Sewage total nitrogen removal device and operation method thereof

An operation method and nitrogen removal technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve the effects of low effluent turbidity, convenient adjustment, and excellent energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a device for removing total nitrogen from sewage.

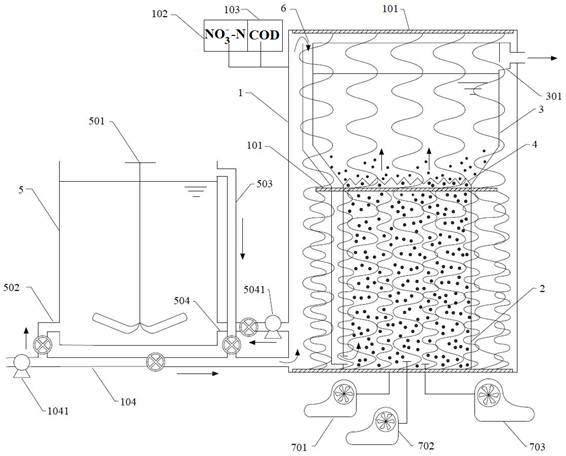

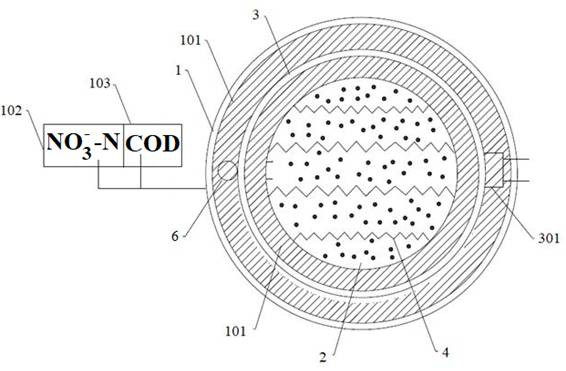

[0055] like figure 1 and figure 2 As shown, the sewage total nitrogen removal device includes a denitrification tank 1, a supplementary reaction zone 2, a sedimentation separation zone 3 and a standby anaerobic tank 5, wherein:

[0056] The precipitation separation zone 3 and the supplementary reaction zone 2 are located inside the denitrification tank 1, and the precipitation separation zone 3 is located above the supplementary reaction zone 2 and passes through a three-phase separator with the supplementary reaction zone 2 4 is connected, the upper part of the inner cavity of the sedimentation separation zone 3 is provided with an overflow weir 301, the overflow weir 301 protrudes from the side wall of the sedimentation separation zone 3, and the denitrified sewage flows through the overflow weir 301 to the denitrification zone 3. Outside nitrogen pool 1;

[0057] The outer wall of the se...

Embodiment 2

[0067] This embodiment provides a method for treating sewage by using the device provided in Embodiment 1.

[0068] (1) Turn on the inlet water pump 1041 and the main inlet valve, and the raw water enters the denitrification tank 1 for reaction. At this time, the primary aerator 701 and the tertiary aerator 703 are in operation, and the secondary aerator 702 is closed. state, the online COD detector 103 and the online nitrate detector 102 record the COD concentration and nitrate nitrogen concentration of the raw water of the denitrification tank 1 at a fixed frequency, and calculate the ratio of the COD concentration to the nitrate nitrogen concentration;

[0069] (2) The reacted raw water flows into the supplementary reaction zone 2 through the guide pipe 6 for supplementary reaction, and forms an upward flow by gravity flow;

[0070] (3) The upflow passes through the three-phase separator 4 to remove air bubbles and part of the aerobic granular sludge and then enters the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com