River channel dredging, screening and mud-cleaning method and equipment

A river dredging and screening technology, applied in mechanically driven excavators/dredgers, earthmoving machines/shovels, construction, etc. The effect of silt mechanization, strong self-priming ability and stable conveying operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

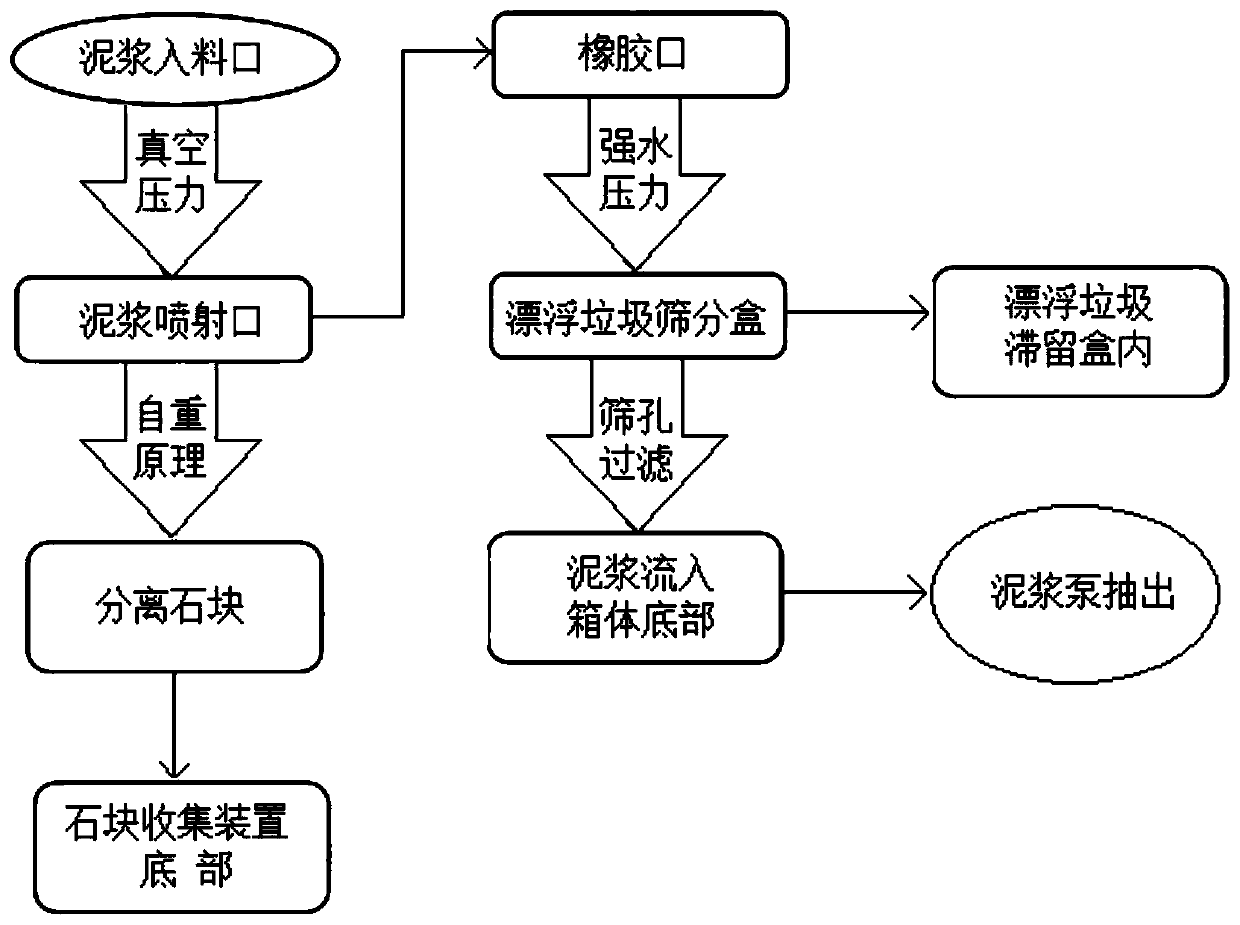

Method used

Image

Examples

Embodiment 1

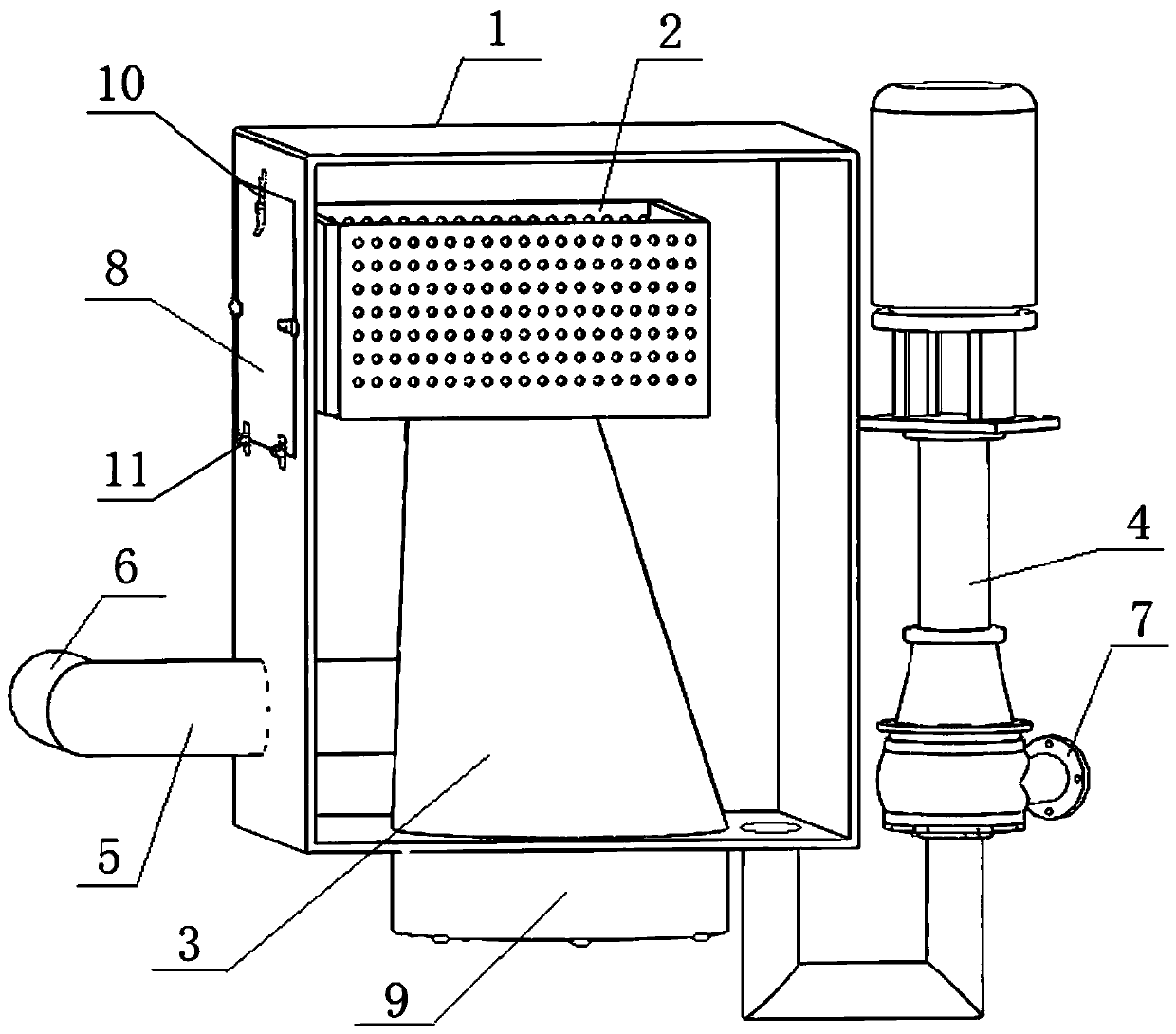

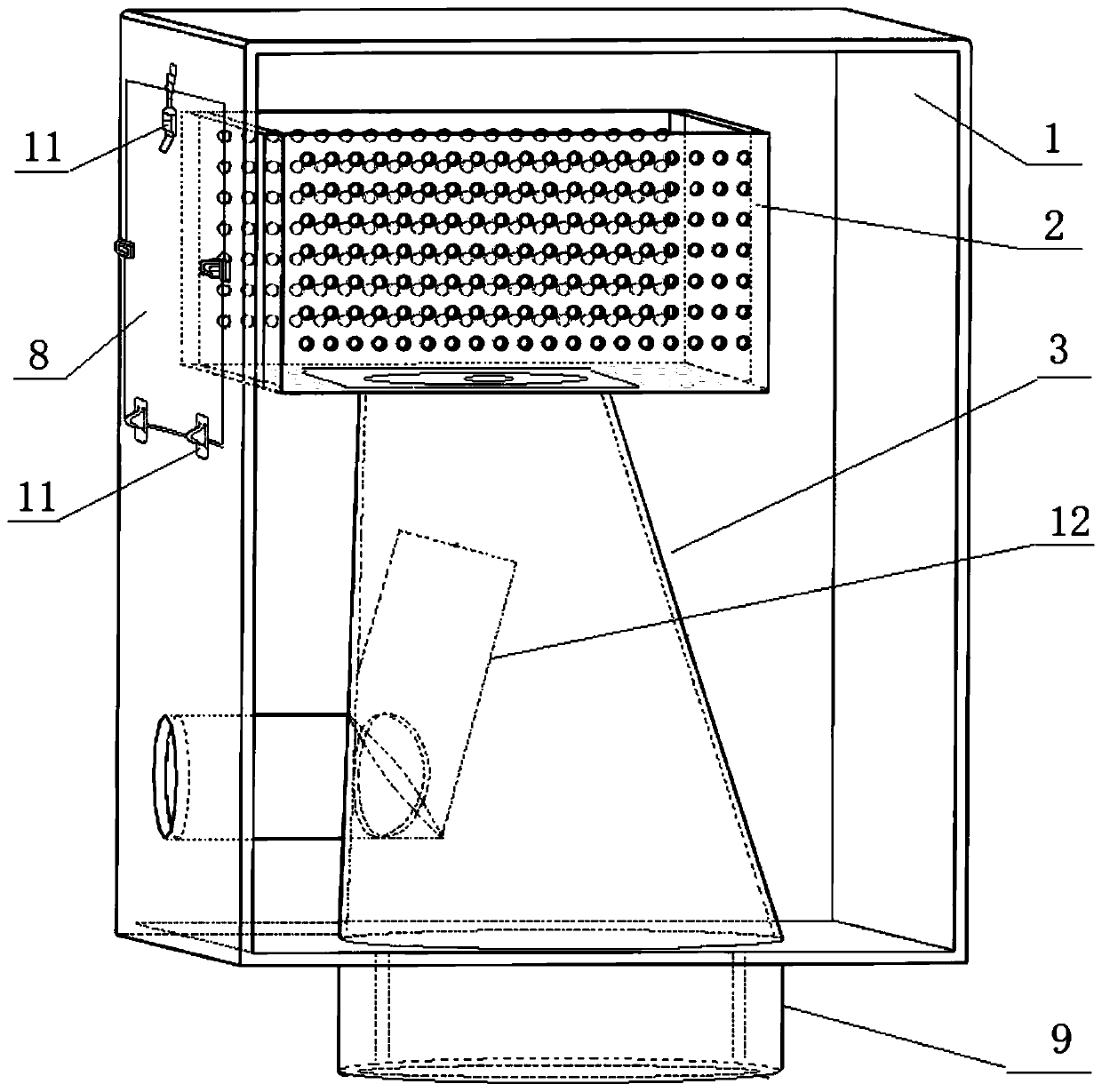

[0036] Embodiment 1: as attached figure 2 As shown, a mud pump 4 is installed on the outer side of the casing 1, and a mud pipe 5 is installed on the lower part of the other side outside the casing 1. The outer end of the mud pipe 5 has a mud inlet 6, and the inner end of the mud pipe 5 is connected through the mud injection port 12. In the stone collection device 3 installed vertically in the box body 1, the mud injection port 12 is inclined upwards, and the floating garbage screening box 2 is installed on the top of the stone collection device 3, and the mud pump 4 is connected to the mud discharge port 7 outwards, and the mud The pump 4 is inwardly connected to the gap between the outer wall of the bottom stone collection device 3 of the box body 1 and the inner wall of the box body 1. The bottom end of the stone collection device 3 is connected to the bottom of the box body 1 and connected to the stone discharge port 9. There is a middle hole 201 on the connection interfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com