Underground line monolithic roadbed expansion joint form reinforcing device and construction method thereof

A technology of reinforcement device and integral track bed, applied in the directions of roads, tracks, ballast layers, etc., can solve the problems of affecting the appearance quality, prone to floating, and the bending of expansion joints is not straight, so as to achieve a simple and feasible combined structure, easy installation and The effect of dismantling and improving the appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

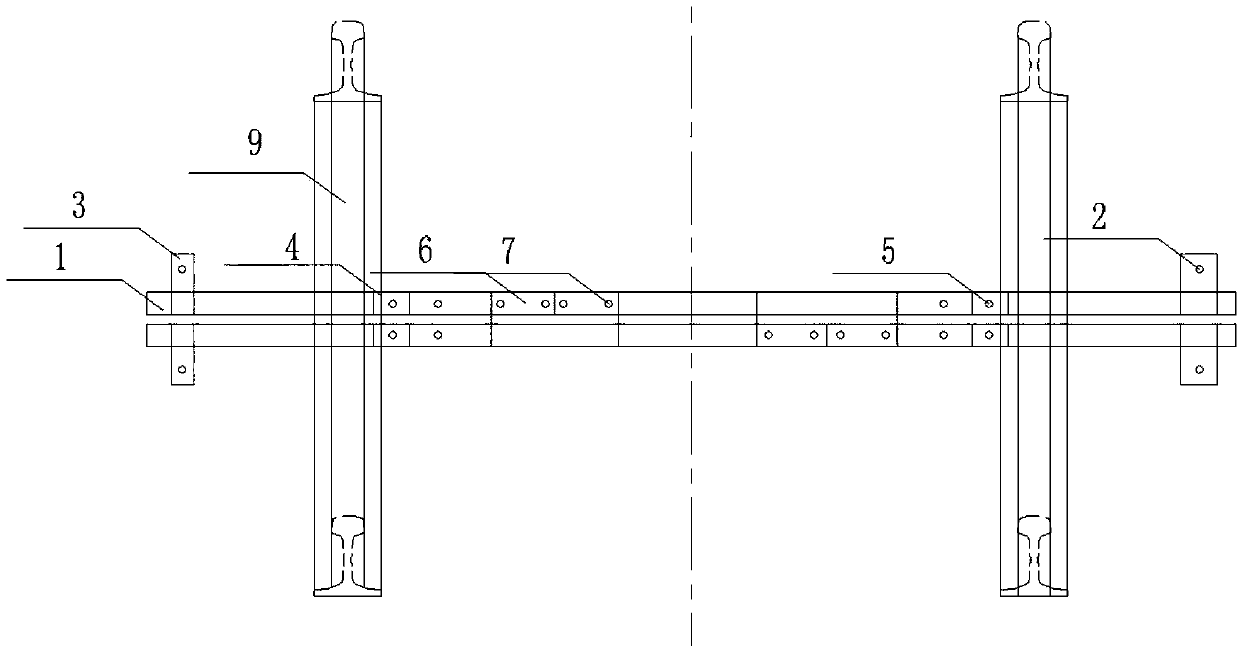

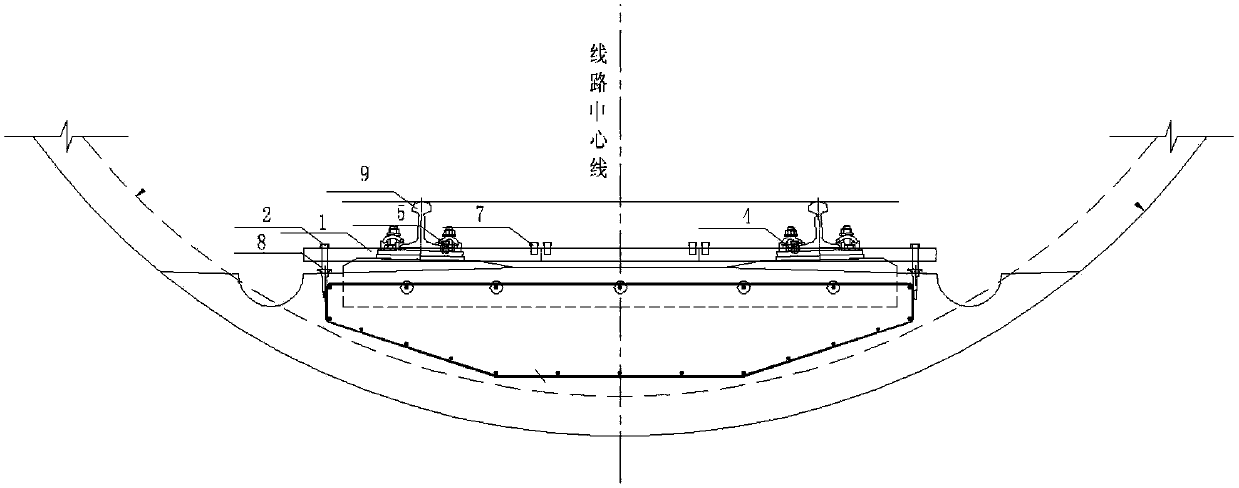

[0027] The construction method of the expansion joint formwork reinforcement device is as follows:

[0028] First, determine the size of the angle iron according to the design drawings for cutting, and drill bolt holes at the corresponding positions.

[0029] Then, after the expansion joint flat steel welding is completed, the expansion joint formwork is placed at the construction position, and the angle iron structures are respectively placed and fixed on both sides of the expansion joint formwork.

[0030] Next, fix the angle iron structure on one side on the rail in the middle of the two sleepers with the rail fixing pressure plate and the rail fixing bolts, and adjust the position of the expansion joint template. After the position of the expansion joint template is fixed, fix the angle iron on the other side to the rail with the rail fixing plate and rail fixing bolts.

[0031] Finally, use the terminal fixing steel plate and the connecting terminal fixing bolt to fix th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com