Patents

Literature

35results about How to "Will not stop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

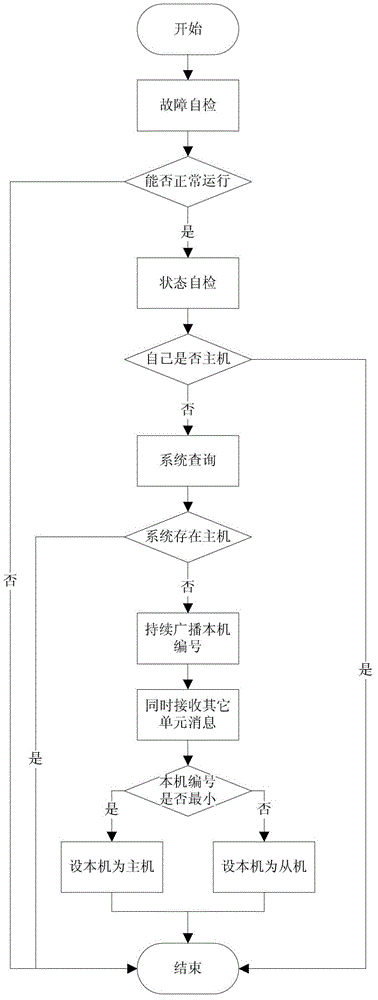

Start and stop control method for parallelly-connected multi-unit photovoltaic grid-connected inverter system

ActiveCN103178544AImprove efficiencyWill not stopSingle network parallel feeding arrangementsPhotovoltaic energy generationMulti unitGrid connected inverter

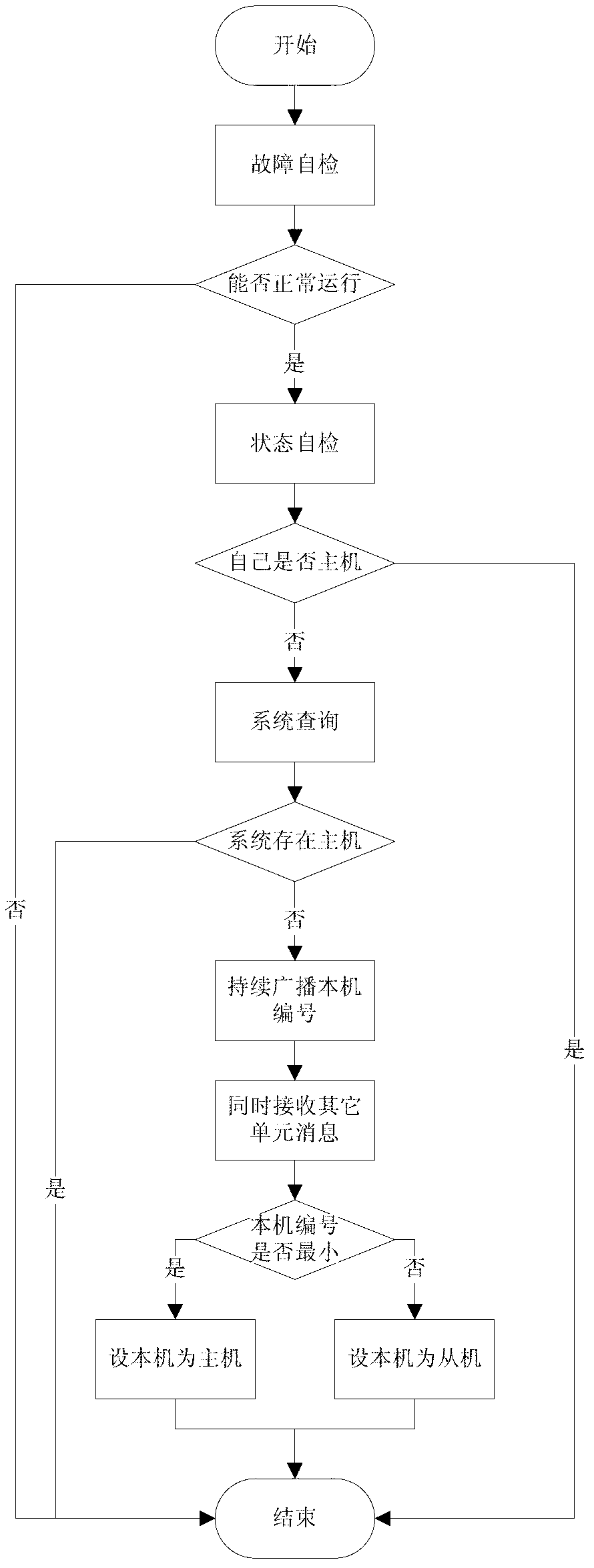

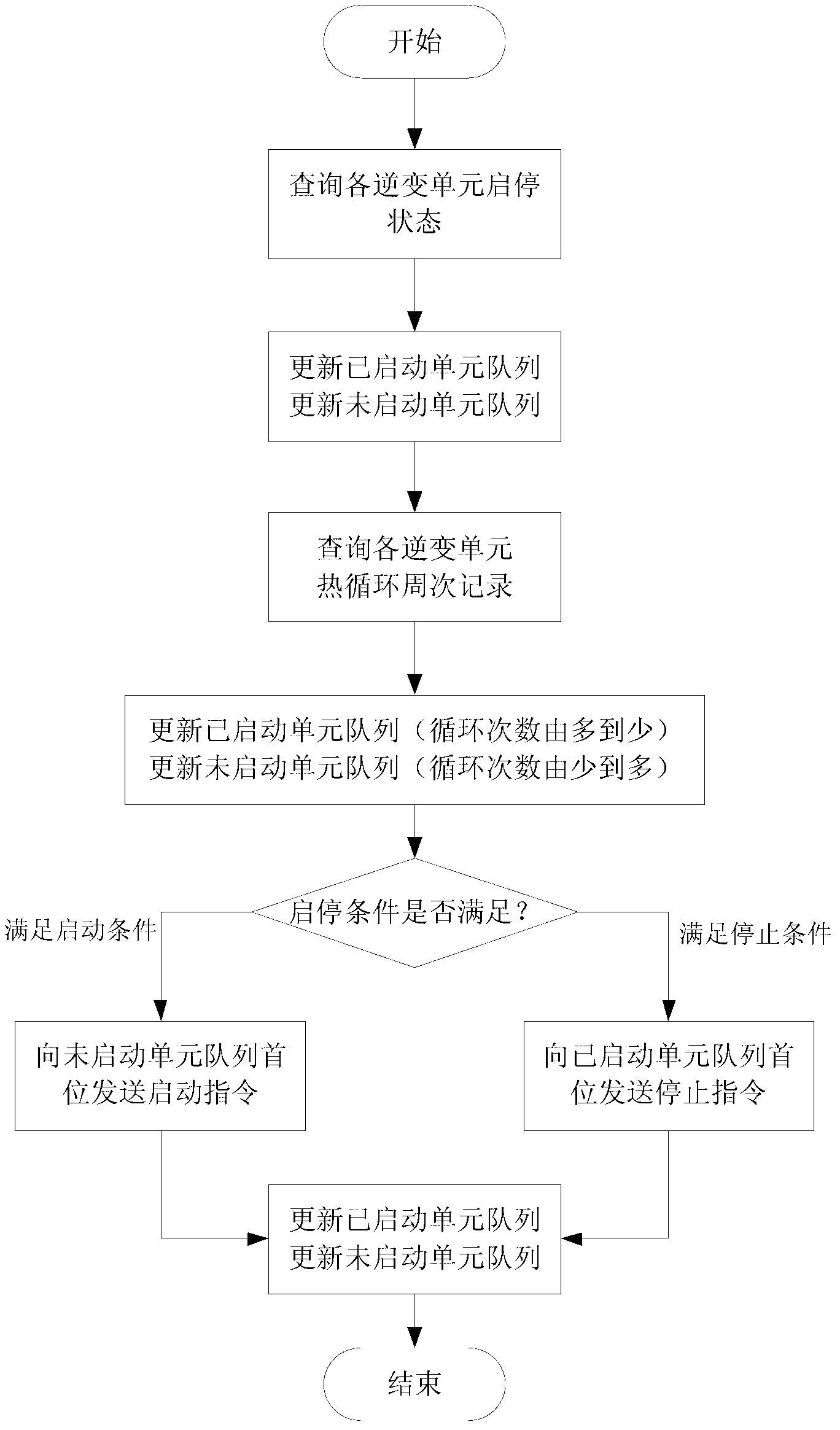

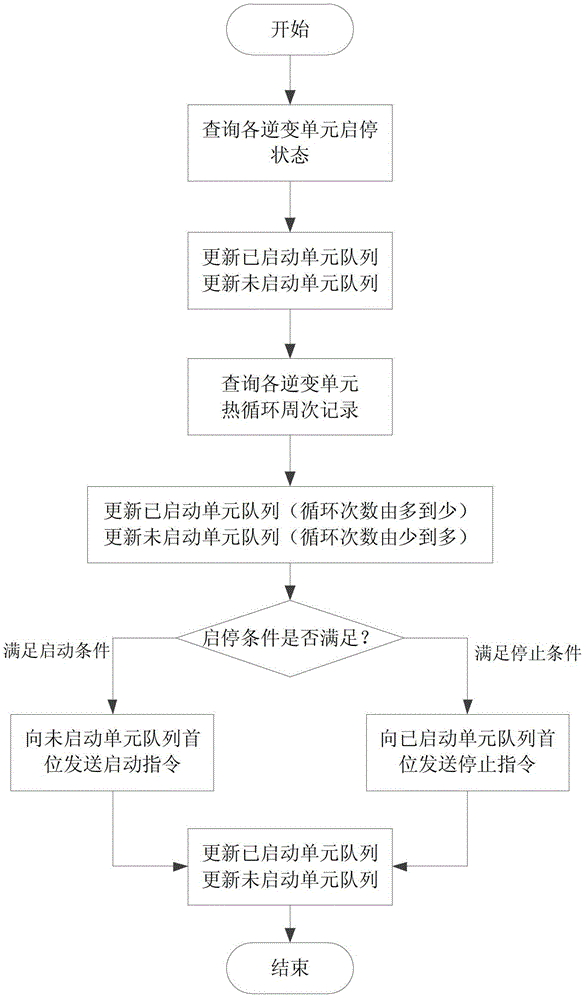

The invention discloses a start and stop control method for a parallelly-connected multi-unit photovoltaic grid-connected inverter system. The start and stop control method includes steps of selecting a main photovoltaic inverter unit, realizing highest efficiency of a parallel system; establishing a stop array (start array) of inverter units according to sequence of thermal circulation times from more to less (from less to more) of parallelly-connected photovoltaic inverter units in the start and stop conversion logic aspect of the parallelly-connected photovoltaic inverter units, and guaranteeing running time of all units to tend to be uniform. In the aspect of selecting a host, any photovoltaic inverter units which can normally run can be involved in competition with the host, and accordingly, halt of the parallel system caused by breakdown of the host is avoided.

Owner:TBEA XIAN ELECTRIC TECH +1

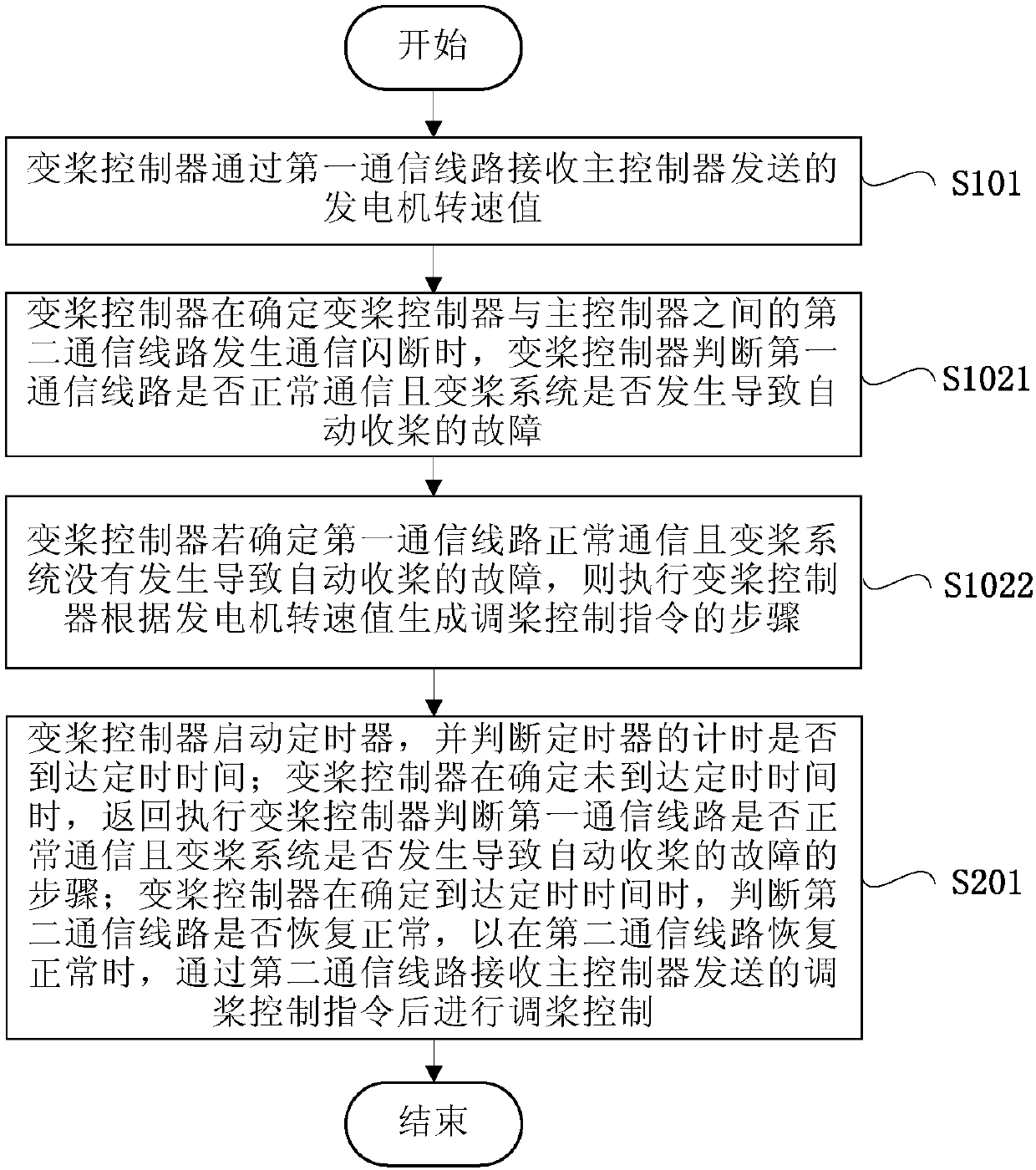

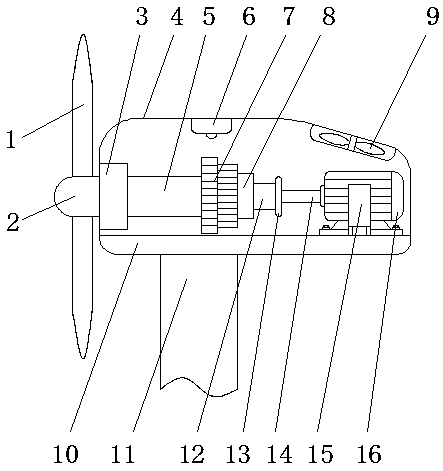

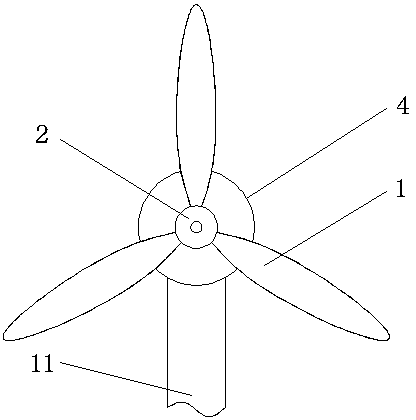

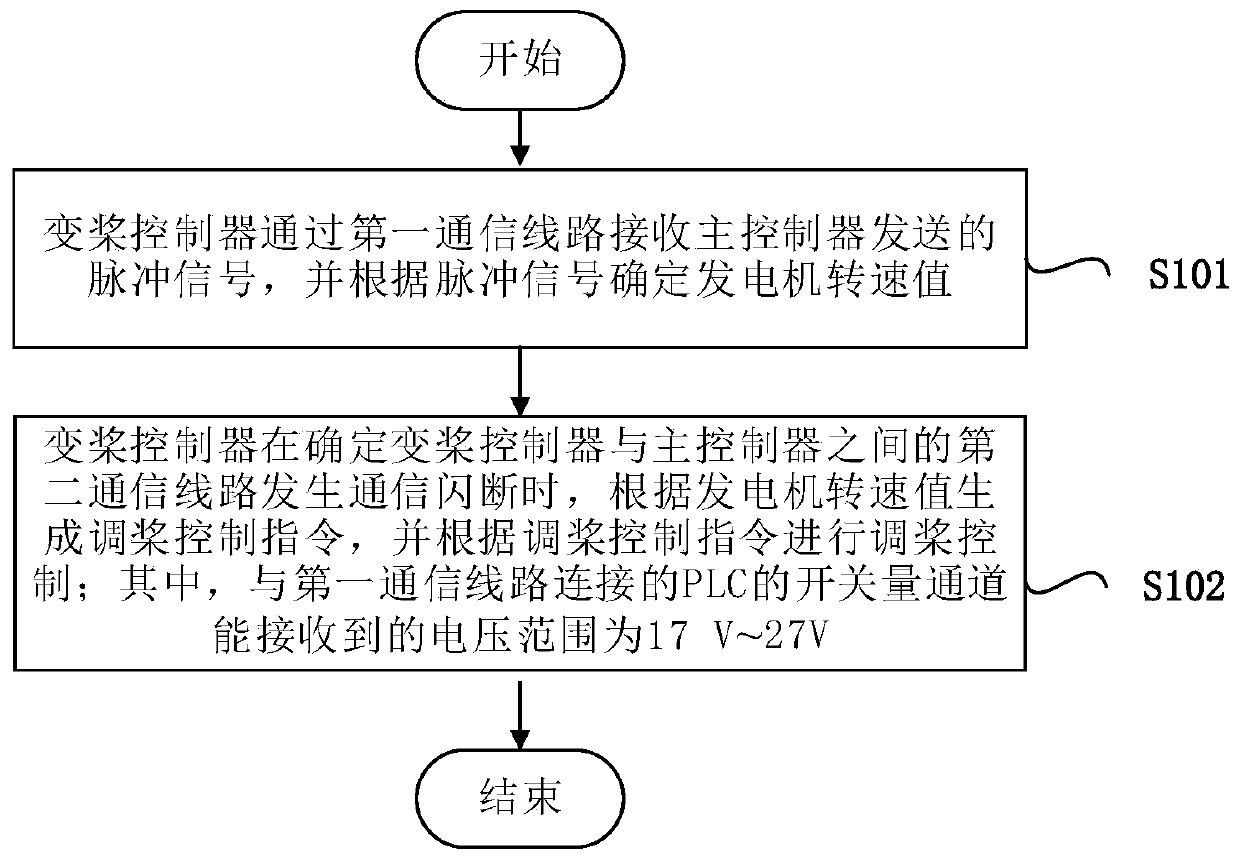

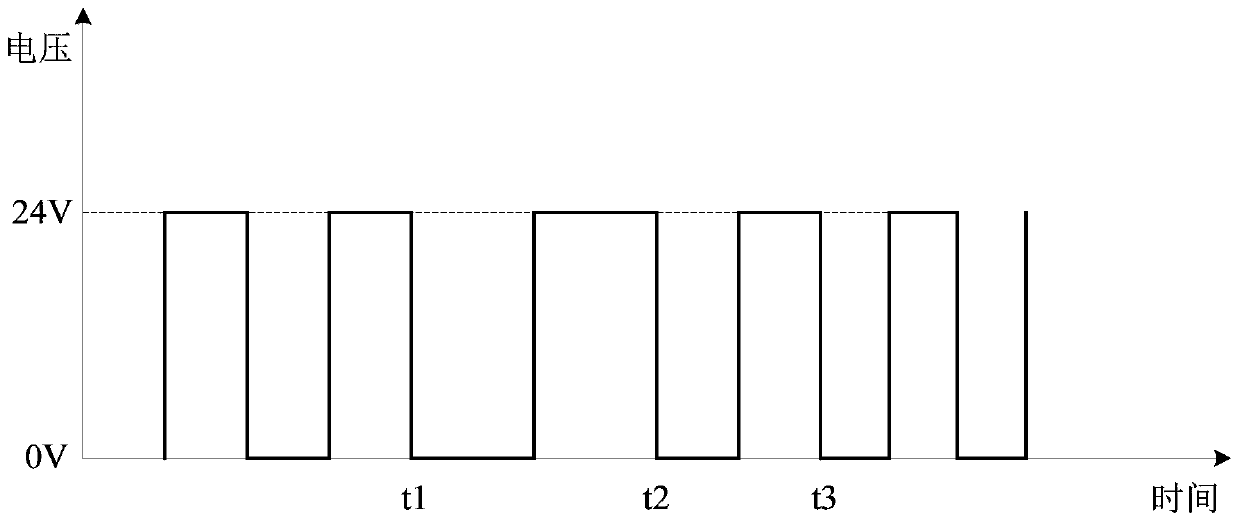

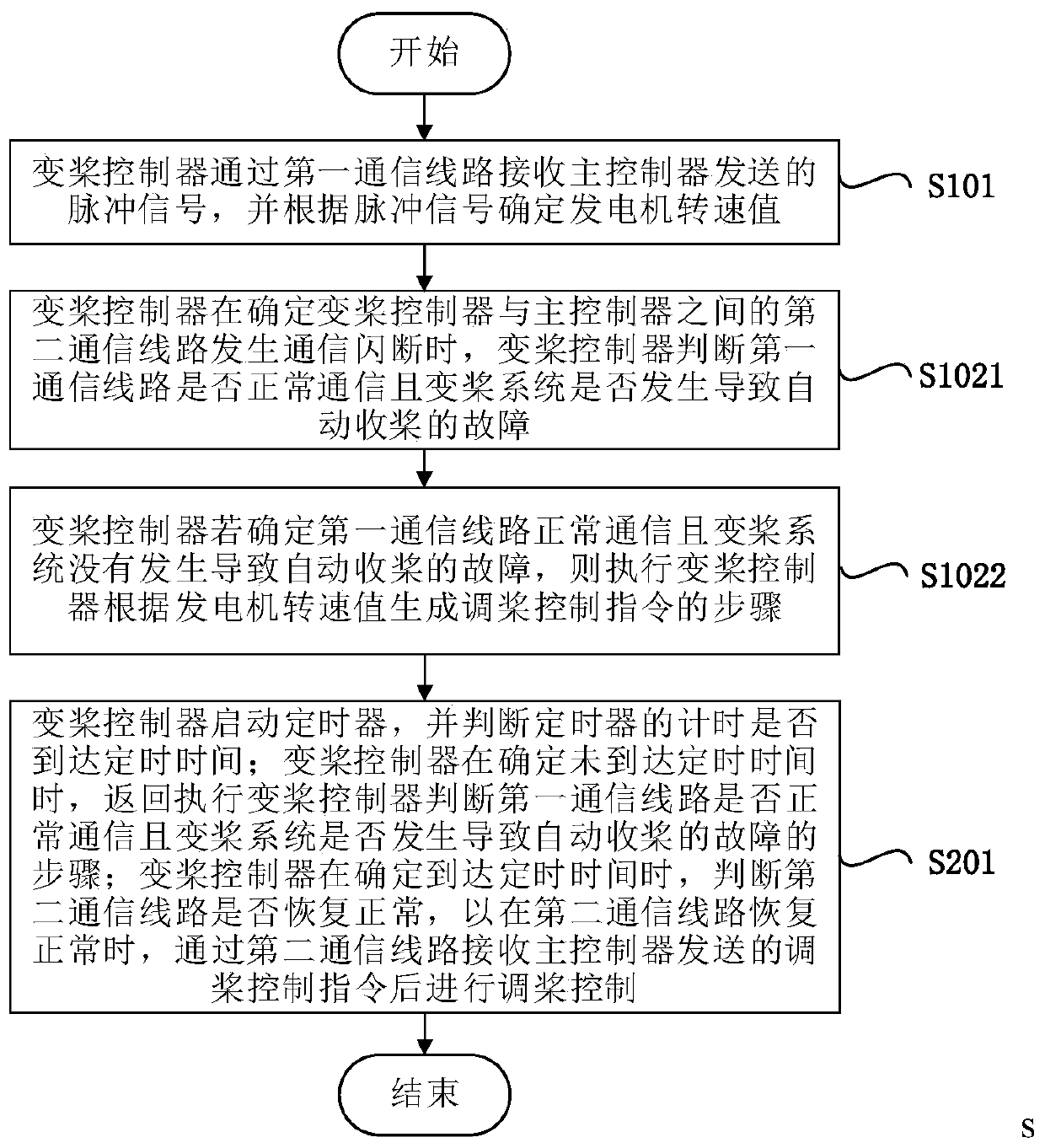

Processing method and system for communication flash breakdown of wind driven generator

ActiveCN107917043AGuaranteed power generationImprove work efficiencyWind motor controlMachines/enginesWind drivenWind force

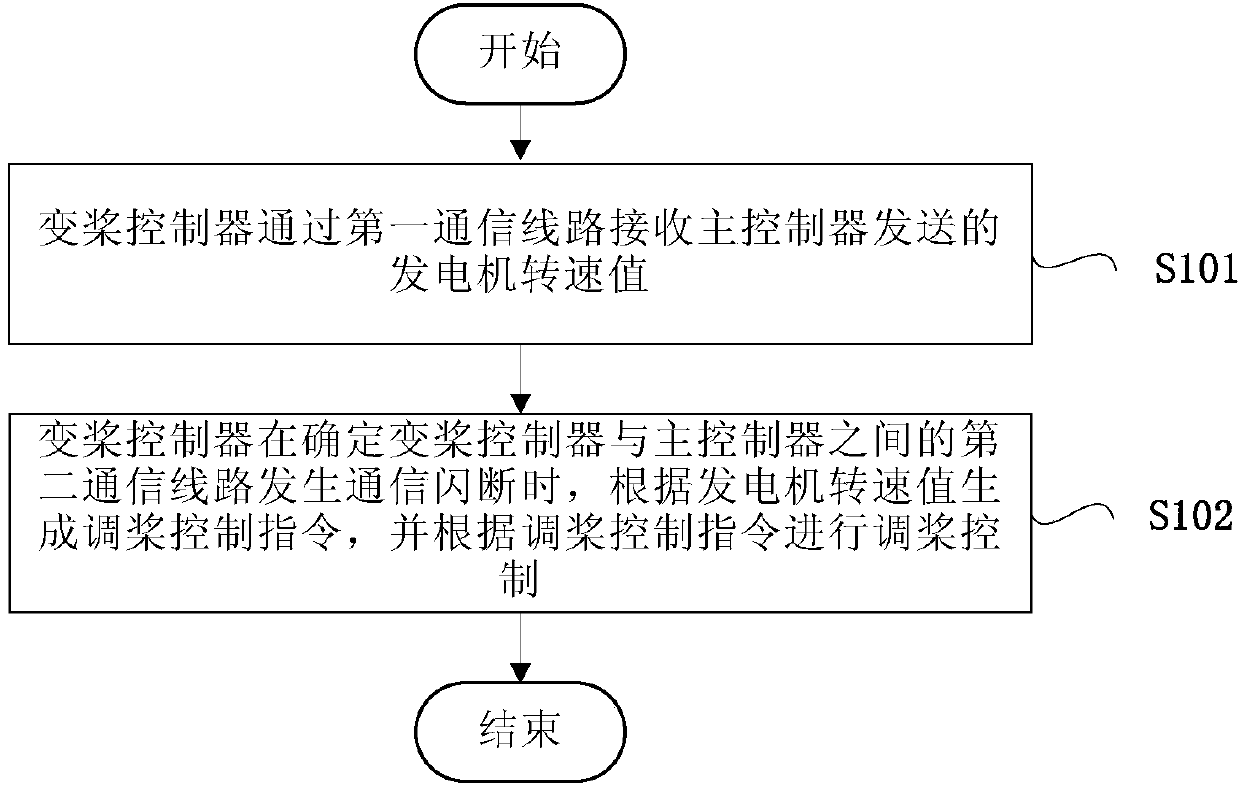

The invention provides a processing method and system for communication flash breakdown of a wind driven generator. The processing method comprises the following steps that a variable-pitch controllerreceives a generator rotating speed value sent by a main controller through a first communication line; when the variable-pitch controller is used for determining that communication flash breakdown is generated on a second communication line between the variable-pitch controller and the main controller, a pitch adjustment control command is generated according to the rotation speed value of the generator, and pitch adjustment control is carried out according to the pitch adjustment control command. According to the processing method and system, when communication flash breakdown is generatedon the second communication line between the variable-pitch controller and the main controller, the variable-pitch controller is ensured to receive the accurate generator rotating speed value, pitch adjustment control is continued so that the communication flash breakdown crossing function can be realized in a guaranteed mode, furthermore, a wind generating set is prevented from being stopped, malfunctions of a variable-pitch system are avoided, the generating capacity of the wind driven generator is guaranteed, the wind driven generator is prevented from being stopped due to frequent failures, and the utilization rate of the wind driven generator is improved.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

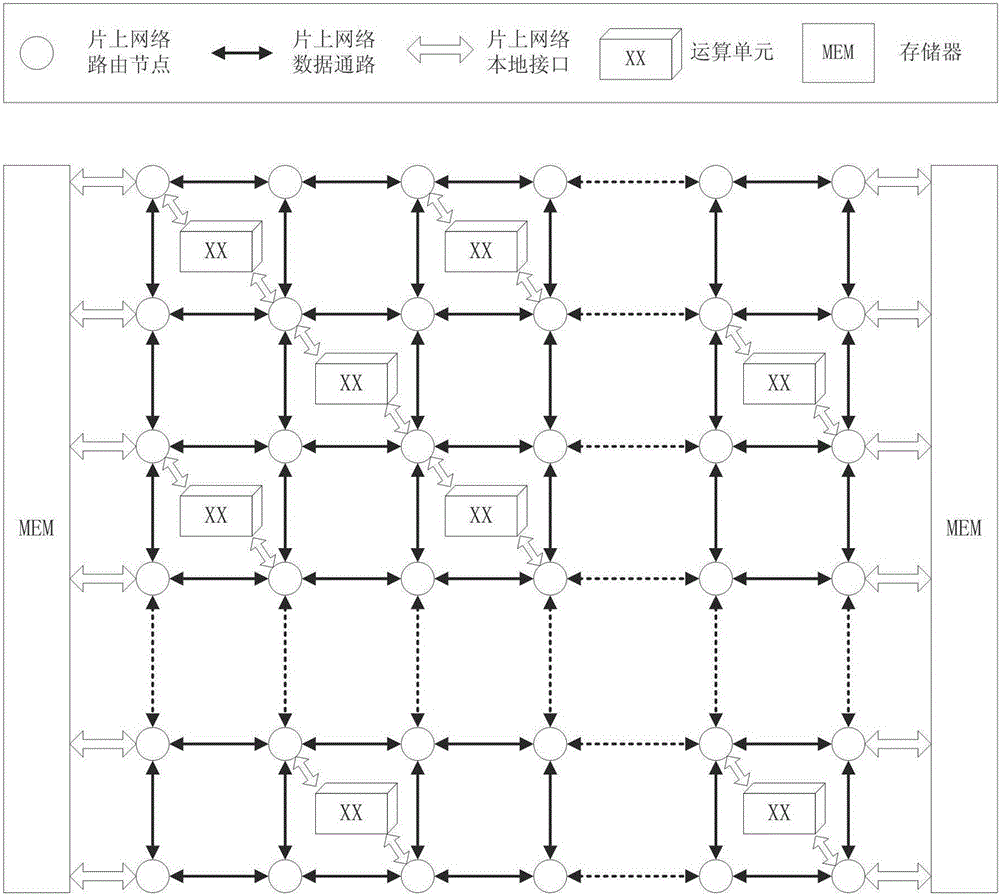

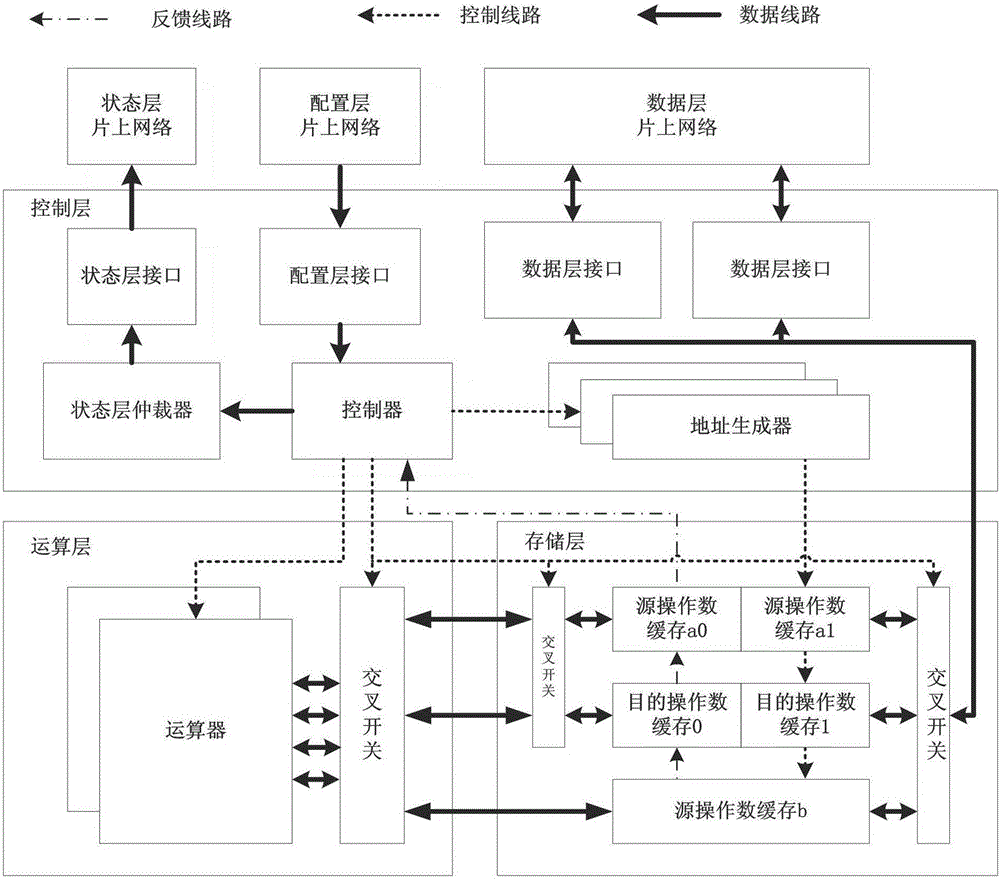

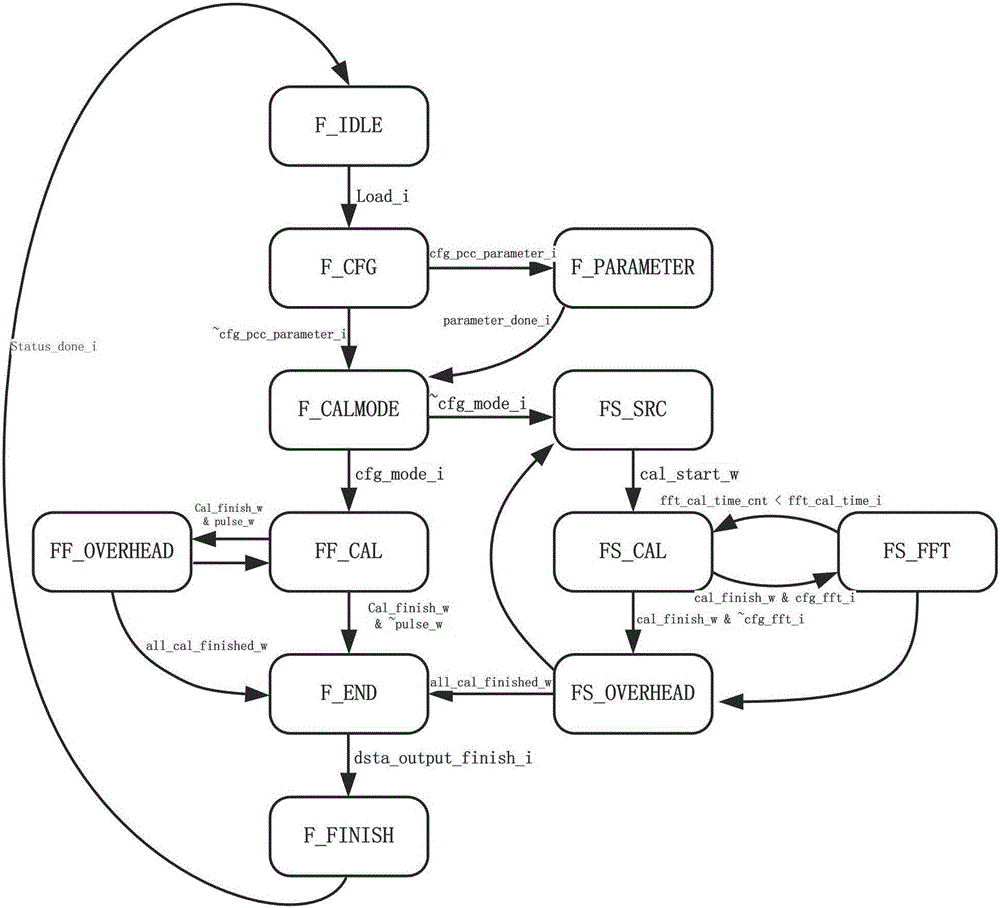

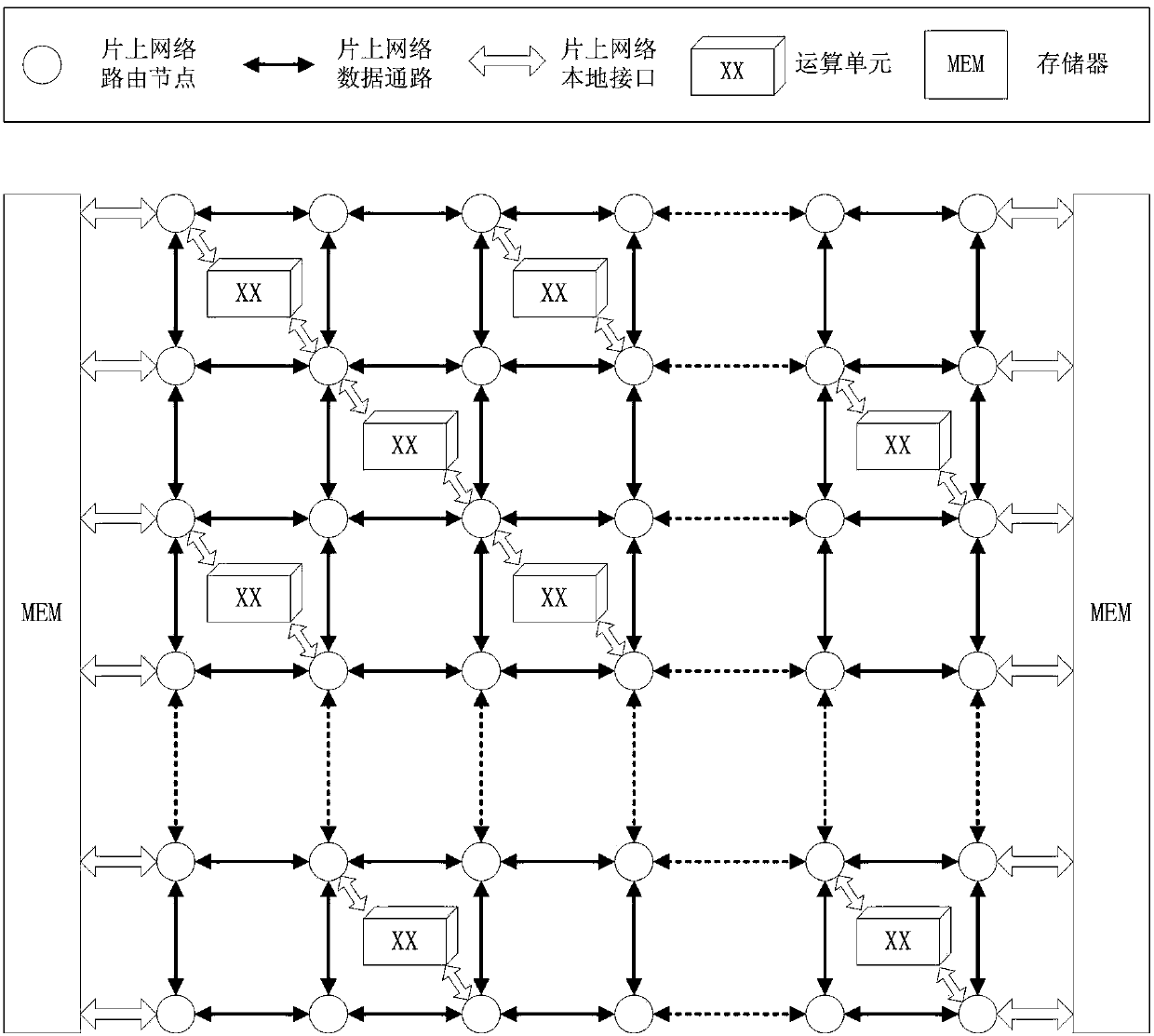

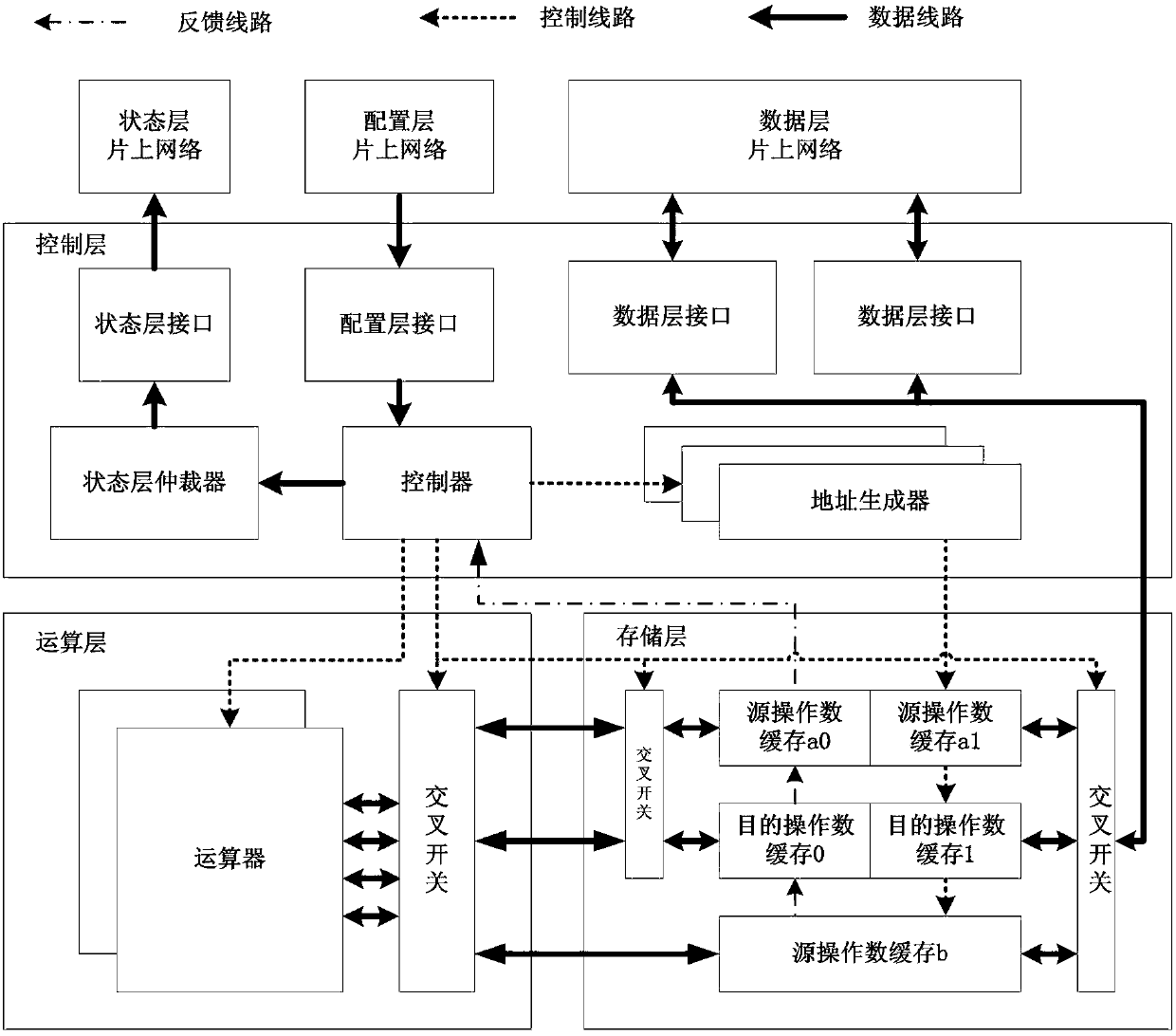

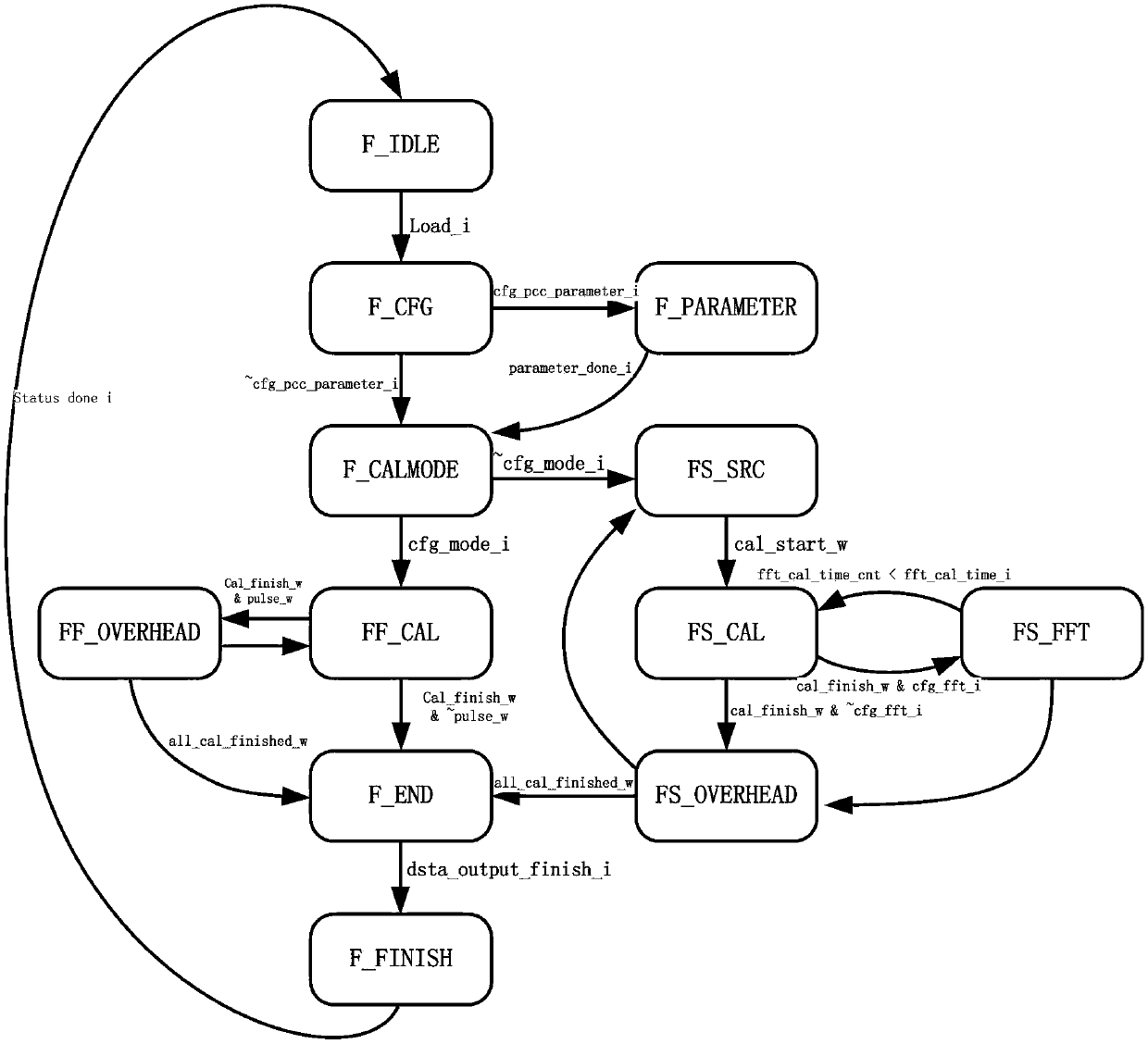

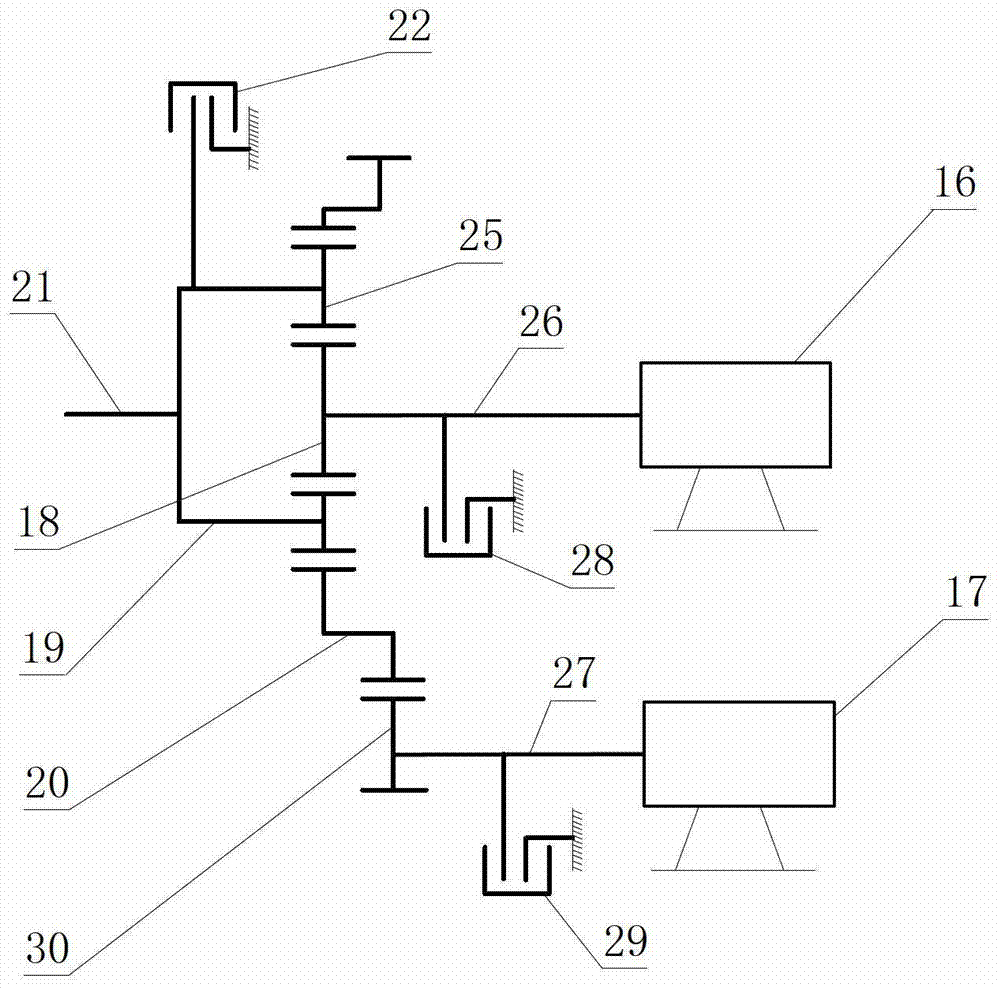

Reconfigurable arithmetic unit supporting multiple working modes and working modes thereof

ActiveCN106155814AImprove work efficiencyEasy to integrateResource allocationDigital computer detailsControl layerLayer interface

The invention discloses a reconfigurable unit supporting multiple working modes and the working modes thereof. The reconfigurable unit is characterized by comprising a control layer, an arithmetic layer and a storage layer; the control layer comprises a state layer interface, a configuration layer interface, a data layer interface, an address generator and a controller; the arithmetic layer comprises an arithmetic device; the storage layer comprises a source operand cache unit and a destination operand cache unit. The working modes of the reconfigurable arithmetic unit comprise the storage arithmetic mode, the pulse arithmetic mode and the stream arithmetic mode, and higher flexibility is provided for algorithm mapping of a computing system. When task mapping is carried out in the computing system, the specific working modes of the reconfigurable arithmetic unit can be selected according to specific features and the bottleneck of the algorithm to be mapped and in combination with specific conditions of network communication and storage bandwidth in the computing system, therefore, the arithmetic throughput capacity and network communication and storage access pressure are considered, and the working efficiency of the whole system is improved.

Owner:HEFEI UNIV OF TECH

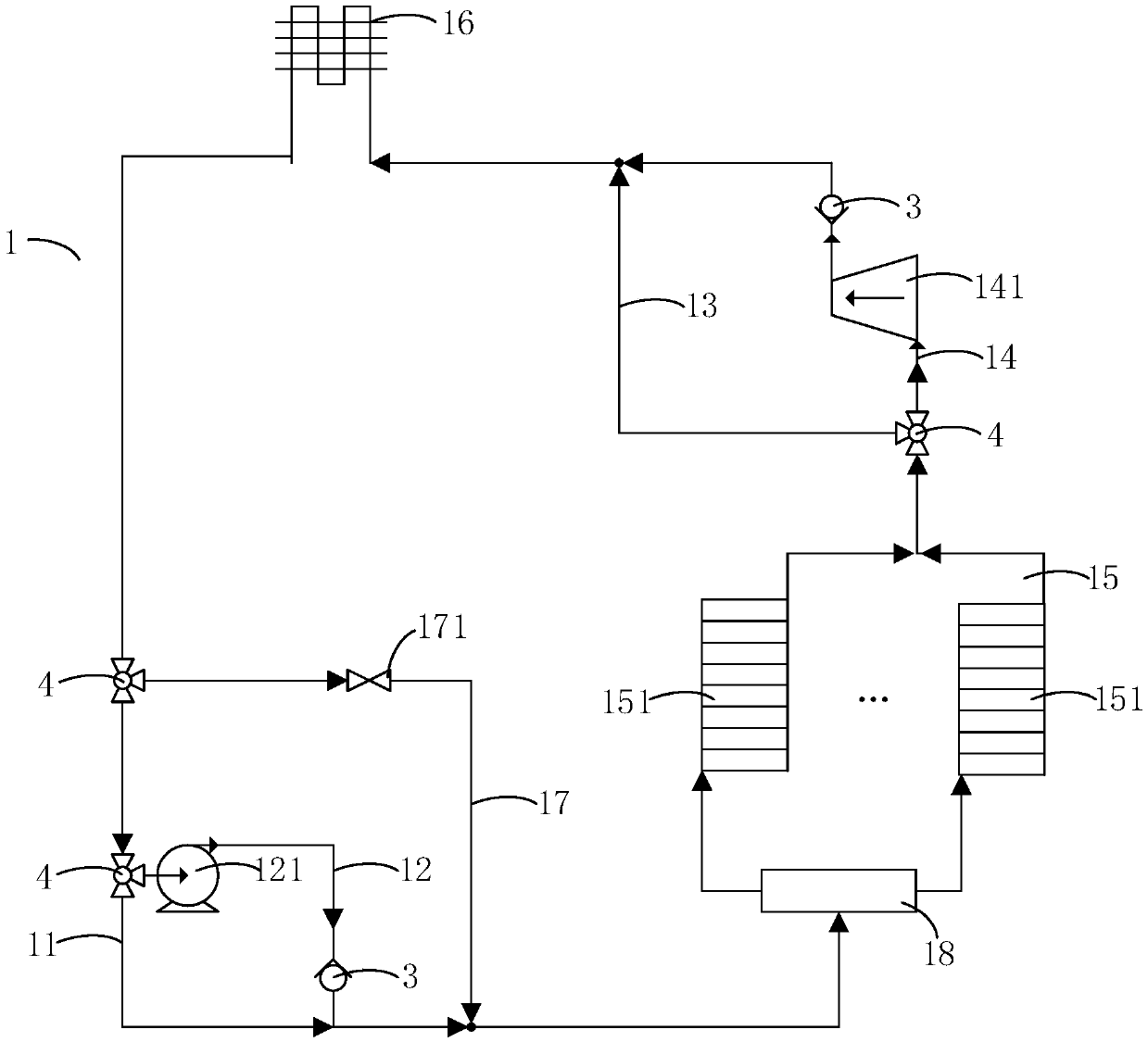

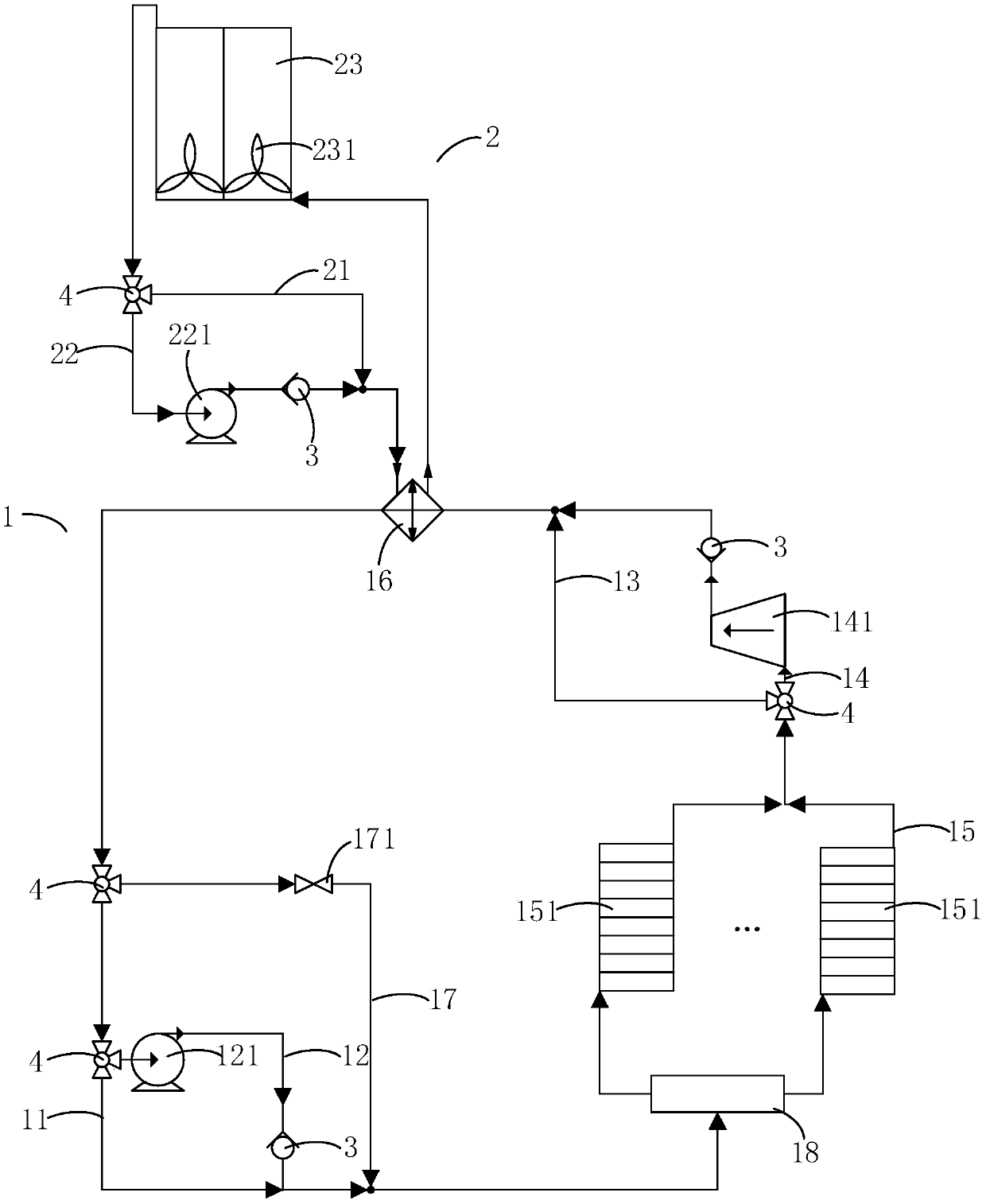

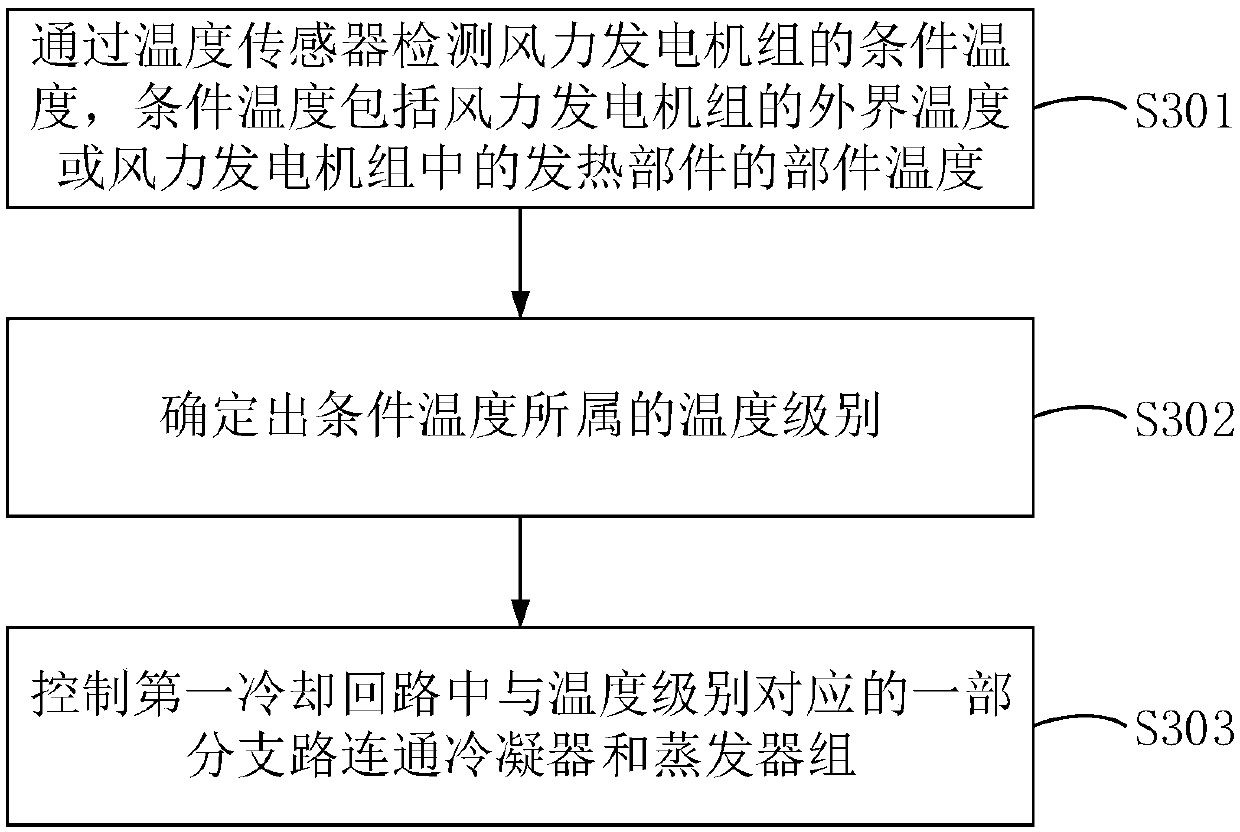

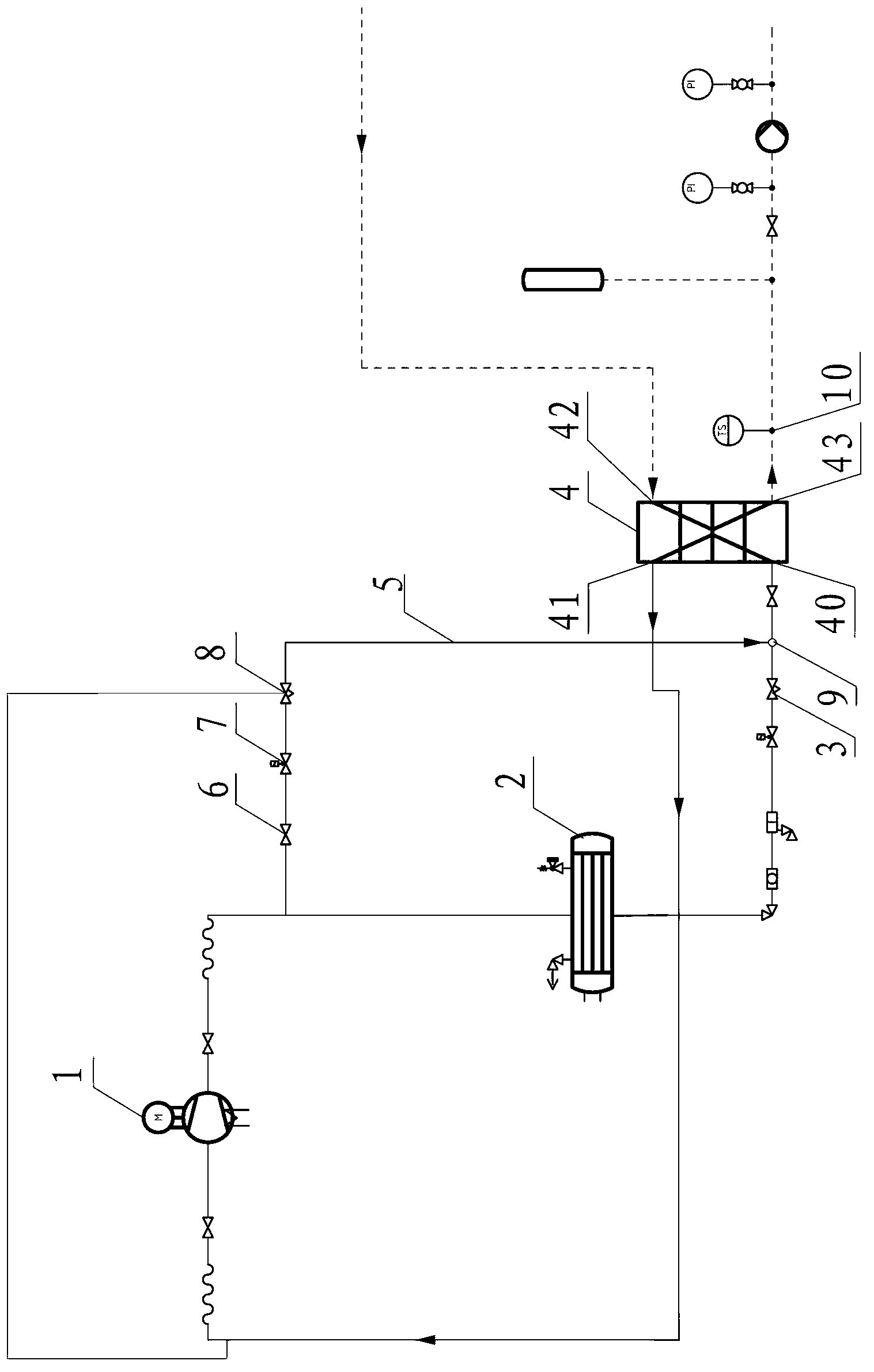

Wind generating unit, cooling system and control method of cooling system

ActiveCN109578228AReduce energy consumptionCompact structureMachines/enginesWind energy generationEvaporatorElectricity

The embodiment of the invention provides a wind generating unit, a cooling system and a control method of the cooling system. The cooling system comprises a first cooling loop, temperature sensors anda controller; the first cooling loop comprises an evaporator set, a condenser and a plurality of branches; the evaporator set corresponds to multiple heating components of the wind generating unit; each branch is in liquid-path connection with the evaporator set and the condenser in a selectable mode; the multiple temperature sensors are arranged on the outer face and the heating components of the wind generating unit; the temperature sensors are used for detecting the condition temperature of the wind generating unit and outputting the condition temperature; the condition temperature comprises an outer temperature or component temperatures of the heating components; and the controller is electrically connected with the first cooling loop and the temperature sensors, is used for determining the temperature grade which the condition temperature belongs to, and controls part of branches, corresponding to the temperature grade, in the first cooling loop to communicate with the evaporatorset and the condenser. The wind generating unit is cooled with zero energy consumption.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

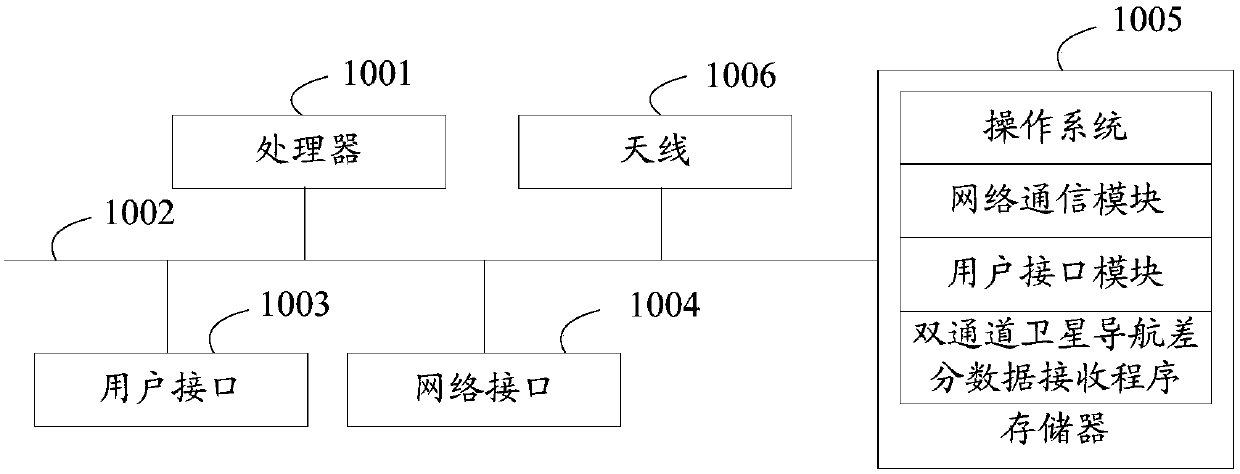

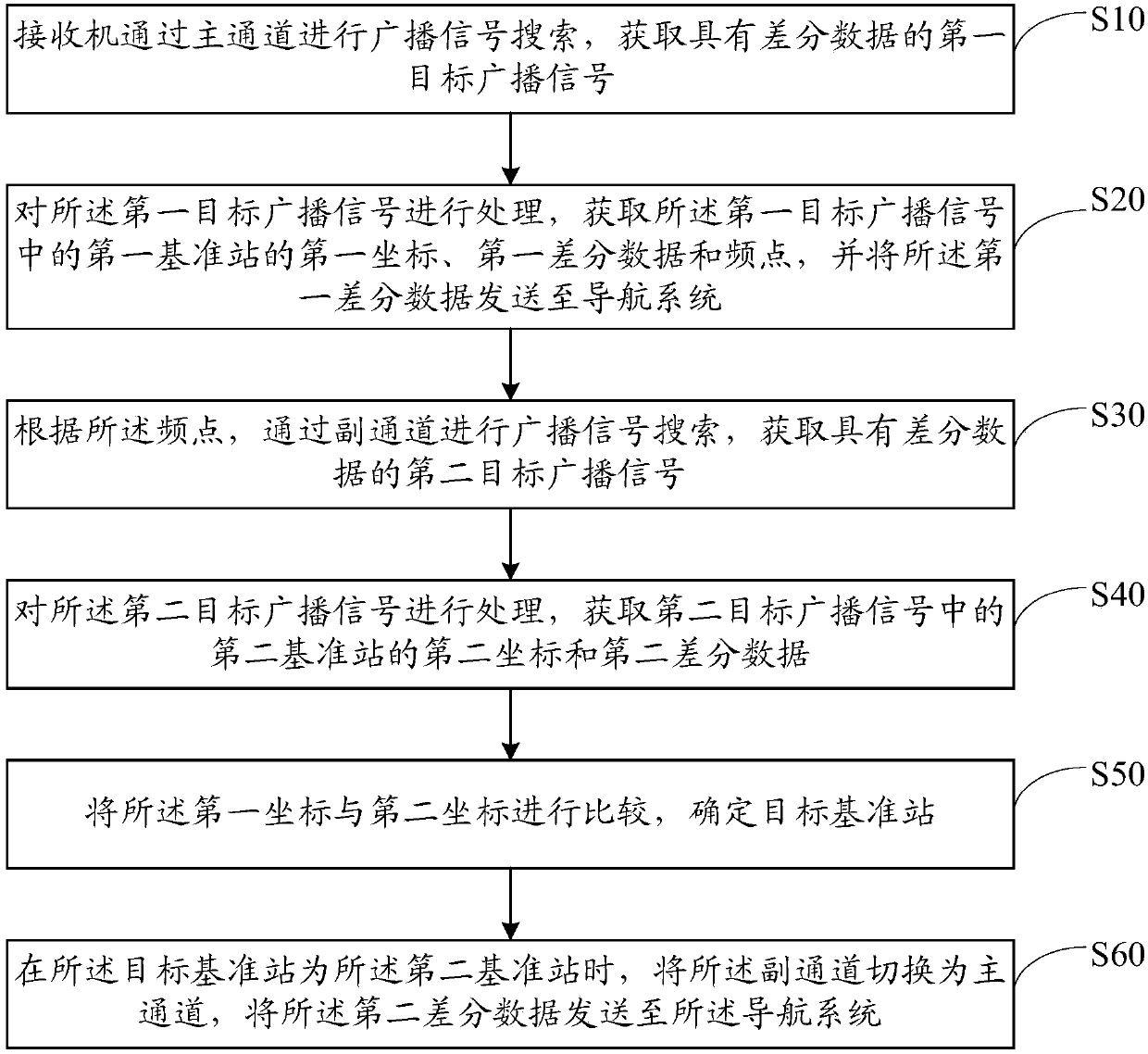

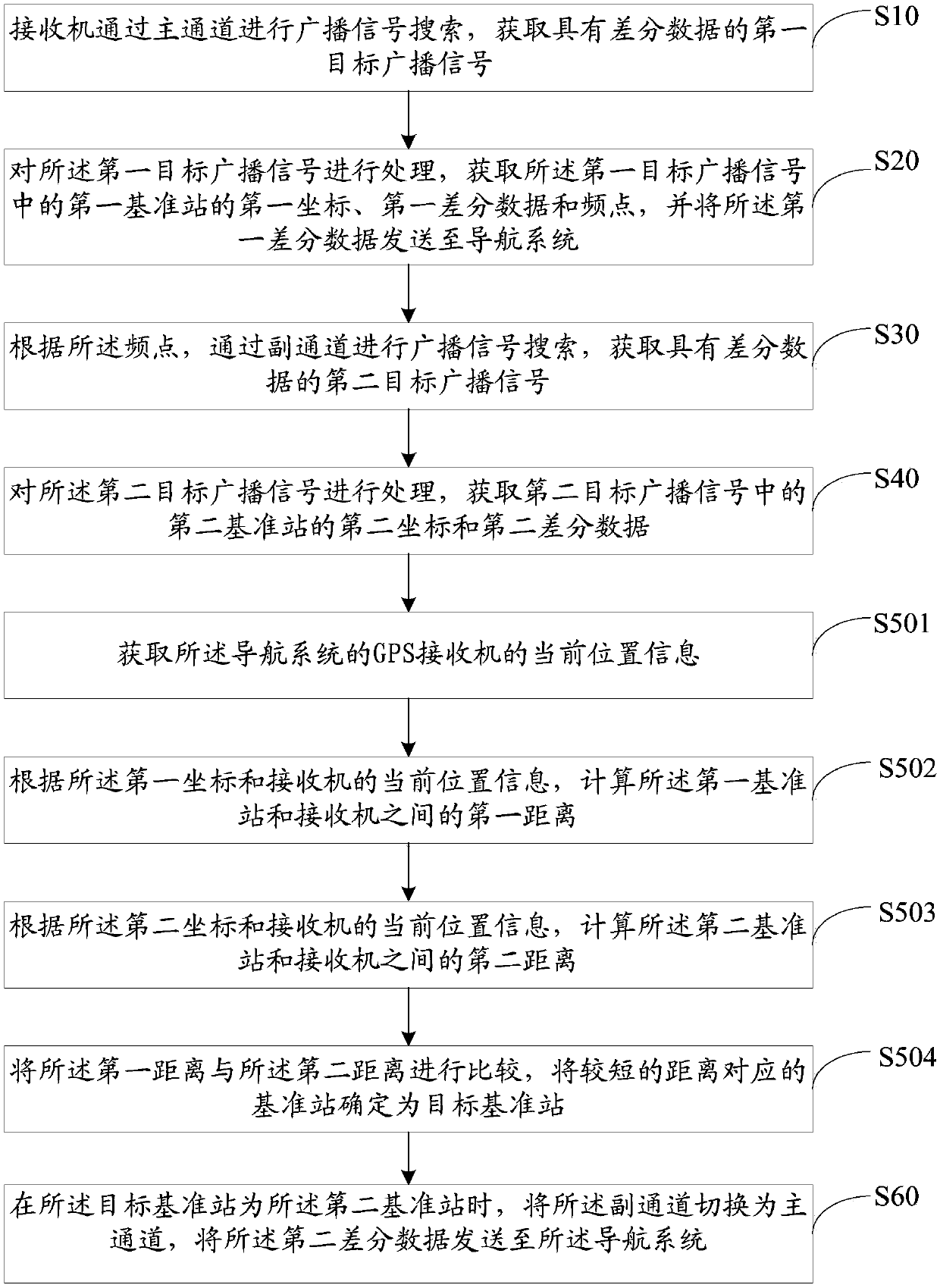

Dual-channel satellite navigation differential data receiving method, receiver and storage medium

ActiveCN107942353AWill not stopImprove experienceBroadcast transmission systemsSatellite radio beaconingNavigation systemPrimary channel

The invention discloses a dual-channel satellite navigation differential data receiving method, a receiver and a storage medium. The receiver of the invention searches for a first target broadcast signal having differential data through a primary channel, processes the first target broadcast signal, acquires first coordinates, first differential data and a frequency point of a first base station in the first target broadcast signal, and sends the first differential data to a navigation system; and searches for a second broadcast signal with differential data through a secondary channel according to the frequency point, processes the second target broadcast signal, acquires second coordinates and second differential data of a second base station in the second target broadcast signal, compares the first coordinates with the second coordinates, switches the secondary channel into the primary channel when determining the second base station as a target base station, and sends the second differential data to the navigation system to ensure that the differential data will not be cut off and seamless switching is realized.

Owner:SHENZHEN SIKAIWEI ELECTRONICS CO LTD

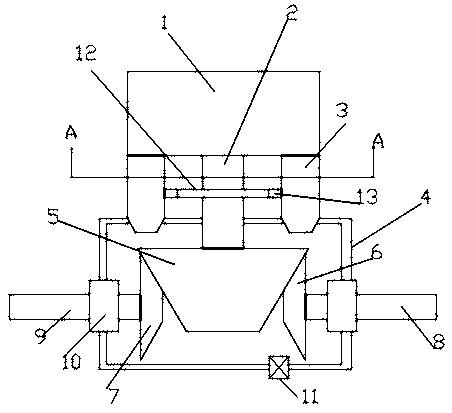

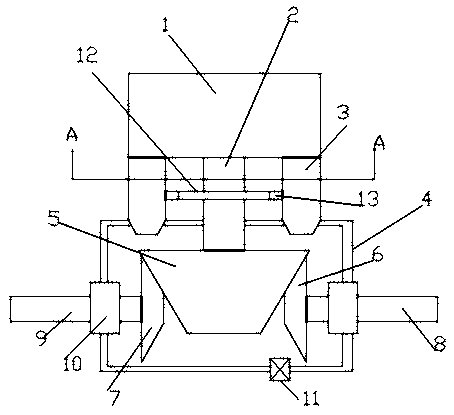

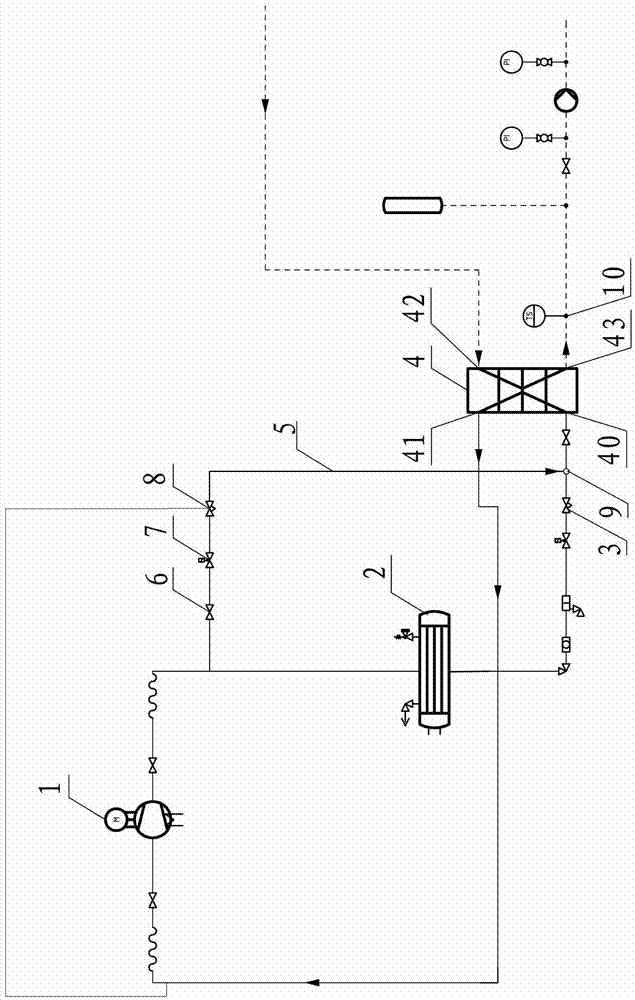

Low sulfur oil cooling unit and cooling compressor unit thereof

ActiveCN103291508ATimely coolingLarge adjustment scaleMachines/enginesFluid circulation arrangementEngineeringOil cooling

The invention relates to a low sulfur oil cooling unit and a cooling compressor unit of the low sulfur oil cooling unit. The cooling compressor unit comprises a compressor, a condenser, a throttling component and an evaporator, wherein the evaporator is provided with a refrigerant inlet, a refrigerant outlet, a cooling water outlet and a cooling water inlet, and the refrigerant outlet of the evaporator is connected with the air inlet end of the compressor through pipelines. The cooling compressor unit further comprises a hot air bypass sub-channel with the two ends connected with the air discharging end of the compressor and the refrigerant inlet of the evaporator respectively, a temperature sensor and a PLC connected with the temperature sensor, and a stop valve, an electromagnetic valve, an energy regulating valve and a liquid-and-gas mixer are sequentially arranged on the hot air bypass sub-channel, wherein the energy regulating valve is further connected with the air inlet end of the compressor through pipelines, and the electromagnetic valve is connected with the PLC. Although the lower pressure protection exists, the compressor of the cooling compressor unit will not stop working under the condition of low loads, the compressor can continually work, and timely cooling of low sulfur oil is ensured.

Owner:苏州利玛特能源装备有限公司

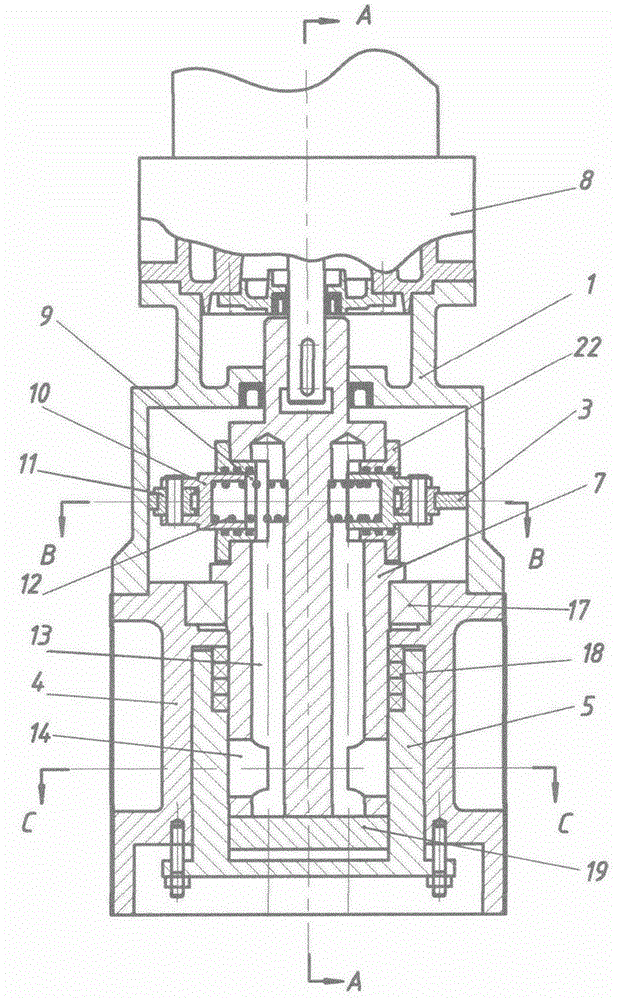

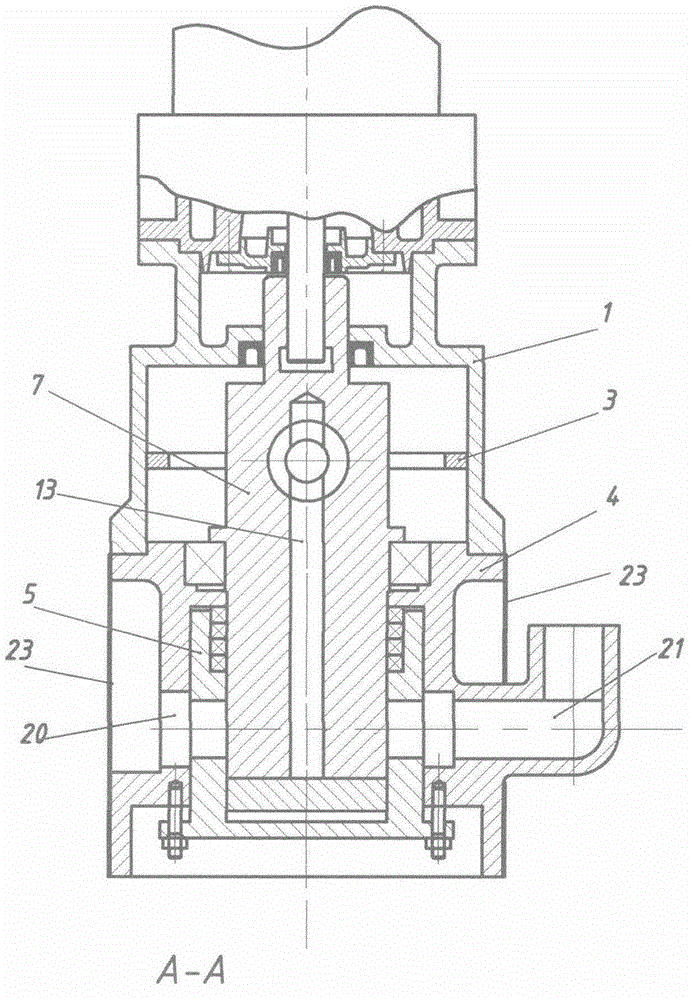

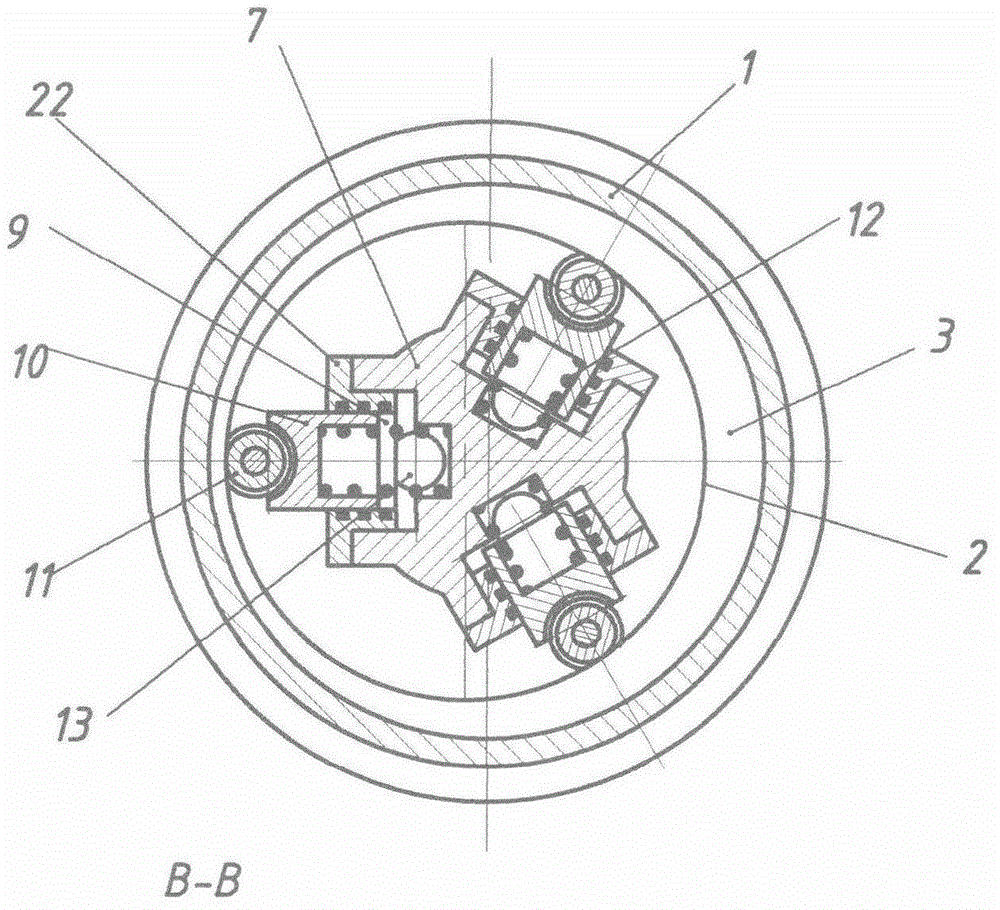

Efficient multifunctional rotor type submersible sewage pump

InactiveCN105179231APass smoothlyStrong blocking abilityRotary piston pumpsRotary piston liquid enginesFiberRadial piston pump

The invention discloses an efficient multifunctional rotor type submersible sewage pump and belongs to positive displacement pumps. Sewage delivery is conducted through the theory of a radial piston pump. When a submersible motor drives a rotor to rotate, plungers on the rotor move in a reciprocating mode in the radial direction under the control of an eccentric stator; when the plungers move outwards, media are sucked from a suction port in a pump body through a central channel and radial holes in the pump body; when the plungers move inwards, the media are discharged towards a discharging port through the central channel and the radial holes. Due to the fact that the multiple plungers which are distributed uniformly convey the media uninterruptedly, liquid flows are quite stable, consistent and free of pulses; baffle tongues on a baffle tongue sleeve prevents the leakage from a high-pressure area to a low-temperature area inside the pump body; meanwhile, the baffle tongues and the radial holes in the rotor form cutting pairs, long fibers are cut automatically and continuously, and winding is eliminated. The pump is high in self-section function, and gas-liquid-solid mixed transportation can be conducted. Furthermore, the pump has a bidirectional operation function, liquid can be conveyed when the pump rotates in the positive direction, and the pump can wash a filter screen and eliminate blockage without stopping a machine when rotating in the negative direction.

Owner:余文凌

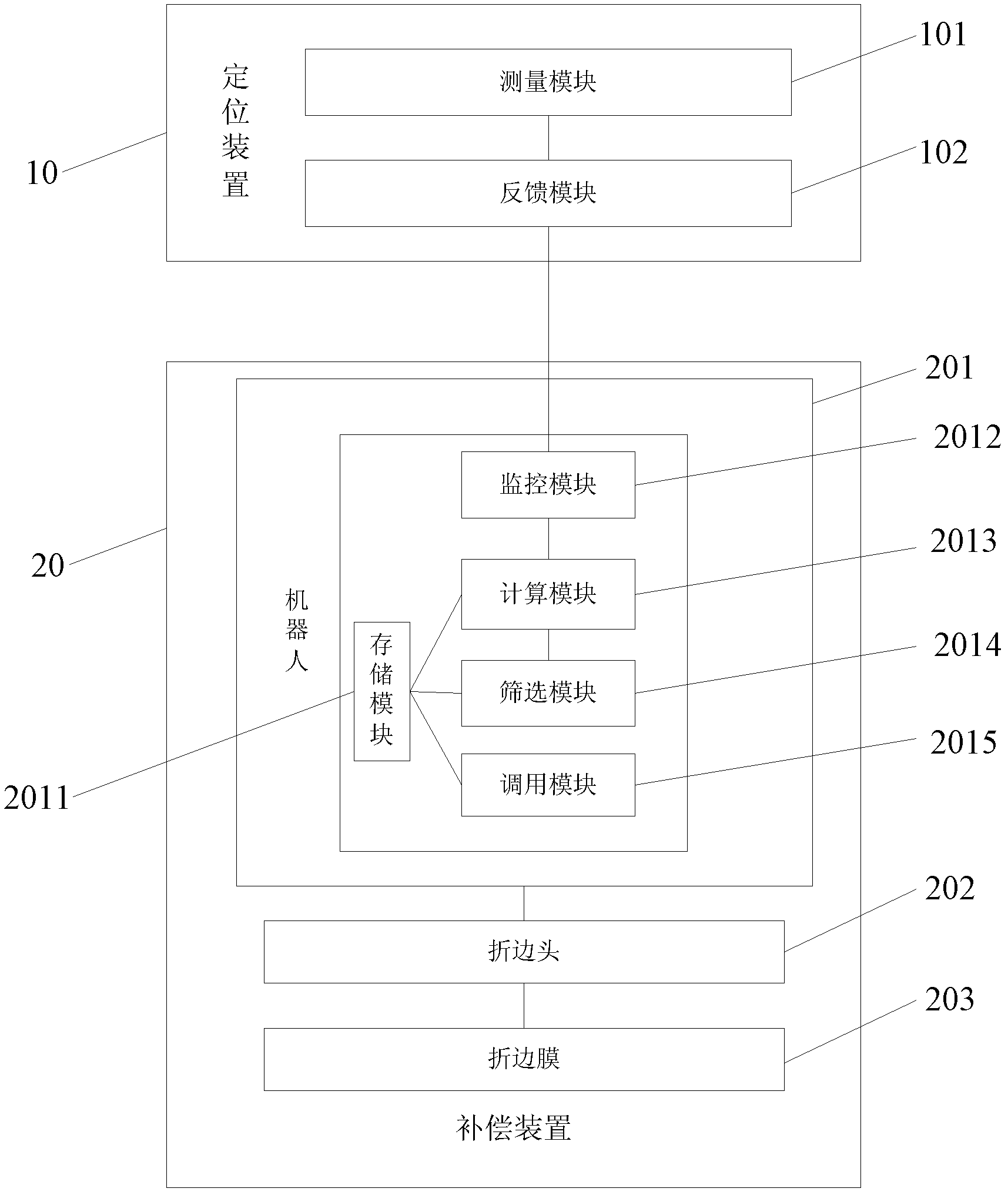

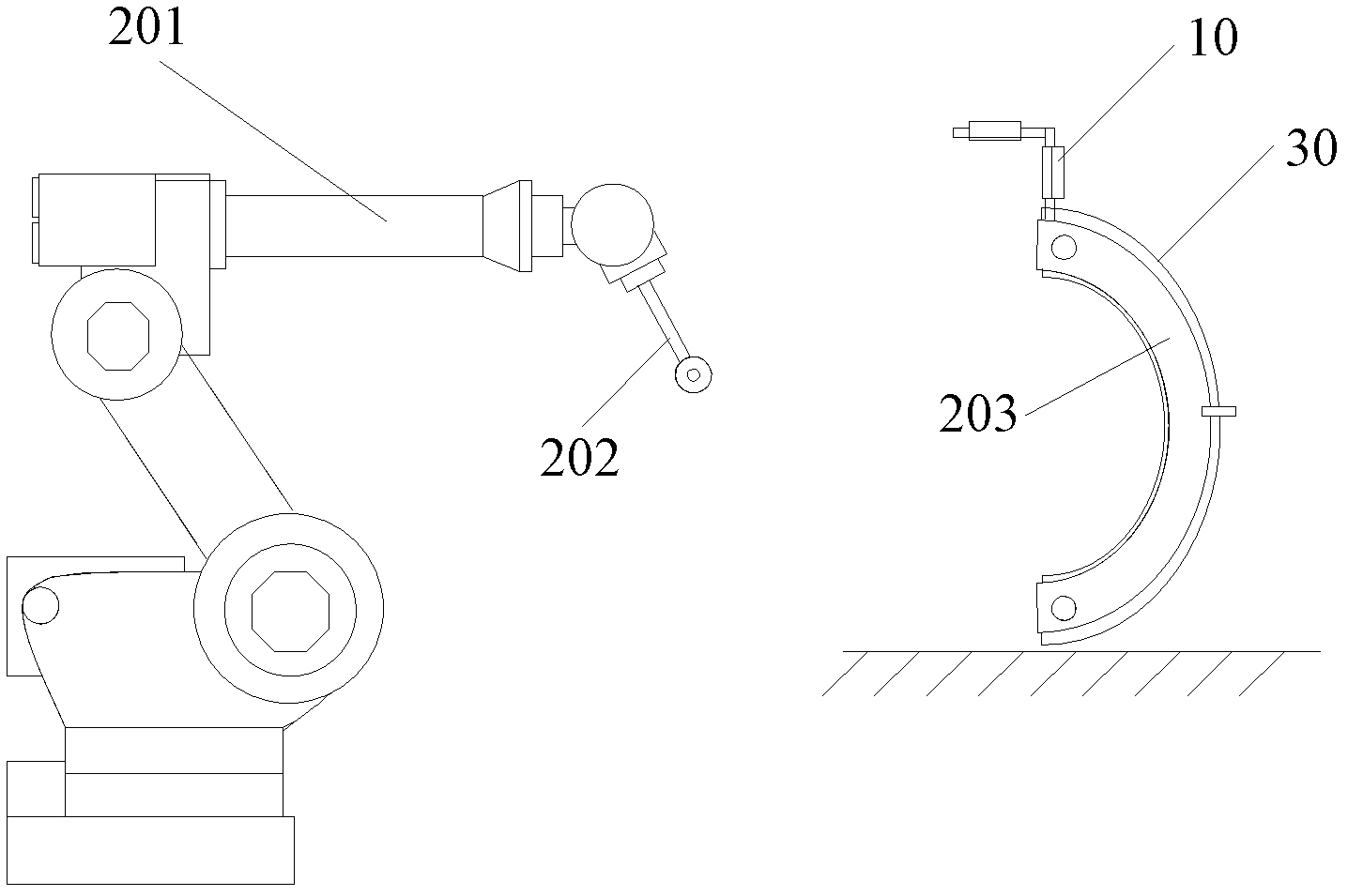

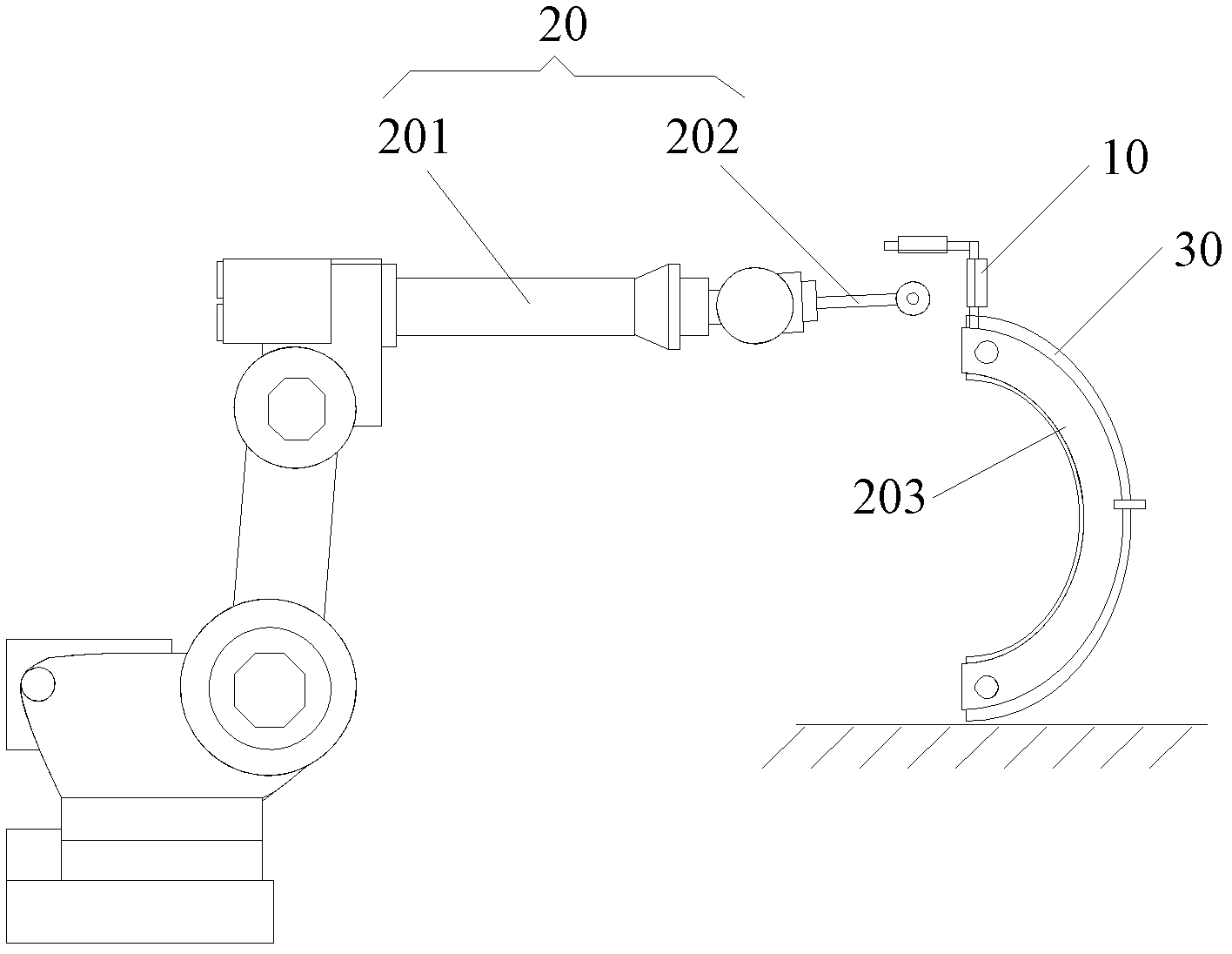

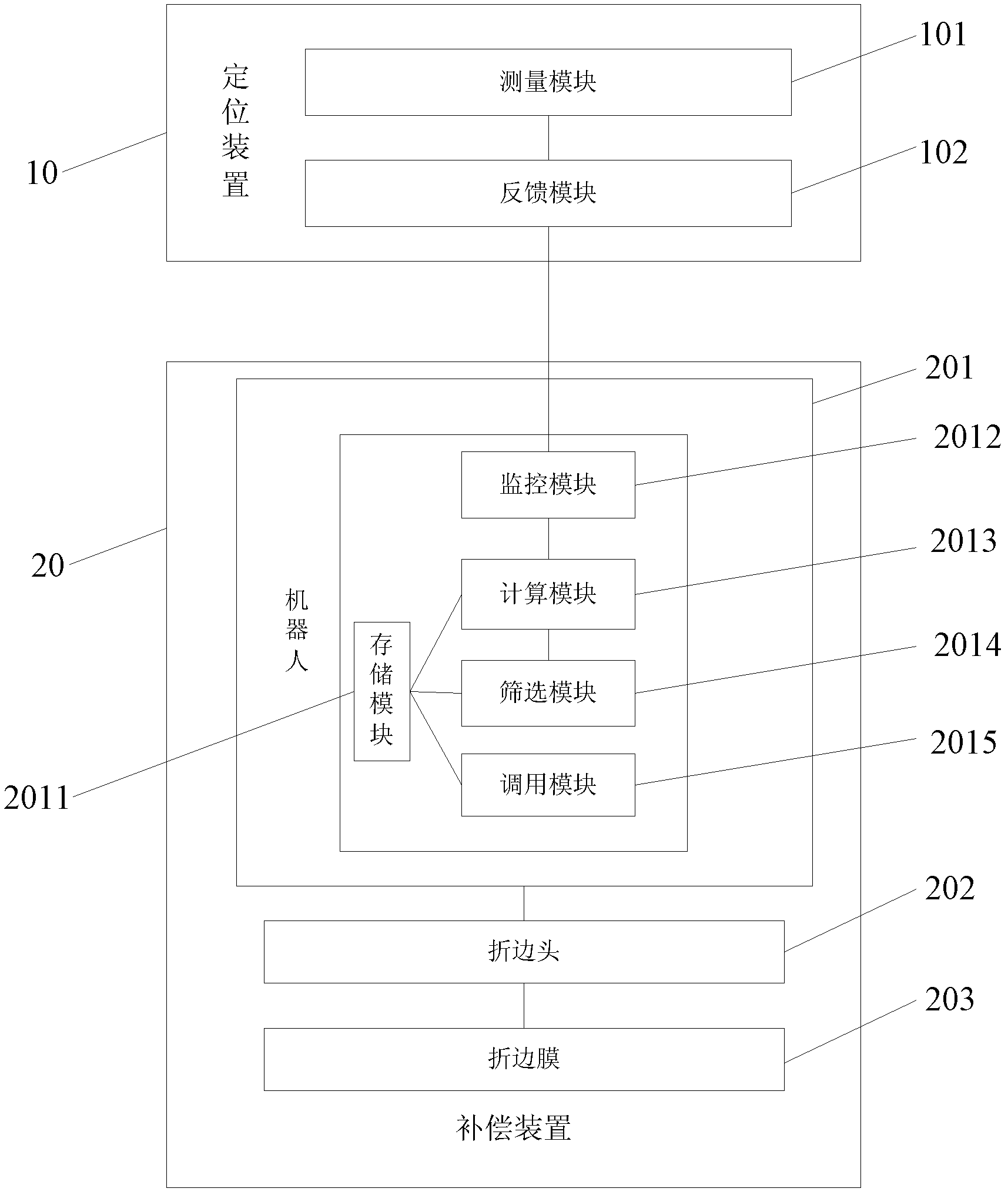

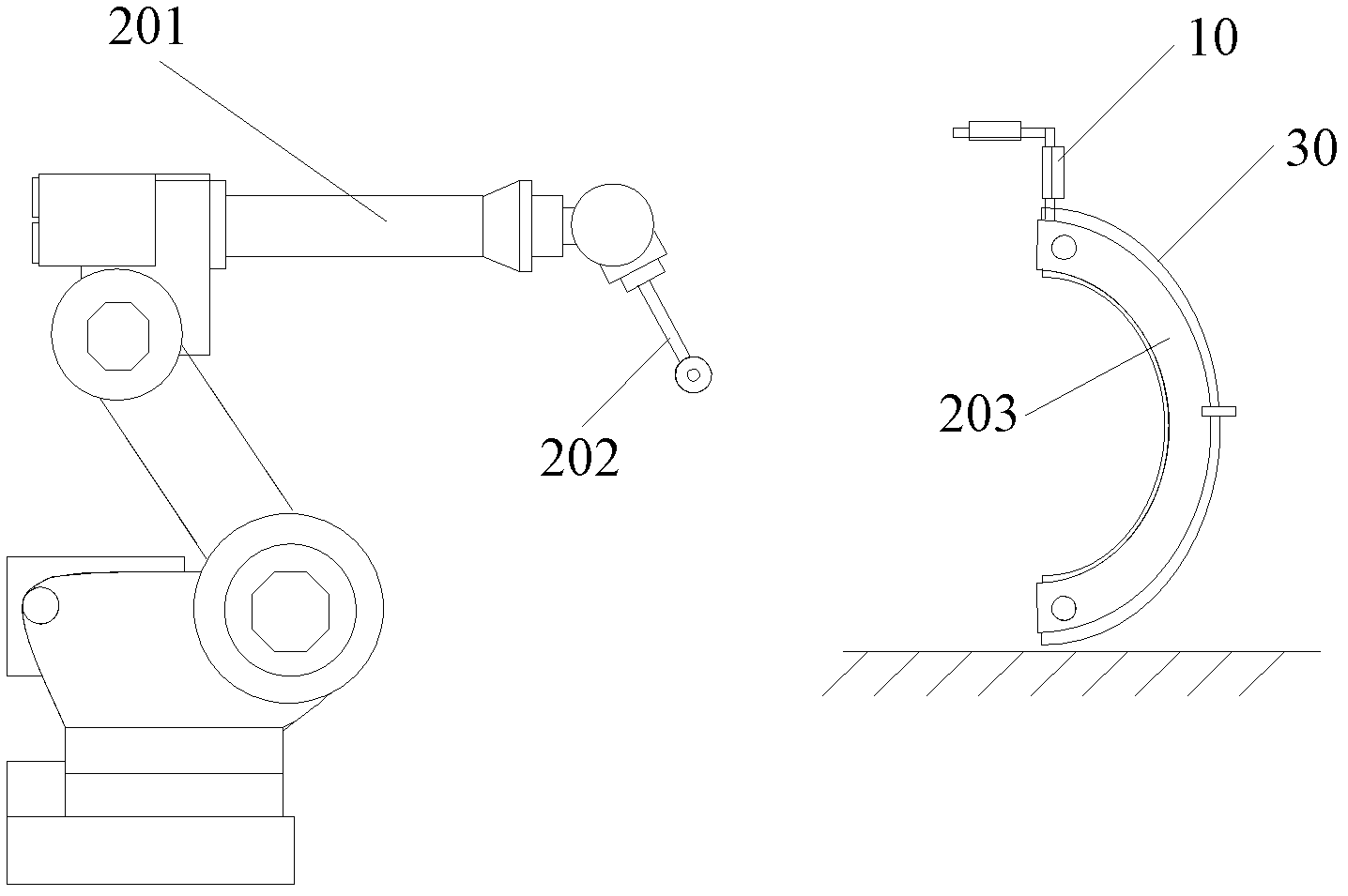

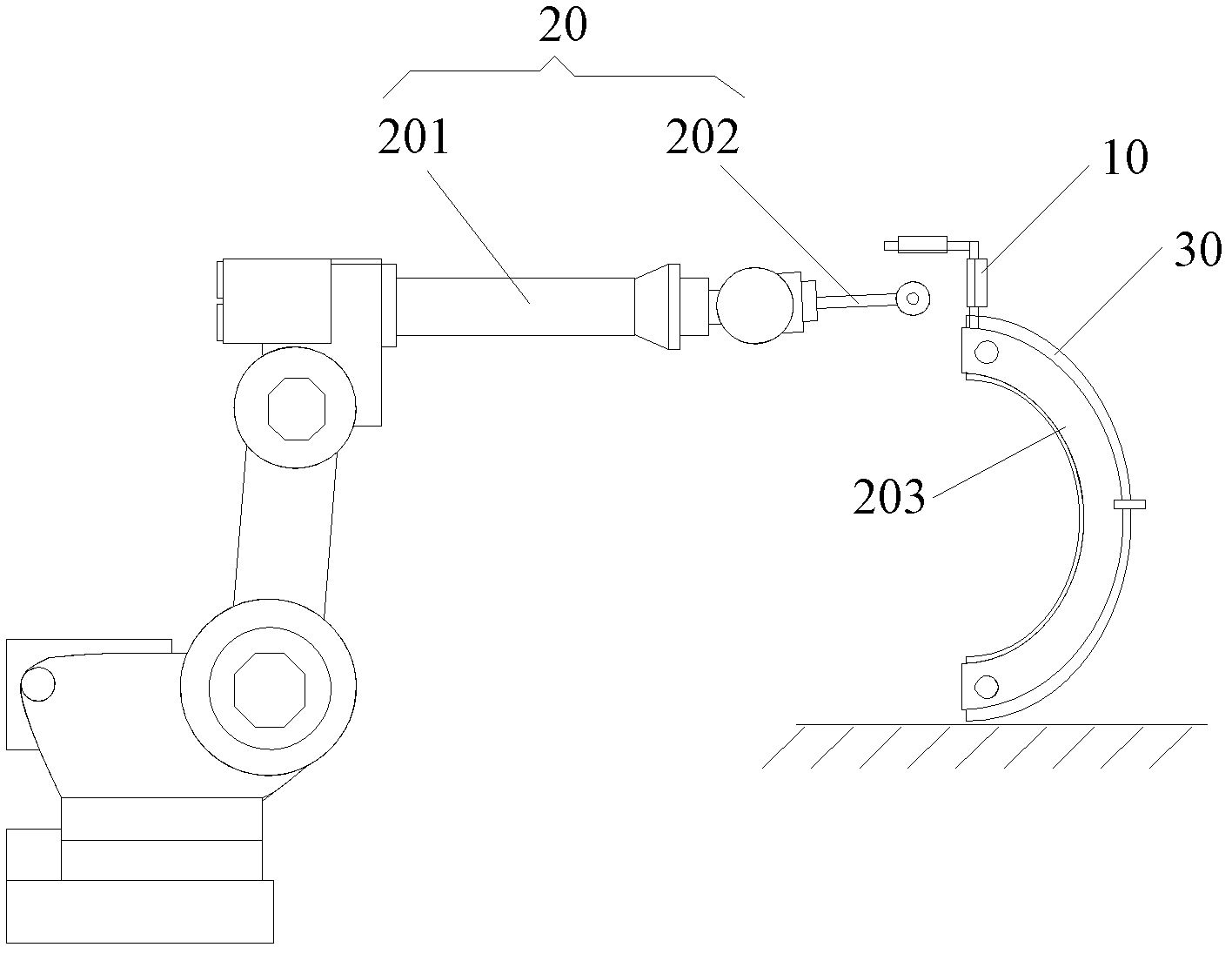

Positioning compensation system and method applied to automobile wheel casing edge covering

ActiveCN102489570AWill not stopImprove work efficiencyControl using feedbackEngineeringCompensation methods

The invention discloses a positioning compensation system applied to automobile wheel casing edge covering. The positioning compensation system comprises a positioning device and a compensation device, wherein the positioning device is arranged on an automobile wheel casing and used for measuring a distance between the compensation device and the automobile wheel casing and feeding a measurement result back to the compensation device; the compensation device comprises a monitoring module and a calling module; the monitoring module is used for receiving the measurement result and indicating the calling module to call an initial optimal compensation amount to compensate a reference edge covering trace of the automobile wheel casing according to the measurement result; and the initial optimal compensation amount is the optimal value for compensating the reference edge covering trace of the automobile wheel casing, which is screened by the positioning compensation system at the last time. Compared with the prior art, the positioning compensation system applied to the automobile wheel casing edge covering has the advantages that: the problems of failure of edge covering and shutdown of a production line caused by a failed positioning device are solved, and the work efficiency is improved. The invention also discloses a positioning compensation method for automobile wheel casing edge covering.

Owner:广州风神汽车有限公司

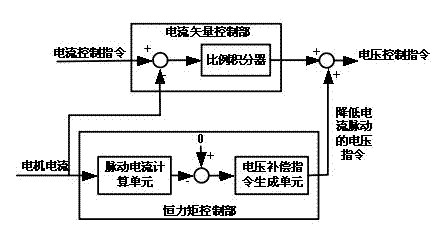

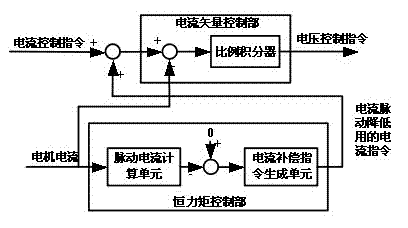

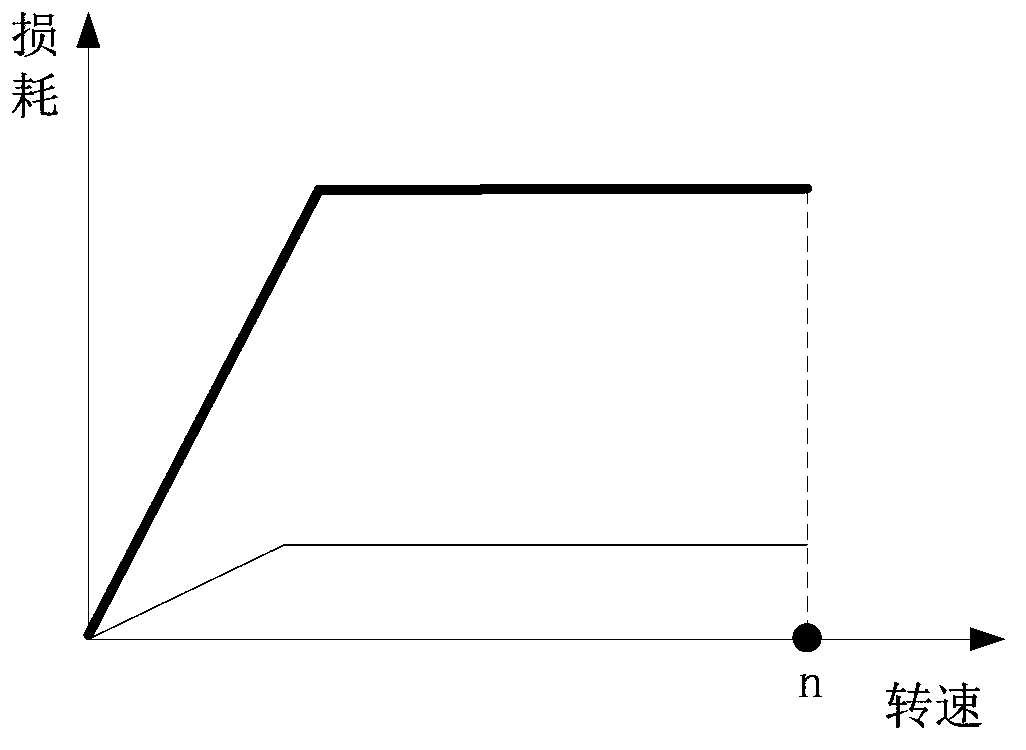

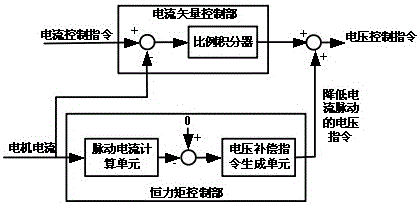

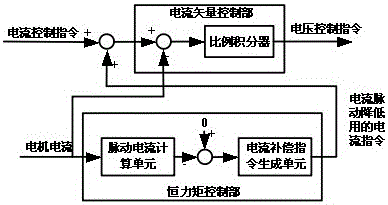

Air conditioner inverter compressor frequency-domain constant torque control system and method

ActiveCN104728090AStable currentGuaranteed uptimePump controlPositive-displacement liquid enginesVoltage controlCurrent vector

The invention relates to an air conditioner inverter compressor frequency-domain constant torque control system and method. The air conditioner inverter compressor frequency-domain constant torque control system comprises a current vector control portion and a constant torque control portion; the constant torque control portion outputs a current command which is used for reducing current pulse and adds the current command which is used for reducing the current pulse and an input signal of the current vector control portion to serve as input of the current vector control portion; the current vector control portion outputs a voltage control command to control a compressor. The improved constant torque compensation control method can be applied to a full frequency domain of a compressor; the constant torque control portion compensates currents to an input end of the current vector control portion; during a high band operation process, the currents are stable, a wave crest value at every period is uniformly distributed, the compressor stably operates.

Owner:HAIER GRP CORP +1

Transmission device for wind power generation

InactiveCN107740754ASmooth runningAvoid stuck teethMachines/enginesMechanical power transmissionParticulatesForeign matter

The invention discloses a transmission device for wind power generation. The transmission device comprises a cabin shell, a drop lubricator and an exhaust fan, wherein one side of the cabin shell is provided with a wheel hub disk, the periphery of the wheel hub disk is provided with three blades, the bottom of the cabin shell is provided with a cabin pedestal, a bearing seat is arranged inside thecabin shell, and the bearing seat is installed on one side of the wheel hub disk. By arranging the drop lubricator at the top of a gear case, the drop lubricator can be used for adding lubricant oilto a gear regularly, so as to enable the gear to operate stably all the time, and the situation of gear latching is prevented, so that the whole transmission device can operate stably and cannot stop;by arranging the exhaust fan at the top of one end of a cabin, dust particulate matter that enters the cabin with wind can be discharged in time and cannot fall on the transmission device in the engine cabin, so that foreign matters cannot accumulate on a whole unit, the safe operation of equipment is guaranteed, and various maintenance costs are reduced.

Owner:黄玉琰

Method and system for dealing with communication interruption of wind power generator

ActiveCN107917043BRealize flash through functionAccurate speed valueWind motor controlMachines/enginesGenerating capacityControl theory

The present invention provides a method and system for processing communication interruptions of wind power generators, wherein the method includes: the pitch controller receives the generator speed value sent by the main controller through the first communication line; When the second communication line between the pitch controller and the main controller is disconnected, a pitch control command is generated according to the generator speed value, and the pitch control is performed according to the pitch control command. Ensure that when the second communication line between the pitch controller and the main controller has a communication flash, the pitch controller receives the accurate generator speed value and continues to control the pitch, which can ensure communication flash through function, so that the wind turbine will not shut down and the pitch system will not malfunction, which ensures the power generation of the wind turbine, avoids the frequent failure of the wind turbine and stops it, and improves the availability of the wind turbine.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

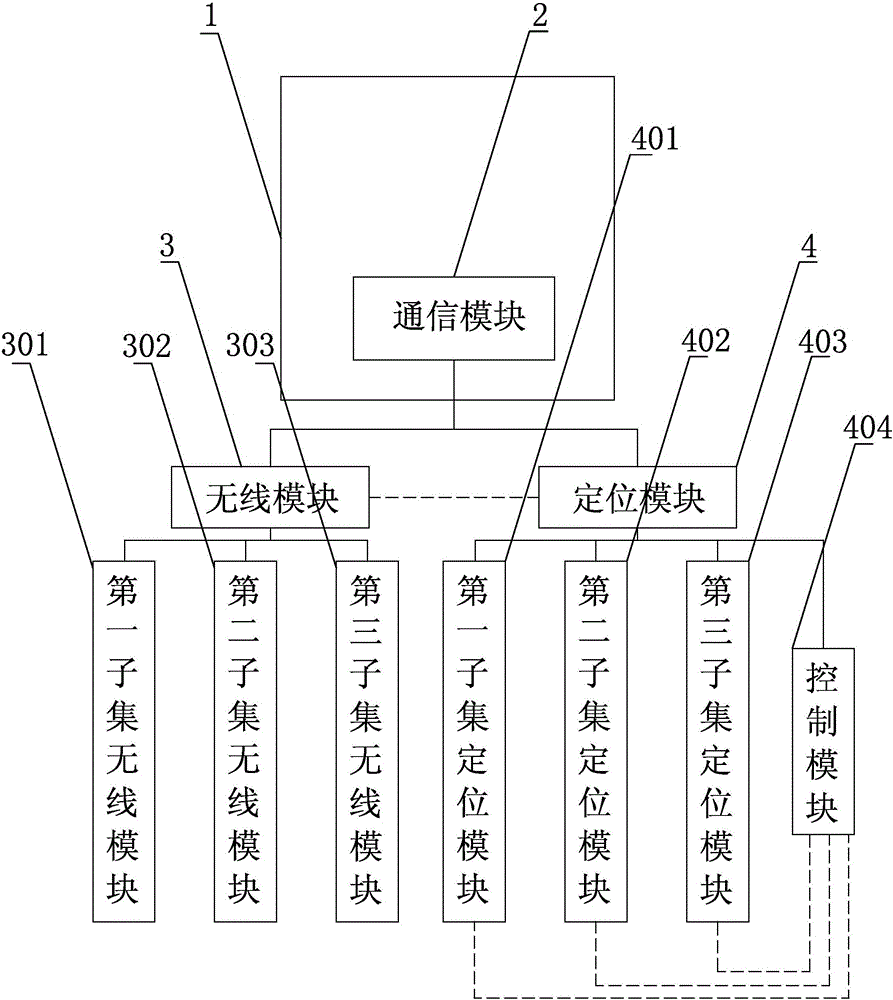

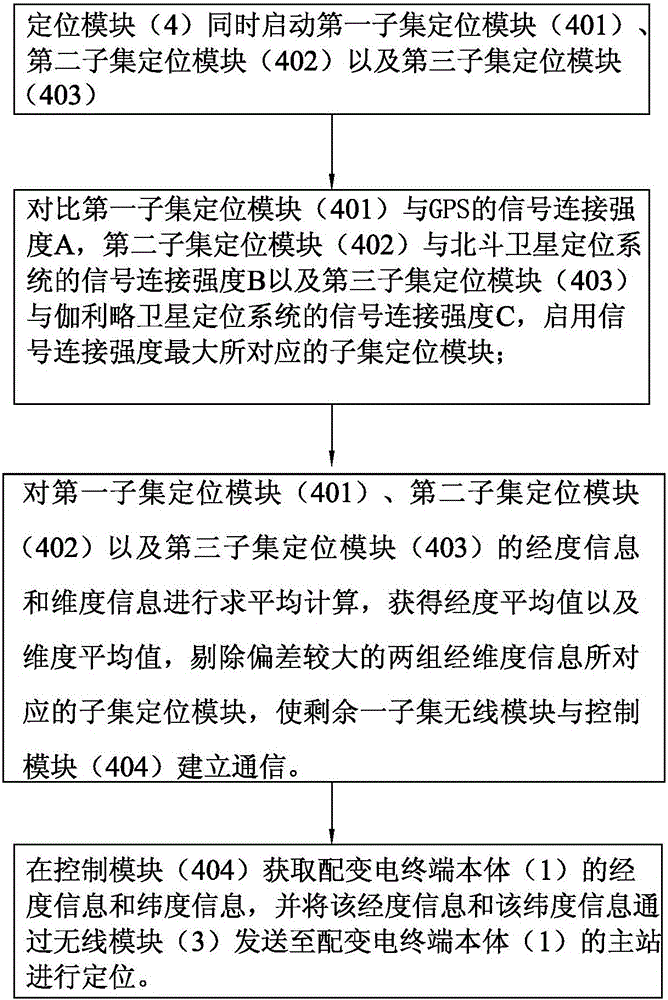

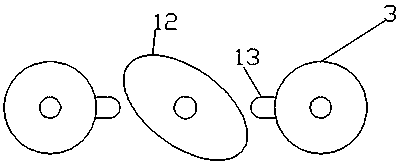

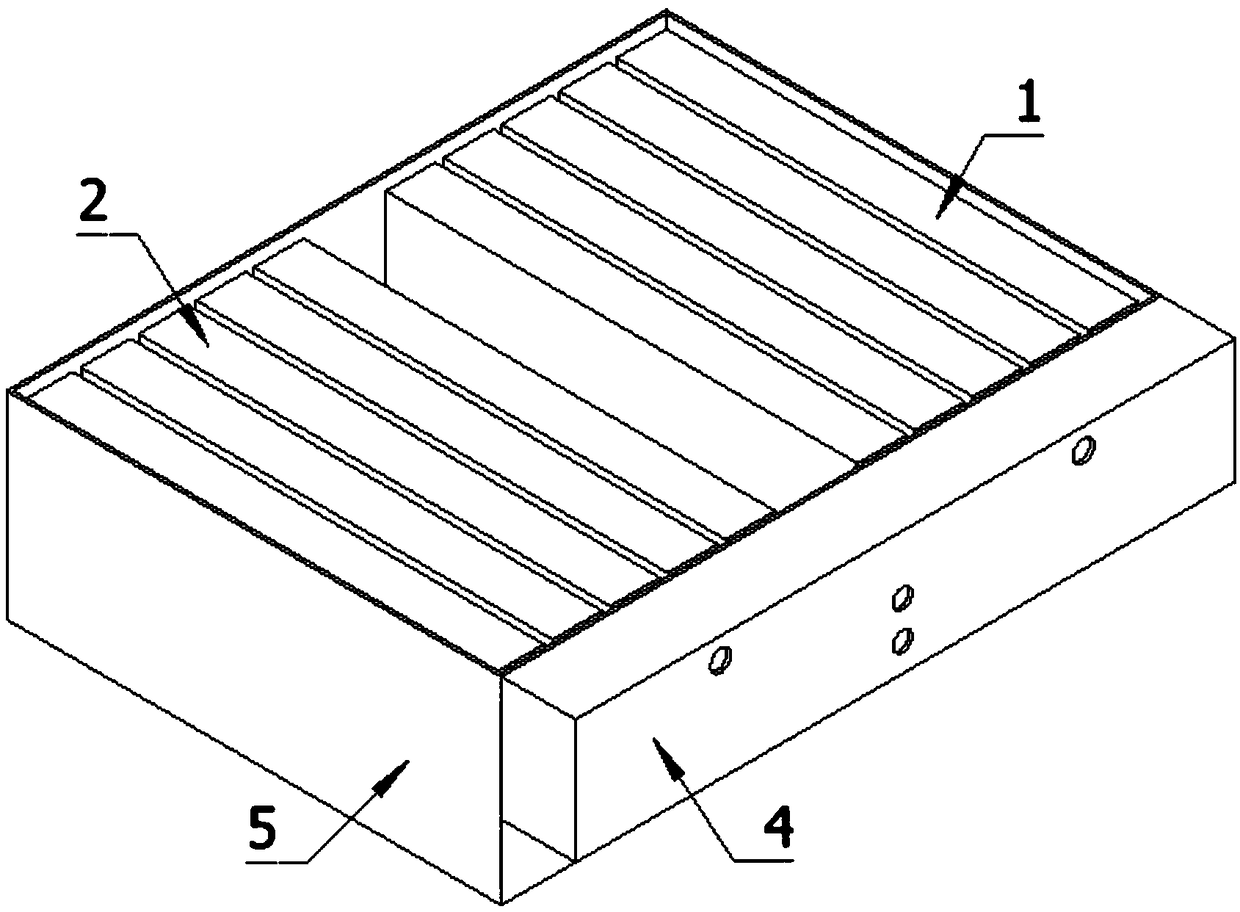

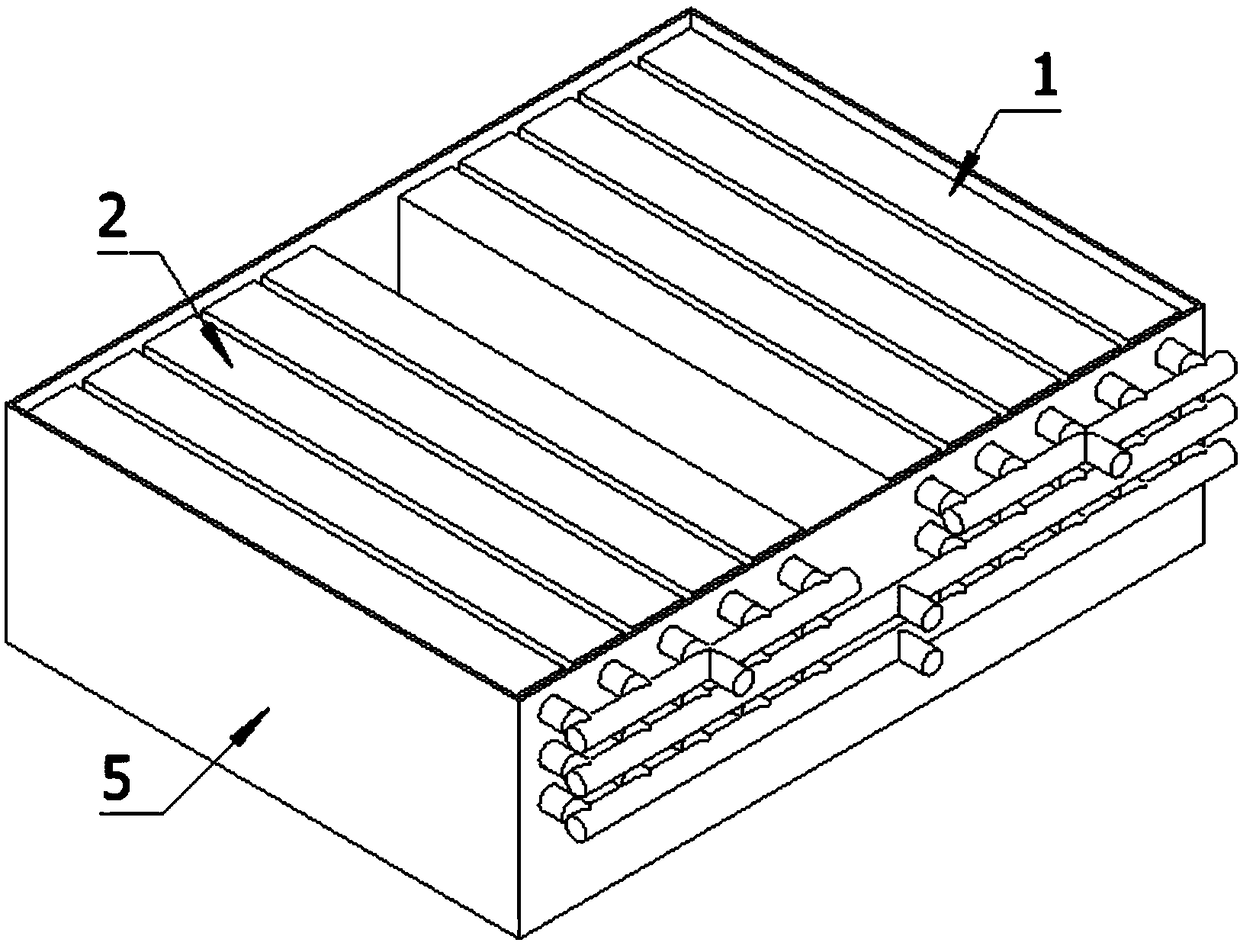

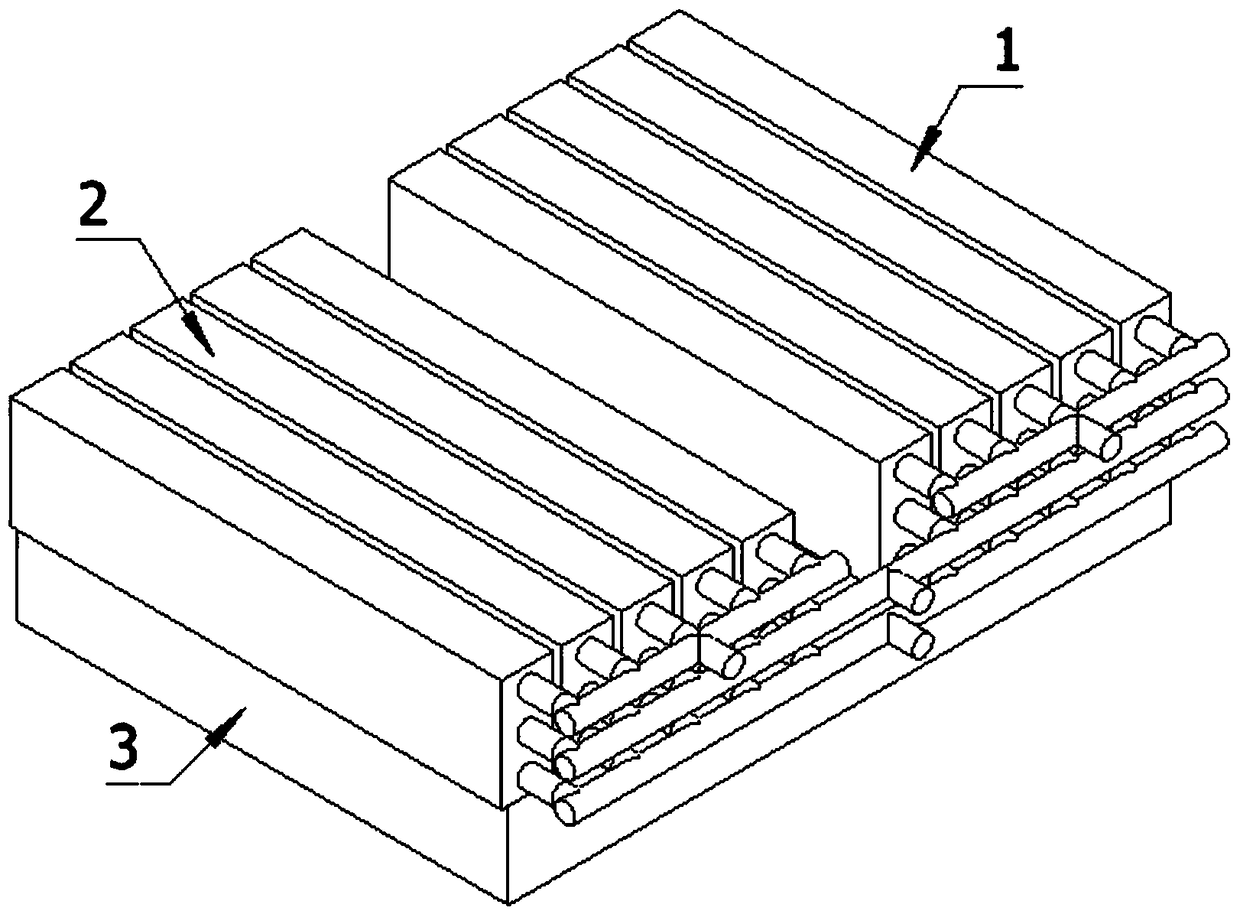

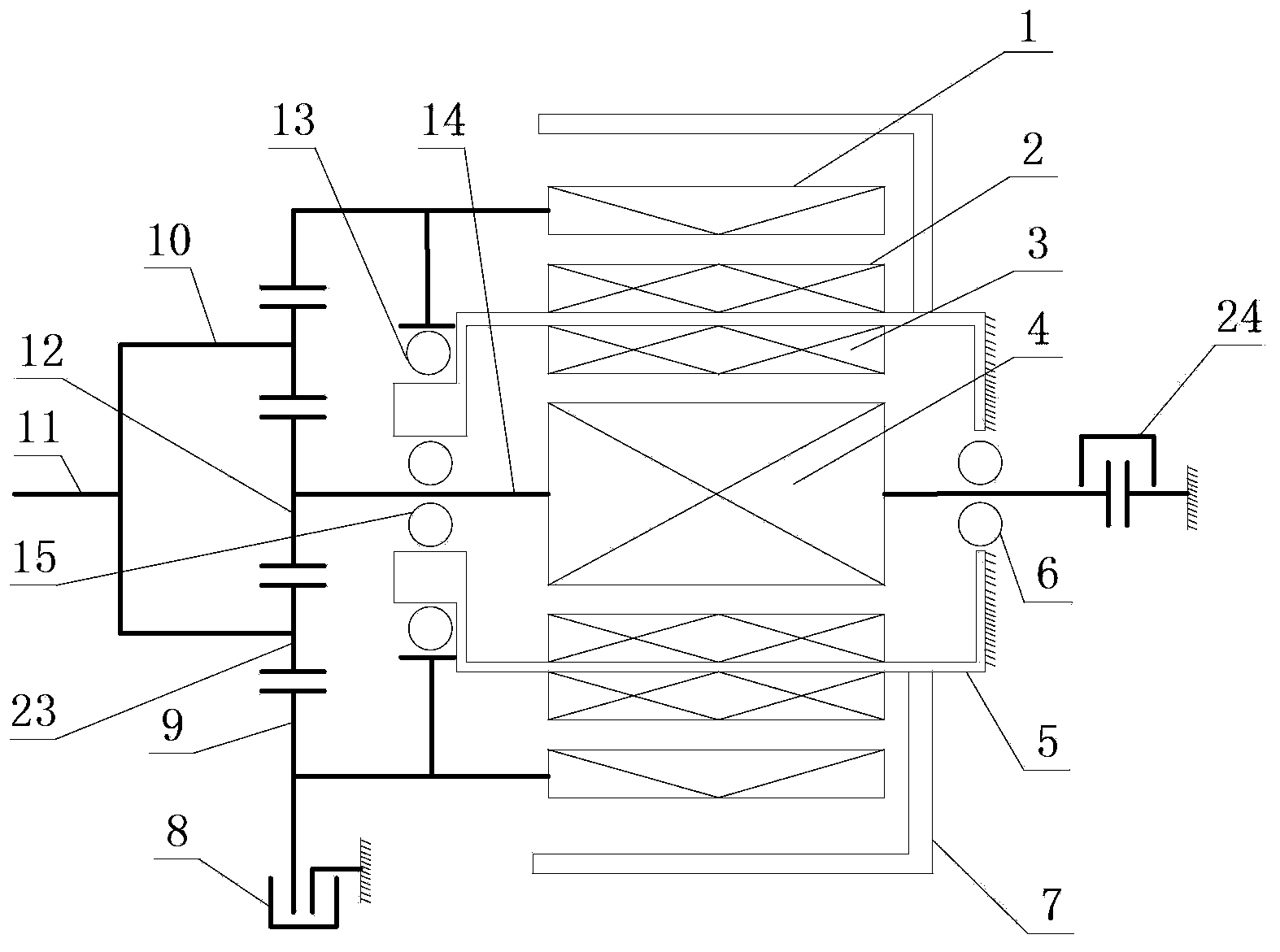

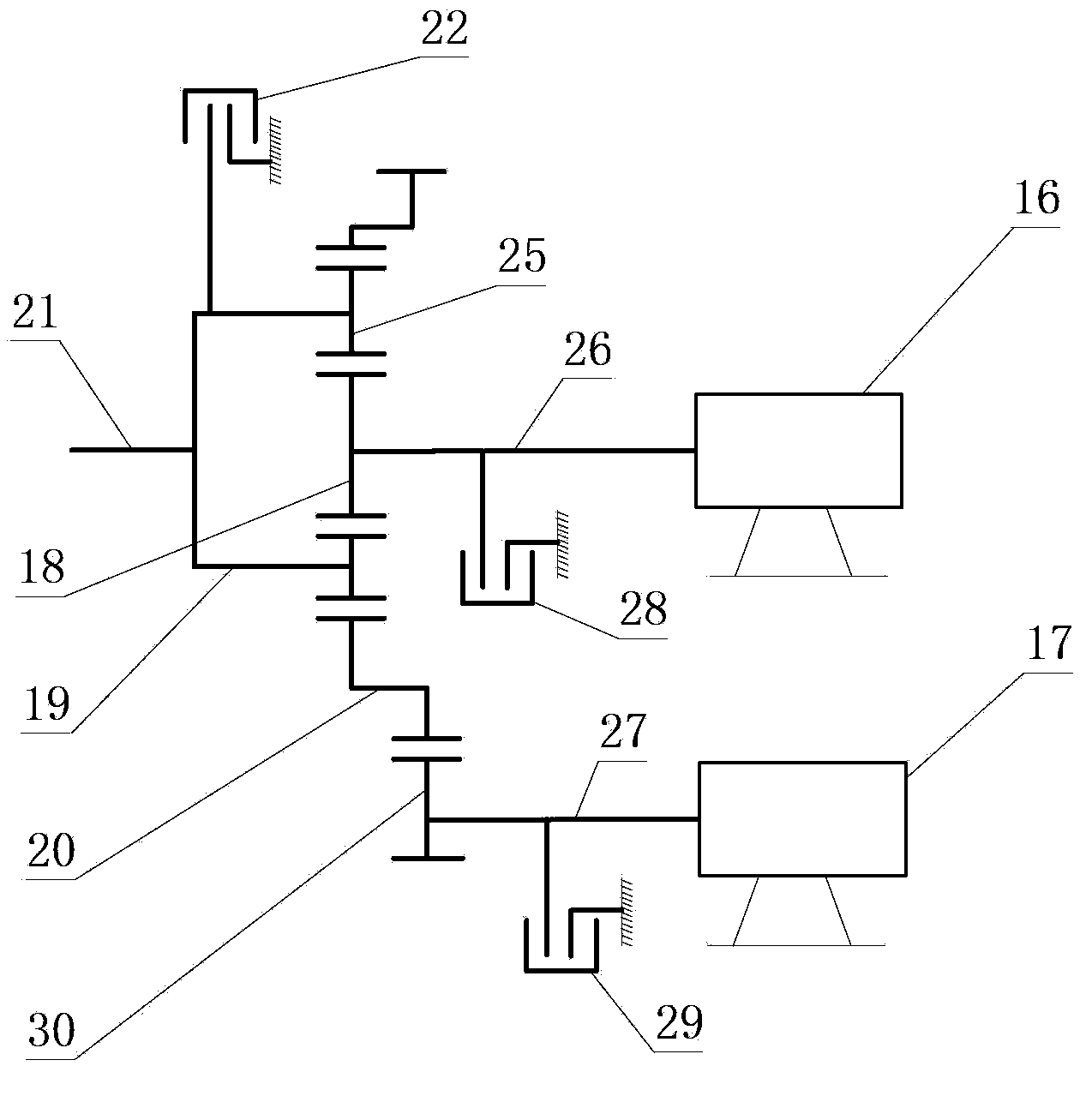

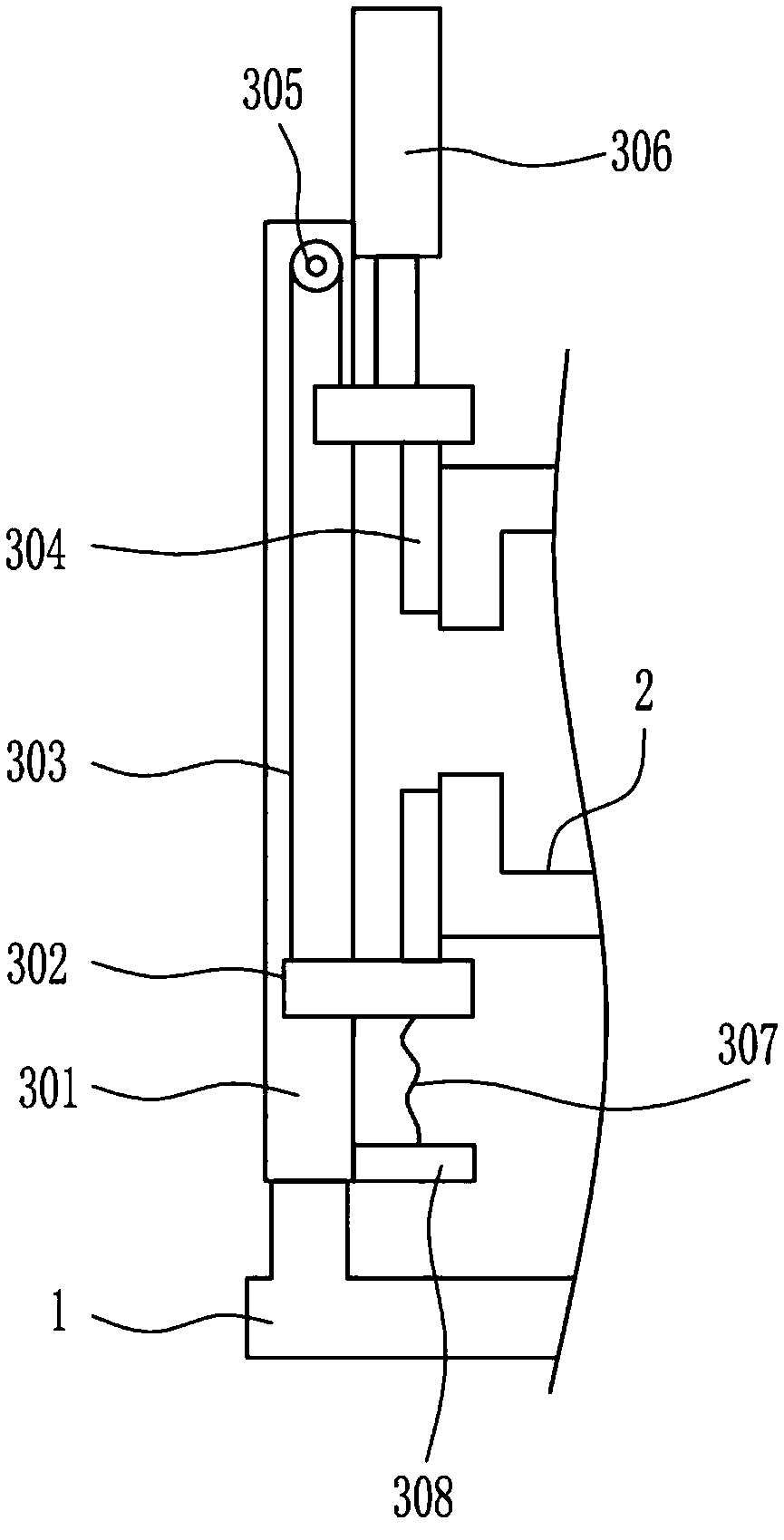

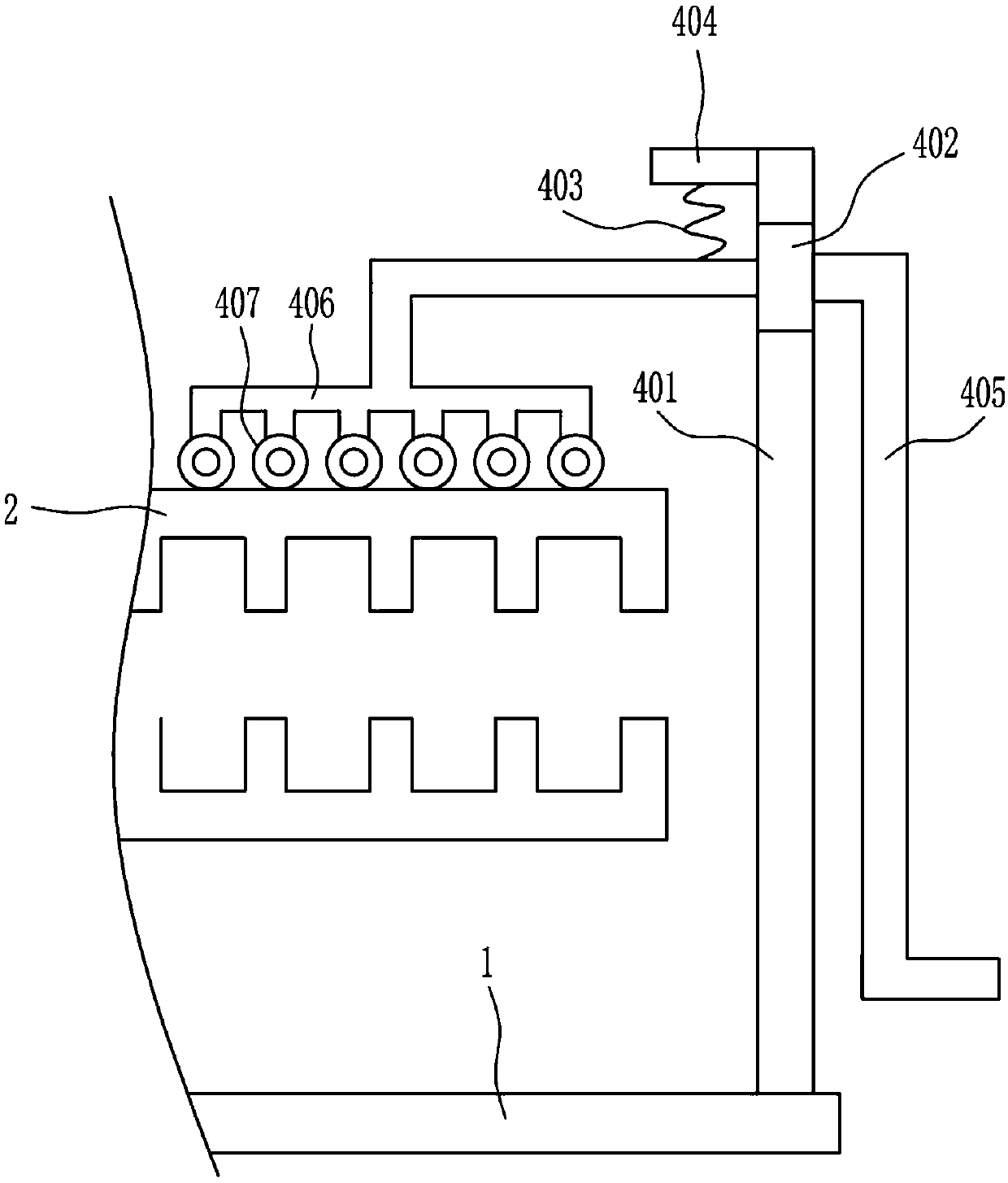

Distribution substation terminal with positioning function and positioning implementation method therefor

InactiveCN106093988AGuaranteed uninterruptedReduce limitationsSatellite radio beaconingElectricityComputer module

The invention discloses a distribution substation terminal with a positioning function and a positioning implementation method therefor. The distribution substation terminal comprises a distribution substation terminal body (1) which is provided with a communication module (2). The communication module (2) comprises a wireless module (3) supporting multi-standard networks and a positioning module (4) supporting multiple positioning systems and capable of starting the multiple positioning systems at the same time. The positioning module (4) and the wireless module (3) are electrically connected with each other, and longitudinal information and latitudinal information is sent to the main station of the distribution substation terminal body (1) for positioning via the wireless module (3). The invention is advantaged by few positioning restriction and small positioning error probability.

Owner:NINGBO SANXING INTELLIGENT ELECTRIC

Start and stop control method for parallelly-connected multi-unit photovoltaic grid-connected inverter system

ActiveCN103178544BImprove efficiencyWill not stopSingle network parallel feeding arrangementsPhotovoltaic energy generationMulti unitGrid connected inverter

The invention discloses a start and stop control method for a parallelly-connected multi-unit photovoltaic grid-connected inverter system. The start and stop control method includes steps of selecting a main photovoltaic inverter unit, realizing highest efficiency of a parallel system; establishing a stop array (start array) of inverter units according to sequence of thermal circulation times from more to less (from less to more) of parallelly-connected photovoltaic inverter units in the start and stop conversion logic aspect of the parallelly-connected photovoltaic inverter units, and guaranteeing running time of all units to tend to be uniform. In the aspect of selecting a host, any photovoltaic inverter units which can normally run can be involved in competition with the host, and accordingly, halt of the parallel system caused by breakdown of the host is avoided.

Owner:TBEA XIAN ELECTRIC TECH +1

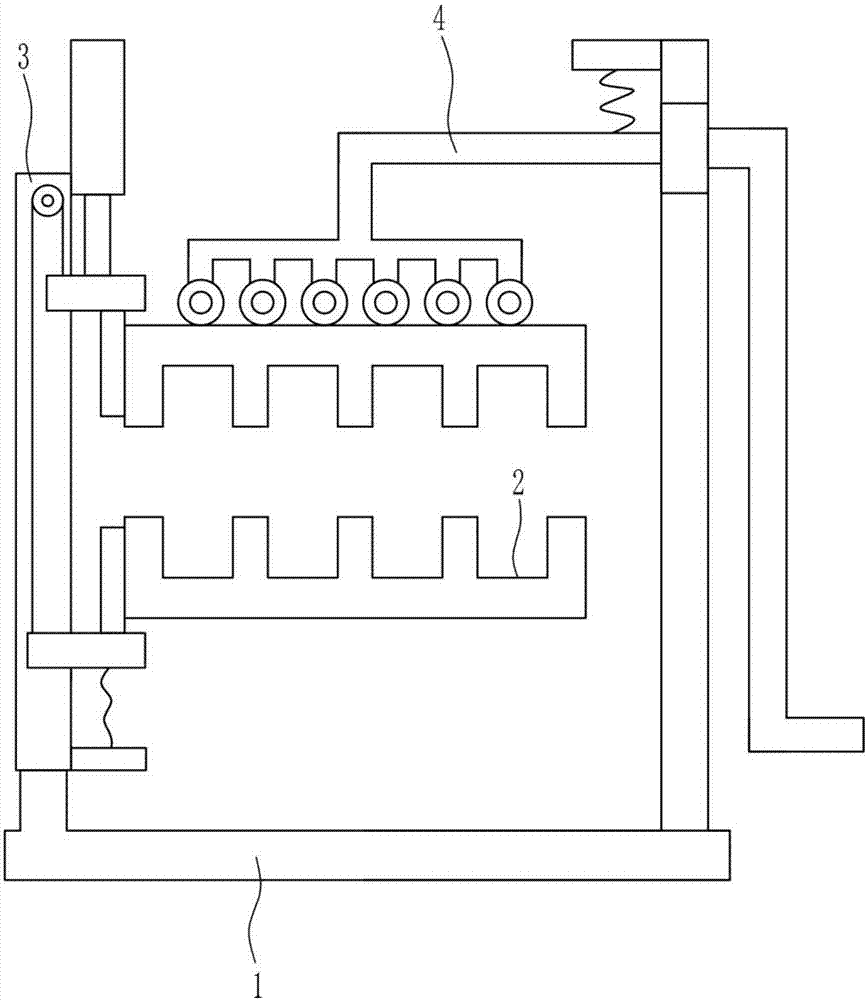

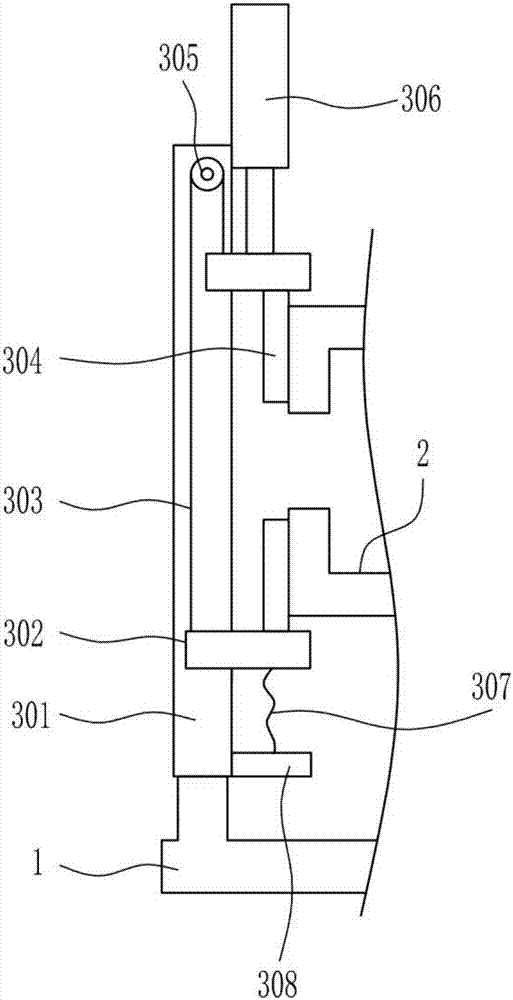

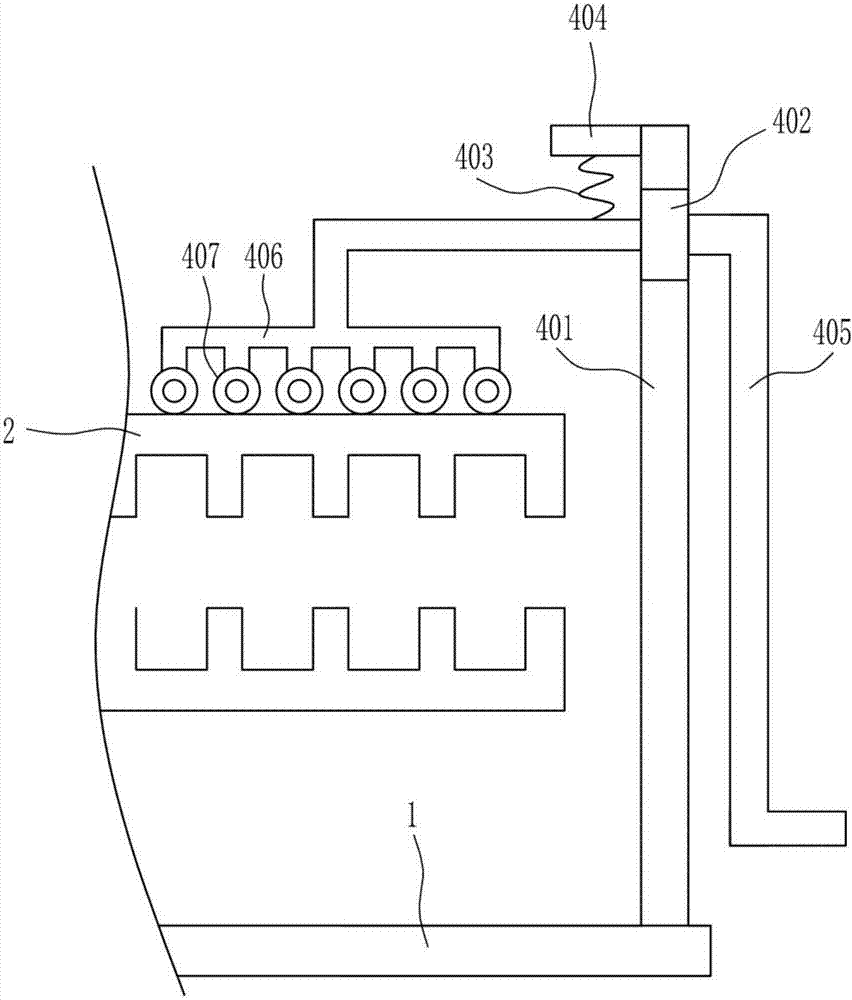

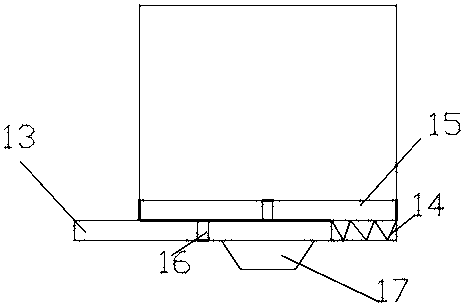

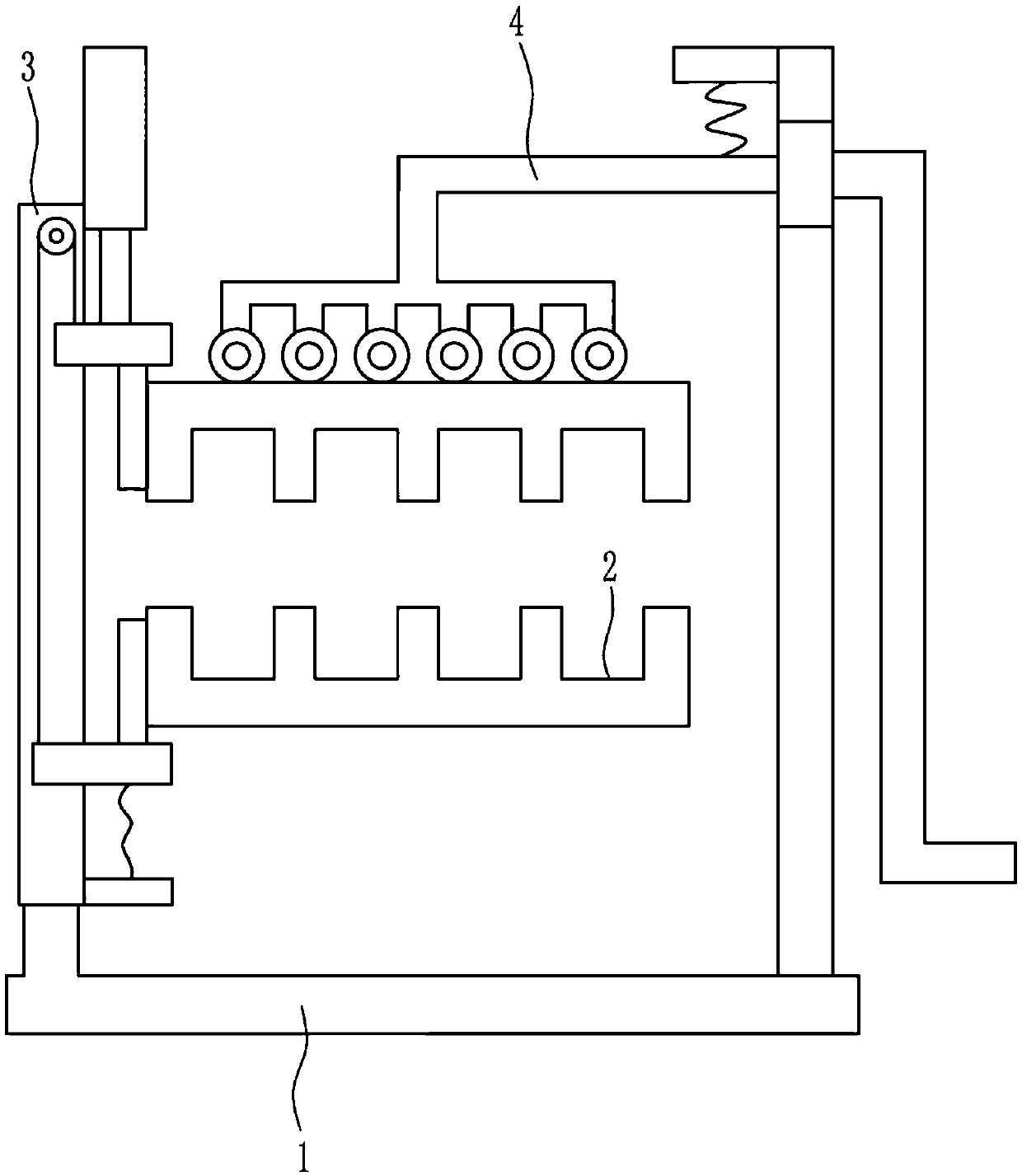

Plastic mold with vibration function

ActiveCN107364093AWith vibration functionVibration Function GuaranteeEngineeringMechanical engineering

The invention relates to a plastic mold, in particular to a plastic mold with a vibration function. According to the plastic mold with the vibration function, the result that raw materials are not cut off can be ensured, so that female molds are filled with molten plastic; the labor efficiency and the production efficiency are improved; and meanwhile, the yield also can be predicted and ensured. The plastic mold with the vibration function comprises a bottom plate and the like. A closing mechanism is connected to the top of the left side of the bottom plate. Mold cavities are connected to the right end of the closing mechanism up and down. A lifting mechanism is connected to the right side of the top of the bottom plate. The bottom of the lifting mechanism makes contact with the tops of the upper-side mold cavities. By means of the plastic mold with the vibration function, the effects that the result that the raw materials are not cut off can be ensured, so that the female molds are filled with the molten plastic; the labor efficiency and the production efficiency are improved; and meanwhile, the yield also can be predicted and ensured are achieved.

Owner:กวางตุ้ง คิวแมน คัลเจอร์ คอมมูนิเคชั่น โค แอลทีดี

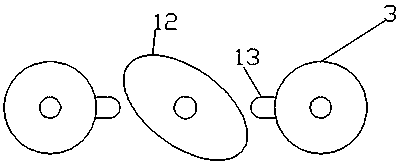

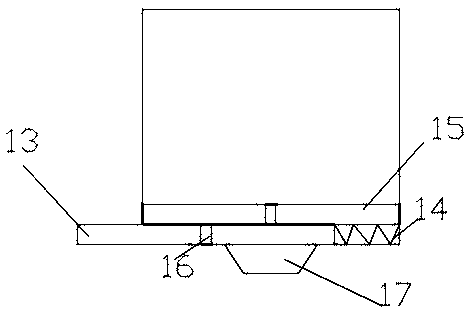

Multi-direction transmission device

InactiveCN108506425AGuaranteed uptimeSmooth runningGear lubrication/coolingToothed gearingsSlide plateEngineering

The invention discloses a multi-direction transmission device. The multi-direction transmission device comprises a motor, an input shaft, drop oilers, a shell, a first bevel gear, a second bevel gear,a third bevel gear, a first output shaft, a second output shaft, an oil drain valve, a convex block, sliding plates, springs, baffles, holes and oil drip nozzles. The motor is provided with the inputshaft. The shell is arranged below the input shaft. The input shaft penetrates through the shell to be connected with the first bevel bear. The two sides of the first bevel gear are connected with the second bevel gear and the third bevel gear correspondingly. The second bevel gear is connected with the first output shaft. The third bevel gear is connected with the second output shaft. The firstoutput shaft and the second output shaft penetrate through the shell. The oil drain valve is arranged below the shell. The convex block is arranged on the input shaft. The oil drip nozzles are arranged on the two sides of the input shaft and can add lubricating oil to the gears dropwise so that the gears can operate stably all the time. The situation that the gears get stuck is eradicated. The whole transmission device can operate stably without stopping operating.

Owner:DONGGUAN UNIV OF TECH +1

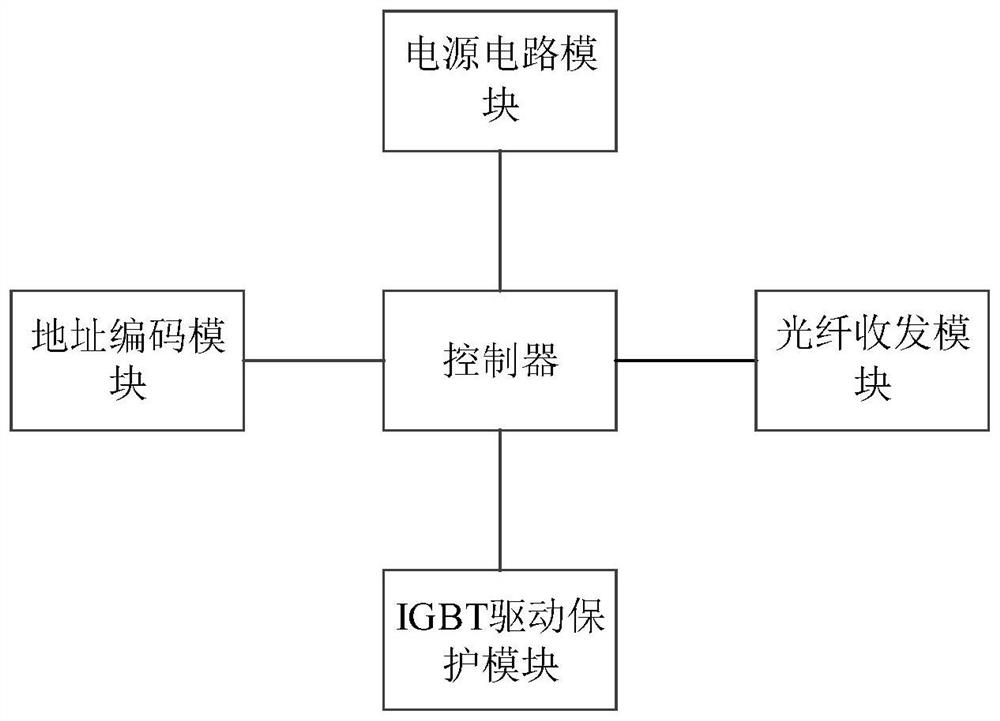

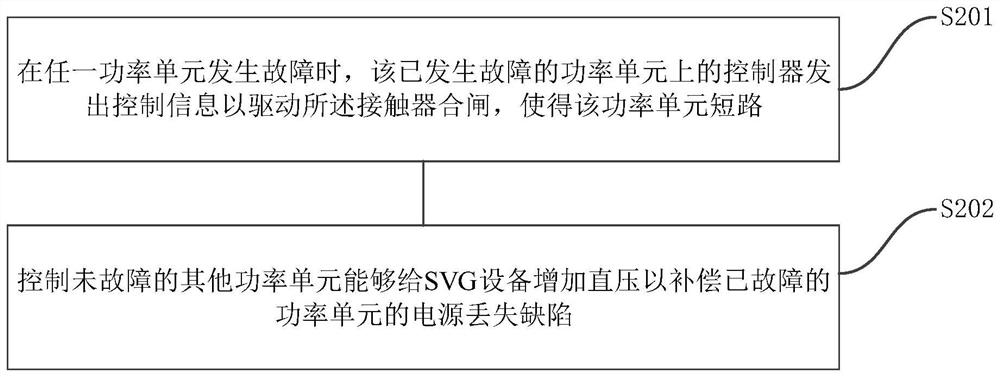

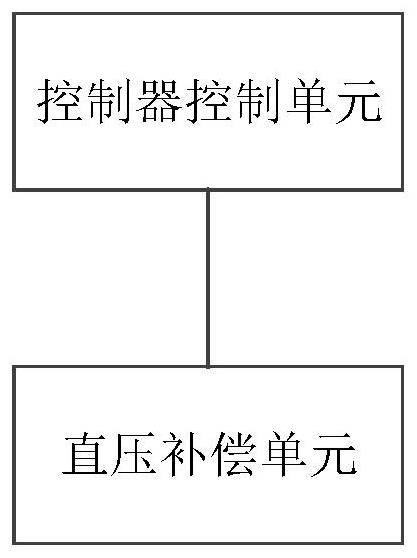

H-bridge mechanical bypass control circuit, control method and system

PendingCN114336661ACompensation for missing defectsGuaranteed uptimeFlexible AC transmissionEmergency protective circuit arrangementsControl engineeringHemt circuits

The embodiment of the invention provides an H-bridge mechanical bypass control circuit, control method and system, and belongs to the technical field of high-voltage dynamic reactive compensation. The H-bridge mechanical bypass control circuit comprises the following components configured on each power unit: a controller, and an IGBT driving protection module and a power supply circuit module which are electrically connected with the controller; wherein the IGBT driving protection module is connected to a contactor installed on the power unit where the IGBT driving protection module is located, and is used for receiving control information from the controller to drive the contactor to be switched on when the power unit where the IGBT driving protection module is located fails. The current failed power unit is short-circuited, and other non-failed power units can increase the direct voltage to the SVG equipment so as to compensate the power loss defect of the failed power unit; the power supply circuit module is used for providing working voltage for the controller and the IGBT driving protection module.

Owner:ANHUI USEM TECH CO LTD

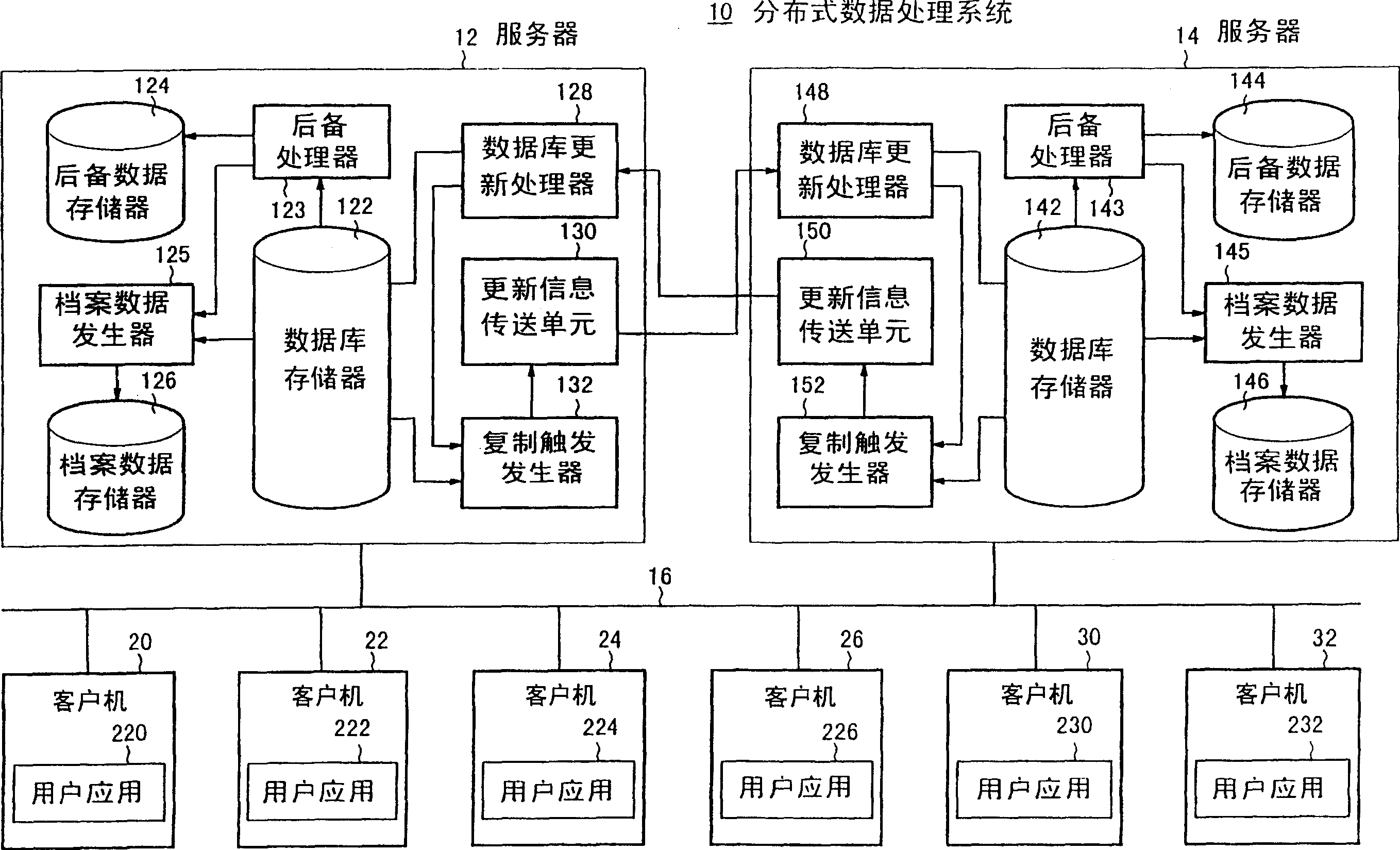

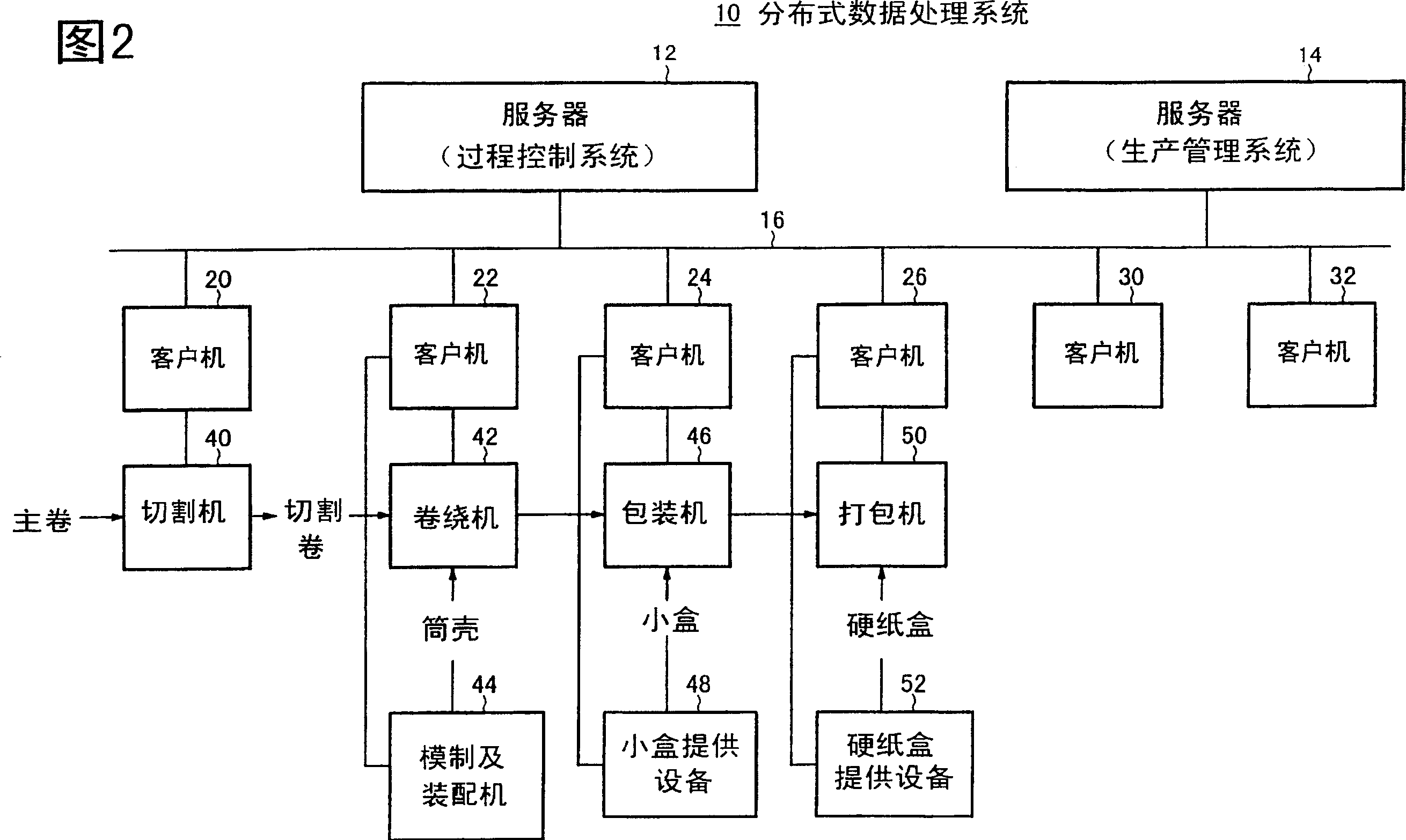

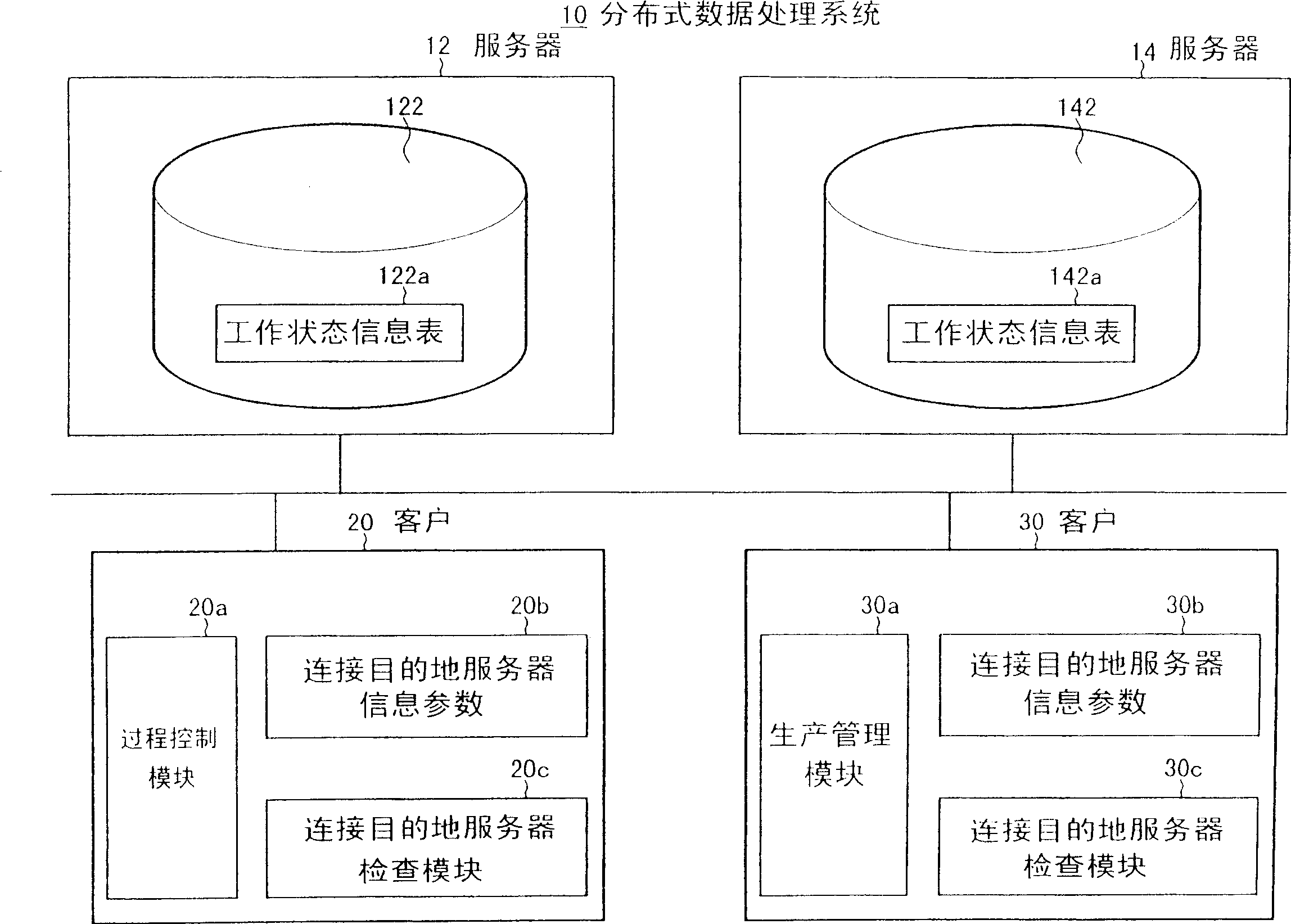

Distribution data processing system and method for processing data in said system

InactiveCN1251087CWill not stopDatabase distribution/replicationTransmissionData processing systemInformation transfer

When a database of a database memory (122, 142) of a server (12, 14) is updated by a distributed data processing process performed by clients (20, 22, 24, 26, 30, 32) on an object to be controlled, a replication trigger generator (132, 152) generates a replication trigger. Based on the replication trigger, an updating information transfer unit (130, 150) transfers updating information to another server (12, 14). A database updating processor (128, 148) of the server (12, 14) which has received the updating information updates the database stored in the database memory (122, 142).

Owner:FUJIFILM CORP

A reconfigurable computing unit supporting multiple working modes and its working method

ActiveCN106155814BImprove work efficiencyEasy to integrateResource allocationDigital computer detailsControl layerLayer interface

The invention discloses a reconfigurable unit supporting multiple working modes and the working modes thereof. The reconfigurable unit is characterized by comprising a control layer, an arithmetic layer and a storage layer; the control layer comprises a state layer interface, a configuration layer interface, a data layer interface, an address generator and a controller; the arithmetic layer comprises an arithmetic device; the storage layer comprises a source operand cache unit and a destination operand cache unit. The working modes of the reconfigurable arithmetic unit comprise the storage arithmetic mode, the pulse arithmetic mode and the stream arithmetic mode, and higher flexibility is provided for algorithm mapping of a computing system. When task mapping is carried out in the computing system, the specific working modes of the reconfigurable arithmetic unit can be selected according to specific features and the bottleneck of the algorithm to be mapped and in combination with specific conditions of network communication and storage bandwidth in the computing system, therefore, the arithmetic throughput capacity and network communication and storage access pressure are considered, and the working efficiency of the whole system is improved.

Owner:HEFEI UNIV OF TECH

Positioning compensation system and method applied to automobile wheel casing edge covering

ActiveCN102489570BWill not stopImprove work efficiencyControl using feedbackProduction lineComputer module

The invention discloses a positioning compensation system applied to automobile wheel casing edge covering. The positioning compensation system comprises a positioning device and a compensation device, wherein the positioning device is arranged on an automobile wheel casing and used for measuring a distance between the compensation device and the automobile wheel casing and feeding a measurement result back to the compensation device; the compensation device comprises a monitoring module and a calling module; the monitoring module is used for receiving the measurement result and indicating the calling module to call an initial optimal compensation amount to compensate a reference edge covering trace of the automobile wheel casing according to the measurement result; and the initial optimal compensation amount is the optimal value for compensating the reference edge covering trace of the automobile wheel casing, which is screened by the positioning compensation system at the last time. Compared with the prior art, the positioning compensation system applied to the automobile wheel casing edge covering has the advantages that: the problems of failure of edge covering and shutdown of a production line caused by a failed positioning device are solved, and the work efficiency is improved. The invention also discloses a positioning compensation method for automobile wheel casing edge covering.

Owner:广州风神汽车有限公司

A multi-directional transmission device

InactiveCN108506425BGuaranteed uptimeSmooth runningGear lubrication/coolingToothed gearingsGear wheelElectric machinery

The invention discloses a multi-direction transmission device. The multi-direction transmission device comprises a motor, an input shaft, drop oilers, a shell, a first bevel gear, a second bevel gear,a third bevel gear, a first output shaft, a second output shaft, an oil drain valve, a convex block, sliding plates, springs, baffles, holes and oil drip nozzles. The motor is provided with the inputshaft. The shell is arranged below the input shaft. The input shaft penetrates through the shell to be connected with the first bevel bear. The two sides of the first bevel gear are connected with the second bevel gear and the third bevel gear correspondingly. The second bevel gear is connected with the first output shaft. The third bevel gear is connected with the second output shaft. The firstoutput shaft and the second output shaft penetrate through the shell. The oil drain valve is arranged below the shell. The convex block is arranged on the input shaft. The oil drip nozzles are arranged on the two sides of the input shaft and can add lubricating oil to the gears dropwise so that the gears can operate stably all the time. The situation that the gears get stuck is eradicated. The whole transmission device can operate stably without stopping operating.

Owner:DONGGUAN UNIV OF TECH +1

Uninterrupted power supply

PendingCN108429340ASaving switching power supply configurationReduce AC/DC conversion and DC/AC conversion linksPower network operation systems integrationCharging managementBattery management systemsBattery system

The invention discloses an uninterrupted power supply. The uninterrupted power supply comprises a 220 VAC power module and\or a 12 VDC power module, a battery system, a common base and a frame body, the 220 VAC power module and the 12 VDC power module both comprise power monitoring modules and battery accessing modules, and the battery system comprises a battery managing system and a battery pack;the 220 VAC power module, the 12 VDC power module and the battery managing system are all arranged in the frame body, the common base is arranged at one side of the frame body, and the 220 VAC powermodule is provided with a 220 VAC output port, a battery accessing port and a 220 VAC input port; the 12 VDC power module is provided with a 12 VDC output port, a battery accessing port and a 220 VACinput port, the common base is provided with a 12 VDC output port, a 220 VAC output port, a battery accessing port and a 220 VAC input port which correspond to the 220 VAC power module and the 12 VDCpower module, the 220 VAC power module and the 12 VDC power module are arranged on the common base, and the battery accessing ports are connected with the battery system. The uninterrupted power supply can make a system simpler, more reliable and more energy-saving.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

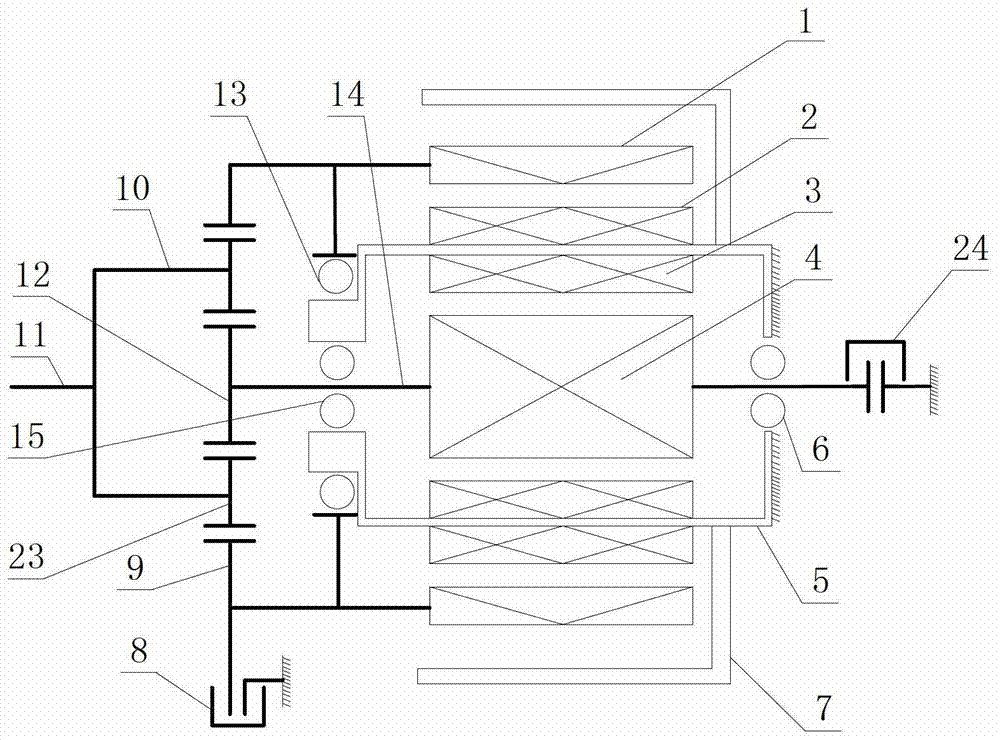

Different connection motor

ActiveCN103986278AAchieve no-load start effectSave energyAsynchronous induction motorsMachines/enginesFluid couplingPower factor

The invention relates to a different connection motor, for solving the technical problems of large size, heavy weight, large mechanical loss and rotation difference, quite low efficiency, unstable speed control, low power factor, poor speed regulation precision and high maintenance cost of a conventional fluid coupling device. The different connection motor comprises a primary motor working under power frequency and a secondary motor working under variable frequency. A planetary gear mechanism is connected between the primary motor and the secondary motor, the planetary gear mechanism is provided with a planet carrier, and the planet carrier is fixedly connected with an output shaft. The different connection motor can be used for motor driving or wind power generation.

Owner:WEIHAI DENGTONG PURIFICATION EQUIP

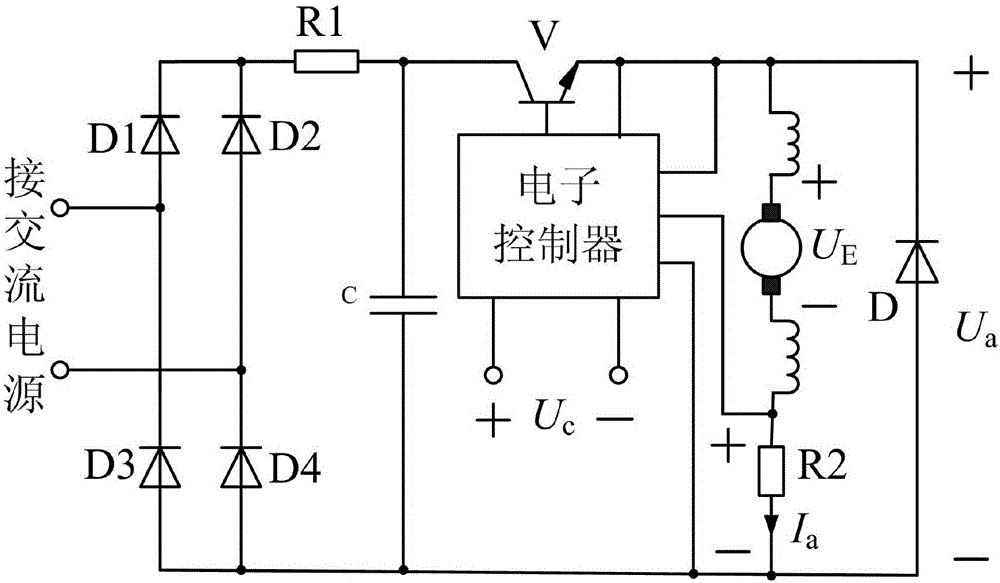

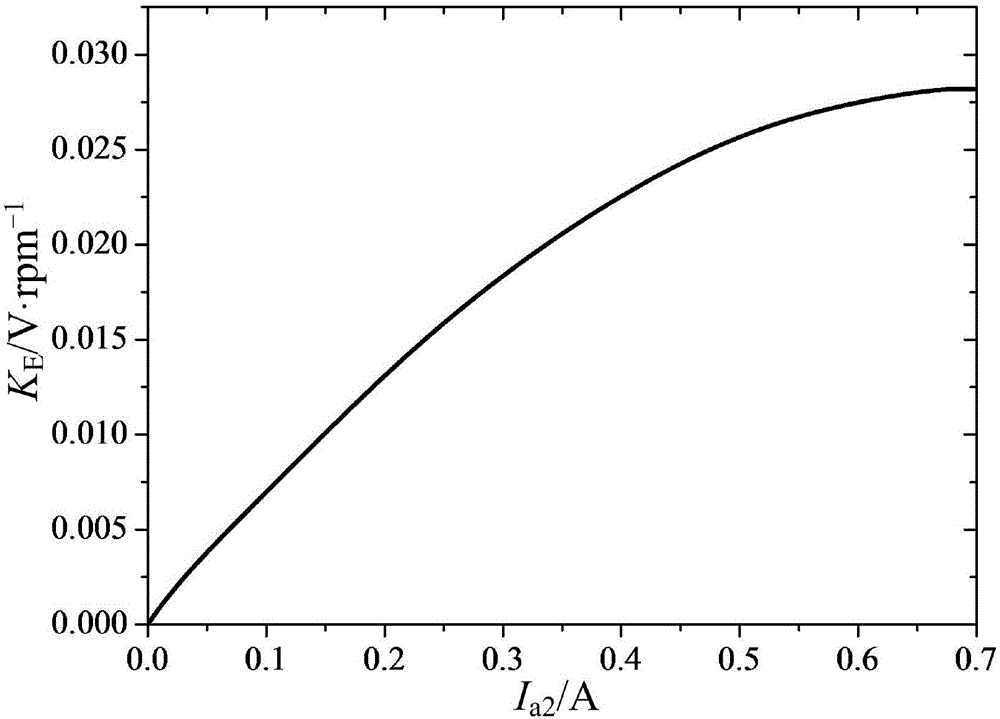

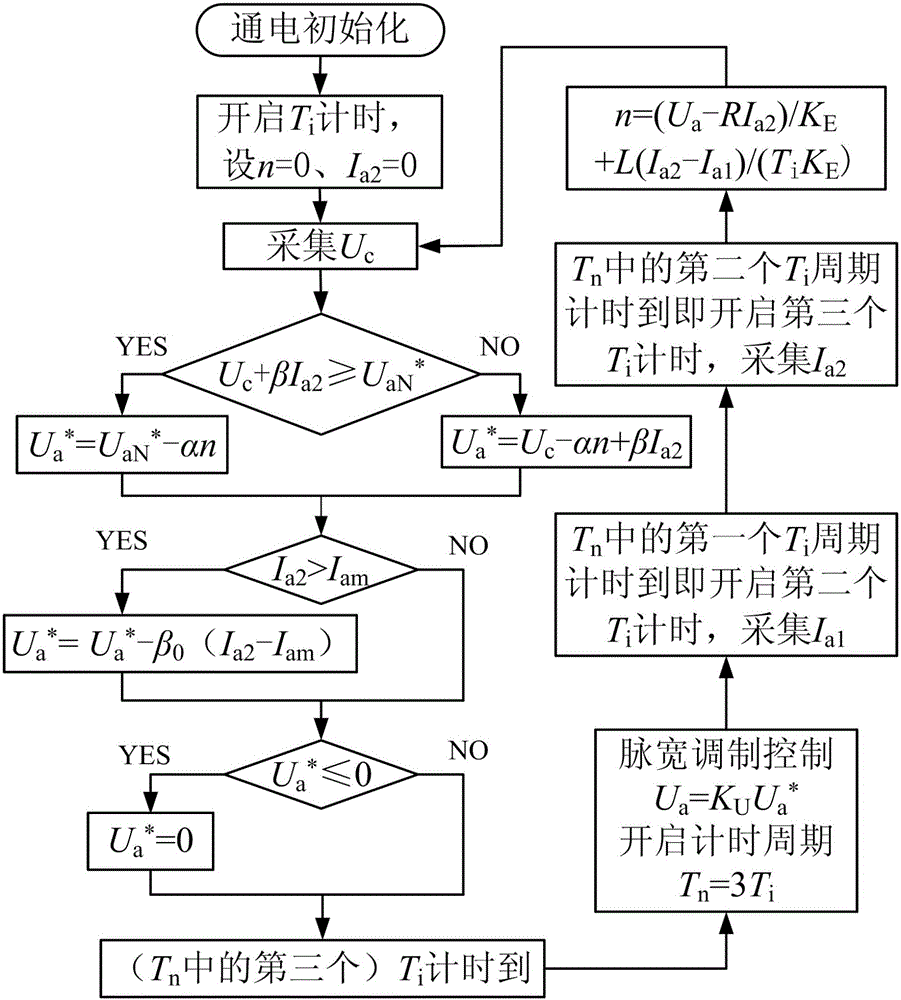

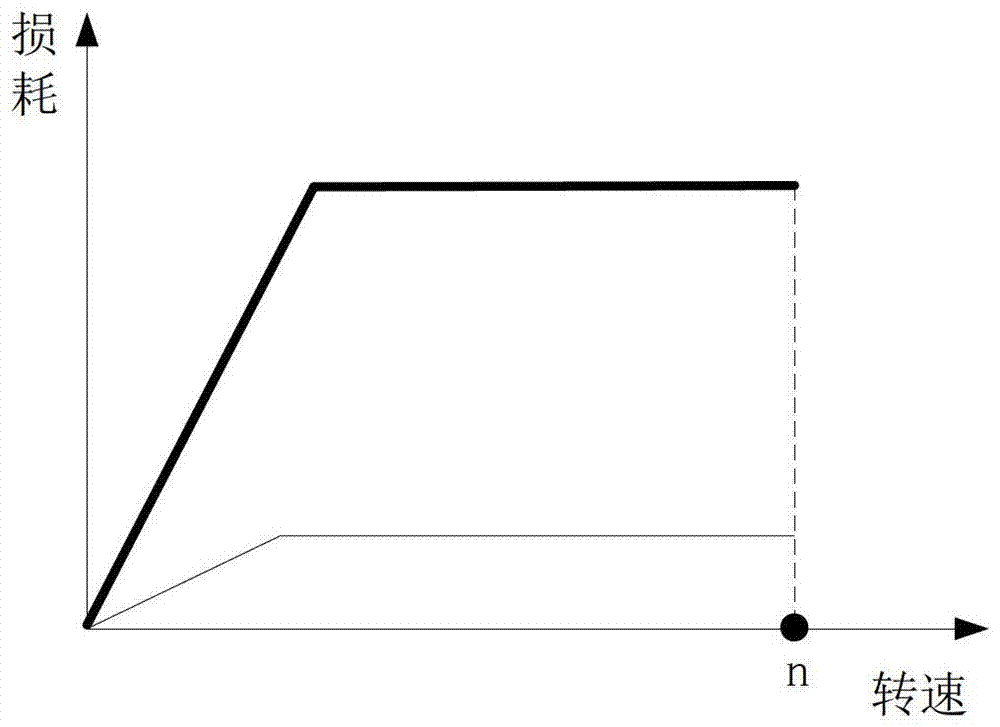

A control method for a speed-regulating drive system of a series-excited motor

ActiveCN103326644BWill not stopEliminate defects in mechanical propertiesField or armature current controlMotor speedLow speed

The invention discloses a control method for a speed adjustment driving system of a series motor. According to the invention, a direct-current chopping voltage-regulating power source is adopted to supply power to the series motor, and an electronic controller is adopted to adjust the on-off duty ratio of power electronic switching devices in the direct-current chopping voltage-regulating power source and control the terminal voltage of the motor in a manner of pulse width modulation. The control method disclosed by the invention has the advantages that the rotating speed of the series motor can be detected without a speed sensor; rotating speed and current feedback control is introduced, so that on the premise of maintaining the soft mechanical properties of the system, the defects, for instance that the rotating speed increases to a dangerous value when the system is in idle running at high voltage, serious overload happens during locked rotor and the locked rotor phenomenon easily happens during low speed running at low voltage, in the mechanical properties of the speed adjustment driving system of the open-loop series motor are eliminated.

Owner:LISHUI UNIV +1

A low-sulfur oil cooling device and its cooling compressor unit

ActiveCN103291508BTimely coolingLarge adjustment scaleMachines/enginesFluid circulation arrangementOil coolingElectromagnetic valve

The invention relates to a low sulfur oil cooling unit and a cooling compressor unit of the low sulfur oil cooling unit. The cooling compressor unit comprises a compressor, a condenser, a throttling component and an evaporator, wherein the evaporator is provided with a refrigerant inlet, a refrigerant outlet, a cooling water outlet and a cooling water inlet, and the refrigerant outlet of the evaporator is connected with the air inlet end of the compressor through pipelines. The cooling compressor unit further comprises a hot air bypass sub-channel with the two ends connected with the air discharging end of the compressor and the refrigerant inlet of the evaporator respectively, a temperature sensor and a PLC connected with the temperature sensor, and a stop valve, an electromagnetic valve, an energy regulating valve and a liquid-and-gas mixer are sequentially arranged on the hot air bypass sub-channel, wherein the energy regulating valve is further connected with the air inlet end of the compressor through pipelines, and the electromagnetic valve is connected with the PLC. Although the lower pressure protection exists, the compressor of the cooling compressor unit will not stop working under the condition of low loads, the compressor can continually work, and timely cooling of low sulfur oil is ensured.

Owner:苏州利玛特能源装备有限公司

A full-frequency-domain constant-torque control system and method for an air-conditioning inverter compressor

ActiveCN104728090BStable currentGuaranteed uptimePump controlPositive-displacement liquid enginesEngineeringVoltage control

The invention relates to an air conditioner inverter compressor frequency-domain constant torque control system and method. The air conditioner inverter compressor frequency-domain constant torque control system comprises a current vector control portion and a constant torque control portion; the constant torque control portion outputs a current command which is used for reducing current pulse and adds the current command which is used for reducing the current pulse and an input signal of the current vector control portion to serve as input of the current vector control portion; the current vector control portion outputs a voltage control command to control a compressor. The improved constant torque compensation control method can be applied to a full frequency domain of a compressor; the constant torque control portion compensates currents to an input end of the current vector control portion; during a high band operation process, the currents are stable, a wave crest value at every period is uniformly distributed, the compressor stably operates.

Owner:HAIER GRP CORP +1

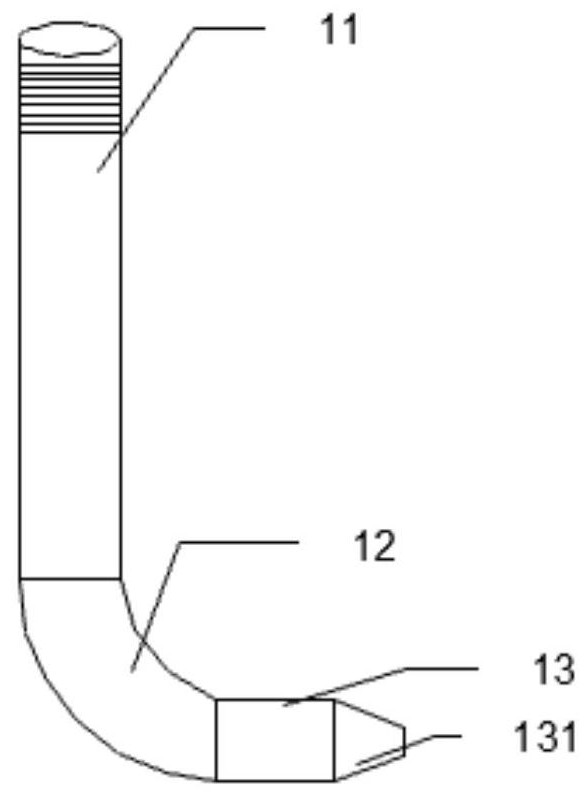

High-sulfur concentrate pump slurry feeding equipment and anti-blocking device and installation method thereof

PendingCN113908997ANo cloggingReduce the risk of pipe blockageHollow article cleaningSecuring devicesProcess engineeringSlurry

The invention provides a high-sulfur concentrate pump slurry inlet pipe anti-blocking device which comprises a first pipeline, a bent pipe and a second pipeline, wherein a water inlet of the bent pipe is communicated with a water outlet of the first pipeline, a water outlet of the bent pipe is communicated with a water inlet of the second pipeline, and the water inlet of the first pipeline is used for being communicated with a water outlet of a faucet. A water outlet of the pipeline II is formed in the bottom of the slurry inlet pipe of the sulfur concentrate pump. The invention further provides pulp feeding equipment of the high-sulfur concentrate pump. The invention further provides a mounting method of the anti-blocking device for the slurry inlet pipe of the high-sulfur concentrate pump. According to the anti-blocking device for the pulp inlet pipe of the high-sulfur concentrate pump, when sulfur concentrate pulp conditions change, the pulp inlet pipe of the sulfur concentrate pump cannot be blocked, and it is ensured that pulp in a pulp conveying pipe cannot be cut off, and the water pressure is enough to flush and disperse the pulp foam. The anti-blocking device for the slurry inlet pipe of the high-sulfur concentrate pump is simple in structure, small in size and convenient to install and operate.

Owner:SHUI KOU SHAN NONFERROUS METALS LTD

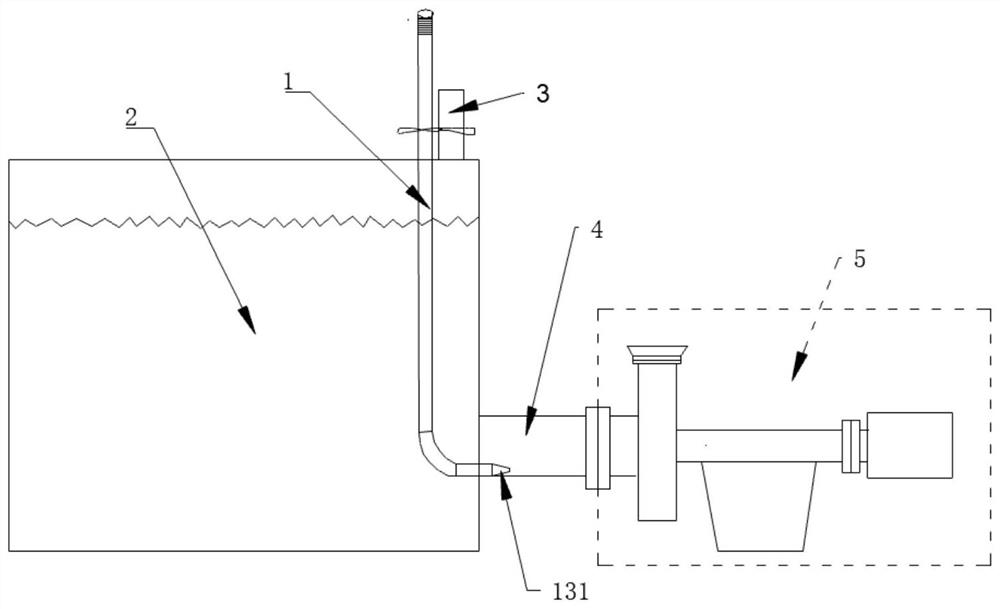

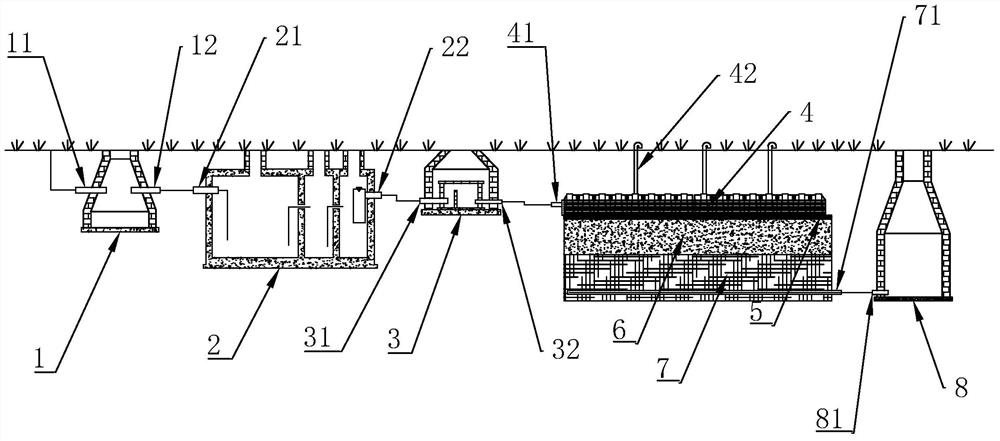

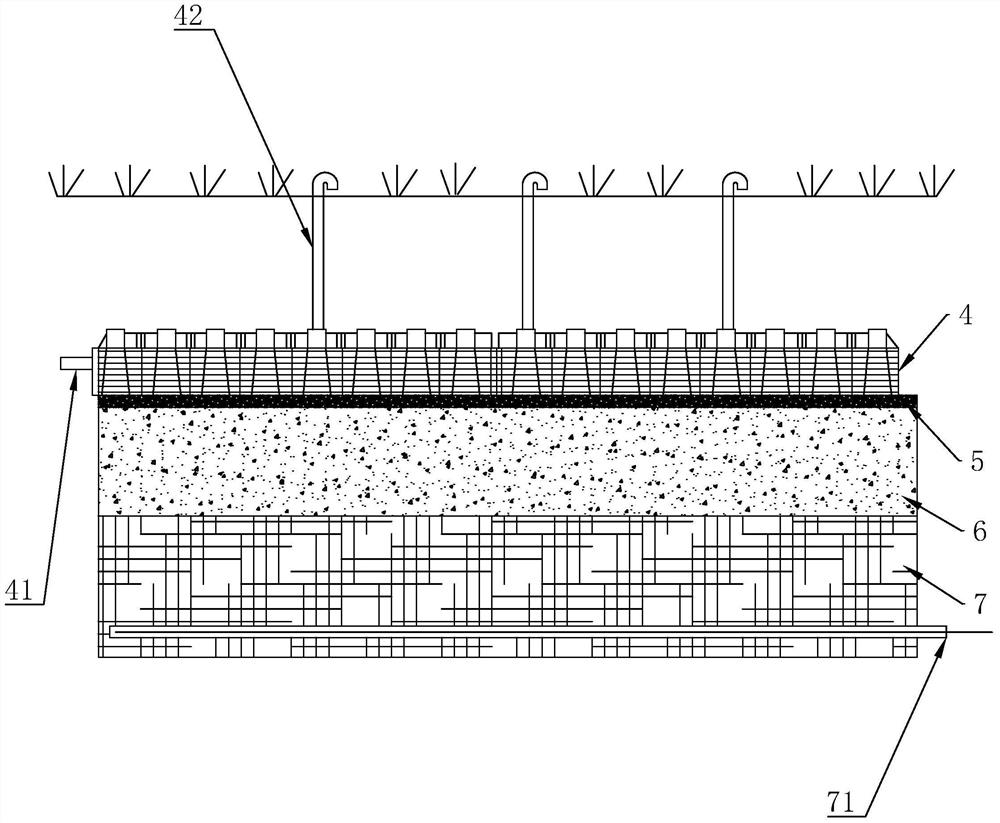

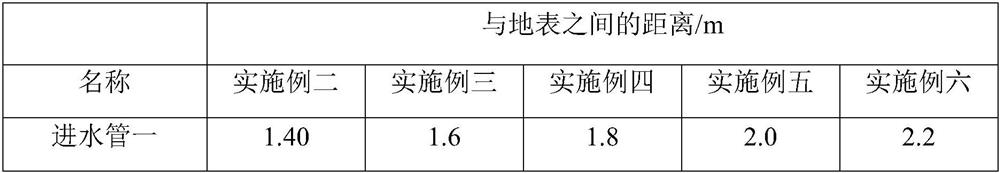

A kind of owt sewage treatment system

ActiveCN107572656BContinuous operationExempt from replacementTreatment with aerobic and anaerobic processesChemical treatmentWater treatment system

The invention provides an OWT sewage processing system. The system comprises a buffer well with a water inlet pipe (A) and a water outlet pipe (A); a separation hydrolysis tank with a water inlet pipe(B) and a water outlet pipe (B); a water diversion tank with a water inlet pipe (C) and a water outlet pipe (C); a standard osmotic chamber with a water inlet pipe (D); and a water storage tank witha water inlet pipe (E). A biological pad, a seepage area, and a saturation area with a water outlet pipe (D) are arranged under the standard osmotic chamber in sequence. The buffer well is sequentially communicated with the separation hydrolysis tank, the water diversion tank, the standard osmotic chamber, and the water storage tank. The buffer well, the separation hydrolysis tank, the water diversion tank, the standard osmotic chamber, and the water storage tank are all arranged under a frozen soil layer. The opening of the water inlet pipe (A) is not higher than a sewage pipeline. All devices are arranged under the frozen soil layer, and thus thermal insulation facilities are not needed in winter. Sewage can go through each processing apparatus under the effect of self gravity, so the system does not need extra power, and a large amount of energy is saved. Moreover, the system does not need management. At the same time, sewage is subjected to an anaerobic treatment, an aerobic treatment, a physical and chemical treatment, a sterilization treatment, a phosphor removing treatment, and a de-nitrification treatment, and the sewage is converted into clean water.

Owner:北京市鸿旭环境技术有限责任公司

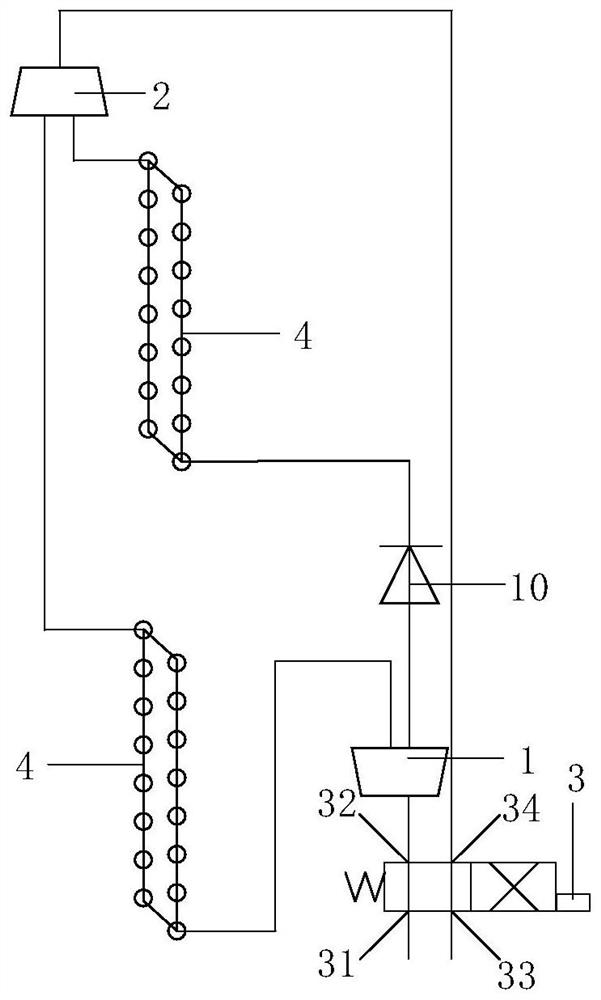

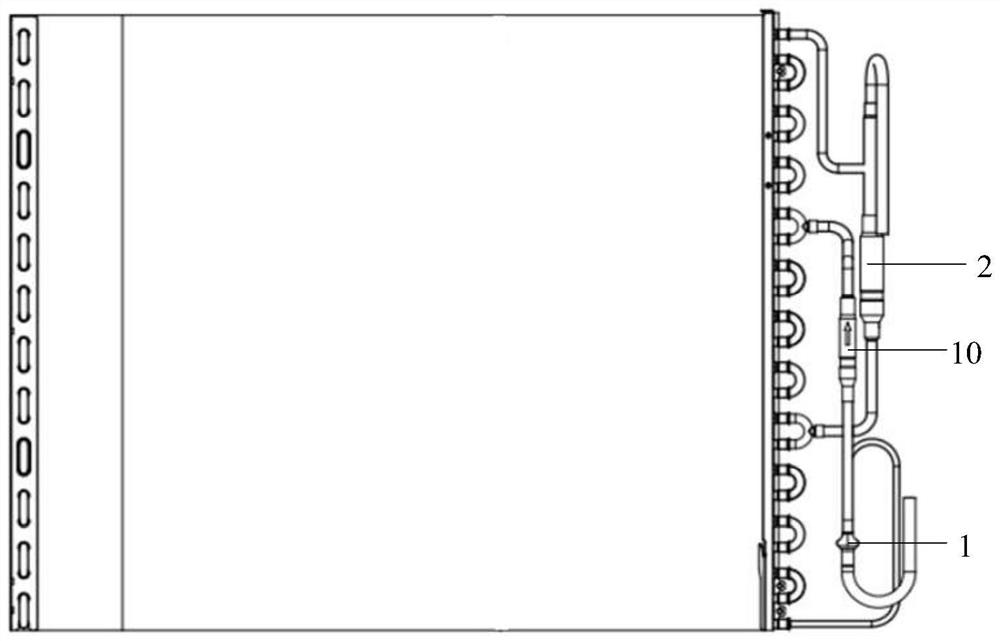

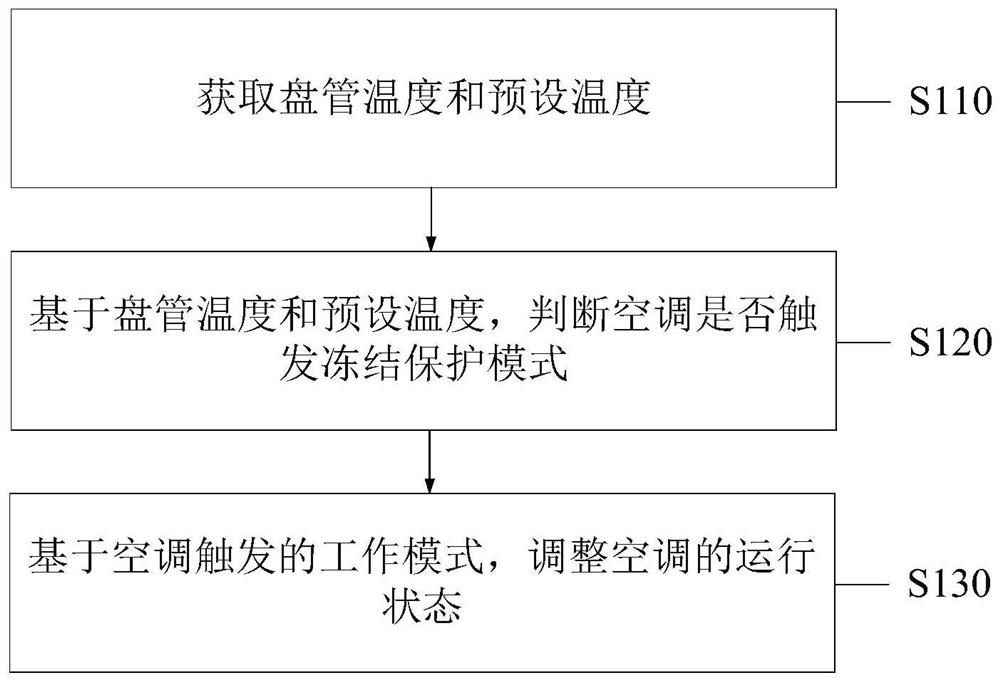

Control method and control system for preventing air conditioner from freezing, electronic equipment and medium

The invention provides a control method and system for preventing an air conditioner from freezing, electronic equipment and a medium. The control method comprises the steps that the coil pipe temperature and the preset temperature are obtained; judging whether the air conditioner triggers a freezing protection mode; adjusting the running state of the air conditioner based on the working mode triggered by the air conditioner; the operation state comprises a variable shunting state and a fixed shunting state; during variable shunting, a refrigerant in a heat exchanger of the air conditioner adjusts the shunting state according to the working mode of the air conditioner; and during fixed shunting, the shunting state of the refrigerant in the heat exchanger is fixed. According to the control method for preventing the air conditioner from freezing, the coil pipe temperature and the preset temperature are obtained firstly, whether the air conditioner triggers the freezing protection mode or not is judged based on the coil pipe temperature and the preset temperature, and the operation state of the air conditioner is adjusted based on the working mode triggered by the air conditioner, so that the air conditioner is switched between the variable shunting state and the fixed shunting state. And the shunting state of the heat exchanger is changed, so that the air conditioner cannot be shut down due to freezing protection in a certain low-temperature interval.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

A plastic mold with vibration function

ActiveCN107364093BWith vibration functionVibration Function GuaranteeEngineeringMechanical engineering

The invention relates to a plastic mold, in particular to a plastic mold with a vibration function. According to the plastic mold with the vibration function, the result that raw materials are not cut off can be ensured, so that female molds are filled with molten plastic; the labor efficiency and the production efficiency are improved; and meanwhile, the yield also can be predicted and ensured. The plastic mold with the vibration function comprises a bottom plate and the like. A closing mechanism is connected to the top of the left side of the bottom plate. Mold cavities are connected to the right end of the closing mechanism up and down. A lifting mechanism is connected to the right side of the top of the bottom plate. The bottom of the lifting mechanism makes contact with the tops of the upper-side mold cavities. By means of the plastic mold with the vibration function, the effects that the result that the raw materials are not cut off can be ensured, so that the female molds are filled with the molten plastic; the labor efficiency and the production efficiency are improved; and meanwhile, the yield also can be predicted and ensured are achieved.

Owner:กวางตุ้ง คิวแมน คัลเจอร์ คอมมูนิเคชั่น โค แอลทีดี

Different motor

ActiveCN103986278BAchieve no-load start effectSave energyAsynchronous induction motorsMechanical energy handlingFluid couplingElectric machine

An asynchronous connection motor, which solves the technical problem that the existing hydraulic coupler has large volume, heavy weight, large mechanical loss and slip loss, lower efficiency, instable speed control, low power factors, poor speed adjustment accuracy and high maintenance costs. The asynchronous connection motor comprises a main motor which operates at a power frequency, and an auxiliary motor which operates at a variable frequency, wherein a planetary gear mechanism is connected between the main motor and the auxiliary motor; the planetary gear mechanism is provided with a planet carrier; and the planet carrier is fixedly connected to an output shaft. The asynchronous connection motor can be used for driving a motor or wind power generation.

Owner:WEIHAI DENGTONG PURIFICATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com