Patents

Literature

103 results about "Nitrogen Handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transportation /Handling Liquid nitrogen should be handled in well-ventilated areas. Handle the liquid slowly to minimize boiling and splashing. Do not transport liquid nitrogen in wide-mouthed glass Dewars or Dewars not protected with safety tape.

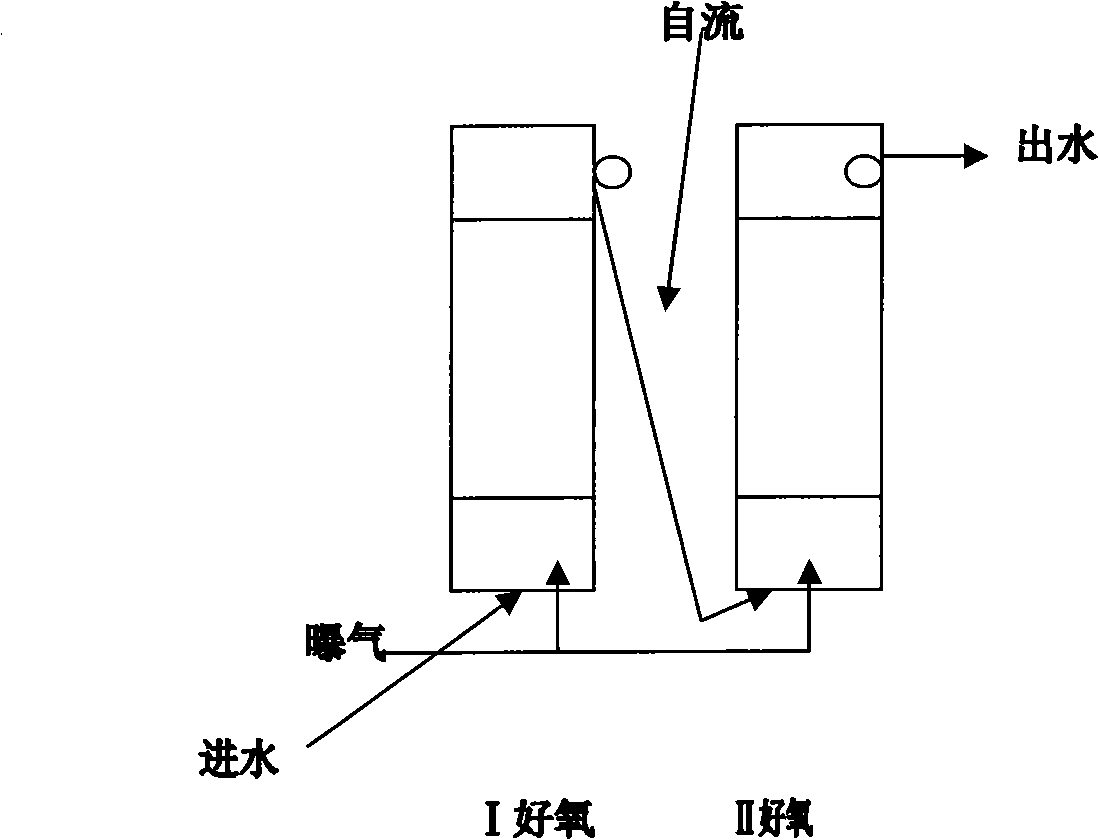

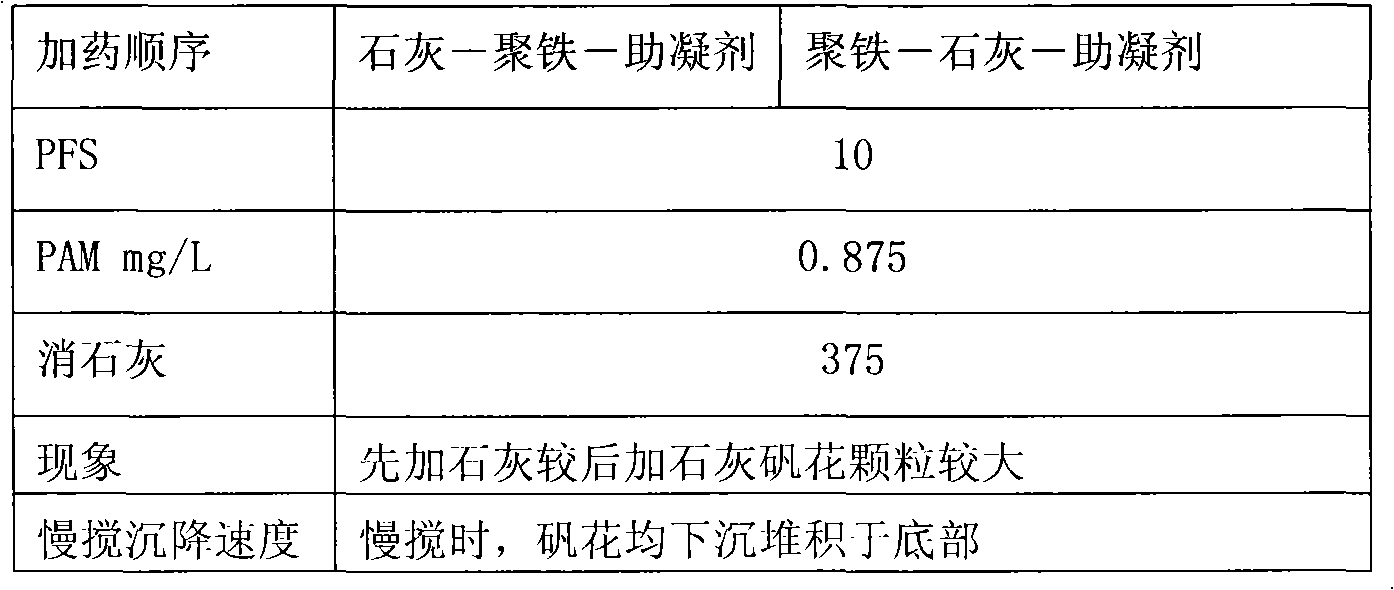

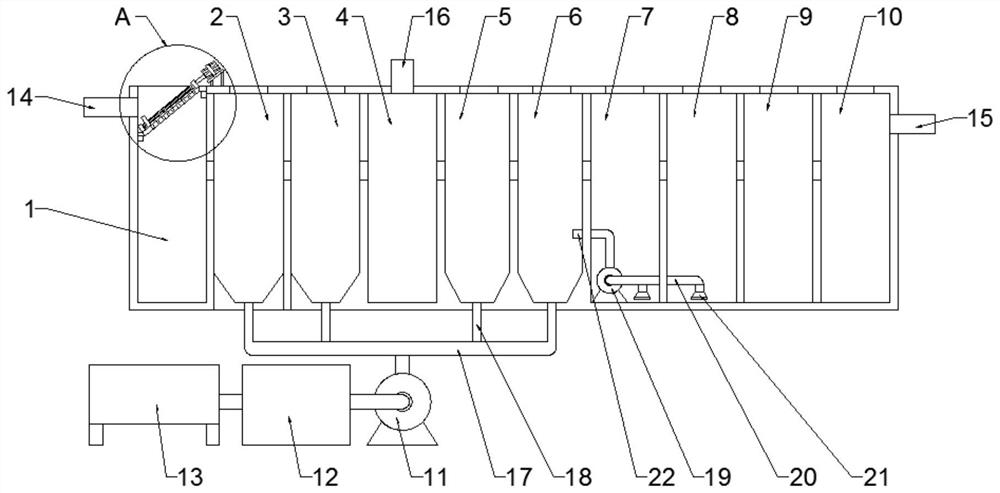

Advanced treatment method for urban water of electric power plant

InactiveCN101318747AScale removal and water softeningMultistage water/sewage treatmentIron sulfateWater use

The invention relates to a method for treating municipal intermediate water, in particular to an advanced treatment method for treating the municipal intermediate water which is used as cooling water for a power plant. The method comprises the following specific steps that: water in a municipal sewage treatment plant is introduced into a pool, respectively added with lime hydrate, polymeric ferric sulfate as a coagulant and polyacrylamide as a coagulant aid and clarified; a clarifying solution is added with an disinfectant for disinfection, added with sulphuric acid for adjusting the PH value of the clarifying solution to between 8 and 8.5 and filtered; and intermediate water after filtration is added with a composite scale corrosion inhibitor, evenly mixed and added to circulating water in the power plant. The advanced treatment method solves the relevant technological difficult problems of advanced treatment, disinfection, scale inhibition, anticorrosion, ammonia nitrogen treatment, etc. of the intermediate water recycled by the power plant and provides technological support for the safe and economic use of the intermediate water in the power plant; and the intermediate water in the power plant is used as circulating water and replenishing water for recycling and has remarkable economic, social and environmental benefits.

Owner:SHANDONG ELECTRIC POWER RES INST

Anti-corrosive insulated wear-resistant treatment method for petroleum pipeline surface

ActiveCN104726873AHigh surface hardnessImprove bindingSolid state diffusion coatingChemical vapor deposition coatingCarbon filmElectrolysis

The invention provides an anti-corrosive insulated wear-resistant treatment method for a petroleum pipeline surface. The method comprises the following steps: 1 carrying out surface gas nitriding treatment; 2 carrying out surface electrolytic polishing treatment in an electrolytic polishing pond; 3 carrying out surface cleaning treatment in an ultrasonic cleaning tank; 4 carrying out surface argon ion bombardment cleaning treatment in chemical vapor deposition equipment; and 5 carrying out vapor deposition on a diamond-like carbon film which is 1-10micron thick in the chemical vapor deposition equipment. Through the technical scheme provided by the invention, the hardness of a dense anti-corrosive insulated protection film formed on the petroleum pipeline surface is 2,000-3,000HV; the electrical resistivity is greater than 2*10<9>ohm.cm; the film deposition process can be carried out below 500 DEG C; the mechanical property of the material of a petroleum pipeline workpiece can be well reserved; meanwhile, the film which is not greater than 10 microns can cover the inner surface and the outer surface of the workpiece; the anti-corrosive, wear-resistant and insulating properties of the part surfaces of screw threads and flanges of the petroleum pipeline are greatly improved; and the process is simple and easy to popularize.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

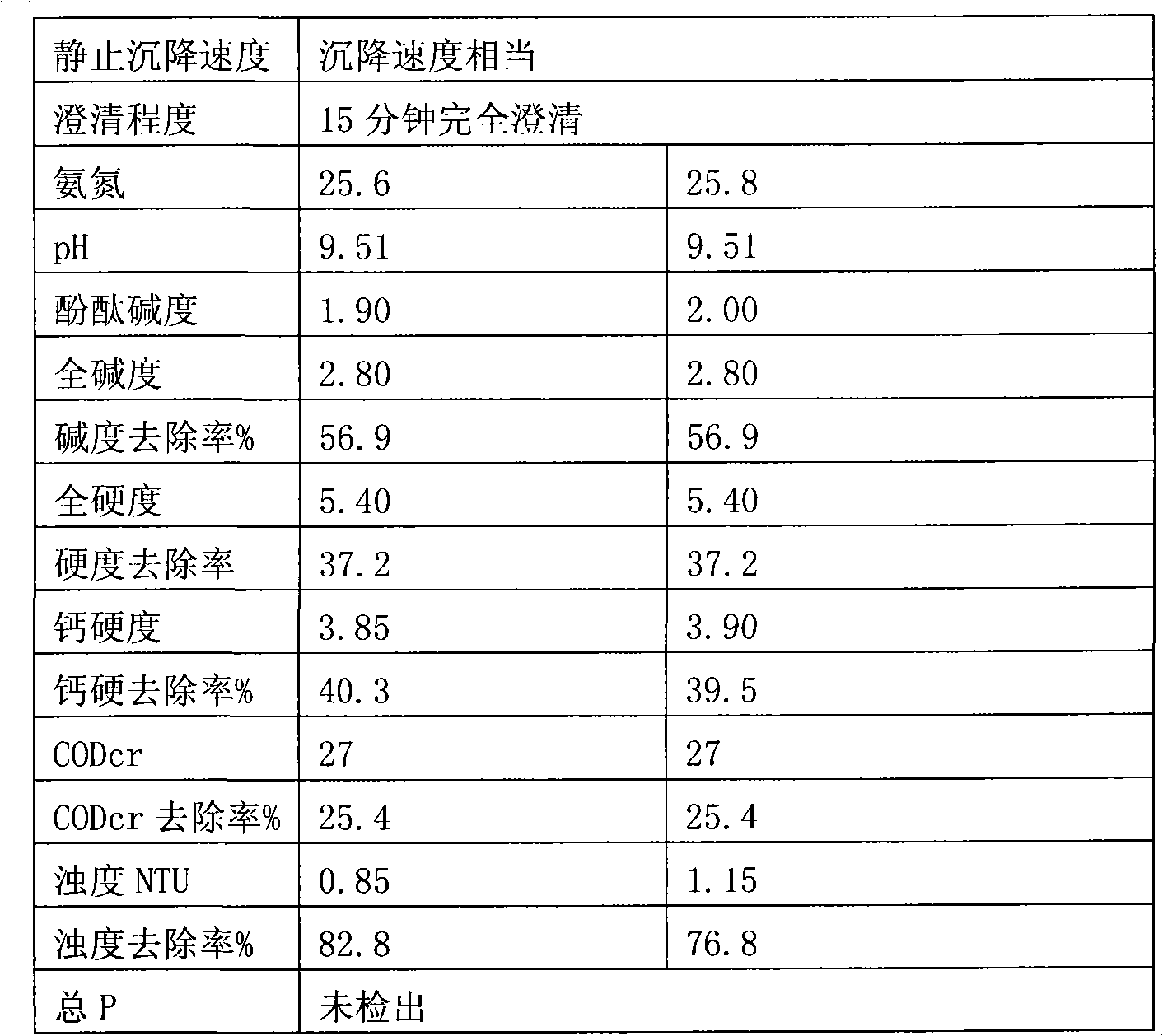

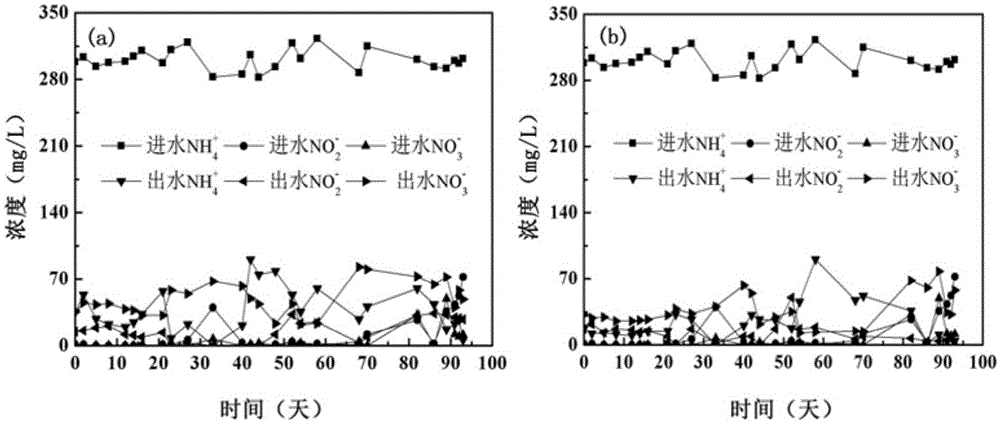

Interactive type three-chamber biological fuel cell device and method for denitriding wastewater by using device

ActiveCN103872368ALess accessibleReduced electricity production capacityTreatment with anaerobic digestion processesBiochemical fuel cellsEnergy conservationEnvironmental chemistry

The invention discloses an interactive type three-chamber biological fuel cell device and a method for denitriding wastewater by using the device, belongs to the sewage biological remediation and in particular relates to a denitrification treatment method applicable to wastewater containing nitrate nitrogen. By adopting the method, nitrate instead of oxygen is taken as an electron acceptor of a negative electrode on the basis of a conventional two-chamber biological fuel cell, and a three-chamber biological fuel cell consisting of a middle positive electrode chamber and two side negative electrode chambers is built; meanwhile, the conditions of switching on and off a middle positive electrode and two side negative electrodes are controlled interactively through a control switch, so that an electrode denitrification process and a non-electrode denitrification process of the negative electrode are reasonably matched to process. The method is capable of sustainably generating current and effectively removing nitrate nitrogen and saving an organic carbon source needed for denitrification; the method is a novel sewage treatment method based on energy conservation and consumption reduction and is good in application prospect.

Owner:NANJING HEHAI TECH

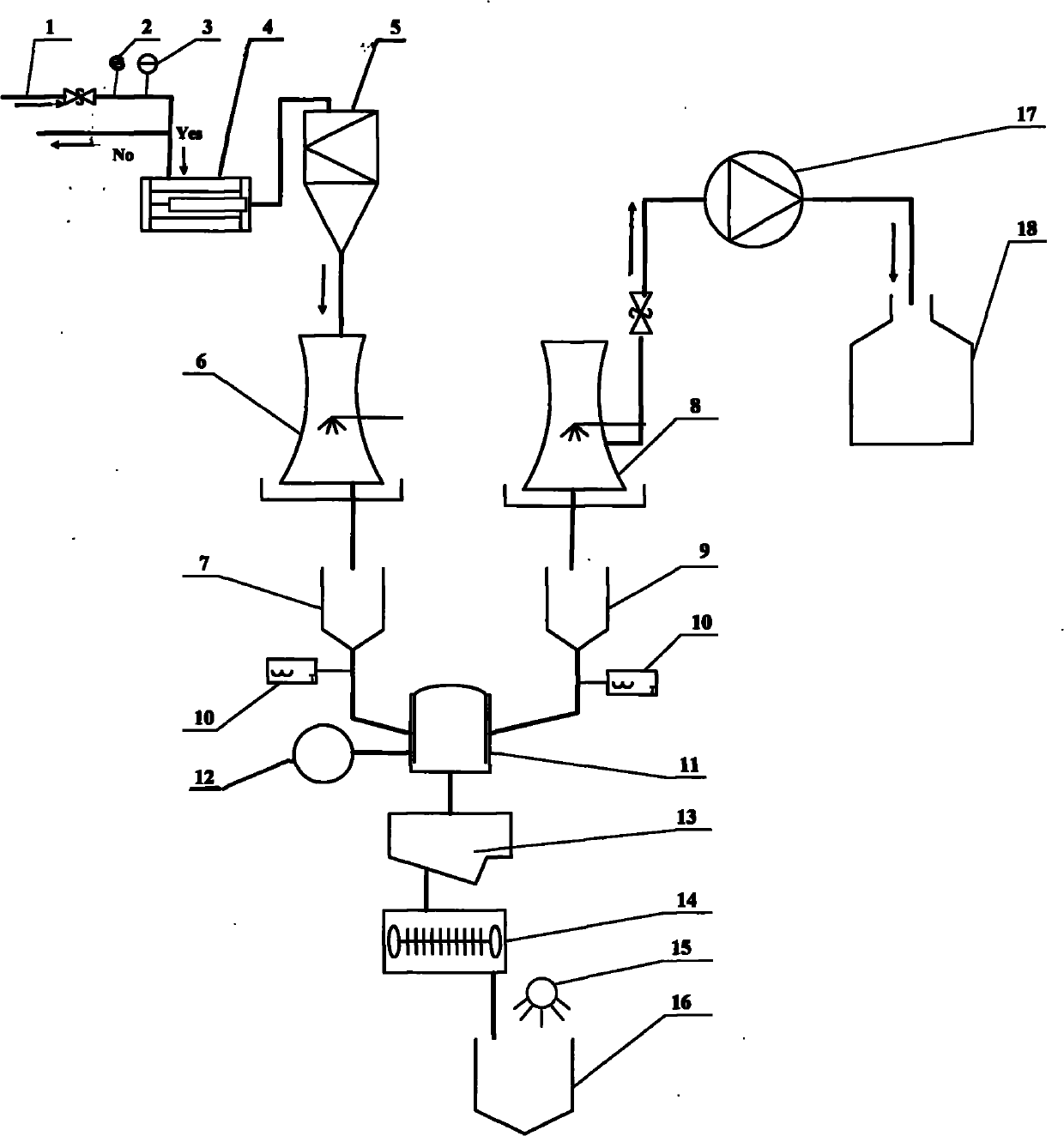

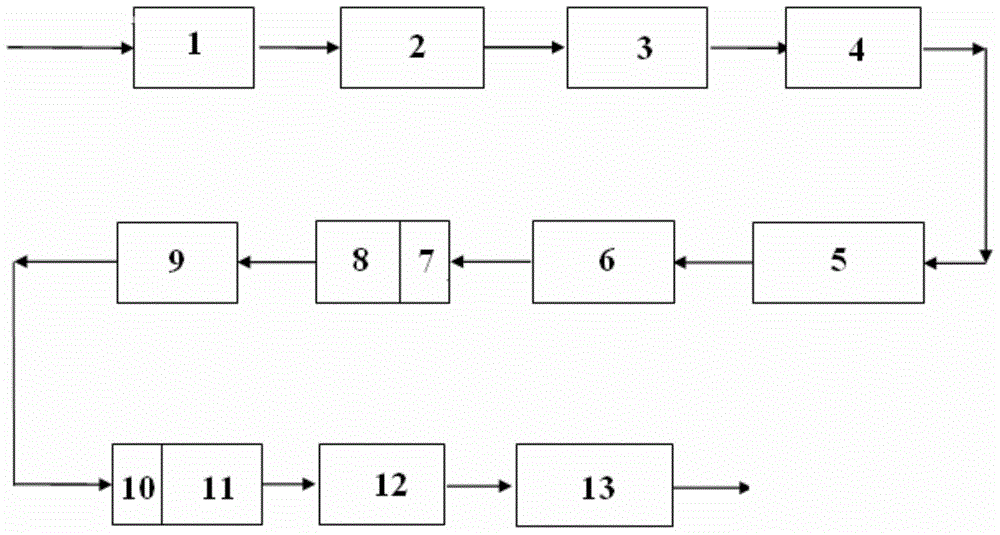

Method and device for purifying calcium carbide furnace tail gas by using negative pressure dry process

InactiveCN101816873AWill not affect normal operationSolve the problem of dust collection surface cleaningCombination devicesDispersed particle filtrationTreatment effectFiltration

The invention discloses a method and a device for removing dust from calcium carbide furnace tail gas by using a negative pressure dry process, which belong to the field of the dust extraction of the calcium carbide furnace tail gas. The method of the invention comprises the following steps of: cooling the calcium carbide furnace tail gas by two stages; introducing the cooled gas into a cloth bag filter and filtering the cooled gas to ensure that the dust content is less than 50 mg / Nm<3> after the filtration; and delivering clean CO2 gas into a waste heat boiler by using a main draft fan and a booster fan, wherein a dust-removal system adopts self-control decompression and is explosion-proof. The device for removing the dust from the calcium carbide furnace tail gas by using the dry process of the invention comprises the following components: an air inlet tube, a decompression and anti-explosion device, an oxygen content alarm, a water cooling sleeve cooling system, a cyclone dust collector, a primary cooler, a settling tank, a secondary cooler, a settling tank, a thermometer, a low-pressure nitrogen protection system, a waste nitrogen processor, a bag-type dust filter, a closed and embedded scraper conveyor and the like. The method and the device have the advantages of simple process, convenient operation, simple equipment structure, safety, reliability, obvious treatment effect and low operation cost, and solve the problems of dust-removal system stoppage caused by the blockage of the traditional pipelines, cooling systems and filter bags.

Owner:YUNNAN YUNWEI CO LTD +1

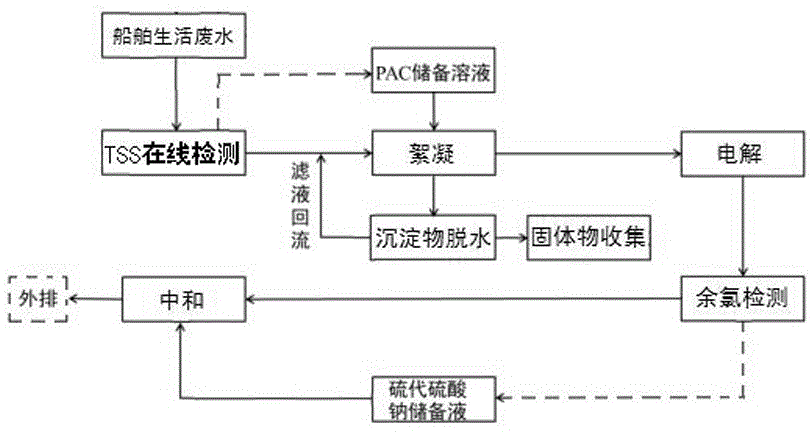

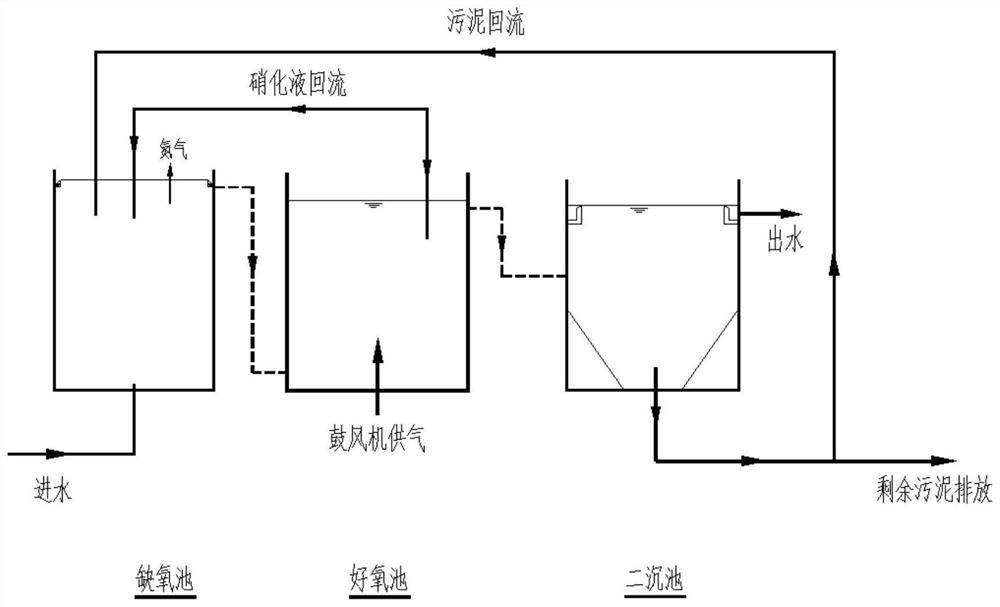

Denitrificaiton treatment method and system of ship domestic sewage

PendingCN106746053AReduce generationSmall footprintWater treatment parameter controlSpecific water treatment objectivesElectrolysisDisinfection by-product

The invention discloses a denitrification treatment method and system of ship domestic sewage. The denitrification treatment method and system of the ship domestic sewage is invented by use of a method of combining an electrolytic oxidization electrode and an electrolytic chlorine-producing electrode. The system is simple in equipment flow process, and only needs to serially connect three systems; the floor area is small and is a half of the traditional treatment process area; the automation degree is high; the dosage of a flocculating agent is fed back by use of TSS online monitoring value as the index; each unit realizes intelligent control, is strong in oxidation, strong in effect of killing pathogen microorganism, and stable in denitrification effect which is guaranteed at 90% and more; the energy consumption for ton of water is a half of the primary electrolysis method, the electrode life is greatly prolonged, and the amount of the disinfection byproduct produced by ship domestic treatment is lower than the traditional electrolysis method. Therefore, the method and system disclosed by the invention have an extremely good application prospect in the denitrification treatment field of the ship domestic sewage.

Owner:SUNRUI MARINE ENVIRONMENT ENG

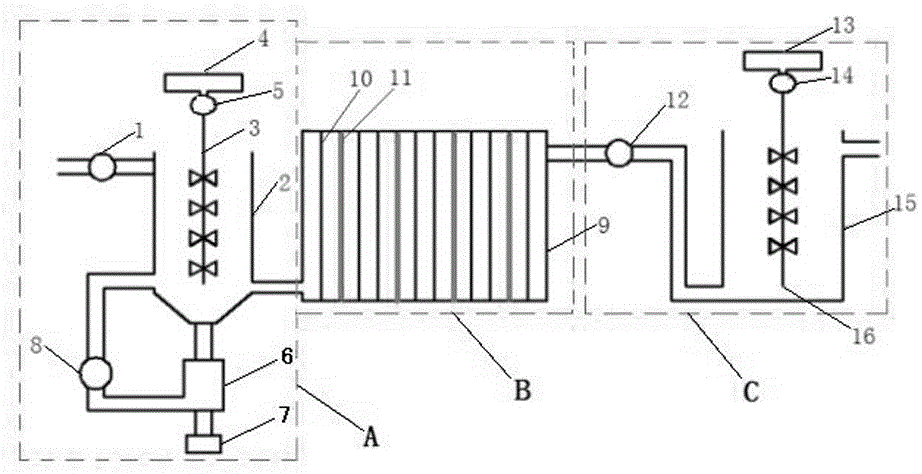

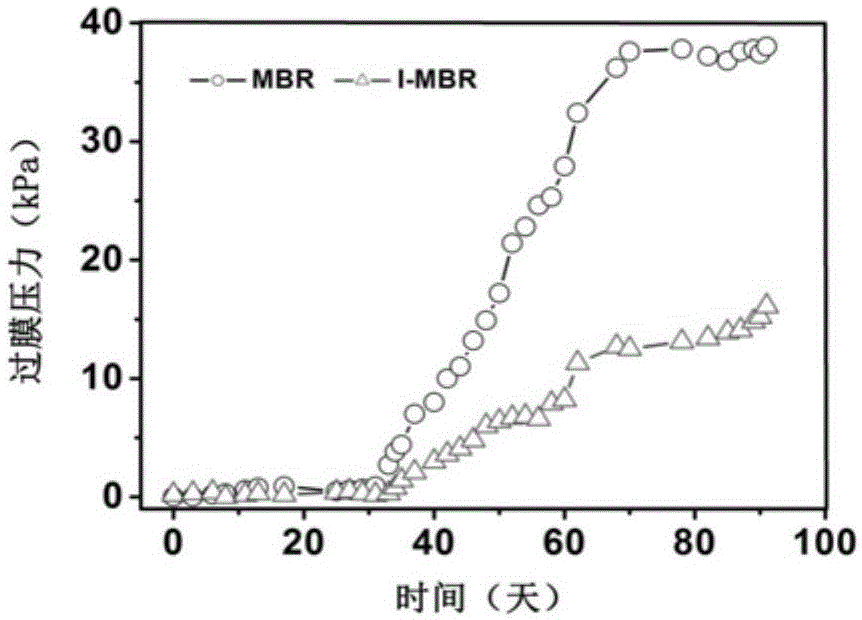

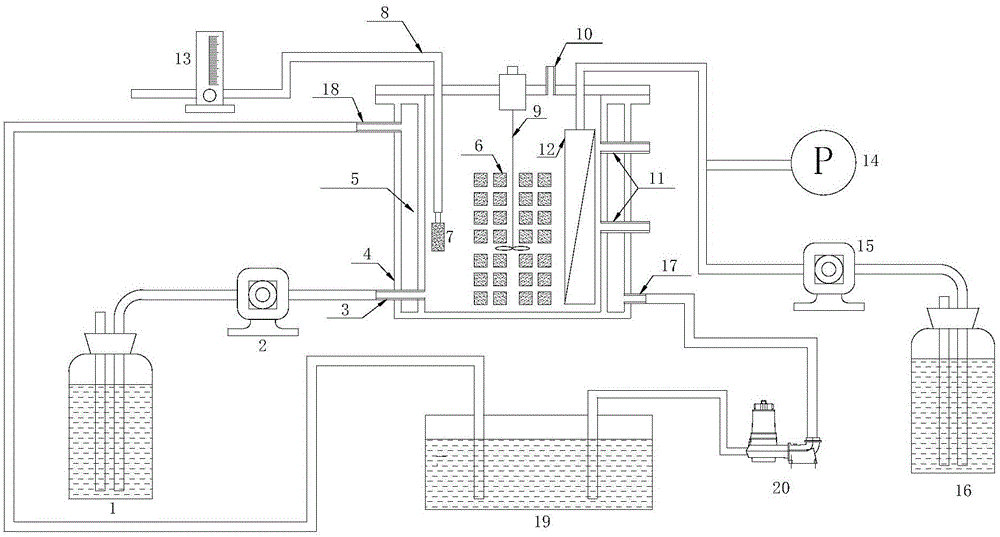

Apparatus for treating coking wastewater through immobilized MBR autotroph nitrogen removal, and method thereof

ActiveCN105060482AImprove processing efficiencyGood water qualityTreatment with aerobic and anaerobic processesChemistryCarbon source

The invention relates to an apparatus for treating coking wastewater through immobilized MBR autotroph nitrogen removal, and a method thereof. The apparatus is composed of a water feeding system, an aeration system, a membrane bioreactor, a water discharging system and a water-bath circulating system. An autotroph nitrogen removal technology is carried out by adopting the membrane bioreactor, a microbe immobilization technology is introduced, and a carrier used by microbe immobilization is arranged in the membrane bioreactor to improve the running performances of the reactor, so microenvironment suitable for growth of aerobic ammonia oxidizing bacteria and anaerobic ammonium oxidation bacteria is provided, and the membrane pollution is alleviated. The method has the advantages of no external carbon source, good wastewater treatment effect and low cost.

Owner:PEKING UNIV

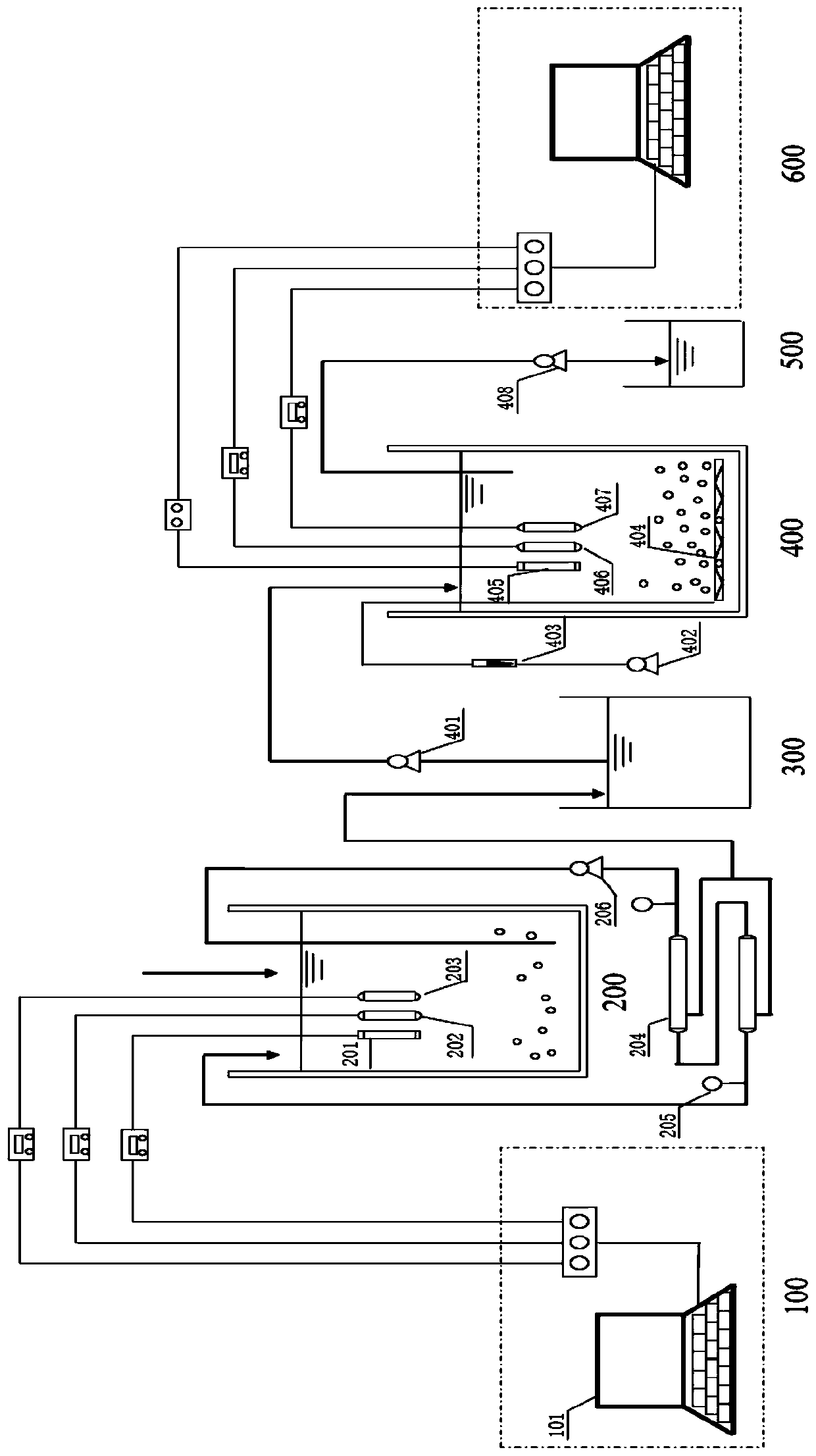

Wastewater treatment method and wastewater treatment system utilizing combination of anaerobic membrane bioreaction and shortcut nitrification and denitrification

PendingCN110902966ASmall footprintEasy to operate and manageWater contaminantsTreatment involving filtrationNitrogen removalControl system

The invention discloses a wastewater treatment method and a wastewater treatment system utilizing a combination of an anaerobic membrane bioreaction and shortcut nitrification and denitrification. Thewastewater treatment method comprises the following steps: carrying out an anaerobic reaction on to-be-treated wastewater to obtain first wastewater; and filtering the first wastewater, and carryingout a biological denitrification reaction to allow the first wastewater to reach the standard, thereby completing wastewater treatment. After the wastewater is subjected to anaerobic-shortcut denitrification treatment, effluent quality is stable and reaches the standard; wastewater treatment equipment is centralized, so an occupied area is reduced, and operation and management are convenient; a shortcut nitrification and denitrification reactor control system detects and controls the changes of water quality parameters in the shortcut nitrification-denitrification nitrogen removal process in real time, so automatic control over shortcut nitrification-denitrification nitrogen removal is easy to achieve.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

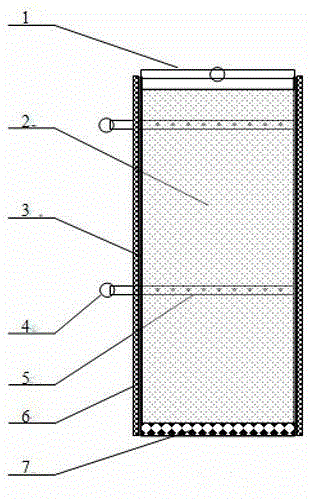

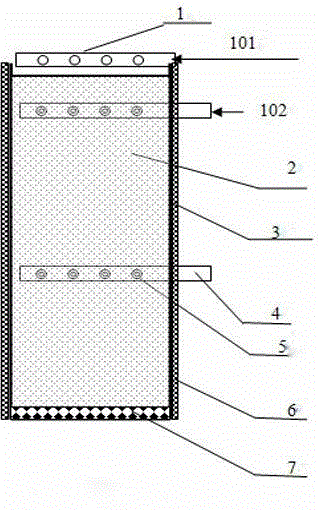

Mineralized refuse packed bed and wastewater denitrification method

ActiveCN104445613ASimple processReduce energy consumptionWater contaminantsTreatment with aerobic and anaerobic processesThermal insulationChemistry

In order to realize low-cost denitrification of nitrogen-containing wastewater and reasonably utilize the mineralized refuse, the invention provides a mineralized refuse packed bed and a method of removing the nitrogen in the nitrogen-containing wastewater based on the mineralized refuse packed bed. The blockage problem of the packed bed is solved by lowering BOD5 in inlet water, cooperation of partial nitrification and the anaerobic ammonia oxidation is realized by an additionally-arranged vent pipe, and the treatment efficiency is guaranteed by use of a thermal insulation layer, so that the mineralized refuse packed bed is a mineralized refuse packed bed which has low energy consumption, low cost and low carbon footprint. Besides, the wastewater denitrification method is a nitrogen-containing wastewater denitrification treatment method.

Owner:湖南亿纳环保科技有限公司

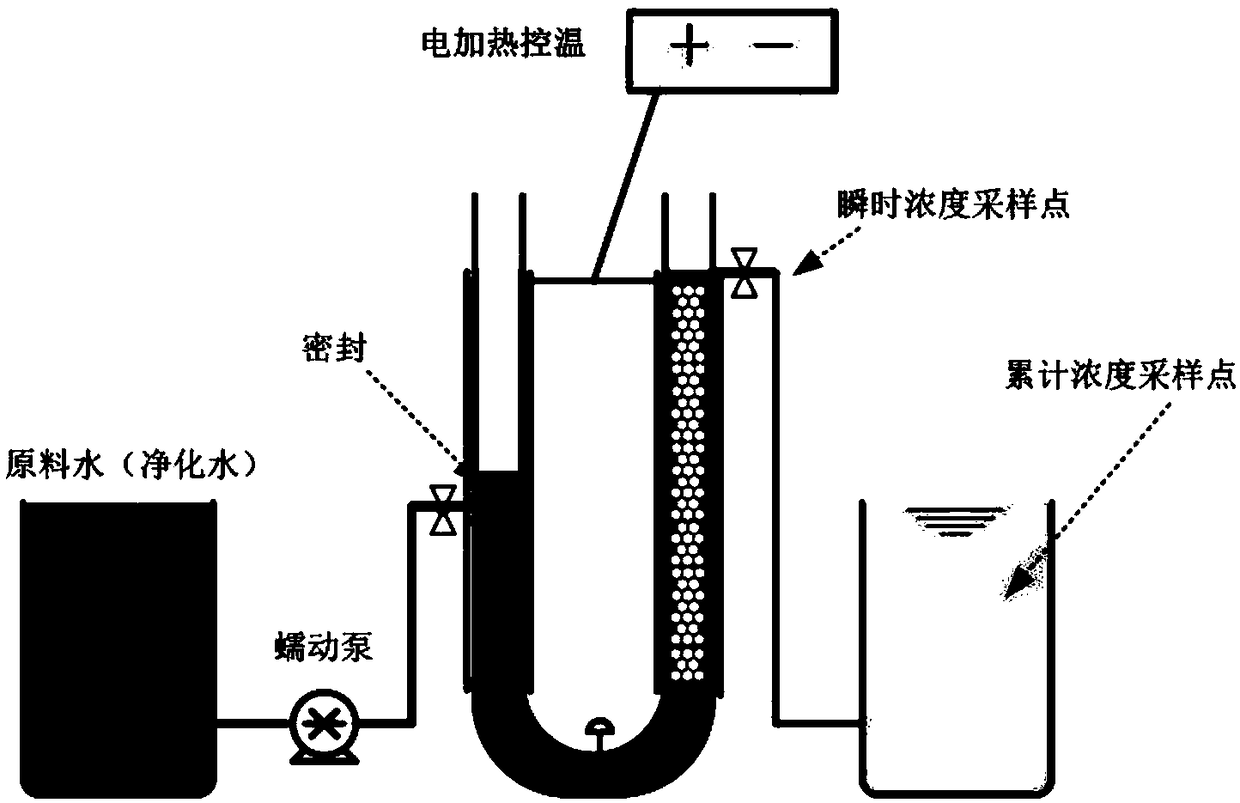

Method for adsorbing and removing ammonia and nitrogen in wastewater by zeolite and adsorption denitrification device

InactiveCN108502965AReduce consumptionImprove adsorption efficiencySpecific water treatment objectivesNature of treatment waterChemistryWater cycling

The invention provides a method for adsorbing and removing ammonia and nitrogen in wastewater by zeolite and an adsorption denitrification device. The method for adsorbing and removing ammonia and nitrogen in wastewater comprises the following steps of allowing wastewater containing ammonia and nitrogen to flow through an adsorption device filled with zeolite to undergo adsorption denitrificationtreatment, wherein the temperature for adsorption denitrification treatment is 30-75 DEG C, and the wastewater containing ammonia and nitrogen stays in the adsorption device for 15-30 minutes; and discharging the purified wastewater containing ammonia and nitrogen to an integrated sewage treatment plant and discharging the water with standard level, wherein the saturated zeolite material is regenerated through a method of alkali liquor reverse cycle plus blasting plus steam stripping, and the renewed alkali liquor is recycled as alkali water of a high-ammonia and nitrogen sewage steam stripping treatment device.

Owner:PETROCHINA CO LTD +1

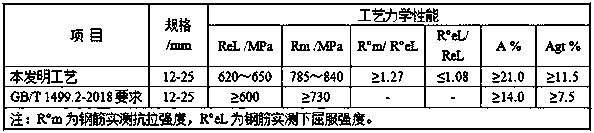

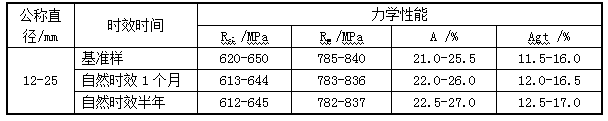

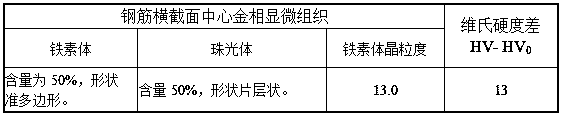

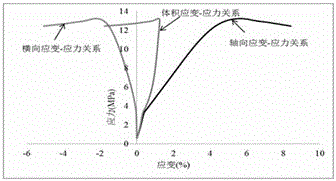

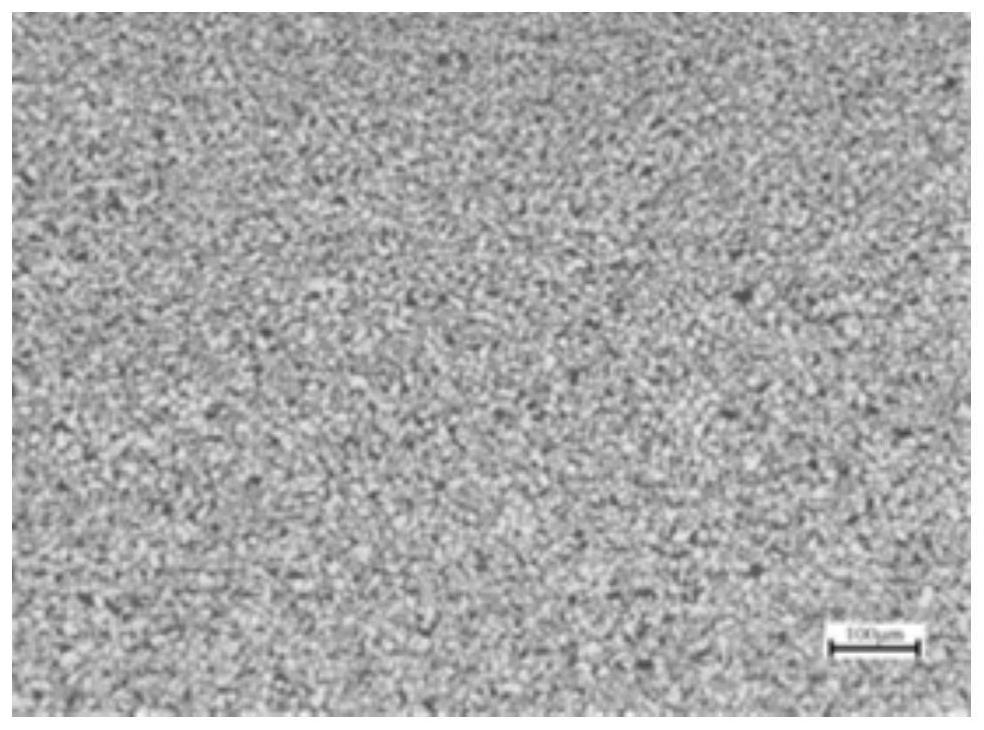

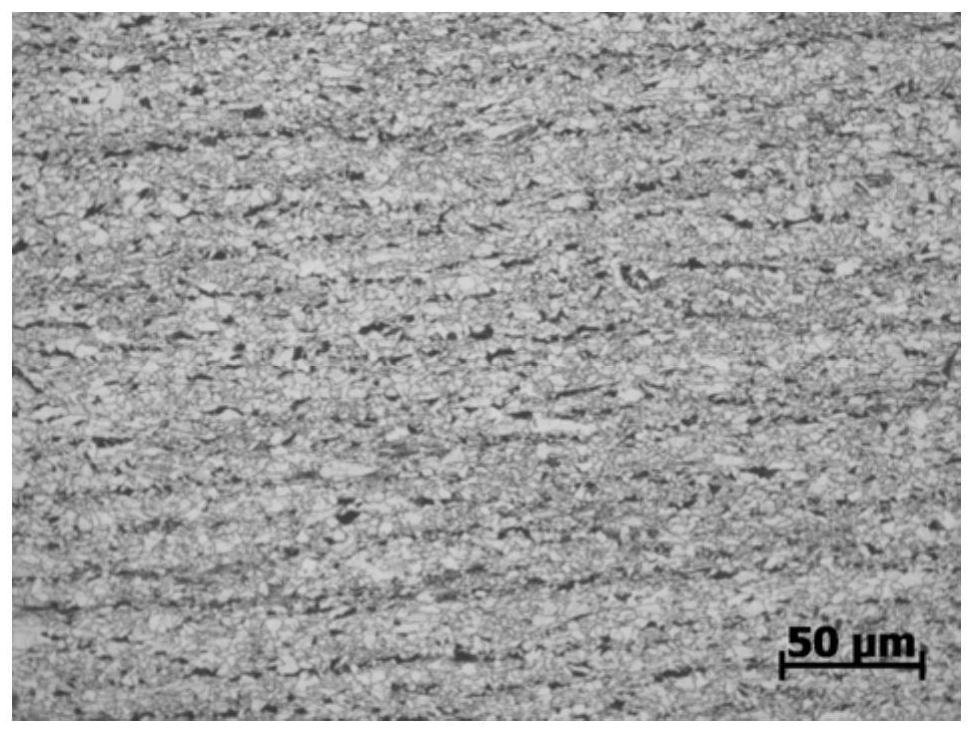

High nitrogen-vanadium microalloying large-scale anti-seismic reinforcing steel bar preparation method

ActiveCN111020393AImprove precipitation strengthening effectHigh tensile strengthFurnace typesManufacturing convertersSteelmakingRebar

The invention discloses a high nitrogen-vanadium microalloying large-scale anti-seismic reinforcing steel bar preparation method. In the steelmaking converter steel tapping process and the ladle furnace (LF) refining process, a certain amount of vanadium pig iron is added to replace an expensive vanadium alloy, so that the molten steel V content is increased; and in the steelmaking deoxidation alloying process, a high nitrogen-vanadium alloy and appropriate amount of silicon-nitrogen alloys are added, and molten steel is subjected to LF refining and nitrogen-blowing treatment, so that the nitrogen content in the molten steel is increased, a V / N matching ratio in steel is remarkably reduced, and a steel precipitation strength effect is remarkably improved. According to the high nitrogen-vanadium microalloying large-scale anti-seismic reinforcing steel bar preparation method provided by the invention, through the integrated innovation of chemical composition design, converter smelting, deoxidation alloying, LF refining, continuous casting, a rolled steel heating schedule, rolling temperature and a controlled cooling technology, a produced reinforcing steel bar has the advantages of excellent and stable process mechanical property, fine and uniform microscopic structure, good ductility and toughness, low strain timeliness, excellent anti-seismic property and the like, the production cost is reduced, the anti-seismic property is improved, and the market competitiveness of products is improved.

Owner:WUKUN STEEL

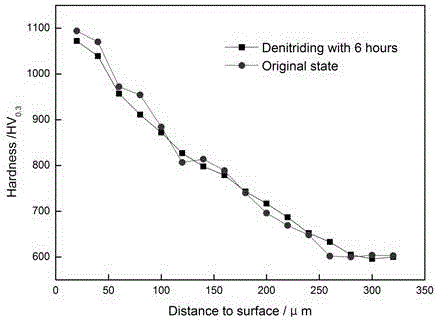

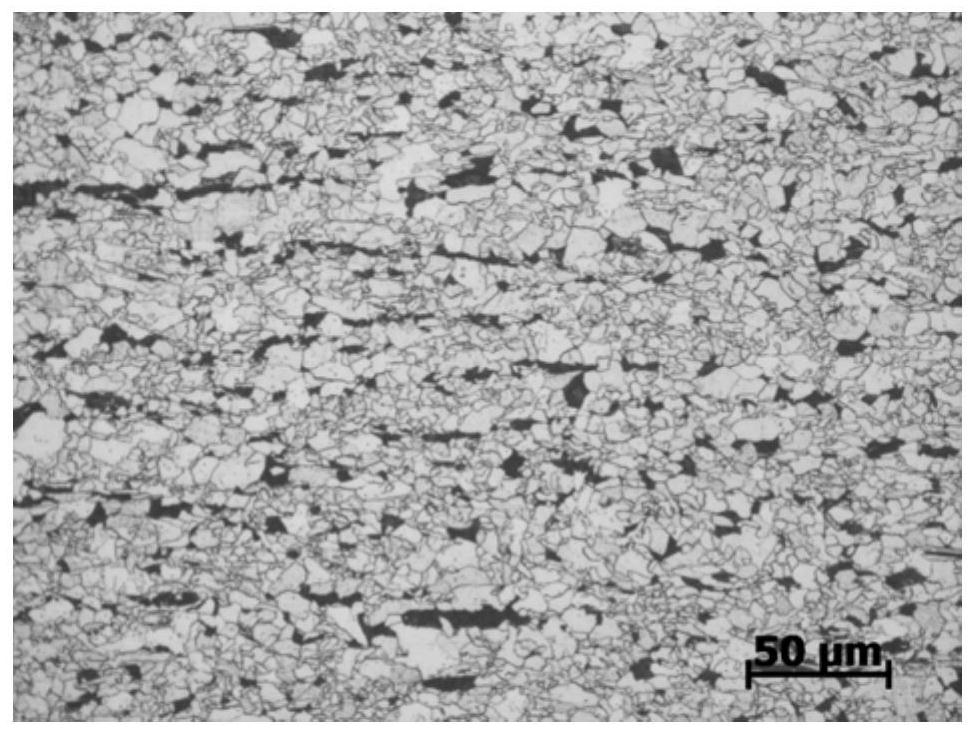

Ion nitrocarburizing compound layer phase adjustment and control method for SDC 99 steel

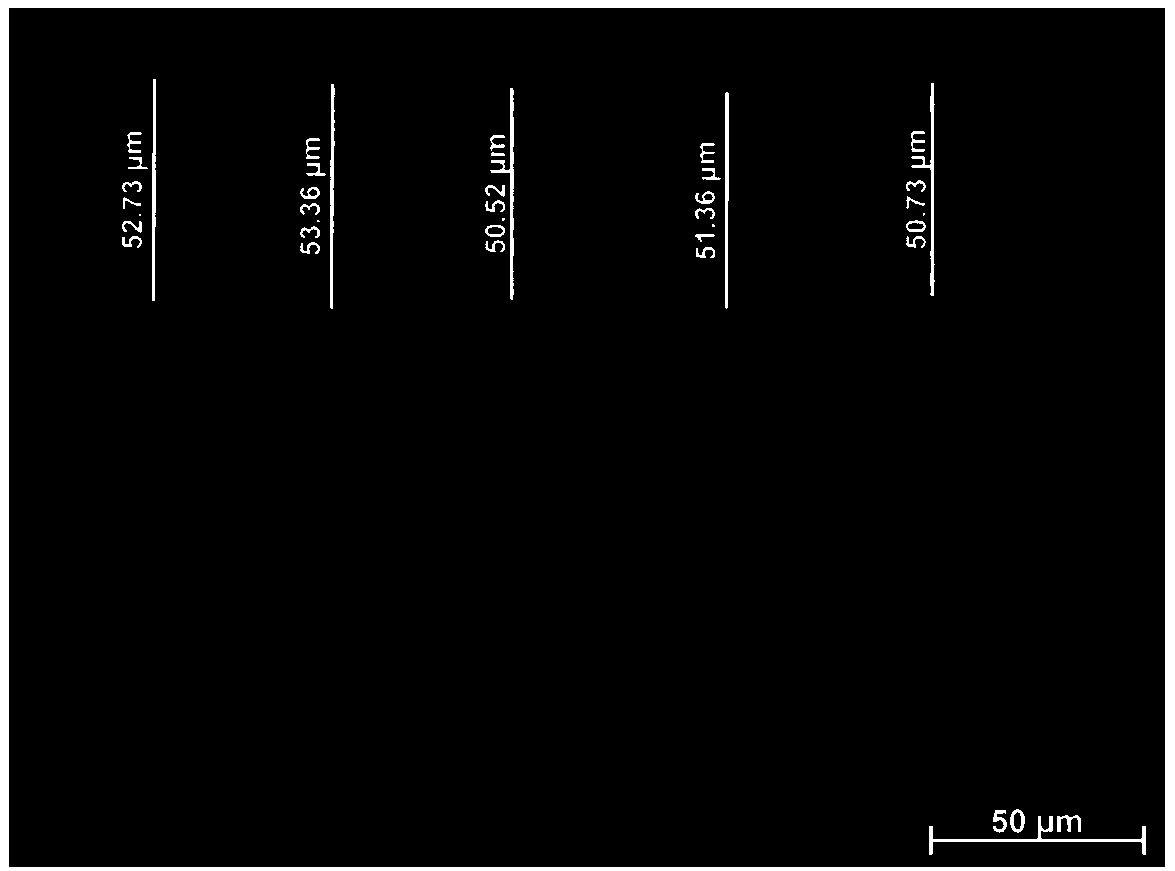

InactiveCN105039900AReduce brittlenessImprove surface wear resistanceSolid state diffusion coatingNitrogen removalPhysical chemistry

The invention discloses an ion nitrocarburizing compound layer phase adjustment and control method for SDC 99 steel. The nitrocarburizing temperature ranges from 520 DEG C to 540 DEG C, the flow of NH3 ranges from 550 mL / min to 620 mL / min, the equation that NH3:CO2=16:1 is satisfied, and the furnace pressure ranges from 450 Pa to 500 Pa. Argon bombardment is performed on the surface layer of a compound of the SDC 99 steel with nitrocarburizing finished for nitrogen removal, the nitrogen removal temperature ranges from 490 DEG C to 510 DEG C, and the argon bombardment time ranges from 4 hours to 7 hours. By the adoption of the method, the brittleness of a nitrocarburizing layer is further reduced, the abrasion resistance of a material surface is improved, compound layer phase adjustment and control are performed after ion nitrocarburizing is finished, and a compound layer phase mainly comprises Fe4N after nitrogen removal treatment; under the condition of a phase adjustment and control process, the thickness of a white bright layer is reduced by 4 micrometers to 5 micrometers compared with that of the white bright layer before nitrogen removal, and the thickness of the total nitrocarburizing layer is increased by 40 micrometers; and the hardness and the gradient of a section are more smooth after nitrogen removal treatment, the brittleness of a compound layer is remarkably reduced, abrasion resistance is remarkably improved, and the service life of the SDC 99 steel is effectively prolonged.

Owner:SHANGHAI UNIV

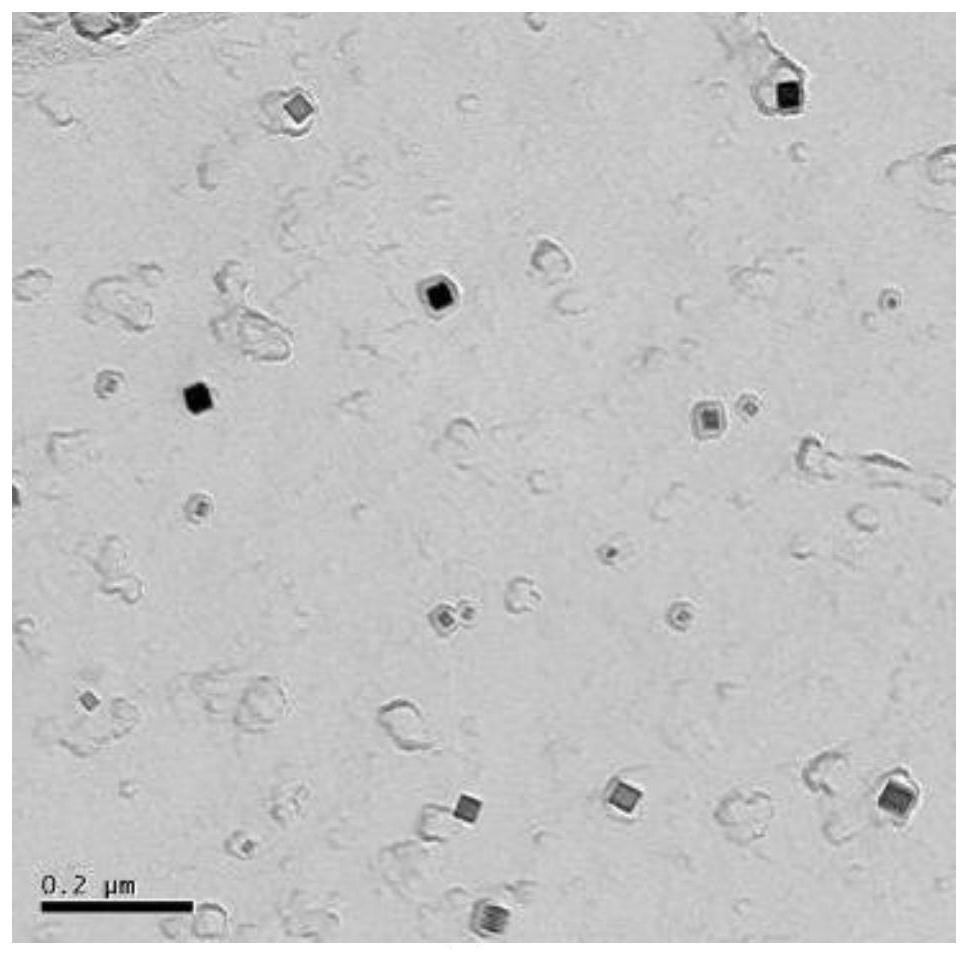

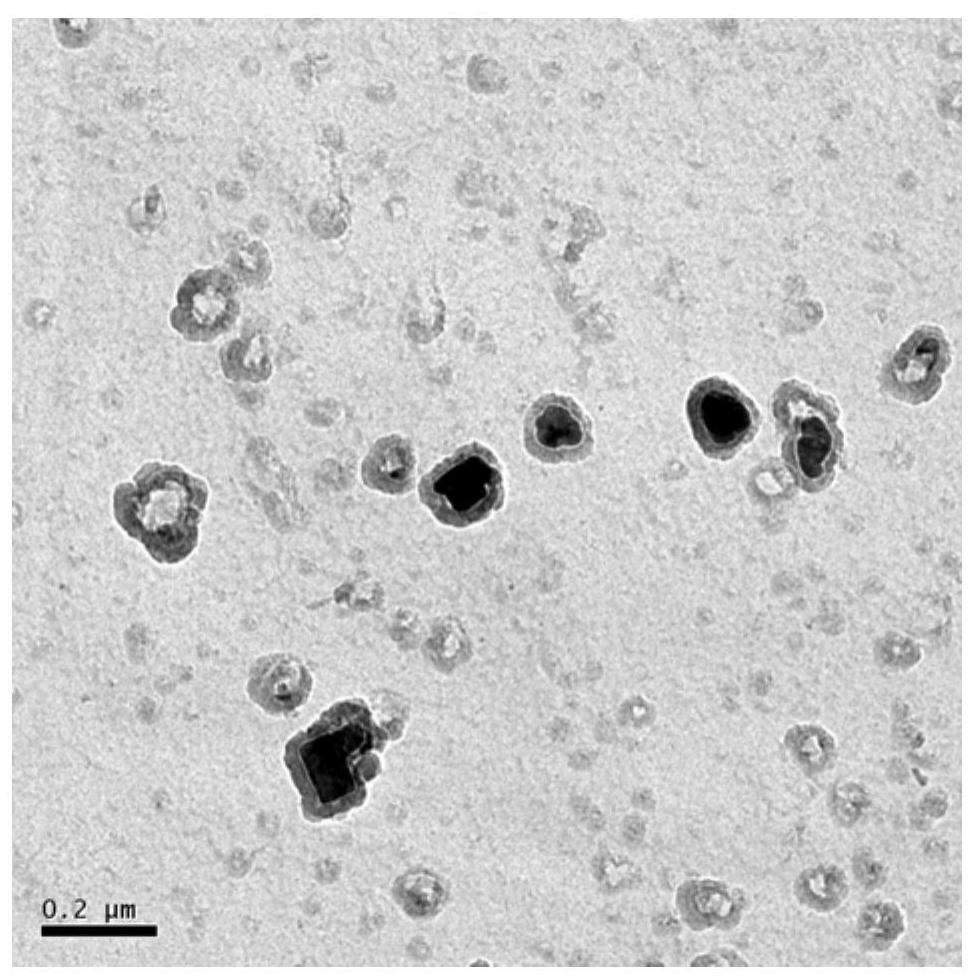

Nitriding chromizing layer, preparing method of nitriding chromizing layer

ActiveCN110714182AHigh hardnessReduce wearSolid state diffusion coatingNitrogen sourceNitrogen Handling

The invention discloses a nitriding chromizing layer, a preparing method of the nitriding chromizing layer and application. The preparing method includes the steps that a glow ion nitriding technologyis adopted, highly-pure NH3 is adopted as a nitrogen source, and a nitriding layer is at least formed on the surface layer of a base material; and a vacuum chromizing technology is adopted, under theprotective atmosphere, a chromizing agent is used, diffusion chromizing is at least conducted on the surface layer of the base material obtained after nitriding treatment, and the nitriding chromizing layer is obtained. By means of the nitriding chromizing layer, the preparing method of the nitriding chromizing layer and the application, the problems that the traditional nitriding technology is high in temperature, the traditional chromizing technology is low in chromizing speed, Cr2N phase formation is difficult, and oxidization exists are solved, and high-performance nitriding chromizing surface treatment is achieved; in addition, the obtained nitriding chromizing layer has the beneficial effects that hardness is high, wear resistance is high, and the good service performance is achieved in a liquid sodium environment; and a good protection effect is achieved on parts operated under complex work conditions, the effect of preventing fasteners from being seized and the effect of selfwelding can be achieved, and therefore the comprehensive performance of parts is effectively improved, and the service life of the parts are effectively improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

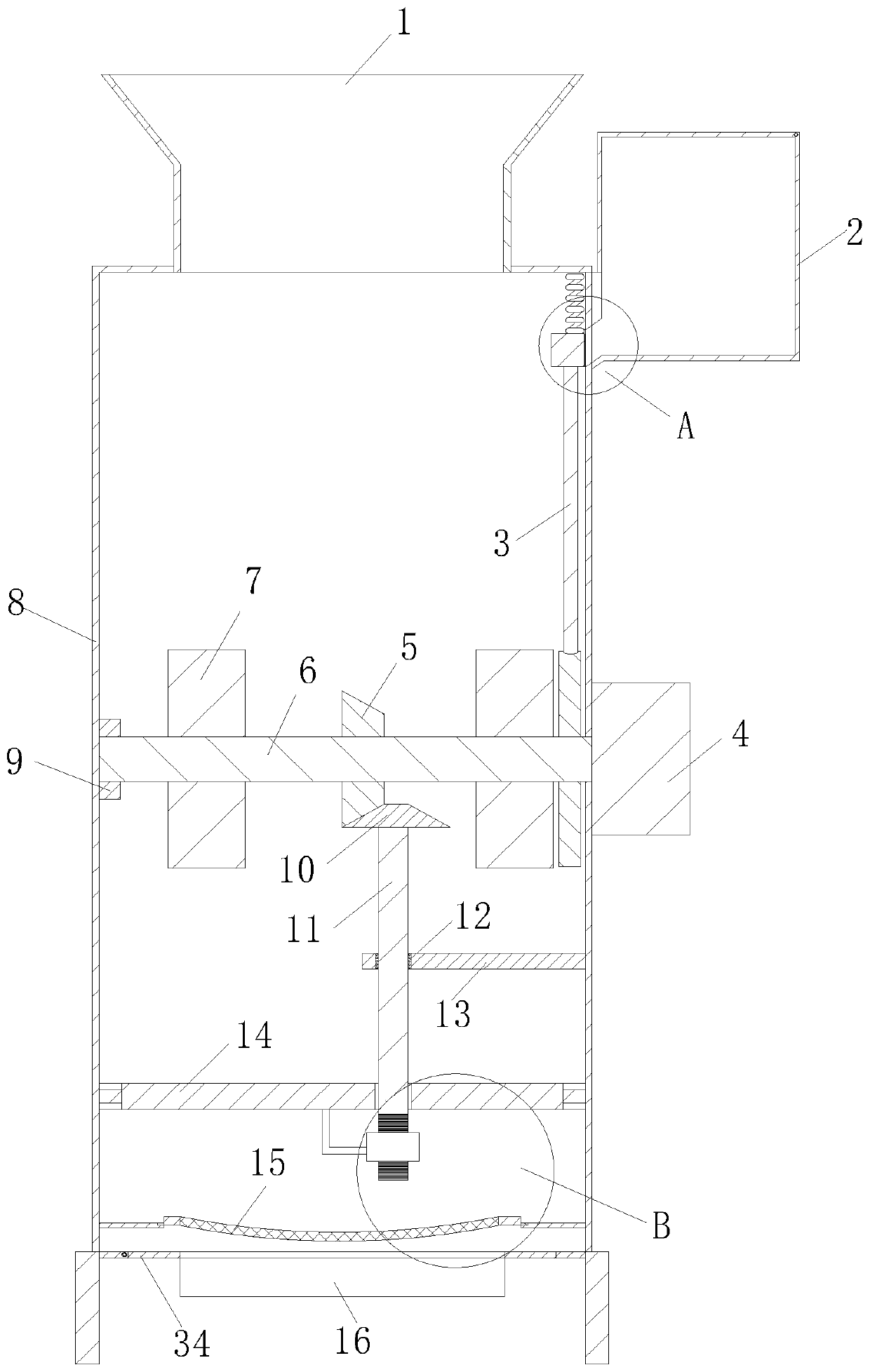

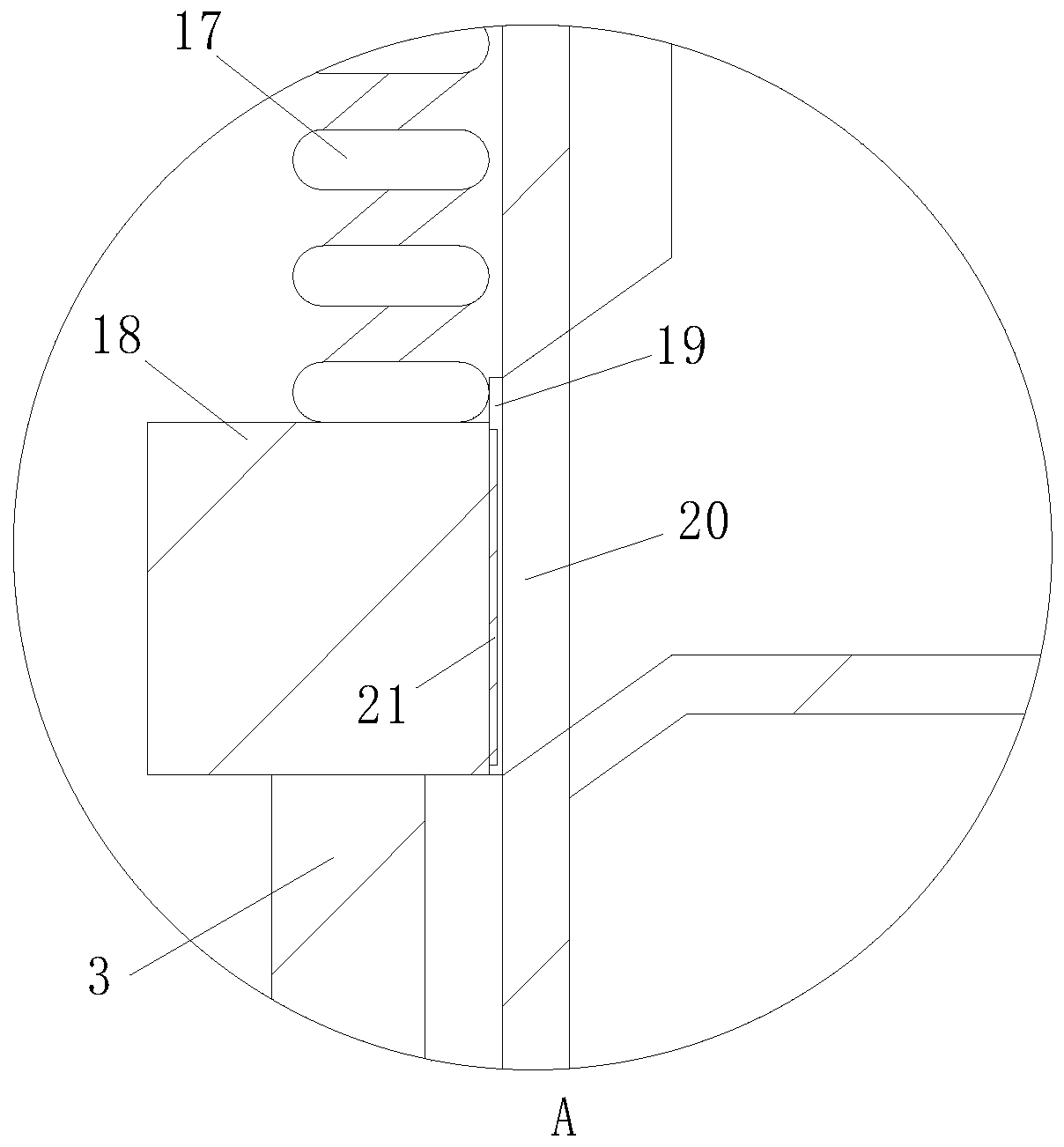

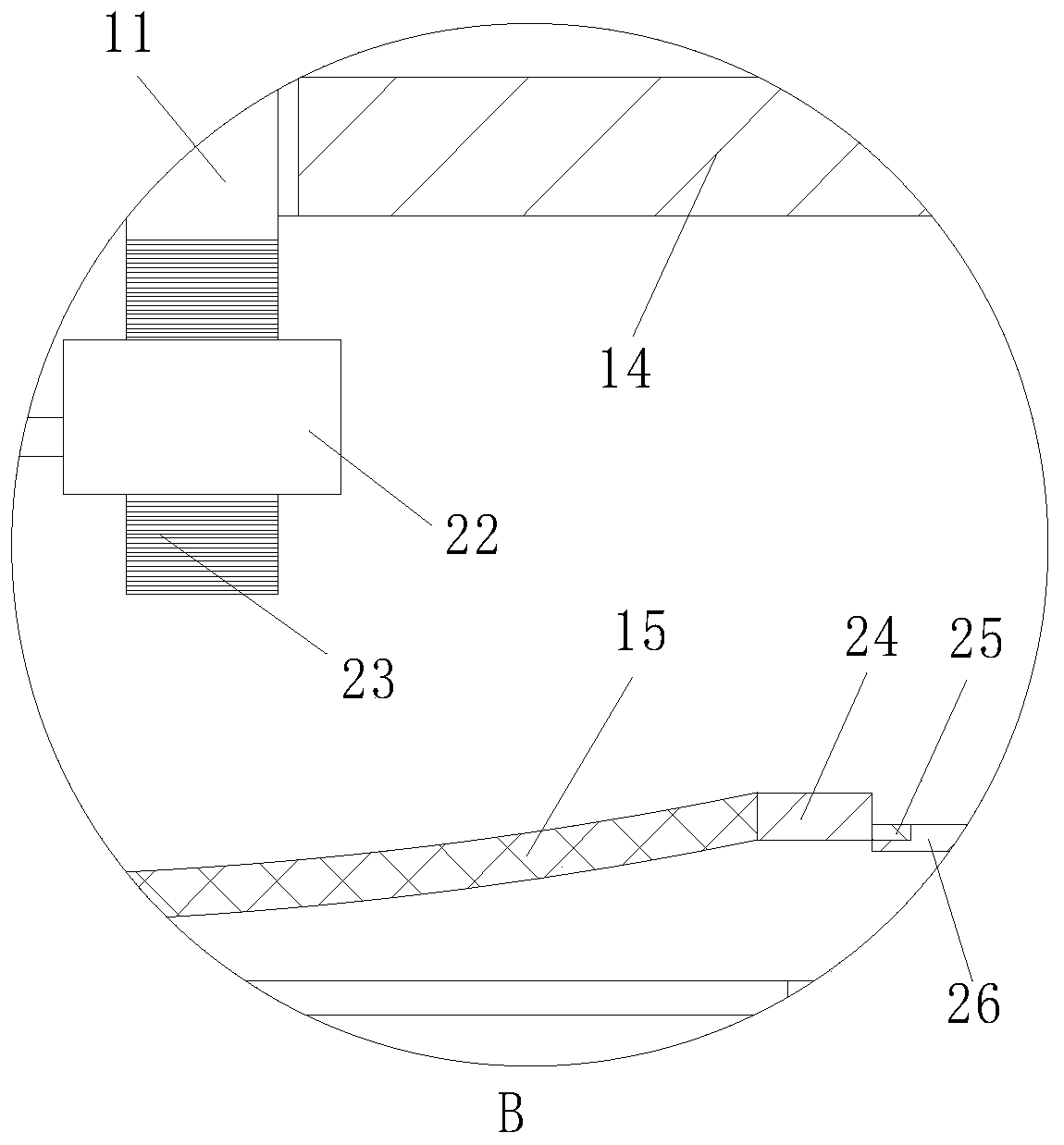

Sewage denitrification treatment device for domestic sewage and use method thereof

InactiveCN111252947AQuick breakFast integrationTransportation and packagingRotary stirring mixersAmmoniacal nitrogenSewage

The invention discloses a sewage denitrification treatment device for domestic sewage. Domestic sewage needing denitrification can be added into a pipeline from a water inlet hopper. A Seajer ammonianitrogen removing agent is discharged through a discharging mechanism to enter the interior of the pipe body. Through stirring by a stirring mechanism, the Seajer ammonia nitrogen removing agent can be more quickly blended into the sewage. An arranged motor rotates to drive a transmission rod to rotate, and the transmission rod rotates to drive stirring blades to stir the domestic sewage. Throughrotation of a rotating wheel, an ejector rod on the rotating wheel can be jacked up to move up and down, a sealing plate can open and close a liquid discharging opening, the discharging speed of the Seajer ammonia nitrogen removal agent can be controlled, and the device can be used for a long time by adding the agent into a metering box once. A good filtering function can be achieved through an arranged filter screen, and nitrogen in domestic sewage can be rapidly separated.

Owner:杭州尚内环保技术开发有限公司

Method for manufacturing high-tenacity automobile hardware

InactiveCN105063581AImprove toughnessImprove polishing effectSolid state diffusion coatingLiquid/solution decomposition chemical coatingCasting moldAmmonia gas

The invention discloses a method for manufacturing high-tenacity automobile hardware. The method is characterized by including the following steps of S01, casting a mould, S02, manufacturing a blank, S03, conducting machining and forming, S04, conducting galvanizing, S05, conducting chromate passivating, S06, conducting nickel plating, S07, conducting nitriding, wherein the hardware generated after nickel plating is conducted is placed into a part heat treatment furnace to be subjected to nitriding processing, the nitriding temperature ranges from 700 DEG C to 800 DEG C, the nitriding time ranges from 20 hours to 40 hours, ammonia gas serves as a nitriding agent, diffusion is conducted for 3 hours to 4 hours after nitriding is completed, and a product is sent to quenching liquid after diffusion is completed, S08, conducting cleaning and polishing, wherein parts generated after quenching treatment is conducted are cleaned and dried, and deburring is conducted after polishing is conducted and S09 conducting inspecting. According to the method for manufacturing the high-tenacity automobile hardware, the hardware is good in machinable property, good in tenacity and suitable for being widely applied and popularized.

Owner:昆山—邦泰汽车零部件制造有限公司

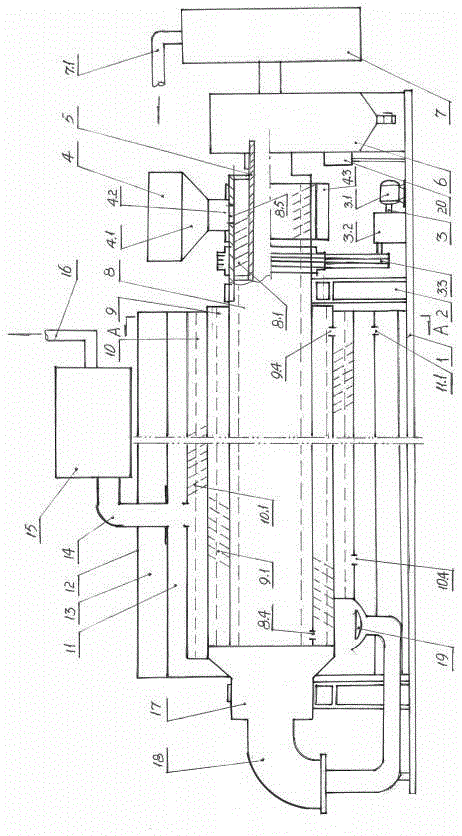

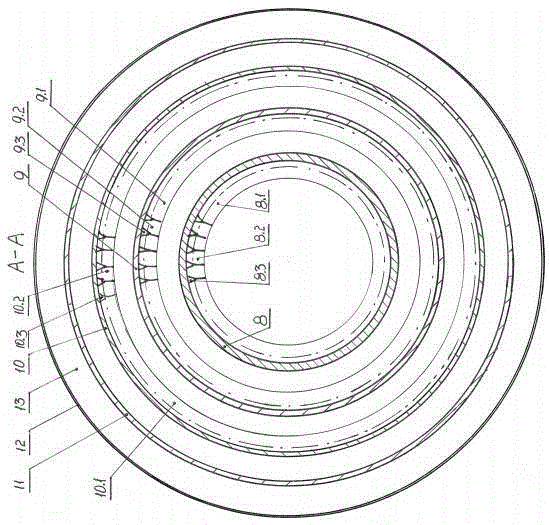

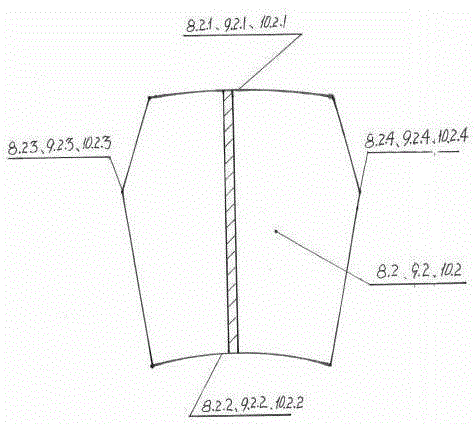

Designing method of sludge processing apparatus and apparatus thereof

ActiveCN105347634AAlleviate the contradiction between sludge output and sludge treatment capacity lagReliable technical solutionSludge treatmentWater contentHeavy metals

The invention discloses a designing method of a sludge processing apparatus and an apparatus thereof, which belong to the technical field of sludge processing. The designing method of the sludge processing apparatus comprises an integral design of an engine base, a sludge processing roller, a power drive mechanism, an output pipeline and an engine cover as well as a concrete design of each component, the designing method is characterized in that according to the different heavy metal contents in the sludge, the modified sludge with water content being 25-30% is placed in three different sludge processing rollers in order, quantitative glucose powder is added for mechanical stirring at uniform speed for propulsion, and three technical steps of heavy metal and dehydration / denitrification treatment, carbonization treatment and fixed carbon combustion treatment are carried out under normal pressure condition at temperature of 100-450 DEG C. Compared with the prior art, the designing method and the sludge processing apparatus have the advantages of novel and reliable performance, and no secondary pollution; waste can be changed into valuables, and sludge harmlessness treatment is realized, and the designing method and the sludge processing apparatus realize protrude substantiality characteristic and obvious progress for resource processing.

Owner:徐明好

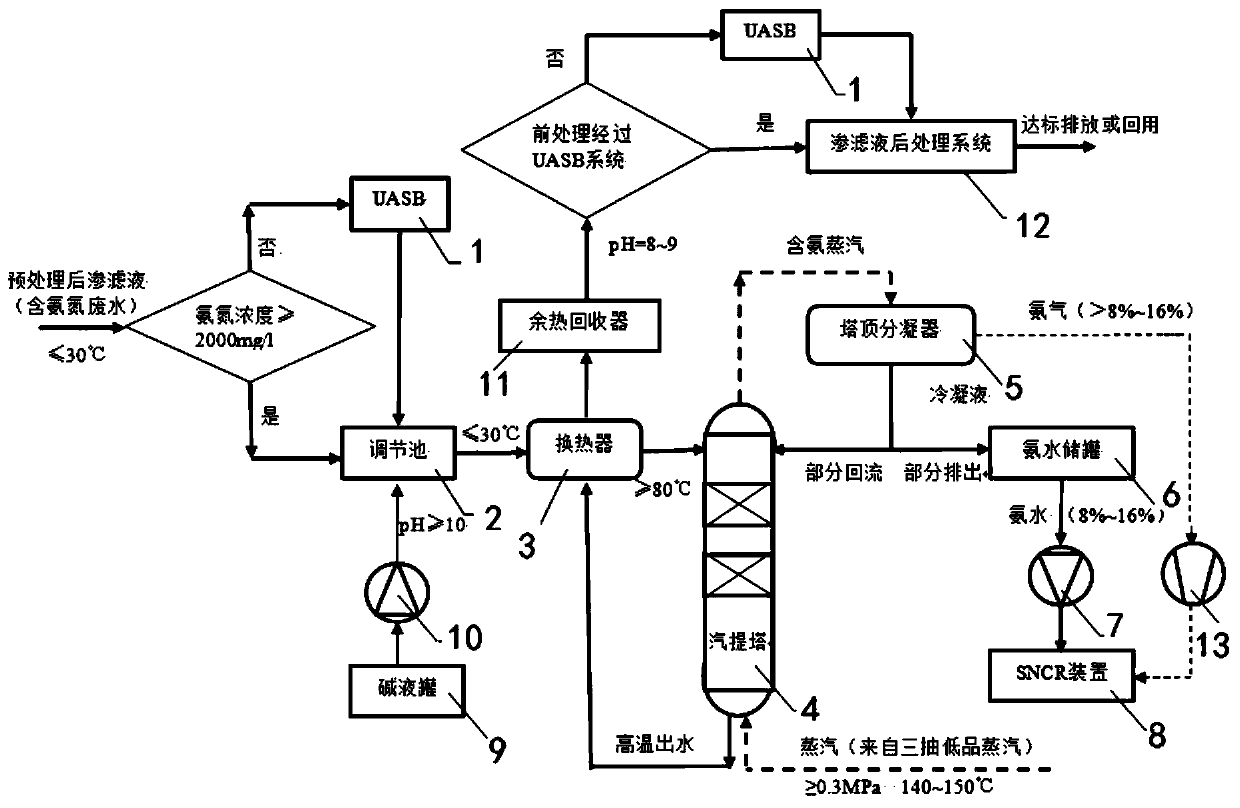

Method for denitrifying waste incineration flue gas by utilizing ammonia in landfill leachate

ActiveCN110772962ASolve the problem of high ammonia nitrogenReduce processing difficultyGas treatmentWater contaminantsWater storage tankTreatment system

The invention discloses a method for denitrifying waste incineration flue gas by utilizing ammonia in landfill leachate, and belongs to the technical field of high-concentration ammonia nitrogen treatment of landfill leachate. The method comprises the following steps: pretreated leachate firstly enters an adjusting tank, the pH value of wastewater is adjusted to 10 or above, then the temperature of the wastewater is increased to about 80 DEG C through a heat exchanger, the wastewater is sent into a stripping tower, and water flows downwards from the top of the tower and is in countercurrent contact with high-temperature steam introduced from the bottom of the tower through a filler or a distributor; ammonia-containing steam is discharged from the top of the stripping tower, and goes through a tower top fractional condenser to generate ammonia water; ammonia water with the concentration of 8-16% is finally prepared by controlling the reflux quantity of the ammonia water and the operation temperature of the tower top fractional condenser, and is stored in an ammonia water storage tank; gas-phase ammonia generated by the fractional condenser can be directly blown into a hearth throughthe induced draft fan and undergoes a denitration reaction; and effluent of the stripping tower is subjected to waste heat recovery and neutralization, then enters a leachate post-treatment system, is continuously treated, and is discharged when reaching standards.

Owner:BMEI

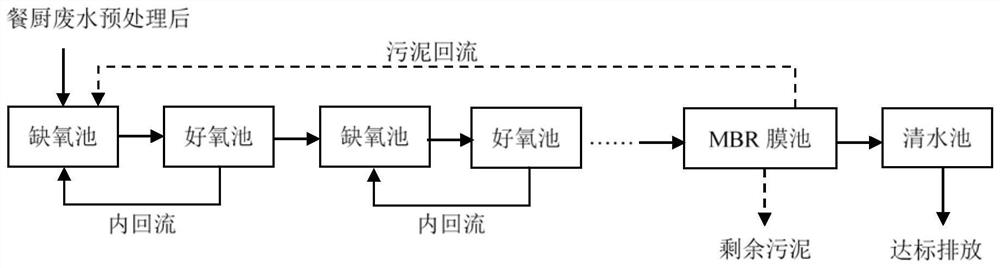

Efficient denitrification treatment method for kitchen wastewater

InactiveCN112299653AReduce refluxImprove denitrification effectWater/sewage treatment by irradiationWater contaminantsSludgeNitrate nitrogen

The invention discloses an efficient denitrification treatment method for kitchen wastewater. The method comprises the following steps: 1, pretreating the kitchen wastewater; 2, inputting the kitchenwastewater into a first-stage anoxic tank, and mixing the kitchen wastewater with sludge returned by a membrane tank and a mixed solution returned by a first-stage aerobic tank for denitrification reaction; 3, enabling the kitchen wastewater to enter the first-stage aerobic tank, conducting aeration to remove most of organic matter, and achieving a nitration reaction 4, enabling the kitchen wastewater to enter the next-stage anoxic tank, and continuously performing denitrification reaction on the residual nitrate nitrogen; 5, repeatedly executing the step 2 to the step 4, so as to enable the kitchen wastewater to be treated by the multiple stages of anoxic tank treatment and corresponding aerobic tank treatment; 6, enabling the kitchen wastewater to enter the membrane tank, and further degrading residual organic matter; and 7, putting the kitchen wastewater treated by the membrane tank into a clean water pool. The application of the invention can fully ensure the stable operation, highefficiency and reliability of the kitchen wastewater denitrification treatment process.

Owner:SHANGHAI HONESS ENVIRONMENTAL TECH CORP

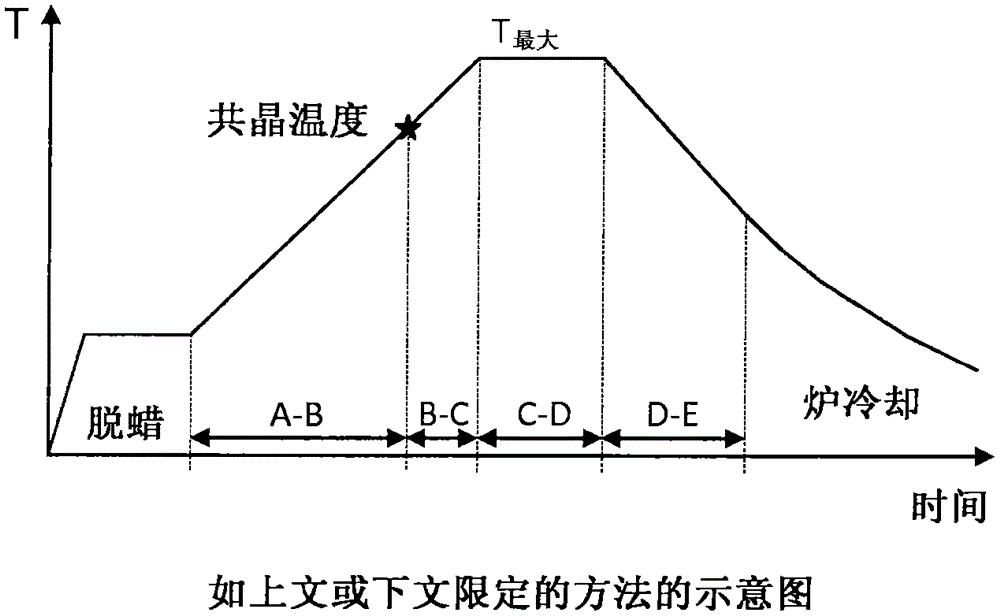

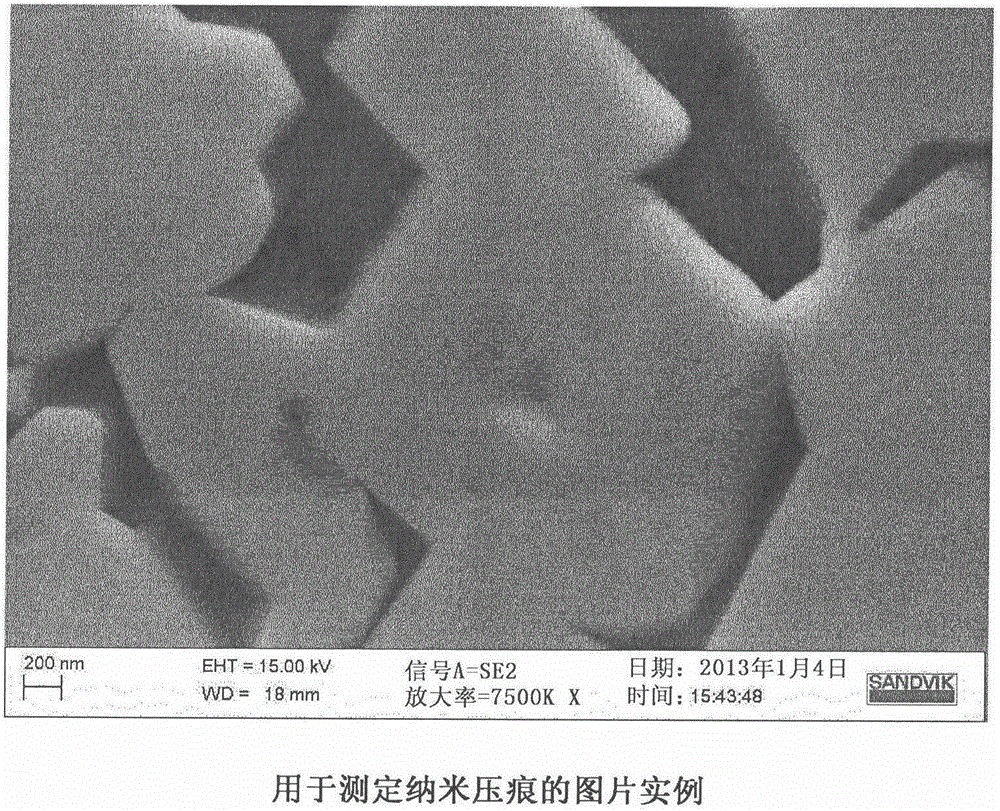

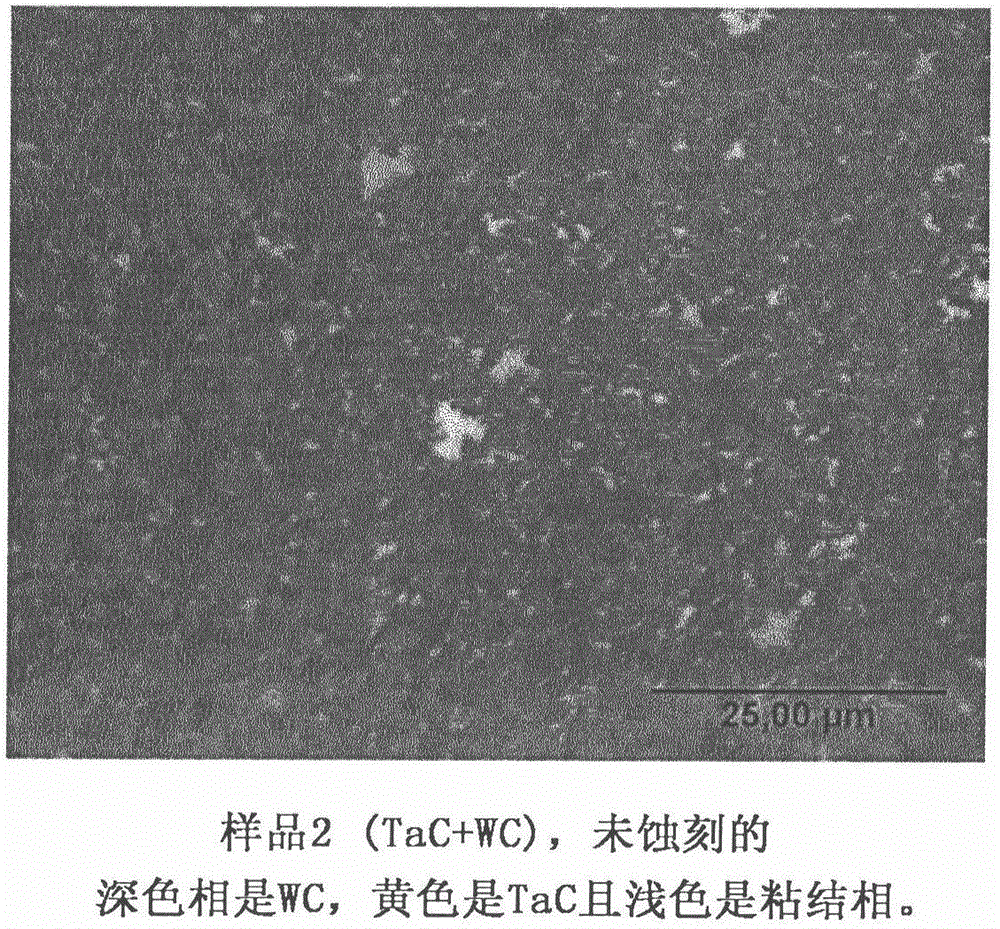

New process of manufacturing cemented carbide and a product obtained thereof

Owner:SANDVIK INTELLECTUAL PROPERTY AB

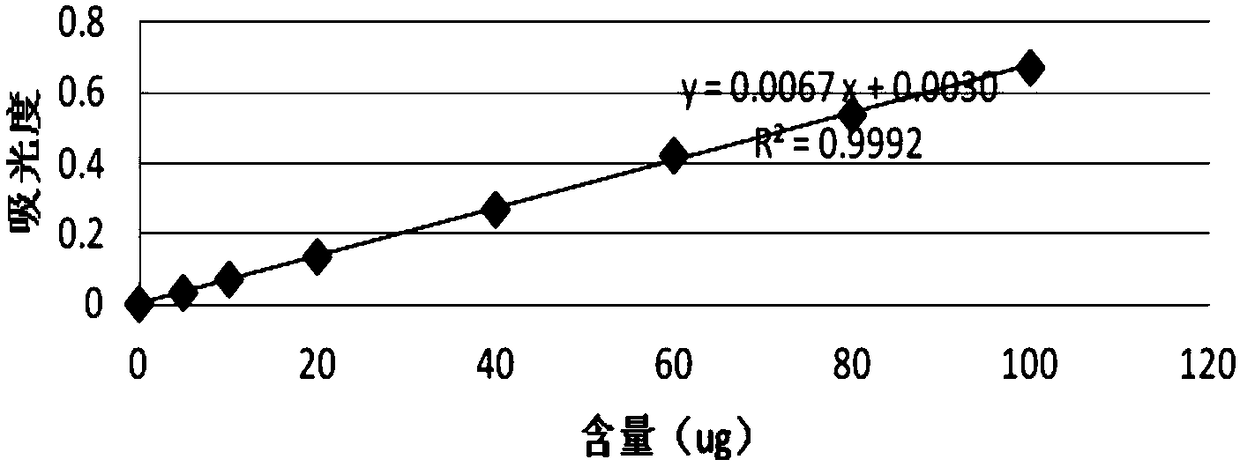

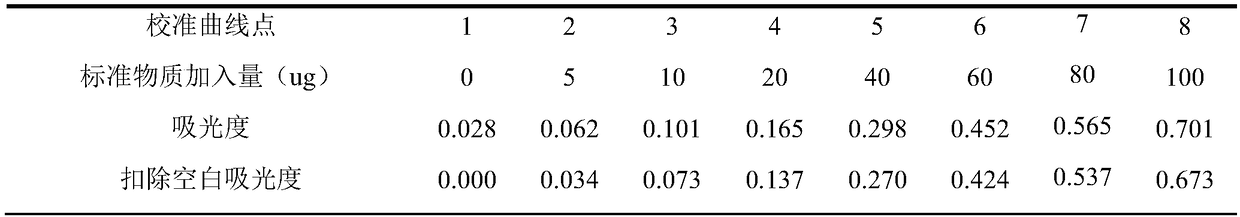

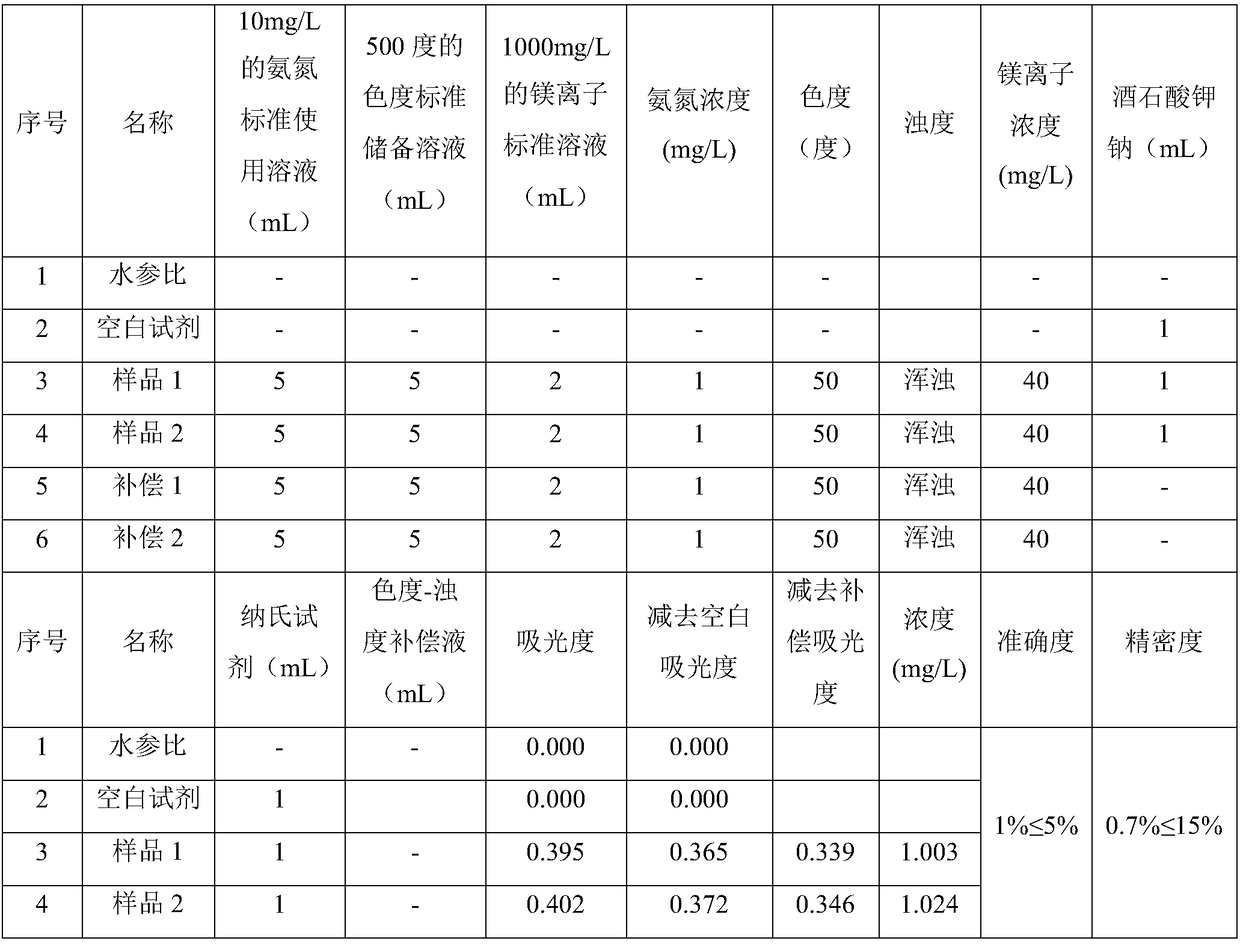

Colority and turbidity compensation determination method for ammonia nitrogen in distilled spirit industrial wastewater

InactiveCN109187388AAvoid the impact of test resultsDoes not affect the accuracy of the experimentColor/spectral properties measurementsIndustrial effluentPotassium sodium tartrate

The invention discloses a colority and turbidity compensation determination method for ammonia nitrogen in distilled spirit industrial wastewater. The method comprises the following steps: adopting Nessler reagent spectrophotometry, directly developing to determine the absorbance without pretreatment, preparing a blank sample, adding 2mL of colority-turbidity compensation liquid into the sample, and eliminating the colority or turbidity in the sample, wherein the potassium sodium tartrate and Nessler reagent solution are not added; and deducting the absorbance of the blank sample from the absorbance of the sample. The method is simple, convenient, accurate and reliable, and the requirement on timely regulation of the ammonia nitrogen treatment process in the distilled spirit industrial wastewater is met.

Owner:安徽润安信科检测科技有限公司

Method for treating acid-containing heavy crude oil refining saline sewage

ActiveCN104628221ASolve the standard problemReduce CODcr valueMultistage water/sewage treatmentTotal nitrogenHydrolysis

The invention discloses a method for treating acid-containing heavy crude oil refining saline sewage. The method comprises the following treatment on the saline sewage: gravity settling oil removal treatment, inclined plate settling oil removal treatment, two-stage air floatation treatment, bio-aeration treatment, anaerobic hydrolysis acidification treatment, nitrification-denitrification treatment and catalytic ozonization treatment. The water body treated by adopting the method can meet the requirements that COD cr is less than or equal to 60mg / L, petroleum is less than or equal to 5mg / L, ammonia nitrogen is less than or equal to 10mg / L and the total nitrogen is less than or equal to 40mg / L.

Owner:CHINA NAT OFFSHORE OIL CORP +3

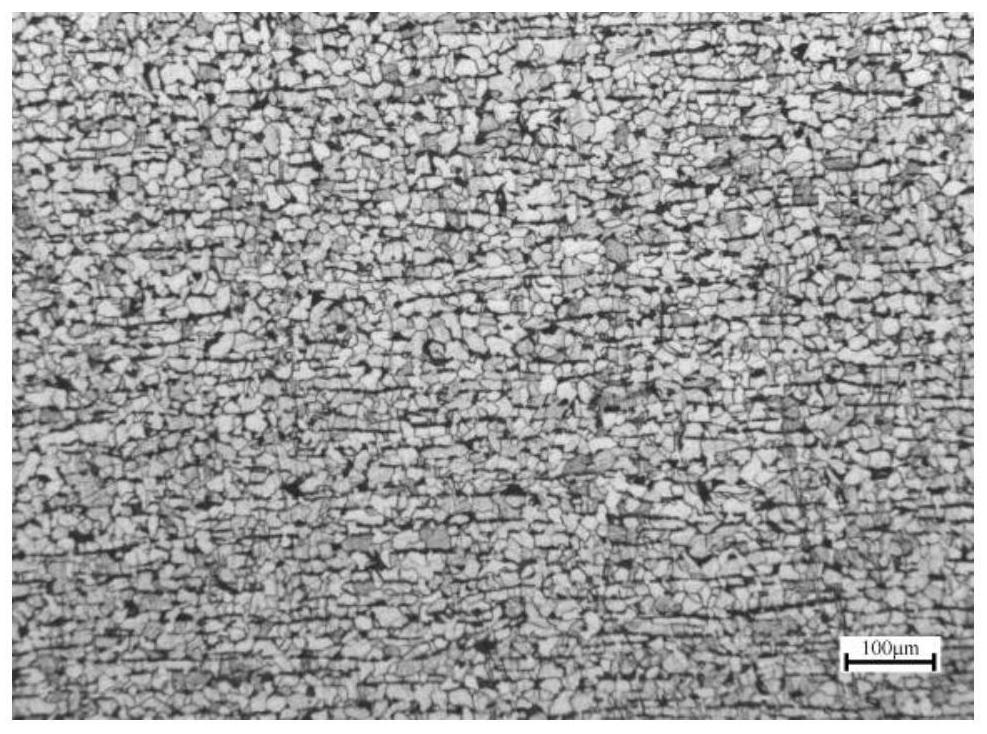

Nitriding treatment method for 1Cr18Ni9Ti austenitic steel

InactiveCN107723653AGuaranteed toughnessImprove wear resistanceSolid state diffusion coatingHigh resistanceSS - Stainless steel

The invention discloses a nitriding treatment method for 1Cr18Ni9Ti austenitic steel, and relates to the technical field of metal surface modification. Aiming at the problem that the nitriding treatment technology can lead to a substantial reduction in the corrosion resistance of austenitic stainless steel, a nitriding treatment method for 1Cr18Ni9Ti austenitic steel of the present invention includes 1) preliminary processing, 2) hardening treatment, 3) nitrogen immersion heat treatment and 4) Steps such as cooling, wherein step 3) nitrogen soaking heat treatment includes heat preservation, first-stage nitriding and second-stage nitriding. The nitriding treatment method of the present invention forms a highly wear-resistant and corrosion-resistant Fe_3N compound layer on the surface of the 1Cr18Ni9Ti austenitic steel, while fully exerting the corrosion-resistant advantages of the 1Cr18Ni9Ti austenitic steel and ensuring the internal toughness of the steel, making it The surface layer has high wear resistance and fatigue resistance.

Owner:SICHUAN QIXING ELECTRONICS

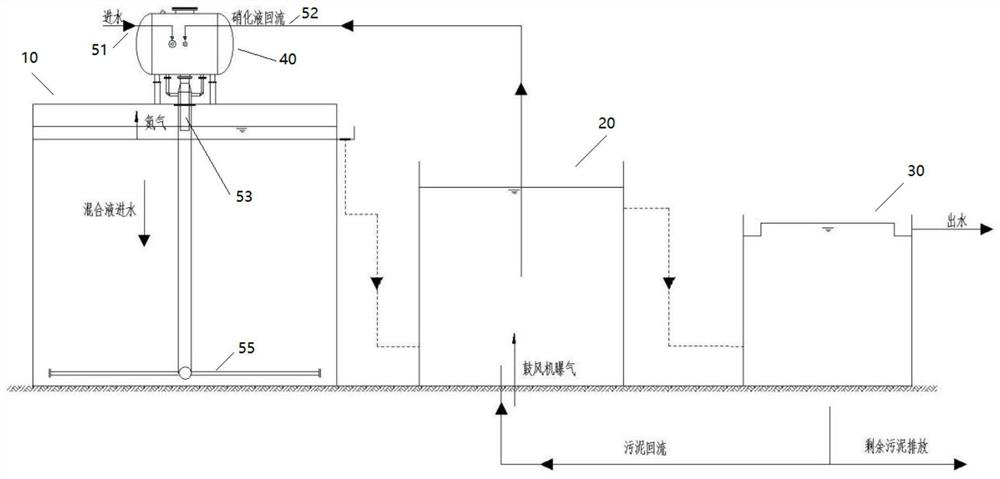

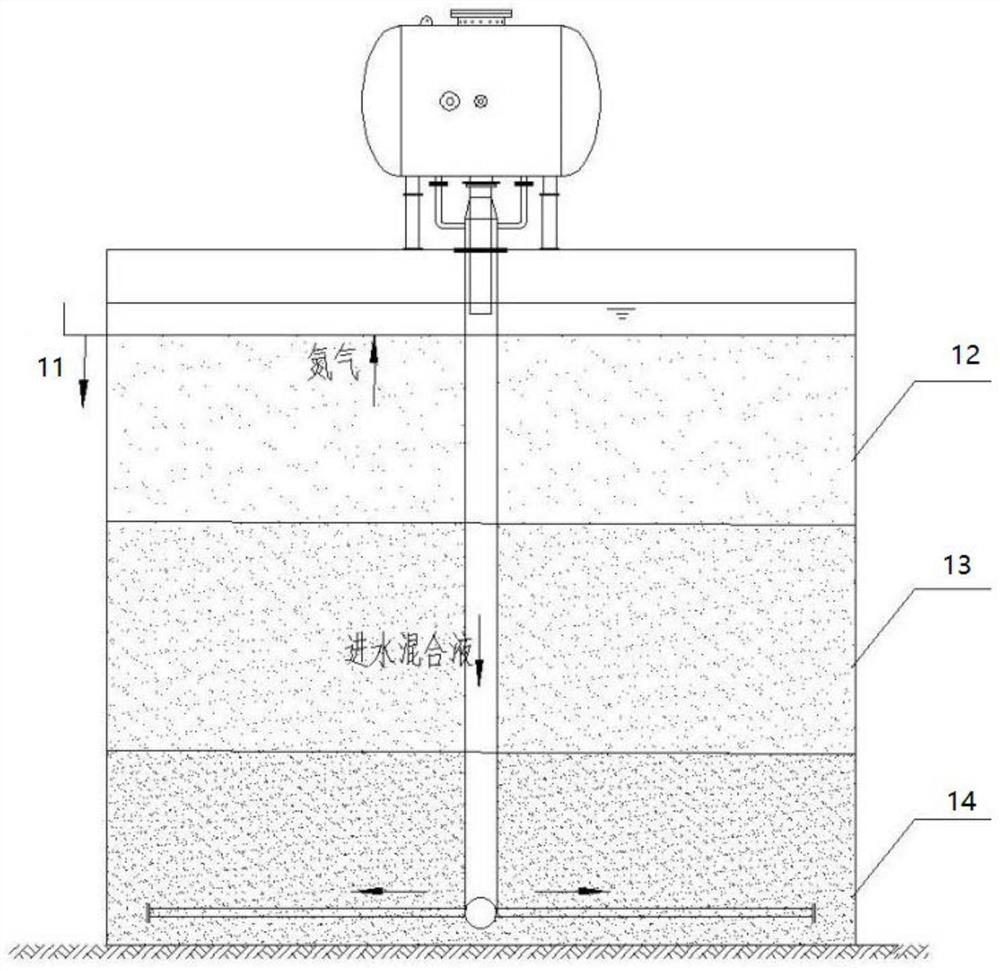

Efficient pulse water distribution anaerobic sludge denitrification reaction method and device

PendingCN112978922AHigh and stable total nitrogen removal rateReduce dosageTreatment with aerobic and anaerobic processesWater treatment flow arrangementsWater dischargeAnaerobic reactor

The invention discloses an efficient pulse water distribution anaerobic sludge denitrification reaction method and device. The device comprises an anaerobic reactor, an aerobic tank and a secondary sedimentation tank, wherein the anaerobic reactor comprises a pulse tank, a reactor body and a bottom uniform water distribution pipe; the pulse tank is arranged at the top of the reactor body and is connected with a water inlet, a nitrification liquid return pipe and a pulse tank water discharge pipe; the pulse tank water discharge pipe extends into the reactor body from the upper part of the reactor body and is connected with a bottom uniform water distribution pipe positioned at the bottom of the reactor body; the anaerobic reactor maintains a high sludge concentration and effective biomass in the reactor body through a refluxed mixed nitrification liquid, so that sludge does not need to be supplemented through sludge refluxing of the secondary sedimentation tank. The device and the method have the advantages of uniform mud-water mixing, low energy consumption, simple daily operation, maintenance and management and high treatment efficiency, and can realize biological denitrification treatment of high-concentration nitrogen-containing organic wastewater.

Owner:武汉森泰环保股份有限公司

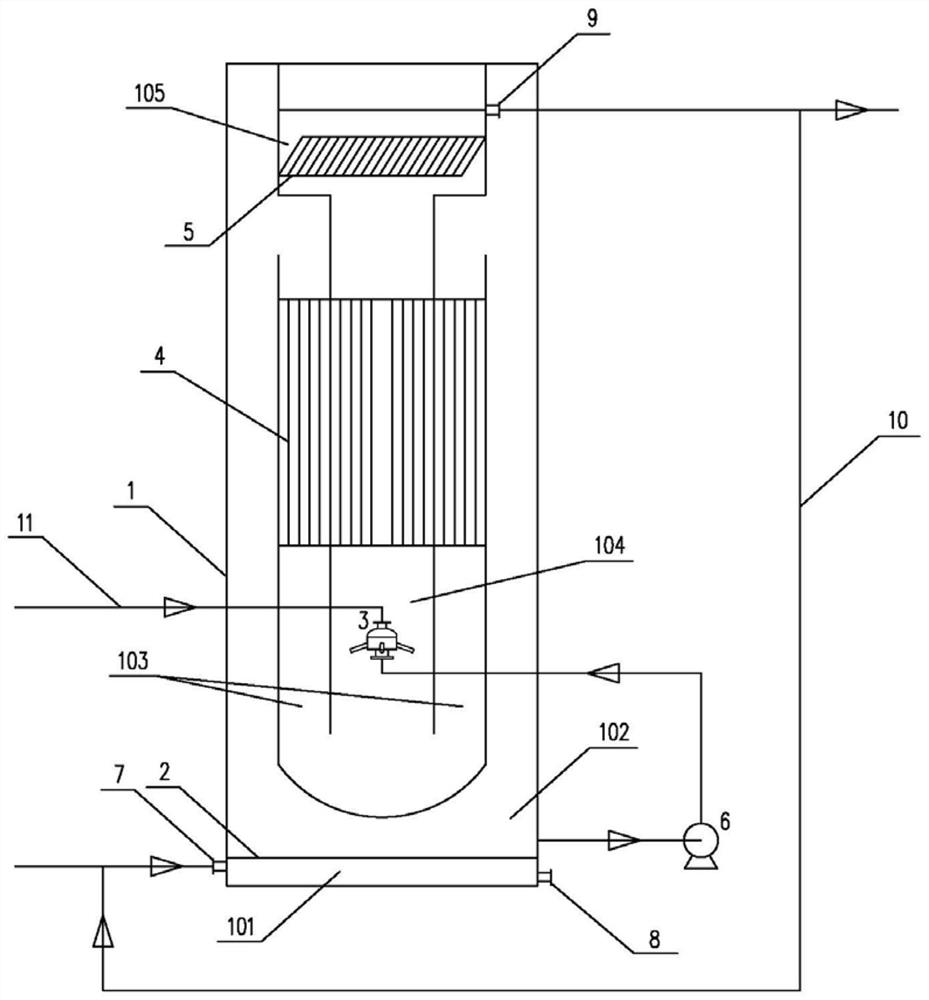

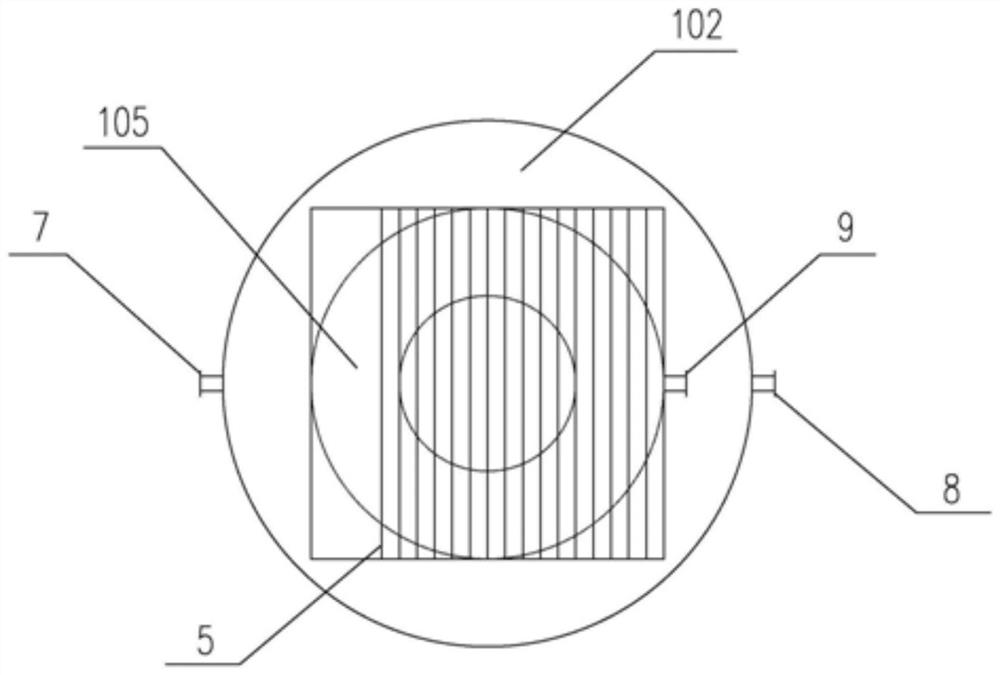

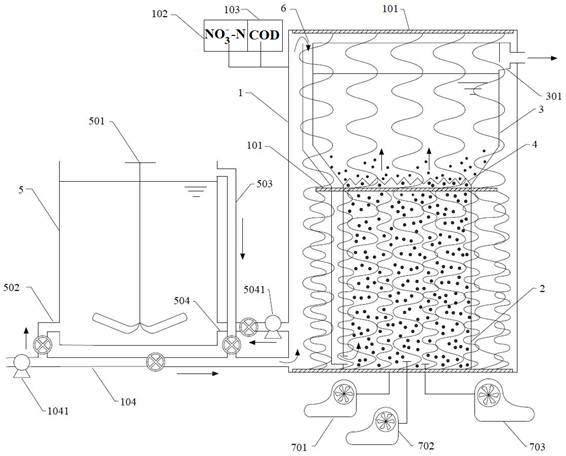

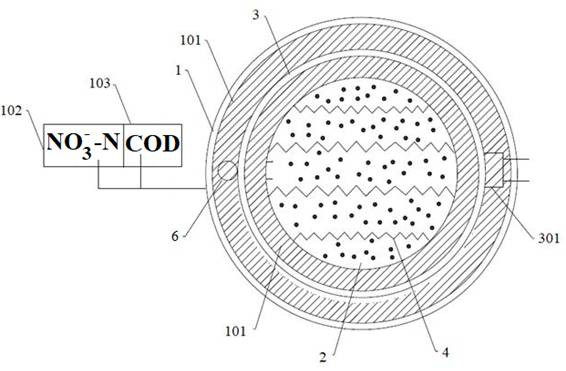

Short-cut nitrification coupled anaerobic ammonia oxidation denitrification reactor

ActiveCN112499763ASave floor spaceSave costsWater contaminantsTreatment with aerobic and anaerobic processesAmmoniacal nitrogenSludge

The invention discloses a short-cut nitrification coupled anaerobic ammonia oxidation denitrification reactor, which comprises a tank body, wherein the tank body internally comprises a mixing zone, ananaerobic zone, an anoxic zone, an aerobic zone and a solid-liquid separation zone; the anaerobic zone, the anoxic zone and the aerobic zone are biochemical reaction zones and are separated in the tank body through a cylindrical inner tank body with an upper opening and a lower opening; the mixing zone is positioned at the bottom of the tank body, is internally provided with a water distributor and is communicated with the outside through a water inlet and a sludge outlet; the anaerobic zone is close to the water inlet, and the water inlet is connected with the position, close to the bottom,of the anaerobic zone; a jet aerator is arranged at a position, close to the lower part, in the middle of the aerobic zone; the jet aerator is respectively connected with an aeration pipe and an outercirculating pump; enzyme floating fillers are arranged at the middle upper parts of the anoxic zone and the aerobic zone; and the solid-liquid separation zone is provided with an inclined plate separator and is connected with the water inlet through a return pipe. The high-ammonia-nitrogen and low-C / N wastewater is treated by coupling short-cut nitrification with anaerobic ammonia oxidation denitrification, so that the occupied area and the investment operation cost are saved.

Owner:SHANGHAI HONESS ENVIRONMENTAL TECH CORP

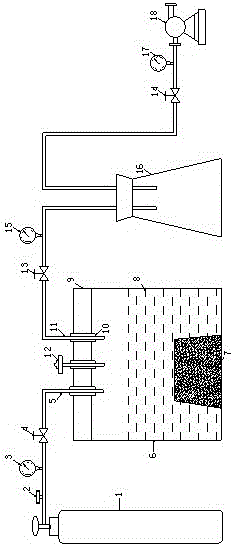

Soft coal rock sample preparation system and method

ActiveCN105823667ASimple structureEasy to operatePreparing sample for investigationTest sampleInlet valve

The invention relates to a soft coal rock sample preparation system and method .The system comprises a box with a box cover and a safety relief valve .Holes are formed in the box cover, the box cover is connected with a liquid nitrogen treatment system and a vacuumizing system through pipelines, and the liquid nitrogen treatment system comprises a liquid inlet valve, a first pressure gauge, a liquid nitrogen tank stop valve and a liquid nitrogen tank which are sequentially connected through a liquid inlet pipeline .The safety relief valve penetrates through the box cover and stretches into the box .The joint of the safety relief valve and the box cover is sleeved with a sealing sleeve .According to the system, the vacuumizing system is adopted for vacuum degassing, soft coal rock fractures and other microdefect spaces are filled with water, and a water absorption saturation state is achieved .The liquid nitrogen treatment system is utilized for carrying out ultralow temperature treatment on soft coal rock, the soft coal rock is frozen, and the difficulty that the soft coal rock is prone to be broken when used for preparing a test sample is solved .The system is simple in structure and convenient to use, the soft coal rock test sample is prepared fast and efficiently, and advantageous test determination conditions are provided for physical and mechanical property parameters of the soft coal rock.

Owner:HENAN POLYTECHNIC UNIV

Longitudinal-profiled (LP) high-strength ship plate and production method

ActiveCN112126853AImprove mechanical propertiesLow cost productionWork cooling devicesMetal rolling arrangementsChemical compositionMolten steel

The invention discloses a longitudinal-profiled (LP) high-strength ship plate and a production method. A steel plate comprises the following chemical components in percentage by mass: 0.140 percent to0.180 percent of C, 0.20 percent to 0.40 percent of Si, 1.00 percent to 1.40 percent of Mn, 0.030 percent to 0.070 percent of V, 0.003 percent to 0.018 percent of Ti, 0.0100 percent to 0.0150 percentof N, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent of S and 0.015 percent to 0.030 percent of Als. The method comprises the following steps: performing nitrogen blowing treatment on molten steel in a converter or a RH refining furnace; heating casting billets to 1100 DEG C to 1250 DEG C and keeping the temperature for 0.5 hour to 5.0 hours; setting a initial rolling temperature to be between 1050 DEG C and 1130 DEG C, and rolling the casting billets to ensure that the thickness of the casting billets is 2.0 times to 3.0 times of the maximum thickness of a final LP steel plate; performing rolling when the temperature of intermediate billets is at 880 DEG C to 920 DEG C, and performing rolling to ensure that the thickness of the intermediate billets is 1.5 times to 2.0 times of the maximum thickness of the final LP steel plate; controlling the final rolling temperature of the steel plate to reach 800 DEG C to 850 DEG C by adopting a profiling rolling way; and performing air-cooling on the steel plate until room temperature is reached so as to obtain the final LP steel plate. According to the longitudinal-profiled (LP) high-strength ship plate and theproduction method disclosed by the invention, the steel plate is high in uniformity of mechanical property in the length direction, and the intensity difference between a thick position and a thin position is in the range of 15MPa, and thus, the toughness and the plasticity are consistent, and therefore, the steel plate is applied to any shapes of LP high-strength ship plates.

Owner:ANGANG STEEL CO LTD

Sewage total nitrogen removal device and operation method thereof

ActiveCN114735903AReduce energy consumptionEasy to adjustWater treatment parameter controlWater contaminantsSludgeNitrate nitrogen

The invention relates to a sewage total nitrogen removal device and an operation method thereof, the sewage total nitrogen removal device comprises a denitrification tank, a precipitation separation zone and a supplementary reaction zone, the precipitation separation zone and the supplementary reaction zone are located in the denitrification tank, the precipitation separation zone is located above the supplementary reaction zone and is communicated with the supplementary reaction zone through a three-phase separator, and the three-phase separator is communicated with the three-phase separator. Sewage in the denitrification tank can flow into the supplementary reaction zone, and sewage subjected to denitrification treatment in the settling zone can directly flow out of the denitrification tank; the top surface of the precipitation separation area is sealed, the diameter of the top surface is larger than that of the bottom surface, and the supplementary reaction area is filled with aerobic granular sludge; an MABR membrane assembly is arranged in a space formed by the outer side walls of the precipitation separation area and the supplementary reaction area and the inner cavity of the denitrification tank, and an online COD detector and an online nitrate nitrogen detector are arranged on the side wall of the denitrification tank. The device provided by the invention is simple in operation, energy-saving and good in effluent quality.

Owner:GREENTECH ENVIRONMENTAL CO LTD

Longitudinal variable-thickness ultrahigh-strength ship plate and production method

ActiveCN111996462AImprove mechanical propertiesLow cost productionMetal rolling arrangementsMolten steelUltimate tensile strength

The invention discloses a longitudinal variable-thickness ultrahigh-strength ship plate and a production method. The steel plate comprises the following chemical components: 0.060% to 0.120% of C, 0.15% to 0.50% of Si, 1.10% to 1.70% of Mn, 0.040% to 0.070% of V, 0.20% to 0.50% of Cu, 0.10% to 0.50% of Ni, 0.005% to 0.020% of Ti, 0.0120% to 0.0180% of N, smaller than or equal to 0.010% of P, smaller than or equal to 0.005% of S and 0.015% to 0.030% of Als. The method comprises the following steps of performing nitrogen blowing treatment on molten steel in a converter or RH, heating a casting blank to 1130 to 1250 DEG C and keeping for 40 to 240 minutes; enabling the initial rolling temperature to be 1040 to 1120 DEG C, and rolling the thickness of the casting blank to 2.0 to 3.0 times of the maximum thickness of the final LP steel plate; rolling an intermediate billet at 850 to 910 DEG C, and rolling the thickness to be 1.5 to 2.0 times of the maximum thickness of the final LP steel plate; adopting variable-thickness rolling, and controlling the finish rolling temperature of the steel plate to be 800 to 850 DEG C; and performing air-cooling on the steel plate to the room temperature in order to obtain the final longitudinal variable-thickness steel plate. The steel plate is good in mechanical property uniformity in the length direction, the strength difference between the thickposition and the thin position is within 15 MPa, the toughness and plasticity are consistent, and the steel plate is suitable for the longitudinal variable-thickness high-strength ship plates in anyshape.

Owner:ANGANG STEEL CO LTD

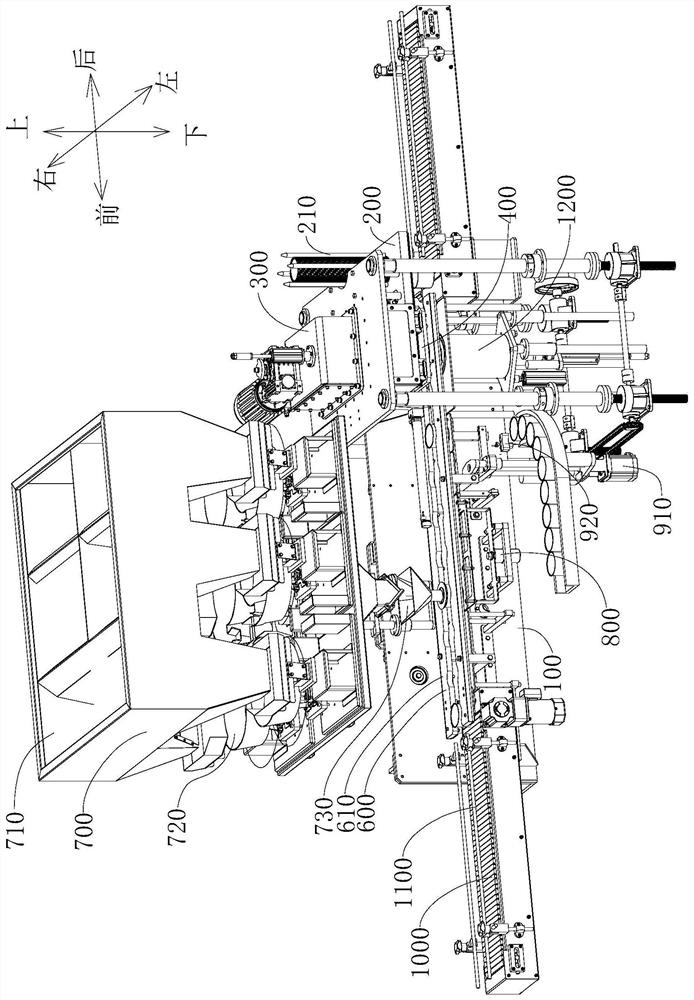

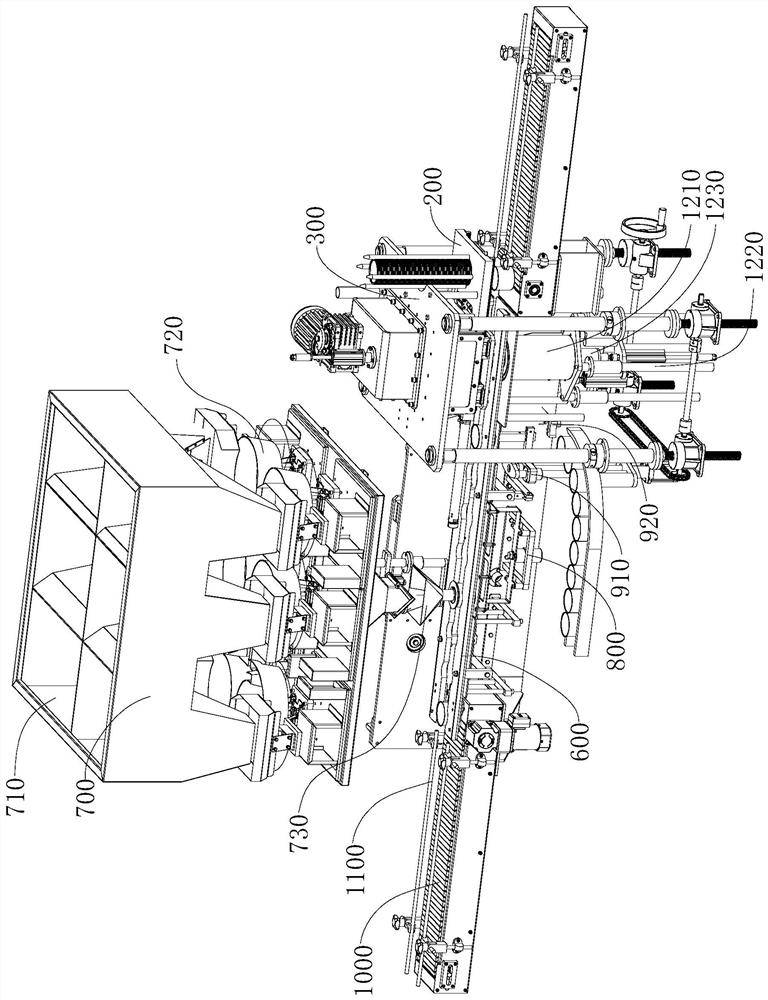

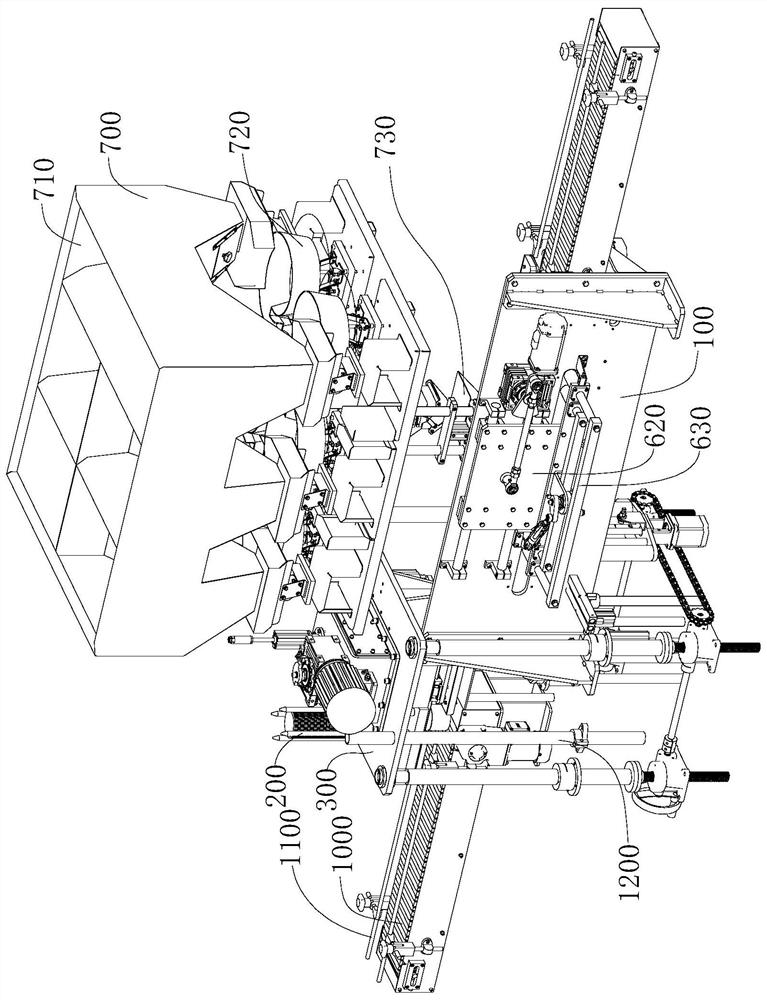

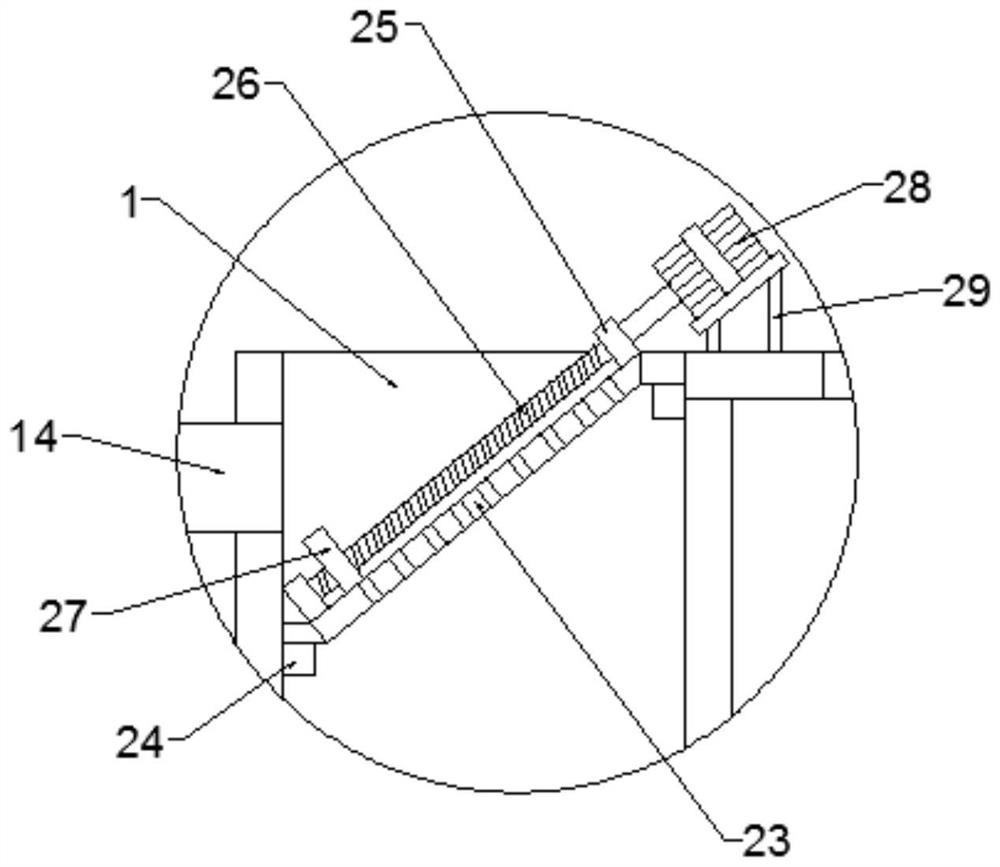

Automatic filling production line

The invention discloses an automatic filling production line. The automatic filling production line comprises a rack, a cover falling device, a vacuum pumping and nitrogen charging device, a cover conveying device, a lifting device and a cover sealing device, wherein the rack comprises a workbench; the workbench is provided with a cover sealing position; the cover falling device can separate stacked cover bodies one by one; the cover conveying device can convey individual cover bodies separated by the cover falling device to the position below the vacuum pumping and nitrogen filling device; the lifting device can lift a tank body located at the cover sealing position and is matched with the vacuum pumping and nitrogen filling device to form a closed cavity, so that vacuum pumping and nitrogen filling treatment on the tank body is completed; and the lifting device can continue to lift the tank body into the vacuum pumping and nitrogen filling device to complete cover sealing under the action of the cover sealing device. According to the automatic filling production line, the steps of vacuum pumping, nitrogen filling, cover sealing and the like of the tank body can be automatically completed, so that the production efficiency can be improved, and the practicability of the automatic filling production line can be improved.

Owner:广州华飞包装科技有限公司 +1

Leachate denitrification device of garbage transfer station and use method

InactiveCN111977909AReduce shockEfficient removalSpecific water treatment objectivesWater contaminantsSludge cakeFilter press

The invention discloses a leachate denitrification device of a garbage transfer station and a use method. The device comprises a primary filter tank, a regulating tank and a flocculation sedimentationtank, wherein the primary filter tank communicates with the regulating tank; the regulating tank communicates with the flocculation sedimentation tank; the flocculation sedimentation tank communicates with an ammonia stripping tank; the ammonia stripping tank communicates with a hydrolytic acidification tank; the hydrolytic acidification tank communicates with an aerobic tank; the aerobic tank communicates with an ultrafiltration membrane filter tank; the ultrafiltration membrane filter tank communicates with a disinfection tank; the disinfection tank communicates with a clean water tank; andthe regulating tank, the flocculation sedimentation tank, an anaerobic reaction tank and the hydrolytic acidification tank communicate with a sludge distributing pipe. A sludge pump is started to pump out sludge in the regulating tank, the flocculation sedimentation tank, the anaerobic reaction tank and the hydrolytic acidification tank, the sludge enters a sludge concentration tank through the sludge distributing pipe and a main sludge pipe, and the sludge is treated with a pressure filter, sludge cake is transported out; and according to the garbage penetrating fluid denitrification treatment device, the effluent quality is relatively good, the water quality index can meet the discharge requirement, and the effluent quality is stable.

Owner:杭州乾景环保工程有限公司

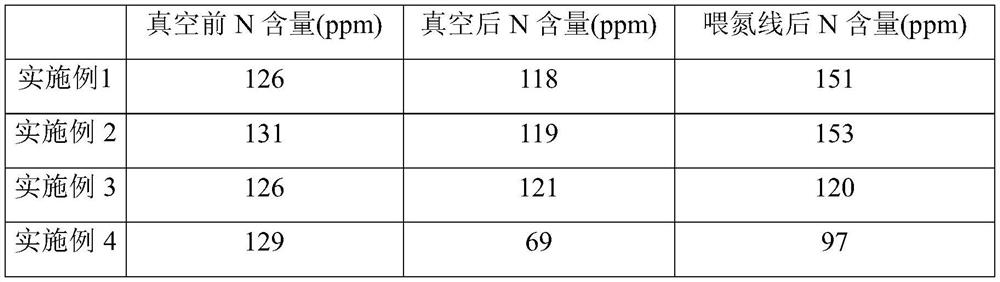

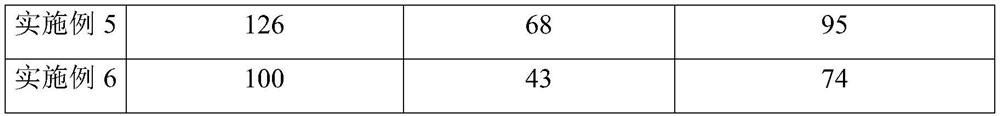

Method for controlling nitrogen content of nitrogen-containing non-sulfur-containing steel grades

InactiveCN111961790AHigh sulfur contentImprove nitrogen efficiencyManufacturing convertersMolten steelNitrogen gas

The invention discloses a method for controlling the nitrogen content of nitrogen-containing non-sulfur-containing steel grades. The method includes the following steps that (1) converter smelting iscarried out, nitrogen is used for a whole converter bottom blowing process, and nitrogen blowing treatment is carried out on molten steel; (2) LF furnace treatment is carried out, at the end of LF furnace smelting, sulfur lines are fed in a supplemented mode according to the sulfur content in the molten steel, and the sulfur mass percentage content is controlled to 0.008-0.015%; and (3) RH furnacetreatment is carried out, nitrogen is used as a vacuum lifting gas, after breaking is carried out, samples are taken to analyze the nitrogen content, and nitrogen lines are fed in a supplemented modeaccording to the nitrogen content until the required range of the nitrogen content of the steel grades is reached. It is ensured that the high sulfur content is maintained in the steel grades by feeding the sulfur lines in a supplemented mode at the end of LF smelting, the nitrogen fixation effect of the nitrogen-containing non-sulfur-containing steel grades is improved, the denitrification ratein the vacuum process is reduced, the nitrogen content in steel reaches 120-200ppm, the nitrogen content is controlled stably, and a foundation is laid for subsequent product preparation.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com