Leachate denitrification device of garbage transfer station and use method

A waste transfer station and landfill leachate technology, which is applied in the field of leachate denitrification devices in waste transfer stations, can solve problems such as poor effluent quality, environmental pollution, and unstable water quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

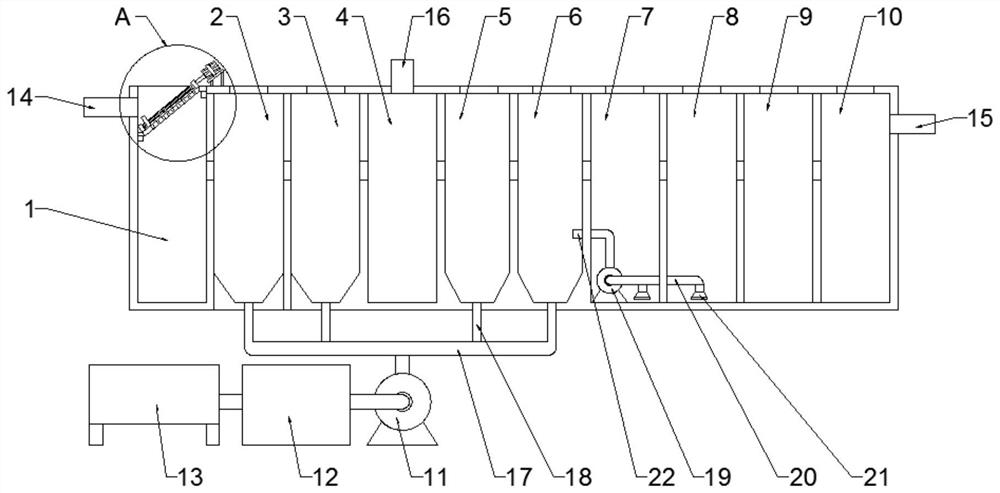

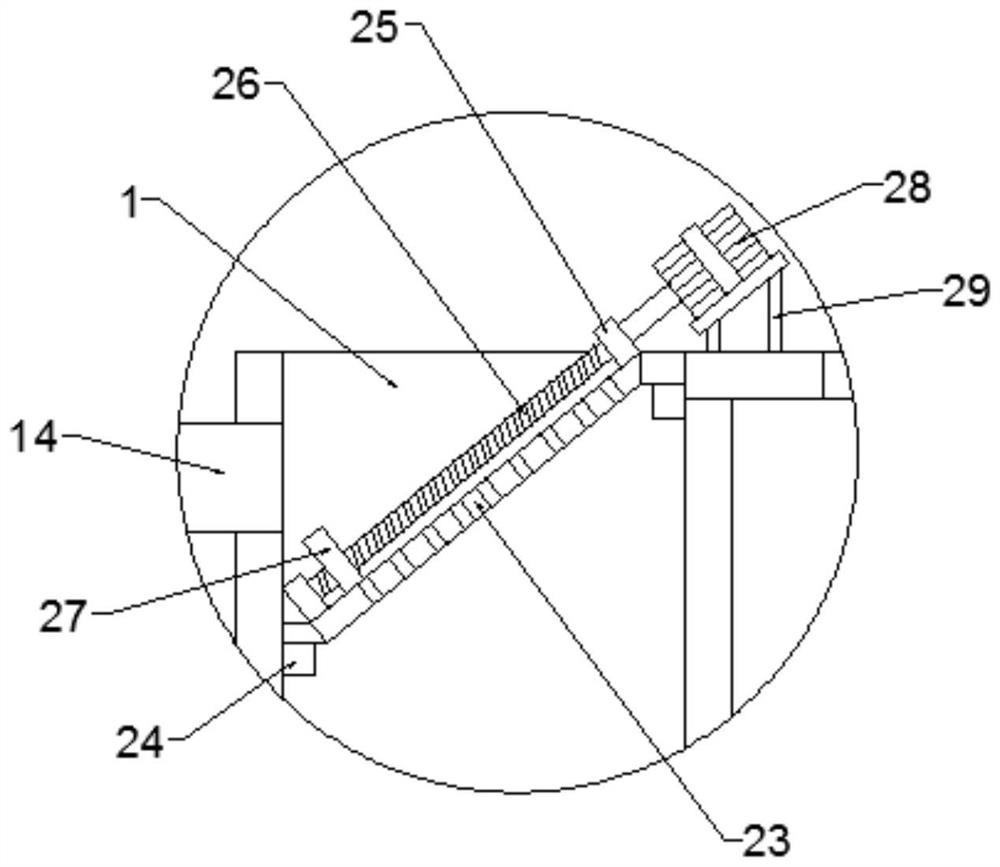

[0015] Example 1. Such as figure 1 As shown, it includes a primary filter tank 1, a regulating tank 2 and a flocculation sedimentation tank 3. The primary filter tank 1 is connected to the regulating tank 2, the regulating tank 2 is connected to the flocculation sedimentation tank 3, the flocculation sedimentation tank 3 is connected to the ammonia stripping tank 4, and the ammonia Blow off tank 4 is connected to hydrolysis and acidification tank 6, hydrolysis and acidification tank 6 is connected to aerobic tank 7, aerobic tank 7 is connected to ultrafiltration membrane filter tank 8, ultrafiltration membrane filter tank 8 is connected to disinfection tank 9, disinfection tank 9 is connected to clean water tank 10 The regulating tank 2, the flocculation sedimentation tank 3, the anaerobic reaction tank 5 and the hydrolysis acidification tank 6 are connected to the sludge dividing pipe 18, the other end of the sludge dividing pipe 18 is connected to the main sludge pipe 17, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com