A control method for a speed-regulating drive system of a series-excited motor

A drive system and control method technology, applied in the direction of excitation or armature current control, etc., can solve problems such as excessive locked-rotor current, reduced motor drive capability, and increased system manufacturing costs, so as to eliminate defects in mechanical characteristics, control delays, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

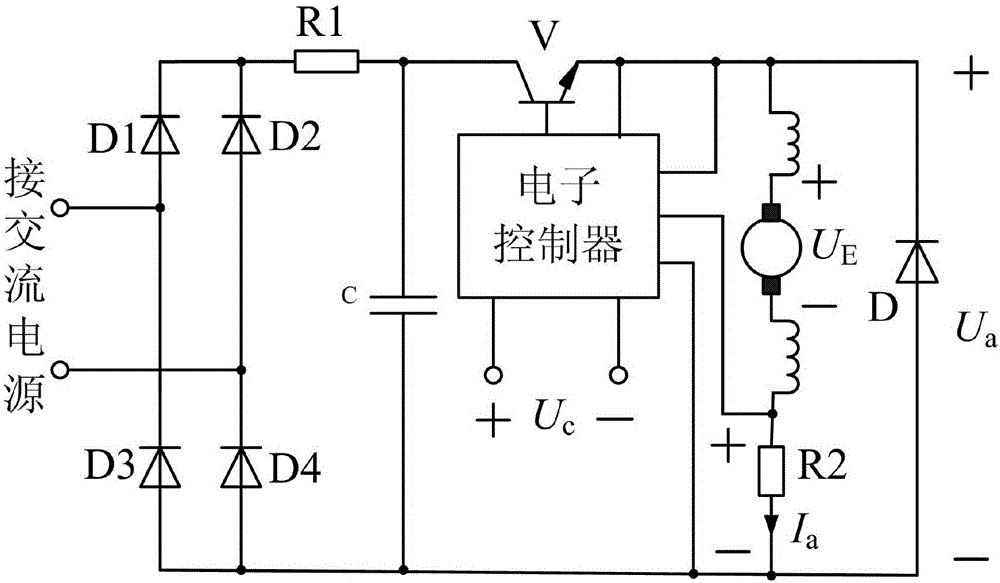

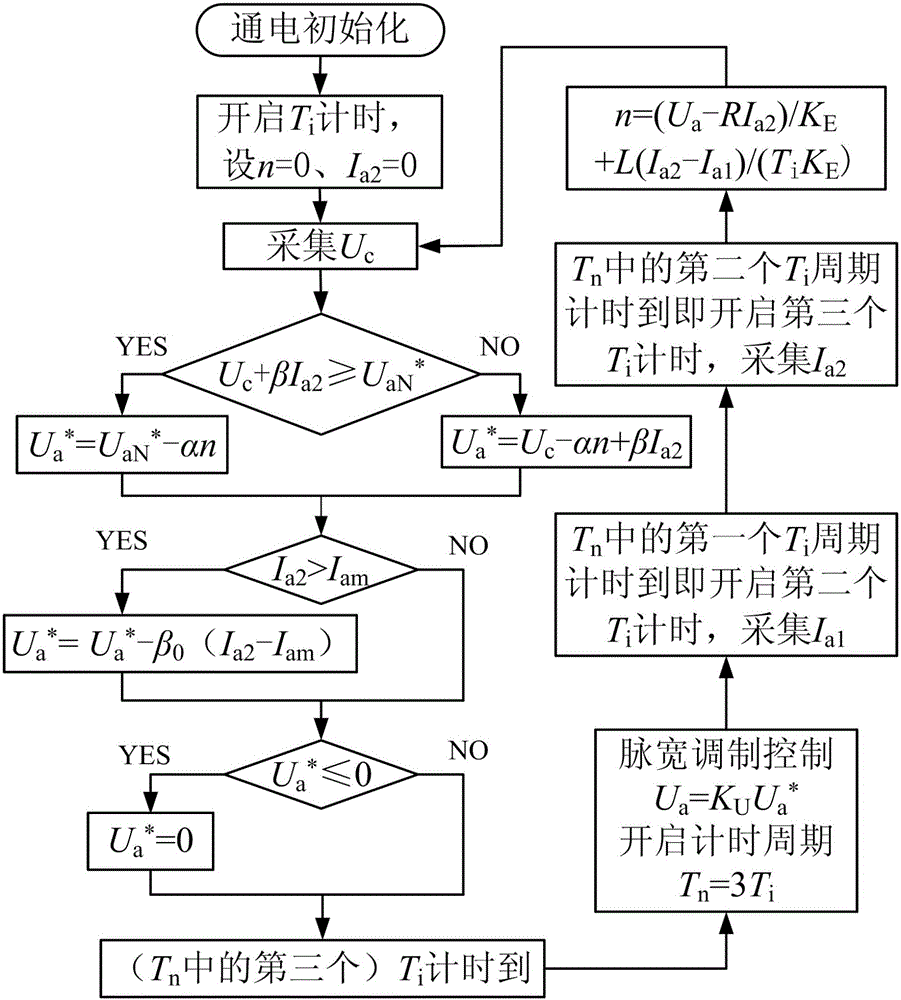

[0018] like figure 1 As shown, the series-excited motor speed control drive system includes an uncontrollable rectification part composed of diodes D1, D2, D3, D4, resistor R1 and capacitor C, an electronic controller, a fully-controlled power electronic switching device V, and a sampling resistor R2 And the pulse width modulation step-down chopper circuit part composed of diode D. The single-phase AC power supply is transformed into a DC power supply through uncontrollable rectification, and then an adjustable DC voltage is output to the series-excited motor through a step-down chopper circuit. In the figure, R2 is the sampling resistance for measuring the motor current. The electronic controller adopts the pulse width modulation method to adjust the on-off duty ratio of the fully-controlled power electronic switching device V in the chopper circuit, and controls the terminal voltage U of the series-excited motor. a = K U U a * .

[0019] The electronic controller is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com