Alternative rotary pump

A technology of alternating rotation and pump body, applied in the direction of rotary piston pump, rotary piston machine, pump, etc., can solve the problems of difficult to increase pumping pressure, short service life, complex structure, etc., and achieve strong self-priming ability, high Pressure, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

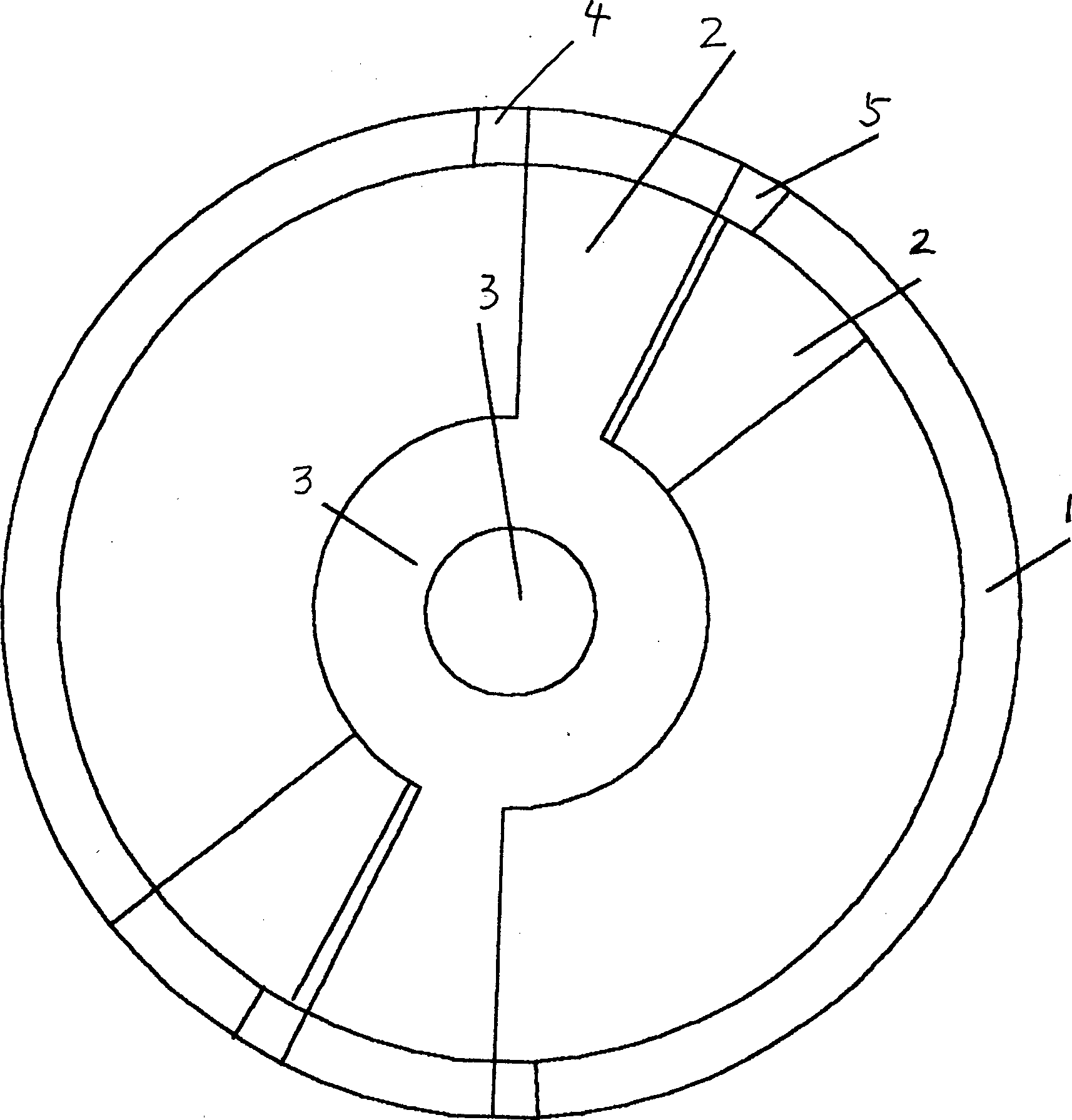

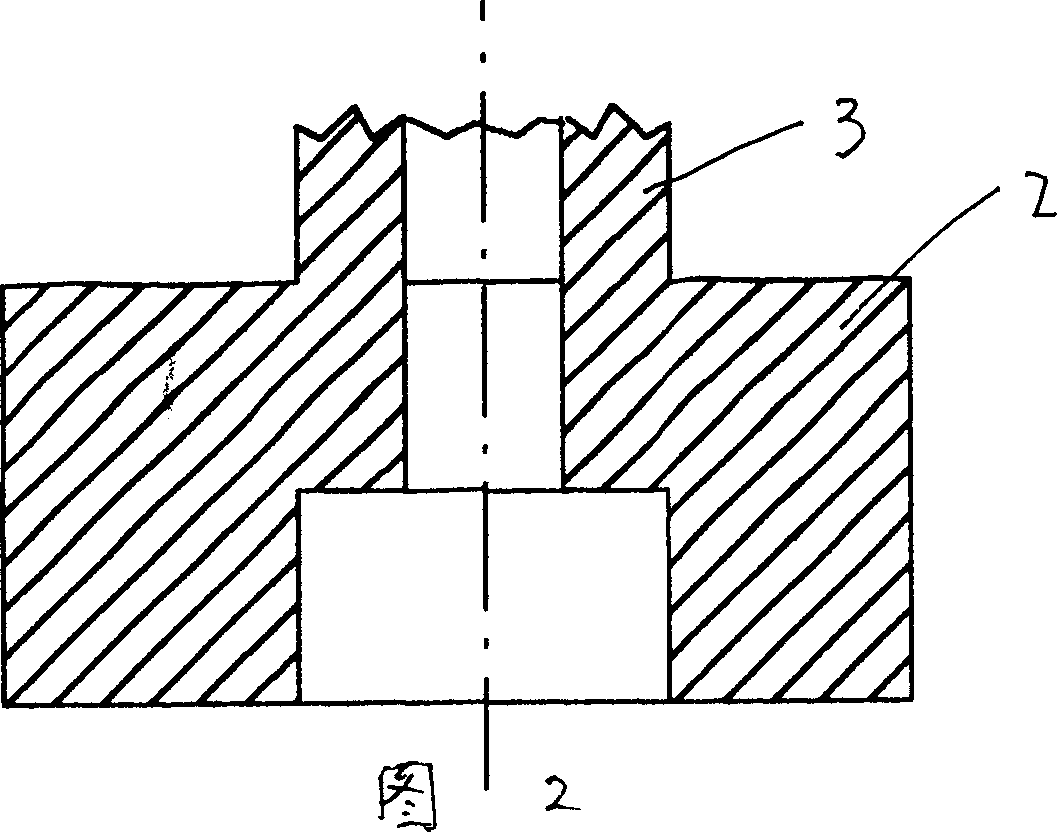

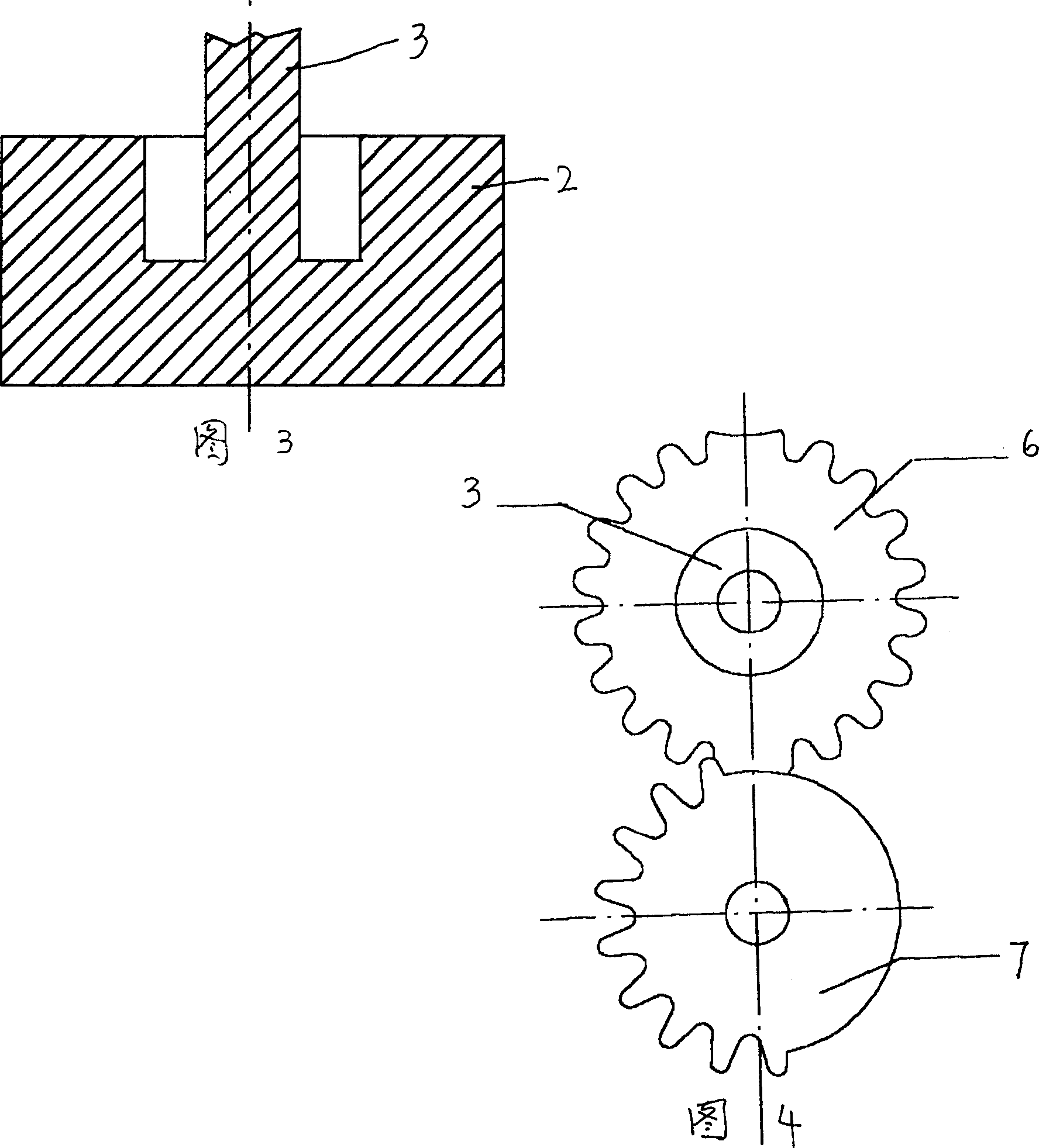

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings: the present invention mainly includes a pump body 1, a pump blade 2 in the pump body, and a driving mechanism connected to the pump blade 2, etc. FIG. The pump body 1 is provided with two rotary vanes 2 which are nested with each other through their respective intermediate rotary vane shafts 3 . The respective two ends of the two rotary vanes 2 are close to the inner wall of the pump and can move relative to each other. The two rotary vanes 2 are placed adjacent to each other and are at the initial position. A suction port 4 and a discharge port 5 are symmetrically opened on the top. A driven gear 6 is respectively fixed on the two rotating blade shafts 3, and a driving gear 7 connected to the driving mechanism meshes with the driven gear 6, and the driven gear 6 and the driving gear 7 constitute a group of incomplete gear transmission mechanisms, That is, the driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com