Automatic filling production line

An automatic filling and production line technology, applied in the direction of automatic packaging control, packaging, packaging protection, etc., can solve the problems of vacuum leakage, nitrogen leakage, large size, poor effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

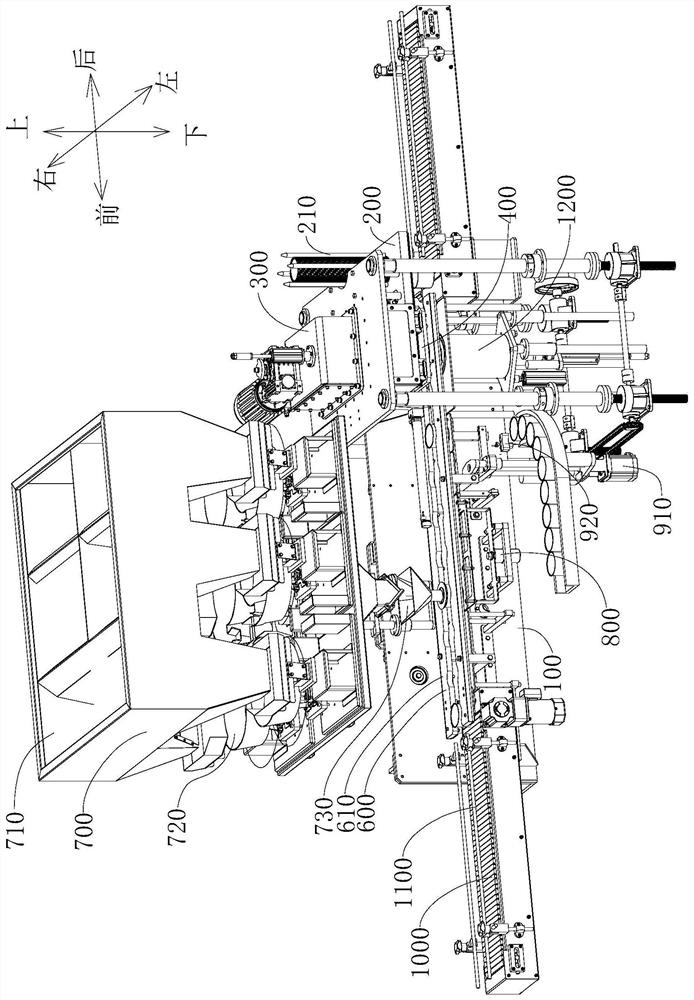

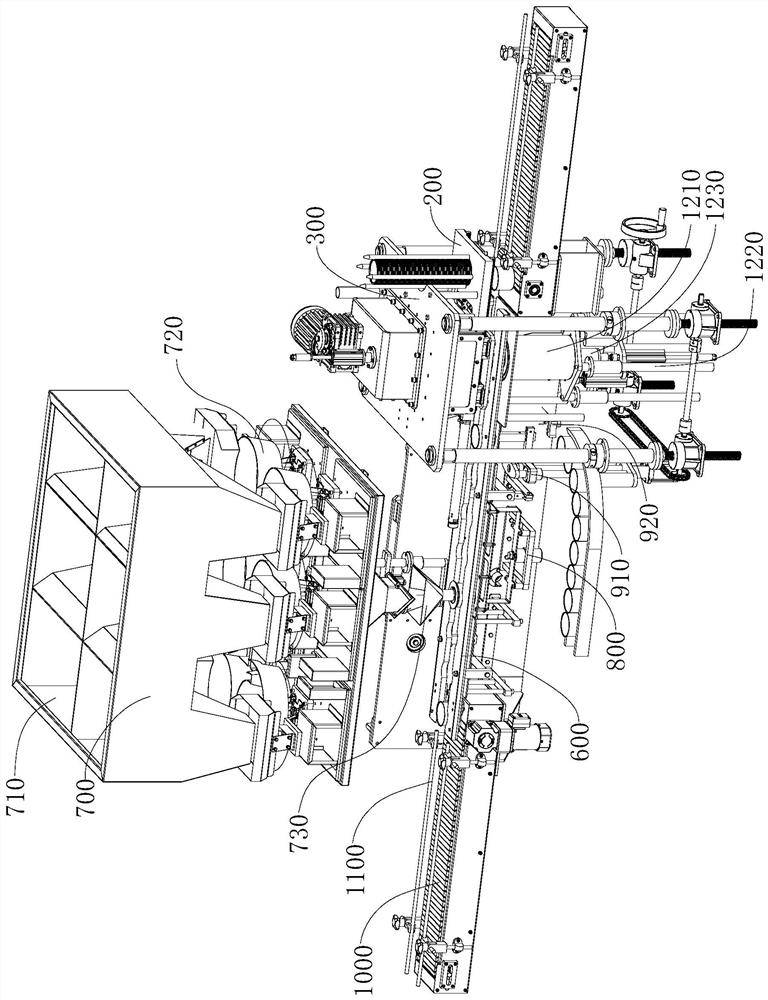

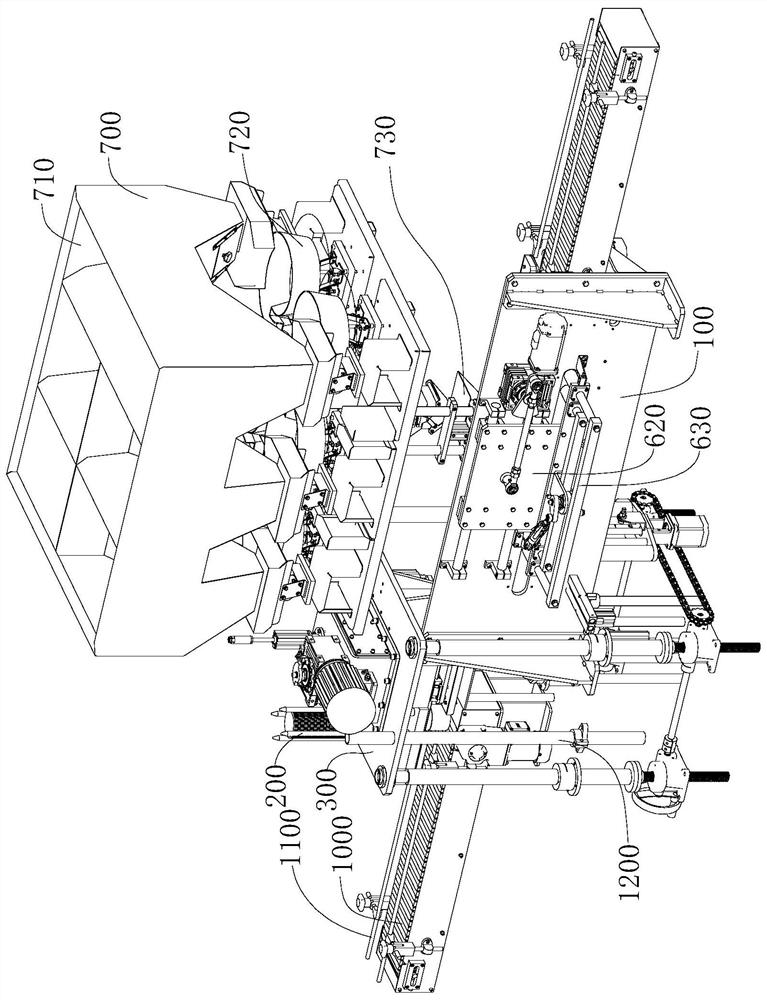

[0043] Embodiment one, see figure 1 , figure 2 , image 3 , Figure 6 and Figure 7 , the embodiment of the present invention provides an automatic filling production line, including: a frame 100 , a cap dropping device 200 , a vacuum nitrogen filling device 300 , a cap feeding device 400 , a lifting device 1200 and a capping device 500 .

[0044] Among them, a workbench is set on the frame 100, and the workbench is used to support containers such as tanks and barrels that need to be filled and packaged, and several stations are set on the workbench, so that during the tank body conveying process Complete the filling, vibrating, weighing, sorting, capping and other working steps of materials.

[0045] The cap drop device 200 includes a cap storage support 210 and a cap drop assembly 220. The cap drop assembly 220 is arranged at the lower end of the cap storage support 210, and the lower end surface of the cap storage support 210 is provided with an opening. The cap storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com