Anti-collision drilling assembly for vertical sections in dense cluster well groups and anti-collision method thereof

A drill bit and drill collar technology, applied in drill pipe, drill pipe, drilling equipment, etc., can solve problems such as applicability limitation, failure, and inability to obtain real-time wellbore trajectory, and achieve the effect of simple principle, stable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

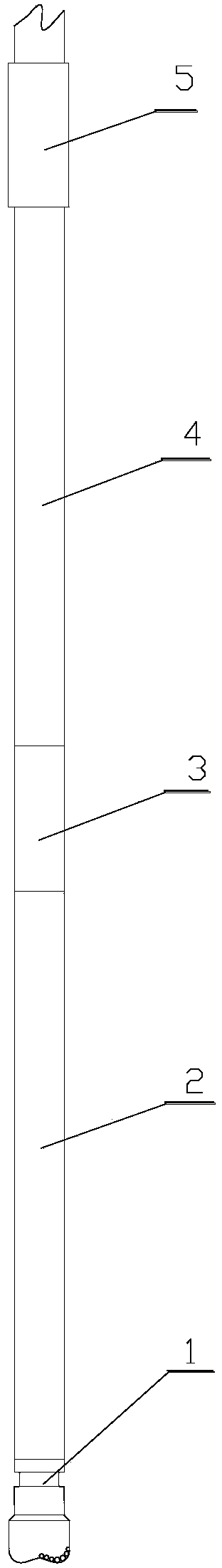

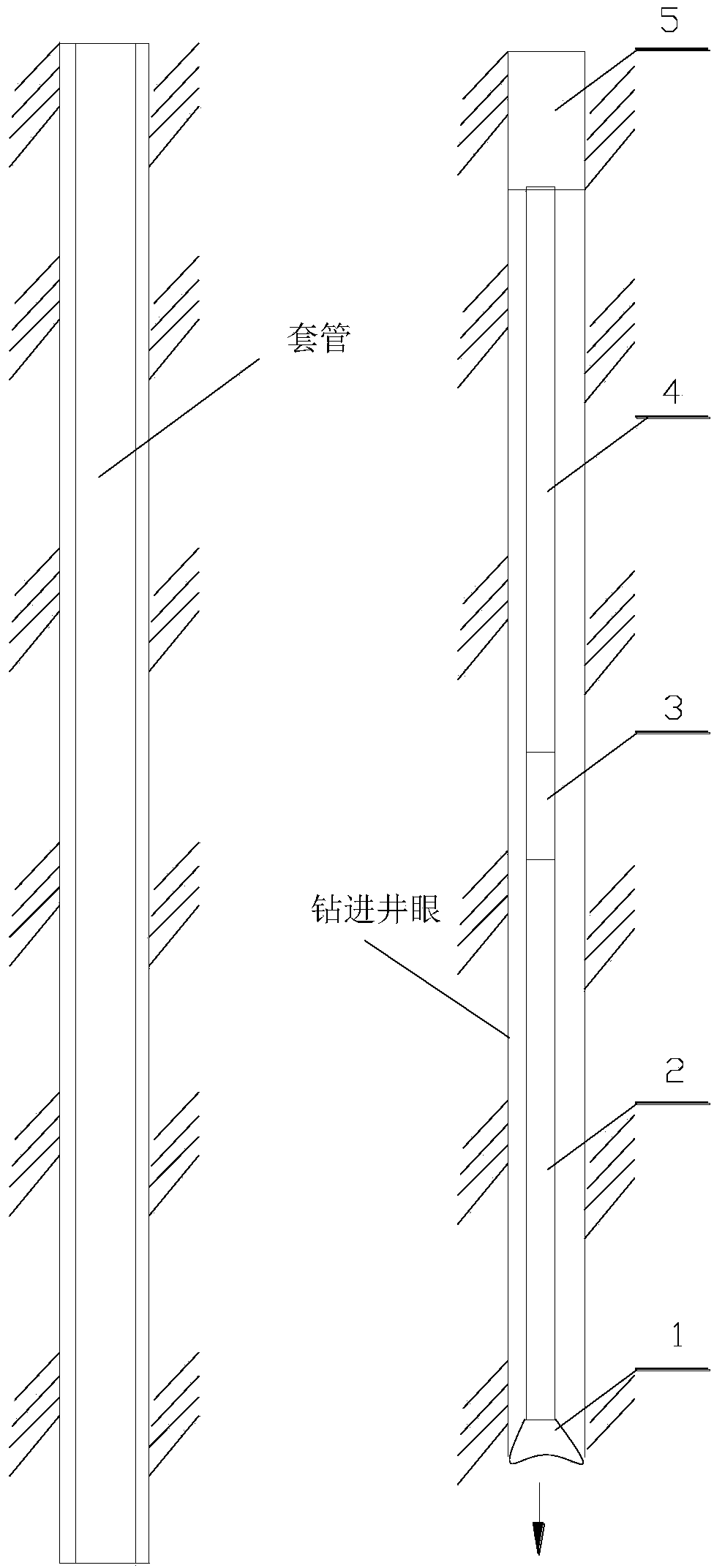

[0033] figure 1 As shown, the anti-collision drilling tool assembly for the vertical well section of dense cluster well group includes: drill bit 1, drill bit upper collar 2, strong magnetic nipple 3, centralizer lower collar 4, full-hole centralizer 5; drill bit 1, drill bit upper The drill collar 2, the strong magnetic short joint 3, the drill collar 4 at the lower part of the centralizer, and the full eye centralizer 5 are connected by threads in sequence. During the drilling process, the drill bit 4 is located at the bottom of the well and is used for rock-breaking drilling; the upper drill collar 2 of the drill bit, the strong magnetic short joint 3, the lower drill collar 4 of the centralizer, and the full-hole centralizer 5 are combined to form a combined structure for changing The drilling tendency of the drill bit; the centralizer 5 is connected with the drilling tool assembly on the upper part of the centralizer 5 .

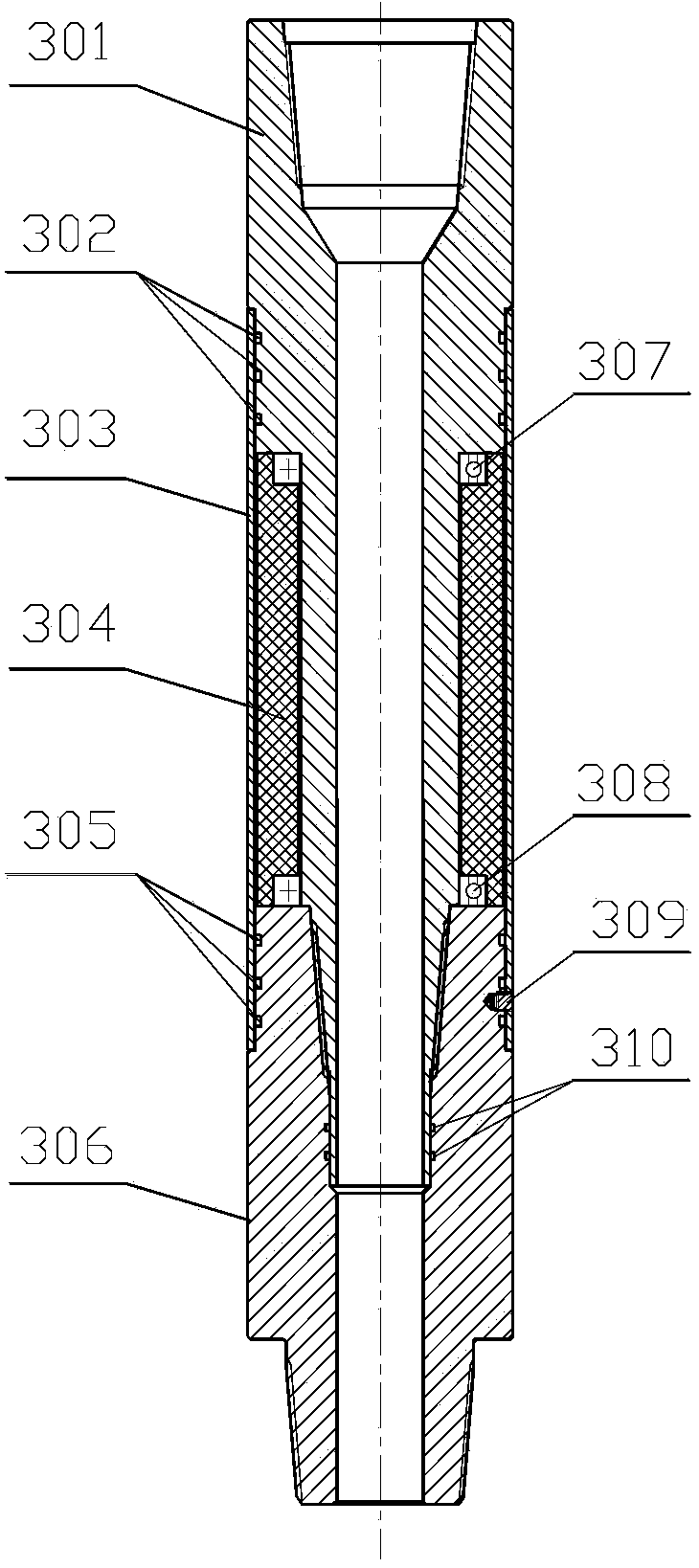

[0034] figure 2 As shown, the strong magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com