A kind of owt sewage treatment system

A sewage treatment system and water pipe technology, applied in the field of OWT sewage treatment system, can solve problems such as strategic goals that are unfavorable to sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

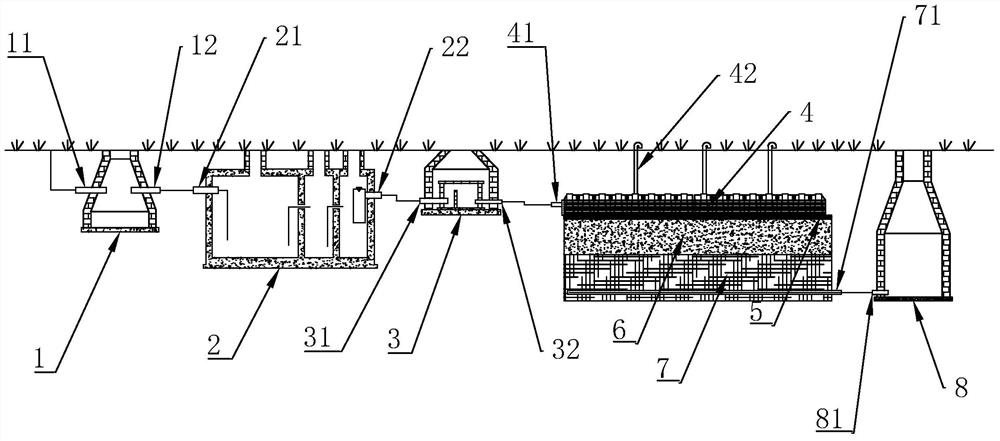

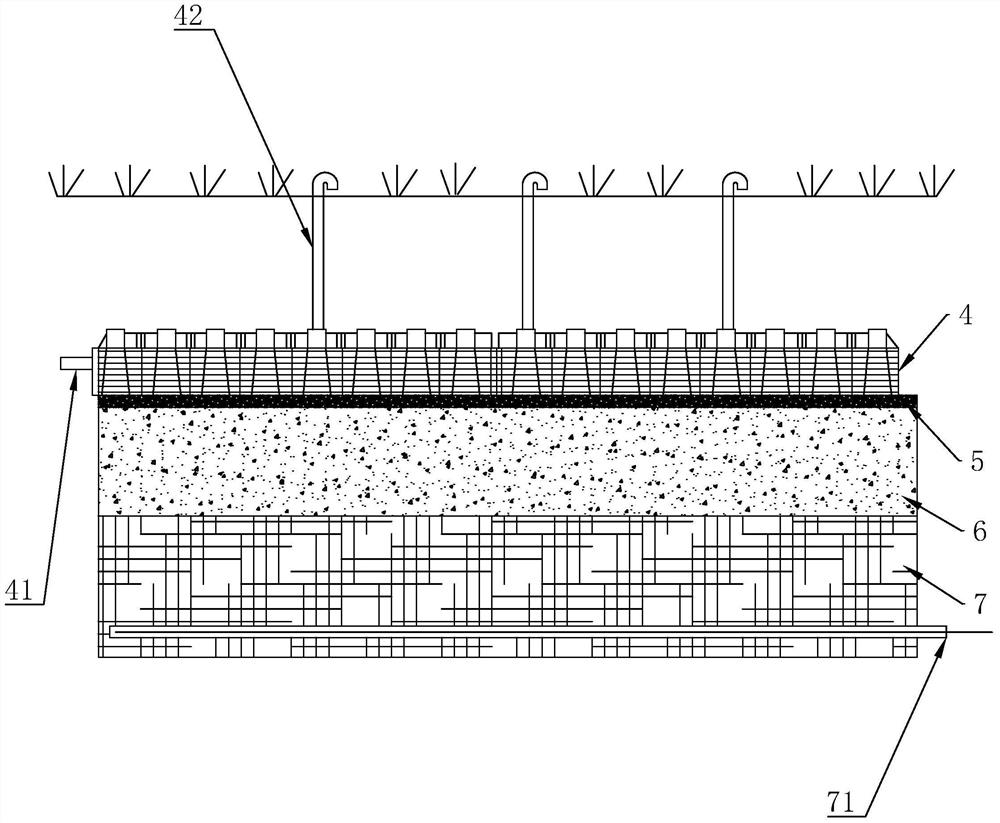

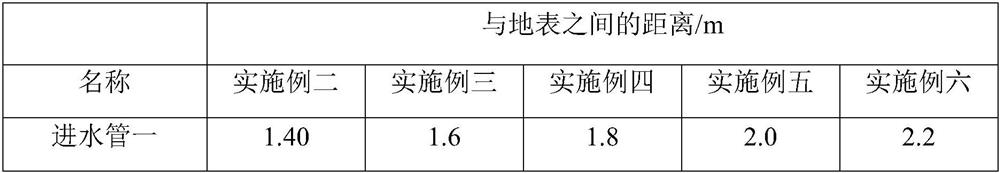

[0046]An OWT sewage treatment system, comprising a buffer well 1 with an inlet pipe 11 and an outlet pipe 12, a separation hydrolysis tank 2 with an inlet pipe 21 and an outlet pipe 22, a water inlet pipe 31 and three outlet pipes 3 32 of the water separation tank 3, the standard permeation chamber 4 with the water inlet pipe 441 and the water storage tank 8 with the water inlet pipe 581, the bottom of the standard permeation chamber 4 is successively provided with the biological pad 5, the seepage area 6 and the water outlet pipe 471 Saturation zone 7, buffer well 1 is sequentially connected to separation hydrolysis tank 2, water separation tank 3 and standard permeation chamber 4, saturation zone 7 below standard permeation chamber 4 is connected to storage tank 8, and the horizontal section of water inlet pipe 11 is 1.20m from the ground surface , the outlet pipe 12 is 0.10m lower than the inlet pipe 11, the inlet pipe 21 is 0.01m lower than the outlet pipe 12, the outlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com