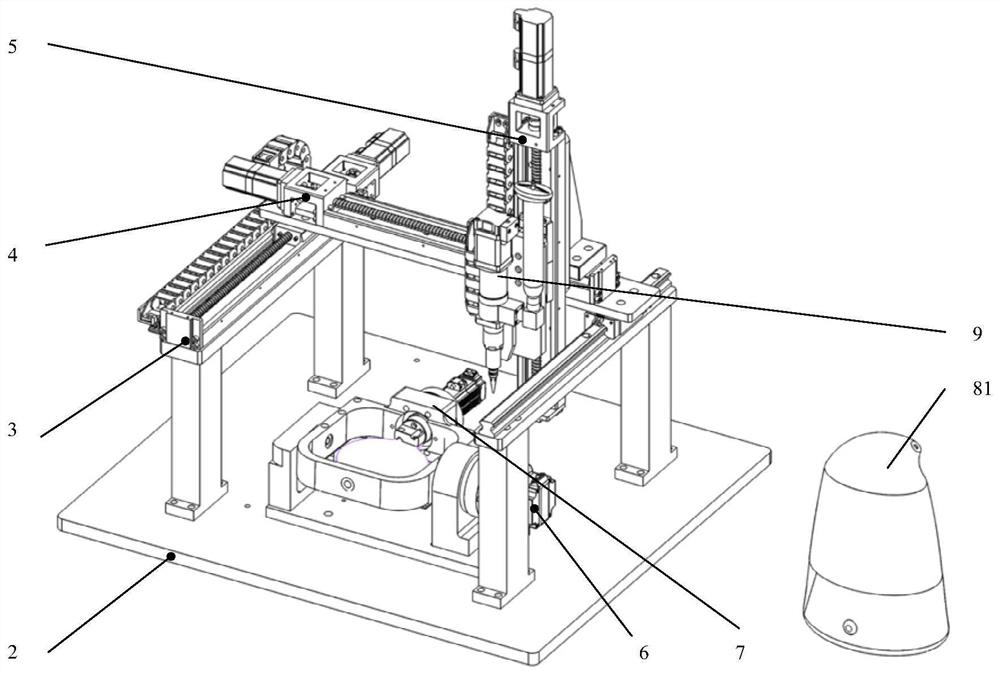

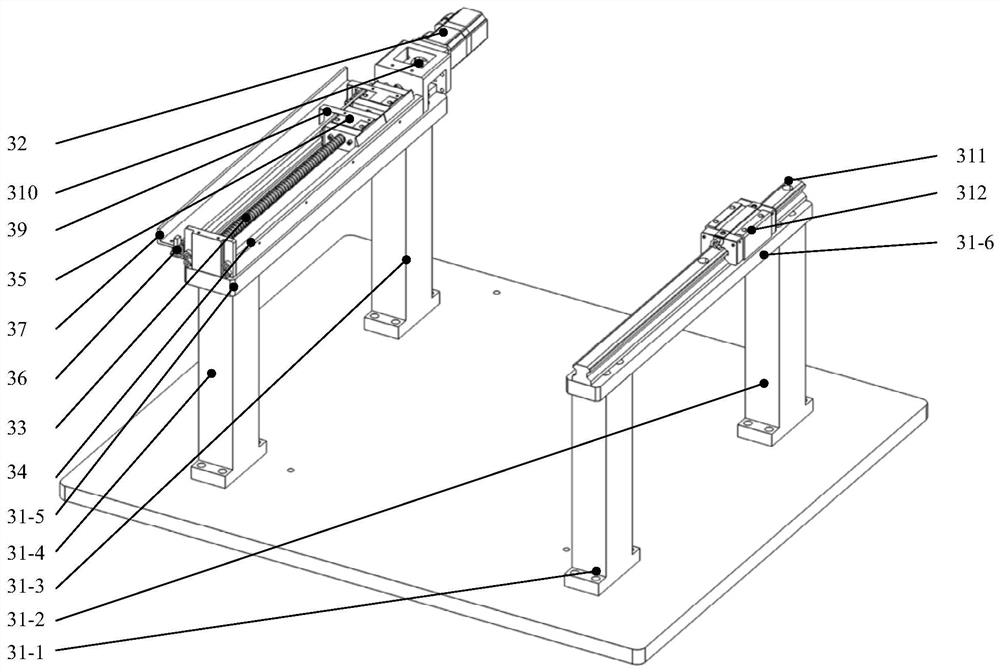

Five-axis silica gel 3D printer and printing method thereof

ActiveCN112622260AReduce difficultyAchieve preparationManufacturing platforms/substratesManufacturing driving meansRotational axisControl system

The invention discloses a five-axis silica gel 3D printer and a printing method thereof. The 3D printer comprises a base, an extrusion device, a three-axis motion platform, a control system and a two-axis motion platform. The two-axis motion platform comprises a first rotating assembly and a second rotating assembly, the first rotating assembly comprises a base, two rotating shaft supporting seats, a swing frame and a first motor, and the second rotating assembly comprises a workbench, a second motor and a rotating shaft supporting plate. The control system controls the first motor to rotate so as to adjust the first rotating angle of the swing frame and controls the second motor to rotate so as to adjust the second rotating angle of the workbench, so that two motion adjusting rotating shafts move according to a preset angle change path. Through cooperative movement of five axes, the extrusion device extrudes shaft vectors at will relative to a workpiece coordinate system and moves to any position in the workpiece coordinate system, the workpiece printing difficulty is greatly reduced, the printing time is shortened, and even complex-shape workpiece manufacturing which cannot be achieved through a three-axis 3D machine can be achieved.

Owner:HEFEI UNIV OF TECH

Hydraulic gas vacuum pump

InactiveCN103470473ASimple structureAdd partsPiston pumpsPositive-displacement liquid enginesHydraulic cylinderExhaust valve

The invention discloses a hydraulic gas vacuum pump. The vacuum pump comprises an oil cylinder part, a left compression cylinder part and a right compression cylinder part, wherein the oil cylinder part for driving hydraulic oil is arranged in the middle of the hydraulic gas vacuum pump, and the left compression cylinder part and the right compression cylinder part are connected at the two ends of the oil cylinder part; the oil cylinder part comprises an oil cylinder barrel and an oil cylinder piston in the oil cylinder barrel; each compression cylinder part comprises a compression cylinder barrel and a compression cylinder piston, and the two ends of each compression cylinder barrel are provided with an air suction valve and a vent valve. The compression cylinder pistons and the oil cylinder piston are connected on the same piston rod. The hydraulic oil cylinder part adopts a hydraulic control way and performs commutation control by a hydraulic control reciprocating machine, so that the reciprocating motion of the hydraulic oil cylinder can be realized. According to the hydraulic gas vacuum pump, the pistons are directly driven to move through hydraulic oil driving so as to realize the low-jig-frequency and long-stroke motion of the pistons, so that the service life is long, the trouble is little and the maintenance cost is low. The gas vacuum pump is simple in structure, few in parts, small in size and light in weight. Compared with a traditional mechanical drive triplex pump, the number of the parts of the hydraulic gas vacuum pump is reduced by 65%, and the size and weight is reduced by more than 60%.

Owner:天津市海雅实业有限公司

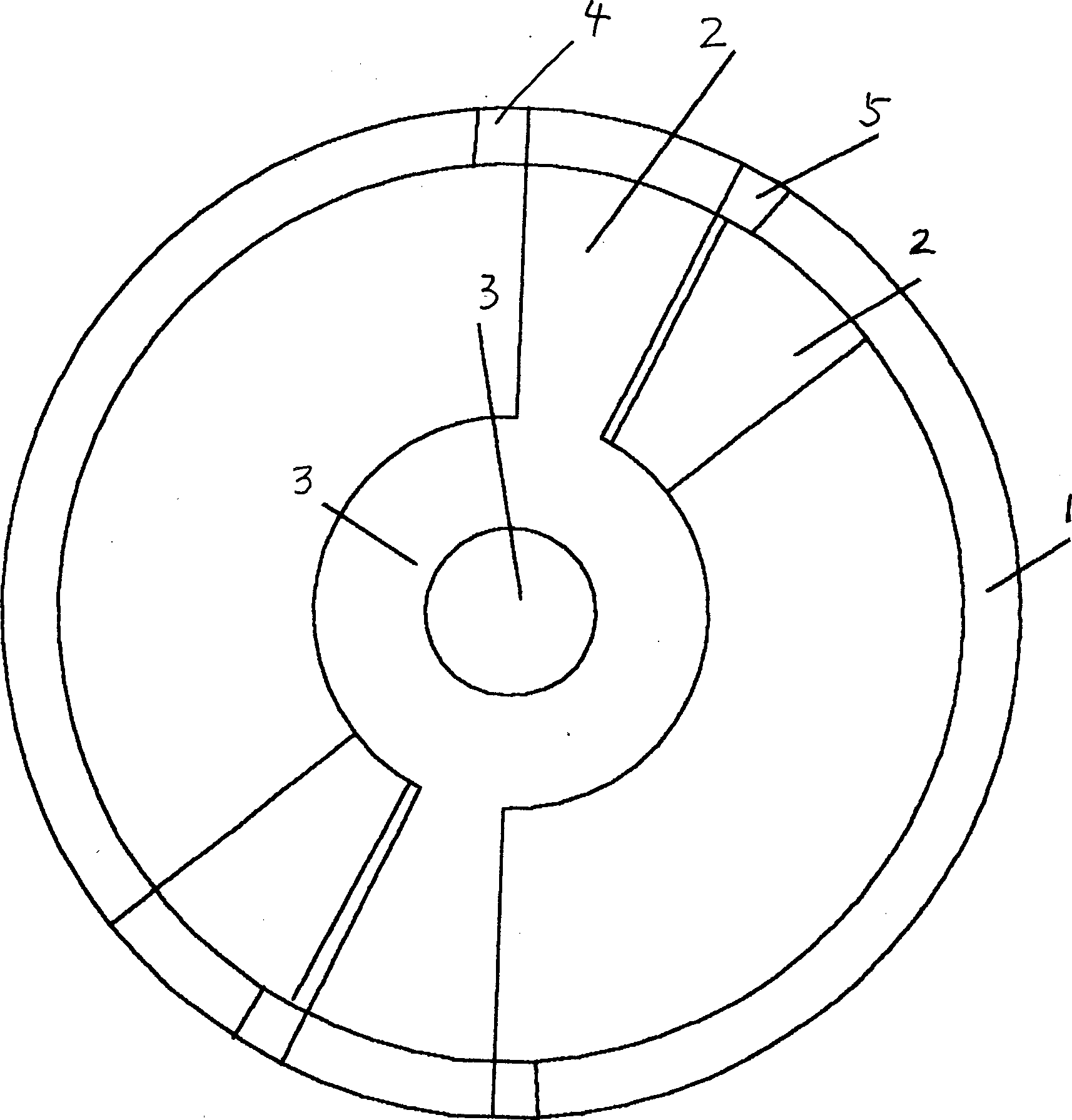

Alternative rotary pump

InactiveCN1378042AIncrease or decrease of working volumeImprove efficiencyRotary piston pumpsRotary piston liquid enginesRotary pumpHigh pressure

The alternative rotary pump includes mainly pump body and driving mechanism connected to pump blade, the pump blade consists of at least two rotary sheets cascaded via the shaft, the the driving mechanism is connected via separate gear units to the rotary sheet shaft. The present invention has high efficiency, high pressure, no effluence of the pressure variation to flow rate, constant flow rate and powerful spontaneous imbibitions capacity.

Owner:蔡康人

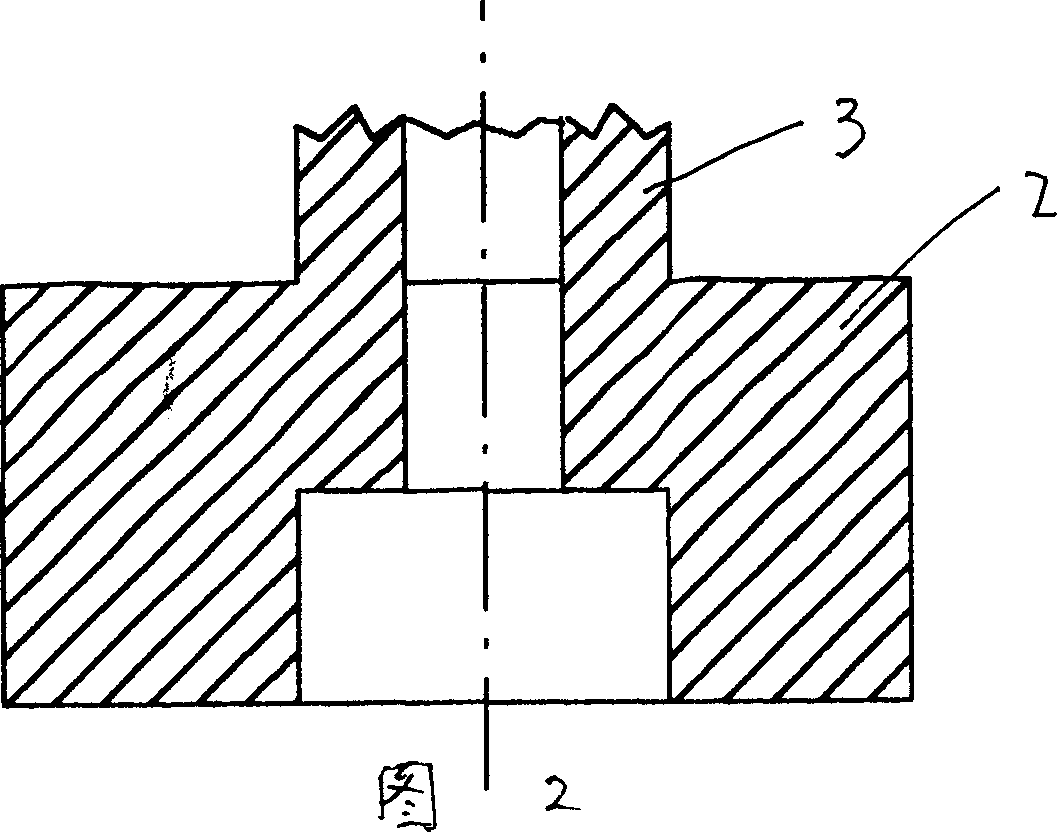

Dynamic and static pressure bearing circular tooth gear oil pump

InactiveCN105298835AExtended service lifeCompact structureRotary piston pumpsLubricating pumpsAxial forceHigh pressure

The invention relates to a dynamic and static pressure bearing circular tooth gear oil pump. A dynamic pressure bearing for bearing a gear shaft of a driving circular arc gear and a gear shaft of a driven circular arc gear is arranged on the inner side of a pump cover. The dynamic pressure bearing comprises a gear shaft hole formed in the inner end face of the pump cover. A plurality of shaft side dynamic pressure grooves extending in the axial direction are formed in the inner wall of the gear shaft hole in the circumferential direction, wherein the shaft side dynamic pressure grooves in one side of a low-pressure cavity form a static pressure balance groove. An oil way is further formed inside the pump cover, one end of the oil way penetrates a high pressure cavity, and the other end of the oil way penetrates the static pressure balance groove. Supporting rings are arranged between the inner wall of the gear shaft hole and shaft shoulders of the gear shafts of the driving circular arc gear and the driven circular arc gear. A plurality of wheel side dynamic pressure grooves extending in the radial direction are formed in the inner end face of the pump cover in the circumferential direction of the outer side of the gear shaft hole. The wheel side dynamic pressure grooves in the two sides of the driving circular arc gear and the driven circular arc gear are symmetric and provide the axial force in the same magnitude and opposite directions.

Owner:CENT RES INST OF TIANJIN BENEFO MECHANICAL EQUIP GRP CO LTD

Efficient multifunctional rotor type submersible sewage pump

InactiveCN105179231APass smoothlyStrong blocking abilityRotary piston pumpsRotary piston liquid enginesFiberRadial piston pump

The invention discloses an efficient multifunctional rotor type submersible sewage pump and belongs to positive displacement pumps. Sewage delivery is conducted through the theory of a radial piston pump. When a submersible motor drives a rotor to rotate, plungers on the rotor move in a reciprocating mode in the radial direction under the control of an eccentric stator; when the plungers move outwards, media are sucked from a suction port in a pump body through a central channel and radial holes in the pump body; when the plungers move inwards, the media are discharged towards a discharging port through the central channel and the radial holes. Due to the fact that the multiple plungers which are distributed uniformly convey the media uninterruptedly, liquid flows are quite stable, consistent and free of pulses; baffle tongues on a baffle tongue sleeve prevents the leakage from a high-pressure area to a low-temperature area inside the pump body; meanwhile, the baffle tongues and the radial holes in the rotor form cutting pairs, long fibers are cut automatically and continuously, and winding is eliminated. The pump is high in self-section function, and gas-liquid-solid mixed transportation can be conducted. Furthermore, the pump has a bidirectional operation function, liquid can be conveyed when the pump rotates in the positive direction, and the pump can wash a filter screen and eliminate blockage without stopping a machine when rotating in the negative direction.

Owner:余文凌

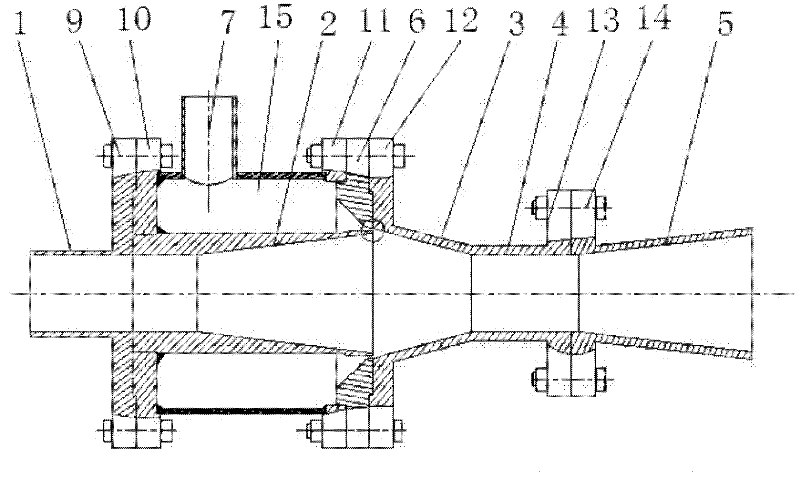

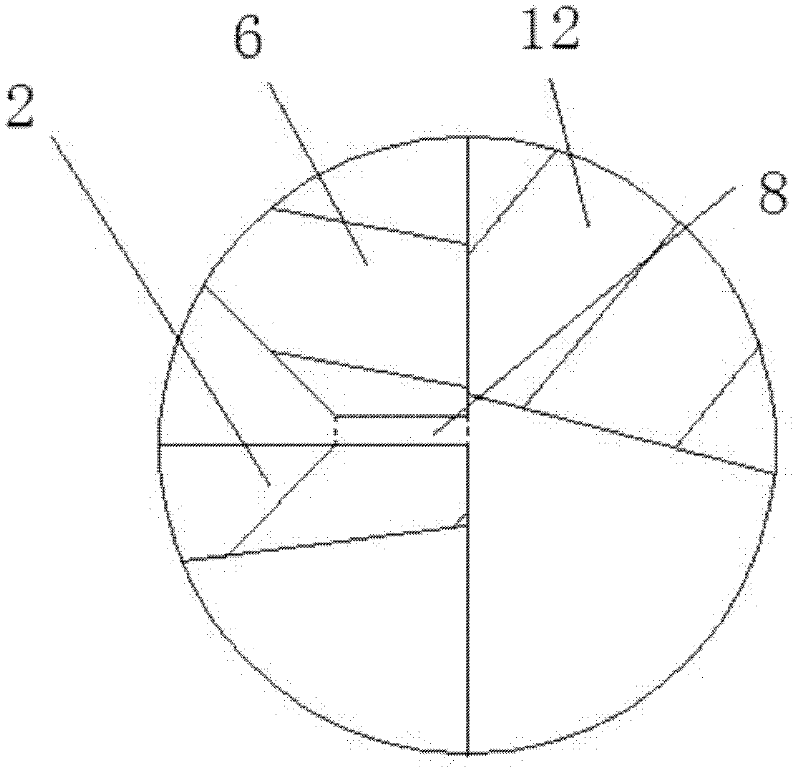

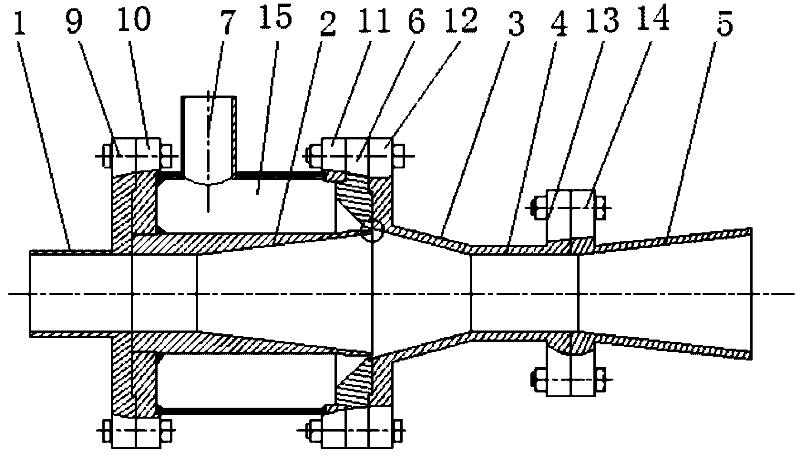

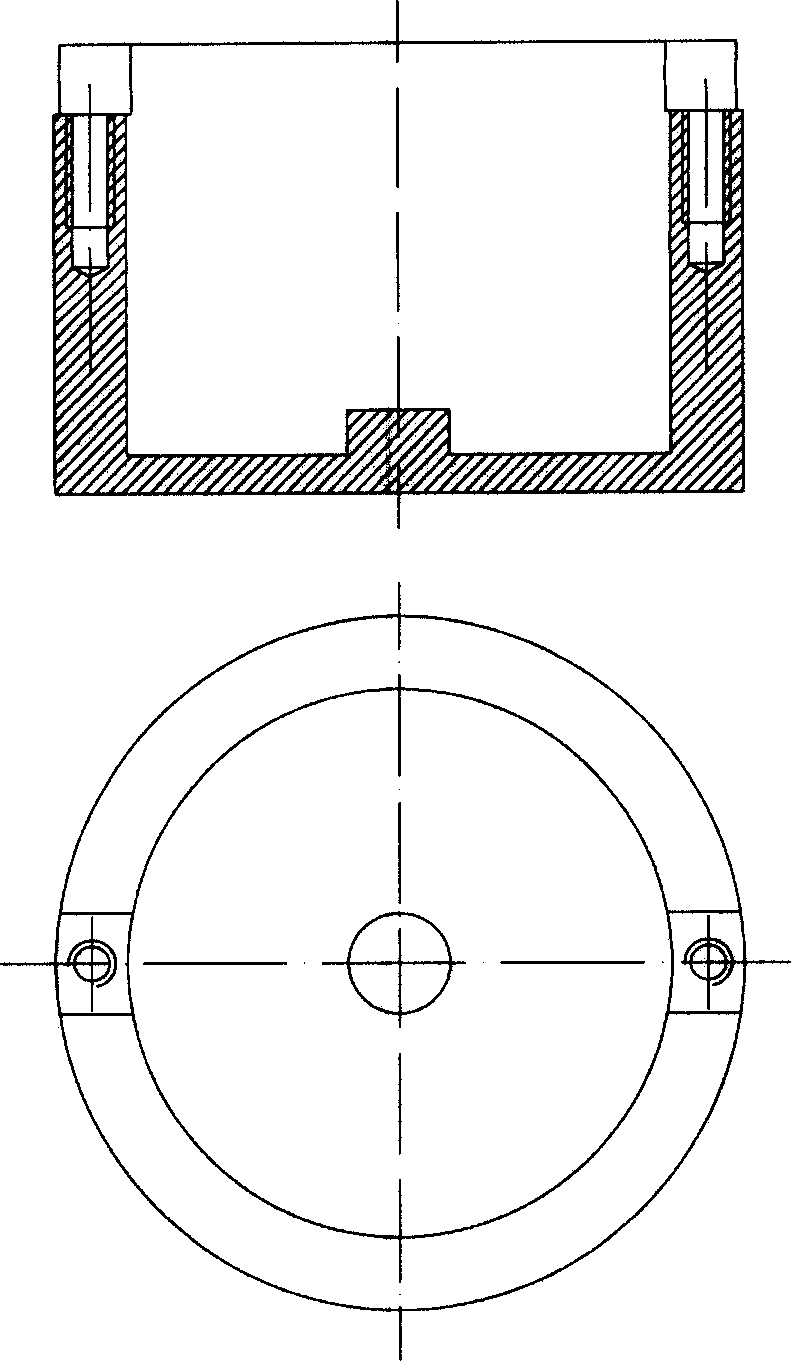

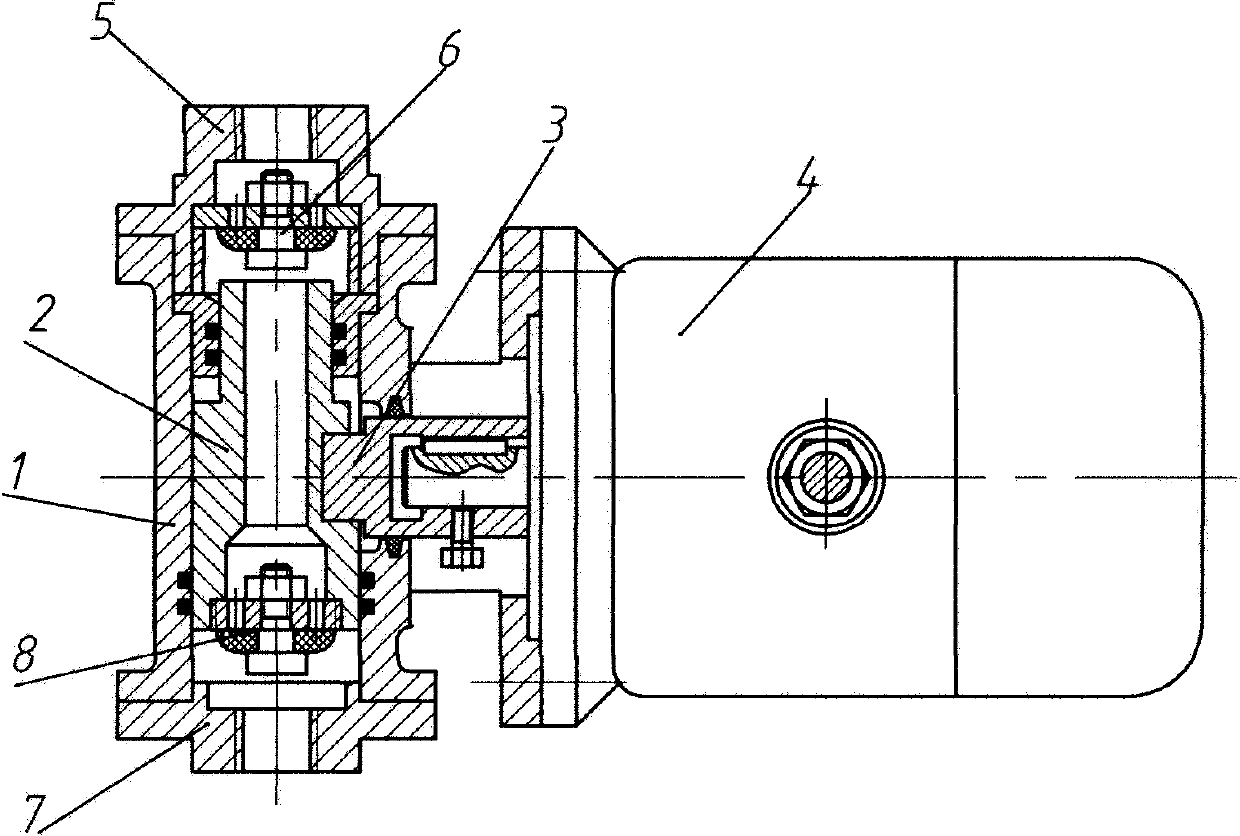

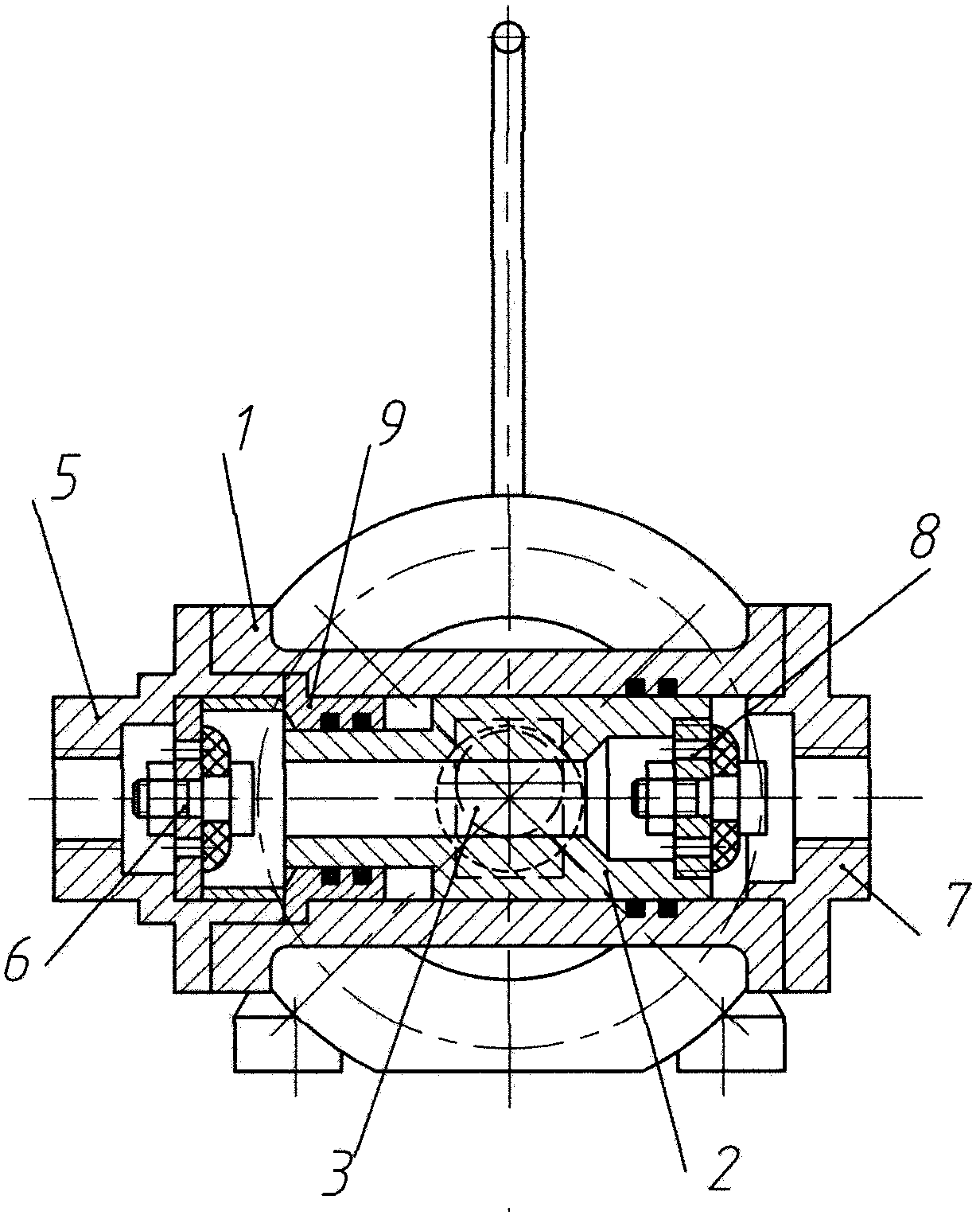

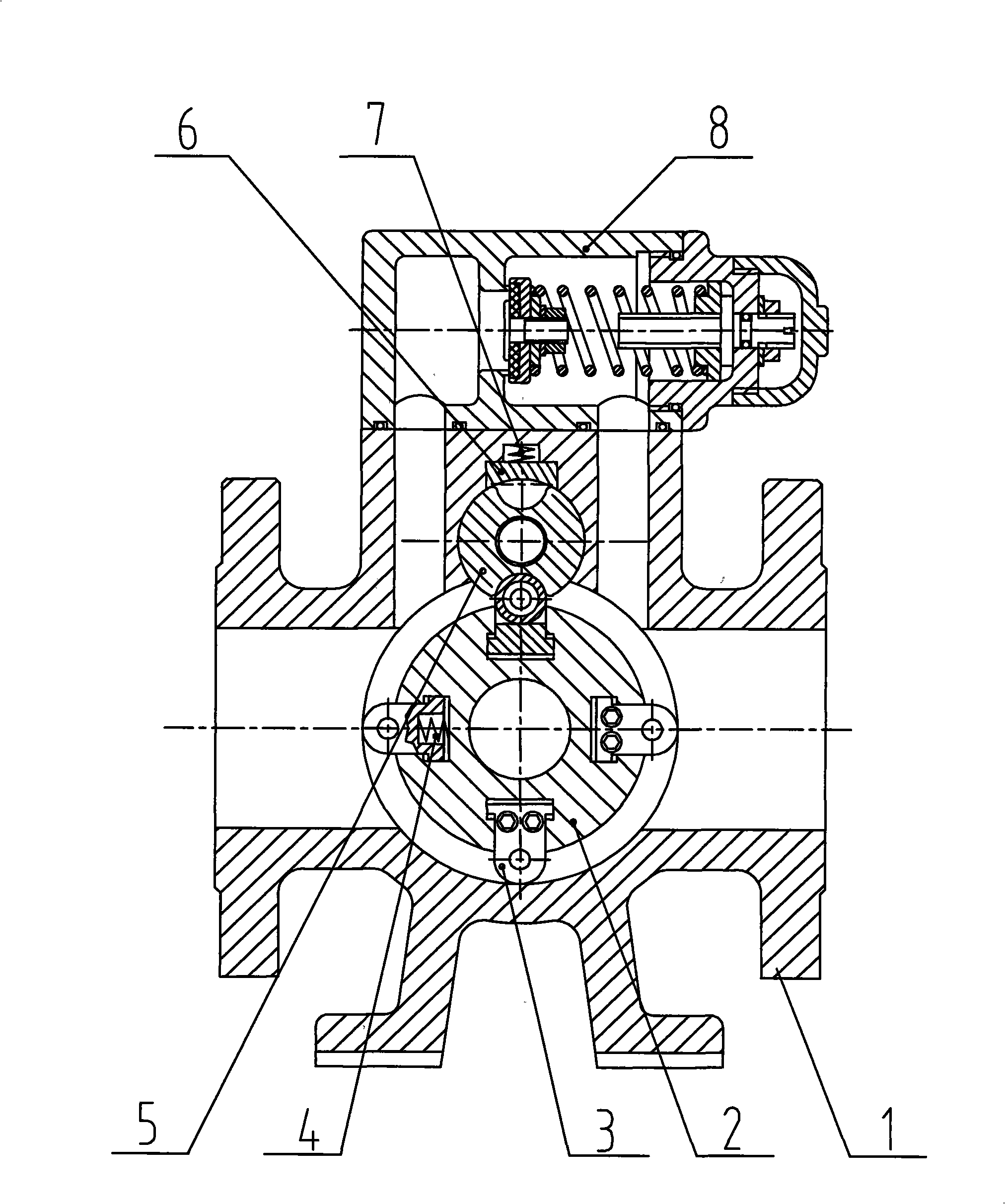

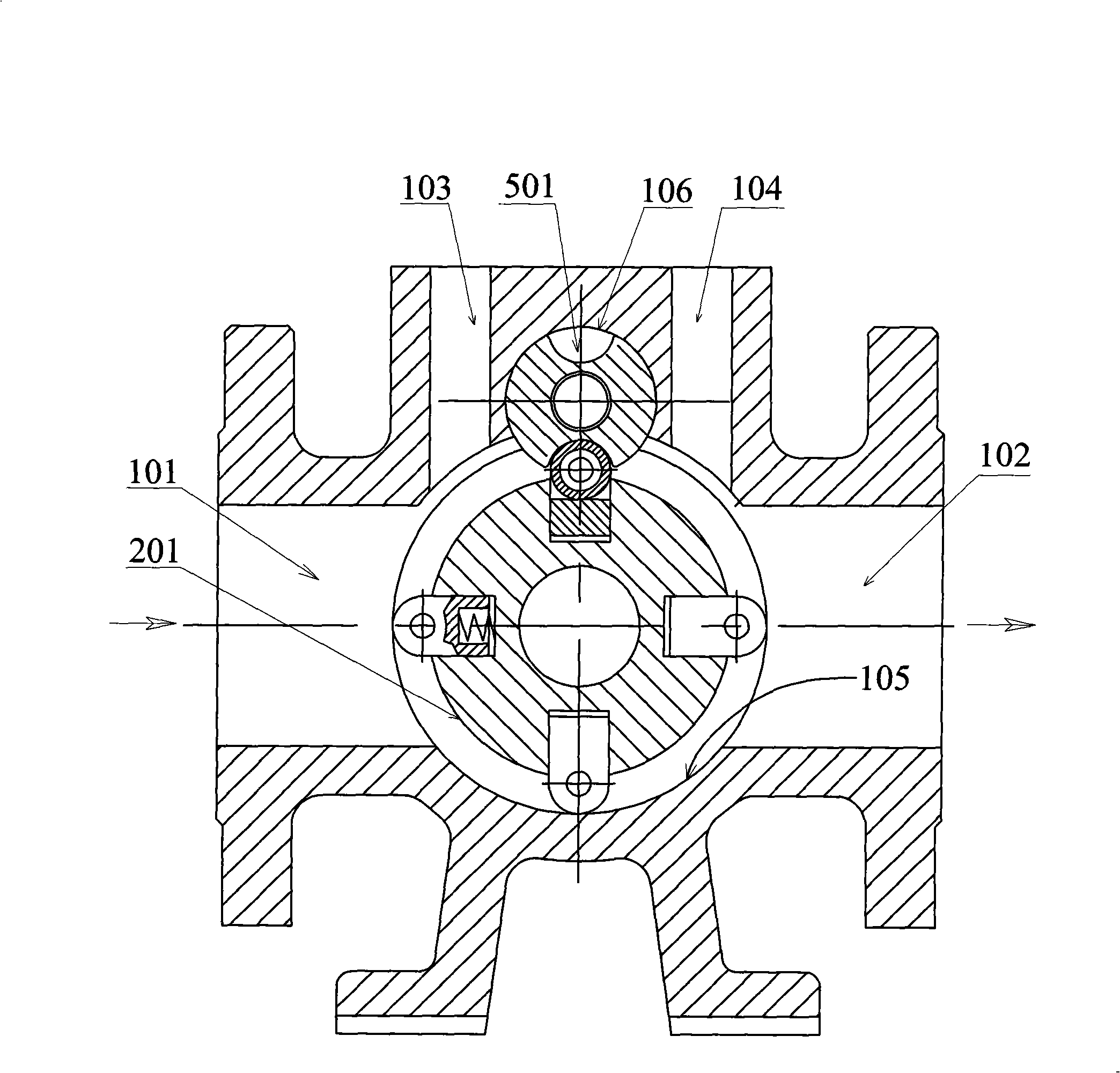

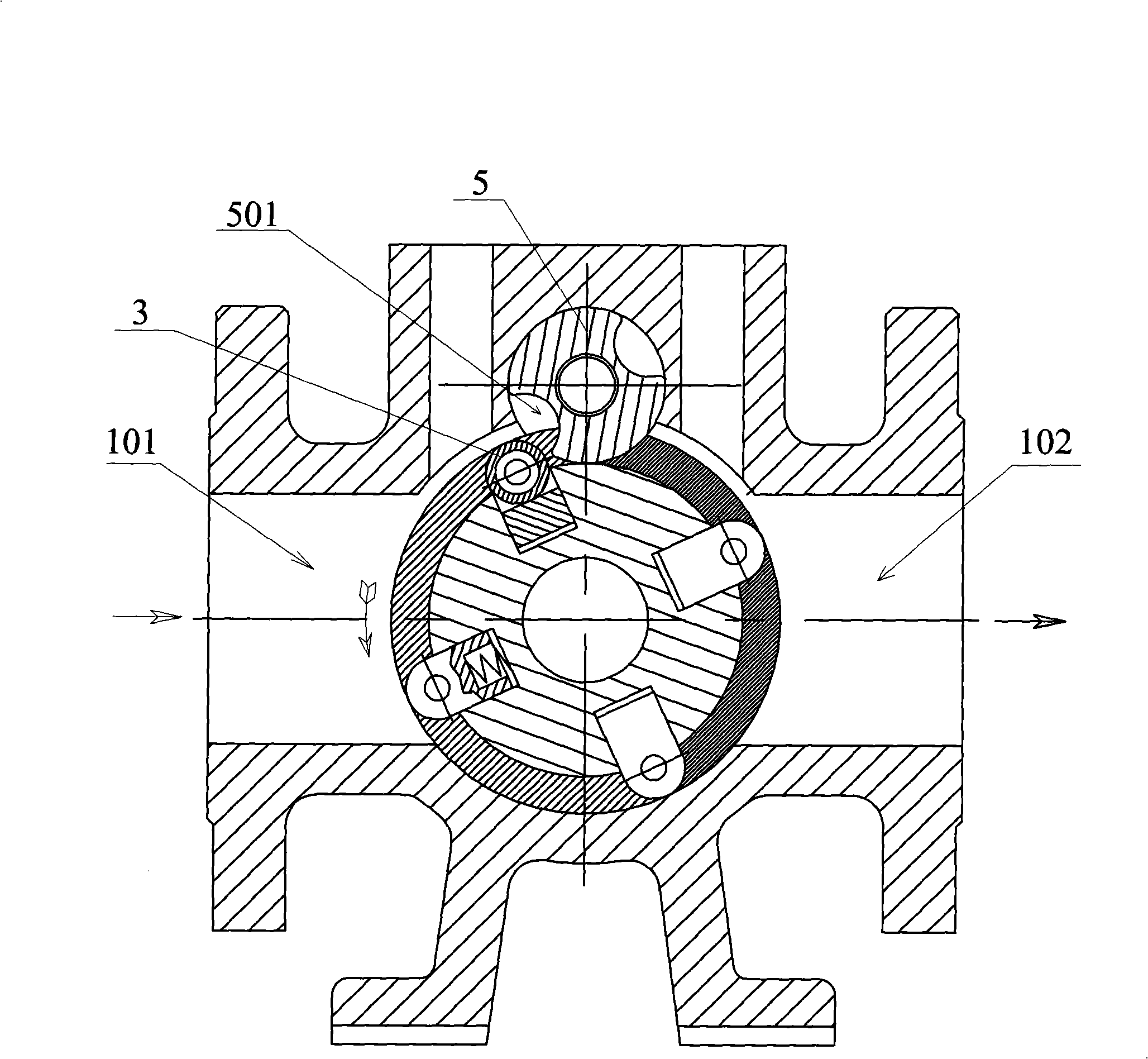

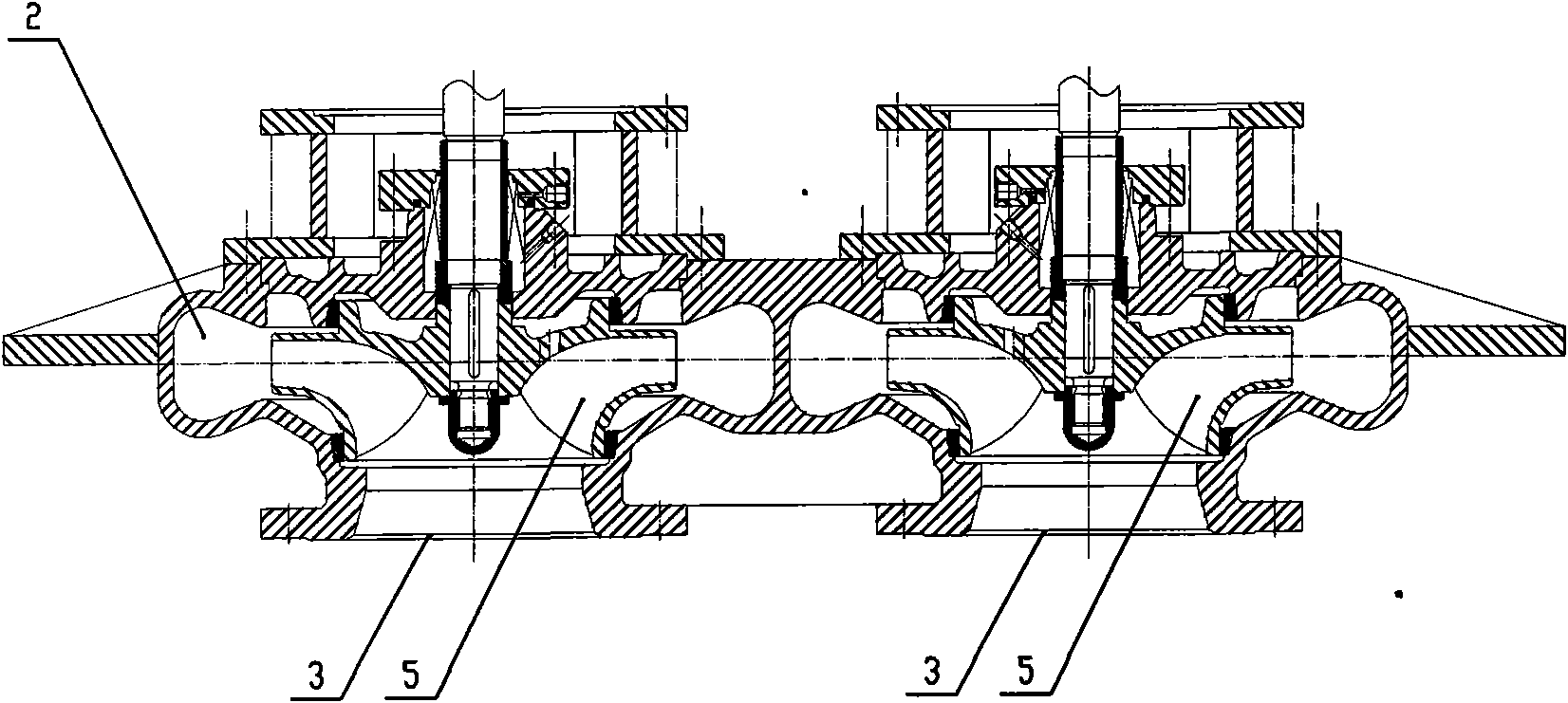

Spherical puffing pump for ice cream machine

The patent discloses a spherical puffing pump for an ice cream machine. The spherical puffing pump comprises a spherical pump, a clamping plate (4) and an intake valve (12), wherein a liquid inlet hole (201) of the spherical pump communicates with a milk pulp tank to inhale milk pulp raw materials; the intake valve (12) is connected to a liquid inlet channel of the liquid inlet hole (201) to inhale air; a liquid draining hole (202) of the spherical pump communicates with a liquid inlet of a freezing vat of the ice cream machine; a pump seat (6) is fixed on the ice cream machine, and the end ofthe pump seat (6) is protruded from the inner wall of the milk pulp tank of the ice cream machine; a cylinder body (3) of the spherical pump is in mechanical connection to the end of the pump seat (6) through the clamping plate (4); and a main shaft (5) of the spherical pump is in mechanical connection with a motor shaft arranged in the ice cream machine through a connecting shaft (7) for transmitting power. The spherical puffing pump disclosed by the invention has the advantages of being simple in structure, convenient to disassemble and wash, high in self-absorption capacity and convenientfor arrangement of the milk pulp tank; the puffing rate can be adjusted according to the magnitude of an air inlet and the motor speed; and the air and milk pulp are thoroughly mixed.

Owner:深圳市球形动力科技有限公司

Engine electric control oil supply device for model airplane and unmanned aerial vehicle

InactiveCN106704061AEfficient dischargeStable pressureMachines/enginesLiquid fuel feedersJet aeroplaneGear pump

The invention discloses an engine electric control oil supply device for a model airplane and an unmanned aerial vehicle. The device comprises an oil tank 1, an oiling pipe 2, an oil tank cover 3, an oil sucking pipe 4, a heavy hammer 5, a micro gear pump 6, a one-way valve 7, a high-pressure oil pipe 8, a micro pressure adjuster 9 and an exhaust pipe 10. The oil tank cover is provided with an oiling port, an exhaust port and an oil sucking port. One end of the oiling pipe penetrates through the oiling port of the oil tank cover, and is connected with the heavy hammer to sunk into the bottom of the oil tank; the other end of the oiling pipe is leaded to the external of the oil tank; and the end needs to be blocked by a plug besides of the time of oiling. One end of the oil sucking pipe penetrates through the oil sucking port of the oil tank cover, and is connected with the heavy hammer to sunk into the bottom of the oil tank; and the other end is connected with an oil inlet of the micro gear pump. The micro gear pump drives a gear structure of a main body to generate suction through an internal motor, sucks out fuel in the oil tank through the oil sucking pipe, and provides the fuel with pressure into the high-pressure oil pipe through an oil outlet of the micro gear pump.

Owner:石家庄益科创新科技有限公司

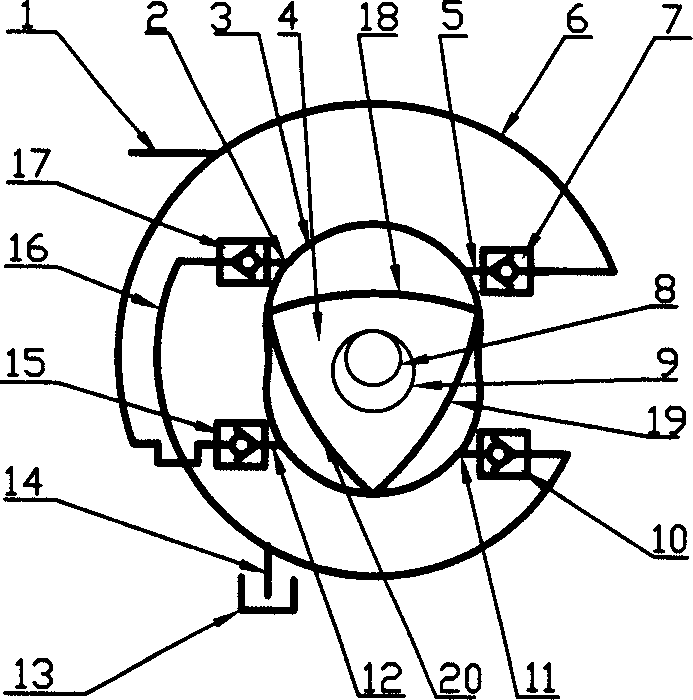

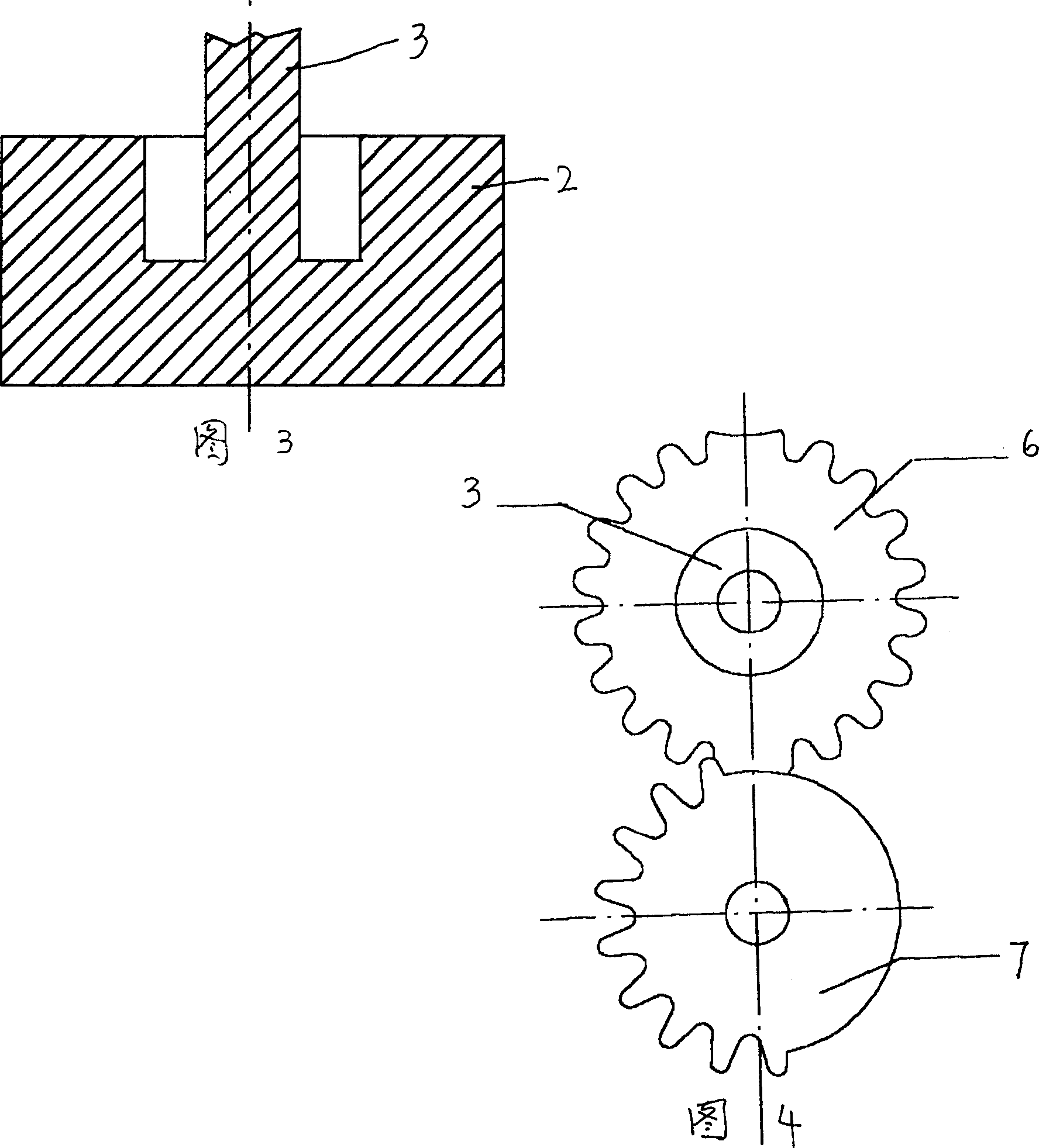

Rotor pump with rotary slices

InactiveCN101298868AExtended service lifeImprove efficiencyRotary piston pumpsRotary piston liquid enginesDynamic balanceFace seal

The invention discloses a rotary vane rotor pump, comprising a pump body and a fluid transportation mechanism arranged between the import and the export of the pump, wherein, a big rotor is arranged on a large shift which is arranged on the pump body, and a plurality of rotary vanes which stretches to move in a radial direction are arranged on the external circumference surface of the big rotor, and a small rotor is arranged on a small shift meshing to drive with the large shift, and an arc groove supplied for the projecting rotary vane to mesh is arranged on the circumference surface of the small rotor, and a first slide way region which simultaneously is sealed to contact with at least two rotary vanes and a second slide way region which is sealed to copulate with the external circumference surface of the small rotor are arranged on the pump body, so that fluid in the import of the pump is transported to the export of the pump via the first slide way region. Adopting the rotary vane, an end face seal structure and a radial seal structure can better solve a seal problem of positive displacement pump, and the rotor adopts a mode of cylindrical surface symmetrically slotting and has simple structure, easy processing and good dynamic balance performance, so as to have the advantages of high efficient, strong self- suction capacity, long service life, low manufacturing cost, wide medium applicability and so on.

Owner:PLA AIR FORCE OIL MATERIAL RES INST

Screw and vertex combined slurry pump

InactiveCN103527493ASimple structureReasonable designSpecific fluid pumpsPump componentsFiberHigh concentration

The invention discloses a screw and vortex combined slurry pump. The screw and vortex combined slurry pump comprises a cylinder body and pump shafts; the pump shafts penetrate the cylinder body along the axial direction and two ends of the pump shafts are arranged outside the cylinder body; a casing is fixed at one end of the cylinder body; a slurry inlet connector is fixed at the other end of the cylinder body; the pump shafts are formed by a first pump shaft and a second pump shaft; a screw blade is installed on the second pump shaft; a second seal device and a second supporting device are arranged on the second pump shaft and outside the slurry inlet connector; a hub is installed on the first pump shaft; a vortex blade and a first slurry blocking disc are installed on the hub; the screw direction of the vortex blade and the screw direction of the screw blade are opposite; the first slurry blocking disc is connected with the vortex blade; a first seal device and a first supporting device are arranged on the first pump shaft and outside the casing; a slurry outlet of the casing is vertical to the cylinder body; a transitional connector which is connected with a slurry outlet connector is connected to the end portion of the casing. The screw and vortex combined slurry pump solves the problem of conveying high concentration and high flow slurry which contains large hardness particles and long fibrous matters.

Owner:陕西省水土保持局

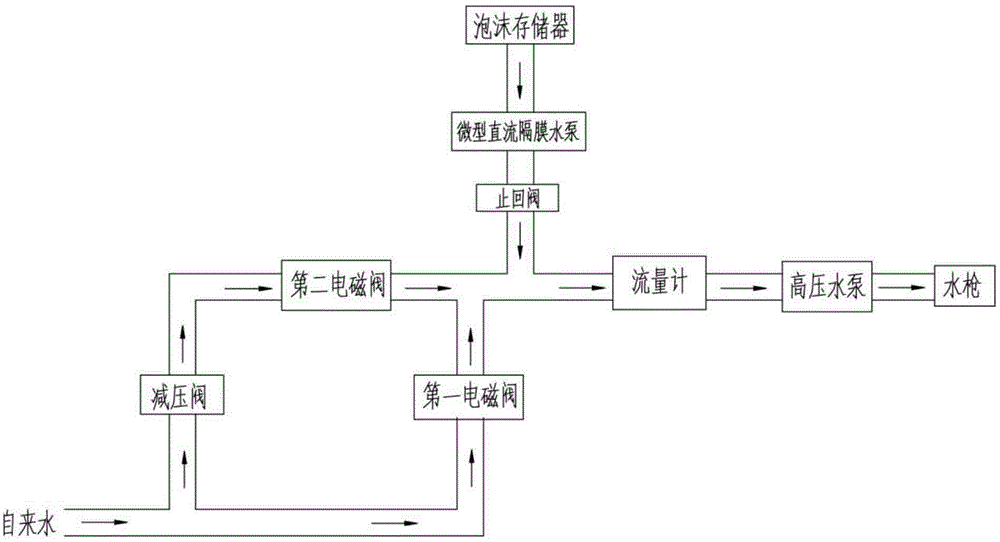

Self-service car washing system

InactiveCN104015701AStrong self-priming abilityGood effectCleaning apparatus for vehicle exteriorsHigh pressure waterHigh pressure

The invention relates to a self-service car washing system which belongs to the technical field of car washing. The self-service car washing system comprises a water washing channel and a foam washing channel, wherein the water washing channel comprises a first water inlet pipe, a first electromagnetic valve, a flow meter, a high-pressure water pump and a water gun; the foam washing channel comprises a water supply pipeline and a foam supply pipeline, wherein the foam supply pipeline comprises a foam storage and a micro direct-current diaphragm water pump, and the water supply pipeline comprises a second water inlet pipe and a second electromagnetic valve; the first water inlet pipe and the second water inlet pipe are connected with a water pipe through a tee; foam supplied by the foam supply pipeline and water supplied by the water supply pipeline are collected to a water outlet pipe and then pass through the flow meter and the high-pressure water pump, so as to be sprayed by the water gun. According to the self-service car washing system, under the action of suction of the micro direct-current diaphragm water pump, rich foam forms high-pressure liquid to be fully and uniformly mixed with the water, and the foam washing effect is better.

Owner:邢巍

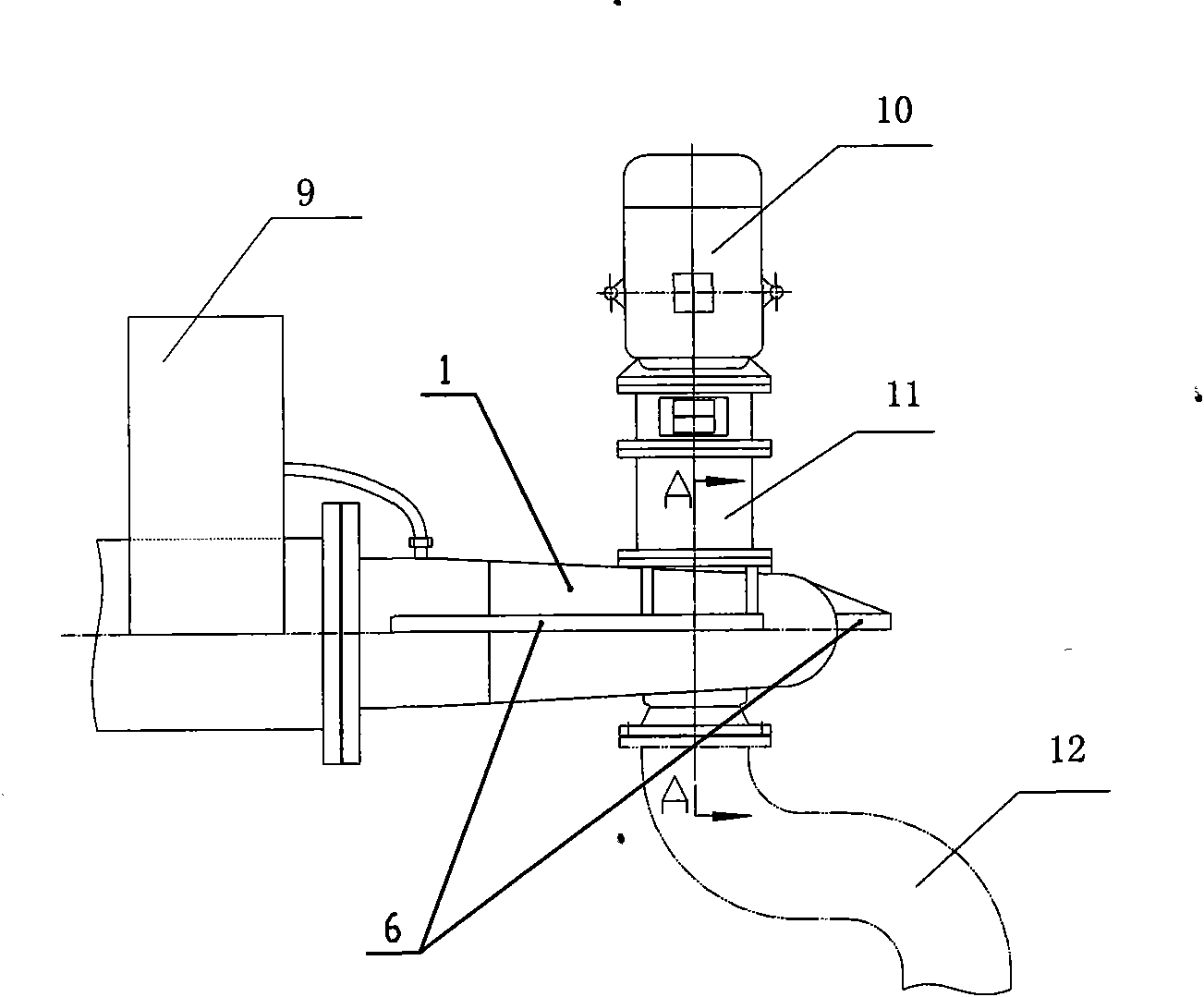

Turbine parallel multiple-suction single-discharge vertical-type lifting pump

InactiveCN101846082AIncreased vacuum heightHigh trafficPump componentsPriming pumpImpellerEngineering

The invention relates to a turbine parallel multiple-suction single-discharge vertical-type lifting pump, which can be also called a radial split large-scale single discharge pump. The pump can suck water by using a built-in vacuum turbine, and the bottom of the pump body is provided with a plurality of suction ports. The lifting pump comprises a pump body and an external suction pipe, wherein at least two spiral housings are arranged in the pump body, and the suction ports are respectively arranged under the spiral housings; a water pump impeller is arranged in each spiral housing and is connected with a motor through a pump shaft; the pump body is provided with an outlet pipe, and the outlet pipe is communicated with each spiral housing; and the outler pipe is provided with a vacuum interface, the vacuum interface is airtightly connected with one end of an air suction pipe, and the other end of the air suction pipe is connected with the vacuum turbine. The invention has the advantages of high suction performance, stable operation and convenient maintenance; and the pump can be installed above the liquid level, thereby breaking through the tradition that a large-scale lifting pump must be installed below the liquid level, and realizing the revolution of installing the large-scale lifting pump above the liquid level.

Owner:SHENYANG ANTI CORROSION ALLOY PUMP

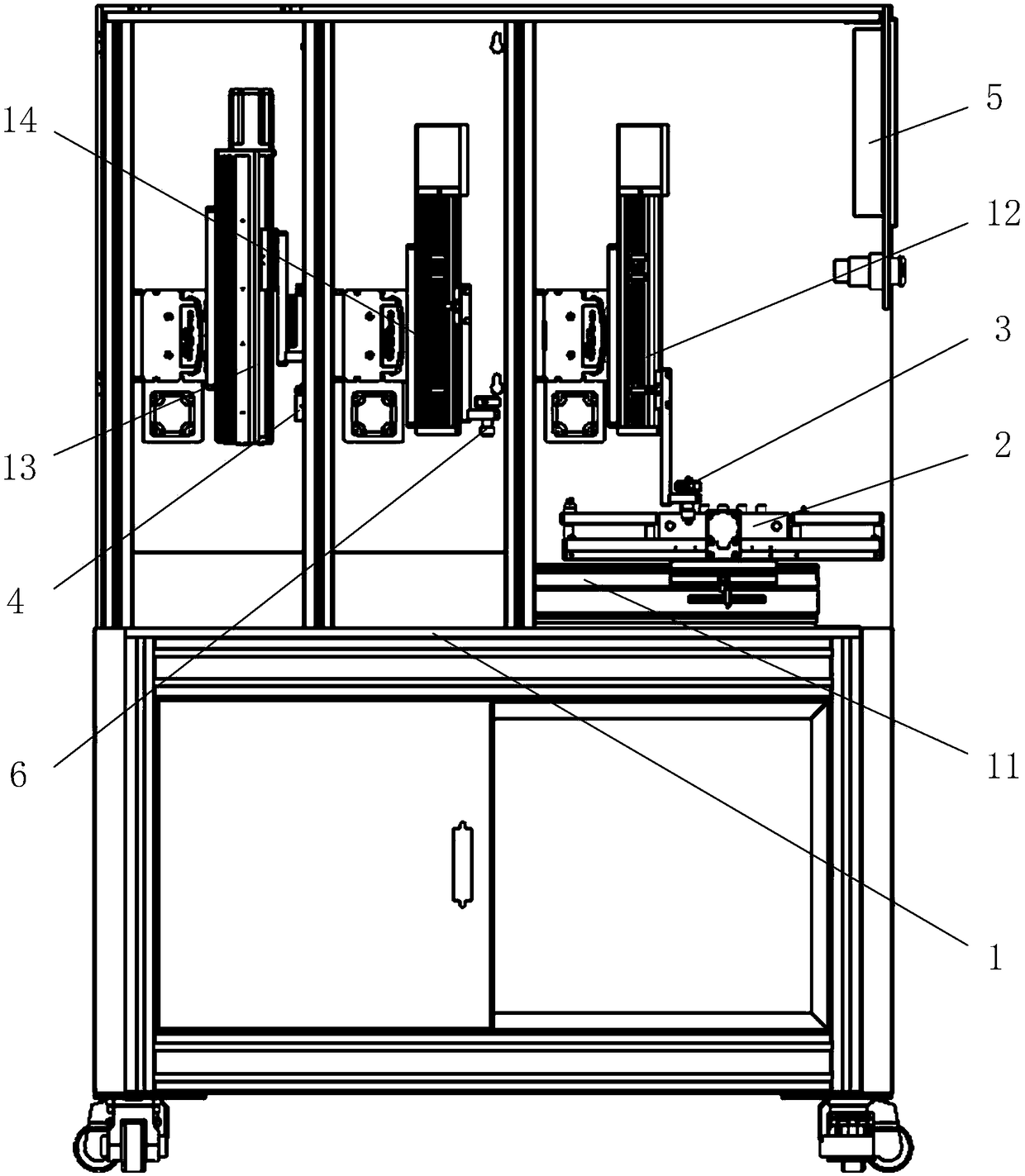

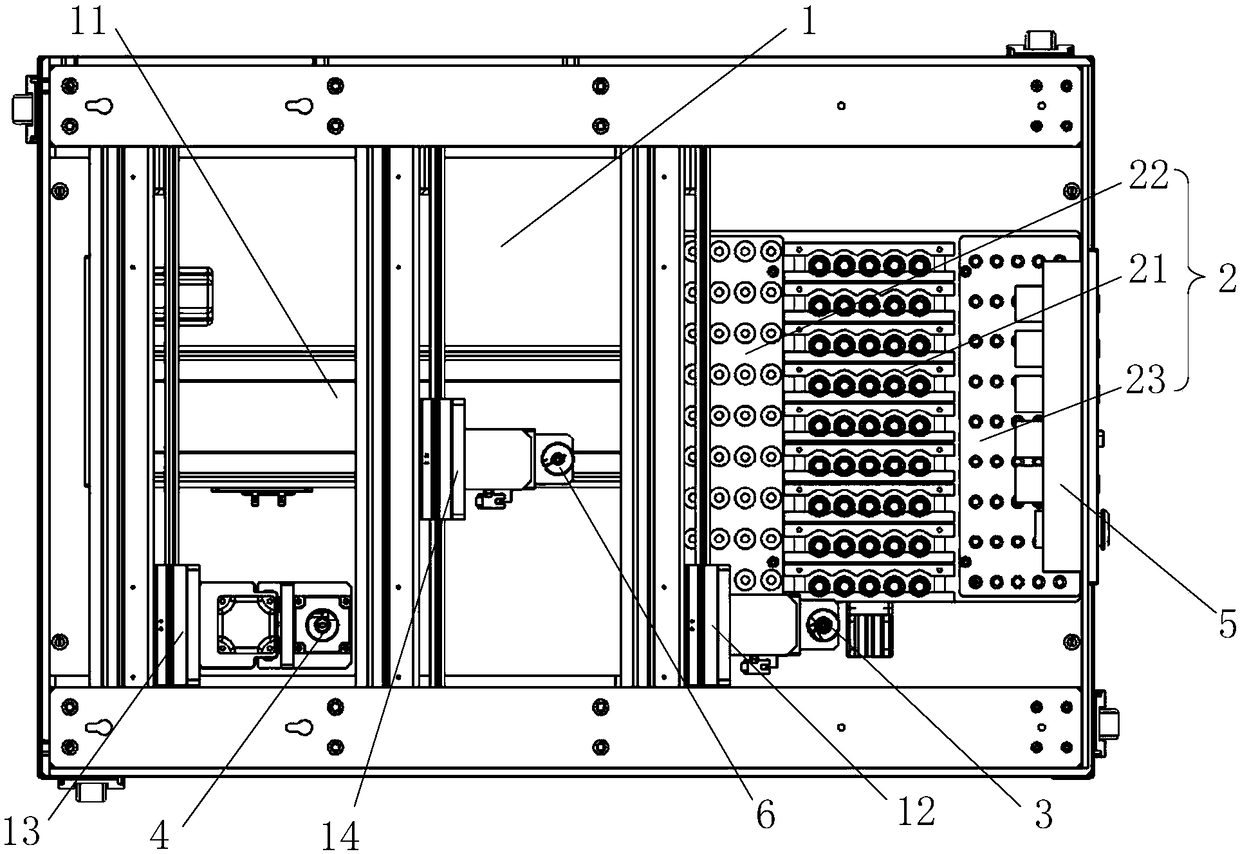

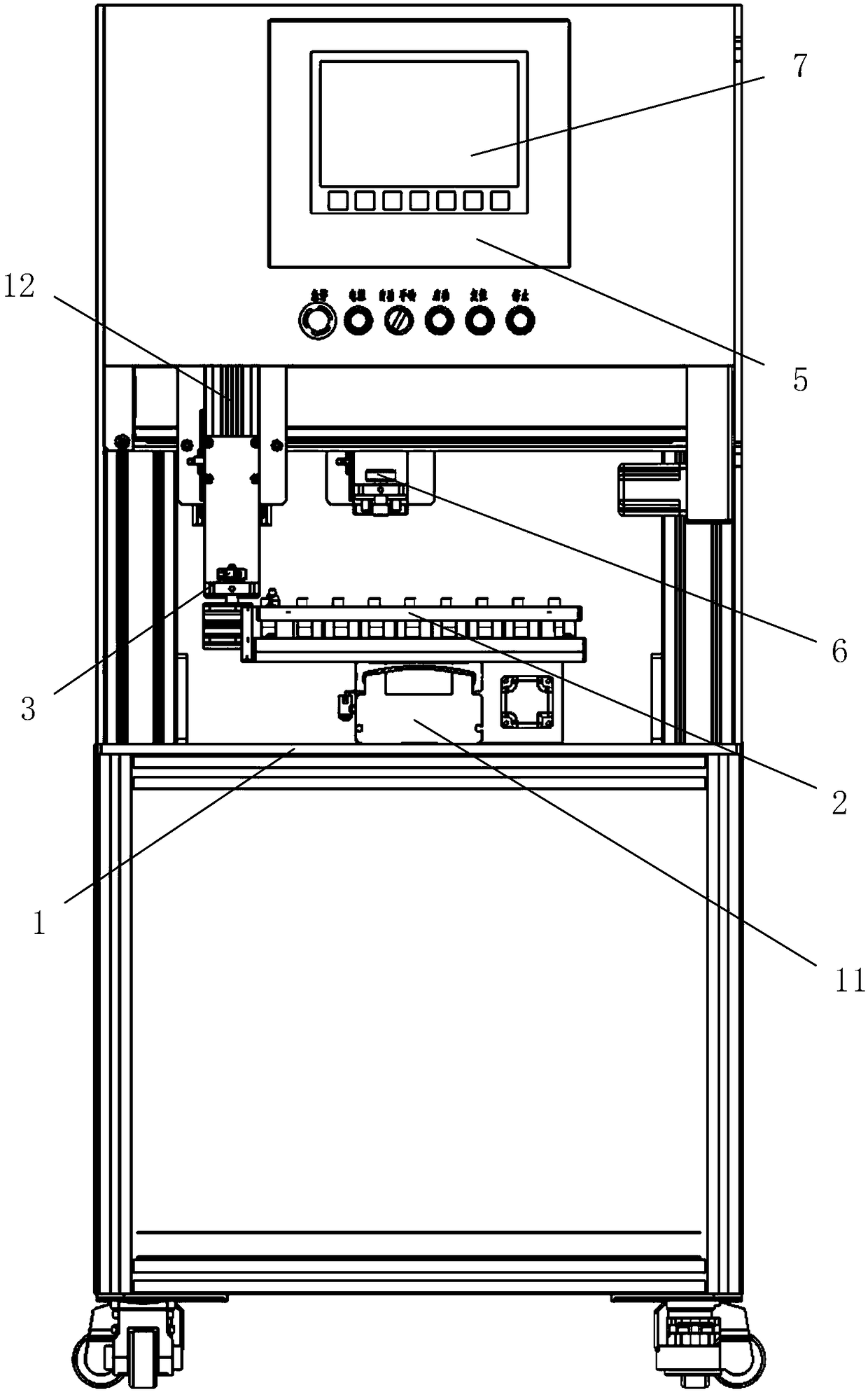

Electronic cigarette liquid filling equipment and use method thereof

InactiveCN108936818AMeet the needs of filling and storageSimple structureTobacco treatmentTobacco devicesElectronic cigaretteBottle

The invention discloses electronic cigarette liquid filling equipment and a use method thereof. The equipment comprises a body, a cigarette liquid bottle storage unit, a filling unit, a capping unit,a storage unit and a control unit, wherein the cigarette liquid bottle storage unit, the filling unit, the capping unit, the storage unit and the control unit are arranged on the body. The cigarette liquid bottle storage unit comprises a bottle body containing module and a cap body containing module, wherein the bottle body containing module is detachably mounted on the body. The filling unit andthe capping unit can relatively move independently. The storage unit is used for recording and storing cigarette liquid bottle containing information in the bottle body containing module, cap body containing information in the cap body containing module, position information of the filling unit and position information of the capping unit. The control device controls the filling unit to quantitatively inject electronic cigarette liquid into cigarette liquid bottles according to the cigarette liquid bottle containing information and the position information of the filling unit and further controls the capping unit to take cap bodies out of the cap body containing module to cover the cigarette liquid bottles in which the electronic cigarette liquid is injected according to the cigarette liquid bottle containing information, the cap body containing information and the position information of the capping unit.

Owner:QINGDAO ETSONG TECH CO LTD

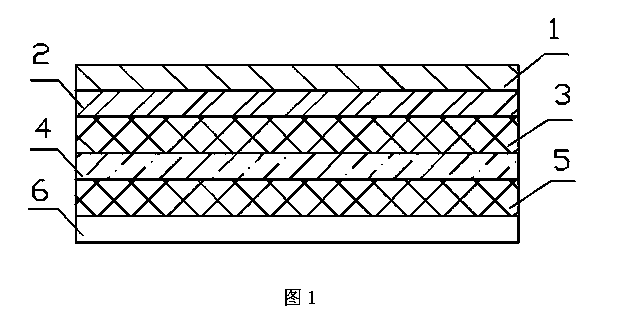

Environment-friendly and easy-to-attract floor and manufacturing method thereof

InactiveCN103382761AImprove toughnessInsulationSynthetic resin layered productsGlass/slag layered productsGlass fiberEngineering

The invention discloses an environment-friendly and easy-to-attract floor and a manufacturing method thereof. The environment-friendly and easy-to-attract floor is characterized by comprising a wearproof layer, a printing leather layer, a first packed layer, a glass fiber layer, a second packed layer, and a self-suction layer. The manufacturing method comprises the following steps: firstly, placing the printing leather layer, the first packed layer, the glass fiber layer, the second packed layer and the self-suction layer in sequence, and pressing and forming at the temperature of 150 DEG C and under the pressure of 40-50 tons; secondly, adopting the UV technology to coat the upper surface of the printing leather layer with UV coating of 8-10 g / square meter; thirdly, performing high temperature tempering and subcooling; fourthly, punching and forming. The environment-friendly and easy-to-attract floor has the advantages of water resistance, moisture resistance, deformation resistance, good elasticity, firm attraction to ground, and convenience in use.

Owner:上海进丰塑胶建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com