Engine electric control oil supply device for model airplane and unmanned aerial vehicle

A fuel supply device and engine technology, applied in the direction of machines/engines, engine components, charging systems, etc., can solve the problem that the carburetor cannot absorb oil, reduce the endurance time, and cannot accurately control the fuel supply and fuel atomization Effect and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

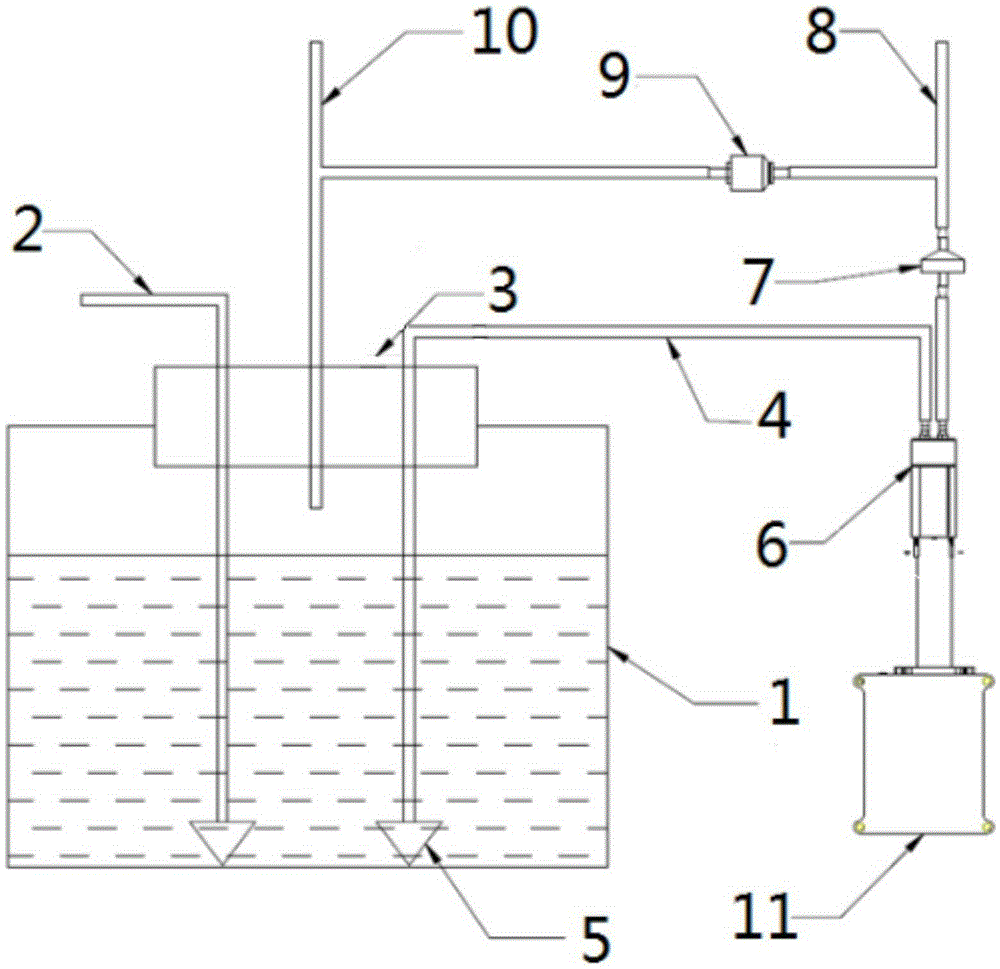

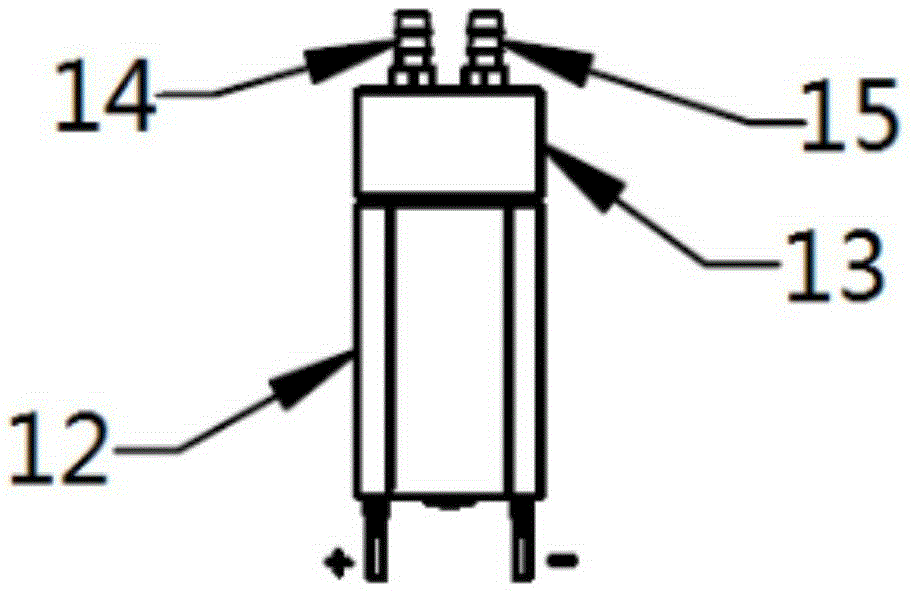

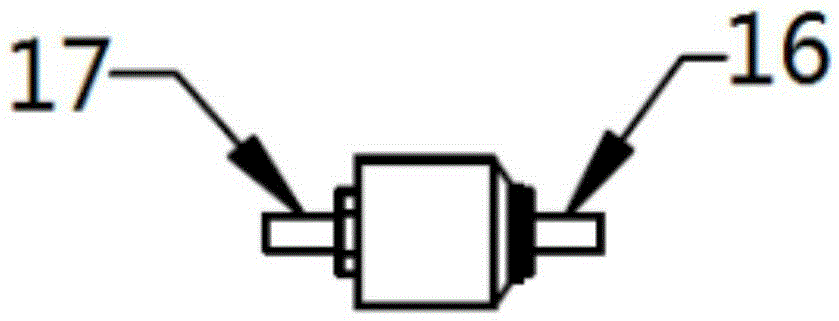

[0017] like Figures 1 to 3 As shown, the small UAV oil supply system provided by the present invention includes a fuel tank 1, a refueling pipe 2, a fuel tank cover 3, an oil suction pipe 4, a weight 5, a micro gear pump 6, a one-way valve 7, a high-pressure oil pipe 8, Micro pressure regulator 9, exhaust pipe 10. The fuel tank cap 3 is provided with a filler port, one end of the fuel filler pipe 2 passes through the fuel filler port of the fuel tank cap 2, and sinks into the bottom of the fuel tank 1 through the weight 5, and the other end of the fuel filler pipe 2 leads to the outside of the fuel tank, except that this end needs to be used when refueling. Plug it up. One end of the oil suction pipe 4 passes through the fuel tank cap 2 and sinks into the bottom of the fuel tank 1 through the weight 5 , and the other end is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com