Urban rail transit engineering highway-railway dual-purpose rail layer and using method thereof

A dual-purpose technology for urban rail transit, road and rail, applied in tracks, track laying, track maintenance, etc., can solve problems such as inability to better improve work efficiency, inability to play an advantageous role, and inability to give full play to advantages, and achieve outstanding environmental protection advantages. , The effect of improving work efficiency and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

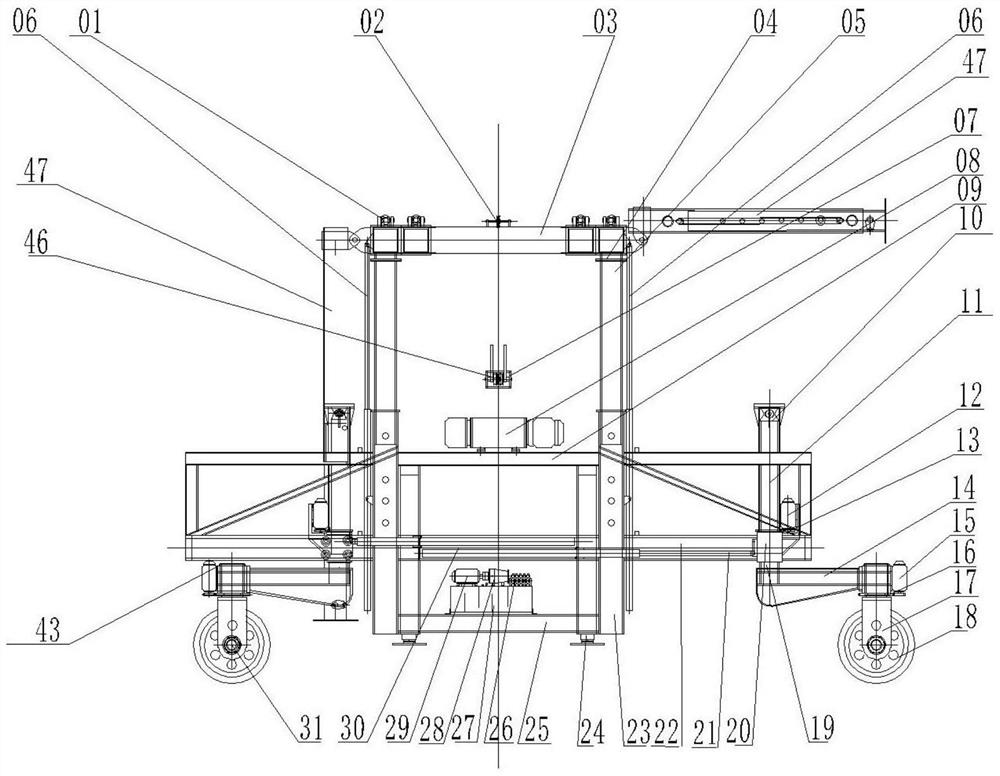

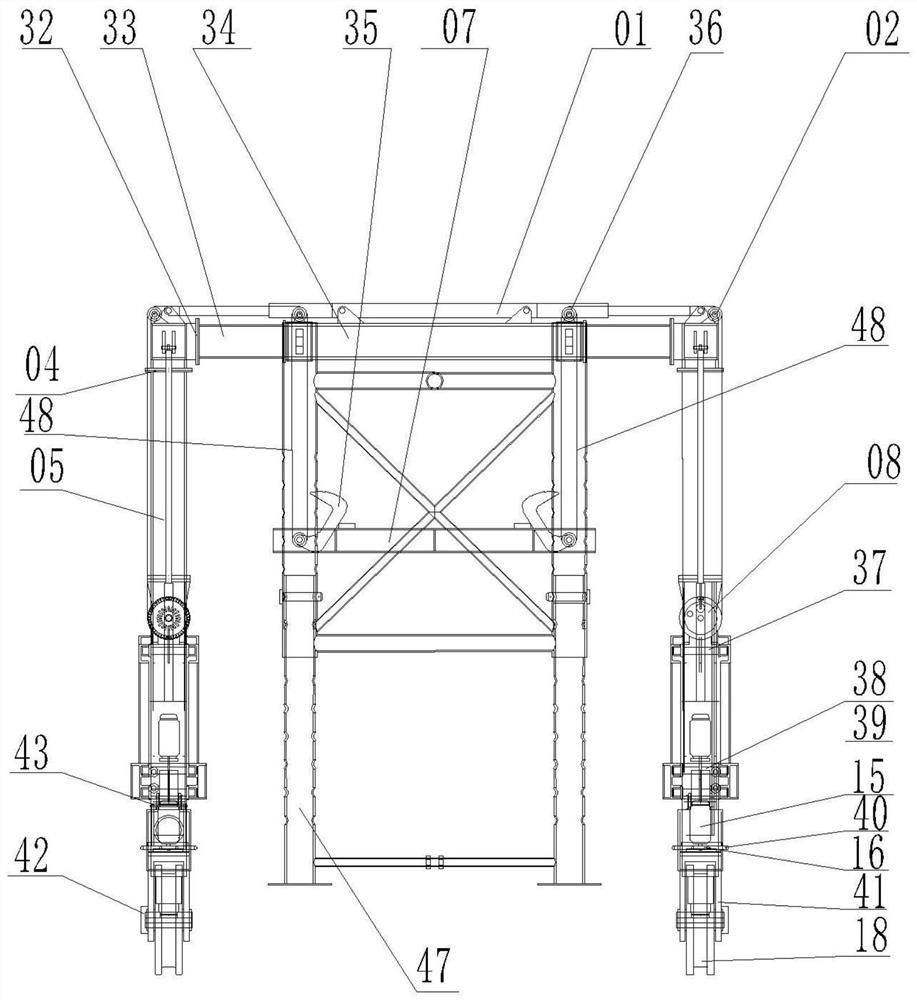

[0083] First of all, the road-rail track-laying machine should be in place on the working surface. Such as Figure 14 As shown, the gantry crane of the track laying base is used to lift the road-rail track-laying machine and move it to the rail material discharge port, and put it on the transport flatbed on the main track smoothly, such as transferring the road-rail track-laying machine The supporting legs are placed on the flatbed car and fixed with a fixed jack rope to complete the loading operation of the road-rail dual-purpose track laying machine. Then the rail tractor pushes the loaded rail-rail laying machine to the place where the operation is required, and then stops to prepare for unloading.

[0084] When unloading, first of all, remove the jack rope that fixes the road-rail track-laying machine, and check whether the surrounding environment meets the unloading and parking conditions of the road-rail track-laying machine. After everything is correct, start the powe...

Embodiment 2

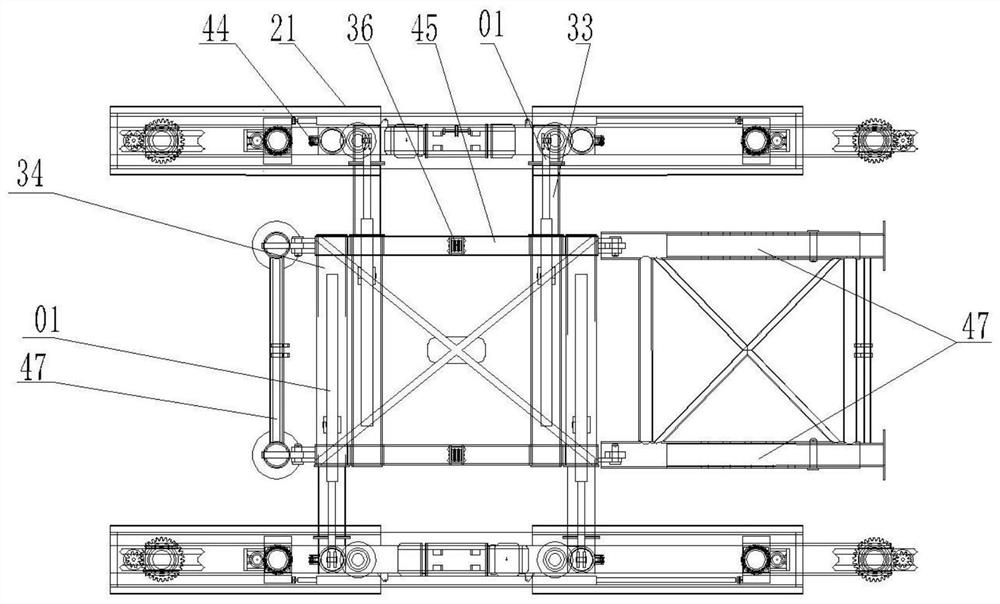

[0095] The working surface transfer and long-distance transfer operation of the road-rail track-laying machine are as follows. When the road-rail track-laying machine completes the track-laying operation of the working surface and needs to transfer to the new working surface for operation, follow the steps below.

[0096] 1. Homework preparation

[0097] Stop the road-rail dual-purpose track-laying machine at the position where the poured integral track bed is convenient for loading, release the double-machine linkage and resume single-machine operation.

[0098] 1. Turn the first road-rail track-laying machine into the working state of hoisting new rail rows and stop the operation. Command the track tractor to push the unloaded transport flatbed car to park at a suitable position near the road-rail dual-purpose track laying machine (one flatbed car is equipped with two road-rail dual-purpose track laying machines) to stop and brake.

[0099] 2. Micro-move the height elevatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com