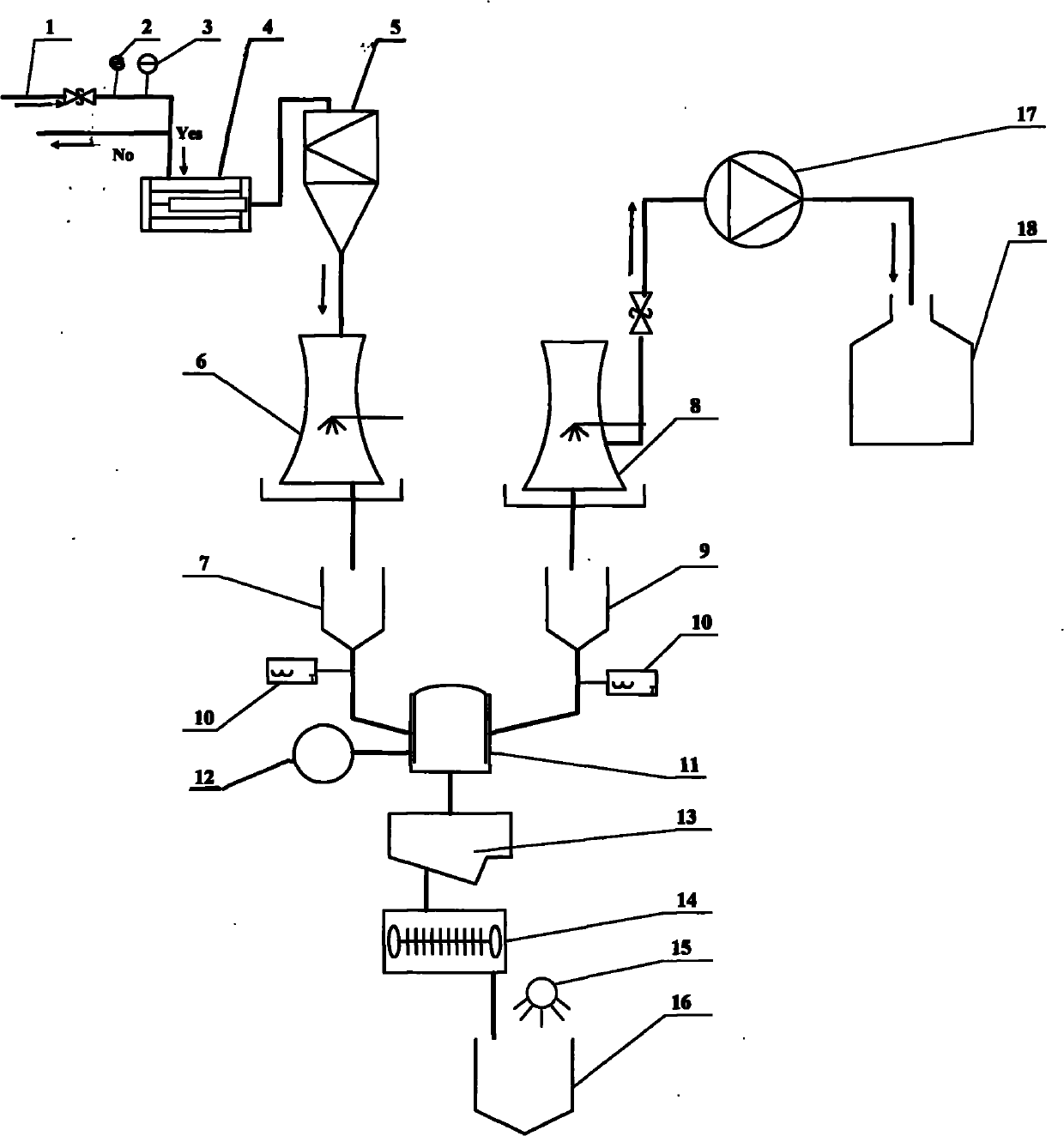

Method and device for purifying calcium carbide furnace tail gas by using negative pressure dry process

A technology of calcium carbide furnace tail gas and dry dust removal, which is applied to chemical instruments and methods, combined devices, carbon monoxide, etc., can solve the problems of system tube Louis scaling and blockage, cannot be recovered, and high operating resistance, and achieve low maintenance costs and dust removal effect Visible, system-reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: with the inventive method and system device thereof, purify 50Nm 3 / h calcium carbide furnace tail gas, normal operation for 5 months, from the dust content of 130g / Nm 3 , down to 20mg / Nm 3 , the purification effect is remarkable, and the system runs without secondary pollution.

Embodiment 2

[0019]Embodiment 2: In a calcium carbide furnace manufacturer in Yunnan Province, the method of the present invention and its system device will be used to purify 2400Nm 3 / h calcium carbide furnace tail gas, normal operation for 12 months, from dust content of 145g / Nm 3 , down to 50mg / Nm 3 , the purification effect is remarkable, and the system runs without secondary pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com