Mineralized refuse packed bed and wastewater denitrification method

A technology for mineralizing garbage and packed beds, applied in chemical instruments and methods, water pollutants, biological water/sewage treatment, etc., can solve problems affecting the efficiency and stability of anammox reactors, growth inhibition, alkalinity pH problems such as decline, to achieve the effect of being conducive to recycling, simple process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Influent water properties: coking wastewater, ammonia nitrogen content 1433-2134 mg / L, COD 1577-2544 mg / L, BOD 5 574-763 mg / L, pH 10.5-11.3.

[0034] Pretreatment: use activated sludge method to remove BOD 5 Reduce the pH to 25-51 mg / L, adjust the pH of the wastewater to 7.8-8.9, and use a partition heater at 20-40°C to obtain wastewater 101.

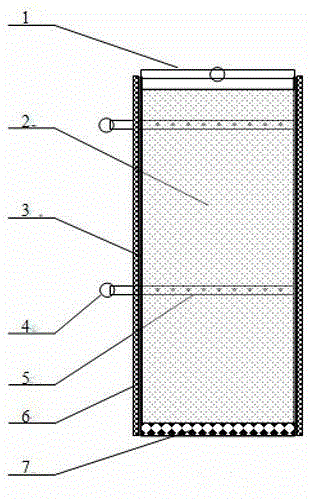

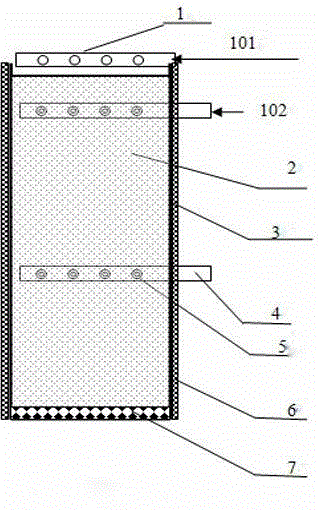

[0035] Mineralized waste packing bed: Mineralized waste packing 2 is the urban domestic waste that has been buried for 8 years. After being screened at 30mm, large particles of glass, battery residues, metals, and stones are removed to obtain brown loose soil-like materials. The bed wall 3 of the mineralized garbage packing bed is 3.5m high, and there are 4 aerobic zones and 3 anaerobic zones inside, and the anaerobic zone and the aerobic zone are arranged alternately. The aerobic zone at the bottom of the packed bed is realized by natural ventilation, and the formation of the other three aerobic zones is realized by arranging ...

Embodiment 2

[0041] Influent water quality: the leachate of middle-aged and elderly waste landfills with a landfill age of 8 years, COD is 1834~2433mg / L, ammonia nitrogen is 2430~3071mg / L, BOD 5 It is 244~336mg / L, and the pH value is 7.4~8.5.

[0042] Pretreatment: by Fenton oxidation, BOD 5 Reduce it to 87~200 mg / L, add soda ash to make the pH of the wastewater 8.0-8.8, and adjust the temperature to 30±2°C by directly filling it with high-temperature steam to obtain wastewater 101.

[0043] Mineralized waste packing bed: Mineralized waste packing 2 is a brown loose soil-like material obtained after 10-year-old municipal solid waste is sieved through a 10mm sieve to remove large particles of glass, battery residues, metals, and stones. The bed wall 3 of the mineralized garbage packing bed is 2m high, and there are 2 aerobic zones and 1 anaerobic zone inside, and the anaerobic zone and the aerobic zone are arranged alternately. The aerobic zone at the bottom of the packed bed is realized ...

Embodiment 3

[0047] Influent water properties: Pig farming wastewater, ammonia nitrogen content 209-1100 mg / L, COD 847-1544 mg / L, BOD 5 363-758 mg / L, pH 7.1-7.6.

[0048] Pretreatment: Activated sludge method, effluent BOD 5 45-96 mg / L, pH 6.9-7.3, ammonia nitrogen content 247-683 mg / L.

[0049] Mineralized Garbage Bed: Mineralized Garbage Filler 2 is a brown loose soil-like material obtained after 10-year-old municipal solid waste has been sieved through a 10mm sieve to remove large particles of glass, battery residues, metals, and stones. The bed wall 3 of the mineralized garbage packing bed is 2m high, and there are 2 aerobic zones and 1 anaerobic zone inside, and the anaerobic zone and the aerobic zone are arranged alternately. The aerobic zone at the bottom of the packed bed is realized by natural ventilation, and the formation of the aerobic zone at the top is realized by arranging a single-layer pipe diameter of 25mm porous ventilation pipes. The ventilation main pipe 4 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com