Jet self-sucking centrifugal water pump

A centrifugal pump and jetting technology, applied in the field of jetting self-priming centrifugal water pumps, can solve the problems of increasing matching power, increasing matching costs, and short self-priming time, and achieve reduction in shaft power, lowering supporting costs, and self-priming time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to accompanying drawing.

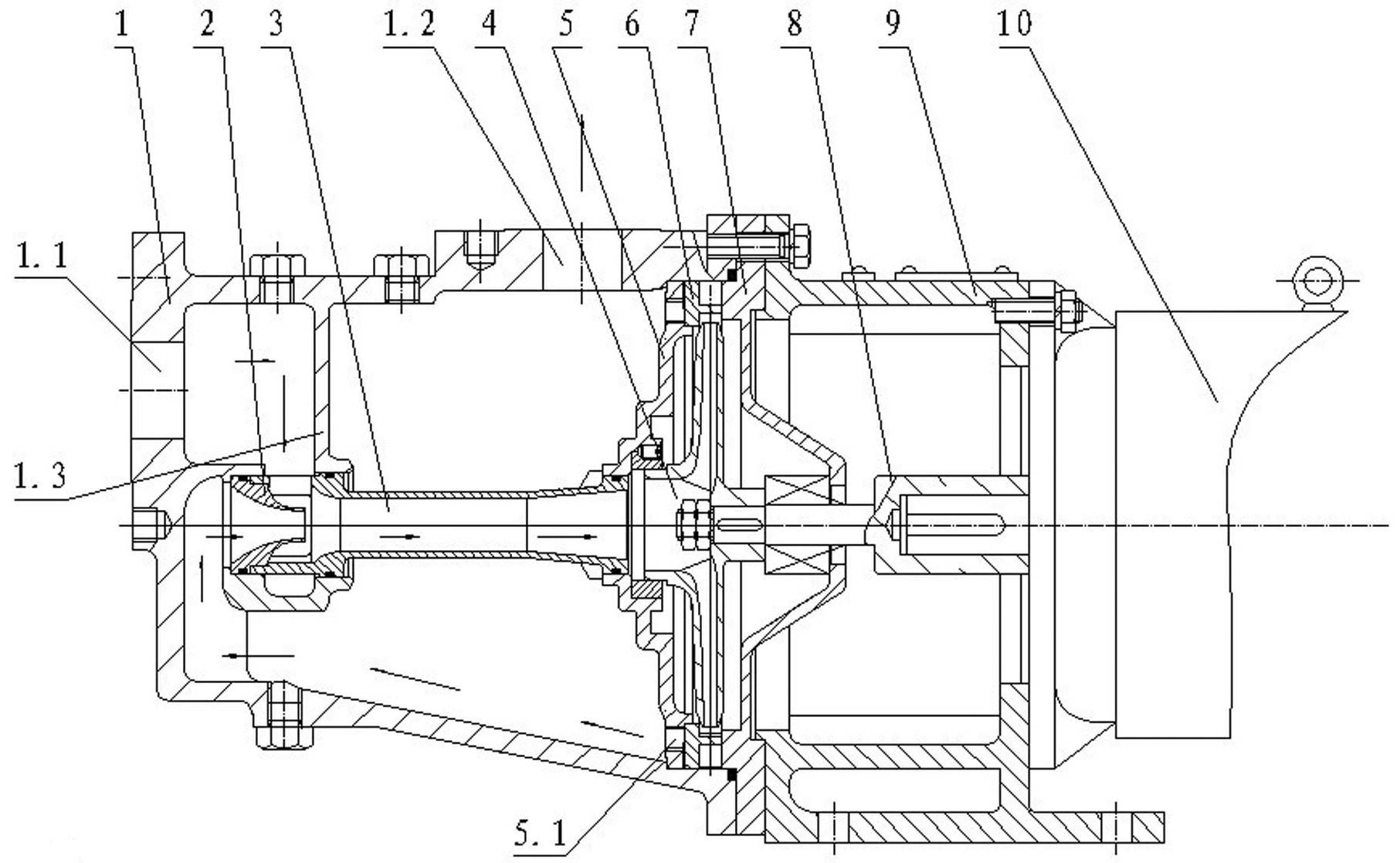

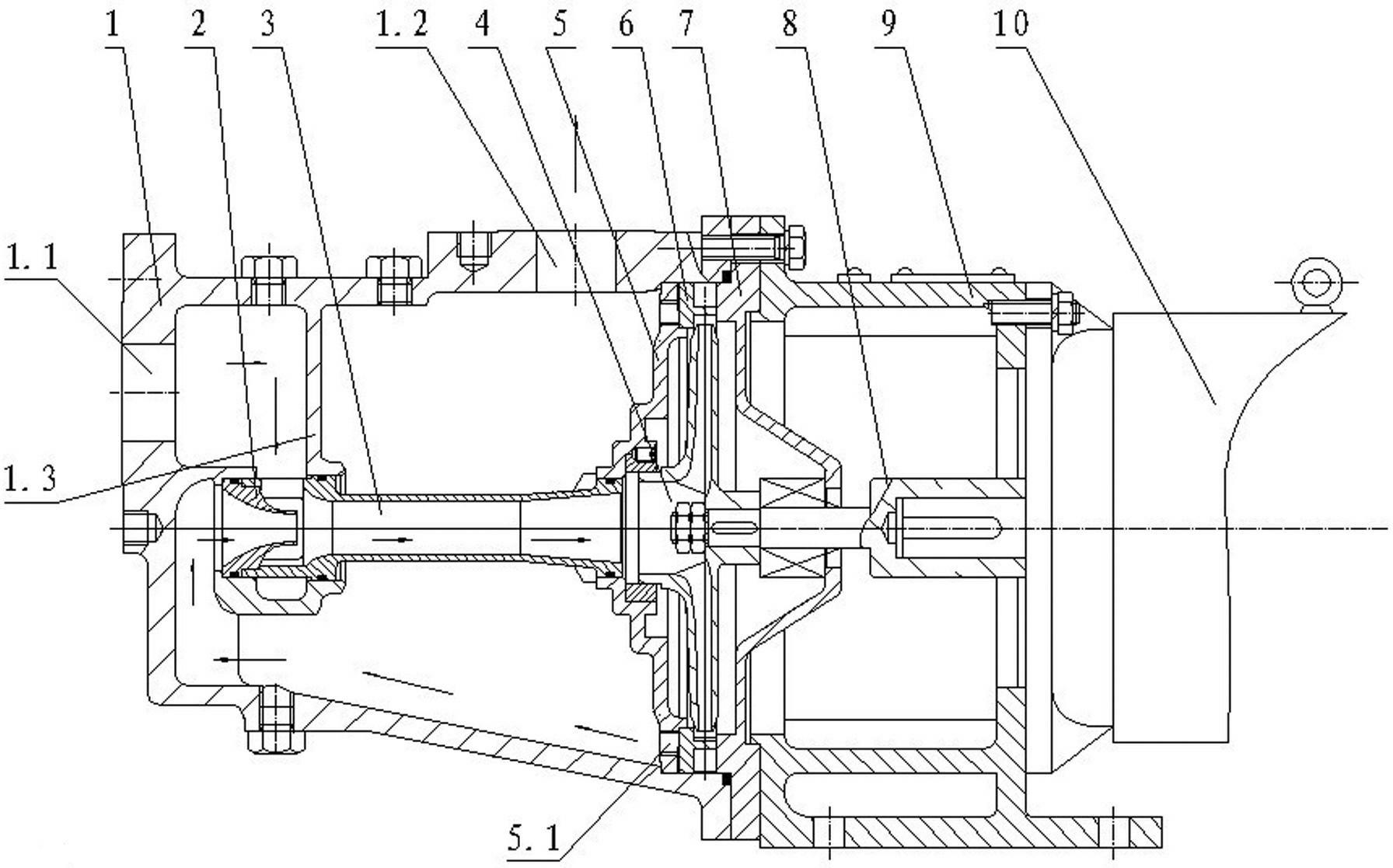

[0013] figure 1 The jet type self-priming centrifugal pump shown is a pump with horizontal structure, including pump body 1, nozzle 2, diffuser 3, impeller 4, inner pump cover 5, guide vane 6, outer pump cover 7, pump Shaft 8, carriage 9 and motor 10. The end face of the output shaft of the supporting motor 10 is directly connected to the bracket 9, the pump shaft 8 is coaxially connected with the motor 10, the impeller 4 is positioned and installed on the end of the pump shaft 8, and the two sides of the impeller 4 are respectively composed of the outer pump cover 7, the guide vane 6 and the inner pump cover 7. The pump cover 5 cooperates to form the pump chamber structure of the centrifugal pump. The pump body 1 is an open container in a lying position, with a water suction port 1.1 on the half of the outer end surface, and a water outlet port 1.2 on the top surface of the pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com