Efficient multifunctional rotor type submersible sewage pump

A multi-functional, rotor-type technology, applied in the field of volumetric pumps, can solve the problems of reducing winding, motor burnout, difficult pollutants, etc., and achieves the effects of strong anti-winding ability, strong self-priming ability, and strong non-clogging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

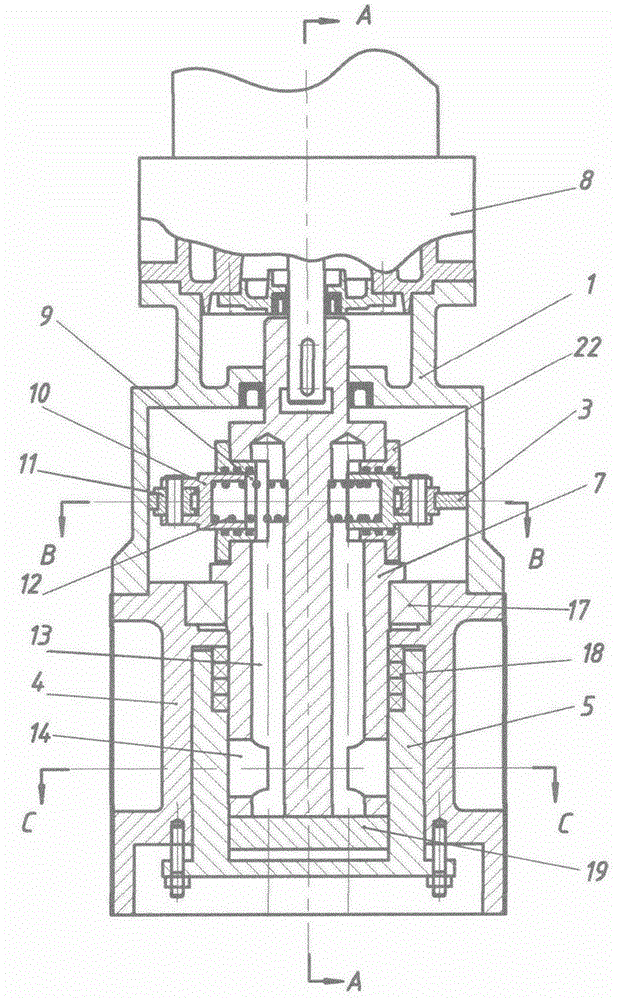

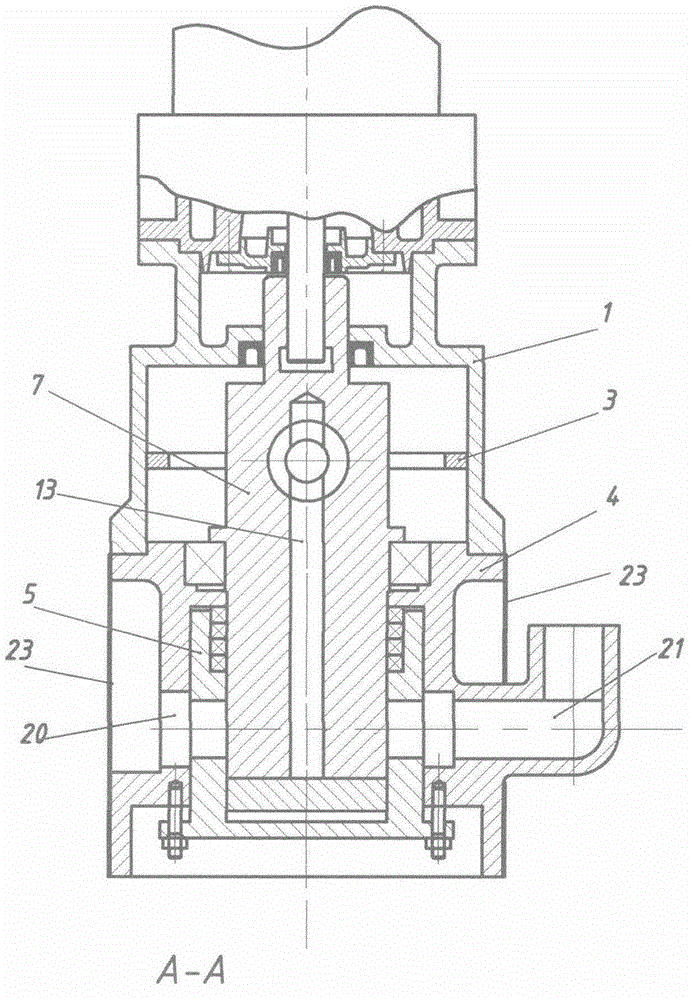

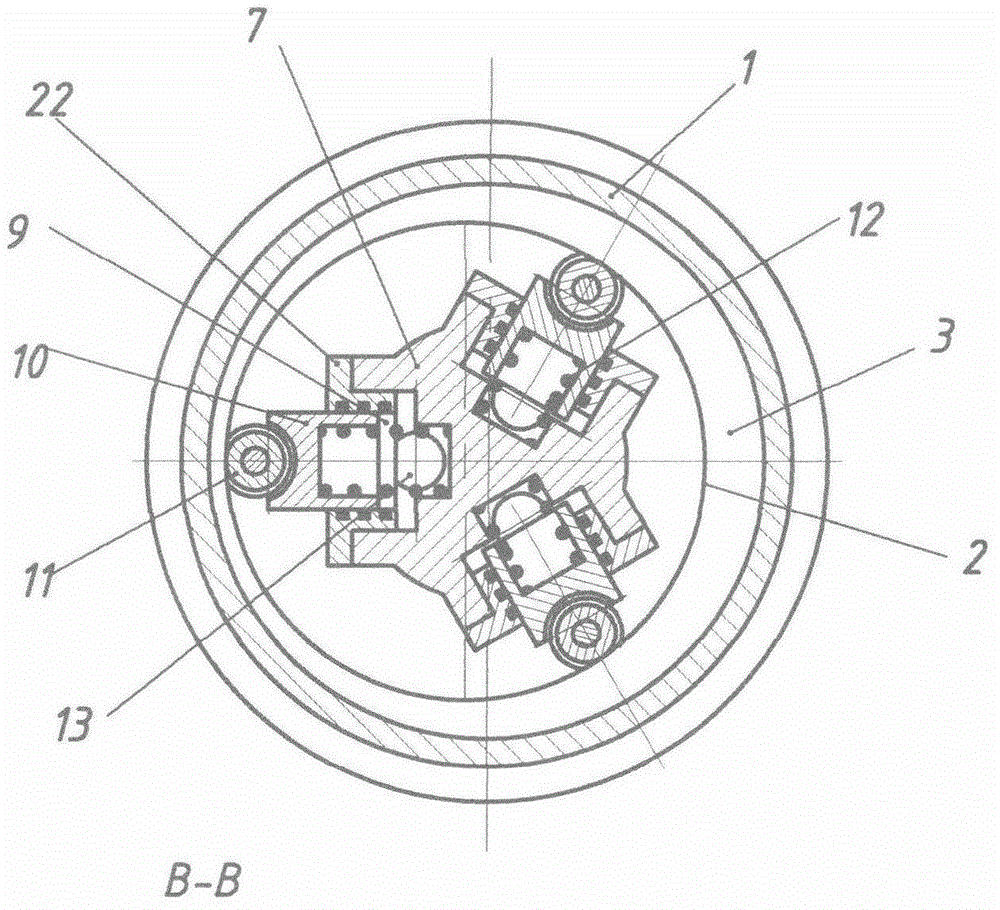

[0027] figure 1 It is a structural diagram of the submersible sewage pump with a row of plungers 10 in the present invention, figure 2 yes figure 1 A-A sectional view of, image 3 yes figure 1 The B-B sectional view, Figure 4 yes figure 1 C-C section view.

[0028] The figure shows: the submersible motor 8 is fixed on the top of the body 1, the pump body 4 is fixed on the bottom, the cylindrical inner cavity of the body 1 is fixed with a stator 3, and the stator 3 has an eccentric hole 2; the cylindrical inner cavity of the pump body 1 and the cylindrical body 1 The shaped inner cavity is coaxial and is equipped with a partition tongue sleeve 5 that can move axially. A pair of partition tongues 6 are formed on the partition tongue sleeve 5 to separate the high pressure area and the low pressure area in the pump body 4. The axis of the rotor 7 is in line with the body 1 and the pump body. The inner cavity of the body 4 is coaxial, and the upper end of the rotor 7 is dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com