Micro closed-circuit continuous flotation machine

A flotation machine, closed-circuit technology, applied in flotation, solid separation, etc., can solve the problems of increased equipment investment, increased operating costs, affecting flotation data collection, etc., and achieves the effect of large aeration volume and strong self-priming ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

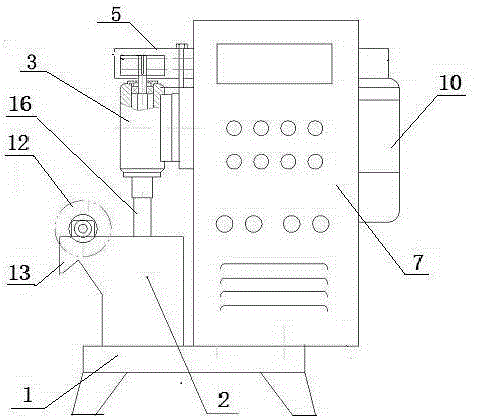

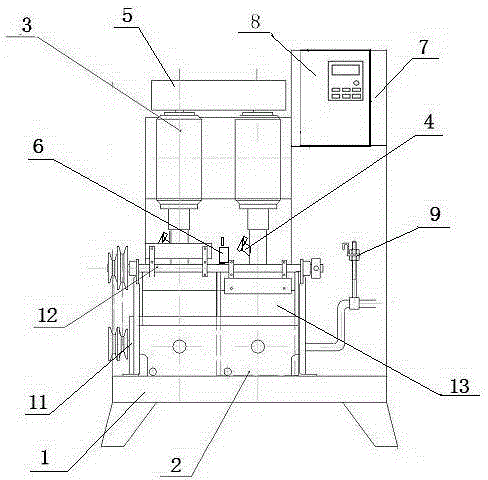

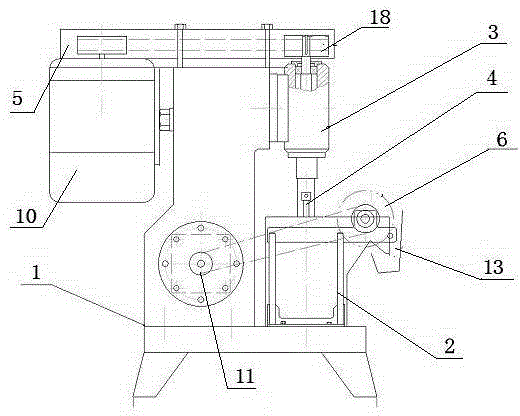

[0020] A miniature closed-circuit continuous flotation machine mainly includes a slurry storage tank, a mixing tank, a micro-dosing machine rubber hose pump, and a flotation machine. Plate motor 11, scraper 12, foam tank 13, liquid level regulating tube 9, frequency converter 8, electric control box 7, stirring shaft 15, impeller 14, the slurry storage poke is connected to the mixing tank, and the mixing tank is connected to the micro-dosing machine and rubber hose The pump is connected to the flotation tank 2, the frequency converter 8 is connected to the control main motor 10, the liquid level regulating pipe 9 is installed on the flotation tank, the dosing machine is connected to the mixing tank, and the auxiliary absorbent foaming agent and regulator are used for supply flotation. It is characterized in that: the flotation cell capacity of the flotation machine is divided into three groups of 1 liter tank, 0.75 liter tank and 0.5 liter tank, among which the first unit has e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com